Abstract

Crystallization of colloidal nanocrystals into superlattices represents a practical bottom-up process with which to create ordered metamaterials with emergent functionalities1,2,3. With precise control over the size, shape and composition of individual nanocrystals4,5,6, various single- and multi-component nanocrystal superlattices have been produced, the lattice structures and chemical compositions of which can be accurately engineered7,8,9. Nanocrystal superlattices are typically prepared by carefully controlling the assembly process through solvent evaporation or destabilization2,10,11,12,13,14,15 or through DNA-guided crystallization16,17,18. Slow solvent evaporation or cooling of nanocrystal solutions (over hours or days) is the key element for successful crystallization processes10,18. Here we report the rapid growth (seconds) of micrometre-sized, face-centred-cubic, three-dimensional nanocrystal superlattices during colloidal synthesis at high temperatures (more than 230 degrees Celsius). Using in situ small-angle X-ray scattering, we observe continuous growth of individual nanocrystals within the lattices, which results in simultaneous lattice expansion and fine nanocrystal size control due to the superlattice templates. Thermodynamic models demonstrate that balanced attractive and repulsive interparticle interactions dictated by the ligand coverage on nanocrystal surfaces and nanocrystal core size are responsible for the crystallization process. The interparticle interactions can also be controlled to form different superlattice structures, such as hexagonal close-packed lattices. The rational assembly of various nanocrystal systems into novel materials is thus facilitated for both fundamental research and for practical applications in the fields of magnetics19, electronics3 and catalysis20.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Main

Crystallization is a process in which atoms or molecules nucleate and grow into highly ordered structures21,22,23. Although this process is governed by many thermodynamic and kinetic factors, traditional crystallization techniques often rely on slow cooling of concentrated solutions24 or on controlled solvent evaporation25. These slow processes allow atoms or molecules to sample and find thermodynamic minima, leading to the energetically most stable structures, which are usually ordered crystals. In analogy to atomic crystallization, monodisperse nanocrystals have been intensively studied as artificial atoms for creating nanocrystal superlattices2,3,8. Typical crystallization of single- or multi-component nanocrystals into long-range ordered superlattices relies on slow cooling processes18 or slow evaporation/destabilization of nanocrystal solutions on a timescale of up to several days2,8,14,26. Rapid destabilization of equilibrium growth often results in disordered aggregates27. Here we show that uniform nanocrystals rapidly crystallize into close-packed superlattices during synthesis at high temperatures, illustrating a new mode of crystallization process that is governed by the interplay in ligand coverage on nanocrystal surfaces and nanocrystal size.

We use in situ synchrotron-based small-angle X-ray scattering (SAXS), in combination with a custom-made reactor, to monitor the formation in real time of palladium (Pd) nanocrystals, a well studied system28,29 (Extended Data Fig. 1 and Methods). In a typical experiment, Pd nanocrystals are synthesized by thermal decomposition of a Pd–TOP complex (where TOP is trioctylphosphine) in the presence of hexanoic acid, using 1-octadecene as solvent. Figure 1a shows representative two-dimensional SAXS patterns at different reaction times. In the first minute of the reaction, we observe diffuse scattering in the SAXS pattern arising from the contribution of the form factor of the well dispersed nanocrystals. On the basis of the fits of multiple SAXS patterns in this first phase, the Pd nanocrystal formation is in line with a traditional LaMer-type mechanism involving a burst nucleation event followed by a subsequent, slower growth stage (Extended Data Fig. 2a and b)21. The polydispersity of Pd nanocrystals decreases quickly to below 7% within 44 s. As the Pd nanocrystal diameter increases beyond 5.3 nm at 66 s, a weak diffraction peak at scattering vector q = 0.1075 Å−1 starts to appear, indicating the formation of an ordered crystalline phase (Fig. 1a). Within 11 s after this peak appears (the timescale resolution of the in situ experiments), strong diffraction peaks of these ordered structures replace the diffuse scattering of the dispersed nanocrystals (Fig. 1b and Extended Data Fig. 2c). The peak positions show ratios of qn/q1 = 1,  ,

,  ,

,  and 2 (where qn refers to the position of the nth peak), which correspond to a face-centred cubic (f.c.c.) lattice (Extended Data Fig. 2d). Post-synthesis electron microscopy of the final black precipitate reveals micrometre-sized three-dimensional superlattices composed of monodisperse nanocrystals (Fig. 1c and d). Common crystal defects such as vacancies and step edges are also observed. The three-dimensional lattices can be re-dissolved in non-polar solvents (such as hexanes or toluene) in the presence of additional surfactants such as oleylamine. The isolated Pd nanocrystals are monodisperse with a diameter of 8.1 ± 0.4 nm derived from SAXS measurements, in excellent agreement with the size derived from transmission electron microscopy (TEM) (8.0 ± 0.3 nm) (Fig. 1e and Extended Data Fig. 3a).

and 2 (where qn refers to the position of the nth peak), which correspond to a face-centred cubic (f.c.c.) lattice (Extended Data Fig. 2d). Post-synthesis electron microscopy of the final black precipitate reveals micrometre-sized three-dimensional superlattices composed of monodisperse nanocrystals (Fig. 1c and d). Common crystal defects such as vacancies and step edges are also observed. The three-dimensional lattices can be re-dissolved in non-polar solvents (such as hexanes or toluene) in the presence of additional surfactants such as oleylamine. The isolated Pd nanocrystals are monodisperse with a diameter of 8.1 ± 0.4 nm derived from SAXS measurements, in excellent agreement with the size derived from transmission electron microscopy (TEM) (8.0 ± 0.3 nm) (Fig. 1e and Extended Data Fig. 3a).

a, Representative two-dimensional SAXS patterns at different reaction times. Time 0 s represents the moment when nucleation of Pd nanocrystals occurs. b, Representative one-dimensional SAXS patterns at different reaction times. Both axes are logarithmic. Patterns are offset for clarity. c, SEM image of a representative f.c.c. superlattice. d, TEM images of a f.c.c. superlattice viewed along the (110) plane projection, together with a lattice sphere model. e, TEM image of the final dispersed Pd nanocrystals. f, Kinetics of the growth of Pd nanocrystals and their crystallization into superlattices over reaction time. Error bars result from the fits to the SAXS data. g, Schematic of the growth of individual Pd nanocrystals in solution and subsequent formation of f.c.c. superlattices, followed by continuous growth of individual nanocrystals inside the superlattices. The organic surfactants on nanocrystal surfaces are omitted for clarity.

