Abstract

Maltotetraose (G4) consists of four glucose units linked by an α-1,4-glycosidic bond. This compound demonstrates remarkable versatility in food processing and exhibits specific physiological functions, suggesting promising applications in the medical, chemical, and food sectors. However, due to the closely related physical and chemical properties of maltotriose (G3), G4, and maltopentose (G5), achieving high-purity G4 has been challenging, resulting in a staggering price of US$438.88 per gram. In this study, a novel and efficient bio-physical method was developed to produce high-purity G4. Initially, multi-enzymatic hydrolysis yielded G4 at a 65.83% purity. Subsequent processes involving yeast fermentation and SMB separation further enhanced the purity to an impressive 93.15%. Notably, this pioneering method represents the successful separation of G3, G4, and G5 to exclusively obtain high-purity G4 from maltooligosaccharides, surpassing previous purity achievements. Every facet of this bio-physical method underwent meticulous design and optimization, ensuring a production process that is environmentally friendly, safe, and efficient. To validate its practicality, pilot-scale production tests were conducted. The cost analysis indicates that producing high-purity G4 through this method amounts to only US$0.013 per gram, representing that the actual selling price of G4 was 33,760 times the production cost under this process.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Maltotetraose (G4) stands out as a novel functional starch sugar that holds significant promise in the medical, chemical, and food industries. This compound offers various benefits such as sustaining continuous energy supply to the human body, enhancing dough rheology and baking quality [1], maintaining water retention and moisturizing properties [2], inhibiting early stages of atherosclerosis [3], and suppressing the growth of certain pathogenic bacteria [4], etc. Its exceptional food processability and physiological effects have been well-documented [5].

Currently, G4 is primarily derived from the hydrolysis of starch or maltodextrin. Traditional methods for G4 production encompass acid hydrolysis, enzyme hydrolysis, and acid-enzyme combinations, with enzyme hydrolysis being the predominant approach [6]. However, the product obtained through enzymatic methods is a maltodextrin mixture containing around 50% G4, which complicates the realization of G4’s inherent benefits. The escalating market demand for high-purity G4, as opposed to maltodextrin blends containing 50–55% G4, underscores the need for more refined purification processes. The exorbitant cost associated with high-purity G4 has impeded its widespread adoption for years. The reported purification methods for maltotetraose primarily include physical and chemical approaches. For instance, Li et al. [7] utilized a physical method for G4 purification, which theoretically appears viable; however, the actual production only yielded a G4 product with a purity of 81.32%, indicating limitations in the physical approach. In contrast, Maruo and Yohji [8, 9] employed a chemical method for G4 purification. This approach entails high production costs, stringent reaction conditions, and is not conducive to industrial-scale production. Notably, biological methods present clear advantages. Utilizing yeast, a common industrial strain used for fermentation, can efficiently segregate fermentable and non-fermentable sugars [10, 11].

To promote the advancement of the G4 purification industry, two new amylases (MFAPS and MFAPS-ΔCBM) have been developed by our research team, both originating from Pseudomonas saccharophila STB07 [12, 13]. They hydrolyze maltodextrin to produce a G4 solution with a purity greater than 55%. Before purifying G4, a multi-enzyme hydrolysis method was established to further increase the G4 content. This enhances the utilization rate of the raw materials and improves the purification process. In this study, a novel bio-physical method was introduced aiming to reduce the production cost of high-purity G4 and expedite its market development. This approach comprises two components: yeast fermentation and simulated moving bed (SMB) separation. The yeast fermentation effectively removes Glucose (G1), maltose (G2), maltotriose (G3) from the G4 hydrolysate. This single biological step simplifies the composition of the G4 solution, enabling the SMB purification of G4 and the removal of G5 ~ Gn (Gn represents a carbohydrate composed of n glucose molecules, n ≥ 5) from the G4 solution. These findings provide a fresh perspective on advancing G4 purification methods and stimulate further considerations on functional sugar purification.

