Abstract

Phycobiliproteins (PBPs) are light collecting pigments of cyanobacteria that attract growing interest for several industrial applications. Each step of the extraction process is crucial for yield, concentration and quality of obtained pigments. In the current work, we present an optimization scheme of major limiting steps for PBPs extraction from Arthrospira platensis biomass. As first step, the effects of pretreatment, extraction time, and separation conditions on the recovery of PBPs were compared. Subsequently, the influence of pH and concentration of the extraction buffer as well as the addition of preservatives (Polyethylene glycol (PEG), Magnesium chloride (MgCl2), and Calcium chloride (CaCl2)) was studied. In addition, the effect of the biomass type (dried vs wet) and its concentration in the extraction buffer was also investigated. Optimal extraction required the use of dry biomass at relatively low ratio (1:50, solvent:biomass), without previous treatment. The use of concentrated phosphate buffer (100 mM) at a neutral pH gave the highest PBPs recovery and concentration after 6 h of extraction followed with a separation at 6000 rpm during 15 min. Calcium chloride used at 1.5% improved by 30% both PBPs recovery and concentration in the crude extract. The optimized protocol allowed the recovery of 464.5 mg/g PBPs from spirulina biomass with concentration of 15.9 mg/ml. The crude PBPs obtained with this extraction method reduced the stable radical DPPH with a percentage scavenging activity of 86.45 ± 1.2%. This protocol could reduce both PBPs time and cost extraction and is easily scalable for industrial application.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Phycobiliproteins (PBPs) are light-harvesting pigments complexes found in cyanobacteria and red algae to collect light energy, since chlorophyll a has the highest absorption at 430 nm and 660 nm (Glazer 1994). Depending on their absorbing properties, PBPs are divided into 3 categories: Phycoerythrin (PE: pink-purple, λmax = 540–570 nm), Phycocyanin (PC: blue, λmax = 610–620 nm) and Allophycocyanin (APC: bluish-green, λmax = 650–655 nm), assembled in the phycobilisome located on the outer surface of thylakoid membranes (Kuddus et al. 2014).

The aforementioned proteins are used in food industry as natural coloring agents (soft candy, jellies and ice sherbets), for cosmetic applications (makeup and personal care products, perfumes, etc.) and for biomedical application (as fluorescent labeling reagent for flow cytometry, fluorescent immunoassay, immunohistochemistry, etc.). PBPs have also wide spectrum biological activities which increases their attractivity in the field of cosmetics, nutraceuticals and pharmaceuticals (Choi and Lee 2018; Hsieh-Lo et al. 2019).The cyanobacteria Arthrospira (Spirulina) sp. is the major source of PBPs whose concentration and proportion vary following the strain and culture conditions (de Jesus Raposo et al. 2013). Nevertheless, whatever the conditions, C-phycocyanin is the most abundant form of PBPs in Spirulina (Pan-utai and Iamtham 2019a; Fratelli et al. 2021).

Arthrospira platensis usually known as Spirulina is a microscopic filamentous cyanobacterium used in human diets by ancient civilizations (Sili et al. 2012). Nowadays, it is the most produced microalgae worldwide to being used as food supplement for its high content in proteins (up to 70%), vitamins (A, B and K complex) and pigments, mainly PBPs (Hsieh-Lo et al. 2019; Costa et al. 2020). Recently, the valuation of PBPs as high-added value product extracted from Spirulina’s biomass is gaining a growing interest. This is mostly due to the scientific results linking the biological activities of this microalgae to its PBPs content (Yang et al. 2021; Manirafasha et al. 2021; Mercier et al. 2022). Indeed, several studies have demonstrated that C-Phycocyanin and Phycoerythrin present antioxidant, anticarcinogenic, immunomodulatory and anti-inflammatory properties (de Jesus Raposo et al. 2013; Xie et al. 2015; Mercier et al. 2022). Nevertheless, only few data are available regarding biological activities of Allophycocyanin (Ge et al. 2006). In addition to their use in bioassays due to their fluorescent prosperities, PBPs are being used in agroindustry as natural colorants. C-Phycocyanin is the closest natural alternative matching the shade of Brilliant Blue FCF (Prasanna et al. 2007), while Phycoerythrin appears generally pink or red (Bermejo Román et al. 2002). Moreover, they have the added advantage of being water-soluble and safe (Soni et al. 2010).

Spirulina produces C-Phycocyanin (C-PC) as major PBPs followed by Allophycocyanin (APC) at a 10:1 ratio (Sotiroudis and Sotiroudis 2013). Some studies detected only small amounts of Phycoerythrin in Spirulina while others didn’t detect it (Rizzo et al. 2015; Rodrigues et al. 2018).

