Abstract

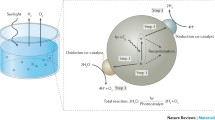

Overall water splitting, evolving hydrogen and oxygen in a 2:1 stoichiometric ratio, using particulate photocatalysts is a potential means of achieving scalable and economically viable solar hydrogen production. To obtain high solar energy conversion efficiency, the quantum efficiency of the photocatalytic reaction must be increased over a wide range of wavelengths and semiconductors with narrow bandgaps need to be designed. However, the quantum efficiency associated with overall water splitting using existing photocatalysts is typically lower than ten per cent1,2. Thus, whether a particulate photocatalyst can enable a quantum efficiency of 100 per cent for the greatly endergonic water-splitting reaction remains an open question. Here we demonstrate overall water splitting at an external quantum efficiency of up to 96 per cent at wavelengths between 350 and 360 nanometres, which is equivalent to an internal quantum efficiency of almost unity, using a modified aluminium-doped strontium titanate (SrTiO3:Al) photocatalyst3,4. By selectively photodepositing the cocatalysts Rh/Cr2O3 (ref. 5) and CoOOH (refs. 3,6) for the hydrogen and oxygen evolution reactions, respectively, on different crystal facets of the semiconductor particles using anisotropic charge transport, the hydrogen and oxygen evolution reactions could be promoted separately. This enabled multiple consecutive forward charge transfers without backward charge transfer, reaching the upper limit of quantum efficiency for overall water splitting. Our work demonstrates the feasibility of overall water splitting free from charge recombination losses and introduces an ideal cocatalyst/photocatalyst structure for efficient water splitting.

Similar content being viewed by others

Main

Demonstrating photocatalytic overall water splitting at an internal quantum efficiency (IQE) of 100% is an important challenge in the study of photocatalysis. Overall water splitting is a greatly uphill (Gibbs energy of +237 kJ mol−1) reaction consisting of multiple electron transfer processes. To achieve a 100% IQE, the first requirement is that all photoexcited carriers must migrate to surface reaction sites before bulk recombination. In addition, two-electron injection for the hydrogen evolution reaction (HER) and four-hole injection for the oxygen evolution reaction (OER) must proceed consecutively without any backward charge transfer. However, because there are many opportunities for backward electron transfer, overall water splitting with an external quantum efficiency (EQE) greater than 50% has rarely been demonstrated, even when using ultraviolet-responsive photocatalysts3,7,8,9,10. Thus, it is important to establish whether a 100% IQE can be realized, by completely inhibiting backward electron transfer, and conclusively determine an effective photocatalyst structure.

SrTiO3 is a suitable photocatalytic material for the assessment of this possibility. This compound is a well characterized photocatalyst with a bandgap energy of 3.2 eV (ref. 11,12,13,14), and its EQE for overall water splitting has been improved by up to 69% over the past years using various refinements3,4,9,14. Here, we increased the EQE to its upper limit by constructing highly active HER and OER cocatalysts on SrTiO3:Al particles site-selectively. This was accomplished by using a stepwise photodeposition method instead of an impregnation process, which results in random dispersion of the cocatalysts.

The water-splitting activity of SrTiO3:Al loaded with Rh, Cr and Co species as cocatalysts via either photodeposition or conventional impregnation methods is shown in Fig. 1a. The photocatalyst loaded with Rh (0.1 wt%) and subsequently with Cr2O3 (0.05 wt%) via two-step photodeposition5 evolved H2 and O2 at the expected stoichiometric ratio for water splitting (Fig. 1a, left). The additional photodeposition of CoOOH (0.05 wt%)3,6 onto this sample further increased the water-splitting activity (Fig. 1a, middle). These photocatalysts, modified through sequential photodeposition, split water approximately 2 and 2.5 times faster than the sample loaded with a Rh–Cr oxide (0.1 wt% of each metal) by coimpregnation2 (Fig. 1a, right). The highest water-splitting activity was obtained with Cr and Co loadings of 0.05 wt% each (Extended Data Fig. 1a, b). The activity was enhanced reproducibly and was maintained at 94% at least for 12.5 h (Extended Data Fig. 2). Figure 1b shows the wavelength dependence of the EQE during overall water splitting using the most active sample (Fig. 1a, middle) and the ultraviolet–visible diffuse reflectance spectrum of unmodified SrTiO3:Al. The EQE values at 350 nm, 360 nm and 365 nm were determined to be 95.7%, 95.9% and 91.6%, respectively; to our knowledge, these are the highest values reported so far for a water-splitting photocatalyst. The EQE values at 370 nm and 380 nm were decreased to 59.7% and 33.6%, respectively, as a result of decreased light absorption and probably the lower IQE at these wavelengths. The IQE obtained on the basis of the number of absorbed photons should be close to 100% in the wavelength region of 350–360 nm considering that the EQE exceeded 95%, although it is difficult to precisely determine the number of photons absorbed by the photocatalyst owing to scattering of incident photons towards the exterior of the reactor (see Extended Data Table 1 for details). The solar-to-hydrogen (STH) efficiency under simulated sunlight illumination was 0.65% (Extended Data Fig. 3).