Materials and methods

Materials and microorganisms

MFAPS was produced by using the recombinant Bacillus subtilis WB600 harboring the plasmid MFAPS/pST as the host, which contained the MFAPS gene from Pseudomonas saccharophila STB07 (GenBank accession number: X16732.1) [12]. MFAPS-ΔCBM was obtained by removing the Carbohydrate Binding Module (CBM) at the original C-terminal of MFAPS [13]. MFAPS and MFAPS-ΔCBM were both stored in our laboratory. Pullulanase was purchased from Macklin (Shanghai, China). Maltodextrin (DE7-9) was purchased from Baolingbao Biotech Corporation (Shandong, China). Sodium acetate and NaOH were all purchased from Sigma-Aldrich (Shanghai, China). SMB was purchased from Shanghai Zhaoguang Bioengineering Design and Research Institute (Shanghai, China). Sugar-tolerant yeast, baker’s yeast and Ayer yeast were purchased from Angel Yeast (Hubei, China). Saccharomyces cerevisiae, Pichia pastoris, Candida lipolyticus and Yarrowia lipolytica were all preserved in our laboratory. Standards for maltooligosacchaeides (≥ 97%) were purchased from Huicheng (Shanghai, China). Other reagents were analytically pure and purchased from Shanghai Chemical Reagent Co., Ltd. (Shanghai, China).

Multi-enzymatic hydrolysis

In this study, MFAPS, MFAPS-ΔCBM and pullulanase were utilized for the multi-enzymatic hydrolysis of maltodextrin to produce G4. MFAPS and MFAPS-ΔCBM were both typical glucoamylases capable of cleaving every four glucose units from the non-reducing end of starch. They primarily produced G4 during the hydrolysis of starch or dextrin [12]. The former possesses CBM, enabling it to actively bind substrates for hydrolysis, which offered advantages in hydrolyzing high molecular weight substrates. In contrast, the latter, lacking CBM, exhibited a weaker substrate-binding ability and could only hydrolyze substrates with smaller molecular weights [13]. Pullulanase used in this study was obtained from Macklin (Shanghai, China). This pullulanase belongs to type I pullulanase category, capable of hydrolyzing only α-1,6 glycosidic bonds without affecting G4 [14].

Maltodextrin (a dextrose equivalent of 7–9, DE7-9) was dissolved in water to create a 30% (w/w) aqueous solution. This solution was placed in a constant temperature water bath. The reaction commenced with the addition of amylases to the neutral maltodextrin (DE 7–9) solution. Specific procedural details can be found in Table S1. Subsequently, a crude G4 solution was obtained, and the calculation method for the G4 content ratio is detailed as follows:

In which m1 is content of G4 / (mg), m is the content of dry matter in sugar solution / (mg).

Yeast fermentation

The prepared crude G4 solution was cooled from 50 °C to 35 °C, transferred to a fermentation tank with supplying air, and inoculated with yeast fermenting for 24 h. G4 content ratio and removal rate of G1 ~ G3 (G1 ~ G3 RR) were used as evaluation criteria. Finally, a G4 purified product (pG4) was obtained after yeast fermentation, and the calculation method for the G1 ~ G3 RR is detailed as follows:

In which m2 is G1 ~ G3 content in crude G4 solution, m3 is G1 ~ G3 content in pG4 solution.

Yeast cell wall breaking

Ultrasonic breaking treatment

The yeast cells were suspended in 10 mL of 0.05 mol/L Tris-HCl buffer (pH 8.0). The yeast cells were then subjected to sonication at 400 W for 35 min. The sonication was operated with a 3 s on and 2 s off cycle, and the entire process was conducted in an ice water bath [15].

Liquid nitrogen grinding

Take 50 mL of acquired bacterial liquid and centrifuge it at 8000 rpm for 15 min at 4 °C. After centrifugation, the bacterial cells are collected. These cells are introduced into a grinding bowl that has been pre-cooled using liquid nitrogen, to which an appropriate amount of liquid nitrogen is added. The mixture is ground thoroughly with the liquid nitrogen until achieving a consistent powder-like texture. Following this, the resulting material is dissolved in 40 mL of a 0.05 mol/L Tris-HCl buffer solution and transferred to a pristine centrifuge tube [16].

