Abstract

Electrical breakdowns of multilayer ceramic capacitors (MLCCs) manifest an increase in leakage current and are characterized as a function of atmospheric reoxidation. The atmospheric reoxidation is controlled with respect to the theoretical oxygen partial pressure for the oxidation of Ni internal electrodes. The breakdowns are characterized by a Maxwell–Wagner polarization technique, which dominantly exhibits space-charge-limited and Poole–Frenkel currents for all measured samples. The threshold voltage for the transition between these two conduction modes is suggested as an index for the robustness of the grain boundary resistance of BaTiO3; therefore, the breakdown voltage. The reoxidation atmosphere, which prevents the Ni oxidation, increases the threshold voltage, dramatically enhancing the breakdown voltage and insulation resistance. Impedance spectroscopy and scanning transmission electron microscopy–energy-dispersive X-ray spectroscopy reveal that the cation distribution throughout BaTiO3 grains and grain boundaries changes during the reoxidation, including Ni cations from the internal electrodes, which affects the grain boundary resistance and determines the breakdown voltage of MLCCs with Ni internal electrodes. These observations emphasize that the reoxidation should be concurrently optimized in terms of the cation redistribution and elimination of oxygen vacancies.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

A ferroelectric thin film of a few hundred nanometers is a prerequisite to develop high-end multilayer ceramic capacitors (MLCCs) and nanoelectronic devices such as non-volatile random-access memories and high-permittivity gate dielectrics [1]. As the thickness of a ferroelectric layer reduces, it may be treated as a semiconductor with a large band gap, rather than an insulator [2]. Therefore, the electrical breakdown of a ferroelectric film, defined as an abrupt increase in leakage current, should be understood and controlled to fully exploit the ferroelectric-based devices [3]. Controlling the breakdowns is a significant step in the development of high-end MLCCs, which are generally fabricated with Ni internal electrodes. This is because ferroelectric BaTiO3 (BT) layers undergo reductive annealing to prevent the Ni oxidation, which could generate additional charge carriers owing to the oxygen vacancies and electrons within the BT layers, resulting in an increase in leakage currents [4]. Considering this, reoxidation after the reductive annealing during the fabrication of MLCCs was introduced to eliminate the generated charge carriers [4, 5]. In general, the reoxidation of BT is conducted under a nitrogen atmosphere in which Ni could be oxidized because the pO2 of the nitrogen atmosphere, ca. 10–5 atm is much higher than the pO2 of Ni/NiO equilibrium, which is in a range of 10–11 atm near 1000 °C. In this regard, it can be conceived that this reoxidation condition kinetically retards Ni oxidation, only preventing complete loss of electrical contact [4, 5].

During the reoxidation, the grain boundaries of BT become highly resistive compared to the BT grains, which serve as an electrical barrier [3, 6,7,8]. Upon the oxidation of segregated cations at grain boundaries, a Schottky-like barrier is established across the grain boundaries, which hinders the migration of oxygen vacancies and electronic carriers. This resistive barrier (or resistive grain boundaries) is formed because of the cation redistribution during reoxidation in the presence of acceptor segregation at the grain boundaries [6, 9]. The reoxidation of BT also accompanies the migration of cations or titanium vacancies; therefore, a slower cation migration determines the reoxidation kinetics [10, 11]. Hence, the reoxidation condition should also be investigated in terms of the cation redistribution and resultant grain boundary resistance along with the elimination of ionic defects, such as, oxygen vacancies.

The equilibration of various dopants can be affected by Ni oxidation. Ni readily diffuses through the BT grain boundaries during the reoxidation; thus, it always exists at the grain boundaries [12]. Ni itself can act as an acceptor when doped into BT [13]; hence, its oxidation state may alter the solubility of Ni in BT, changing the grain boundary resistance. However, the formation of NiO can change the solubility of additive elements because NiO can act as an oxide matrix for the additives, mostly in the form of oxides, so that NiO can remove the additives from BT. These possibilities suggest that the oxidation state of Ni may determine the grain boundary properties of BT. Thus, the leakage current characteristics need to be studied in terms of Ni oxidation.

In this study, the electrical breakdown of MLCC is studied in terms of the leakage current characteristics as a function of the reoxidation atmosphere. The reoxidation atmosphere is adjusted in the pO2 range near the Ni/NiO equilibrium. The leakage current characteristics were studied by a Maxwell–Wagner polarization technique and analyzed with conduction theories of space-charge-limited and Poole–Frenkel currents.