Several protocols were used to isolate PBPs from Spirulina’s biomass and it was clear that each step is determining for yield and quality of the final product. Early protocols usually employed physical or chemical methods to destroy trichomes and extract PBPs by using water as major solvent (Doke 2005; Eriksen 2008). More recent works combined chemical and physical methods for cell walls disruption and introduced other methods like enzymatic cell wall digestion or supercritical CO2 extraction (Tavanandi and Raghavarao 2019; Marzorati et al. 2020; Berrouane et al. 2022). The conclusion was that PBPs concentration and quality depend on key extraction conditions such as: cell wall disruption method, used solvent, extraction time and separation conditions. In addition, for a large-scale production, the scalability and the economic feasibility, are additional aspects that influence the extraction technique choice. Both on laboratory and industrial scales, limited information is available on PBPs key extraction factors affecting its recovery, quality and biological activities. In this way, we studied here the influence of each extraction step on PBPs recovery from Spirulina’s biomass, it's purity and antioxidant activity as well as the proportion of C-PC, APC and PE in the crude extract.

Material and methods

Spirulina biomass production

Spirulina platensis used is a local linear strain isolated from a natural lac near Rabat (North of Morocco). Culture was carried out on spirulina medium (Aiba and Ogawa 1977) in open raceway ponds measuring 3 × 1 × 1 m (LxlxH) with an approximate volume of 600 L, under outdoor conditions, in a semi-continuous mode (Fig. 1). Biomass was harvested at 1.5 g/L and separated from medium by mechanical filtration system (50 µm mesh). Obtained biomass was weither at 45 °C during 12 h or immediately stored at 4 °C for wet form.

Optimization of PBPs extraction protocol

First, a simple PBPs extraction protocol, commonly used in our laboratory was followed. Spirulina dry biomass (ratio 1:24 w:v) was resuspended in 100 mM potassium phosphate buffer, pH 7. The extraction was carried out for 3 h at room temperature (RT) under stirring at 150 rpm. Broken trichomes as well as other cells debris were removed by centrifugation at 4000 rpm for 15 min at 4 °C and supernatant recuperated was the crude PBPs extract. All experiments were performed in triplicate (Fig. 2).

Step 1: The effect of pretreatment was studied by testing a cycle of freezing (− 20 °C/ 12 h)/thawing (25 °C/ 3 h) under different extraction times by stirring the biomass/extraction buffer mixture during: 3, 6, 9, 12 and 24 h. The recovery of PBPs from biomass debris and broken trichomes was carried out at 3 centrifugation speeds (4000, 6000 and 9000 rpm) during 15 and 30 min.

Step 2: Optimal conditions from step 1 were applied to investigate the effect of the extraction buffer on PBPs yield and composition. First, 3 concentrations of potassium phosphate buffer (PPB) pH 7 were used: 10, 50 and 100 mM and water served as control. The effect of pH was further investigated by adjusting PPB pH to 5, 6 and 7. Finally, the effect of some additives (used as to destabilize cell walls or to stabilize PBPs) was studied: 1) Polyethylene glycol (PEG) 300 (30% w:w),PEG 6000 (30% w:w), 2) CaCl2 (1.5% w/v) and 3) MgCl2 (1.5%; w/v). All additives were incorporated to the extraction buffer before its use.

Step 3: With the optimal conditions found in previous steps, the effect of biomass type (dry vs. wet) as well as its concentration in the buffer were investigated. For each type of biomass, several concentrations (ratio extraction buffer:biomass) were tested (v/w):: 1:24, 1:50, 1:100,1:150, 1:200 and 1:300. One L of extraction buffer was used for all conditions.

Qualitative and quantitative PBPs analysis

PBPs composition and concentration were estimated following the equations of modified by (Zavřel et al. 2018):

The extraction yield of PBPs was estimated following the equation of (Silveira et al. 2007):

V is the solvent volume (ml) and DB is dry biomass (g).

PBPPs purity

Purity was determined by using the formula bellow (Minkova et al. 2003):

Where A280, A618, A652 and A562 are the maximum absorbance of the total protein, C-PC, APC and PE, respectively.

Measurement of the DPPH Free Radical-Scavenging Activity of PBPs extracts

The antioxidant scavenging activity against α.α-diphenyl-β-picrylhydrazyl radical (DPPH) was evaluated using the previously described method by Kang et al. (2004). First, 2 ml PBPs extract were mixed with 1 ml of DPPH in ethanol solution (0.02 mM) and DPPH served as the control. After 30 min of incubation in darkness at RT, the absorbance at 517 nm was measured. Antioxidant activity (AA) was evaluated following the equation:

AA (%) = (Control absorbance − Sample absorbance)/(Control absorbance) × 100.

Statistical analysis

The significant difference between mean values was assessed by one-way analysis of variance (ANOVA). Tukey test was carried out using SPSS 20.0 software to determine whether there was any significant difference at the level of p < 0.05.

Results and discussion

Optimization of PBPs extraction

Phycobiliproteins (PBPs) present in Spirulina, are composed of C-phycocyanin (C-PC), Allophycocyanin (APC) and Phycoerythrin (PE) at different proportions. In all experiments C-PC was the major component of PBPs extracted from used Spirulina. The concentration of the three components varied according to the extraction conditions: 1.05–8.52 mg/ml, 0.14–4.02 mg/ml and 0.10–3.39 mg/ml for C-PC, APC and PE, respectively. Moreover, PBPs recovery was between 53.8 and 664.5 mg/g depending on the used protocol.

