Abstract

Small- and medium-sized enterprises (SMEs) account for 97.4% of all businesses in Australia and, contribute, by revenue, 32% to the country’s economy. In the last decade, Australian SMEs have become increasingly aware of the importance of sustainability and need to shift away from a linear to circular economy (CE). Since 2019, there has been considerable growth on CE adoption research in SMEs, but empirical research examining Australian SMEs has yet to be undertaken. This study has used a survey and aims to understand the enablers and barriers of CE adoption in Australian SMEs. The research addresses three specific research questions—What are the barriers that impact CE adoption in Australian SMEs?; What enablers facilitate CE adoption in Australian SMEs?; and What is the effect of industry type, geographic location and job roles on enablers and barriers identification for CE adoption in Australian SMEs? Based on 352 responses from the survey of Australian SMEs, the paper identifies and analyses the enablers and barriers that these organizations face as they transition towards circular economy. The impact that location, industry sector and the role respondents undertake within the organization provides some interesting insights into how Australian SMEs are managing the process of adoption of CE. The research demonstrates that there is an overwhelming need for the development of consistent, sectoral, industry and location-specific policies by the federal and state governments to support internal policy development and the acquisition of new technologies in order to stimulate Australian SME CE adoption. In addition, Australian SMEs need to have a better understanding of how budgetary constraints, the lack of customer awareness and an absence of clearly defined business process impact CE adoption.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The concept of circular economy (CE) has been gaining substantial attention in recent years. The focus of CE is to assist transformation of linear business models to circular across different industry sectors [1]. Application of CE helps in creating, capturing and delivering new economic values to industries [2, 3]. It is argued that unregulated economic growth has a direct impact in deterioration of environmental conditions and natural resources [4]. A CE framework argues that there could be a closed-loop material flow, meaning that “everything is an input to everything else” [5]. Given the significant attention CE has received, there is little agreement over the definition of many of its components [6]. One possible reason is because the discipline is relatively new [7] and work on it has evolved almost in parallel with roots in different schools of thought and discipline [8, 9]. Industrial ecology, ecological economics and environmental science are some of the scientific disciplines CE can trace its origins to, and this has led to it being associated with a wide variety of different concepts [10]. Importantly, we find CE being discussed along with the concepts of, for example, green economy, sustainability and bioeconomy, with whom it shares the objectives of coordination between environmental, social and economic issues [11]. CE being a resource-oriented framework takes into account both the input and output sides of the production process [12]. As a result, studies related to waste management and the minimization of waste production through closing the loop or slowing the loop [9] are also commonly discussed areas within the CE discipline. Thus, we see that not only are the roots in which CE literature is based very widespread, the boundaries around which CE is focused are also equally broad. This wide association gives CE the role of being an “umbrella concept” which may help “reduce the knowledge gap, group pre-existing concepts and operationalize them” [7].

In spite of the fact that in the last decade there has been an increase in publications focusing on CE, overall research within the area is still at an embryonic stage [13]. Most of the research publications in CE until now focus either on large organizations or on supply chain efficiencies [3, 14]. The focus of CE research on SMEs is still an evolving area and most of the research focuses on systematic literature reviews such as [15], on business models in SMEs, or [16] on CE systems adopted by Chinese SMEs.

Halog et al. [17] in their review on CE efforts in Australia have found that the country has made impressive progress in overcoming the barriers to CE adoption and developing wealth-to-waste creation strategies. Business and government agencies (located in major cities such as Melbourne, Sydney and Brisbane) have sought to seamlessly adopt CE into their strategic plans, as well as focus on developing partnerships to enhance operational synergies. The review found that CE initiatives in Australia are quite advanced, in areas such as mining, and there is growing focus towards industrial cooperation in order to reduce not only waste but also the cost of waste management. ASBFEO [18] also suggest that the government has a fundamental role to play in developing relevant policies, which will strengthen and reinforce CE initiatives in Australia, as well as develop metrics to assist businesses determine the progress of their efforts in this area. Similar to other regions of the world, Australian SMEs are also playing ever increasing role in the regional and national economy. In Australia, SMEs comprise approximately 97% of all businesses and employ 49% of the private sector workforce [18]. As per [18] report, small business employment is largest in the construction sector with small business employing close to 61% of all apprentices and trainees.

Unless some very targeted new waste strategies are developed , environmental deterioration will continue to occur in SMEs [1]. A number of barriers stop SMEs from developing novel strategies and these include ambiguity regarding the cost benefits of achieving energy efficiency, progress environmental performance, weak external pressure/incentives, lack of internal capacity, weak supporting frameworks and in many cases political indulgence by policy makers [19]. Irrespective of the barriers, the majority of SMEs in Australia see sustainability, through circular economy adoption, as one of the key drivers for successful growth [3]. Therefore, understanding the enablers and barriers from the perspective of Australian SMEs is extremely important for the advancement of the discipline. Based on the review of published literature, there is limited empirical work globally looking at the enablers and barriers of CE adoption from the viewpoint of SMEs. The purpose of this work is to bridge this “critical research and practice (knowledge) gap” [1] and identify the enablers and barriers in Australian small and medium enterprises (SMEs) and their impact on Australian SMEs. The study will answer the following research questions:

-

i.

What are the barriers that impact CE adoption in Australian SMEs?

-

ii.

What enablers facilitate CE adoption in Australian SMEs?

-

iii.

What is the effect of industry type (based on size), geographic location and job roles on the enablers and barriers for CE adoption in Australian SMEs?

The paper is structured as follows. The “Theoretical Background” section presents the theoretical background including the enablers and barriers related to CE adoption in SMEs. This is followed by the “Methodology” section showing the development and design of the survey questionnaire and data collection method for the survey. The “Results and Discussion” section provides the discussion around the survey results, followed by the “Conclusion” section. The “Conclusion” section is focused on major limitations of the research along with the suggestions for future works.

Theoretical Background

Circular Economy

Circular economy (CE) is widely recognized as an effective way to reduce the carbon footprint of supply chains by improving the recycling of waste through industrial symbiosis [20]. Irrespective of the recognized benefits of low carbon supply chains, it is often hard for small and medium enterprises (SMEs) to implement CE practices due to barriers, such as the behaviour of suppliers, lack of technical skills and financial restrictions [6].

While there is no agreed upon definition of CE in both academia and industry, interpretations by three major proponents of CE are discussed. While the first publication exclusively dedicated to CE was published in 2004 [21], it was not until 2008 [22] that CE became a globally recognized research area. Importantly, from 2005 to 2013, a significant number of articles published on CE focused on developments in China [7].

