Abstract

Solution-processed optoelectronic and electronic devices are attractive owing to the potential for low-cost fabrication of large-area devices and the compatibility with lightweight, flexible plastic substrates. Solution-processed light-emitting diodes (LEDs) using conjugated polymers or quantum dots as emitters have attracted great interest over the past two decades1,2. However, the overall performance of solution-processed LEDs2,3,4,5—including their efficiency, efficiency roll-off at high current densities, turn-on voltage and lifetime under operational conditions—remains inferior to that of the best vacuum-deposited organic LEDs6,7,8. Here we report a solution-processed, multilayer quantum-dot-based LED with excellent performance and reproducibility. It exhibits colour-saturated deep-red emission, sub-bandgap turn-on at 1.7 volts, high external quantum efficiencies of up to 20.5 per cent, low efficiency roll-off (up to 15.1 per cent of the external quantum efficiency at 100 mA cm−2), and a long operational lifetime of more than 100,000 hours at 100 cd m−2, making this device the best-performing solution-processed red LED so far, comparable to state-of-the-art vacuum-deposited organic LEDs2,3,4,5,6,7,8. This optoelectronic performance is achieved by inserting an insulating layer between the quantum dot layer and the oxide electron-transport layer to optimize charge balance in the device and preserve the superior emissive properties of the quantum dots. We anticipate that our results will be a starting point for further research, leading to high-performance, all-solution-processed quantum-dot-based LEDs ideal for next-generation display and solid-state lighting technologies.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Main

Quantum dots are solution-processable semiconductor nanocrystals9,10,11 that promise size-tunable emission wavelengths, narrow emission linewidths, near-unity-photoluminance quantum yield and inherent photophysical stability. As inorganic crystalline emission centres, quantum dots are expected to be promising candidates to overcome stability problems of both polymer LEDs and small-molecule organic LEDS (OLEDs), such as drastic efficiency roll-off at high current densities and low operational lifetime. To fully exploit the superior properties of quantum dots, a number of quantum-dot-based LED (QLED) structures were developed and various materials, including small molecules, conjugated polymers and inorganic oxides, were explored as charge-transport interlayers3,12,13,14,15,16,17,18,19,20.

Our device (Fig. 1a, b) consists of multiple layers of, in the following order, indium tin oxide (ITO), poly(ethylenedioxythiophene):polystyrene sulphonate (PEDOT:PSS, 35 nm), poly (N,N′-bis(4-butylphenyl)-N,N′-bis(phenyl)-benzidine) (poly-TPD, 30 nm), poly(9-vinlycarbazole) (PVK, 5 nm), CdSe–CdS core–shell quantum dots (QDs, 40 nm), poly(methyl methacrylate) (PMMA, 6 nm), ZnO nanoparticles (150 nm) and silver (Ag, 100 nm). Figure 1c shows a schematic of the flat-band energy level diagram of the layers. The energy level values for ITO, PEDOT:PSS and ZnO were obtained by ultraviolet photoelectron spectroscopy and optical measurements. Other energy level values were taken from refs 3, 21, 22, 23. Phase-pure zinc blende CdSe–CdS core–shell nanocrystals with ten monolayers of CdS shell are used. These quantum dots possess a photoluminance quantum yield of >90% and outstanding optical properties24 (Extended Data Fig. 1). Bilayer-structured hole-transport interlayers of poly-TPD/PVK take advantage of the deep highest-occupied-molecular-orbit energy level of PVK to realize efficient hole injection into the quantum dot layers and the relatively high hole mobility of poly-TPD to achieve low turn-on voltage and high power efficiency. Thin films of colloidal ZnO nanocrystals (Extended Data Fig. 2) are employed as electron-transport interlayers (ETLs) because of their unique combination of high electron mobility, ease of preparation and the previously identified benefit of efficient electron injection into the quantum dot layers17,18. The key component of this device, a thin insulating PMMA layer (Fig. 1d), is inserted between the ZnO ETL and the quantum dot emissive layer.

a, Device structure. b, Cross-sectional transmission electron microscopy image showing the multiple layers of material with distinct contrast. Scale bar, 100 nm. The PMMA layer is evident only when the cross-sectional sample is sufficiently thin (d) because the neighbouring quantum dot layer and the ZnO layer can obstruct the imaging of the PMMA layer. HTL, hole-transport interlayer. c, Flat-band energy level diagram. d, High-magnification transmission electron microscopy image of an extremely thin cross-sectional sample revealing the presence of the PMMA layer between the ZnO layer and the quantum dot layer. Scale bar, 5 nm.