Step 1 optimization

Table 1 showed the effect of pretreatment under different extraction times on PBPs recovery. The highest PBPs yield was obtained without pretreatment and with an extraction time of 6 h (232 mg/g vs. 84 mg/g for the control ‘no pretreatment and 3 h of extraction’) and the use of longer extraction times diminished the PBPs extraction efficiency. Tan et al. (2020) showed also that longer extraction times (24 h and more) decreased the extraction efficiency of phycobiliproteins from Spirulina biomass. This can be due to a pigments denaturation under used conditions since other studies extracted efficiently PBPs after 24 h of incubation (Vali Aftari et al. 2015; Pan-utai and Iamtham 2019a).

After 6 h of extraction, the crude extract contained 2.53, 1.77 and 0.92 mg/ml of C-PC, APC and PE, respectively in a ratio of 1:0.7:0.36 (Table 1). In addition, the evaluation of the effect of these conditions on PBPs composition (ratio C-PC:APC:PE) indicated an increase of APC and PE concentrations in the crude extract at 6 h, allowing a best equilibrium between these phycobiliproteins. However, longer extraction times didn’t improve obtained results. The pretreatment used decreased extraction efficiency to 155 mg of PBPs by g of biomass (Table 1) and after an extraction time of 12 h, the crude extract contains more APC than C-PC (1.5 vs. 1 mg/ml, receptively). Here, the effect of the extraction time was less visible before 24 h. Previous work found no variation in the proportion on the three pigments in the crude extract depending on the extraction time with a ratio of 1:0.07:0.08 C-PC:APC:PE (Pan-utai and Iamtham 2019a). APC and PE percentages were lower than obtained in the current study.

In general, freezing–thawing has been widely used for cyanobacteria cell disruption during PBPs extraction (Tan et al. 2020; Yu 2017; Ores et al. 2016; Xie et al. 2015; Moraes et al. 2011). Controversial results were obtained and extraction efficiency depended on the number of freezing–thawing cycles and additional combination with physical or chemical methods. In our experimental conditions, the use of a pretreatment prior to PBPs extraction didn’t improve yield and a lot of debris remained in the extract. Moreover, high polysaccharides content was observed in hydrolysates in such condition, (data not shown) which could be hindering for downstream process. It has been previously demonstrated that polysaccharides affect the structure and stability of proteins including PBPs by forming electrostatic interactions (Li et al. 2021; Zhao et al. 2022). This may explain the difficulty to extract PBPs in the presence of large peptidoglycans that have not been broken during the drying biomass period.

The conditions of PBPs separation from broken trichomes (centrifugation speed and time) were also important to optimize the extraction yield as well as PBPs concentration in the extract. Indeed, the increase of centrifugation speed to 6000 rpm improved both the extraction yield and PBPs concentration by 30%, independently from the separation time (Table 2). Nevertheless, no additional improvement was obtained with faster separation.

Step 2 optimization

Phycobiliproteins are water soluble and the use of water can easily extract them. Nevertheless, it has been demonstrated that their concentration and stability were improved after use of some extraction buffers like potassium phosphate buffer (PPB), protic ionic liquid (N-methyl-2-hydroxyethylammonium acetate (2-HEAA) + N-methyl-2-hydroxyethylammonium formate (2-HEAF) or Tris–HCl (Poojary et al. 2016; Ores et al. 2016; Rodrigues et al. 2019).In addition, PBPs are pH sensitive since it affects their quaternary structure causing denaturation (Camara-Artigas et al. 2012; González Ramírez et al. 2014).In general, a maximal PBPs stability is reached in pH from 5.5 to 7 and decreased out of this range (Chaiklahan et al. 2012). When extraction was carried out with water, about 120 g of PBPs were extracted per g of biomass with a final concentration in the extract close to 3 mg/ml (Fig. 3). The use of phosphate buffer improved significantly both results in a dose dependent manner. Indeed, phosphate buffer at 100 mM allowed to extract about 300 mg/g of PBPs with a concentration of 6.8 mg/ml. This increased by 150 and 120% PBPs recovery and concentration, respectively, in comparison with water as extraction buffer. Controversial results were found regarding phosphate buffer vs. water efficiency. Some authors obtained better PBPs concentration with phosphate buffer while others with distilled water (İlter et al. 2018; Tan et al. 2020). In our study, high buffer concentration increased PBPs recovery. Similar results were found with sodium phosphate buffer (Pan-utai and Iamtham 2019b).