Surprisingly, the Pd nanocrystals continue to grow in solution from 5.3 nm to 8.1 nm in the presence of unreacted precursor after they crystallize into superlattices, representing a 350% volumetric increase. The SAXS data demonstrate continuous expansion of the f.c.c. lattice, as shown by a distinct shift of the diffraction peaks to smaller q values (Fig. 1b). To obtain a complete picture of the nanocrystal size evolution, we measured the lattice constant at different stages using SAXS data (Extended Data Fig. 2e–g) and calculated the nanocrystal diameter d using the equation  , where a is the f.c.c. lattice parameter, and di is the interparticle separation for the nearest neighbours (see Methods). Even after superlattice formation, the Pd nanocrystals continue to grow in size, unaffected by the assembled state (Fig. 1f and g). This phenomenon may be caused either by fast diffusion of the Pd precursors within the superlattice promoted by the high reaction temperatures and crystal defects in the superlattices, or by a dynamic process in which nanocrystals located on the outer surface of the superlattices grow in size, detach and reassemble in superlattices, thus allowing inner nanocrystals to become exposed to the precursors. As the Pd nanocrystal size inside the superlattices increases, diffraction intensities increase concurrently, owing to the enhanced effective form factor of the nanocrystals (Extended Data Fig. 2f). The controlled growth of nanocrystals within the superlattices is further tested ex situ by using pre-formed superlattices of 9.6 ± 0.4 nm Pd nanocrystals (Fig. 2e and f and Extended Data Fig. 4a–d) to grow even larger Pd nanocrystals of 11.9 ± 0.5 nm with preserved superlattice structures upon addition of additional Pd–TOP precursor (Extended Data Fig. 4e and f). The superlattices serve as templates for continued Pd nanocrystal growth, suggesting that they could be used to explore the formation of size- and composition-controlled nanocrystals by post-modification in the assembled state. These f.c.c. lattices are also very stable at high temperatures, and maintain their structure even at the solvent (1-octadecene) boiling point (about 315 °C).

, where a is the f.c.c. lattice parameter, and di is the interparticle separation for the nearest neighbours (see Methods). Even after superlattice formation, the Pd nanocrystals continue to grow in size, unaffected by the assembled state (Fig. 1f and g). This phenomenon may be caused either by fast diffusion of the Pd precursors within the superlattice promoted by the high reaction temperatures and crystal defects in the superlattices, or by a dynamic process in which nanocrystals located on the outer surface of the superlattices grow in size, detach and reassemble in superlattices, thus allowing inner nanocrystals to become exposed to the precursors. As the Pd nanocrystal size inside the superlattices increases, diffraction intensities increase concurrently, owing to the enhanced effective form factor of the nanocrystals (Extended Data Fig. 2f). The controlled growth of nanocrystals within the superlattices is further tested ex situ by using pre-formed superlattices of 9.6 ± 0.4 nm Pd nanocrystals (Fig. 2e and f and Extended Data Fig. 4a–d) to grow even larger Pd nanocrystals of 11.9 ± 0.5 nm with preserved superlattice structures upon addition of additional Pd–TOP precursor (Extended Data Fig. 4e and f). The superlattices serve as templates for continued Pd nanocrystal growth, suggesting that they could be used to explore the formation of size- and composition-controlled nanocrystals by post-modification in the assembled state. These f.c.c. lattices are also very stable at high temperatures, and maintain their structure even at the solvent (1-octadecene) boiling point (about 315 °C).

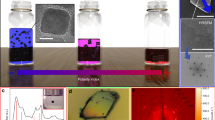

a, b, SEM images of the superlattices synthesized using oleic acid as the surfactant. c, d, SEM and TEM images of the superlattices synthesized using 2-hexyldecanoic acid as the surfactant. e, f, SEM and TEM images of the superlattices synthesized using oleic acid as both the surfactant and solvent.

Superlattice crystallization kinetics is monitored by analysing the change in concentration of dispersed nanocrystals in solution via in situ SAXS. Nearly complete crystallization of Pd nanocrystals into f.c.c. superlattices occurs within only tens of seconds at elevated temperatures (>230 °C) (Fig. 1f). This observation is in contrast with most nanocrystal crystallization processes, which occur at low temperatures for extended periods of time14,18. The average three-dimensional lattice crystallite size (estimated from the scattering correlation length using ξ ≈ 2p/∆q, where ∆q is the full-width at half-maximum of the (111) peak)16, greatly increases to about 150 nm within only 11 s from the beginning of the crystallization process, and further increases to about 170 nm during continuous growth of individual nanocrystals. This value is smaller than the overall superlattice crystal size (>500 nm) measured from scanning electron microscope (SEM) images, which suggests the existence of defects and thus polycrystalline domains in these three-dimensional lattices. It is worth mentioning that reducing the nanocrystal concentration by 40% does not affect the crystallization kinetics.

To understand better the driving force guiding the crystallization process, we first study the contribution of ligand entropy30. We substitute hexanoic acid with either oleic acid or 2-hexyldecanoic acid, which provide different degrees of organizational flexibility and ligand–solvent interactions. Formation of Pd superlattices still occurs regardless of the acid used (Fig. 2a–d). In both cases superlattices start to form when the nanocrystals reach a size of about 5 nm, with subsequent continuous growth of nanocrystals inside the superlattices (Extended Data Figs 5 and 6). A common critical nanocrystal size for superlattice formation suggests that the dominant driver for the crystallization is most probably inorganic core–core interactions. The final Pd nanocrystal samples are still monodisperse with sizes of 6.8 ± 0.4 nm and 6.1 ± 0.3 nm using oleic acid and 2-hexyldecanoic acid, respectively (Extended Data Fig. 3b and c). In contrast with superlattices obtained from hexanoic or oleic acid, those from 2-hexyldecanoic acid are less stable and tend to dissolve into dispersed Pd nanocrystals at elevated temperatures (Extended Data Fig. 6e–g). An equilibrium state showing that about 30% of total nanocrystals dispersed in solution is reached at 280 °C. This difference is attributed to higher solubility promoted by branched ligands, which have been reported to increase favourable entropic interactions with solvents30.

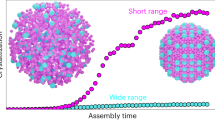

The presence of a carboxylic acid ligand is critical for the crystallization of Pd nanocrystals into superlattices. When it is replaced with oleylamine, the resulting nanocrystals remain fully dispersed in the reaction mixture even though their sizes29 grow larger than 5 nm. This result, taken together with the critical crystallization size of Pd nanocrystals observed by in situ SAXS experiments, suggests that the crystallization process is dependent on both the size of Pd nanocrystals and the type of surface ligands. We found that the bonding between acid ligands and Pd nanocrystals is rather weak, such that washing the nanocrystals with 2-propanol easily removes the acid ligands. In contrast, oleylamine ligands on oleylamine-treated Pd nanocrystals are more stable and resist multiple washing cycles (Extended Data Fig. 7). A much smaller ligand density on the acid-capped nanocrystals (3.4 nm−2) is confirmed by thermogravimetric analysis when compared to the oleylamine-capped ones (5.5 nm−2), which is responsible for an interparticle separation between nanocrystals in close-packed monolayers that is about 1 nm shorter, as demonstrated by TEM images (Fig. 3a–d). The difference in ligand density and change in interparticle separation is further confirmed by in situ SAXS measurements, in which oleylamine is added to a suspension of pre-formed superlattices of 7.8 ± 0.5 nm Pd nanocrystals, causing a 0.80-nm increase in interparticle separation (Fig. 3f). All these results suggest that densely packed ligands on the nanocrystal surface, such as oleylamine, provide stronger steric repulsion, thus keeping the nanocrystals well dispersed in solution. When the ligand coverage is reduced, as with a carboxylic acid, ligand repulsion is weakened (Fig. 3e). As nanocrystal size increases, attractive forces from van der Waals interactions of inorganic cores increase substantially and dominate over repulsive forces to drive nanocrystal assembly into superlattices14.