2 Materials and methods

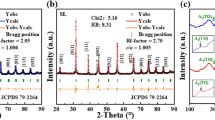

The MLCC samples used in this study were X5R type commercial MLCCs with Ni internal electrodes fabricated by Samsung Electro-Mechanics. The dielectric layers were made from hydrothermally synthesized BT powders with Dy2O3, MgCO3, Mn3O4, V2O5 as the doping additives and SiO2 as a sintering agent. The total doping concentration was 1.8 mol% of BT. All samples were sintered under the same conditions at 1140 °C, and they were reoxidized under various pO2 conditions at 1000 °C.

The breakdowns of MLCCs were quantified in terms of the leakage current characteristics. To measure the leakage currents precisely, the current responses of the ferroelectrics must be understood. When an electric field is applied to an MLCC, the charging currents (JC) can be measured, which predominantly includes the polarization current (JP) and ‘true’ leakage current (JL) as follows [14, 15]:

Therefore, the polarization current during charging should be subtracted from the measured charging current. There are two general techniques for this: (i) the staircase mode, in which the leakage current under a certain electric field is measured after a finite charging period for saturation of the polarization current. Consequently, the whole voltage profile looks like a staircase, or step-like function; (ii) pulse mode, in which the leakage current at a specific voltage is determined by subtracting the discharging current from the charging current [14, 15]. This concept is based on the characteristics of the Maxwell–Wagner polarization. Under a voltage pulse with a time duration t, the charging current at time t is identical to the discharging current at time 2t because the transient variations of charging and discharging currents are almost same [7]. Therefore, in pulse mode, the voltage profile consists of successive steps separated by the intervals of the same duration [14, 15]. In this study, the pulse mode is applied to examine the leakage current characteristics. The charging and discharging times were 5 s each and the voltage step was set to 1 V. Breakdown voltage (BDV) of a sample was defined as the voltage at which the leakage current exceeded 20 mA. All electrical measurements were conducted with a DC meter (SourceMeter 2410, Keithley). The time-dependent IR degradation of MLCC was tested under a constant DC bias of 6.3 V for 12 h at 105 °C with the same ammeter. The impedance spectra were obtained with an AC amplitude of 0.1 V in the frequency range of 1 MHz–0.1 Hz using an impedance analyzer (AlphaA, Novocontrol).

After the electrical measurements, the representative samples were mechanically polished and chemically etched to observe the microstructures of the samples by scanning electron microscopy (SEM, Sigma 300, Zeiss). Furthermore, the samples were thinned with a focused ion beam (FIB, Helios NanoLab 660, FEI) for scanning transmission electron microscopy (STEM, Tecnai Osiris, FEI)–energy-dispersive X-ray spectroscopy (EDS).

3 Results and discussion

The BDVs as functions of the reoxidation atmospheres, represented as pO2, are shown in Fig. 1. The corresponding electromotive forces (EMFs) from a Nernst-type oxygen sensor at each pO2 are also indicated for reference. BDVs as functions of oxygen partial pressures show a step-like increase with a threshold pO2 of 4.52 × 10–11 atm, which corresponds to the equilibrium pO2 of Ni/NiO at 1000 °C [16]. When reoxidized above the equilibrium pO2, BDVs drop below 50 V, while those below the equilibrium rise above 60 V. These observations imply that BDV degrades when Ni oxidation takes place above the Ni/NiO equilibrium pO2. Therefore, it can be inferred that the Ni oxidation results in BDV degradation.

The microstructure of each sample was investigated by SEM to observe inter-electrode distances and grain growth characteristics, as shown in Fig. 2. Thus, the strength of the electric field increases as the inter-electrode distance decreases, inducing a more pronounced leakage current under the same voltage pulse. However, anomalous grain growth reduces the number of grain boundaries in a dielectric layer, which exhibits a much larger resistance than bulk owing to the space charge layer [6, 17]. The MLCC reoxidized under the equilibrium pO2 of Ni/NiO (denoted as Equilibrium) has an average gran size of 342 (± 139) nm. The grain size of the one reoxidized in an oxidative atmosphere (pO2 of 9.86 × 10–10 atm, represented as Oxidative) is 322 (± 138) nm. The grain size of the one in a reducing atmosphere (pO2 of 7.11 × 10–13 atm, expressed as Reductive) is 267 (± 102) nm. Considering the BDVs of each sample, 68, 32, and 62 V for equilibrium, oxidative, and reductive, respectively, the grain size or number of grain boundaries has a minor effect on the BDV of these samples. No distinctive difference was found in the inter-electrode distance as well. The average distances were 436, 438, and 458 nm for the oxidative, equilibrium, and reductive samples, respectively. Therefore, the step-like increase in BDV at the equilibrium atmosphere, as shown in Fig. 1, does not originate from the microstructural changes upon the reoxidation atmosphere.