Three very significant forces are explored that have led to a thrust in CE in practice. China was one of the first countries to plan a closed-loop-based economy, with the focus on pursuing environmental sustainability while maintaining strong economic growth [23]. China incorporated CE as the central objective in their 11th (2006–2012) and 12th (2011–2015) 5-year plans for the National Economic and Social Development [5]. The main strategy behind these policies was to recycle metal and minerals and stimulate remanufacturing [24]. The approach that China has adopted is top-down, which is in sharp contrast with the other major proponent of CE, that is, the European Union.

The European Union issued communications in 2014 and 2015 detailing packages, programs and plans towards promoting circular economy to reduce waste [25]. They define CE as “…where the value of products, materials and resources is maintained in the economy for as long as possible, and the generation of waste minimized”. Unlike China, one of the major pushes for activity around CE emerged as a result of work carried out by the Ellen MacArthur Foundation [26], which takes a bottom-up approach to CE. The Ellen MacArthur Foundation is an organization that is committed to spreading the principles of CE. They define CE as:

"an industrial system that is restorative or regenerative by intention and design. It replaces the “end-of-life” concept with restoration, shifts towards the use of renewable energy, eliminates the use of toxic chemicals, which impair reuse, and aims for elimination of waste through the superior design of materials, products, systems and within this, business models (https://ellenmacarthurfoundation.org/topics/circular-economy-introduction/overview) [27]."

The Ellen MacArthur Foundation also proposed the widely used ReSOLVE framework to comprehensively categorize CE practices. ReSOLVE stands for Regenerate, Share, Optimize, Loops, Virtualize and Exchange, which are some of the commonly used CE practices in the industry.

Kirchherr et al. [28] offered a different perspective in their review of 114 definitions of CE and provided a comprehensive definition of their own, which aligns with the authors’ understanding of CE adoption in SMEs. The definition includes different CE business models, followed by CE operational levels (macro, meso and micro), and includes a number of sustainable performance indicators (environmental quality, economic prosperity and social equity). All these elements are important in understanding CE adoption in SMEs. The definition provided by [28] is:

"A circular economy describes an economic system that is based on business models which replace the ‘end-of-life’ concept with reducing, alternatively reusing, recycling and recovering materials in production/distribution and consumption processes, thus operating at the micro level (products, companies, consumers), meso level (eco-industrial parks) and macro level (city, region, nation and beyond), with the aim to accomplish sustainable development, which implies creating environmental quality, economic prosperity and social equity, to the benefit of current and future generations."

In this transition from the linear economy model to the CE model, academia has actively supported firms and governments by conducting basic research attempting to better define the components, providing models and developing tools that facilitate this transition [7].

The impact that these top-down and bottom-up models have had on the studies conducted by academics is of significant importance. In their review, [7] argued that most papers in CE could be classified into three distinct levels, macro (CE activities oriented towards recycling and occur at city, province, region and national levels), meso (this includes industrial symbiosis and eco-industrial parks, i.e. firms with geographical proximity) and micro (this includes only one firm activity).

The macro approach is observed mostly in European studies [7]. This is because the European Action Plan for CE follows a bottom-up approach with the aim of spreading sustainable practices and culture among all of societies stakeholders [29]. This approach recognizes the need to involve all of the participants (for example, institutions, firms and consumers) at every stage of the value chain, to design and implement innovative strategies for consumption and production. Identifying business models that can help introduce circularity in their business practices while maintaining profitability is critical and without which a firm is unlikely to adopt CE [30]. Similarly, it is just as important for consumers to see the value of products that are created through CE practices. A low adoption rate by consumers would make it very difficult for firms to invest in CE practices [14]. Meso describes inter-firm relationships within close geographic proximity, which focuses on the satisfaction of societal needs [7]. This is based on the industrial ecology paradigm with a focus supporting the transition towards CE through the identification of an alternative use of material and waste flows [31]. This level largely focuses on the planning and evaluation of eco-industrial parks and networks that concentrate on environmental improvements [32] and industry cooperation [7]. Singular corporate-level strategies are termed as micro. At this level, the consideration is mostly focused on the needs of single or clustered firms [7].

While the above discussion has focused on the macro, meso and micro levels of CE, other literature identifies CE as a path to achieve sustainable development through the employment of a triple bottom line (TBL) framework of the environment, economic and social performance [33]. Waste management is one of the major parts of CE implementation through TBL and is undertaken either through biological or industrial processes. SMEs are a very important participant in the waste management cycle (WMC), as they react quickly to environmental concerns. However, many SMEs see the WMC as a significant cost, rather than a mitigating factor between environmental practice and profits [33]–[35].

CE and SMEs

The role played by the SMEs in global economic wellbeing cannot be understated, as they account for a high proportion of jobs, industries and GDP in most of the countries [1]. They not only facilitate employment and currency flow, but also promote savings and investment. The significance of these enterprises for wealth and job creation has guided scholars to look for factors predicting SME endurance and success [36]. SMEs constitute approximately 90% of the world’s businesses and employ 50–60% of the world’s population. Close to 50 million SMEs in India contribute more than 30% in GDP and employ more than 80% of the workforce [33, 34]. While their contribution to the global economy is significant, SMEs are responsible for more than 50% of the industrial pollution in Asia–Pacific [3, 17]. Transforming them into sustainable entities (right balance among economic, environment and social aspects) is a major challenge to policy makers and SME owners/managers, as SMEs are exposed to intense competition [37]. Deloitte, in their survey on business responses to climate change, found that most SMEs do not include emission reduction and climate management in their overall strategy and also attribute low importance to greenhouse gas emissions [23]. It is observed by the environmental agency of the UK that 8 out of 10 incidents of pollution are due to SMEs [38]. Conversely, the adoption of CE SMEs has been shown to reduce their energy consumption by in excess of 30% [1, 6].

Enablers and Barriers

In last 5 years, most reviews have focused on enablers, drivers, motivators, barriers, challenges and problems related to CE adoption in different industries, supply chains and a small number of SMEs [14, 39, 40]. In this paper, the terms enablers and barriers are used to classify and group the positive and negative aspects of CE adoption identified in the literature. Some of the enablers and barriers mentioned in the literature are context dependent, such as those based on specific industries [41, 42], supply chains [14] and technologies [43]. Many of these articles have also developed classification systems for both enablers and barriers in terms of environmental, economic, social, policy, external or internal and product or service design factors [1, 14, 43, 44].

Some of the major enablers and barriers mentioned in the literature are tabulated in Table 1.

Table 1 illustrates that there are a variety of different enablers and barriers identified in the literature, and these are mostly based on CE adoption in supply chains. It is important to note that these enablers and barriers are based on the review of other literature, rather than validated through empirical research. Consequently, there is a need to not only identify enablers and barriers but validate them through empirical research to confirm their applicability to practice, particularly in SMEs.