a, Time course of H2 and O2 evolution on SrTiO3:Al loaded with various cocatalysts during photoirradiation. Left, loaded with Rh (0.1 wt%)/Cr2O3 (0.05 wt%) by two-step photodeposition. Middle, loaded with Rh (0.1 wt%)/Cr2O3 (0.05 wt%)/CoOOH (0.05 wt%) by three-step photodeposition. Right, loaded with Rh (0.1 wt%)–Cr (0.1 wt%) oxide by co-impregnation. Solid lines are guides for the eye. b, Ultraviolet–visible diffuse reflectance spectrum of bare SrTiO3:Al (black solid line) and wavelength dependence of external quantum efficiency (EQE) during water splitting on Rh (0.1 wt%)/Cr2O3 (0.05 wt%)/CoOOH (0.05 wt%)-loaded SrTiO3:Al (red symbols).

During the photodeposition process, photoexcited electrons and holes migrated to the surfaces of semiconductor particles and reduced or oxidized metal ions, respectively, to form deposited nanoparticles. The resulting nanoparticles acted as cocatalysts. In this case, a Rh core/Cr2O3 shell structure was formed during a two-step photodeposition, through the reduction of Rh3+ to Rh0 and a subsequent conversion of Cr(vi)O42− to Cr(iii)2O3 using photoexcited electrons5. We note that a shell made of Cr species is expected to be hydrated in water to form Cr(iii)O1.5−m(OH)2m·xH2O, but herein it is denoted as Cr2O3 for brevity. The Rh promotes both the HER and the oxygen reduction reaction (ORR; a major backward electron transfer process), whereas the Cr2O3 shell inhibits only the ORR by blocking the access of evolved O2 to the surface of the Rh core5. Therefore, the water-splitting rate was almost independent of the gas phase pressures (Extended Data Fig. 4). The Co2+ ions added as a precursor were oxidatively photodeposited as the oxyhydroxide Co(iii)OOH (ref. 6), which promotes the OER15. Loading none of these species or only one of the Rh, Cr, Co, Rh/Co or Cr/Co components resulted in lower or negligible photocatalytic activity (Extended Data Fig. 1c).

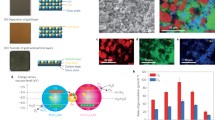

The microstructure of the photocatalysts modified with cocatalysts via photodeposition was investigated by electron microscopy. Figure 2a–d presents scanning electron microscopy (SEM) images of the samples at each step of the cocatalyst photodeposition. The SrTiO3:Al particles were not completely cubic and various non-equivalent facets were exposed. Rh particles were deposited on specific crystal facets, and subsequent Cr2O3 deposition did not change the distribution of the cocatalyst particles, indicating the formation of Cr2O3 shells on Rh cores. Following the photodeposition of CoOOH, CoOOH nanoparticles were observed on other crystal facets, separate from the Rh/Cr2O3 nanoparticles. This was also confirmed by scanning transmission electron microscopy and energy-dispersive X-ray spectroscopy (STEM-EDS) analyses (Fig. 2e). Figure 3a shows the selected-area electron diffraction pattern obtained from the single-crystalline SrTiO3:Al particle shown in Fig. 3b. The Rh/Cr2O3 cocatalyst was found to be preferentially deposited on the {100} crystal facets. The facets on which the CoOOH cocatalyst was deposited were not clearly defined because of the exposure of curved facets, but appeared to be primarily located in the ⟨110⟩ direction, as illustrated in Fig. 3c. Similar phenomena have been observed for other photocatalyst materials with anisotropic crystal habits exposing different facets16,17,18,19,20,21,22. These observations, together with the over 90% EQE values, indicate that photoexcited electrons and holes migrated to separate crystal facets, so the HER and OER subsequently occurred on these separate facets.

a–d, SEM images of SrTiO3:Al loaded with various cocatalysts. Unloaded (a) and loaded with Rh (0.1 wt%) (b), Rh (0.1 wt%)/Cr (0.05 wt%) (c) and Rh (0.1 wt%)/Cr2O3 (0.05 wt%)/CoOOH (0.05 wt%) (d). e, STEM-EDS elemental mappings of SrTiO3:Al loaded with Rh (0.1 wt%)/Cr2O3 (0.05 wt%)/CoOOH (0.05 wt%). EDS data were obtained from the area in the red dashed box.

