Abstract

Successful delivery of the United Nations sustainable development goals and implementation of the Paris Agreement requires technologies that utilize a wide range of minerals in vast quantities. Metal recycling and technological change will contribute to sustaining supply, but mining must continue and grow for the foreseeable future to ensure that such minerals remain available to industry. New links are needed between existing institutional frameworks to oversee responsible sourcing of minerals, trajectories for mineral exploration, environmental practices, and consumer awareness of the effects of consumption. Here we present, through analysis of a comprehensive set of data and demand forecasts, an interdisciplinary perspective on how best to ensure ecologically viable continuity of global mineral supply over the coming decades.

Similar content being viewed by others

Main

The current oversupply of raw materials1 in world markets masks a persistent underlying global challenge, namely, how to supply raw materials to an expanding global population that is expected to reach 8.5 billion by 2030—the target date for the United Nations sustainable development goals2. Three events highlight the urgency and complexity of the challenge. First, on 12 December 2015, a historic international agreement on climate change was formally adopted in Paris3. This adds momentum to a transition to a low-carbon society, a change that will require vast amounts of metals and minerals4. Mineral resourcing and climate change are inextricably linked, not only because mining requires a large amount of energy, but also because the world cannot tackle climate change without an adequate supply of raw materials to manufacture clean technologies5,6,7. Likewise, the UN sustainable development goals, launched in September 2015, will also require minerals for infrastructure, but scant attention has been paid to the science and policy needed to meet these targets8. Second, the global mining industry is continuing to downsize, despite some stabilization in commodity prices, which will delay its response to future increases in demand. This is also derailing efforts that should be directed towards exploration for new primary resources and an improvement in the recovery efficiencies in metal recycling. Third, events such as the Samarco tailings dam collapse in Brazil9 illustrate the perils of supply disruption and the erosion of community confidence that can be caused by major accidents at mining sites. Thus miners may be subject to far more stringent regulations, levied by legislators or imposed by local communities, which will prevent access to some resources and render exploitation of others more difficult and costly.

In this Perspective, we evaluate these trends, and propose measures to avert the crisis that is looming in the sphere of geological mineral exploration, recycling and the governance of supply chains.

Recent evaluations of shorter-term supply risk and criticality10,11,12,13 suggest that, over the next 2–3 decades (when the availability of metals for recycling is expected to remain low14) an unprepared minerals industry will struggle to meet demand for several metals (for example, copper15) for which substitutes are not readily available. In addition, speciality metals such as germanium are by-products of mining other minerals, in this case zinc sulfide, which contains trace amounts of germanium, and are thus dependent on the mining of their host mineral. Given the rapid pace of technological and demographic change, broader discussion of current and future mineral supply is needed to avoid disruptive volatility in prices and supply. To stimulate the discussion, we initially evaluate various approaches to charting supply problems. The modelling in Fig. 1 shows that a peak in production of primary and recycled copper will not be reached before the middle of this century. However, in the coming decades, supply will be tight because accelerating demand will not be met by increasing recycling or substitution, and because decreasing use of fossil fuels to mitigate the effect of climate change will require increasing consumption of metals.

Thick dashed black line, modelled primary copper production, and thick dashed grey line, modelled secondary copper production; data show values to 2100. Thick solid black line, historical data of primary23,24 copper production, and thick solid grey line, historical data of recycled copper production; data show values for 1966–2010. Fine solid black line, sum of the modelled primary and secondary production. Fine black dashed line, modelled primary production of the Northey et al.24 projection of primary production (comparison used with permission from Northey et al.). Further information on modelling methods is in Supplementary Information section SI-1, together with graphs of the evolution of copper reserves through time (Supplementary Fig. 1), annual end-of-life copper generated (Supplementary Fig. 2) and stocks in use (Supplementary Fig. 3). Mt, megatonnes.