Australian Scenario

The contribution that the current research makes is that it is one of the first empirical surveys investigating CE adoption in Australian SMEs. There have been prior studies done in the Australian context, but they are either review papers [17] or analysis of data from secondary sources [59]. According to [17], the last 2 years has seen a dramatic increase in the number of Australian-derived articles on CE. Some of the major industries to adopt CE are the metal industry, the e-waste sector and urban planning and the built environment [17, 60]. CE adoption is already occurring at the macro level, but in order for its full benefits to be realized, there needs to be a significant increase in participation levels by businesses and their relevant stakeholders. This will help in configuring and assimilating different strategies for CE adoption and develop ways to reuse, repurpose, refurbish, remanufacture and ultimately recycle various products to achieve the goal of waste elimination [17, 60]–[62]. Australian SMEs see CE adoption as one of the key drivers for future economic growth and success. They also recognize the importance of implementing sustainable measures that will help them withstand economic shocks and improve resilience in the post-COVID world. Despite this recognition of CE’s importance as a survival tool, many of Australia’s SMEs are still struggling [3, 63]. It is therefore both timely and important to explore and understand the actual enablers and barriers to CE adoption by SMEs in Australia, so as to recognize how CE practice might be used to inform SME viability.

Methodology

As suggested by [64], the selection of a research strategy depends on the type of research questions; the degree to which an investigator has a control over the actual behaviour of the events; and the focus of the research on contemporary, rather than historical events. This study focused on contemporary topic of circular economy adoption in Australian SMEs, where researchers do not have any control over the events. To this end, the use of a questionnaire-based survey aligns well with the intended research and focus of the study.

Development of a Survey

Design/Structure

Before answering any questions, the respondents were provided with an introduction to CE, in order to ensure that they were fully conversant with the terminology being used in the questionnaire. A link to the Ellen MacArthur Foundation was also included, and provided the respondents with a more comprehensive understanding of CE.

The response format of the questionnaire is an important design consideration. According to [65], the response format helps in determining the type and wording of the questions and also the type of analysis researchers will undertake. The questionnaire was divided into three sections. The first section collected demographic data from the SMEs. The questions in this section included, for example, type of industry, employee numbers, types of certifications the companies have and job role of the respondents. The second section concentrated on CE adoption. These questions were related to CE actions (design, procure, process, distribution, use and recover); barriers and enablers; and resource and energy efficiency. The final section focused on questions related to sustainable performance including economic, environmental and social perspectives.

The variables relating to CE adoption and sustainability performance are widely acknowledged as being notoriously difficult to measure directly; therefore, multi-scale items were developed to capture the complexity of the items. CE adoption and sustainable performance were evaluated using a 5-point Likert scale (1—strongly disagree, 5—strongly agree) as suggested by [66]. Likert scale (1–5) was used in order to provide a more precise measure, as compared to binary options such as yes/no or true/false, which only provide indications of a single direction. This allowed respondents to indicate the relative importance of choices [67, 68].

Target Audience/Respondents

The literature suggests that the pre-testing of survey instrument is critical to maintain reliability, as well as ensure that no constructs have been omitted [68]. Pre-testing allows for the modification of vocabulary and structure of the questions, and also helps in eliminating measurement-related errors [66, 69]. The pre-testing/review of the survey questionnaire [66] was undertaken by four senior academics with extensive experience and expertise in the field of sustainability and circular economy, as well as in conducting survey-based research. Two of the reviewers had extensive international experience in leading and participating in CE or sustainability-related projects.

The target population is managers or production/process engineers, who were responsible for CE adoption in SMEs. The survey was conducted using Qualtrics, which is a commercial survey and administration company (www.Qualtrics.com). Respondents were selected from the existing pool of participants in the Qualtrics network, which is referred to as Marketplace [70]. The survey was sent to 648 respondents, and after filtering and the removal of incomplete responses, a total of 352 valid questionnaires (54.3%) were returned.

For the current study, the response rate was around 54.3%, which is similar to the studies in this area such as [1]. In spite of attaining a reasonable return, there is still considerable debate in academic circles regarding the precise limits of an acceptable response rate. Many researchers argue that these limits are dependent upon the research questions’ intent; the specific characteristics surrounding the knowledge to be created from the topic being researched; and non-response bias [71, 72].

Sample Characterization

The respondents to the survey were all full-time employees of the SMEs. Most of the respondents held managerial position (36%), followed by senior-level executives, administrative employees and technical-level employees (see Table 2). The sample also included respondents who were sole traders.

Table 3 provides details about company size, industry sector and the certifications acquired. The SMEs were from across all of the different states within Australia except Northern Territory (NT). They are from Victoria (VIC), New South Wales (NSW), Queensland (QLD), South Australia (SA), Western Australia (WA), Tasmania (TAS) and Australian Capital Territory (ACT).

The ANZSIC (Australia and New Zealand Standard Industrial Classification) classification was used to code the responses. According to ANZSIC, responses were received from C11, food product manufacturing; C21, primary metal and metal product manufacturing; C22, fabricated metal product manufacturing; C24, machinery and equipment manufacturing; and C25, other manufacturing. The other set of responses, which includes service SMEs, was primarily from E32, construction services; G, retail; H, accommodation and food services; I52, transport and support services; K, financial and insurance services; N, administrative and support services; P, education and training; Q, health care and social assistance; and S, other services such as repair and maintenance services.

The two highest survey responses were from service sector (47%), followed by manufacturing sector (17%); a number of other sectors comprise the remaining set of respondents to the survey. The “Other” sector classification included SMEs from sectors such as real estate, gardening, administration, not for profit and engineering.

Growing global competition has necessitated that SMEs invest in formal certification programs. These certifications are part a management system, which helps organizations to develop their operational objectives through a set of interacting elements [73]. These management systems can be used to address either single or multiple areas, such as quality management system; environment management system; or health and safety management system. Complexity for SMEs is manifest in the plurality of accrediting associations [74], where approximately 43% of the respondents reported that they are not accredited because of the difficulties in finding the right standard to meet their needs [63, 74]. The remaining 57% have various certifications, which include, but are not limited to, ISO9001, ISO14001, ISO18001, OHSAS18001 and SA8000.

Results and Discussion

The focus of this research is to identify major enablers and barriers of CE adoption in Australian SMEs. The score for enablers ranges between 3.43 and 3.76, out of 5 (refer Fig. 1). In reviewing the data, all 352 respondents have reported that, at least to some degree, the enablers are important for CE adoption. However, there is no agreement regarding which enablers are the most influential, or critical to the adoption process. Evidence also suggests that the enabler importance mostly varies due on owner preference, as well as sectoral factors.