The normalized electroluminescence spectrum of the QLED is shown in Fig. 2a. The symmetric emission peak at 640 nm with a narrow full-width at half-maximum of 28 nm corresponds to Commission Internationale de l’Eclairage (CIE) colour coordinates of (0.71, 0.29), which are close to the spectral locus and represent colour-saturated deep-red emission ideal for display applications (Fig. 2b). Figure 2c shows the current density–voltage and luminance–voltage characteristics of a device with the best efficiency. The current density and luminance increase steeply once the voltage reaches ∼1.7 V, yielding a maximum brightness of over 42,000 cd m−2 at 8 V. The peak external quantum efficiency (EQE), 20.5%, is achieved at a current density of ∼7 mA cm−2 and a brightness of ∼1,200 cd m−2. The peak EQE of this device, 20.5%, is the highest value for QLEDs3,12,13,14,15,16,17,18,19,20. High EQE can be maintained in a wide range of current densities (Fig. 2d), that is, EQE > 18% when the current density is in the range of 1–42 mA cm−2, which corresponds to a brightness in the range of 100–6,600 cd m−2. When the current density reaches 100 mA cm−2, an EQE of >15% is sustained. The low efficiency roll-off of this device, which is better than that of the other high-efficiency QLED (peak EQE, 18.5%) with vacuum-deposited hole-transport interlayers3 and is comparable to those of state-of-the-art vacuum-deposited OLEDs8, suggests that our QLEDs are promising for high-power applications. The established solution-processing protocol leads to devices with excellent reproducibility. As shown by the histograms for 27 devices from four batches (Fig. 2e), both the high average peak EQE, 18.7%, and the low relative standard deviation of peak EQE, 4.3%, are encouraging.

a, Electroluminescence spectrum at an applied voltage of 3 V and, inset, a photograph of a device with the Zhejiang University logo. a.u., arbitrary units. b, The corresponding CIE coordinates. c, Current density and luminance versus driving voltage characteristics for the device with the best efficiency. d, EQE versus current density and luminance for the device with the best efficiency. e, Histogram of peak EQEs measured from 27 devices. f, Stability data for a QLED device (L, luminance). The device was test at ambient conditions (temperature, 20–25 °C; relative humidity, 50–70%).

Our QLEDs, simply sealed by ultraviolet-curable resin and without other complicated encapsulation techniques, exhibit outstanding ambient stability under high-brightness conditions. As shown in Fig. 2f, for a typical device tested at a constant driving current density of 100 mA cm−2, which corresponds to an initial luminance, L0, of 10,600 cd m−2, the half-lifetime, T50, defined as the time for the luminance to decrease to L0/2, is 95 h. By using the relation L0nT50 = const. and assuming an acceleration factor of n = 1.5 (ref. 25), T50 for this device at 100 cd m−2 is predicted to be over 100,000 h. The remarkable operational stability of our device, along with its outstanding efficiency, low efficiency roll-off, sub-bandgap turn-on voltage and excellent reproducibility, marks a milestone in the production of QLEDs for practical applications.

For solution-processed LEDs, layer-by-layer deposition of high-quality films without intermixing is essential for constructing high-performance devices. In our QLEDs, six layers, including PEDOT:PSS, poly-TPD, PVK, quantum dots, PMMA and ZnO, are deposited from solution. The top Ag electrodes are fabricated by vacuum deposition. Atomic force microscopy and scanning Kelvin probe microscopy analyses show that the six solution-processed layers have pin-hole-free features (Extended Data Fig. 3) and evenly distributed surface potentials (within ±40 meV; Extended Data Fig. 4). Confocal microscopy imaging reveals that the quantum dot layers have homogeneously emissive properties. Specifically, optical measurements (Extended Data Fig. 5) indicate an average thickness of ∼6 nm for the PMMA layer in the QLEDs. The root mean squared roughness of the quantum dot film is in the range of 1.6–2.6 nm. After depositing the PMMA layer, the root mean squared roughness decreases to 0.6–1.6 nm. On the basis of the above facts, we suggest that the PMMA layer on the quantum dot film is continuous, and that the local thickness of the PMMA layer fluctuates owing to the relatively rough quantum dot surface (Fig. 1d).