SEM microstructural images as functions of reoxidation atmospheres. a Oxidative, b equilibrium, and c reductive. The brighter layer in contrast is a Ni internal electrode, while the darker one is a dielectric layer as indicated in c. All images are in the same scale. The scale bar in image c represents 1 μm

The leakage current characteristics were characterized to study the breakdowns as functions of the reoxidation conditions. The nonlinear behaviors of the leakage currents under an electrical field have been extensively explained with various conduction mechanisms in a dielectric [7, 14, 17,18,19,20,21]. The degradation of insulation resistance (IR), or an increase in leakage current, is mainly demonstrated by Schottky emission, space-charge-limited-current, and Poole–Frenkel emission.

Schottky emission is an emission of charge carriers aided by the reduction in barrier at the electrode–dielectric interface upon an applied electric field [20]. The current density (J)–electric field (E) relationship for the Schottky emission is given by

where A*, ΦB, e, ε, and ε0 are the modified Richardson–Dushman constant, interfacial barrier height, elementary charge, permittivity of dielectric, and vacuum permittivity, respectively.

Space-charge-limited current is the current across a space charge layer. Space charge layers at the electrode–dielectric interface and grain boundary impede the current flow, and the barrier height can be reduced by the applied field, allowing the current flow [17]. This type of behavior can be described as

where μ denotes the carrier mobility, and d denotes the dielectric thickness.

Poole–Frenkel emission is a thermionic emission of trapped carriers from the bulk dielectric owing to the barrier reduction [21, 22]. The Poole–Frenkel emission current is expressed as

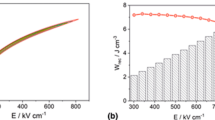

where n0 and ΦT are the initial carrier concentration before barrier reduction and trap energy, respectively. There are two behaviors distinguishable by slope, as shown in Fig. 3a. The first one, observed as a gentle slope under relatively low electric fields, can be regarded as the space-charge-limited currents, in which the current density increases proportionally to the square of the electric field [J ∝ E2 as revealed in Eq. (3)]. This behavior originates from a space charge layer, and therefore, resistive grain boundaries [17]. However, the linearity at high fields [Eq. (4), logJ ∝ E1/2] represents Poole–Frenkel emissions, which occurs owing to the detrapping of electrons from the bulk BT [21, 22]. There is no additional linear relation in logJ and E1/2, that is, the Schottky emission behavior is not dominant in these samples. The breakdown retarded when the space-charge-limited currents prevailed longer, as shown in Fig. 3b. The robustness of the grain boundary barrier can be expressed with a threshold voltage at which the conduction mode changes from the space-charge-limited to Poole–Frenkel emission. Figure 3b reveals that BDV increases monotonically with the threshold voltage; therefore, we suggest that the threshold voltage can be utilized as a reliability descriptor. It should be noted that the E–J characteristics merge into one plot if the reoxidation pO2 is lower than the Ni/NiO equilibrium pO2, which indicates that the grain boundary resistance is augmented to slow down the breakdowns, resulting in a high BDV. Hence, it is postulated that the breakdown strength of MLCCs is not degraded if Ni is kept metallic. The degradation of BDV upon Ni oxidation may be related to a decrease in grain boundary resistance, because the oxidative sample exhibits a much lower threshold voltage than the others.