Investigation of the data reveals that within many SMEs, there are a number of CE initiatives and projects that are already underway. Closer scrutiny of the evidence reveals that many SMEs see CE adoption as an opportunity to acquire new technologies, develop resource efficient strategies and enhance their brand image to improve market positioning, as well as develop environmental management policies, which target operational efficiencies.

In contrast, and although not the primary focus of this study, the researchers noted that there is broad concern and, in some cases, clearly expressed frustration regarding the regulatory (or lack thereof) involvement of both federal and state governments, in enabling SMEs to adopt CE. This requires further investigation, to understand the impact of government policies and regulations on CE adoption by SMEs.

The score for barriers ranges between 3.26 and 3.47 (refer Fig. 2). Analysis of the data shows that time and business support are not major barriers to CE adoption by SMEs. Although the difference between the scores is not significant, the largely neutral response indicates that the absence of clearly defined business processes and budgeting issues, compounded by the lack of customer awareness regarding refurbished or recycled products [44], have served to slow CE adoption in some Australian SMEs.

The research into CE adoption by Australian SMEs is still evolving, and there is a limited understanding in the literature regarding the enablers and barriers that are specific to SME operations. The acquisition of new technologies by SMEs as an enabler of CE adoption is highlighted in the literature, where technology is perceived as a cornerstone of Industry 4.0 [43]. The literature also highlights the important role that marketing plays, which is driven by two factors; one is identification of markets for remanufactured, reused and recycled products and services, and the other is growing consumer awareness regarding environmentally friendly products and services, thereby creating pressure on SMEs to adopt CE practices [14, 49, 75].

As argued by [17], SMEs, and industry more generally, will require a significant behavioural shift in their own practices, as well their customers, in order to transition towards CE. In case of Australian SMEs, [76] has identified a number of barriers to CE adoption, for example, economic recession, primarily due to the pandemic; issues related to data availability and accessibility; disparity in data and information; the lack of incentives; or even providing the choice for businesses to convert from linear to circular economy. In order to overcome these barriers, the Australian Circular Economy Hub has developed a strategic plan, which focuses on CE adoption by inspiring and amplifying the need for businesses to transform their activities, through education and building cooperative networks that support and promote CE.

Location, Industry Sector and Job Role Effect on Enablers and Barriers of CE adoption

Geographic Location—State-Based Differences

The data collected for this survey includes SMEs from different states within Australia (refer Fig. 3). The responses are analysed by state where NSW leads with 35% of the overall responses followed by VIC (25%) and QLD (21%).

The majority of the data for each state has been collected from the capital cities. For example, 108 responding SMEs are located in Sydney, New South Wales (NSW), while there were 67 responses from Brisbane, Queensland (QLD), and 66 from Melbourne, Victoria (VIC). Distribution of responses from capital city and regional areas of states is presented in Fig. 4.

In the case of the enablers, evidence indicates that there is a distinction between how much importance SMEs attribute to federal and state government’s policies, laws and regulation in relation to CE adoption (refer Fig. 5). The SMEs from NSW, TAS and SA have a higher level of agreement regarding federal and state government policies being helpful towards CE adoption. In contrast, SMEs from VIC, QLD and WA have a significantly lower level of agreement regarding the role of government policy. Interestingly, there is a notable variance to this, in that VIC, QLD and WA respondents held that their respective state government’s policies are more helpful than the federal government’s in stimulating CE adoption.

Another important observation is that SMEs from TAS see significant opportunities in operating as a prime contractor to develop greater market share through the implementation of strategically orientated internal environmental management policies and the acquisition of new technologies through CE adoption. This is in contrast to the responses received from SMEs from other states who focused less on market share and more on internal efficiencies.

Analysis shows similarity in the level of agreement towards barriers from NSW, VIC and QLD, where responses have very similar scores (Fig. 6). Closer scrutiny shows that median value of responses from these states varies between 3 and 4. The majority of respondents from these three states argue that customer awareness of CE is not as yet sufficiently developed or mature enough in Australia to significantly impact purchasing behaviour.

Other barriers highlighted in the responses from SMEs of these three states relate to budget constraints, the lack of clearly defined business processes and limited financial support to acquire technological resources for CE adoption. The SMEs in South Australia (SA) and Tasmania (TAS) seem to contradict the responses from SMEs in NSW, VIC and QLD regarding the barriers. The SMEs from those two states contend that budgets and business support are not significant constraints on the implementation of CE, but that there is a definite need for clearly defined business processes to assist more broadly in the adoption of CE.

The evidence points towards the need for consistency across Australia (and across all levels of federal, state and local government) on how to manage the process of CE adoption by SMEs. The responsibility for managing environmental issues is largely a function of each of the states [3, 17]. The inefficiencies in this process are immediately apparent, as each state develops their own policies and governance models independent of the other states, in spite of the fact that they are connected economically and environmentally. Waste management strategies exist in most states; South Australia has been active in this space since 1977, whereas other states, such as the Northern Territories, introduced waste management as a core strategy in 2012, New South Wales in 2017, Queensland in 2018 and Western Australia in 2018, while the Australian Capital Territory (ACT) and Tasmania introduced their strategies in 2020. Victoria is the only Australian state without a fully implemented strategic plan [17].

Industry-Based Differences

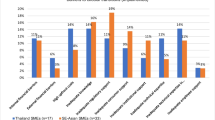

Analysing the enablers for the service and manufacturing sectors (refer Fig. 7) shows that manufacturing SMEs are more positive about the enablers in comparison with the service SMEs. The median score for service SMEs is 3 (neither agree nor disagree). The biggest difference between the manufacturing and service SMEs can be observed most clearly in three particular enablers: positive impact on market positioning; clear internal environmental management policy development; and becoming the preferred supplier/producer or service provider. This difference is possibly due to the inherent differences between manufacturing and service companies regarding the role that intangibility, heterogeneity, inseparability and perishability all play in defining products and services [77]. The tangible nature of manufacturing clearly provides more opportunities for positive market impact, and the importance of becoming the preferred producer or supplier, compared with service SMEs who, by their very definition, have little that they can leverage to make a perceptible difference. The low response score with regard to a clear internal environment management policy for service SMEs is somewhat surprising and needs further investigation, in order to understand why this is the case. It may relate to the notion of tangibility, but clarification needs to be sought.

In addition, and with regard to service organization responses to the importance of federal and state government policies and regulation, further exploration is required in order to understand the type of support service SMEs may need to assist with CE adoption.