We develop a hybrid approach supported by various research programmes on resource scarcity and climate policy, using copper as an example. Copper is widely used throughout the economy in conventional and renewable electricity generation and in electric vehicles and buildings. It has major recycling potential but its end-of-life recycling rate is about 60%, and because of delays between manufacturing and scrapping, the recycling input rate (a measure of the share of secondary sources in raw material supply)16 is only about 33%. The future availability of metals and other mineral products will depend both on economic and market factors (metal prices, anticipated supply and demand) and on social and environmental pressures17. We anticipate a need for greater environmental diplomacy to assure access to mineral deposits which are irregularly distributed and often occur in areas of conflict18.

Challenges facing future mineral supply

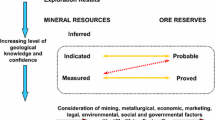

Future supply challenges for copper are illustrated in Figs 1 and 2. When considering future supply, geologists estimate the total potential amount of copper available for mining. This amount comprises reserves, the term applied to deposits that are economic to mine at the present time, and resources, which include already identified and undiscovered deposits that are not economic to mine at present but have reasonable prospects for eventual economic extraction. In the case of copper, estimates of resources in 2008 projected 5,500 years of extraction potential up to 3 km subsurface depth19. Higher selling prices and improved extraction techniques can make marginal deposits economically viable, but social conflict and environmental constraints on production can limit or deny access to resources yet to be developed. While the former factors have long been taken into account when identifying accessible and economic ore deposits, consideration of the latter has been patchy. According to some surveys, the rate of discovery has slowed in the past decade as many easily accessible deposits are exhausted. The current dearth of exploration activity exacerbates the problem20. The obligation to mine in an environmentally acceptable manner has added a vast array of regulations that has greatly increased the cost of mineral exploration and mining. In addition, the need to obtain the community’s social licence to operate, and a scarcity of legislative, economic and governance stability in the host country, will place further constraints on mineral supply21.

The size of each plotting symbol indicates the projected size of the extractable deposit. This analysis is based on 271 primary copper deposits of more than 0.1 Mt Cu found in the world.

Figure 1 compares the results of modelling current and future production of copper from two sources, primary (mined) production and recycling, while assuming population stabilization projections (see Supplementary Information section SI-1 for details). If population does not stabilize after 2050 and continues to grow, the demand scenario could be even higher, leading to further supply concerns. Nevertheless, the supply of metals available for recycling, combined with encouragement from governments to move towards a circular economy (one predicated on reuse and recycling of resources), is slowly decreasing the relative contribution from primary production22. Secondary sources will eventually displace primary production (Fig. 1), but this will not occur until the middle of the century because most of the supply of recyclable material is locked up in long-life assets.

At least one-quarter of known copper resources are in countries with less than satisfactory governance, as assessed using the Natural Resource Governance Index of 2014 (see ref. 23 for the methodology by which this is calculated, and see details in Supplementary Information section SI-2), which quantifies the quality of “institutional and legal setting, reporting practices, safeguards and quality controls, and enabling environment”. Although the quality of governance will no doubt vary in the future as governments are replaced, the global trend provides little evidence that the problem will disappear in the near future. Production from countries with poor governance will certainly be needed to meet global demand and this issue will need to be taken into account.

An analysis of major copper mines worldwide (Fig. 2) shows long delays in project approvals in many of the locations where copper will be sourced in the future. Figure 2 shows that, depending on the location, the average lead-time between discovery and development is 13 to 23 years and the rate of conversion seems to be slowing. When combined with the need to satisfy regulations that assure that mineral exploration and mining is done in an environmentally and socially acceptable manner, Fig. 2 demonstrates that the mining industry is not in a strong position to quickly find and bring on stream new capacity to meet a shortfall in production.