The observed anisotropic deposition of cocatalysts can be attributed to a charge rectification effect inside each photocatalyst particle that is induced by an internal electric field. This field, in turn, originates from the work function difference between the respective facets, just as in the p–n junction of a solar cell using the Fermi level difference. The effects of work function differences between HER and OER facets on anisotropic charge separation were simulated using a simplified two-dimensional model. The electronic energy gradient and charge distribution in a semiconductor particle with a work function difference of 0.2 eV between the {110} and {100} surfaces are plotted in Fig. 4a–e. Increasing the work function difference obviously increases the extent of anisotropic charge separation, as well as the concentration of electrons at the {100} facets and of holes at the {110} facets, as seen from Fig. 4f. A work function difference of 0.2 eV is sufficient for anisotropic charge separation (see Extended Data Fig. 5 for details). Although it is not possible at present to experimentally observe the electric field in a semiconductor particle under actual working conditions, surface dipoles resulting from unbalanced cation/anion ratios on distinct facets may induce this work function difference even without forming junctions or composites.

a–e, Mapping of conduction-band energy, Ec (a); density of electrons (e−), n (b); density of holes (h+), p (c); energy band diagram (d); and electron and hole densities (e) as functions of position (x′, y′) with work function difference ΔWel = 0.2 eV. f, Effect of ΔWel on electron-to-hole-density ratio at the {100} and {110} facets.

The Rh/Cr2O3 cocatalyst was reductively photodeposited on electron-attracting {100} facets, and subsequently mediated electron transfer from the semiconductor to protons. Similarly, the CoOOH cocatalyst was oxidatively photodeposited on the hole-collecting {110} facets and neighbouring facets, and mediated hole transfer. These phenomena were central to obtaining consecutive charge transfers with minimum charge recombination for the studied cocatalyst/photocatalyst system. The concept of separating reduction and oxidation sites by facet engineering has been reported repeatedly16,17,18,19,20,21,22. However, the EQE of water splitting achieved was below 1%, and charge recombination loss was dominant. Therefore, the validity of this concept has remained controversial. This study demonstrates overall water splitting with an IQE close to unity by applying aluminium doping for defect suppression4,14, flux treatment to improve the crystallinity3,4, and a Cr2O3 shell to inhibit ORR5, in addition to facet engineering, and thus gives a definitive answer to this problem. The selection of high-performance cocatalysts for the HER and OER is another important aspect, because prompt HER and OER suppress accumulation of photoexcited electrons and holes and the resulting recombination. This work therefore reveals a photocatalyst design that enables almost complete utilization of photoexcited electrons and holes.

In light-dependent reactions involved in photosynthesis, almost all the absorbed photons can be used to drive chemical reactions based on the functions of complex protein structures that enable prompt, one-way multistep electron transfers. At present, it is not possible to reproduce such efficient but complicated photosynthesis systems artificially. However, the particulate semiconductor system developed in this study can utilize photons at comparable quantum efficiencies during water splitting despite its simple structure. Recently, Ta3N5 and Y2Ti2O5S2 have been reported to split water into hydrogen and oxygen under visible light23,24. These materials absorb visible light with wavelengths of up to 600 nm and 640 nm, respectively, and the STH efficiency can reach 10% once the EQE is improved to a level similar to that of SrTiO3:Al (refs. 2,5). The suitable photocatalyst design presented here should provide impetus to the development of particulate semiconductor photocatalysts for practical solar hydrogen production from water.

Methods

Synthesis of Al-doped SrTiO3

SrTiO3 doped with Al (SrTiO3:Al) was synthesized using molten-salt mediation, according to a previously reported method3. Briefly, SrCl2 (Kanto Chemical Co.), Al2O3 (Merck) and SrTiO3 (Wako Pure Chemical Industries) were mixed by grinding in an agate mortar in a 10:0.02:1 molar ratio. The mixture was subsequently heated in an alumina crucible at 1,423 K for 10 h in air and then allowed to cool to room temperature. The product was then separated from residual SrCl2 and Al2O3 and related compounds by washing with distilled water three times, at which point the supernatant solution was neutral. The amount of Al incorporated in the SrTiO3 via this process was slightly lower than one atom per cent with respect to Ti (ref. 3).