a, b, TEM images of the as-synthesized Pd nanocrystals using oleic acid as the surfactant (a), and after post-synthesis treatment with oleylamine (b). Both scale bars are 20 nm. c, Histograms of interparticle separations in a and b. d, Thermogravimetric analysis profiles of the as-synthesized oleic-acid-capped and oleylamine-treated Pd nanocrystals. e, Schematic representation of the interparticle interactions at varying nanocrystal diameters and ligand coverage. f, One-dimensional SAXS data of Pd nanocrystal superlattices in 1-octadecene before and after the addition of oleylamine (dotted vertical line). g, Interaction potentials between two Pd nanocrystals modelled as a function of interparticle separation. Here d is the diameter of the Pd nanocrystals and T = 503 K is the crystallization temperature observed during the experiments. Energy is reported in units of kBT.

To gain more insight into the crystallization process, we modelled the interactions between Pd nanocrystals as two-body pair potentials that resemble the Lennard–Jones potential: an attraction well forms as a result of the competition between long-ranged van der Waals attraction and short-ranged steric repulsion (Fig. 3g and Methods). The position and the depth of the attraction well are governed by particle size, the Hamaker constant (a material property that quantifies the strength of van der Waals interactions in a medium) and ligand coverage. For small particle sizes, the potential well is too small to induce particle assembly. As particle size grows above 5 nm, the potential well reaches a value of 0.2kBT at an interparticle separation of 2.5 nm. Beyond this point, the steric repulsion dominates and prevents particles from forming kinetically trapped aggregates. At this optimal separation, the particles can find the most favourable (ordered) packing assembly. Once the superlattice forms and nanocrystals grow further, the well deepens, providing even stronger core–core attractive interactions between nanocrystals locked in the ordered structure, which supports the thermodynamic-driven crystallization. At this stage, the ligand–ligand van der Waals attraction also contributes to the increased stability of the superlattices under these experimental conditions1.

Manipulating ligand coverage further allows for programmable crystallization of nanocrystals into superlattices. Fixing the TOP concentration but reducing the molar ratio of oleic acid:TOP from 1:1 to 1:10 results in nanocrystals that are well dispersed in solution, despite a particle size larger than 5 nm (6.2 ± 0.4 nm, Extended Data Fig. 8a–e). That nanocrystals do not assemble when the concentration of oleic acid is small is probably due to the competitive coverage by bulky, branched TOP ligands on the nanocrystal surface, providing stronger steric repulsion. However, the dispersed Pd nanocrystals can crystallize into mainly f.c.c. superlattices by adding extra oleic acid into the solution, and the crystallized lattices are less stable and can reversibly dissolve–recrystallize during heating–cooling cycles (Extended Data Fig. 8f–k). The crystallization of Pd nanocrystals can be further tuned by directly changing the molar ratio of oleic acid:TOP used in the synthesis. For example, with a 1:4 molar ratio of oleic acid:TOP, we observed the formation of f.c.c. superlattices above 230 °C and their subsequent dissolution at 280 °C (Fig. 4a and b). Cooling the nanocrystal dispersion does not lead to superlattice formation until the temperature is reduced to about 100 °C. At this point, however, hexagonal close-packed (h.c.p.) lattices form rather than f.c.c. ones (Fig. 4c–e). The fact that f.c.c. lattices are favoured at high temperatures while h.c.p. lattices are favoured at low temperatures further suggests that the crystallization process is thermodynamically controlled. All these results demonstrate that the crystallization equilibrium and superlattice structures can be elaborately controlled by carefully tuning the composition of surface ligands.

a, One-dimensional SAXS patterns of Pd nanocrystals synthesized using a 1:4 molar ratio of oleic acid:TOP. Rapid formation of f.c.c. superlattices is observed at 230 °C, and complete dissolution of the superlattices is observed at 280 °C. b, Kinetics of the growth of Pd nanocrystals and their crystallization into superlattices over reaction time, showing crystallization and dissolution of the f.c.c. superlattices. Error bars result from the fits to the SAXS data. c, Representative one-dimensional SAXS patterns of the recrystallization process of Pd nanocrystals into h.c.p. superlattices during the cooling process from the previous dispersed state. d, Comparison of the structure factor of f.c.c. superlattices at 268 °C and h.c.p. superlattices recrystallized at 50 °C. e, SEM image of the obtained h.c.p. superlattice, showing hexagonal plate-like morphology.

Additional experiments show that rapid crystallization of nanocrystals at high temperature is not limited to metals with large Hamaker constants, but is potentially ubiquitous in colloidal systems. For example, we found that uniform Fe nanoparticles form f.c.c. superlattices in solution at 180 °C during their synthesis, similarly to the case of Pd, with continuous growth inside the f.c.c. lattices (Extended Data Fig. 9). Owing to much weaker core–core interactions resulting from a smaller Hamaker constant but similar steric repulsions (see Methods), the crystallization process starts at larger core diameters (about 11 nm), which is in line with what the thermodynamic model predicts (Extended Data Fig. 9g). Other than metallic systems, we also observed high-temperature crystallization of semiconductor PbTe nanocrystals into superlattices during synthesis (Extended Data Fig. 10). It is very likely that this unique crystallization and post-growth behaviour of nanocrystals is present in a wide range of systems, yet it may have gone unnoticed because of the absence of in situ tools to probe it. These stable superlattices, combined with the possible chemical modification of the nanocrystals (such as size, shape and composition) while in the assembled form, provide opportunities to create diverse metamaterials with complex compositions and structures.

Methods

Syntheses of nanocrystals and their superlattices

Pd nanocrystals were synthesized via thermal decomposition of the Pd–TOP complex in the presence of organic acid ligands. In a typical synthesis, 0.25 mmol of Pd(acac)2 (where acac is acetylacetonate) (35% Pd, Acro Organics) and 1.25 mmol of hexanoic acid (≥99%, Sigma Aldrich) were mixed with 10 ml of 1-octadecene (90%, Sigma Aldrich) in a custom-made flask under magnetic stirring. The flask was purged with Ar gas for 15 min. Then 1.25 mmol of trioctylphosphine (TOP, 97%, Sigma Aldrich) was added and the solid Pd(acac)2 immediately dissolved, forming a light-yellow complex31. The mixture was maintained at 60 °C for 30 min under continuous Ar purge to remove air and moisture. Then under a blanket of Ar gas, the mixture was heated up to 280 °C at a rate of 10–20 °C min−1 and kept at 280 °C for 2 min. On heating, SAXS patterns were consecutively collected with an acquisition frequency of a pattern every 11 s (5 s of exposure time and 6 s of data collecting and storing time). Afterwards, the heating tape was turned off and the reaction mixture was cooled down to room temperature. The final black precipitate (three-dimensional superlattices) and supernatant solvent were collected for further characterization, and eventually subjected to purification by centrifugation if needed. To study the effect of different acid ligands on superlattice formation, hexanoic acid was replaced by the same molar amount (1.25 mmol) of oleic acid (90%, Sigma Aldrich) or 2-hexyldecanoic acid (96%, Sigma Aldrich) while keeping other reactants the same. The effect of the amount of oleic acid on the formation of Pd nanocrystals and their superlattices was studied by changing the molar amount of oleic acid while keeping other conditions the same.