A prerequisite for a resistive grain boundary is the grain-boundary segregation of dopants [6, 9]. The segregated cations at the grain boundary bring about a space charge layer of enriched negative charges, that is, electrons and cation vacancies, while the positive charges of holes and oxygen vacancies are depleted, making it resistive for both holes and oxygen vacancies. Therefore, the grain boundary segregation and dissolution of cations determine the grain boundary resistance. Ni is known as an acceptor-type dopant for BT and it readily dissolves into Ti sites by introducing oxygen vacancies in BT [23]. Oxygen vacancies are one of the major causes for IR degradation during constant poling with a DC bias [8]. If the oxidative sample exhibits a more rapid IR degradation than equilibrium, it can be inferred that the solubility of Ni in BT is facilitated when the Ni is oxidized. Another possibility is that Ni oxidation might increase the solubility of other additives. NiO forms an ideal solid solution with MgO, while Ni hardly does [24]. MgO rapidly diffuses into BT forming a shell-like layer on BT; subsequently, the shell-like layer disturbs the diffusion of other additives, resulting in a core–shell structure [25]. Therefore, the formation of NiO can remove MgO from BT, which allows for the facile dissolution of additive acceptors, increasing the oxygen vacancy concentrations. In both cases, it is expected that the oxidative sample exhibits more drastic IR degradation than the equilibrium sample.

The IR degradations at 105 °C were tested, as shown in Fig. 4a. The drastic IR degradation of the reductive sample can be related to the high oxygen vacancy concentration, because BT might be significantly reduced due to the reducing atmosphere of this sample. The equilibrium sample exhibited almost no IR degradation during the test, while the oxidative sample showed a slight degradation behavior. Because the absolute pO2 value for the oxidative sample is much higher than that of equilibrium, 9.86 × 10–10 and 4.52 × 10–11 atm for oxidative and equilibrium, respectively, the vacancies generated by the reduction of BT for oxidative should be less than that for equilibrium. Therefore, if the superior IR stability of equilibrium predominantly originates from a low concentration of oxygen vacancy, it can be concluded that the acceptor solubility of equilibrium is suppressed.

Impedance spectroscopy at temperatures below ~ 250 °C can be an effective tool to assess the oxygen vacancy concentration in BT. At this temperature range, BT or SrTiO3 dominantly exhibits ionic conductivity rather than electronic [26,27,28,29]. Therefore, the oxygen vacancy concentration can be estimated from the conductivity values. Figure 4b shows Nyquist plots of complex impedances for the three samples. Complex impedance plots can be interpreted with an RC circuit with a Warburg-type element, designated for ionic conduction and ion blocking behaviors at the dielectric–electrode interface, respectively [27]. To compare the oxygen vacancy concentration among the samples, the ionic conduction behavior, represented as a semicircle in the Nyquist plot, is only considered, which is expressed as a solid line in Fig. 4b. The diameter of the semicircle reveals resistance to ionic conduction. Because ionic conductivity is a function of carrier concentration and mobility, the similarity of mobility for the three samples needs to be checked. The activation energies for all samples determined from the resistances measured at three different temperatures of 210, 220, and 230 °C were near to ~ 1.5 eV. Therefore, the resistance can be related to the oxygen vacancy concentration in BT. The resistances of the three samples show the same tendency with IR degradation behaviors: largest for equilibrium, smallest for reductive. Therefore, it can be concluded that the solubility of acceptor dopants is suppressed when Ni is kept metallic.

To study the microscopic features of the additive elements in the reoxidation atmospheres, STEM–EDS analyses were conducted for the oxidative and equilibrium samples. The EDS spectra at the BT grain boundaries after reoxidation exhibited a strong enhancement of the Ni signal as compared to those of the as-sintered samples (Fig. 5a). Dy Lα and Lβ spectra for each sample were normalized to compare the Ni spectra, because Dy was added with a controlled amount. This observation clearly suggests that Ni from electrodes actively diffuses toward BT through grain boundaries; thus, it can interact with BT and additives affecting the grain boundary property. EDS elemental maps of the two samples show a distinctive difference in Mg distribution, as shown in Fig. 5b and c. Mg agglomerates were clearly observed only in the oxidative sample near the Ni electrode region, as indicated by the red arrows in Fig. 5b. This can be conceived as the formation of a NiO–MgO solid solution upon Ni oxidation, as mentioned earlier. In this regard, BDV and IR degradation of the oxidative sample can be ascribed to the MgO agglomeration with NiO, which is not doped in BT, resulting in the weakening of the grain boundary resistance due to the limited grain boundary segregation without the Mg shell layer.

4 Conclusions

The electrical breakdowns of X5R type MLCCs were studied as functions of the reoxidation of pO2. MLCCs reoxidized below the equilibrium pO2 of Ni/NiO showed a drastic increase in BDV compared to the one reoxidized in a more oxidizing atmosphere. The E–J characteristics showed a more pronounced space-charge-limited conduction mode for those samples, which can be conceived as a stronger grain boundary barrier. IR degradation and impedance spectroscopy studies revealed that the oxygen vacancy concentration increases as Ni is oxidized, inducing IR degradation. STEM–EDS analyses demonstrated that Ni oxidation caused the NiO–MgO solid solution to weaken the grain boundary resistance. These studies suggest that the oxidation state of Ni should be delicately controlled to achieve highly reliable MLCCs with Ni internal electrodes.