Cocatalyst loading

Photodeposition was performed in situ by first dispersing SrTiO3:Al (0.1 g) in 100 ml of distilled water in the same vessel employed for the photocatalytic reactions, using a brief sonication. Aqueous solutions of RhCl3·6H2O (Wako Pure Chemical Industries), K2CrO4 (Kanto Chemical Co.) and Co(NO3)2·6H2O (Kanto Chemical Co.) were prepared. We note that the aqueous solution of RhCl3·6H2O should be prepared freshly before use. The concentration of the metal species (Rh, Cr and Co) was 2 mg ml−1. Calculated amounts of these aqueous solutions were added into the reaction solution for successive photodeposition. To deposit 0.1 wt% Rh, 0.05 wt% Cr and 0.05 wt% Co on 0.1 g of SrTiO3:Al, the RhCl3 aqueous solution (50 μl) was first added to the reaction suspension with magnetic stirring, and the resulting mixture was irradiated with a Xe lamp (300 W, full arc; details in Extended Data Fig. 6) for 10 min. Subsequently, the K2CrO4 aqueous solution (25 μl) was added to the suspension with additional irradiation for 5 min, followed by the addition of a specific quantity of Co(NO3)2 solution and another 5-min irradiation. We note that photodeposition of these components was performed in a sequence without exchanging the solvent. A cocatalyst based on a mixture of Rh–Cr oxides was also deposited on the main catalyst using a previously reported impregnation method2. In this process, SrTiO3:Al was dispersed in a small amount of distilled water containing specific amounts of Na3RhCl6 (Mitsuwa Chemicals Co.) and Cr(NO3)3 (Kanto Chemical Co.), after which the mixture was heated on a hot water bath until dry, followed by heating in air for 1 h at 623 K. Regardless of the chemical state of the deposited cocatalyst, the loading amount of each component was calculated assuming a metallic state for simplicity.

Characterization

The crystal structure of the SrTiO3:Al was evaluated by X-ray diffraction (XRD; Cu Kα radiation, Miniflex 300, Rigaku Co.; see Extended Data Fig. 7). The optical absorption spectrum of the SrTiO3:Al (Fig. 1b) was determined using a ultraviolet–visible spectrometer equipped with an integrating sphere (V-670, JASCO), employing a spectralon block as a reference to adjust the 100% reflectance level and set the reflectance of the sample holder to 0%. Absorptance was given by 1 − reflectance. The microstructure of the photodeposited samples was analysed by field-emission SEM (SU-8020, Hitachi High-Technologies Co.) and by field-emission (scanning) transmission electron microscopy (JEM-2800F, JEOL) in conjunction with EDS using an X-MAX 100TLE SDD detector (Oxford Instruments). Selected-area electron diffraction patterns were indexed using a ReciPro diffraction simulator.

Photocatalytic reactions

Photocatalytic reactions were carried out in an overhead-irradiation-type glass vessel connected to a closed gas circulation system. Prior to each reaction, all air was evacuated from the reaction system and filled with Ar (about 1 kPa unless otherwise noted). The suspension was subsequently irradiated using a Xe lamp (300 W, full arc). Evolved gases accumulated in the closed gas circulation system were analysed by gas chromatography (GC-8A, Shimadzu Co., thermal conductivity detector, Ar carrier gas, molecular sieve 5 Å column). The STH efficiency was measured under simulated sunlight irradiation (AM1.5G, 9 cm2 illuminated area, solar simulator HAL-320, Asahi Spectra Co.). The STH efficiency was determined according to the following equation

Here, \({r}_{{{\rm{H}}}_{2}}\), \(\Delta {G}_{{{\rm{H}}}_{2}{\rm{O}}}\), I and S represent the H2 evolution rate, the reaction Gibbs energy of water splitting, the light energy flux and the irradiation area, respectively.