Fe nanoparticles were synthesized according to a reported method with slight modifications32. 10 ml of 1-octadecene were mixed with 0.05 ml of oleylamine (70%, Sigma Aldrich) and degassed at 120 °C under continuous Ar flow for 30 min to remove air and moisture. The mixture was then heated under a blanket of Ar gas up to 180 °C, followed by addition of 0.35 ml of Fe(CO)5 (>99.99%, Sigma Aldrich). The reaction mixture was kept at 180 °C for 20 min before it was cooled down to room temperature. SAXS pattern collection was started with the addition of Fe(CO)5. The final black precipitate of Fe nanoparticles was collected for further characterization.

PbTe nanocrystals were synthesized following ref. 33 with some modification. 2 mmol of Pb(CH3CO2)2∙3H2O (≥99%, Sigma Aldrich) was mixed with 2 ml of oleic acid and 4 ml of 1-octadecene under magnetic stirring and degassed under vacuum at 80 °C for 30 min. After flushing with N2, the mixture was heated to 160 °C. 2 mmol of tellurium dissolved in 2 ml of TOP were rapidly injected into the reaction flask. The reaction solution was kept at 160 °C for 15 min before cooling down to room temperature. The obtained black precipitate in 1-octadecene was collected for further characterization without purification.

Templated growth of Pd nanocrystals inside the superlattices

Superlattices of Pd nanocrystals were synthesized first following the procedure described above and using 0.25 mmol of Pd(acac)2, 10 ml of oleic acid and 1.25 mmol of TOP. The reaction was performed at 280 °C for 2 min. After cooling to room temperature, faceted microcrystals of uniform 9.6 ± 0.4 nm Pd nanocrystals were obtained. A solution of Pd–TOP complex (0.25 mmol of Pd(acac)2, 1.25 mmol of TOP, and 3 ml 1-octadecene mixed together and degassed under vacuum) was added into the superlattice suspension. The mixture was heated up again to 280 °C at a heating rate of about 3 °C min−1 and kept at 280 °C for 15 min. The reaction mixture was then cooled down to room temperature, and the obtained black precipitate was collected without purification for further characterization.

Preparation of dispersed nanocrystals

To obtain dispersed nanocrystals from superlattices, the three-dimensional lattices were dispersed in 5 ml of hexanes by adding 0.1 ml of oleylamine. After sonication for 5 min, the superlattices were completely dissolved and the dispersed nanocrystals were purified by four cycles of precipitation (5 ml of hexanes were used to disperse the nanocrystals, followed by adding 20 ml of 2-propanol), and centrifugation at 8,000 r.p.m. (837.75 rad s−1) for 5 min. The purified nanocrystals were then re-dispersed in hexane for further characterization.

Characterization

TEM images were collected on a FEI Tecnai transmission electron microscope operating at 200 kV. TEM samples for nanocrystal superlattices were prepared by directly drop-casting the pre-formed superlattices from 1-octadecene on carbon-coated 300 mesh Cu grids, followed by cleaning with 2-propanol five times to remove extra 1-octadecene. TEM samples for dispersed nanocrystals were prepared by drop-casting their diluting hexane dispersion on Cu grids. SEM and energy-dispersive X-ray spectroscope analysis was performed on a FEI Magellan 400 XHR SEM operating at 5 kV. Samples were prepared on Si substrates (0.8 cm × 0.8 cm). Fourier transform infrared (FT-IR) spectra were recorded on a Nicolet iS50 spectrometer with attenuated total reflectance. Thermogravimetric analysis was carried out using a TA Instrument Q500.

SAXS measurements were performed at Beamline 1-5 at the Stanford Synchrotron Radiation Lightsource (SSRL) of the SLAC National Accelerator Laboratory. The X-ray energy was 15 keV and the sample-to-detector distance was calibrated using a silver behenate standard. The beam-spot size is 500 μm × 500 μm. Exposure time for every frame was 5 s. The scattered patterns were collected using a Rayonix 165 SX charge-coupled device (CCD) area detector. The experimental apparatus was a custom-made flask reactor with two flat glass windows (0.5 mm in thickness) to allow sufficient X-ray transmission during in situ measurements. The two-dimensional SAXS data were integrated into one-dimensional scattering curve I(q) presented as a function of scattering vector q = (4p/λ)sin(θ/2), where λ is the wavelength of the incident X-ray and θ is the scattering angle.

SAXS modelling

SAXS data of dispersed nanocrystals were analysed by fitting to a quantitative model using the Irena package (available at http://usaxs.xray.aps.anl.gov/staff/ilavsky/irena.html from the APS)34. The size and size distribution of disperse nanocrystals were modelled using the Modelling II module of the IRENA package. A spherical form factor, with an aspect ratio of 1, and a Gaussian size distribution provided the best fits to the data, while simultaneously being the most physically meaningful given the corroborating electron microscopy data and size histograms extracted from the data. In the case of the form factor fitting used, the scattering intensity is expressed by the formula  , where Δρ is the scattering contrast, F(q, r) is the scattering form factor, V(r) is the nanocrystal volume, N is the total number of nanocrystals, and P(r) is the probability of the nanocrystal at size of r. As I(q) is not in absolute units, we leave Δρ to its default value of 1 × 10−9 cm−2 in the package for the modelling, such that relative values for N are obtained. The Pd nanocrystals are spherical, so the spherical form factor

, where Δρ is the scattering contrast, F(q, r) is the scattering form factor, V(r) is the nanocrystal volume, N is the total number of nanocrystals, and P(r) is the probability of the nanocrystal at size of r. As I(q) is not in absolute units, we leave Δρ to its default value of 1 × 10−9 cm−2 in the package for the modelling, such that relative values for N are obtained. The Pd nanocrystals are spherical, so the spherical form factor  is used.

is used.