We highlight that the incorporation of the insulating PMMA layer with a suitable thickness between the ZnO ETL and the quantum dot emissive layer optimizes charge balance in the device. In our device, there is a moderate energetic barrier for hole injection owing to the deep valance-band energy level of the quantum dots (Fig. 1c). Furthermore, the hole mobility of poly-TPD21 (1 × 10−4 cm2 V−1 s−1) and PVK22 (2.5 × 10−6 cm2 V−1 s−1) are one to three orders of magnitude lower than the electron mobility of ZnO nanocrystal films (∼1.8 × 10−3 cm2 V−1 s−1) (Extended Data Fig. 2b). These factors can lead to excess electron injection into the quantum dot emissive layer. The unbalanced charge injection in the QLEDs is reflected by the significantly higher current densities of the electron-only devices (ITO/Al/QDs/ZnO/Al) than those of the hole-only devices (ITO/PEDOT:PSS/poly-TPD/PVK/QDs/Pd) (Extended Data Fig. 6).

The excess electron current in the QLED without the PMMA layer degrades device performance. As shown in Fig. 3a, for the QLED without the PMMA layer, both the turn-on voltage and the brightness in the entire range of forward bias are nearly the same as for the device with the 6 nm PMMA layer, whereas the current densities are much greater. Therefore, the excess electron current substantially lowers the efficiency of the device. Furthermore, the QLEDs without the PMMA layers exhibit relatively poor stability. As shown in Fig. 3b, when tested at a constant driving current density of 100 mA cm−2, T50 for this device with an L0 of 6,600 cd m−2 is only 10 h. Converting to the values at the same initial brightness of 100 cd m−2, this is only ∼5% of that for the device with the 6 nm PMMA layer. Therefore without efficient radiative recombination to release the energy, the excess electron current can deteriorate the QLEDs rapidly under operational conditions.

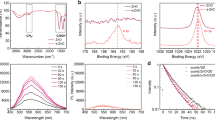

a, Current density and luminance versus voltage characteristics for QLEDs without and with the 6 nm PMMA layer. b, Stability data for a QLED without the PMMA layer. c, Current density–voltage curves for the electron-only devices showing that the 6 nm PMMA layer results in a ∼1.8-fold decrease in current density. The thicknesses of the ZnO layer and the quantum dot layer are 150 and 40 nm, respectively. d, Time-resolved photoluminance decay for the quantum dot films contacting different layers. The thicknesses of the layers are identical to those in the optimized QLED.

It is possible to modulate the electron injection from the ZnO ETLs to the quantum dot layers and eliminate excess electron currents in the QLEDs by adjusting the thickness of the inserted PMMA layers. When a PMMA layer is applied in the electron-only devices (ITO/Al/QDs/PMMA/ZnO/Al; Fig. 3c and Extended Data Fig. 7a), the current density gradually reduces as the thickness of the PMMA layer increases.

For the working devices, a gradual decrease in current density on the increase of the thickness of the PMMA layers is also observed (Fig. 3a and Extended Data Fig. 7b). For the device with the 6 nm PMMA layer, a peak EQE of 20.5% (Fig. 2d), corresponding to a close-to-unity internal quantum efficiency (estimated to be 88.6% by assuming a Lambertian emission profile26), indicates almost perfect charge balance in this device. This is consistent with the low efficiency roll-off and improved operational stability of the QLEDs with the 6 nm PMMA layers (Fig. 2d, f). Further increasing the thickness of the PMMA layers to >6 nm results in both increase of the turn-on voltage and decease of the brightness (Extended Data Fig. 7c, d). These control experiments, along with the results described above, clearly suggest that charge balance in the QLEDs can be optimized by inserting an insulating layer with a suitable thickness. Either excess electron injection or over-blocking electron current deteriorates charge balance in the QLEDs and thereby degrades device performance.

For both photoluminance27 and electroluminescence19, charging degrades the emissive properties of the quantum dots. In our case, when the quantum dots are in direct contact with the ZnO ETLs, a spontaneous charge transfer process occurs owing to the work function difference, leaving positively charged quantum dots3. Charging of the quantum dots causes inefficient trion emissions27, as indicated by the fact that the average photoluminance lifetime of the quantum dot films decreased from 21.6 to 10.6 ns after the deposition of the top ZnO films (Fig. 3d). The insertion of a thin PMMA layer modifies the QD/ZnO interfacial interaction, increasing the lifetime of the quantum dot film to 19.5 ns (Fig. 3d). These results indicate that the PMMA layers help to maintain charge neutrality of quantum dot emitters and preserve their superior emissive properties.

Finally, the strategy of inserting insulating layers between oxide ETLs and quantum dot layers can be extended to improve hybrid QLEDs with other types of quantum dot emitters. Wurtzite-structured CdSe–CdS core–shell nanocrystals with four monolayers of CdS shell28 are used as an example. When these thin-shell quantum dots are used as emitters, a device structure of ITO/PEDOT:PSS/poly-TPD/PVK/QDs/ZnO/Ag yields a peak EQE of 2.5%. When a 6 nm PMMA layer is inserted, the peak EQE of the QLEDs increases to 4.7% (Extended Data Fig. 8).