The buffer’s pH affected both PBPs concentration and extraction yield (Fig. 4) in the same manner. With acid pH (5), protein extraction yield and concentration were reduced to half (Fig. 4). Previous studies obtained an optimal PBPs (specially C-Phycocyanin) extraction from spirulina’s at pH 7, while no detailed studies were found for Allophycocyanin and Phycoerythrin (Doke 2005; Li et al. 2020). In this way, it has been demonstrated that pH affects conformational structure charge of C-PC (Chang et al. 2018; Cottas et al. 2021). The use of concentrated phosphate buffer (100 mM) at pH7 for phycobiliproteins extraction, mainly C-PC, was previously described and seems to give good results due to its high biocompatibility with proteins (Ajayan et al. 2012; Pan-utai and Iamtham 2019b; Cottas et al. 2021).

The optimized extraction buffer was used to study the effect of some additives on PBPs extraction yield and concentration. No significant improvement was obtained excepted with1.5% CaCl2 that increased by more than 30% PBPs yield and concentration (Fig. 5). Calcium chloride is used in agroindustry for stabilization and precipitation of specific components. And it is also used for cell disruption through a change of osmotic pressure, enabeling it to efficiently be used for C-PC extraction and conservation (Cisneros and Rito-Palomares 2004; İlter et al. 2018). A previous work obtained a good C-PC extraction efficiency by using 1.5% CaCl2 (İlter et al. 2018). In such conditions, a darkest blue and concentrated C-PC extract was obtained, who’s also occurred in our experimentation (Fig. 6).

The PEG is widely used for cell disruption mainly during electroporation and few studies used it to extract and purify C-PC from spirulinaV (Patil and Raghavarao 2007; Antelo et al. 2015). The system is designed to allow the target molecule to partition to the more soluble phase, whereas contaminants partition to the opposite phase, enabling simultaneous extraction and purification (Fratelli et al. 2021). For this reason, we studied the effect of two PEG molar masses on PBPs extraction. PEG300 reduced drastically PBPs yield and concentration, while PEG6000 gave no difference with the control (Fig. 6). Previous work found a positive correlation between PEG molecular mass and C-PC extraction yield that was 81% highest with PEG4000 in comparison with PEG2000 (Chew et al. 2019). Antelo et al. (2015) found also an effect of the PEG concentration on extraction with optimal recovery with PEG6000 (Antelo et al. 2015).

Step 3 optimization

The extractability of total phycobiliproteins was strongly affected with biomass ratio. When dry biomass was used, a positive correlation was obtained between extraction solvent: biomass ratio and PBPs yield and concentration (Fig. 7). The yield improved by 22% in comparison with initially used ratio (1:24) and PBPs concentration in the extract reached 15 mg/ml (Table 3). However, beyond a ratio of 1:50, biomass remained in the extract and could not be removed despite several centrifugation cycles (Fig. 7). We suppose that 50 g/l here was near to saturation point. The available bibliography used a wide range of ratios extraction solvents: biomass with controversial results. Tan et al. (2020) extracted a maximum of PBPs (97 mg/g) from Spirulina when a ratio of 1:5 was used. This remains less concentrated than our tested ratios. Other works showed that both total PBPs and C-PC were best extracted with highest (1:60 and 1:80) biomass concentration (Silveira et al. 2007; Pan-utai and Iamtham 2019a). In such conditions, close to our optimal ratio (1:50), about 16 mg/g PBPs were extracted while we extracted more than 400 mg/g.

We were not able to obtain a clean PBPs crude extract from fresh biomass. As shown in Fig. 7, biomass could not resuspend correctly to start proteins extraction process, even at the lowest used ratio. The initial biomass type (dry or fresh) seems influence the PBPs extraction efficiency and purity. İlter et al. (2018) obtained high C-PC when dry biomass was used (41.8% vs. 11.2% for fresh biomass). The same protocol was used satisfactory by Tavanandi et al. (2018) for C-PC extraction (Tavanandi et al. 2018). Nevertheless, other authors preferred fresh biomass that gave best results and avoided pigment losses (Manirafasha et al. 2016). The results seem depend on the used Spirulina strain and the pre-extraction conditions. Indeed, biomass drying can affect phycobiliproteins content and activity, while fresh biomass, highly perishable, can lead to their degradation during the storage. The choice may depend finally on several factors such as used strain and PBPs extraction and valuation industrial scheme. In the current work, we used a Moroccan linear Arthrospira strain. A recent study demonstrated that such strain has longer cell wall and higher peptidoglycan content, that can explain the difficulty to extract PBPs from fresh biomass (Zhao et al. 2022).

Effect of extraction process on purity

-

C-Phycocyanin, Allophycocyanin and Phycoerythrin are generally graded according to its purity ratio, which corresponds to the contamination of the extract by proteins, other than PBPs. A purity of 0.7 is considered as food grade, 3.9 as reactive grade and greater than 4.0 as analytical grade (Rito-Palomares et al. 2001). Table 4 shows the effect of the extraction process on crude PBPs extract purity:

-

1st step: The extraction time is a critical factor for PBPs recovery. However, it didn´t impact the purity ratio, as demonstrated by our study. Gorgich et al. (2020) showed similar results, without improvement of purity ratio after 24h of orbital shaking. On the other hand, the increase of centrifugation speed to 6000 rpm improved purity ratio from 0.44, 0.11, 0.28 to 0.73, 0.31, 0.54 for C-PC, APC and PE, respectively. The separation speed applied induced a good separation of the PBPBs from debris and impurities resulting in a purity ratio improvement.