Particle–particle separation in superlattices

The interparticle separation (di) was determined via the equation  , where a is the f.c.c. lattice parameter, and d is the nanocrystal diameter. The f.c.c. lattice parameter is calculated from the (111) peak position q(111) by using

, where a is the f.c.c. lattice parameter, and d is the nanocrystal diameter. The f.c.c. lattice parameter is calculated from the (111) peak position q(111) by using  It is straightforward to calculate the di using the final nanocrystal size and final lattice parameter. Alternatively, di can be calculated from SAXS data of the very first superlattices, which give both a clear lattice parameter a from q(111) and a nanocrystal size d from form factor fitting. In the case of hexanoic acid, di was calculated to be 1.80 nm. It is worth noting that di is constant while nanocrystals inside superlattices continue growing. Using similar methods, the interparticle separation was determined to be 1.95 nm for oleic-acid-capped nanocrystals and 1.88 nm for 2-hexyldecanoic-acid-capped nanocrystals. With known interparticle distance, nanocrystal sizes inside the f.c.c. superlattices were calculated via the equation

It is straightforward to calculate the di using the final nanocrystal size and final lattice parameter. Alternatively, di can be calculated from SAXS data of the very first superlattices, which give both a clear lattice parameter a from q(111) and a nanocrystal size d from form factor fitting. In the case of hexanoic acid, di was calculated to be 1.80 nm. It is worth noting that di is constant while nanocrystals inside superlattices continue growing. Using similar methods, the interparticle separation was determined to be 1.95 nm for oleic-acid-capped nanocrystals and 1.88 nm for 2-hexyldecanoic-acid-capped nanocrystals. With known interparticle distance, nanocrystal sizes inside the f.c.c. superlattices were calculated via the equation  .

.

Interactions between two nanocrystals

The van der Waals interactions between inorganic cores are calculated using the equation35:

where A is the Hamaker constant, r is the nanocrystal radius, and di is the interparticle separation. To the leading order, the Lifshitz theory predicts that the non-retarded Hamaker constant between particles labelled 1 in medium 3 is given by the equation

where A is the Hamaker constant, r is the nanocrystal radius, and di is the interparticle separation. To the leading order, the Lifshitz theory predicts that the non-retarded Hamaker constant between particles labelled 1 in medium 3 is given by the equation  , where h is the Planck constant and

, where h is the Planck constant and  is the dielectric response of materials or medium35,36 at frequency ν. The dielectric response of metals and dielectric medium can be estimated as

is the dielectric response of materials or medium35,36 at frequency ν. The dielectric response of metals and dielectric medium can be estimated as  and

and  , respectively, where νe is the metal plasma frequency, νe,d is the plasma frequency of the dielectric medium, and n is the refractive index of the medium. Completing the frequency integral yields

, respectively, where νe is the metal plasma frequency, νe,d is the plasma frequency of the dielectric medium, and n is the refractive index of the medium. Completing the frequency integral yields

For metallic particles, the temperature-dependent term in the equation contributes less than 1% to metal–metal interactions. The pre-factor  is the value of the Hamaker constant for metals in vacuum35. With n = 1.44 and νe,d = 3.0 × 1015 Hz for 1-octadecene34, and νe = 6.2 × 1015 Hz for Pd (ref. 37), the Hamaker constant for the Pd/1-octadecene/Pd system is calculated to be 2.6 eV. Using νe = 3.8 × 1015 Hz for Fe (ref. 37), the Hamaker constant for the Fe/1-octadecene/Fe system is calculated to be 1.4 eV. For superparamagnetic Fe particles, the dipole–dipole interactions between fluctuating magnetic dipoles known as Keesom interactions are approximated via the equation37

is the value of the Hamaker constant for metals in vacuum35. With n = 1.44 and νe,d = 3.0 × 1015 Hz for 1-octadecene34, and νe = 6.2 × 1015 Hz for Pd (ref. 37), the Hamaker constant for the Pd/1-octadecene/Pd system is calculated to be 2.6 eV. Using νe = 3.8 × 1015 Hz for Fe (ref. 37), the Hamaker constant for the Fe/1-octadecene/Fe system is calculated to be 1.4 eV. For superparamagnetic Fe particles, the dipole–dipole interactions between fluctuating magnetic dipoles known as Keesom interactions are approximated via the equation37  , where μ0 is the permeability constant, V is the volume of Fe particles, M is the saturation magnetization of the Fe particles (for these amorphous Fe particles M = 4.7 × 105 A m−1)32, r is the radius of Fe particles, and di is the interparticle separation. For the superparamagnetic Fe particles smaller than 12 nm, Udd ≪ UvdW. Owing to a smaller Hamaker constant than that of Pd nanocrystals, Fe nanoparticles need to grow to a larger size for aggregating and ordering into f.c.c. lattices.

, where μ0 is the permeability constant, V is the volume of Fe particles, M is the saturation magnetization of the Fe particles (for these amorphous Fe particles M = 4.7 × 105 A m−1)32, r is the radius of Fe particles, and di is the interparticle separation. For the superparamagnetic Fe particles smaller than 12 nm, Udd ≪ UvdW. Owing to a smaller Hamaker constant than that of Pd nanocrystals, Fe nanoparticles need to grow to a larger size for aggregating and ordering into f.c.c. lattices.

The repulsive interparticle potential is estimated using the theory developed for the flexible polymer brush via the Derjaguin approximation38,39. The steric repulsion is given by the equation  , where

, where  , σ is the ligand grafting density, L0 is the full length of the ligand layer, and

, σ is the ligand grafting density, L0 is the full length of the ligand layer, and  measures the entropic cost of compressing the ligand layer which is set to 20 nm2. We stress that, given the level of approximation, the precise value of this compression constant is not important, which only changes the steepness of the repulsion when ligands layer overlaps and does not affect the depth of the attractive well substantially.

measures the entropic cost of compressing the ligand layer which is set to 20 nm2. We stress that, given the level of approximation, the precise value of this compression constant is not important, which only changes the steepness of the repulsion when ligands layer overlaps and does not affect the depth of the attractive well substantially.

Data availability

Source Data for Figs 1, 3 and 4 are provided with the paper. Any additional data supporting the findings of this study are available from M.C. and C.J.T. upon reasonable request.

References

Boles, M. A., Engel, M. & Talapin, D. V. Self-assembly of colloidal nanocrystals: from intricate structures to functional materials. Chem. Rev. 116, 11220–11289 (2016)

Dong, A. G., Chen, J., Vora, P. M., Kikkawa, J. M. & Murray, C. B. Binary nanocrystal superlattice membranes self-assembled at the liquid–air interface. Nature 466, 474–477 (2010)

Cargnello, M. et al. Substitutional doping in nanocrystal superlattices. Nature 524, 450–453 (2015)

Park, J. et al. One-nanometer-scale size-controlled synthesis of monodisperse magnetic iron oxide nanoparticles. Angew. Chem. Int. Ed. 44, 2872–2877 (2005)

Ye, X. C. et al. Competition of shape and interaction patchiness for self-assembling nanoplates. Nat. Chem. 5, 466–473 (2013)

Sun, S. H., Murray, C. B., Weller, D., Folks, L. & Moser, A. Monodisperse FePt nanoparticles and ferromagnetic FePt nanocrystal superlattices. Science 287, 1989–1992 (2000)

Murray, C. B., Kagan, C. R. & Bawendi, M. G. Self-organization of CdSe nanocrystallites into three-dimensional quantum-dot superlattices. Science 270, 1335–1338 (1995)