References

M. Stengel, D. Vanderbilt, N.A. Spaldin, Enhancement of ferroelectricity at metal–oxide interfaces. Nat. Mater. 8, 392–397 (2009). https://doi.org/10.1038/nmat2429

M. Dawber, K.M. Rabe, J.F. Scott, Physics of thin-film ferroelectric oxides. Rev. Mod. Phys. 77, 1083–1130 (2009). https://doi.org/10.1103/RevModPhys.77.1083

R. Waser, T. Baiatu, K. Hardtl, DC electrical degradation of perovskite-type titanates: I, ceramics. J. Am. Ceram. Soc. 73, 1645–1653 (1990). https://doi.org/10.1111/j.1151-2916.1990.tb09809.x

S. Sumita, M. Ikeda, Y. Nakano, K. Nishiyama, T. Nomura, Degradation of multilayer ceramic capacitors with nickel electrodes. J. Am. Ceram. Soc. 74, 2739–2746 (1991). https://doi.org/10.1111/j.1151-2916.1991.tb06837.x

M.R. Opitz, K. Albertsen, J.J. Beeson, D.F. Hennings, J.L. Routbort, C.A. Randall, Kinetic process of reoxidation of base metal technology BaTiO3-based multilayer capacitors. J. Am. Ceram. Soc. 86, 1879–1884 (2003). https://doi.org/10.1111/j.1151-2916.2003.tb03576.x

Y.-M. Chiang, T. Takagi, Grain-boundary chemistry of barium titanate and strontium titanate: I, high-temperature equilibrium space charge. J. Am. Ceram. Soc. 73, 3278–3285 (1990). https://doi.org/10.1111/j.1151-2916.1990.tb06450.x

R. Waser, M. Klee, Theory of conduction and breakdown in perovskite thin films. Integr. Ferroelectr. 2, 23–40 (1992). https://doi.org/10.1080/10584589208215729

S. Rodewald, J. Fleig, J. Maier, Resistance degradation of iron-doped strontium titanate investigated by spatially resolved conductivity measurements. J. Am. Ceram. Soc. 83, 1969–1976 (2000). https://doi.org/10.1111/j.1151-2916.2000.tb01499.x

M. Vollman, R. Waser, Grain boundary defect chemistry of acceptor-doped titanates: space charge layer width. J. Am. Ceram. Soc. 77, 235–243 (1994). https://doi.org/10.1111/j.1151-2916.1994.tb06983.x

H.-I. Yoo, C.-E. Lee, Two-fold diffusion kinetics of oxygen re-equilibration in donor-doped BaTiO3. J. Am. Ceram. Soc. 88, 617–623 (2005). https://doi.org/10.1111/j.1551-2916.2005.00123.x

W. Preis, W. Sitte, Electronic conductivity and chemical diffusion in n-conducting barium titanate ceramics at high temperatures. Solid State Ionics 177, 3093–3098 (2006). https://doi.org/10.1016/j.ssi.2006.07.053

J. Itoh, I. Yashima, N. Ohashi, I. Sakaguchi, H. Haneda, J. Tanaka, Ni ion diffusion in barium titanate perovskite. J. Ceram. Soc. Jpn. 109, 955–959 (2001). https://doi.org/10.2109/jcersj.109.1275_955

S.K. Das, R.N. Mishra, B.K. Roul, Magnetic and ferroelectric properties of Ni doped BaTiO3. Solid State Commun. 191, 19–24 (2014). https://doi.org/10.1016/j.ssc.2014.04.001

I. Stolichnov, A. Tagantsev, Space-charge influenced-injection model for conduction in Pb(ZrxTi1−x)O3 thin films. J. Appl. Phys. 84, 3216–3225 (1998). https://doi.org/10.1063/1.368888

K. Lee, B.R. Rhee, C. Lee, Leakage current-voltage characteristics of ferroelectric thin film capacitors, J. Kor Phys. Soc. 38, 723–728 (2001). https://www.jkps.or.kr/journal/view.html?uid=4426&vmd=Full