The present work demonstrates the best-performing solution-processed red LEDs with colour-saturated emission, record efficiency, low efficiency roll-off, sub-bandgap turn-on voltage, excellent reproducibility and outstanding operational stability, whose overall performance is comparable to state-of-the-art OLEDs produced by vacuum deposition6,7,8 (Extended Data Table 1). Such outstanding optoelectronic performance is achieved by introducing the conceptually new device structure resulting from the insertion of an insulating layer between the quantum dot layer and the oxide ETL, and by using quantum dots with superior properties as solution-processed inorganic emissive centres. We believe that there are no fundamental obstacles to extending these techniques to differently coloured QLEDs, which would lead to low-cost, large-area, high-efficiency, high-colour-quality, stable, all-solution-processed electroluminescent devices for both display and solid-state lighting technologies.

Methods

Materials

PVK (average molecular weight, 25,000–50,000 g mol−1), PMMA (average molecular weight, ∼120,000 g mol−1) and zinc acetate dehydrate (>98%) were purchased from Sigma Aldrich. Tetramethylammonium hydroxide (TMAH, 98%), 1-dodecanethiol (98%), dodecane (99%), octylamine (98%), cadmium oxide (CdO, 99.998%), 1-octadecene (ODE, 90%) and oleic acid (HOl, 90%) were purchased from Alfa-Aesar. Sodium diethyldithiocarbamate trihydrate (NaDDTC·3H2O, 99%) was purchased from Aladdin Reagents. Cadmium acetate dihydrate (Cd(Ac)2·2H2O, 98.5%) was purchased from Shanghai Tingxin Reagents. Chlorobenzene (extra dry, 99.8%), m-xylene (extra dry, 99%), octane (extra dry, >99%), ethanol (extra dry, 99.5%), 2-ethanolamine (99%) and oleylamine (80−90%) were purchased from Acros. Dimethyl sulphoxide (DMSO, HPLC grade) and ethyl acetate (HPLC grade) were purchased from J&K Chemical Ltd. Acetone was purchased from Sinopharm Chemical Reagents. Poly-TPD was purchased from American Dye Source. Patterned ITO-glass substrates (sheet resistance, 15 Ω sq−1) were purchased from Xiamen Weihua company. All materials were used as received.

Synthesis of CdSe–CdS core–shell quantum dots

The CdSe–CdS core–shell quantum dots (ten monolayers of CdS shell) with phase-pure zinc blende structure were synthesized according to ref. 28 with some modifications. Briefly, the zinc blende CdSe cores (3.1 nm) were synthesized and purified according to our recent report28. For the shell coating, dodecane (3.8 ml), octylamine (1.05 ml), oleylamine (0.45 ml) and purified CdSe core solution containing 2 × 10−7 mol of nanocrystals were mixed and heated to 80 °C under an argon flow. Reaction cycles, that is, addition of the Cd(DDTC)2-amine precursor solutions at 80 °C and growth of CdS monolayers at 150 °C for ∼20 min, were performed for the growth of the first six monolayers. Desirable amounts of Cd(DDTC)2-amine solutions, that is, 0.08, 0.12, 0.16, 0.21, 0.26 and 0.32 ml, were used for the growth of first, second, third, fourth, fifth and sixth monolayers, respectively. For the seventh to tenth monolayers of CdS, the precursor solution was changed to 50 mol% of Cd(DDTC)2 and 50 mol% of Cd(Ol)2, and the growth temperature was set at 160 °C. Quantities 0.39, 0.47, 0.55, and 0.64 ml of the precursor solutions were used for the growth of seventh, eighth, ninth and tenth monolayers of CdS, respectively. The resulting CdSe–CdS core–shell nanocrystals were purified and subjected to a ligand exchange procedure. The original ligands were replaced by 1-dodecanethiol. The ligand-exchanged quantum dots were dispersed in octane and filtered before use.

Colloidal ZnO nanocrystals

Colloidal ZnO nanocrystals were synthesized by a low-temperature solution-precipitation method29 with some modifications. A DMSO solution (30 ml) of zinc acetate hydrate (3 mmol) was mixed with an ethanol solution (10 ml) of TMAH (5.5 mmol) and stirred for 24 h under ambient conditions. Then the ZnO nanocrystals were precipitated by adding ethyl acetate and redispersed in ethanol. Additional ligands of 2-ethanolamine (160 μl) was introduced to stabilize the nanoparticles. The ZnO nanocrystals were further washed with ethyl acetate and redispersed in ethanol. The solutions were filtered before use.