Fostering further exploration and recycling

Our analysis also reveals that the incentives for investment in exploration are not always aligned with societal needs and constraints. The market determines investment based on short-term returns rather than long-term scarcity planning. Figure 3 shows the historical investment in exploration over time, as well as a wide variation in the preferred commodity. The high investment in uranium during the Cold War was due to government subsidies, while the recent emphasis on gold is due to high return on investment. In both cases, exploration was stimulated by high commodity prices.

a, Percentage of total exploration investment broken down by commodity and year. b, Total exploration investment broken down by region and year. In b, ‘rest of world’ refers to Mongolia, Middle East and Southwest Asia (including India and Pakistan), FSU indicates former Soviet Union.

Figure 3b shows how the spurt of investment in exploration during the recent resource boom was followed by a steep decline after 2012 due to a fall in metal prices triggered by a weakening of demand. Metal prices remain low and exploration investment in such a climate is unattractive.

The supply of some metals from recycled sources has the potential to increase, due in part to government incentives to move towards a circular economy that minimizes material usage and maximizes the use of recycled materials22,24. However, the supply of recycled material is limited by the time the metals are tied up in industrial infrastructure and consumer products. The more durable the infrastructure, the less available the metal supply for recycling for other uses. Residence times of metals in infrastructure are highly variable, and depend on design practices and goals25. Durability has its own environmental benefits in terms of material and energy conservation, but high durability counters the recycling imperative to meet metal demand. End-of-life recycling rates vary from about 1% for potentially critical metals like the rare earth elements to 55% or so for aluminium26 and 70% or more for iron27. To meet growing demand once the global economy improves, mining will need to continue to the foreseeable future.

Global resource governance needed

The development of renewable energy sources and other high-technology applications will require new infrastructure that will consume a different mix of minerals from current applications, including not only ‘critical’28 metals such as the rare earths, but also vast amounts of common commodities such as copper, steel and cement2,3,4. Of major concern is a potential period when primary metal production may peak and start to decline before the social and capital infrastructure for secondary metal production will allow recycling to contribute substantially to supply (Fig. 1).

Three policy paths have been explored to understand and assure an adequate supply of metals and other mineral products. First, certain countries have focused on boosting supply through a national security agenda from sources that are politically more feasible to access29,30. The US Department of Energy’s Critical Materials Institute was established through a $120 million grant to a consortium led by Ames National Laboratories in 2013. The European Union has established the European Institute of Technology Knowledge and Innovation Community on Raw Materials, and launched programmes such as the European Innovation Partnership on Raw Materials and the ERA-MIN network. The European Commission identifies 20 raw materials as critical for the EU economy, based on their economic importance for European industries and their high supply risk (see Supplementary Information section SI-3)31. The Geological Surveys of the United States32 and Britain33 produced similar lists. It should be noted that there is no uniformly agreed definition of criticality; country lists vary depending on how the nation and its industries use various materials34.

Second, international programmes have assembled data on resource demand and governance of natural resources (for example, see the large body of work prepared by the International Resources Panel; http://www.unep.org/resourcepanel/). The International Resource Panel of the United Nations Environment Programme and the Intergovernmental Forum on Mining, Minerals, Metals and Sustainable Development are key examples. Both have undertaken important work on mineral availability and governance but so far they have largely focused on knowledge exchange, with limited regard to developing policy for resource scarcity. The World Resources Forum and Future Earth have brought together scholars, industry and policymakers to grapple with the science of resource scarcity but have no policy-making power.

Third, whereas industry organizations such as the International Council on Metals and Mining (ICMM) have worked on environmental and social aspects of present and future mineral supply (see the ICMM web site for details on their publications; http://www.icmm.com), projections of future mineral resources have been the purview of exploration divisions of companies and national geological surveys. Although there may be common metallurgical processes between them, mining and recycling operations remain largely separate in their corporate management—the former are carried out mainly by private mining companies, and the latter by a different group of companies or by government agencies. Given the common trading markets for metals, whether from mined or recycled sources, there are further opportunities for harnessing ecologically efficient sourcing pathways for metal users.