SMB separation

SMB experiments for continuous purification of G4 separated product (sG4) from the pG4 were conducted [17]. The SMB is composed of a four-zone structure [18], which is assembled with twelve columns (φ 3.9 × 65 cm) that are packed with Dow 310 K resin (Dow Co., China). The main part of SMB is twelve chromatographic columns, which are divided into six groups (1#, 2#, 3#, 4#, 5#, 6#) of two. The operating system is a two-component separation system. A large cycle is composed of six identical small cycles, which is divided into five steps. The first step: 1# enters the mobile phase and discharges extract, 4# enters raw material and 5# discharges raffinate. The second and fourth steps: circulation step. The third step: valves switch counterclockwise. The fifth step: 2# enters Mobile phase and 6# discharges raffinate. Specific operations were done by referring to previous research [7], as shown in Table S3. Optimal separation conditions were identified by adjusting the duration of the small cycle, ultimately resulting in high-purity G4.

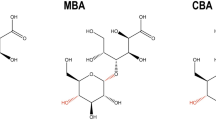

Determining G4 content by HPAEC-PAD

The solution to be tested was centrifuged at 10,000 rpm for 3 min, diluted 10,000 times, and then passed through a 0.22 μm aqueous membrane for detection. The G1 ~ G7 mixed standard with a certain concentration gradient was used as the control for qualitative and quantitative analysis, and the content of each component in the product was analyzed by HPAEC-PAD ICS6000 (Thermo Scientific, Waltham, MA, USA) [19]. The analysis conditions were as follows: a CarboPac PA200 (Thermo Scientific, Waltham, MA, USA) chromatographic column was used, 100 mM NaOH, 500 mM NaAc, and ultrapure water were used as mobile phases, the flow rate was set to 0.5 mL/min, the column temperature was 35 °C, and the injection volume was 20 µL.

Statistical analysis

The experimental results reported represent the means of triplicate measurements. Statistical analyses were carried out using the statistical package from SPSS Inc., USA. Significant differences (p < 0.05) between means were identified using one-way analysis of variance and the Student − Newman − Keuls procedure.

Results and discussion

Production process of G4

The purification of G4 presents challenges due to the presence of G1 ~ G3 and G5 ~ Gn. In the study, a novel and efficient bio-physical production method for obtaining high-purity G4 was developed. This method consists of three distinct steps: (1) The extraction of a crude G4 solution from maltodextrin (DE7-9) using MFAPS, MFAPS-ΔCBM and pullulanase. (2) The removal of G1 ~ G3 through yeast fermentation. (3) The separation of high-purity G4 via SMB. The overarching framework of this process emphasizes both environmental sustainability and efficiency, as delineated in Fig. 1. Upon recovery and activation, both yeasts and activated carbon, isolated through centrifugal filtration, find reuse in subsequent fermentation and decolorization processes. Likewise, the purified water and solutions of G5 ~ Gn, acquired through evaporative concentration and SMB separation, could be recycled for maltodextrin (DE7-9) dissolution. Each operational unit seamlessly integrated with the others, ensuring scalability to an industrial level. Post this refined production method, the purity of G4 escalated from 65.83 to 93.15%, marking a pinnacle in recent purity standards. Drawing from this methodological framework, an industrial scale production system with a capacity of 16 tons was successfully implemented, slashing the production cost of high-purity G4 to approximately US$0.013 per gram, as shown in Table S2. This cost-efficiency starkly contrasts with the prevailing market rate of roughly US$438.88 per gram for G4 of equivalent purity, underscoring the potential economic advantages of this bio-physical approach and its capacity to invigorate further research and development in the domain of G4. The subsequent text offered a detailed description of this biophysical method.