Device fabrication

PEDOT:PSS solutions (Baytron P VP Al 4083, filtered through a 0.45 μm N66 filter) were spin-coated onto the ITO-coated glass substrates at 4,000 r.p.m. for 60 s and baked at 140 °C for 10 min. The PEDOT:PSS-coated substrates were transferred into a nitrogen-filled glove box (O2 < 1 p.p.m., H2O < 1 p.p.m.). Poly-TPD (in chlorobenzene, 8 mg ml−1), PVK (in m-xylene, 1.5 mg m−1), quantum dots (in octane, 15 mg ml−1), PMMA (in acetone, 1.8 mg ml−1) and ZnO nanocrystals (in ethanol, 50 mg ml−1) were deposited layer by layer by spin coating at 2,000 r.p.m. for 45 s. The poly-TPD and PVK layers were baked at 110 °C for 20 min and at 170 °C for 30 min, respectively, before the deposition of the next layer. Finally, Ag electrodes (100 nm) were deposited using a thermal evaporation system through a shadow mask under a high vacuum of ∼6 × 10−7 torr. The device area was 4 mm2 as defined by the overlapping area of the ITO and Ag electrodes. The devices were encapsulated in the glove-box by the cover glasses using ultraviolet-curable resin.

Characterizations

We used a Keithley 2400 electrometer for current density–voltage characterizations and a fibre integration sphere (FOIS-1) coupled with a QE-65000 spectrometer for light output measurements (Extended Data Fig. 9). Note that the ITO glass substrates are in close contact with the input port of the integration sphere (but are not inserted into the integration sphere). The area of the QLED device (4 mm2) is much smaller than that of the input port (9.5 mm in diameter) so that the coupling factor for the photons emitted into the forward viewing directions30 (from the QLED to the integration sphere) is unity. The electroluminescence characteristics of the QLEDs were cross-checked using a system comprising a photometer (Spectra Scan PR655) coupled with a computer-controlled Keithley 2400 electrometer in L. Liao’s laboratory. The half-lifetime T50 and the driving voltages are measured at the same time using an ageing system made by Shanghai University.

The absorption spectra of the nanocrystals were measured using a Shimadzu UV 3600 spectrophotometer. The photoluminance spectra of the quantum dots were obtained by using an Edinburgh Instruments FLS920 spectrometer. The absolute photoluminance quantum yield of the quantum dot solution was measured using an Ocean Optics FOIS-1 integrating sphere coupled with a QE65000 spectrometer. The time-resolved fluorescence spectra of the quantum dot films were measured by the time-correlated single-photon counting method using an Edinburgh Instruments FLS920 fluorescence spectrometer. The samples were excited by a 405 nm pulsed diode laser (EPL-405). An Olympus confocal laser scanning microscope (FV1000) equipped with an inverted fluorescence microscope (IX81) was used to evaluate the emissive features of the quantum dot films. A 488 nm laser was used to excite the sample, and the signals in the wavelength range of 580–680 nm were collected for imaging. Fourier transform infrared spectroscopy (FTIR) spectra were obtained using a Bruker Vector 27 spectrophotometer.

Transmission electron microscope (TEM) analyses on the cross-sections of the QLEDs were carried out using a Tecnai G2 F20 microscope. The cross-sectional samples were prepared by using focused-ion-beam equipment (Quata 3D FEG). Atomic force microscopy (AFM) measurements were conducted on either a Park XE-120 atomic force microscope or an Agilent 5500 AFM (Agilent Technologies) using silicon AFM tips (HQ:NSC18 and HQ:NSC15, Mikromasch) or high-resolution probes (Hi'RES-C19/AIBS). Scanning Kelvin probe microscopy measurements were performed on a Park XE-120 atomic force microscope using Cr–Au-coated conducting AFM tips (HQ:NSC19, Mikromasch). The thicknesses of the multilayers were measured using a Dektak 150 stylus profilometer.

The transmission electron microscopy images of the quantum dots were made on a Hitachi 7700 TEM operated at 80 keV. The X-ray diffraction measurements were conducted using a Rigaku Ultimate- kV and 40 mA using the Cu Kα line (λ = 1.5418 Å).