-

2nd step: Buffer concentration and pH value showed no significant effect on the purity ratio. Indeed, even if the buffer concentration and pH are directly implicated in the stability of proteins, they may not necessarily improve phycocyanin purity. Vali Aftari et al. (2015) also found that pH value had no significant effect on the purity ratio. Nevertheless, the addition of additives to the buffer solution sems have a great effect on purity ratio. For example, CaCl2 and PEG6000 allowed reach the food-grade standard.

-

3rd step: In this extraction stage, no significant influence of the solvent: biomass ratio was noted on the purity ratio. However, the increase in biomass presents challenges for optical density measurements due to the complexity of separating the solvent from the biomass.

In conclusion, even if several extraction conditions impact significantly the PBPs purity, the improvement of this indicator to other grades seems complicated and need additional steps. Higher PBPs purity ratio can be improved by purification techniques such as precipitation, ultrafiltration and dialysis as well as chromatographic (Yu et al. 2017; Ashaolu et al. 2021).

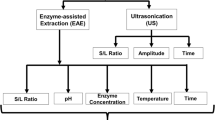

The results obtained in this study showed that all tested factors influenced phycobiliproteins PBPs extraction. The optimized protocol [Extraction buffer (PPB 100 mM, pH 7 + 1.5%CaCl2) used to extract PBPs from dried biomass with a ratio of 1:50, for 6 h followed with a centrifugation at 6000 rpm for 15 min)] allowed to extract 464.5 mg/g of PBPs with a concentration of 16 mg/ml (52% C-PC, 25% APC and 23% PE) and food grade extract (0.94 C-PC, 0.72 APC, 0.81 PE). Several PBPs extraction protocols have been described in literature. For example, the combination of a protic ionic liquid (N-methyl-2-hydroxyethylammonium acetate (2-HEAA) + N-methyl-2-hydroxyethylammonium format (2-HEAF)), mechanical agitation and thermal heating (35 °C) were more performant than sodium phosphate buffer to extract PBPs with a concentration of 3.95 mg/ml (Rodrigues et al. 2019). Enzyme assisted methods were also used and mainly combined to other technics like ultrasound or microwave (Vali Aftari et al. 2015; Tavanandi et al. 2018). Ultrasounds assisted extraction carried out for 3 h at 60 kHz was also used and gave higher PBPs concentrations (15.2 mg/ml) in the crude extract (Choi and Lee 2018). Nevertheless, the cost and safety (with regard to PBPs stability) of these technics is still discuses.

Antioxidant activity

The crude PBPs extract obtained under optimal conditions exhibited a remarkable 86.45 ± 1.2% inhibition of DPPH radicals. This outcome compares favorably to the findings of Fekrat et al. (2019), who, using solvent extraction with potassium phosphate buffer, achieved a 82% reduction in DPPH radicals after 4 h of stirring at 400 rpm at room temperature and subsequent centrifugation at 18,000 × g for 10 min. In contrast, PBPs extracted with alternative solvents or under different conditions, as reported by Rodrigues et al. (2019) and Pan-utai and Iamtham (2019a), demonstrated lower DPPH radical inhibition, typically near 60%. However, the study of Seo et al. (2013) showed that phycocyanin isolated using the high-pressure process and hexane separation method achieved a substantial 83% removal rate of oxygen free radicals. In summary, the DPPH radical inhibition achieved under the optimal conditions in our study highlight the effectiveness of our extraction approach.

Conclusions

Even if phycobiliproteins are water soluble, their extraction from Spirulina’s biomass is a delicate process. Indeed, each step of the extraction protocol is determining for yield and quality of extracted PBPs. Results showed that, for studied Spirulina strain, the use of dry biomass (50 g/l) without pre-treatment gave better results. Moreover, a concentrated phosphate buffer added with 1.5% CaCl2 and a relatively short extraction time (6 h) improved the PBPs recovery. High PBPs yield was obtained with the optimized protocol (464 mg/g) and their concentration reached 15.9 mg/ml. The developed method is easily scalable for phycobiliproteins at large scale for further applications.

Data availability

All data generated or analyzed during this study are included in this published article.