Multi-enzymatic hydrolysis preparing crude G4 solution

The pivotal step in preparing the crude G4 solution involved either single- or multi-enzyme hydrolysis of maltodextrin (DE7-9). Optimal hydrolysis conditions for both MFAPS and MFAPS-ΔCBM were delineated, as illustrated in Fig. 2, specifying a reaction temperature of 50 °C, an enzyme concentration of 20 U/g, a stirring rate set at 500 rpm, a pH level of 7.0, and a reaction time of 12 h [20, 21]. Under these specified optimal conditions, the G4 content ratio for MFAPS registered at 55.69%, while for MFAPS-ΔCBM, it escalated to 58.32%, as documented in Table S1 K-1 and K-2. Maltodextrin (DE7-9) is a typical starch derivative characterized by shorter chain lengths, making it more conducive for MFAPS-ΔCBM utilization rather than MFAPS. Consequently, the G4 content ratio achieved by MFAPS-ΔCBM surpassed that of MFAPS [13]. Enzymatic hydrolysis reaction involving MFAPS and MFAPS-ΔCBM typically concluded within 12 h, as depicted in Fig. 2e and j. The decrease in pH value occurred approximately 14 h after the reaction began. At that time, the initially introduced MFAPS and MFAPS-ΔCBM had undergone partial deactivation. With the decrease in pH, the deactivation of MFAPS and MFAPS-ΔCBM accelerated, culminating in the cessation of the enzymatic hydrolysis reaction. Given this observation, fresh MFAPS and MFAPS-ΔCBM were introduced to the reaction before reaching the turning point, prolonging the duration of the enzymatic hydrolysis and subsequently enhancing the G4 content ratio [22], as detailed in Table S1 A-1 and A-2. Splitting equal amounts of MFAPS and MFAPS-ΔCBM into two additions extended the enzymatic hydrolysis reaction time and enhanced the G4 content ratio. Notably, MFAPS-ΔCBM demonstrated superior performance, elevating the G4 content ratio to 61.31%.

In contrast to single-enzyme methods, multi-enzyme techniques generally enhanced the G4 content ratio. Single-enzyme hydrolysis of maltodextrin often resulted in reduced G4 content ratio and undue substrate wastage, potentially stemming from inherent constraints of single-enzyme methodologies. This limitation found support in previous research findings [7]. Building on the aforementioned two-stage enzyme addition, a dual-enzyme method was developed by combining MFAPS and MFAPS-ΔCBM, which proved to be more effective than relying solely on a single enzyme. As shown in Table S1 B-2, initiating with 10 U/g of MFAPS-ΔCBM for 12 h, followed by 10 U/g of MFAPS for another 12 h, elevated the G4 content ratio from 61.31 to 62.50%. However, commencing with MFAPS and subsequently introducing MFAPS-ΔCBM resulted in a diminished G4 content ratio. Such observations hint at potential competitive interactions between the enzymes, with MFAPS demonstrating greater substrate affinity than MFAPS-ΔCBM. In the absence of substrate protection, MFAPS-ΔCBM tended to deactivate swiftly, making it less advantageous for initial maltodextrin hydrolysis.

Maltodextrin (DE7-9) harbors numerous α-1,6-glycosidic bonds that evade hydrolysis by both MFAPS and MFAPS-ΔCBM. To increase the G4 content ratio, pullulanase was integrated to debranch the maltodextrin (DE7-9). Simultaneous saccharification and debranching indeed diminished the G4 content to roughly 56%, as illustrated in Table S1 K-3, K-4 and K-5. Hence, the sequence for introducing pullulanase holds significant importance, emphasizing the necessity to separate saccharification and debranching processes. Building upon the dual-enzyme methodology, a multi-enzyme hydrolysis technique was formulated, comprising three distinct phases: saccharification, debranching, and resaccharification. As delineated in Table S1 C-2, an initial reaction with 10 U/g of MFAPS-ΔCBM extended for 12 h, succeeded by treatment with 1 U/g of pullulanase for 2 h, and culminated with 10 U/g of MFAPS for 12 h, yielding a crude G4 solution at 65.83% [23]. This multi-enzyme hydrolysis approach alleviated inter-enzyme competition and stood as the enzymatic hydrolysis method with the highest reported G4 content ratio in existing literature. In contrast to the single-enzyme approach, multi-enzyme strategy amplifies the G4 content ratio without necessitating additional quantities of MFAPS or MFAPS-ΔCBM.