Only after collection is there convergence, when refineries controlled by mining companies treat both primary and recycled materials. Without better anticipation of the future aspirations of society, and a better knowledge of the ability of our planet to supply the needed raw materials, we remain at the mercy of short-term decision-making. Much of the debate about long-term criticality remains in the research/policy space and is not reflected in the markets. The issue has not yet been taken up effectively by governments and industry at the global scale.

Actions for sustainable mineral sourcing

The international community must actively plan for the next few decades when mineral supply threatens to be inadequate. This planning needs to consider the vulnerable but flexible nature of mineral resources and the global dependence on critical minerals. An international process is needed to mitigate the shocks of future supply crises, which could be undertaken through a covenant35 or even a treaty36. The G7 (an alliance of seven major industrialized democracies) has tentatively recognized the governance vacuum on raw materials through establishing an “alliance on resource efficiency” in 2015. However, none of the current international agencies has a mandate to plan, oversee or realize efficient and effective exploitation of mineral resources. Even though there is considerable fatigue with too many international treaties, as noted by major resource powers such as China37, we propose that a linkage between the International Resource Panel (Box 1) and the Intergovernmental Forum on Mining, Minerals, Metals and Sustainable Development could use existing treaty mechanisms for more effective resource planning. The recently established United Nations Environment Assembly38 could play a convening role to help ensure that ecological constraints are duly incorporated into effective planning. Six specific measures should be considered:

1. Reach consensus on international targets for global mineral production. As with the targets for emissions reductions in COP21, standards should be set to ensure that mining is conducted with maximum efficiency and minimal negative impact on the environment and society. Design specifications for the modularity of products that can assist in reaching targets for recycling, product design and modularity, waste harvesting and stockpiling should be established at the global rather than national level, the latter being more focused on internal security. These targets should be dynamic and flexible; they should change in response to technological developments, but must remain part of an integrated planning process.

2. Monitor impacts of mineral production and consumption. There is an urgent need to establish a system for tracking mineral use along the entire value chain, from source to end of life, perhaps based on the ‘fingerprinting’ developed by the German Geological Survey for tantalum39,40. Such a system could also incorporate a global chain-of-custody programme, similar to that of the food industry. Furthermore, there is a need to promote domestic production and consumer cognizance of mineral use, incorporating a notion of ‘metal miles’; that is, reduction of the environmental cost of transport through increased consumption of local products.

3. Improve coordination of mineral exploration. Private–public cooperation is needed to develop new techniques for mineral exploration in new locations, from deep in the crust to the bottom of the ocean, drawing on lessons from programs such as Australia’s ‘UNCOVER: Searching the Deep Earth’ or the European Union’s Blue Mining initiative for deep oceanic mineral deposits. Data sharing between industry and geological surveys is also essential. Geophysical and geochemical data both need to be shared in greater detail through dynamic databases (see Supplementary Information section SI-5 for an example of European geochemical database efforts).

4. Support investment and research into new mineral extraction technologies. Technology to maximize efficiency, minimize waste and reduce the consumption of water should be shared more effectively through intellectual property arrangements like the reforms proposed in pharmaceutical patent sharing for development outcomes41. Extraction processes should be improved. Typical copper grades are less than 1% of the total mass and the recovery rate of this small amount should be optimized. In addition, all valuable metals contained in the ore should be recovered rather than ending up in the tailings dam (for example, indium or germanium in zinc ores, or gallium in bauxite). Lunar42 and asteroid mining, while plausible for long-term planning, as exemplified by the recent unmanned Chinese mission to the Moon and private efforts like the Lunar-XPRIZE, face techno-economic and regulatory uncertainty43, and it will be many decades before they contribute significantly to global mineral production.

5. Harmonize global best practices for responsible mineral resource development. Mineral deposits are irregularly distributed and their locations are fixed by geology. Thus, the value of these mineral resources must be assessed in the context of other land uses. Technological evolution needs to be reinforced by establishing global practices that balance mining and mineral treatment with biodiversity protection, agriculture and urbanization, and other land and water uses. Good environmental practice, proactive and effective stakeholder engagement, and co-existence of mining and other land uses must form the basis of sustainable mineral exploitation. To achieve this, better coordination between industry and governments will be needed.