A median score of 3 for service SMEs indicates that there is a level of uncertainty regarding CE adoption, and both the desire and need to embrace CE practices are still evolving (Fig. 8). In support of this, many of the responses from service SMEs show that they do not have clearly defined business processes, which may act as a major barrier to engaging in CE practices. With regard to customer awareness, manufacturing SMEs have cited a lack of understanding among consumers about the growing importance of transitioning to environmentally friendly or neutral products, as a major barrier in the realization of the benefits that accrue from CE adoption. This is a consistent finding, and researchers, such as [40, 46, 54] and [44], have consistently highlighted that the lack of customer awareness is a significant constraint on CE uptake by Australian SMEs.

Specific studies relating to SME sector and CE adoption in Australia are limited. One of the primary studies completed was by [17], who found that studies involving CE adoption are mostly undertaken in the metallurgic sector, followed by e-waste and urban planning and the built environment. Other sectors, such as agriculture and food processing, construction, transportation, electricity and education, have very few CE adoption studies [3]. As Australia moves towards developing a stronger and broader CE sector, evidence from the survey indicated that a wide range of industry sectors are now looking more actively at CE adoption, as part of their strategic planning.

Organizational Position-Based Differences

Within the operational levels of SMEs, CE functionality is viewed differently. In the current research, this is investigated by analysing the perceptions of enablers and barriers by respondents operating at different levels within the organization. Evidence from the research suggests that most senior corporate-level (C-level) executives and managers are in full agreement about the importance of the enablers. By way of comparison, respondents operating within administrative- and technical-level positions responded neutrally about the importance of the enablers (refer Fig. 9). This difference can be interpreted in two ways: that C-level management sees CE adoption as a strategic imperative and competitive advantage, while administrative and technical staffs, who mostly focus on the operational aspects of the business, regard CE adoption as a performance enhancer or improver. Precisely, how specific roles and functions within SMEs affect CE adoption is an area that requires further investigation.

Analysis of the responses to the barriers is similar to that of the enablers (refer Fig. 10). The research shows that the median scores for the administrative and technical staff are, again, generally lower than those of C-level staff.

There are, however, some similarities in, for example, the level of business support required to acquire new technologies and clearly defined business processes, which are not considered by any of the respondents to major barriers affecting CE adoption. The most notable differences between the roles centre on having sufficient time, budget availability and concerns regarding customer awareness. This is significant because customer awareness helps drive organizational direction, which in turn directs budgets and finances. Importantly, customer awareness can be improved through education and budgets manipulated and managed to suit organizational needs. Time, however, is a recurring constraint because it is finite, and can only be influenced, but not increased. As with the enablers, further research needs to be undertaken to understand the variability in responses between the different functional levels.

Conclusion

SMEs are a significant contributor towards gross domestic product (GDP) and employment within the Australian economy, and while they recognize the strategic importance of CE, they struggle to find ways to incorporate CE into their daily business practices. This study has investigated the enablers and barriers, which are important to facilitate CE adoption within Australian SMEs, and sought to answer three research questions:

-

What are the barriers that impact CE adoption in Australian SMEs?

-

What are the enablers that facilitate CE adoption in Australian SMEs? and

-

What is the effect of industry type, geographic location and job roles on enablers and barriers identification for CE adoption in Australian SMEs?

When investigating these enablers and barriers, it is important to note that there are a variety of internal and external factors that affect CE adoption For example, externally, government support, customer awareness and education are major factors affecting CE adoption, whereas internally, better budget allocation and stronger business processes can all be managed internally. Dey et al. [1] and Sohal et al. [3] argue that the full potential of CE for SMEs is yet to be realized, but its global, regional and local importance cannot be understated.

The findings from this study show that there are a number of important enablers within Australia which assist CE adoption in SMEs. These enablers help SMEs to develop opportunities in acquiring new technologies; enhanced market positioning and brand projection; improvements in strategic alignment; competitive advantage through careful supply chain management; better resource efficiency; and the development of environmentally focused management policies. There are also several barriers, which serve to limit CE adoption in Australian SMEs. Some of the barriers identified in this study include not having clearly defined business processes; inadequate operational budgets; and lack of customer awareness regarding reused, recycled and remanufactured products.

Analysis based on location, industry sector and the role of the respondents within their organization provided a number of interesting insights into the broader perception of the enablers and barriers. It was found that respondents from a number of states (based on economic performanceFootnote 1) such as Victoria and Queensland felt that both federal and state governments’ policies are not sufficiently aligned to facilitate CE adoption. The exception was New South Wales where the respondents perceived that government policies provide a good foundation in supporting CE adoption. Though the responses were not as numerous, a summary of Tasmanian SMEs indicates that CE adoption offers greater opportunities with regard to developing environmentally focused management policies, and also in developing openings for Tasmanian SMEs as the preferred or primary contractor/supplier.

Analysis based on organizational roles highlighted some clear differences in opinion regarding the impact of the enablers. Enablers such as acquiring new technologies, improvement in brand image and better resource efficiency are highly valued by C-level and senior management, and evidence from the research suggests that this is largely strategic. At the administrative and technical levels, the enablers considered to be the most important are having clear internal environment management policies, and aim to become the primary contractor, preferred suppliers, producers or service provider. This aligns well with the view that SME administrators and technical staff see CE as an operational activity, focused on process improvement.

With regard to the barriers, there is common agreement across all levels that not having clearly defined business processes is a significant inhibitor to CE adoption. C-level and senior managers concur that the lack of customer awareness and budgetary constraints also has an impact on CE adoption. As discussed earlier, time is a recurring problem, and perceptions of time and how it constrains CE adoption need to be further investigated.

The literature clearly illustrates that the support of stakeholders external to the organization is crucial in overcoming some of the main barriers for SMEs. For example, unambiguous and consistent guidance by government, at all levels, has the potential to incentivize CE adoption in Australian SMEs [14, 38]. The research, however, shows that many respondents find federal and state government policies and regulations often poorly aligned and unnecessarily bureaucratic. This finding is consistent with the literature in this area. A number of authors also highlight the lack of social awareness and customer hesitancy and uncertainty regarding refurbished, reused, recycled and remanufactured products [14, 78]. Again, the findings in this study clearly support the literature.

Theoretical and Practical Implications

From a theoretical perspective, this paper fills a gap regarding limited empirical research into CE adoption in Australian SMEs [14, 19] and, provides an understanding of the major barriers and enablers of CE adoption in Australian SMEs.

Early CE research has investigated the enablers and barriers either separately or together, predominantly in supply chains located in different parts of the world [14, 29, 79]. Some of the most notable reviews on enablers have been undertaken by [14, 39, 40, 46, 47] and [80], and some of the most accomplished research examining the barriers has been completed by the following authors [1, 14, 46, 51]–[53, 57, 81]. This paper advances industries’ understanding of CE enablers and barriers, beyond simply analysing supply chain activity. The study provides insights into the impact that location, industry sector and organizational role have upon CE adoption.