References

Friend, R. H. et al. Electroluminescence in conjugated polymers. Nature 397, 121–128 (1999)

Supran, G. J. et al. QLEDs for displays and solid-state lighting. MRS Bull. 38, 703–711 (2013)

Mashford, B. S. et al. High-efficiency quantum-dot light-emitting devices with enhanced charge injection. Nature Photon. 7, 407–412 (2013)

Chien, C.-H. et al. Electrophosphorescent polyfluorenes containing osmium complexes in the conjugated backbone. Adv. Funct. Mater. 18, 1430–1439 (2008)

Yook, K. S. & Lee, J. Y. Small molecule host materials for solution processed phosphorescent organic light-emitting diodes. Adv. Mater. 26, 4218–4233 (2014)

Meerheim, R. et al. Influence of charge balance and exciton distribution on efficiency and lifetime of phosphorescent organic light-emitting devices. J. Appl. Phys. 104, 014510 (2008)

Nakanotani, H. et al. High-efficiency organic light-emitting diodes with fluorescent emitters. Nature Commun. 5, 4016 (2014)

Murawski, C., Leo, K. & Gather, M. C. Efficiency roll-off in organic light-emitting diodes. Adv. Mater. 25, 6801–6827 (2013)

Brus, L. E. Electron-electron and electron-hole interactions in small semiconductor crystallites: the size dependence of the lowest excited electronic state. J. Chem. Phys. 80, 4403–4409 (1984)

Murray, C. B., Kagan, C. R. & Bawendi, M. G. Synthesis and characterization of monodisperse nanocrystals and close-packed nanocrystal assemblies. Annu. Rev. Mater. Sci. 30, 545–610 (2000)

Peng, X. G. An essay on synthetic chemistry of colloidal nanocrystals. Nano Res. 2, 425–447 (2009)

Colvin, V. L., Schlamp, M. C. & Alivisatos, A. P. Light-emitting diodes made from cadmium selenide nanocrystals and a semiconducting polymer. Nature 370, 354–357 (1994)

Coe, S., Woo, W.-K., Bawendi, M. G. & Bulovic, V. Electroluminescence from single monolayers of nanocrystals in molecular organic devices. Nature 420, 800–803 (2002)

Zhao, J. et al. Efficient CdSe/CdS quantum dot light-emitting diodes using a thermally polymerized hole transport layer. Nano Lett. 6, 463–467 (2006)

Caruge, J. M., Halpert, J. E., Wood, V., Bulovic, V. & Bawendi, M. G. Colloidal quantum-dot light-emitting diodes with metal-oxide charge transport layers. Nature Photon. 2, 247–250 (2008)

Cho, K.-S. et al. High-performance crosslinked colloidal quantum-dot light-emitting diodes. Nature Photon. 3, 341–345 (2009)

Qian, L., Zheng, Y., Xue, J. & Holloway, P. H. Stable and efficient quantum-dot light-emitting diodes based on solution-processed multilayer structures. Nature Photon. 5, 543–548 (2011)

Kwak, J. et al. Bright and efficient full-color colloidal quantum dot light-emitting diodes using an inverted device structure. Nano Lett. 12, 2362–2366 (2012)

Bae, W. K. et al. Controlling the influence of auger recombination on the performance of quantum-dot light-emitting diodes. Nature Commun. 4, 2661 (2013)

Lee, K.-H. et al. Over 40 cd/A efficient green quantum dot electroluminescent device comprising uniquely large-sized quantum dots. ACS Nano 8, 4893–4901 (2014)

Thesen, M. W. et al. Hole-transporting host-polymer series consisting of triphenylamine basic structures for phosphorescent polymer light-emitting diodes. J. Polym. Sci. A 48, 3417–3430 (2010)

Lee, D.-H., Liu, Y.-P., Lee, K.-H., Chae, H. & Cho, S. M. Effect of hole transporting materials in phosphorescent white polymer light-emitting diodes. Org. Electron. 11, 427–433 (2010)

Sayyah, S. M., Khaliel, A. B. & Moustafa, H. Electronic structure and ground state properties of PMMA polymer: I. Step-by-step formation and stereo-regularity of the polymeric chain—AM1-MO treatment. Int. J. Polym. Mater. 54, 505–518 (2005)

Qin, H. Y. et al. Single-dot spectroscopy of zinc-blende CdSe/CdS core/shell nanocrystals: nonblinking and correlation with ensemble measurements. J. Am. Chem. Soc. 136, 179–187 (2014)

Wellmann, P. et al. High-efficiency p-i-n organic light-emitting diodes with long lifetime. J. Soc. Inf. Disp. 13, 393–397 (2005)

Greenham, N. C., Friend, R. H. & Bradley, D. D. C. Angular dependence of the emission from a conjugated polymer light-emitting diode: implications for efficiency calculations. Adv. Mater. 6, 491–494 (1994)

Javaux, C. et al. Thermal activation of non-radiative auger recombination in charged colloidal nanocrystals. Nature Nanotechnol. 8, 206–212 (2013)