Measurement of quantum efficiencies

The EQE values were determined according to the following equation

where N(H2) and N(photons) denote the number of H2 molecules produced and the number of photons reaching the surface of the reaction solution, respectively. The H2 evolution rate was measured in the same reaction system as the other photocatalytic reactions. To determine the wavelength dependence of the EQE, samples were irradiated with monochromatic light generated by a Xe lamp and sent through bandpass filters with central wavelengths of 350 nm, 360 nm, 365 nm, 370 nm or 380 nm (Edmund Optics). The full-width at half-maximum of each of these bandpass filters was approximately 10 nm. The dependence of the EQE on the irradiance was established using monochromatic light at 365 nm passed through a bandpass filter and neutral density filters (Edmund Optics); see Extended Data Table 1 for details. The numbers of photons were counted using photon-to-current conversion with a Si photodiode and a multimeter in the device shown in Extended Data Fig. 8. The photon flux, I, was calculated from the photocurrent density generated by a Si photodiode, Photocurrent(Si), measured using the device shown in Extended Data Fig. 8a–c, according to the equation

where NA, F and QE(Si) represent the Avogadro constant, the Faraday constant and the quantum efficiency of the Si photodiode, respectively. A cylindrical reactor with an inner diameter of 65 mm with an optically flat window made of quartz and a Xe lamp (300 W) were employed for water splitting. Because the Xe lamp emits divergent light, I is not uniform over the entire light acceptance area. To accurately measure N(photons), a circular mask with an inner diameter of 30 mm was inserted to narrow the distribution of the light intensity. Then, I was measured at various positions by sliding the position of a Si photodiode with an interval of 2 mm, with the level of the Si photodiode maintained at the surface of the reaction solution. This gives I(r), I as a function of the distance from the centre, r. N(photons) can be then calculated by numerically integrating I(r) over the entire light acceptance area of the reactor

where k is a non-negative integer. I(r) was taken as the average of the intensities measured at two points symmetrical to the centre of the circle (see Extended Data Fig. 8d).

Electrical simulations of SrTiO3:Al particulate systems

SrTiO3:Al with a perovskite crystal structure was modelled using an octagonal geometry based on SEM images of SrTiO3:Al nanoparticles, in which the OER and HER proceed at diagonal and non-diagonal edges, respectively. In this model, we defined the x′ and y′ directions relative to the non-diagonal {100} and diagonal {110} edges, respectively. The SrTiO3:Al material parameters required for electrical simulations were obtained from the literature and are provided in Extended Data Table 225,26,27,28,29,30. Charge carrier recombination was simulated based on defect-assisted Shockley–Reed–Hall recombination31, with the defect states located in the middle of the bandgap of SrTiO3:Al. The trapping times or lifetimes of the electrons and holes were fixed so that the diffusion lengths of the charge carriers exceeded the particle size, given that the experimentally observed IQE values were nearly 100%. The illumination conditions were reproduced by providing a uniform generation rate across the particle dimensions, because the random orientation of crystal facets and multiple scattering in the suspension hindered the applicability of the Beer–Lambert law. However, this assumption does not affect the band diagram and hence the description of anisotropic charge transport qualitatively. The boundary conditions were provided by two distinct pseudo Schottky contacts with work functions \({W}_{{\rm{el}}}^{100}\) and \({W}_{{\rm{el}}}^{110}\) at the non-diagonal and diagonal edges, respectively. The \({W}_{{\rm{el}}}^{100}\) value was adjusted to equal the midpoint between the redox potentials for H2 and O2 evolution and further tuned in accordance with the pH level of the electrolyte (pH = 7 for water). On this basis, we obtained \({W}_{{\rm{el}}}^{100}=4.64\,{\rm{eV}}\) relative to the vacuum energy level at a pH of 7 as per the Nernst equation. However, it is known that charging or dipole effects can produce differences in the work functions for the {100} and {110} edges. To include such effects, we fixed the value of \({W}_{{\rm{el}}}^{100}\) and varied \({W}_{{\rm{el}}}^{110}\,\) from 4.64 eV to 5.05 eV. The extraction rates for electrons (for the HER) and holes (for the OER) were non-zero for the non-diagonal and diagonal edges, respectively. Using COMSOL Multiphysics, the model was discretized by physics-controlled meshing that produced an extremely fine mesh near the edges and a relatively fine mesh throughout the particle bulk. The COMSOL Multiphysics Semiconductor Module was used to perform electrical simulations that solved the Poisson, drift–diffusion and continuity equations self-consistently for electrons and holes at each discretized node. Energy band diagrams and electron and hole densities were plotted in one dimension along the x′ and y′ directions to show their respective variations from the {100} to {110} edges.