6. Develop maps and inventories showing the availability of recyclable metals. These maps would show the locations and status of stocks of in-use metals available for future use and recycling, just as geoscience agencies map the locations of ores. In this way, companies seeking to utilize these resources could assess their potential composition and availability over time. Unlike ores, which take a ‘commodity focus’ based on a single metal (for example, copper) or several co-products (for example, zinc, lead, silver), recycling demands a ‘product focus’ that defines the recycling potential of multiple metals contained in the product. Given the huge variation in recyclability of metals, which depend on the product in which the metal is used as well as the future demand for the metal, establishing internationally recognized standards for recyclability would be an important development.

We recognize that in many cases commodity pricing signals run contrary to ecological goals. Regulatory mechanisms would be needed for companies to focus on longer-term resource conservation planning. Furthermore, to meet these challenges, we advocate an early warning system, based on rigorous analysis of data, comprising a series of eight alarms, perhaps through the international mechanisms noted above, as follows. Geological alarms—do we have sufficient reserves? Time lag alarms—we know the reserves are out there, but can they be developed in time? Governance alarms—we know where they are, but can they be sustainably mined? Technological alarms—novel and unanticipated uses for previously unwanted metals (for example, tellurium, germanium, indium). Environmental alarms—are the risks to local ecosystems and populations too high? Social alarms—will, or should, local populations resist mining? Geopolitical alarms—will land ownership or other uses (agriculture, parks, reserves, other industry) preclude mining? Business risk alarms—will changes in tax and investment rules or political instability make mining uneconomic?

Planetary policy for minerals

International environmental policy is currently missing the resource dimension for meeting both ecological and development targets44,45. There is a plethora of international organizations to promote ecologically efficient development such as the Global Green Growth Institute and the International Renewable Energy Agency. Yet the mineral resource requirement needed to carry out their agendas must be evaluated through a coherent planning process, based on the parameters we have discussed in this Perspective. Minerals are a fundamental planetary resource, and should be a base tenet of environmental policy development. Global coordination is needed to ensure that minerals are produced in the most ecologically and economically efficient way. Further research, and institutional collaboration between the private and public sectors, is needed to develop innovative methods to locate and extract future mineral resources. Mining and recycling will need clear metrics of ecological and economic performance. This coordination could be provided by nascent organizations such as the International Resource Panel, Future Earth and the Intergovernmental Forum on Mining, Minerals, Metals and Sustainable Development in partnership with epistemic communities of environmental organizations, such as the International Union for Conservation of Nature. Ultimately, international legal mechanisms may be needed to anticipate and respond to future mineral availability constraints.

References

Rankin, J. Brussels steel summit fails to find answer to oversupply problem. The Guardian https://www.theguardian.com/business/2016/apr/18/brussels-steel-summit-fails-find-answer-oversupply-problem (18 April 2016; accessed June 2016)

UNFPA Revision of Population Prospects (United Nations, 2015)

UNFCCC Adoption of the Paris Agreement by the President: Paris Climate Change Conference. (United Nations, 2015); http://unfccc.int/resource/docs/2015/cop21/eng/l09r01.pdf (accessed August, 2016)

Vidal, O., Goffé, B. & Arndt, N. Metals for a low-carbon society. Nat. Geosci. 6, 894–896 (2013)

Alonso, E. et al. Evaluating rare earth element availability: a case with revolutionary demand from clean technologies. Environ. Sci. Technol. 46, 3406–3414 (2012). Provides detailed analysis of the rapid projected rise in rare-earth mineral demand over the next three decades as a function of the growth in clean energy technologies.