Yeast fermentation removing G1 ~ G3

The primary approach for eliminating G1 ~ G3 was the fermentation of the crude G4 solution with yeast. Yeasts comprised a diverse and extensive group, including strains with the ability to metabolize starch [24,25,26]. To determine that the yeast strains under study do not metabolize G4, an assessment of their hydrolytic activity on G4 was essential. Various yeast strains, at a 5% (w/w) concentration, were introduced into a G4 solution with a concentration of 20 mg/mL and aerobically cultured for seven days. As shown in Table 1, the data revealed no variations in the G4 content, indicating that these yeasts do not metabolize G4 via fermentation. This suggested that the extracellular enzyme systems of these yeasts lack the capability to hydrolyze G4, and their membrane proteins were ineffective in G4 transport. Apart from the role of extracellular enzymes and transport proteins, the intracellular enzyme systems of yeasts could potentially deplete G4. This potential raised due to the possibility of yeast cell breakage during production, which released intracellular components affecting maltotetraose. Methods such as ultrasound or freeze-grinding were employed to disrupt yeast cells and extract their intracellular enzymes. These enzymes were then exposed to a G4 solution at 30 °C for 24 h. As shown in Table 2, G4 content remained unchanged. The intracellular enzymes obtained from this method also indicated no capacity to hydrolyze G4. At the macro level, the application of yeast fermentation for the purification of G4 was scientifically validated.

To produce pG4, suitable strains must be selected to meet the purification standards for G4. In the typical production process of G4, the sugar content generally exceeds 25%. Consequently, the capability of yeast to consume G1 ~ G3 under high sugar concentration became the paramount evaluation criterion. The yeast strains previously identified as not consuming G4 were inoculated at a 5% (w/w) concentration into crude G4 solutions with sugar concentrations of 10% and 30%, respectively, and cultured at 35 °C for 24 h. As depicted in the Fig. 3, within a 10% sugar environment, S. cerevisiae (containing sugar-tolerant yeast, baker’s yeast and ayer yeast) consistently manifested elevated G1 ~ G3 removal rates (G1 ~ G3 RR) compared to other yeast varieties. Notably, the G1 ~ G3 removal rate for sugar-tolerant yeast (S-yeast) reached an impressive 99.43%. Conversely, in the 30% sugar environment, all yeast strains displayed an unsuitable response, failing to effectively metabolize G1 ~ G3. However, S-yeast remained unaffected by these conditions and efficiently consumed G1 ~ G3, maintaining a removal rate of over 99%. At present, selecting S-yeast for G4 purification appeared most suitable.

To enhance the efficiency of yeast fermentation for purifying G4 and reduce production costs, optimization of fermentation conditions was essential. Yeast has the capability to ferment and metabolize sugars in both aerobic and anaerobic environments [27]. However, in anaerobic conditions, yeast colonies perceived the environment as unsuitable for survival. Instead of utilizing sugars for growth and reproduction, yeast transitions to a dormant state, storing sugars [28]. Such microbial behavior impeded the consumption and metabolism of G1 ~ G3. Consequently, an aerobic environment was consistently provided for yeast fermentation. To amplify the S-yeast’s capability to eliminate G1 ~ G3, fermentation conditions were refined. As illustrated in Fig. 4, maintaining the temperature of the crude G4 solution at 35 °C, supplementing with 0.2% (w/w) (NH4)2PO4, and inoculating with more than 5% (w/w) S-yeast for over 24 h resulted in the removal of over 99% of G1 ~ G3 from the crude G4 solution. It’s essential to note that an increase in yeast concentration corresponded to an enhanced G1 ~ G3 removal rate. However, excessive yeast inoculation has been proven inefficient, leading to the production of numerous other compounds [29]. Maintaining an optimal temperature range is crucial; adverse conditions prompt yeast colonies to perceive unfavorable growth circumstances, inducing a collective dormant state [30]. Under the aforementioned optimal conditions, fermentation extracted 99.5% of G1 ~ G3 from the crude G4 solution, elevating the G4 purity from 65.83 to 89.01%. This approach offered a green, safe, efficient, and controllable method to address the challenge of separating G1 ~ G3 from G4, mitigating the impact of suboptimal enzymatic reaction outcomes.