Extended Data Figure 5 shows the effect of the work function difference \(\Delta {W}_{{\rm{el}}}={W}_{{\rm{el}}}^{110}-{W}_{{\rm{el}}}^{100}\) on the energy band diagram and charge carrier density under illumination. The accumulation and depletion regions that appear near the crystal facets are primarily determined by the relative positions of the work functions of the pseudo metal contacts (\({W}_{{\rm{el}}}^{100}\), \({W}_{{\rm{el}}}^{110}\)) and of the semiconductor (Ws). As an example, in the case of \({W}_{{\rm{el}}}^{100},\,{W}_{{\rm{el}}}^{110} < {W}_{{\rm{s}}}\), the semiconductor accumulates electrons from the pseudo metal contacts at the {100} and {110} facets, resulting in a flat energy band diagram for ΔWel = 0.03 eV (with the given particle dimensions). This work function difference does not induce selective transport of charge carriers towards different crystal facets. However, \({W}_{{\rm{el}}}^{100} < {W}_{{\rm{s}}} < {W}_{{\rm{el}}}^{110}\) produces accumulation regions near the {100} facets and depletion regions in the vicinity of the {110} facets when ΔWel > 0.1 eV. The formation of these distinct regions produces downward and upward (asymmetric) band bending around the {100} and {110} facets, respectively, which leads to anisotropic charge transport. The extent of asymmetric band bending, and hence anisotropic charge transport, in the vicinity of the {100} and {110} facets increases with increasing ΔWel. Furthermore, for ΔWel < 0.4 eV, we find that the hole density is less than the electron density in the bulk of the particulate system owing to substantial electron injection from the pseudo metal contacts associated with the {100} facets. By contrast, for ΔWel = 0.4 eV, electron injection into the semiconductor bulk is suppressed by increases in the depletion regions originating from \({W}_{{\rm{el}}}^{110}\) around the {110} facets. As a result, the bulk electron and hole densities become almost equal.

Data availability

Supporting data are available at the Shinshu University Institutional Repository at http://hdl.handle.net/10091/00021822.

References

Kudo, A. & Miseki, Y. Heterogeneous photocatalyst materials for water splitting. Chem. Soc. Rev. 38, 253–278 (2009).

Chen, S., Takata, T. & Domen, K. Particulate photocatalysts for overall water splitting. Nat. Rev. Mater. 2, 17050 (2017).

Goto, Y. et al. A particulate photocatalyst water-splitting panel for large-scale solar hydrogen production. Joule 2, 509–520 (2018).

Ham, Y. et al. Flux-mediated doping of SrTiO3 photocatalysts for efficient overall water splitting. J. Mater. Chem. A 4, 3027–3033 (2016).

Maeda, K. & Domen, K. Photocatalytic overall water splitting: recent progress and future challenges. J. Phys. Chem. Lett. 1, 2655–2661 (2010).

Lyu, H. et al. An Al-doped SrTiO3 photocatalyst maintaining sunlight-driven overall water splitting activity over 1,000 h of constant illumination. Chem. Sci. 10, 3196–3201 (2019).

Sakata, Y., Hayashi, T., Yasunaga, R., Yanaga, N. & Imamura, H. Remarkably high apparent quantum yield of the overall photocatalytic H2O splitting achieved by utilizing Zn ion added Ga2O3 prepared using dilute CaCl2. Chem. Commun. 51, 12935–12938 (2015).

Kato, H., Asakura, K. & Kudo, A. Highly efficient water splitting into H2 and O2 over lanthanum-doped NaTaO3 photocatalysts with high crystallinity and surface nanostructure. J. Am. Chem. Soc. 125, 3082–3089 (2003).

Chiang, T. H. et al. Efficient photocatalytic water splitting using Al-doped SrTiO3 coloaded with molybdenum oxide and rhodium-chromium oxide. ACS Catal. 8, 2782–2788 (2018).

Li, Y. et al. Photocatalytic water splitting by N-TiO2 on MgO(111) with exceptional quantum efficiency at elevated temperatures. Nat. Commun. 10, 4421 (2019).

Wagner, F. T. & Somorojai, G. A. Photocatalytic and photoelectrochemical hydrogen production on strontium titanate single crystals. J. Am. Chem. Soc. 102, 5494–5502 (1980).

Domen, K. et al. Photocatalytic decomposition of water vapour on an NiO-SrTiO3 catalyst. J. Chem. Soc. Chem. Commun. 543–544 (1980).

Lehn, J. M., Sauvage, J. P., Zlessel, R. & Hilaire, L. Water photolysis by UV irradiation of rhodium loaded strontium titanate catalysts. Relation between catalytic activity and nature of the deposit from combined photolysis and ESCA studies. Isr. J. Chem. 22, 168–172 (1982).