Zepf, V., Reller, A., Rennie, C., Ashfield, M. & Simmons, J. B.P. Materials Critical to the Energy Industry (BP Publications, 2014)

Larcher, D. & Tarascon, J.-M. Towards greener and more sustainable batteries for electrical energy storage. Nat. Chem. 7, 19–29 (2014)

Bringezu, S. et al. Multi-scale governance of sustainable natural resource use — challenges and opportunities for monitoring and institutional development at the national and global level. Sustainability 8, 778 (2016)

Phillips, D. Brazil’s mining tragedy: was it a preventable disaster? The Guardianhttps://www.theguardian.com/sustainable-business/2015/nov/25/brazils-mining-tragedy-dam-preventable-disaster-samarco-vale-bhp-billiton (25 November 2015; accessed August 2016)

European Commission. Report on Critical Raw Materials for the EU (European Commission, 2014)

Graedel, T. E., Harper, E. M., Nassar, N. T. & Reck, B. K. On the materials basis of modern society. Proc. Natl Acad. Sci. USA 112, 6295–6300 (2015)

Moss, R. L., Tzimas, E., Kara, H., Willis, P. & Kooroshy, J. Critical Metals in Strategic Energy Technologies: Assessing Rare Metals as Supply-Chain Bottlenecks in Low-Carbon Energy Technologies. JRC Scientific and Technical Report, EUR 24884 EN-2011. (European Union, 2011)

Frenzel, M., Tolasano-Delgado, R. & Gutzmer, J. Assessing the supply potential of high-tech metals — a general method. Resour. Policy 46, 45–58 (2015). Presents a novel methodology for estimating supply using Monte Carlo type statistical simulations of repeated recovery of technology metals from product supply chains.

International Resource Panel. Metals Recycling: Opportunities, Limits and Infrastructure (UNEP, Nairobi, 2007)

Elshkaki, A., Graedel, T. E., Ciacci, L. & Reck, B. Copper demand, supply, and associated energy use to 2050. Glob. Environ. Change 39, 305–315 (2016)

The World Copper Fact Book (International Copper Study Group, 2015); http://www.icsg.org/index.php/component/jdownloads/viewdownload/170/2092 (accessed August 2016)

Franks, D. M. et al. Conflict translates environmental and social risk into business costs. Proc. Natl Acad. Sci. USA 111, 7576–7581 (2014). An evaluative study of the economic cost of social conflict estimated using a detailed analysis of mining projects worldwide through interviews with managers

Susskind, L. & Ali, S. H. Environmental Diplomacy: Negotiating More Effective International Agreements (Oxford Univ. Press, 2014)

Kesler, S. E. & Wilkinson, B. H. Earth’s copper resources estimated from tectonic diffusion of porphyry copper deposits. Geology 36, 255–258 (2008)

USGSAnnual Review 2015: Exploration Review (accessed February 2017)

Meinert, L. D., Robinson, G. R. & Nassar, N. T. Mineral resources: reserves, peak production and the future. Resources 5, 14 (2016)

Gregson, N., Crang, M., Fuller, S. & Holmes, H. Interrogating the circular economy: the moral economy of resource recovery in the EU. Econ. Soc. 44, 218–243 (2015)

Natural Resource Governance Institute. Resource governance index: methodology. http://www.resourcegovernance.org/resource-governance-index (accessed August 2016)

Hatayama, H., Daigo, I. & Tahara, K. Tracking effective measures for closed-loop recycling of automobile steel in China. Resour. Conserv. Recycling 87, 65–71 (2014)

Angrick, M., Burger, A. & Lehmann, H. (eds) Factor X, Eco-Efficiency in Industry and Science (Springer, 2013)

Liu, G., Bangs, C. E. & Muller, D. B. Stock dynamics and emission pathways of the global aluminium cycle. Nat. Clim. Chang. 3, 338–342 (2012)

Graedel, T. et al. What do we know about metal recycling rates? J. Ind. Ecol. 15, 355–366 (2011)