In terms of the implications for managers, understanding how location affects SME strategy development and intent should allow the federal and state governments to craft policies and regulations that facilitate CE adoption. The research highlighted the urgent need to educate the customer and increase their confidence in purchasing or using recycled, reused, remanufactured or refurbished products. In conjunction with customer education, managers need to develop and implement well-defined business processes to support environmental change initiatives such as CE. Finally, managers in SMEs should look at how they might use industry sector specifics and geographic location, in order to customize CE adoption strategies and develop more responsive environmental change management practices.

Limitations and Future Studies

While this study is the first to extensively explore the barriers and enablers of CE adoption in Australian SMEs, there are some important limitations to the research. The first is the cross-sectional nature of survey. A broader longitudinal study would provide a more comprehensive understanding of how circular economy is adopted by SMEs, and also the importance of time with regard to managerial decision making. It is important to note that the research was undertaken during the COVID-19 pandemic, and this may have influenced how managers in SMEs responded to some of the questions. For example, Melbourne was in lockdown for 270 days, while in many of the regional areas, businesses were operating in relative freedom. The pandemic may well have influenced how managers responded to certain questions relating to location, time, customer awareness and budgetary constraints. Longitudinal studies would allow a cross-case comparison looking at decision making in SMEs during the pandemic years, as well as in the post-pandemic period. Finally, further studies need to be undertaken examining the differences between manufacturing and service SMEs and their adoption of CE.

Data Availability

Data used for this study will be made available upon reasonable request and according to approved ethics guidelines.

References

Dey PK, Malesios C, De D, Budhwar P, Chowdhury S, Cheffi W (2020) Circular economy to enhance sustainability of small and medium-sized enterprises. Bus Strateg Environ 29(6):2145–2169. https://doi.org/10.1002/bse.2492

Chizaryfard A, Trucco P, Nuur C (2021) The transformation to a circular economy: framing an evolutionary view. J Evol Econ 31(2):475–504. https://doi.org/10.1007/s00191-020-00709-0

Sohal A, De Vass T (2022) Australian SME’s experience in transitioning to circular economy. J Bus Res 142:594–604. https://doi.org/10.1016/j.jbusres.2021.12.070

Lieder M, Rashid A (2016) Towards circular economy implementation: a comprehensive review in context of manufacturing industry. J Clean Prod 115:36–51. https://doi.org/10.1016/j.jclepro.2015.12.042

Su B, Heshmati A, Geng Y, Yu X (2013) A review of the circular economy in China: moving from rhetoric to implementation. J Clean Prod 42:215–227. https://doi.org/10.1016/j.jclepro.2012.11.020

V. Rizos, K. Tuokko, and A. Behrens, “The circular economy, a review of definitions, processes and impacts,” 2017.

Merli R, Preziosi M, Acampora A (2018) How do scholars approach the circular economy? A systematic literature review. J Clean Prod 178:703–722. https://doi.org/10.1016/j.jclepro.2017.12.112

Blomsma F, Brennan G (2017) The emergence of circular economy: a new framing around prolonging resource productivity. J Ind Ecol 21(3):603–614. https://doi.org/10.1111/jiec.12603

Bocken NMP, Olivetti EA, Cullen JM, Potting J, Lifset R (2017) Taking the circularity to the next level: a special issue on the circular economy. J Ind Ecol 21(3):476–482. https://doi.org/10.1111/jiec.12606

Lazarevic D, Valve H (2017) Narrating expectations for the circular economy: towards a common and contested European transition. Energy Res Soc Sci 31:60–69. https://doi.org/10.1016/j.erss.2017.05.006

D’Amato D, Veijonaho S, Toppinen A (2020) Towards sustainability? Forest-based circular bioeconomy business models in Finnish SMEs. For Policy Econ 110. https://doi.org/10.1016/j.forpol.2018.12.004

Sauvé S, Bernard S, Sloan P (2016) Environmental sciences, sustainable development and circular economy: alternative concepts for trans-disciplinary research. Environ Dev 17:48–56. https://doi.org/10.1016/j.envdev.2015.09.002

Centobelli P, Cerchione R, Chiaroni D, Del Vecchio P, Urbinati A (2020) Designing business models in circular economy: a systematic literature review and research agenda. Bus Strateg Environ 29(4):1734–1749. https://doi.org/10.1002/bse.2466

Govindan K, Hasanagic M (2018) A systematic review on drivers, barriers, and practices towards circular economy: a supply chain perspective. Int J Prod Res 56(1–2):278–311. https://doi.org/10.1080/00207543.2017.1402141

Brendzel-Skowera K (2021) Circular economy business models in the SME sector. Sustain 13(13):7059–7080. https://doi.org/10.3390/su13137059

Min Z, Sawang S, Kivits RA (2021) Proposing circular economy ecosystem for Chinese SMEs: a systematic review. Int J Environ Res Public Health 18(5):1–13. https://doi.org/10.3390/ijerph18052395

Halog A, Balanay R, Anieke S, Yu TY (2021) Circular economy across Australia: taking stock of progress and lessons. Circ Econ Sustain 1(1):283–301. https://doi.org/10.1007/s43615-021-00020-5

ASBFEO (2019) Small business counts: small business in the Australian economy.

Dey PK, Cheffi W (2013) Green supply chain performance measurement using the analytic hierarchy process: a comparative analysis of manufacturing organisations. Prod Plan Control 24(8–9):702–720. https://doi.org/10.1080/09537287.2012.666859

Fang K, Dong L, Ren J, Zhang Q, Han L, Fu H (2017) Carbon footprints of urban transition: tracking circular economy promotions in Guiyang, China. Ecol Modell 365:30–44. https://doi.org/10.1016/j.ecolmodel.2017.09.024

Seyfang G (2004) Consuming values and contested cultures: a critical analysis of the UK strategy for sustainable consumption and production. Rev Soc Econ 62(3):323–338. https://doi.org/10.1080/0034676042000253936

Seuring S, Müller M (2008) From a literature review to a conceptual framework for sustainable supply chain management. J Clean Prod 16(15):1699–1710. https://doi.org/10.1016/j.jclepro.2008.04.020

Zink T, Geyer R (2017) Circular economy rebound. J Ind Ecol 21(3):593–602. https://doi.org/10.1111/jiec.12545

Preston F (2012) A global redesign? Shaping the circular economy,” Energy, Environ. Resour. Gov., no. March, 1–20. [Online]. Available: http://www.chathamhouse.org/sites/files/chathamhouse/public/Research/Energy, Environment and Development/bp0312_preston.pdf.