SMB separation removing G5 ~ gn

After yeast fermentation, only G4 ~ Gn was present in pG4, excluding G1 ~ G3. To enhance the quality and value of the G4 products, SMB separation was utilized to eliminate G5 ~ Gn. Table S3 outlines the specific equipment parameters and operational conditions. Under these parameters, it’s crucial to establish the retention time of G4 within each chromatographic column. Table S4 indicated that the average retention time for G4 was 255 s. Based on the operational sequence for a small cycle, G4 must traverse six chromatographic columns, spanning from the raw material inlet to the raffinate outlet, resulting in an approximate 1500 s small cycle duration. As depicted in Table S5, with this 1500 s cycle duration, the G4 purity attained was 73.11%, accompanied by a G4 yield of 90.17%. This was due to the insufficient separation between G4 and G5 ~ Gn in the chromatographic column [31], analogous to distinct substances displaying overlapping peaks in HPLC. Notably, extending the small cycle duration to 1800 s increased G4 purity from 89.01 to 93.15%, while maintaining a G4 yield of 70%.

The pivotal stages in eliminating G5 ~ Gn involved a multi-step process, encompassing enzymatic hydrolysis of maltodextrin (DE7-9) and subsequent SMB separation. The enzymatic hydrolysis served as the foundational element of this manufacturing sequence. As the conversion of G5 ~ Gn to G1 ~ G4 increased, the resultant G4 purity post-SMB separation also improved. Conversely, SMB separation acted as the final validation step. In scenarios where enzymatic hydrolysis yielded a G4 purity close to 70%, a standard level subsequent to yeast fermentation, the SMB separation became crucial for the elimination of G5 ~ Gn. As depicted in Fig. 5, with a G4 content ratio of 55.55% post-enzymatic hydrolysis and a subsequent G4 purity of 73.84% post-yeast fermentation, the SMB process significantly enhanced the G4 purity to 90.43%. This highlighted the synergistic relationship between enzymatic hydrolysis and SMB separation, effectively addressing challenges in practical production environments.

Conclusion

In the presented study, a biophysical method was developed for the industrial production of G4, achieving a purity of 93.15%. Emphasis was placed on sustainability, safety, and flexibility, including the recycling of materials such as yeast, activated carbon, and distilled water. The production process comprised three distinct phases: multi-enzyme hydrolysis, yeast fermentation, and simulated moving bed (SMB) separation, progressively increasing the G4 purity to 65.83%, 89.01%, and eventually 93.15%. Multi-enzyme hydrolysis facilitated enhanced substrate utilization by harmonizing the distinct capabilities of each enzyme, thereby elevating the purity of the final product. Yeast fermentation effectively isolated G1 ~ G3 from G4, introducing a novel biological method for G4 purification, with evidence highlighting specific yeast strains’ non-metabolism of maltotetraose. SMB separation efficiently differentiated G4 from Gn, underscoring its versatile production adaptability. This separation approach minimized raw material wastage during unforeseen production events. Collectively, the orchestrated processes synergized to optimize costs, bolster efficiency, and yield a high-purity G4 product, offering crucial insights for future G4 research initiatives.

Data availability

The data are available from the corresponding author on reasonable request.

References

Shinde VK, Vamkudoth KR. Maltooligosaccharide forming amylases and their applications in food and pharma industry. J Food Sci Technol. 2021;1–12. https://doi.org/10.1007/s13197-021-05262-7.

Bae W, Lee SH, Yoo SH, et al. Utilization of a maltotetraose-producing amylase as a whole wheat bread improver: dough rheology and baking performance. J Food Sci. 2014;79(8):E1535–E40. https://doi.org/10.1111/1750-3841.12538.