Graedel, T. E., Harper, E. M., Nassar, N. T., Nuss, P. & Reck, B. K. Criticality of metals and metalloids. Proc. Natl Acad. Sci. USA 112, 4257–4262 (2015). A comprehensive evaluation of key limiting factors that lead to potential mineral security concerns from the point of view of mineral demand and supply bottlenecks

Naden, J. Sustainable Use of Natural Resources (Science and Implementation Plan, Security of Supply of Mineral Resources (SoS Minerals) Research Programme 2012–2017, Natural Environment Research Council, UK, 2013); http://www.nerc.ac.uk/research/funded/programmes/minerals/science-and-implementation-plan/

Gunn, G. & Bloodworth, A. Briefing: minerals security of supply: a geological perspective. Proc. ICE Waste Resour. Management 165, 171–173 (2012)

European Commission. Report of the Ad hoc Working Group on Defining Critical Raw Materials (European Commission Report on Critical Raw Materials for the EU, European Commission, 2014)

National Science and Technology Council. Assessment of Critical Minerals: Screening Methodology and Initial Application (The White House, 2016); https://www.whitehouse.gov/sites/whitehouse.gov/files/images/CSMSC%20Assessment%20of%20Critical%20Minerals%20Report%202016-03-16%20FINAL.pdf

British Geological Survey. World Mineral Production 2006–10 https://www.bgs.ac.uk/downloads/start.cfm?id=2255 (British Geological Survey, 2012)

Glöser, S., Tercero Espinoza, L., Gandenberger, C. & Faulstich, M. Raw material criticality in the context of classical risk assessment. Resour. Policy 44, 35–46 (2015)

Wilts, H. & Bleischwitz, R. in Factor X, Eco-Efficiency in Industry and Science (eds Angrick, M., Burger, A. & Lehmann, H. ) Ch. 7 (Springer, 2013)

Henckens, M. L. C. M., Driessen, P. P. J., Ryngaert, C. & Worrell, E. The set-up of an international agreement on the conservation and sustainable use of geologically scarce mineral resources. Resour. Policy 49, 92–101 (2016). Bold article that makes the case for an international agreement on minerals based on both intergenerational equity and resource conservation arguments with a suggested quota development model.

Preston,F., Bailey, R., Bradley, S., Wei, J. & Zhao, C. Navigating the New Normal: China and Global Resource Governance (Chatham House and Development Research Centre of the Chinese State Council, 2015); https://www.chathamhouse.org/publication/navigating-new-normal-china-and-global-resource-governance

Desai, M. The Advent of the United Nations Environment Assembly. Insights from the American Society of International Law 19, https://www.asil.org/insights/volume/19/issue/2/advent-united-nations-environment-assembly (2015)

Melcher, F. et al. Analytical fingerprint for tantalum ores from African deposits. Geophys. Res. Abstr. 11, 2452 (2009)

Franken, G. et al. in Non-Renewable Resource Issues: Geoscientific and Societal Challenges (eds Sinding-Larsen, R. & Wellmer, F. W. ) Ch. 10 (Springer, 2012)

Correa, C. Integrating Public Health Concerns into Patent Legislation in Developing Countries (The South Centre, Geneva, 2000)

Crawford, I. A. Lunar resources: a review. Prog. Phys. Geogr. 39, 137–167 (2015)

Roth, S. E. Developing a law of asteroids: constants, variables, and alternatives. Columbia J. Transnatl. Law 54, 827–872 (2015)

Gielen, D., Boshell, F. & Saygin, D. Climate and energy challenges for materials science. Nat. Mater. 15, 117–120 (2016)

Jeffries, E. Coming clean. Nat. Clim. Chang. 5, 93–95 (2015)

International Resource Panel. Decoupling Natural Resource Use and Environmental Impact from Economic Growth http://www.unep.org/resourcepanel/Portals/50244/publications/Decoupling_Report_English.pdf (UNEP, 2011)