Shevchenko, E. V., Talapin, D. V., Kotov, N. A., O’Brien, S. & Murray, C. B. Structural diversity in binary nanoparticle superlattices. Nature 439, 55–59 (2006)

Tian, Y. et al. Lattice engineering through nanoparticle-DNA frameworks. Nat. Mater. 15, 654–661 (2016)

Shevchenko, E. V., Talapin, D. V., Murray, C. B. & O’Brien, S. Structural characterization of self-assembled multifunctional binary nanoparticle superlattices. J. Am. Chem. Soc. 128, 3620–3637 (2006)

Jiang, Z. et al. Subnanometre ligand-shell asymmetry leads to Janus-like nanoparticle membranes. Nat. Mater. 14, 912–917 (2015)

Geuchies, J. J. et al. In situ study of the formation mechanism of two-dimensional superlattices from PbSe nanocrystals. Nat. Mater. 15, 1248–1254 (2016)

Weidman, M. C., Smilgies, D. M. & Tisdale, W. A. Kinetics of the self-assembly of nanocrystal superlattices measured by real-time in situ X-ray scattering. Nat. Mater. 15, 775–781 (2016)

Rupich, S. M., Shevchenko, E. V., Bodnarchuk, M. I., Lee, B. & Talapin, D. V. Size-dependent multiple twinning in nanocrystal superlattices. J. Am. Chem. Soc. 132, 289–296 (2010)

de Nijs, B. et al. Entropy-driven formation of large icosahedral colloidal clusters by spherical confinement. Nat. Mater. 14, 56–60 (2015)

Nykypanchuk, D., Maye, M. M., van der Lelie, D. & Gang, O. DNA-guided crystallization of colloidal nanoparticles. Nature 451, 549–552 (2008)

Park, S. Y. et al. DNA-programmable nanoparticle crystallization. Nature 451, 553–556 (2008)

Auyeung, E. et al. DNA-mediated nanoparticle crystallization into Wulff polyhedra. Nature 505, 73–77 (2014)

Chen, J. et al. Bistable magnetoresistance switching in exchange-coupled CoFe2O4-Fe3O4 binary nanocrystal superlattices by self-assembly and thermal annealing. ACS Nano 7, 1478–1486 (2013)

Zhao, H. et al. Reversible trapping and reaction acceleration within dynamically self-assembling nanoflasks. Nat. Nanotechnol. 11, 82–88 (2016)

LaMer, V. K. & Dinegar, R. H. Theory, production and mechanism of formation of monodispersed hydrosols. J. Am. Chem. Soc. 72, 4847–4854 (1950)

Erdemir, D., Lee, A. Y. & Myerson, A. S. Nucleation of crystals from solution: classical and two-step models. Acc. Chem. Res. 42, 621–629 (2009)

Xia, Y. N., Xiong, Y. J., Lim, B. & Skrabalak, S. E. Shape-controlled synthesis of metal nanocrystals: simple chemistry meets complex physics? Angew. Chem. Int. Ed. 48, 60–103 (2009)

Jones, A. G. & Mullin, J. W. Programmed cooling crystallization of potassium sulfate solutions. Chem. Eng. Sci. 29, 105–118 (1974)

He, G. W. et al. Direct growth of g-glycine from neutral aqueous solutions by slow, evaporation-driven crystallization. Cryst. Growth Des. 6, 1746–1749 (2006)

Smith, D. K., Goodfellow, B., Smilgies, D. M. & Korgel, B. A. Self-assembled simple hexagonal AB2 binary nanocrystal superlattices: SEM, GISAXS, and defects. J. Am. Chem. Soc. 131, 3281–3290 (2009)

Murray, C. B., Kagan, C. R. & Bawendi, M. G. Synthesis and characterization of monodisperse nanocrystals and close-packed nanocrystal assemblies. Annu. Rev. Mater. Sci. 30, 545–610 (2000)

Kim, S. W. et al. Synthesis of monodisperse palladium nanoparticles. Nano Lett. 3, 1289–1291 (2003)

Cargnello, M. et al. Control of metal nanocrystal size reveals metal-support interface role for ceria catalysts. Science 341, 771–773 (2013)

Yang, Y. et al. Entropic ligands for nanocrystals: from unexpected solution properties to outstanding processability. Nano Lett. 16, 2133–2138 (2016)

Cargnello, M., Doan-Nguyen, V. V. T. & Murray, C. B. Engineering uniform nanocrystals: mechanism of formation and self-assembly into bimetallic nanocrystal superlattices. AIChE J. 62, 392–398 (2015)

Peng, S., Wang, C., Xie, J. & Sun, S. H. Synthesis and stabilization of monodisperse Fe nanoparticles. J. Am. Chem. Soc. 128, 10676–10677 (2006)

Ganguly, S. & Brock, S. L. Toward nanostructured thermoelectrics: synthesis and characterization of lead telluride gels and aerogels. J. Mater. Chem. 21, 8800–8806 (2011)

Ilavsky, J. & Jemian, P. R. Irena: tool suite for modeling and analysis of small-angle scattering. J. Appl. Cryst. 42, 347–353 (2009)

Israelachvili, J. N. Intermolecular and Surface Forces 3rd edn, Ch. 13 (Academic Press, 2011)

Visser, J. On Hamaker constants: a comparison between Hamaker constants and Lifshitz–Van der Waals constants. Adv. Colloid Interf. Sci. 3, 331–363 (1972)

Glicksman, M. Plasmas in solids. Solid State Phys. 26, 275–427 (1971)

Bishop, K. J. M., Wilmer, C. E., Soh, S. & Grzybowski, B. A. Nanoscale forces and their uses in self-assembly. Small 5, 1600–1630 (2009)

Kim, J. U. & Matsen, M. W. Interaction between polymer-grafted particles. Macromolecules 41, 4435–4443 (2008)

Acknowledgements

This work was supported by the US Department of Energy (DOE), Laboratory Directed Research and Development programme at SLAC National Accelerator Laboratory, under contract DE-AC02-76SF00515. In situ SAXS experiments were performed at the Beamline 1-5 at the Stanford Synchrotron Radiation Lightsource (SSRL) of the SLAC National Accelerator Laboratory, and use of the SSRL was supported by the DOE Office of Science, Office of Basic Energy Sciences under contract number DE-AC02-76SF00515. I.S.M. was supported by the Department of Defense through the National Defense Science & Engineering Graduate Fellowship Program, and by the Fannie and John Hertz Foundation through a Hertz Foundation Fellowship. M.C. acknowledges support from the School of Engineering at Stanford University and from a Terman Faculty Fellowship. The electron microscopy characterization of nanocrystals and superlattices was performed at the Stanford Nano Shared Facilities (SNSF) at Stanford University. The work at the Center for Nanoscale Materials of Argonne National Laboratory was supported by the DOE Office of Science under contract number DE-AC02-06CH11357. L.W. thanks T. J. Dunn from SSRL for his assistance during the SAXS measurements. M.C. thanks N. Abbott (University of Wisconsin), D. Talapin (University of Chicago) and C. B. Murray (University of Pennsylvania) for discussions.