References

Aiba S, Ogawa T (1977) (1977) Assessment of growth yield of a blue—green Alga, Spirulina platensis, in Axenic and Continuous Culture. Microbiology 102:179–182. https://doi.org/10.1099/00221287-102-1-179

Ajayan KV, Selvaraju M, Thirugnanamoorthy K (2012) Enrichment of chlorophyll and phycobiliproteins in Spirulina platensis by the use of reflector light and nitrogen sources: an in-vitro study. Biomass Bioenergy 47:436–441. https://doi.org/10.1016/j.biombioe.2012.09.012

Antelo FS, Costa JAV, Kalil SJ (2015) Purification of C-phycocyanin from Spirulina platensis in aqueous two-phase systems using an experimental design. Braz Arch Biol Technol 58:1–11. https://doi.org/10.1590/S1516-8913201502621

Ashaolu TJ, Samborska K, Lee CC et al (2021) Phycocyanin, a super functional ingredient from algae; properties, purification characterization, and applications. Int J Biol Macromol 193:2320–2331. https://doi.org/10.1016/j.ijbiomac.2021.11.064

Bermejo Román R, Alvárez-Pez JM, Acién Fernández FG, Molina Grima E (2002) Recovery of pure B-phycoerythrin from the microalga Porphyridium cruentum. J Biotechnol 93:73–85. https://doi.org/10.1016/s0168-1656(01)00385-6

Berrouane NEH, Attal F-S, Benchabane A et al (2022) Freeze–thaw-, enzyme-, ultrasound- and pulsed electric field-assisted extractions of C-phycocyanin from Spirulina platensis dry biomass. J Food Meas Charact 16:1625–1635. https://doi.org/10.1007/s11694-021-01264-3

Camara-Artigas A, Bacarizo J, Andujar-Sanchez M et al (2012) pH-dependent structural conformations of B-phycoerythrin from Porphyridium cruentum. FEBS J 279:3680–3691. https://doi.org/10.1111/j.1742-4658.2012.08730.x

Chaiklahan R, Chirasuwan N, Bunnag B (2012) Stability of phycocyanin extracted from Spirulina sp.: Influence of temperature, pH and preservatives. Process Biochem 47:659–664. https://doi.org/10.1016/j.procbio.2012.01.010

Chang Y-K, Show P-L, Lan JC-W et al (2018) Isolation of C-phycocyanin from Spirulina platensis microalga using Ionic liquid based aqueous two-phase system. Bioresour Technol 270:320–327. https://doi.org/10.1016/j.biortech.2018.07.138

Chew KW, Chia SR, Krishnamoorthy R et al (2019) Liquid biphasic flotation for the purification of C-phycocyanin from Spirulina platensis microalga. Bioresour Technol 288:121519. https://doi.org/10.1016/j.biortech.2019.121519

Choi W, Lee H (2018) Effect of Ultrasonic Extraction on Production and Structural Changes of C-Phycocyanin from Marine Spirulina maxima. Int J Mol Sci 19:220. https://doi.org/10.3390/ijms19010220

Cisneros M, Rito-Palomares M (2004) A Simplified Strategy for the Release and Primary Recovery of c-phycocyanin Produced by Spirulina maxima. 6

Costa JAV, Freitas BCB, Moraes L et al (2020) Progress in the physicochemical treatment of microalgae biomass for value-added product recovery. Bioresour Technol 301:122727. https://doi.org/10.1016/j.biortech.2019.122727

Cottas AG, Ribeiro EJ, Watanabe EO, Ferreira J de S (2021) Evaluation of extraction methods and purification by aqueous two-phase systems of phycocyanin from Anabaena variabilis and Nostoc sp. Braz J Chem Eng 38:617–627. Doi: https://doi.org/10.1007/s43153-021-00131-4

de Jesus Raposo MF, de Morais RMSC, de Morais AMMB (2013) Health applications of bioactive compounds from marine microalgae. Life Sci 93:479–486. https://doi.org/10.1016/j.lfs.2013.08.002

Doke JM (2005) An Improved and Efficient Method for the Extraction of Phycocyanin from Spirulina sp. Int J Food Eng 1:. https://doi.org/10.2202/1556-3758.1037

Eriksen NT (2008) Production of phycocyanin—a pigment with applications in biology, biotechnology, foods and medicine. Appl Microbiol Biotechnol 80:1–14. https://doi.org/10.1007/s00253-008-1542-y

Fekrat F, Nami B, Ghanavati H et al (2019) Optimization of chitosan/activated charcoal-based purification of Arthrospira platensis phycocyanin using response surface methodology. J Appl Phycol 31:1095–1105. https://doi.org/10.1007/s10811-018-1626-8

Fratelli C, Burck M, Amarante MCA, Braga ARC (2021) Antioxidant potential of nature’s “something blue”: Something new in the marriage of biological activity and extraction methods applied to C-phycocyanin. Trends Food Sci Technol 107:309–323. https://doi.org/10.1016/j.tifs.2020.10.043

Ge B, Qin S, Han L et al (2006) Antioxidant properties of recombinant allophycocyanin expressed in Escherichia coli. J Photochem Photobiol B 84:175–180. https://doi.org/10.1016/j.jphotobiol.2006.02.008

Glazer AN (1994) Phycobiliproteins — a family of valuable, widely used fluorophores. J Appl Phycol 6:105–112. https://doi.org/10.1007/BF02186064

González Ramírez E, Andujar-Sánchez M, Ortiz E, et al (2014) Thermal and pH Stability of the B-Phycoerythrin from the Red Algae Porphyridium cruentum. Food Biophys 9:. https://doi.org/10.1007/s11483-014-9331-x