Commision E (2014) Towards a circular Europe, a zero waste programme for Europe. Commun from Comm to Eur Parliam Counc Eur Econ Soc Comm Comm Reg 2014, no. 0398, 1–18 [Online]. Available: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%5C%3A52014DC0398.

Masi D, Day S, Godsell J (2017) Supply chain configurations in the circular economy: a systematic literature review. Sustainability (Switzerland) 9(9). https://doi.org/10.3390/su9091602

MacArthur E (2013) Towards the circular economy: opportunities for the consumer goods sector. Ellen MacArthur Found 1–112.

Kirchherr J, Reike D, Hekkert M (2017) Conceptualizing the circular economy: an analysis of 114 definitions. Resour Conserv Recycl 127:221–232. https://doi.org/10.1016/j.resconrec.2017.09.005

Ghisellini P, Cialani C, Ulgiati S (2016) A review on circular economy: the expected transition to a balanced interplay of environmental and economic systems. J Clean Prod 114:11–32. https://doi.org/10.1016/j.jclepro.2015.09.007

Lewandowski M (2016) Designing the business models for circular economy-towards the conceptual framework. Sustainability (Switzerland) 8(1):1–28. https://doi.org/10.3390/su8010043

Saavedra YMB, Iritani DR, Pavan ALR, Ometto AR (2018) Theoretical contribution of industrial ecology to circular economy. J Clean Prod 170:1514–1522. https://doi.org/10.1016/j.jclepro.2017.09.260

Geng Y, Fu J, Sarkis J, Xue B (2012) Towards a national circular economy indicator system in China: an evaluation and critical analysis. J Clean Prod 23(1):216–224. https://doi.org/10.1016/j.jclepro.2011.07.005

Ormazabal M, Prieto-Sandoval V, Puga-Leal R, Jaca C (2018) Circular economy in Spanish SMEs: challenges and opportunities. J Clean Prod 185:157–167. https://doi.org/10.1016/j.jclepro.2018.03.031

Ormazabal M, Prieto-Sandoval V, Jaca C, Santos J (2016) An overview of the circular economy among SMEs in the Basque Country: a multiple case study. J Ind Eng Manag 9(5):1047–1058. https://doi.org/10.3926/jiem.2065

Biondi V, Iraldo F, Meredith S (2002) Achieving sustainability through environmental innovation: the role of SMEs. Int J Technol Manag 24(5–6):612–626. https://doi.org/10.1504/IJTM.2002.003074

Carter NM, Stearns TM, Reynolds PD, Miller BA (1994) New venture strategies: Theory development with an empirical base. Strateg Manag J 15(1):21–41. https://doi.org/10.1002/smj.4250150103

Malesios C, Dey PK, Ben Abdelaziz F (2020) Supply chain sustainability performance measurement of small and medium sized enterprises using structural equation modelling. Ann Oper Res 294(1–2):623–653. https://doi.org/10.1007/s10479-018-3080-z

Dey PK, Malesios C, De D, Chowdhury S, Ben Abdelaziz F (2019) Could lean practices and process innovation enhance supply chain sustainability of small and medium-sized enterprises? Bus Strateg Environ 28(4):582–598. https://doi.org/10.1002/bse.2266

Bhatia MS, Jakhar SK, Mangla SK, Gangwani KK (2020) Critical factors to environment management in a closed loop supply chain. J Clean Prod 255. https://doi.org/10.1016/j.jclepro.2020.120239

Dijkstra H, van Beukering P, Brouwer R (2020) Business models and sustainable plastic management: a systematic review of the literature. J Clean Prod 258. https://doi.org/10.1016/j.jclepro.2020.120967

Sandvik IM, Stubbs W (2019) Circular fashion supply chain through textile-to-textile recycling. J Fash Mark Manag 23(3):366–381. https://doi.org/10.1108/JFMM-04-2018-0058

Tsolakis N, Srai JS (2018) Mapping supply dynamics in renewable feedstock enabled industries: a systems theory perspective on ‘green’ pharmaceuticals. Oper Manag Res 11(3–4):83–104. https://doi.org/10.1007/s12063-018-0134-y

Rajput S, Singh SP (2019) Connecting circular economy and industry 4.0. Int J Inf Manage 49:98–113. https://doi.org/10.1016/j.ijinfomgt.2019.03.002

Salim HK, Stewart RA, Sahin O, Dudley M (2019) Drivers, barriers and enablers to end-of-life management of solar photovoltaic and battery energy storage systems: a systematic literature review. J Clean Prod 211:537–554. https://doi.org/10.1016/j.jclepro.2018.11.229

Moktadir MA, Rahman T, Rahman MH, Ali SM, Paul SK (2018) Drivers to sustainable manufacturing practices and circular economy: a perspective of leather industries in Bangladesh. J Clean Prod 174:1366–1380. https://doi.org/10.1016/j.jclepro.2017.11.063

Mura M, Longo M, Zanni S (2020) Circular economy in Italian SMEs: a multi-method study. J Clean Prod 245:118821. https://doi.org/10.1016/j.jclepro.2019.118821

Piyathanavong V, Garza-Reyes JA, Kumar V, Maldonado-Guzmán G, Mangla SK (2019) The adoption of operational environmental sustainability approaches in the Thai manufacturing sector. J Clean Prod 220:507–528. https://doi.org/10.1016/j.jclepro.2019.02.093

Kiefer CP, González PDR, Carrillo-hermosilla J (2019) Drivers and barriers of eco-innovation types for sustainable transitions: a quantitative perspective. Bus Strateg Environ 28(1):155–172. https://doi.org/10.1002/bse.2246

Nasir MHA, Genovese A, Acquaye AA, Koh SCL, Yamoah F (2017) Comparing linear and circular supply chains: a case study from the construction industry. Int J Prod Econ 183:443–457. https://doi.org/10.1016/j.ijpe.2016.06.008

Bhatia MS, Kumar Srivastava R (2019) Antecedents of implementation success in closed-loop supply chain: an empirical investigation. Int J Prod Res 57(23):7344–7360. https://doi.org/10.1080/00207543.2019.1583393

Tura N, Hanski J, Ahola T, Ståhle M, Piiparinen S, Valkokari P (2019) Unlocking circular business: a framework of barriers and drivers. J Clean Prod 212:90–98. https://doi.org/10.1016/j.jclepro.2018.11.202

Shi J, Zhou J, Zhu Q (2019) Barriers of a closed-loop cartridge remanufacturing supply chain for urban waste recovery governance in China. J Clean Prod 212:1544–1553. https://doi.org/10.1016/j.jclepro.2018.12.114

Zhang A, Venkatesh VG, Liu Y, Wan M, Qu T, Huisingh D (2019) Barriers to smart waste management for a circular economy in China. J Clean Prod 240. https://doi.org/10.1016/j.jclepro.2019.118198.