Takata, T. & Domen, K. Defect engineering of photocatalyst by doping of aliovalent metal cations for efficient water splitting. J. Phys. Chem. C 113, 19386–19388 (2009).

Kanan, M. W. & Nocera, D. G. In situ formation of an oxygen-evolving catalyst in neutral water containing phosphate and Co2+. Science 321, 1072–1075 (2008).

Ohno, T., Sarukawa, K. & Matsumura, M. Crystal faces of rutile and anatase TiO2 particles and their roles in photocatalytic reactions. New J. Chem. 26, 1167–1170 (2002).

Liu, G., Yu, J. C., Lu, G. Q. & Cheng, H. M. Crystal facet engineering of semiconductor photocatalysts: motivations, advances and unique properties. Chem. Commun. 47, 6763–6783 (2011).

Xie, Y. P., Liu, G., Yina, L. & Cheng, H. M. Crystal facet-dependent photocatalytic oxidation and reduction reactivity of monoclinic WO3 for solar energy conversion. J. Mater. Chem. 22, 6746–6751 (2012).

Zhen, C., Yu, J. C., Liu, G. & Cheng, H. M. Selective deposition of redox co-catalyst(s) to improve the photocatalytic activity of single-domain ferroelectric PbTiO3 nanoplates. Chem. Commun. 50, 10416–10419 (2014).

Li, R. et al. Spatial separation of photogenerated electrons and holes among {010} and {110} crystal facets of BiVO4. Nat. Commun. 4, 1432 (2013).

Mu, L. et al. Enhancing charge separation on high symmetry SrTiO3 exposed with anisotropic facets for photocatalytic water splitting. Energy Environ. Sci. 9, 2463–2469 (2016).

Luo, Y. et al. Construction of spatial charge separation facets on BaTaO2N crystals by flux growth approach for visible-light-driven H2 production. ACS Appl. Mater. Interfaces 11, 22264–22271 (2019).

Wang, Z. et al. Overall water splitting by Ta3N5 nanorod single crystals grown on the edges of KTaO3 particles. Nat. Catal. 1, 756–763 (2018).

Wang, Q. et al. Oxysulfide photocatalyst for visible-light-driven overall water splitting. Nat. Mater. 18, 827–832 (2019).

Frederikse, H., Thurber, W. & Hosler, W. Electronic transport in SrTiO3. Phys. Rev. 134, A442–A445 (1964).

Weaver, H. Dielectric properties of single crystals of SrTiO3 at room temperatures. J. Phys. Chem. Solids 11, 275–277 (1959).

Zhao, Z. et al. Electronic structure basis for enhanced overall water splitting photocatalysis with aluminum doped SrTiO3 in natural sunlight. Energy Environ. Sci. 12, 1385–1395 (2019).

Konta, R., Ishii, T., Kato, H. & Kudo, A. Photocatalytic activities of noble metal ion doped SrTiO3 under visible light irradiation. J. Phys. Chem. B 108, 8992–8995 (2004).

Cohen, M. I. & Blunt, R. F. Optical properties of SrTiO3 in the region of absorption edge. Phys. Rev. 168, 929–933 (1968).

Zollner, S. et al. Optical properties of bulk and thin film SrTiO3 on Si and Pt. J. Vac. Sci. Technol. B 18, 2242–2254 (2000).

Sze, S. M. Physics of Semiconductor Devices (John Wiley & Sons, 1981).

Acknowledgements

This work was primarily supported by the Artificial Photosynthesis Project of the New Energy and Industrial Technology Development Organization (NEDO) and partly supported by JSPS KAKENHI grant number JP19K05669, JP16K06862. A part of this work was conducted at the Advanced Characterization Nanotechnology Platform of the University of Tokyo, supported by “Nanotechnology Platform” of the Ministry of Education, Culture, Sports, Science and Technology (MEXT), Japan (grant number JPMXP09A-19-UT-0023). We are grateful to M. Yamaguchi and Y. Kuromiya at the University of Tokyo for the preparation and evaluation of photocatalysts.