Nan, W. N. et al. Crystal structure control of zinc-blende CdSe/CdS core/shell nanocrystals: synthesis and structure-dependent optical properties. J. Am. Chem. Soc. 134, 19685–19693 (2012)

Qian, L. et al. Electroluminescence from light-emitting polymer/ZnO nanoparticle heterojunctions at sub-bandgap voltages. Nano Today 5, 384–389 (2010)

Forrest, S. R., Bradley, D. D. C. & Thompson, M. E. Measuring the efficiency of organic light-emitting devices. Adv. Mater. 15, 1043–1048 (2003)

Humphries, M. J., Wilson, R. J., Fernandez, O. & Archer, R. A. Developments in solution processable polymer light-emitting diodes. J. Photon. Energy 1, 011019 (2011)

Giridhar, T. et al. An electron transporting unit linked multifunctional Ir(III) complex: a promising strategy to improve the performance of solution-processed phosphorescent organic light-emitting diodes. Chem. Commun. 50, 4000–4002 (2014)

Andrade, B. D. et al. Phosphorescent OLEDs with saturated colors. Proc. SPIE. 6655, 66550G (2007)

Uoyama, H., Goushi, K., Shizu, K., Nomura, H. & Adachi, C. Highly efficient organic light-emitting diodes from delayed fluorescence. Nature 492, 234–238 (2012)

Acknowledgements

This work is financially supported by the National High Technology Research and Development Program of China (2011AA050520), the National Natural Science Foundation of China (21233005 and 51172203), the Natural Science Funds for Distinguished Young Scholar of Zhejiang Province (R4110189), the Public Welfare Project of Zhejiang Province (2013C31057), the Jiangsu Natural Science Foundation (BK20130006 and BK20131413), the National Basic Research Program of China (2015CB932200) and the Jiangsu Specially-Appointed Professor programme. We thank L. Liao and L. Zhang for assistance in cross-measuring the QLED and OLED devices. We thank Q. Chen for assistance with atomic force microscopy and scanning Kelvin probe microscopy measurements. We thank Z. Zhang and C. Jin for assistance with cross-sectional transmission electron microscopy experiments. We also thank J. Yu and G. Qian for assistance in obtaining the confocal images.

Author information

Authors and Affiliations

Contributions

Y.J. and X.P. had the idea for and designed the experiments and supervised the work. X.D. carried out the device fabrication and characterizations. Z.Z. conducted the optical measurements and participated in device fabrication. Y.N. and H.C. synthesized the quantum dots. X.L. and L.C. carried out the atomic force microscopy and scanning Kelvin probe microscopy experiments. Y.J. wrote the first draft of the manuscript. X.P. and J.W. provided major revisions. All authors discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Extended data figures and tables

Extended Data Figure 1 CdSe–CdS core–shell quantum dots with ten monolayers of CdS shell.

a, A typical TEM image. Scale bar, 20 nm. b, X-ray diffraction profile. c, Ultraviolet–visible absorption and photoluminance spectra.

Extended Data Figure 2 ZnO nanocrystals as ETLs.

a, Ultraviolet–visible absorption spectrum and a typical TEM image (inset: scale bar, 50 nm) of the colloidal ZnO nanocrystals. b, Current density–voltage (J–V) characteristics of an electron-only device (ITO/Al/ZnO/Al). The thickness of the ZnO layer is 300 nm. The electron mobility of the ZnO film is obtained by fitting space-charge-limited-current region (J ∝ V2) with Child’s law,  , where ε0, εr, μe and d are the vacuum permittivity, relative permittivity, electron mobility and film thickness, respectively17. By assuming that εr = 4, μe is determined to be 1.8 × 10−3 cm2 V−1 s−1.

, where ε0, εr, μe and d are the vacuum permittivity, relative permittivity, electron mobility and film thickness, respectively17. By assuming that εr = 4, μe is determined to be 1.8 × 10−3 cm2 V−1 s−1.

Extended Data Figure 3 AFM characterizations of the multilayers of PEDOT:PSS, poly-TPD, PVK, quantum dots, PMMA and ZnO films in the device configuration, respectively.

For each layer, the height image, the line-scan profile, the pseudo-three-dimensional image and the phase image are shown. Note that the surface root mean squared values may change owing to the tip-to-tip and sample-to-sample variations. Extensive AFM measurements show that the root mean squared roughnesses for the quantum dot layer and the PMMA layer are in the ranges of 1.6–2.6 nm and 0.6–1.6 nm, respectively.

Extended Data Figure 4 Scanning Kelvin probe microscopy characterizations of the multilayers of PEDOT:PSS, poly-TPD, PVK, quantum dots, PMMA and ZnO films in the device configuration.