International Resource Panel. Metal Stocks in Society: Scientific Synthesis http://www.unep.org/resourcepanel/Portals/50244/publications/UNEP_report1_Stocks_100920.pdf (UNEP, 2010)

International Resource Panel. Recycling Rates of Metals: A Status Report http://www.unep.org/resourcepanel/Portals/50244/publications/UNEP_report2_Recycling_130920.pdf (UNEP, 2011)

International Resource Panel. Metals Recycling: Opportunities, Limits, Infrastructure http://www.unep.org/resourcepanel/Portals/50244/publications/UNEP_report2b_RecyclingOpportunities_130919.pdf (UNEP, 2013)

International Resource Panel. Environmental Risks and Challenges of Anthropogenic Metal Flows and Cycles http://www.unep.org/resourcepanel/Portals/50244/publications/UNEP_report3_EnvironmentalImpacts130920.pdf (UNEP, 2015)

International Resource Panel. Estimating Long-run Geological Stocks of Metals http://www.unep.org/resourcepanel/Portals/24102/PDFs/GeolResourcesWorkingpaperfinal040711.pdf (UNEP, 2011)

International Resource Panel. Global Material Flow and Resource Productivity http://unep.org/documents/irp/16-00169_LW_GlobalMaterialFlowsUNEReport_FINAL_160701.pdf (UNEP, 2016)

Acknowledgements

The authors are an interdisciplinary group, operating under the Resourcing Future Generations initiative of the International Union of Geological Sciences, the International Council for Science Unions and UNESCO. D. Nyanganyura of the International Council for Science and F. Masotti of Vale Corporation provided comments that led to this Perspective. S. Mohr of the University of Technology Sydney assisted with the model output results presented. Financial support provided by UNESCO, IUGS and ICSU, and logistical support provided by the Namibian Geological Survey, is acknowledged.

Author information

Authors and Affiliations

Contributions

S.H.A. designed and synthesized the written Perspective with N.A. and D.G.; E.N. led S.H.A., D.G., N.A., R.O., L.M., A.D., M.A.E., J.S., G.B., N.Y., A.L., G.S., J.K. and R.D. to develop the analytical framework and policy response recommendations through consensus; O.V. and N.A. contributed data for Fig. 1 and for material in Supplementary Information SI-1; D.G. contributed material in Supplementary Information SI-2; R.S. contributed data for Figs 2 and 3 and material in Supplementary Information SI-4. A.D. contributed material in Supplementary Information SI-5 and provided commentary on geochemical database and other existing tools and their data deficits. M.A.E. and J.S. prepared Box 1.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Additional information

Reviewer Information Nature thanks J. Gutzmer, S. Kesler and B. Reck for their contribution to the peer review of this work.

Supplementary information

Supplementary Information

This file contains Supplementary Methods, Supplementary Figures, Supplementary Tables and additional references. (PDF 1039 kb)

Rights and permissions

About this article

Cite this article

Ali, S., Giurco, D., Arndt, N. et al. Mineral supply for sustainable development requires resource governance. Nature 543, 367–372 (2017). https://doi.org/10.1038/nature21359

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nature21359

- Springer Nature Limited

This article is cited by

-

Reducing supply risk of critical materials for clean energy via foreign direct investment

Nature Sustainability (2024)

-

Case study on the secondary support time and optimization of combined support for a roadway under high in-situ stress

Geomechanics and Geophysics for Geo-Energy and Geo-Resources (2024)

-

Dynamic spillover of upstream primary metals and by-product metals market and its impact from the downstream new energy vehicles market

Mineral Economics (2024)

-

The dynamics and long-term availability of the total resources from the geosphere and technosphere—re-examined

Mineral Economics (2024)

-

Multi-biomarker approach reveals the effects of heavy metal bioaccumulation in the foundation species Prosopis laevigata (Fabaceae)

Environmental Science and Pollution Research (2024)