Author information

Authors and Affiliations

Contributions

L.W., M.C. and C.J.T. conceived and designed the experiments. L.W. carried out the in situ experiments and analysed the SAXS data. L.W., J.J.W. and I.S.M. performed the ex situ characterizations of nanocrystals and superlattices. B.T.D. contributed to data analysis. J.Q. analysed interparticle potentials. M.C. and C.J.T. supervised the entire project. L.W. and M.C. wrote the manuscript. All authors discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Additional information

Reviewer Information Nature thanks E. Kumacheva, D. Vanmaekelbergh and the other anonymous reviewer(s) for their contribution to the peer review of this work.

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data figures and tables

Extended Data Figure 1 In situ SAXS characterization of Pd nanocrystals during the synthesis.

a, A photograph of the in situ reaction setup at Beamline 1-5 of SSRL at SLAC National Accelerator Laboratory. The inset shows a photograph of the custom-made flask reactor. To obtain optimized signal-to-noise ratio for SAXS measurements, the thickness of the two flat glass windows in the reactor is set to be 0.5 mm and the distance between two windows is 4 mm. b, One-dimensional SAXS data of 1-octadecene solvent in the flask reactor at different temperatures used for background subtraction. c, One-dimensional SAXS patterns of the in situ synthesized Pd nanocrystals before superlattice formation. The increase of scattering at low q is due to the formation of nanocrystals. We detect the onset of nanocrystal formation at about 203 °C and this reaction point is set as time 0 (0 s). d, Time-resolved one-dimensional SAXS patterns of the Pd superlattices. With increased reaction time, the diffraction peaks shift to lower q, suggesting the lattice expansion caused by the increased size of individual Pd nanocrystals. In the meantime, peak intensities increase as the size of nanocrystals increase. All the patterns shown here are not background-subtracted. e, Reaction temperature versus time during the in situ experiment. All experiments discussed in this work show similar reaction temperature profiles. (a.u., arbitrary units.)

Extended Data Figure 2 Quantitative analysis of the SAXS data.

a, One-dimensional background-subtracted SAXS patterns of the in situ synthesized Pd nanocrystals before the formation of superlattices. Coloured plots are experimental results and black lines represent the corresponding fits. The SAXS intensity and fits are scaled for clarity. b, Number-weighted size distribution of the Pd nanocrystals from quantitative analysis. c, Quantitative comparison of the form factor from dispersed nanocrystals in solution at 66 s and 77 s. At 77 s, clear scattering peaks appear at q = 0.102 Å−1, 0.117 Å−1, 0.166 Å−1, 0.196 Å−1, 0.204 Å−1, which are indexed to the (111), (200), (220), (311), (222) diffraction planes of f.c.c. structure. The concentration of dispersed nanocrystals decreases by about 90% within 11 s owing to their assembly into f.c.c. superlattices. d, Representative structure factor S(q) of the formed superlattices at 88 s. The S(q) value is calculated by dividing the I(q) value by the form factor of the nanocrystals. The peak positions correspond well to a f.c.c. lattice. e, Change of the lattice parameter with reaction time. f, Change of the (111) peak intensity of the f.c.c. superlattices as the volume (size) of an individual Pd nanocrystal increases during the post-assembly growth. The increased diffraction intensity is due to an increase in the number of scattered electrons by the growing nanocrystals. g, Change of lattice parameter of the final superlattices with temperatures during the cooling process. The lattice parameter is almost constant during a wide range of temperatures, indicating that the temperature has negligible effect on the f.c.c. lattice constant.

Extended Data Figure 3 Size characterization of the final Pd nanocrystals synthesized from different acid ligands.

a, Hexanoic acid; b, oleic acid; c, 2-hexyldecanoic acid. (i), TEM images of the final Pd nanocrystals. The final nanocrystals are re-dispersed in hexane after oleylamine treatment. (ii), Two-dimensional SAXS patterns of the final Pd nanocrystals dispersed in hexane. (iii), Background-subtracted one-dimensional SAXS data of the final Pd nanocrystals (black plots) and their corresponding fits (red lines). (iv), Size distribution of the Pd nanocrystals obtained from TEM characterization (histogram and red lines) and SAXS fits (blue lines, normalized to the same maximum of the red line). The sizes from TEM are 8.0 ± 0.3 nm (a), 6.7 ± 0.2 nm (b), and 6.0 ± 0.3 nm (c). The sizes from SAXS analysis are 8.1 ± 0.4 nm (a), 6.8 ± 0.4 nm (b), and 6.1 ± 0.3 nm (c), which are in good agreement with TEM measurements.

Extended Data Figure 4 Characterization of ex situ templated growth using superlattices of 9.6-nm Pd nanocrystals.

a, TEM image of the templated superlattices. b, TEM image of the dispersed Pd nanocrystals after treatment with oleylamine. The histogram (inset) shows the Pd nanocrystals to be 9.6 ± 0.4 nm. c, d, SEM images of different domains of the templated superlattices showing different morphologies and facets. e, SEM image of a representative superlattice after the templated growth. f, TEM images of the disperse Pd nanocrystals after the templated growth. The inset histogram shows the nanocrystal size to be 11.9 ± 0.5 nm.

Extended Data Figure 5 SAXS characterization of the Pd nanocrystals and their superlattices synthesized using oleic acid as the surfactant.

a, Representative two-dimensional SAXS patterns at different reaction time showing the transition from diffuse scattering to well defined scattering rings. b, Background-subtracted one-dimensional SAXS patterns of the in situ synthesized Pd nanocrystals before the formation of superlattices. The coloured plots are experimental results and the black lines are their corresponding fits. c, One-dimensional SAXS patterns of the Pd nanocrystal superlattices during the in situ experiment. The peak positions show characteristics of f.c.c. structure with the ratios qn/q1 = 1,  ,

,  ,

,  and 2. The shifts of these peaks to lower q indicate lattice expansion by the growth of individual nanocrystals. d, Number-weighted size distribution of the Pd nanocrystals from quantitative analysis of the real-time SAXS data shown in b. e, Kinetics of the growth of Pd nanocrystals and their crystallization into superlattices over reaction time. Error bars result from the fits to the SAXS data.

and 2. The shifts of these peaks to lower q indicate lattice expansion by the growth of individual nanocrystals. d, Number-weighted size distribution of the Pd nanocrystals from quantitative analysis of the real-time SAXS data shown in b. e, Kinetics of the growth of Pd nanocrystals and their crystallization into superlattices over reaction time. Error bars result from the fits to the SAXS data.