Gorgich M, Passos MLC, Mata TM et al (2020) Enhancing extraction and purification of phycocyanin from Arthrospira sp. with lower energy consumption. Energy Rep 6:312–318. https://doi.org/10.1016/j.egyr.2020.11.151

Hsieh-Lo M, Castillo G, Ochoa-Becerra MA, Mojica L (2019) Phycocyanin and phycoerythrin: Strategies to improve production yield and chemical stability. Algal Res. https://doi.org/10.1016/J.ALGAL.2019.101600

İlter I, Akyıl S, Demirel Z et al (2018) Optimization of phycocyanin extraction from Spirulina platensis using different techniques. J Food Compos Anal 70:78–88. https://doi.org/10.1016/j.jfca.2018.04.007

Kang M-Y, Lee Y-R, Koh H-J, Nam S-H (2004) Antioxidative and antimutagenic activity of ethanolic extracts from giant embroynic rices. Appl Biol Chem 47:61–66

Kuddus M, Singh P, Thomas G, Ali A (2014) Production of C-phycocyanin and its potential applications. In: Biotechnology of Bioactive Compounds: Sources and Applications. pp 283–300

Li Y, Zhang Z, Paciulli M, Abbaspourrad A (2020) Extraction of phycocyanin—a natural blue colorant from dried spirulina biomass: Influence of processing parameters and extraction techniques. J Food Sci 85:727–735. https://doi.org/10.1111/1750-3841.14842

Manirafasha E, Ndikubwimana T, Zeng X et al (2016) Phycobiliprotein: potential microalgae derived pharmaceutical and biological reagent. Biochem Eng J 109:282–296. https://doi.org/10.1016/j.bej.2016.01.025

Manirafasha E, Guo L, Jing K (2021) Nutraceutical and Pharmaceutical Applications of Phycobiliproteins. pp 577–654

Marzorati S, Schievano A, Idà A, Verotta L (2020) Carotenoids, chlorophylls and phycocyanin from Spirulina: supercritical CO 2 and water extraction methods for added value products cascade. Green Chem 22:187–196. https://doi.org/10.1039/C9GC03292D

Mercier L, Peltomaa E, Ojala A (2022) Comparative analysis of phycoerythrin production in cryptophytes. J Appl Phycol 34:789–797. https://doi.org/10.1007/s10811-021-02657-z

Minkova KM, Tchernov AA, Tchorbadjieva MI et al (2003) Purification of C-phycocyanin from Spirulina (Arthrospira) fusiformis. J Biotechnol 102:55–59. https://doi.org/10.1016/s0168-1656(03)00004-x

Moraes CC, Sala L, Cerveira GP, Kalil SJ (2011) C-phycocyanin extraction from Spirulina platensis wet biomass. Braz J Chem Eng 28:45–49. https://doi.org/10.1590/S0104-66322011000100006

Ores J da C, Amarante MCA de, Kalil SJ (2016) Co-production of carbonic anhydrase and phycobiliproteins by Spirulina sp. and Synechococcus nidulans. Bioresour Technol 219:219–227. https://doi.org/10.1016/j.biortech.2016.07.133

Pan-utai W, Iamtham S (2019a) Extraction, purification and antioxidant activity of phycobiliprotein from Arthrospira platensis. Process Biochem 82:189–198. https://doi.org/10.1016/j.procbio.2019.04.014

Pan-utai W, Iamtham S (2019b) Physical extraction and extrusion entrapment of C-phycocyanin from Arthrospira platensis. J King Saud Univ - Sci 31:1535–1542. https://doi.org/10.1016/j.jksus.2018.05.026

Patil G, Raghavarao KSMS (2007) Aqueous two phase extraction for purification of C-phycocyanin. Biochem Eng J 34:156–164. https://doi.org/10.1016/j.bej.2006.11.026

Poojary MM, Barba FJ, Aliakbarian B et al (2016) Innovative alternative technologies to extract carotenoids from microalgae and seaweeds. Mar Drugs 14:214. https://doi.org/10.3390/md14110214

Prasanna RA, Sood A, Suresh A et al (2007) Potentials and application of algal pigments in biology and industry. Acta Bot Hung 49:131–156. https://doi.org/10.1556/ABot.49.2007.1-2.14

Rito-Palomares M, Nuñez L, Amador D (2001) Practical application of aqueous two-phase systems for the development of a prototype process for c-phycocyanin recovery from Spirulina maxima: Aqueous two-phase process for recovery of c-phycocyanin. J Chem Technol Biotechnol 76:1273–1280. https://doi.org/10.1002/jctb.507

Rizzo RF, Santos B do NC dos, Castro GFP da S de, et al (2015) Production of phycobiliproteins by Arthrospira platensis under different lightconditions for application in food products. Food Sci Technol Camp 35:247–252. https://doi.org/10.1590/1678-457X.6463