G.M. Kale, D.J. Fray, Oxygen potentials in Ni + NiO and Ni + Cr2O3 + NiCr2O4 systems. Metall. Mater. Trans. B 25, 373–378 (1994). https://doi.org/10.1007/BF02663386

H. Hu, S.B. Krupanidhi, Current–voltage characteristics of ultrafine-grained ferroelectric Pb(Zr, Ti)o3 thin films. J. Mater. Res. 9, 1484–1498 (1994). https://doi.org/10.1557/JMR.1994.1484

W. Osak, K. Tkacz, Investigation of I–V characteristics in polycrystalline BaTiO3, J. Phys. D: Appl. Phys. 22, 1746–1750 (1989). https://iopscience.iop.org/article/10.1088/0022-3727/22/11/028.

D.J. Wouters, G.J. Willems, H.E. Maes, Electrical conductivity in ferroelectric thin films. Microelectron. Eng. 29, 249–256 (1995). https://doi.org/10.1016/0167-9317(95)00155-7

B. Nagaraj, S. Aggarwal, T.K. Song, T. Sawhney, R. Ramesh, Leakage current mechanisms in lead-based thin-film ferroelectric capacitors. Phys. Rev. B 59, 16022–16027 (1999). https://doi.org/10.1103/PhysRevB.59.16022

S.-H. Yoon, S.-H. Kim, D.-Y. Kim, Correlation between I (current)–V (voltage) characteristics and thermally stimulated depolarization current of Mn-doped BaTiO3 multilayer ceramic capacitor. J. Appl. Phys. 114, 074102 (2013). https://doi.org/10.1063/1.4818947

Y. Sakabe, Y. Hamaji, H. Sano, N. Wada, Effects of rare-earth oxides on the reliability of X7R dielectrics, Jpn. J. Appl. Phys. 41, 5668–5673 (2002). https://iopscience.iop.org/article/10.1143/JJAP.41.5668/meta.

A.I. Lebedev, I.A. Sluchinskaya, On the nature of change in Ni oxidation state in BaTiO3−SrTiO3 system. Ferroelectrics 501, 1–8 (2016). https://doi.org/10.1080/00150193.2016.1198196

T. Yoshida, T. Tanaka, H. Yoshida, T. Funabiki, S. Yoshida, Study on the dispersion of nickel ions in the NiO−MgO system by X-ray absorption fine structure. J. Phys. Chem. 100, 2302–2309 (1996). https://doi.org/10.1021/jp952526p

H. Kishi, Y. Okino, M. Honda, Y. Iguchi, M. Imaeda, Y. Takahashi, H. Ohsato, T. Okuda, The effect of MgO and rare-earth oxide on formation behavior of core-shell structure in BaTiO3, Jpn. J. Appl. Phys. 36, 5954–5957 (1997). https://iopscience.iop.org/article/https://doi.org/10.1143/JJAP.36.5954/meta.

R.A. De Souza, A.H.H. Ramadan, Ionic conduction in the SrTiO3|YSZ|SrTiO3 heterostructure. Phys. Chem. Chem. Phys. 15, 4505–4509 (2013). https://doi.org/10.1039/C3CP44399J

R.A. Maier, C.A. Randall, Low-temperature ionic conductivity of an acceptor-doped perovskite: I. Impedance of single-crystal SrTiO3. J. Am. Ceram. Soc. 99, 3350–3359 (2016). https://doi.org/10.1111/jace.14348

R.A. Maier, C.A. Randall, Low temperature ionic conductivity of an acceptor-doped perovskite: II. Impedance of single-crystal BaTiO3. J. Am. Ceram. Soc. 99, 3360–3366 (2016). https://doi.org/10.1111/jace.14347

S. Taibl, G. Fafilek, J. Fleig, Impedance spectra of Fe-doped SrTiO3 thin films upon bias voltage: inductive loops as a trace of ion motion. Nanoscale 8, 13954–13966 (2016). https://doi.org/10.1039/C6NR00814C

Acknowledgements

D. Lee thanks Soojeong Jo at Samsung Electro-Mechanics for the MLCC samples used in this study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing financial interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lee, D., Song, K., Jung, D. et al. Characterizing electrical breakdowns upon reoxidation atmosphere for reliable multilayer ceramic capacitors. J. Korean Ceram. Soc. 58, 445–451 (2021). https://doi.org/10.1007/s43207-021-00121-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s43207-021-00121-9