Bressanelli G, Perona M, Saccani N (2019) Challenges in supply chain redesign for the circular economy: a literature review and a multiple case study. Int J Prod Res 57(23):7395–7422. https://doi.org/10.1080/00207543.2018.1542176

Chauhan C, Singh A (2020) A review of Industry 4.0 in supply chain management studies. J Manuf Technol Manag 31(5):863–886. https://doi.org/10.1108/JMTM-04-2018-0105

Tumpa TJ, Ali SM, Rahman MH, Paul SK, Chowdhury P, Rehman Khan SA (2019) Barriers to green supply chain management: an emerging economy context. J Clean Prod 236 https://doi.org/10.1016/j.jclepro.2019.117617

Jaeger B, Upadhyay A (2020) Understanding barriers to circular economy: cases from the manufacturing industry. J Enterp Inf Manag 33(4):729–745. https://doi.org/10.1108/JEIM-02-2019-0047

Patricio J, Axelsson L, Blomé S, Rosado L (2018) Enabling industrial symbiosis collaborations between SMEs from a regional perspective. J Clean Prod 202:1120–1130. https://doi.org/10.1016/j.jclepro.2018.07.230

Sohal A, De Vass T (2022) Australian SME’s experience in transitioning to circular economy. J Bus Res 142:594–604

Giurco D, Littleboy A, Boyle T, Fyfe J, White S (2014) Circular economy: questions for responsible minerals, additive manufacturing and recycling of metals. Resources 3(2):432–453. https://doi.org/10.3390/resources3020432

Golev A, Corder GD (2016) Typology of options for metal recycling: Australia’s perspective. Resources 5(1):1–10. https://doi.org/10.3390/resources5010001

Golev A, Corder GD (2017) Quantifying metal values in e-waste in Australia: the value chain perspective. Miner Eng 107:81–87. https://doi.org/10.1016/j.mineng.2016.10.021

Sohal A, Nand AA, Goyal P, Bhattacharya A (2022) Developing a circular economy: an examination of SME’s role in India. J Bus Res 142:435–447

Yin RK (2013) Applications of case study research. Appl Soc Res Methods Ser 34:173. https://doi.org/10.1097/FCH.0b013e31822dda9e

Jiju Antony F, Kumar M, Cho BR (2007) Six sigma in service organisations: benefits, challenges and difficulties, common myths, empirical observations and success factors. Int J Qual Reliab Manag 24(3):294–311. https://doi.org/10.1108/02656710710730889

Hair JF, Brunsveld N (2019) Essentials of business research methods.

Neuman W (2013) Social research methods: Pearson new international edition: qualitative and quantitative approaches.

Forza C (2002) Survey research in operations management: a process-based perspective. Int J Oper Prod Manag 22(2):152–194. https://doi.org/10.1108/01443570210414310

Vashishth A, Chakraborty A, Gouda SK, Gajanand MS (2021) Integrated management systems maturity: drivers and benefits in Indian SMEs. J Clean Prod 293:126243. https://doi.org/10.1016/j.jclepro.2021.126243

Miller CA, Guidry JPD, Dahman B, Thomson MD (2020) A tale of two diverse qualtrics samples: information for online survey researchers. Cancer Epidemiol Biomarkers Prev 29(4):731–735. https://doi.org/10.1158/1055-9965.EPI-19-0846

Mundy D (2002) A question of response rate. Sci Ed 25(1):25–26. https://doi.org/10.1038/422341b

Holtom B, Baruch Y, Aguinis H, Ballinger GA (2022) Survey response rates: trends and a validity assessment framework. Hum Relations 1–25. https://doi.org/10.1177/00187267211070769.

ISO (2015) Quality management systems - fundamentals and vocabulary.

Vashishth A (2019) Integrated management system implementation in Indian SMEs,” IIM Tiruchirappalli.

Larsen SB, Masi D, Feibert DC, Jacobsen P (2018) How the reverse supply chain impacts the firm’s financial performance: a manufacturer’s perspective. Int J Phys Distrib Logist Manag 48(3):284–307. https://doi.org/10.1108/IJPDLM-01-2017-0031

ACE Hub (2020) Australian circular economy hub - strategic action plan 2020–23. [Online]. Available: https://assets.ctfassets.net/fqjwh0badmlx/%0A46fuilIwjt8NosSFzILqdN/8f5eb8039f0a14ac5b79f82485003b75/ACEHUB_3YR_STRATEGIC_%0AACTION_PLAN_2020.pdf.

Moeller S (2010) Characteristics of services - a new approach uncovers their value. J Serv Mark 24(5):359–368. https://doi.org/10.1108/08876041011060468

Veleva V, Bodkin G (2018) Corporate-entrepreneur collaborations to advance a circular economy. J Clean Prod 188:20–37. https://doi.org/10.1016/j.jclepro.2018.03.196

Sarja M, Onkila T, Mäkelä M (2021) A systematic literature review of the transition to the circular economy in business organizations: obstacles, catalysts and ambivalences,” J Clean Prod 286. https://doi.org/10.1016/j.jclepro.2020.125492.

Dalhammar C (2016) Industry attitudes towards ecodesign standards for improved resource efficiency. J Clean Prod 123:155–166. https://doi.org/10.1016/j.jclepro.2015.12.035

Werning JP, Spinler S (2020) Transition to circular economy on firm level: barrier identification and prioritization along the value chain. J Clean Prod 245. https://doi.org/10.1016/j.jclepro.2019.118609

Acknowledgements

We thank our colleagues, Prof. Thomas Baumgartl (Director, Future Regions Research Centre), Prof. Vincent Verheyen (Research Stream Leader, Circular Economy), Dr. Moulik Zaveri and Dr. Vaughan Reimers (Institute of Innovation, Science, and Sustainability), who had provided us with valuable feedback and suggestions, which helped us immensely in improving our questionnaire.

Funding

This work is supported in 2021 by erstwhile School of Engineering, IT, and Physical Sciences, Federation University. RSP Funding (RGS21-6).

Author information

Authors and Affiliations

Contributions

All authors were engaged in the discussion of the concept and research plan. All authors were significant contributors in discussions that led up to the drafting of the article.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chakraborty, A., Barton, A., O’Loughlin, A. et al. Exploratory Survey of Australian SMEs: an Investigation into the Barriers and Opportunities Associated with Circular Economy. Circ.Econ.Sust. 3, 1275–1297 (2023). https://doi.org/10.1007/s43615-022-00235-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s43615-022-00235-0