Author information

Authors and Affiliations

Contributions

T.T. conceived the photocatalyst design and performed the photocatalytic reactions. T.H. synthesized Al-doped SrTiO3. J.J. and Y.S. performed quantum efficiency measurements. M.N. and N.S. performed electron microscopy measurements. V.N. and K.S. performed electrical simulations. K.D. supervised the project. T.T., T.H. and K.D. wrote the manuscript with input from all authors.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information Nature thanks David Tilley, Martijn Zwijnenburg and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Extended data figures and tables

Extended Data Fig. 1 Dependence of water-splitting activities on the amounts and components of cocatalysts.

a, b, Dependence of water-splitting activity on the amount of Cr2O3 added to Rh (0.1 wt%)-loaded SrTiO3:Al (a) and CoOOH added to Rh (0.1 wt%)/Cr2O3(0.05 wt%)-loaded SrTiO3:Al (b). c, Time course of H2 and O2 evolution over SrTiO3:Al unloaded (i) and loaded with Rh (0.1 wt%) (ii), Rh (0.1 wt%)/CoOOH (0.05 wt%) (iii), CoOOH (0.05 wt%) (iv) and CoOOH (0.05 wt%)/Cr2O3 (0.05 wt%) (v).

Extended Data Fig. 2 Reproducibility and stability of water-splitting activity of SrTiO3:Al loaded with Rh (0.1 wt%)/Cr2O3 (0.05 wt%)/CoOOH (0.05 wt%).

a, Variation of water-splitting activity of SrTiO3:Al loaded with Rh (0.1 wt%)/Cr2O3 (0.05 wt%)/CoOOH (0.05 wt%) (25 samples) from different batches (B) and lots (L). Batches and lots represent SrTiO3:Al samples and the cocatalysts synthesized and loaded at different timings, respectively. The averages (μ) of the H2 and O2 evolution rates were 3.54 mmol h−1 and 1.78 mmol h−1 and their standard deviations (σ) were 0.26 mmol h−1 and 0.12 mmol h−1, respectively. All the gas evolution rates were within μ ± 2σ. b, Stability test of SrTiO3:Al loaded with Rh (0.1 wt%)/Cr2O3 (0.05 wt%)/CoOOH (0.05 wt%) during photocatalytic water splitting. The produced H2 and O2 accumulated in the reaction system were evacuated every 2.5 h. The inner wall of the reactor window was cleaned before every evacuation.

Extended Data Fig. 3

Time course of H2 and O2 evolution over SrTiO3:Al photodeposited with Rh (0.1 wt%)/Cr2O3 (0.05 wt%)/CoOOH (0.05 wt%) under simulated sunlight irradiation.

Extended Data Fig. 4

Effect of initial background pressure on the photocatalytic water-splitting activity of SrTiO3:Al photodeposited with Rh (0.1 wt%)/Cr2O3 (0.05 wt%)/CoOOH (0.05 wt%).

Extended Data Fig. 5 Simulations of graded band energy values and resulting anisotropic charge separation based on various differences in work function between the {110} and {100} facets.

a, Maps of conduction band energy and logarithms of the electron and hole densities (n and p, respectively). b, c, Energy band diagrams (b) and electron and hole densities (c) as functions of position. See Methods for further discussion.

Extended Data Fig. 6

Power spectrum of the Xe lamp used in the study.

Extended Data Fig. 7

XRD pattern of the synthesized SrTiO3:Al.

Extended Data Fig. 8 EQE measurement.

a, Photographs of the devices used in the measurement. Left, side view of the measurement system. Middle left, top view of the measurement system. Middle right, arrangement of the lamp and reactor. Right, arrangement of the Si photodiode. b, c, Illustrations of water-splitting reactor and photon-counting system (b) and illumination unit (c). d, Example of light intensity distribution (365-nm bandpass filter and 0.1-optical-density neutral density filter; left) and model used to calculate the number of incident photons (right).

Rights and permissions

About this article

Cite this article

Takata, T., Jiang, J., Sakata, Y. et al. Photocatalytic water splitting with a quantum efficiency of almost unity. Nature 581, 411–414 (2020). https://doi.org/10.1038/s41586-020-2278-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41586-020-2278-9

- Springer Nature Limited

This article is cited by

-

Electrolyte-assisted polarization leading to enhanced charge separation and solar-to-hydrogen conversion efficiency of seawater splitting

Nature Catalysis (2024)

-

Bubble-water/catalyst triphase interface microenvironment accelerates photocatalytic OER via optimizing semi-hydrophobic OH radical

Nature Communications (2024)

-

Understanding the in-situ transformation of CuxO interlayers to increase the water splitting efficiency in NiO/n-Si photoanodes

Nature Communications (2024)

-

Achieving a solar-to-chemical efficiency of 3.6% in ambient conditions by inhibiting interlayer charges transport

Nature Communications (2024)

-

Dynamic structural twist in metal–organic frameworks enhances solar overall water splitting

Nature Chemistry (2024)