Note that the data have been linearly fitted to show the spatial uniformity.

Extended Data Figure 5 FTIR analyses to determine the average thickness of the PMMA layers used in the QLEDs.

The sample for FTIR measurements was produced by layer-by-layer spin-coating the PVK (in m-xylene, 1.5 mg ml−1), quantum dots (in octane, 15 mg ml−1) and PMMA (in acetone, 1.8 mg ml−1) at 2,000 r.p.m. onto the cleaned CaF2 substrates. We assume that the average thickness of the PMMA layer in this sample is identical to that of the PMMA layer in the optimized QLEDs. The absorption of the carbonylic groups of this sample was measured multiple times, averaged and compared with that of a 90 nm PMMA film (determined by stylus profilometer). Given that the absorbance of the carbonylic groups is in the dynamic range of the instrument, the thickness of the PMMA layer deposited onto the quantum dot film was determined to be ∼6 nm.

Extended Data Figure 6 Electrical measurements on the electron-only devices (ITO/Al/QDs/ZnO/Al) and the hole-only devices (ITO/PEDOT:PSS/poly-TPD/PVK/QDs/Pd).

The current density of the electron-only device (ITO/Al/QDs/ZnO/Al) is more than one order of magnitude greater than that of the hole-only device (ITO/PEDOT:PSS/poly-TPD/PVK/QDs/Pd). In the above two devices, the thicknesses of all layers are identical to those used in the QLEDs. For the quantum dot layer, the thickness is ∼40 nm. We note that for quasi-type-II CdSe–CdS quantum dots, the electron wavefunction extends to the shell region, whereas the hole wavefunction remains confined to the CdSe core, leading to greater electron mobility than hole mobility. We presume that the recombination zone is close to the PVK/QDs interface due to the very low hole mobility of the quantum dot films. Therefore we also fabricated a hole-only device with a quantum dot layer of ∼20 nm. The results show that the current density of the hole-only device with the 20 nm quantum dot layer is still much smaller than that of the electron-only device with the 40 nm quantum dot layer.

Extended Data Figure 7 Impact of the thickness of the PMMA layer on the QLED performance.

a, Current density–applied bias curves for the electron-only devices (ITO/Al/QDs/PMMA/ZnO/Al). b, c, Current density–driving voltage (b) and luminance–driving voltage (c) curves for the QLEDs (ITO/PEDOT:PSS/poly-TPD/PVK/QDs/PMMA/ZnO/Ag). d, Dependence of peak EQEs and turn-on voltages (Vth) of the QLEDs on the thicknesses of the PMMA layers. The PMMA layers with thicknesses of 5, 6, 7, 8 and 10 nm were deposited from acetone solutions with concentrations of 1.5, 1.8, 2.1, 2.4 and 3.0 mg ml−1, respectively.

Extended Data Figure 8 QLEDs with four-monolayer-shell CdSe–CdS quantum dots as emitters.

a, Current density and luminance versus driving voltage characteristics. b, Curves of EQE versus driving voltage. The thicknesses of the PEDOT:PSS, poly-TPD, PVK, quantum dot, PMMA and ZnO layers are 35, 30, 5, 30, 6 and 150 nm, respectively.

Extended Data Figure 9 QLED characterization system.

a, A Keithley 2400 electrometer is used to obtain current density–voltage characteristics. A fibre integration sphere (FOIS-1) coupled with a QE-65000 spectrometer is used for light output measurements. b, Top-view and side-view of the QLEDs in direct contact with the input port of the fibre integration sphere. The glass substrate (19 mm × 19 mm) is rested on top of (but not inserted into) the integration sphere. The area of the QLED device (4 mm2) is much smaller than that of the input port (9.5 mm in diameter) of the integration sphere so that the coupling factor for the photons emitted into the forward viewing directions (from the QLED to the integration sphere) is unity.

Rights and permissions

About this article

Cite this article

Dai, X., Zhang, Z., Jin, Y. et al. Solution-processed, high-performance light-emitting diodes based on quantum dots. Nature 515, 96–99 (2014). https://doi.org/10.1038/nature13829

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nature13829

- Springer Nature Limited

This article is cited by

-

Towards integrated textile display systems

Nature Reviews Electrical Engineering (2024)

-

Microsecond-response perovskite light-emitting diodes for active-matrix displays

Nature Electronics (2024)

-

Efficient blue electroluminescence from reduced-dimensional perovskites

Nature Photonics (2024)

-

Acceleration of radiative recombination for efficient perovskite LEDs

Nature (2024)

-

Dipole–dipole-interaction-assisted self-assembly of quantum dots for highly efficient light-emitting diodes

Nature Photonics (2024)