Soon YS, You JJ, Yeonjoong Y, et al. Inhibition of PDGF-induced migration and TNF-alpha-induced ICAM-1 expression by maltotetraose from bamboo stem extract (BSE) in mouse vascular smooth muscle cells. Mol Nutr Food Res. 2016;60(9):2086–97. https://doi.org/10.1002/mnfr.201500601.

Kondo H, Honke T, Hasegawa R, et al. Isolation of maltotetraose from Streptomyces as an antibiotic against Erwinia carotovora. J Antibiot. 1975;28(2):157–60. https://doi.org/10.7164/antibiotics.28.157.

Kimura T, Nakakuki T. Maltotetraose, a new saccharide of tertiary property. Starch/Staerke. 1990;42(4):151–57. https://doi.org/10.1002/star.19900420407.

Bláhová M, Štefuca V, Hronská H, et al. Maltooligosaccharides: properties, production and applications. Molecules. 2023;28(7):3281. https://doi.org/10.3390/molecules28073281.

Li J, Ban X, Gu Z, et al. Preparation and antibacterial activity of a novel maltotetraose product. Process Biochem. 2021;108:8–17. https://doi.org/10.1016/j.procbio.2021.05.018.

Maruo S, Yamamoto H, Toda M, et al. Enzymatic synthesis of high purity maltotetraose using moranoline (1-Deoxynojirimycin). J Agricultural Chem Soc Japan. 1993;57(3):499–501. https://doi.org/10.1271/bbb.57.499.

Ezure Y, Maruo S, Kojima M, et al. Manufacturing high purity maltose and maltotetraose from starch by a novel and efficient procedure named reducing end modification method. Biosci Biotechnol Biochem. 1997;61(11):1931–33. https://doi.org/10.1271/bbb.61.1931.

Li Y, Lü F, Xu Y, et al. Purification of Ulva lactuca functional oligosaccharides by yeast fermentation combined with enzyme. J Fujian Agric Forestry University(Natural Sci Edition). 2018;47(1):110–14.

Dasaesamoh R, Youravong W, Wichienchot S. Optimization on pectinase extraction and purification by yeast fermentation of oligosaccharides from dragon fruit (Hyloceus Undatus). Int Food Res J. 2016;23(6):2601–07.

Zhang Z, Jin T, Xie X, et al. Structure of maltotetraose-forming amylase from Pseudomonas saccharophila STB07 provides insights into its product specificity. Int J Biol Macromol. 2020;154:1303–13. https://doi.org/10.1016/j.ijbiomac.2019.11.006.

Duan K, Ban X, Wang Y, et al. Improving the product specificity of maltotetraose-forming amylase from Pseudomonas saccharophila STB07 by removing the carbohydrate-binding module. J Agric Food Chem. 2022;70(42):13709–18. https://doi.org/10.1021/acs.jafc.2c05580.

Thakur M, Sharma N, Rai AK, et al. A novel cold-active type I pullulanase from a hot-spring metagenome for effective debranching and production of resistant starch. Bioresour Technol. 2021;320:124288. https://doi.org/10.1016/j.biortech.2020.124288.

Bhat P, Pawaskar G-M, Raval R, et al. Expression of Bacillus licheniformis chitin deacetylase in E. Coli pLysS: sustainable production, purification and characterisation. Int J Biol Macromol. 2019;131:1008–13. https://doi.org/10.1016/j.ijbiomac.2019.03.144.

Phillips EO, Giovinazzi S, Menz SL, et al. Preparation of cell extracts by cryogrinding in an automated freezer mill. JoVE (Journal Visualized Experiments). 2021;167e61164. https://doi.org/10.3791/61164.

Imamoglu S. Simulated moving bed chromatography (SMB) for application in bioseparation. Mod Adv Chromatogr. 2002;211–31. https://doi.org/10.1007/3-540-45345-8_6.

Seidel-Morgenstern A, Kessler LC, Kaspereit M. New developments in simulated moving bed chromatography. Chem Eng Technology: Industrial Chemistry‐Plant Equipment‐Process Engineering‐Biotechnology. 2008;31(6):826–37. https://doi.org/10.1002/ceat.200800081.