Extended Data Figure 6 SAXS characterization of the Pd nanocrystals and their superlattices synthesized using 2-hexyldecanoic acid as the surfactant.

a, Representative two-dimensional SAXS patterns at different reaction times. b, Background-subtracted one-dimensional SAXS patterns of the in situ synthesized Pd nanocrystals before the formation of superlattices showing experimental results (coloured plots) and corresponding fits of nanocrystal form factor (black lines). c, One-dimensional SAXS patterns of the Pd nanocrystal superlattices during the in situ experiment with continuous shifts of the f.c.c. diffraction peaks. d, Number-weighted size distribution of the Pd nanocrystals from quantitative analysis of the SAXS data in b. e, Kinetics of the growth of Pd nanocrystals and their crystallization into superlattices over reaction time. The branched acid-capped nanocrystal superlattices are less stable at 280 °C and show an equilibrium state of about 30% nanocrystal in isolated form. Error bars result from the fits to the SAXS data. f, Comparison of the SAXS patterns of the final superlattices in solution at 280 °C and 50 °C. After cooling down to 50 °C, the dispersed nanocrystals recrystallized, as shown by the disappearance of scattering at low q from the form factor of the nanocrystals. Two additional peaks at 0.090 Å−1 and 0.101 Å−1 appear, owing to the formation of h.c.p. lattices. g, TEM image of small domains of the superlattices obtained at room temperature. In addition to large three-dimensional f.c.c. superlattices (see Fig. 2c and d), some small h.c.p. lattices are obtained from the recrystallization of the dispersed nanocrystals during the cooling process.

Extended Data Figure 7 Surface characterization of the final Pd nanocrystals synthesized using oleic acid as the surfactant.

a, FT-IR spectra of the as-synthesized Pd nanocrystals showing the absence of C=O stretching mode at about 1,707 cm−1 and the appearance of OCO stretching vibration at about 1,377 cm−1, indicating oleic acid bonding on the surface. b, Enlarged FT-IR spectra of a in wavenumbers 2,600–3,100 cm−1. The CH-stretching vibration of the alkyl group in oleic-acid-capped Pd nanocrystals are shifted to lower wavenumbers owing to the loss of conformational freedom by bonding on Pd nanocrystal surface. c, FT-IR spectra of the oleic acid ligands on Pd nanocrystals after different washing cycles. After the second wash, the alkyl group intensity drops substantially, indicating that most of the oleic acid is stripped off by the washing step owing to the weak bonding between oleic acid and the Pd nanocrystals. d, FT-IR of the Pd nanocrystals after oleylamine treatment. Even after four washing cycles, the oleylamine-capped nanocrystals are still well dispersed and the FT-IR spectrum shows strong CH-stretching vibrations.

Extended Data Figure 8 Characterization of the Pd nanocrystals synthesized with a 1:10 molar ratio of oleic acid:TOP and their superlattices.

a, One-dimensional SAXS patterns of the Pd nanocrystals in solution during the synthesis. All nanocrystals are well dispersed in the solution during the entire synthesis, showing only the form factor of dispersed nanocrystals in the SAXS data. b, Representative one-dimensional background-subtracted SAXS patterns at different reaction time (coloured plots) and their corresponding fits (black lines). c, Evolution of nanocrystal size over reaction time obtained from SAXS fits. Error bars result from the fits to the SAXS data. d, TEM image of the final Pd nanocrystals. e, Size distribution of the as-synthesized nanocrystals from TEM characterization (histogram and red line, 6.0 ± 0.3 nm) and SAXS measurement (blue line, 6.2 ± 0.4 nm). f, SAXS patterns of the obtained Pd nanocrystals after synthesis at 100 °C with and without adding extra oleic acid ligands. Adding extra oleic acid caused the assembly of Pd nanocrystals. g, Energy-dispersive X-ray spectroscopy spectra of the Pd nanocrystals synthesized before and after adding extra oleic acid in the nanocrystal solution. The P:Pd atomic ratio decreases from 0.19 to 0.12 after adding extra oleic acid, indicating less coverage of TOP on the nanocrystal surface. h, Schematic of the dissolution-crystallization of nanocrystal superlattices upon thermal cycling. i, One-dimensional SAXS data showing the dissolution of the superlattices during the heating process. j, One-dimensional SAXS data showing the recrystallization of the Pd nanocrystals into superlattices during the cooling process. k, Plot of the fraction of unassembled nanocrystals as a function of temperature during heating (red squares) and cooling (blue dots) cycles.

Extended Data Figure 9 Characterization of Fe nanoparticles and their superlattices formed during synthesis at 180 °C.

a, Representative background-subtracted one-dimensional SAXS patterns (coloured plots) of the Fe nanoparticles in solution during the synthesis before the formation of superlattices and their corresponding SAXS fits (black lines). b, Representative background-subtracted one-dimensional SAXS patterns of Fe nanoparticles in solution after the formation of f.c.c. superlattices. The diffraction peaks shift to smaller q, confirming postgrowth of Fe nanoparticles inside the superlattices. c, A typical structure factor of the superlattices at 880 s. The structure factor corresponds well with a f.c.c. lattice. d, Kinetics of the growth of Fe nanoparticles and their crystallization into f.c.c. superlattices over reaction time. Error bars result from the fits to the SAXS data. e, TEM image of a representative f.c.c. superlattices of Fe nanoparticles. The inset shows the final dispersed Fe nanoparticles. f, SEM image of a representative f.c.c. superlattice. g, Interaction potential between two Fe nanoparticles as a function of interparticle separation. Here T = 453 K is the reaction temperature. The solid plots are the sum of van der Waals attraction and steric repulsive, while the dotted plot is the sum of van der Waals attraction, steric repulsion and magnetic dipole–dipole interaction. Here d represents the diameter of the Fe nanocrystals.

Extended Data Figure 10 Characterization of ex situ synthesized PbTe nanocrystals and their superlattices.

a, SEM image of a representative superlattice of cubic PbTe nanocrystals formed in 1-octadecene at 160 °C. Inset shows a photograph of the superlattice precipitates in 1-octadecene after the synthesis without any purification. b, TEM image of a representative superlattice loaded directly on a Cu TEM grid. c, TEM image of the PbTe nanocrystals from their hexane dispersion after purification. The inset shows a photograph of PbTe nanocrystals dispersed in hexane. d, Size histogram of PbTe nanocrystals obtained from c, showing the PbTe nanocrystal size to be 14.8 ± 2.1 nm.

Rights and permissions

About this article

Cite this article

Wu, L., Willis, J., McKay, I. et al. High-temperature crystallization of nanocrystals into three-dimensional superlattices. Nature 548, 197–201 (2017). https://doi.org/10.1038/nature23308

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nature23308

- Springer Nature Limited

This article is cited by

-

Real-time monitoring of CdTe quantum dots growth in aqueous solution

Scientific Reports (2024)

-

Poly (heptazine imide) nanocrystal for hydrogen peroxide evolution in the dark by accumulating photo-generated electrons

Nano Research (2024)

-

Crystallization of binary nanocrystal superlattices and the relevance of short-range attraction

Nature Synthesis (2023)

-

Nanocluster superstructures assembled via surface ligand switching at high temperature

Nature Synthesis (2023)

-

Surface-ligand-induced crystallographic disorder–order transition in oriented attachment for the tuneable assembly of mesocrystals

Nature Communications (2022)