Barber E, Houghton MJ, Visvanathan R, et al. Measuring key human carbohydrate digestive enzyme activities using high-performance anion-exchange chromatography with pulsed amperometric detection. Nat Protoc. 2022;17(12):2882–919. https://doi.org/10.1038/s41596-022-00736-0.

Maalej H, Ben Ayed H, Ghorbel-Bellaaj O et al. Production and biochemical characterization of a high maltotetraose (G4) producing amylase from Pseudomonas stutzeri AS22. BioMed research international. 2014;2014. https://doi.org/10.1155/2014/156438.

Matsumoto T, Makimoto S, Taniguchi Y. Effect of pressure on the mechanism of hydrolysis of maltotetraose, maltopentaose, and maltohexose catalyzed by porcine pancreatic α-amylase. Biochim et Biophys Acta (BBA)-Protein Struct Mol Enzymol. 1997;1343(2):243–50. https://doi.org/10.1021/jf970137h.

Quéméneur M, Bittel M, Trably E, et al. Effect of enzyme addition on fermentative hydrogen production from wheat straw. Int J Hydrogen Energy. 2012;37(14):10639–47. https://doi.org/10.1016/j.ijhydene.2012.04.083.

Ming Z. Research on the Production Technology of Maltotetraose. Journal Of Wuxi University Of Light Industry; 1999.

Adhiraj R, David JI, Hong CK, et al. Understanding the mechanism of glucose-induced relief of Rgt1-mediated repression in yeast. Febs Open Bio. 2014;4(1):105–11. https://doi.org/10.1016/j.fob.2013.12.004.

Zhang X. Glucose repression of the mal genes in the yeast Saccharomyces cerevisiae, Yeshiva University1996.

Stambuk B, Silva MD, Panek A, et al. Active α-glucoside transport in Saccharomyces cerevisiae. FEMS Microbiol Lett. 1999;170(1):105–. https://doi.org/10.1111/j.1574-6968.1999.tb13361.x. 10.

Jones RP, Greenfield PF. Effect of carbon dioxide on yeast growth and fermentation. Enzym Microb Technol. 1982;4(4):210–23. https://doi.org/10.1016/0141-0229(82)90034-5.

Zhao G, Chen Y, Carey L, et al. Cyclin-dependent kinase co-ordinates carbohydrate metabolism and cell cycle in S.cerevisiae. Mol Cell. 2016;62(4):546–57. https://doi.org/10.1016/j.molcel.2016.04.026.

Ming Z, Hong C, Jing S, et al. Inoculum size-dependent interactive regulation of metabolism and stress response of Saccharomyces cerevisiae revealed by comparative metabolomics. J Biotechnol. 2009;144(4):279–86. https://doi.org/10.1016/j.jbiotec.2009.09.020.

White J, Munns DJ. Influence of temperature on yeast growth and fermentation. J Inst Brew. 1951;57(4):280. https://doi.org/10.1002/j.2050-0416.1951.tb01628.x. – 84.

Lee C-g, Choi J-H, Park C, et al. Standing wave design and optimization of a simulated moving bed chromatography for separation of xylobiose and xylose under the constraints on product concentration and pressure drop. J Chromatogr A. 2017;1527:80–90. https://doi.org/10.1016/j.chroma.2017.10.067.

Author information

Authors and Affiliations

Contributions

Liyuan Jiang: Conceptualization, Investigation, Data curation, Writing – original draft. Haocun Kong: Methodology, Data curation. Xiaofeng Ban: Writing - review & editing. Zhengbiao Gu: Conceptualization, Methodology, Resources. Caiming Li: Resources, Supervision. Yue-E Sun: Writing - review & editing. Zhaofeng Li: Conceptualization, Methodology, Resources, Supervision.

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jiang, L., Kong, H., Ban, X. et al. Enhanced maltotetraose purity in industrial production by a sustainable bio-physical process. Syst Microbiol and Biomanuf 4, 1028–1038 (2024). https://doi.org/10.1007/s43393-024-00243-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s43393-024-00243-1