Rodrigues RDP, de Castro FC, de Santiago-Aguiar RS, Rocha MVP (2018) Ultrasound-assisted extraction of phycobiliproteins from Spirulina (Arthrospira) platensis using protic ionic liquids as solvent. Algal Res 31:454–462. https://doi.org/10.1016/j.algal.2018.02.021

Rodrigues RDP, de Lima PF, de Santiago-Aguiar RS, Rocha MVP (2019) Evaluation of protic ionic liquids as potential solvents for the heating extraction of phycobiliproteins from Spirulina (Arthrospira) platensis. Algal Res 38:101391. https://doi.org/10.1016/j.algal.2018.101391

Seo YC, Choi WS, Park JH et al (2013) Stable Isolation of Phycocyanin from Spirulina platensis Associated with High-Pressure Extraction Process. Int J Mol Sci 14:1778–1787. https://doi.org/10.3390/ijms14011778

Sili C, Torzillo G, Vonshak A (2012) Arthrospira (Spirulina). In: Whitton BA (ed) Ecology of Cyanobacteria II. Springer, Netherlands, Dordrecht, pp 677–705

Silveira ST, Burkert JFM, Costa JAV et al (2007) Optimization of phycocyanin extraction from Spirulina platensis using factorial design. Bioresour Technol 98:1629–1634. https://doi.org/10.1016/j.biortech.2006.05.050

Soni B, Visavadiya NP, Dalwadi N et al (2010) Purified c-phycoerythrin: safety studies in rats and protective role against permanganate-mediated fibroblast-DNA damage. J Appl Toxicol JAT 30:542–550. https://doi.org/10.1002/jat.1524

Sotiroudis T, Sotiroudis G (2013) Health aspects of Spirulina (Arthrospira) microalga food supplement. J Serbian Chem Soc 78:395–405. https://doi.org/10.2298/JSC121020152S

Tan HT, Khong NMH, Khaw YS et al (2020) Optimization of the Freezing-Thawing Method for Extracting Phycobiliproteins from Arthrospira sp. Molecules 25:3894. https://doi.org/10.3390/molecules25173894

Tavanandi HA, Mittal R, Chandrasekhar J, Raghavarao KSMS (2018) Simple and efficient method for extraction of C-Phycocyanin from dry biomass of Arthospira platensis. Algal Res 31:239–251. https://doi.org/10.1016/j.algal.2018.02.008

Tavanandi H, Raghavarao K (2019) Ultrasound-assisted enzymatic extraction of natural food colorant C-Phycocyanin from dry biomass of Arthrospira platensis. LWT- Food Sci Technol YFSTL_108802:YFSTL_108802. https://doi.org/10.1016/j.lwt.2019.108802

Vali Aftari R, Rezaei K, Mortazavi A, Bandani AR (2015) The Optimized Concentration and Purity of Spirulina platensis C-Phycocyanin: A Comparative Study on Microwave-Assisted and Ultrasound-Assisted Extraction Methods: Extraction Modeling to Optimize the Phycocyanin. J Food Process Preserv 39:3080–3091. https://doi.org/10.1111/jfpp.12573

Xie Y, Jin Y, Zeng X et al (2015) Fed-batch strategy for enhancing cell growth and C-phycocyanin production of Arthrospira (Spirulina) platensis under phototrophic cultivation. Bioresour Technol 180:281–287. https://doi.org/10.1016/j.biortech.2014.12.073

Yang Y, Xu J, Qiu B (2021) Phycobiliproteins. In: Gao K, Hutchins DA, Beardall J (eds) Research Methods of Environmental Physiology in Aquatic Sciences. Springer, Singapore, pp 107–114

Yu J (2017) Application of an Ultrafine Shearing Method for the Extraction of C-Phycocyanin from Spirulina platensis. Molecules 22:2023. https://doi.org/10.3390/molecules22112023

Yu P, Wu Y, Wang G et al (2017) Purification and bioactivities of phycocyanin. Crit Rev Food Sci Nutr 57:3840–3849. https://doi.org/10.1080/10408398.2016.1167668

Zavřel T, Chmelík D, Sinetova MA, Červený J (2018) Spectrophotometric Determination of Phycobiliprotein Content in Cyanobacterium Synechocystis. J Vis Exp JoVE 58076. https://doi.org/10.3791/58076

Zhao Y, Shang M, Xu X et al (2022) Analysis of morphological change mechanism of linear Arthrospira platensis based on transcriptome results. Gene 834:146573. https://doi.org/10.1016/j.gene.2022.146573

Funding

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by LI, STHK and WI. The first draft of the manuscript was written by LI and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest related to funding or otherwise.

Ethical approval

As no human or mammalian subjects were involved in this research, no ethical approval was required.

Consent for publication

All authors consent to publication.

Consent to participate

Informed consent was obtained from all individual participants included in the study.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

lijassi, I., Arahou, F., Koudi, S.T.H. et al. Optimized extraction of phycobiliproteins from Arthrospira platensis: quantitative and qualitative assessment of C-Phycocyanin, Allophycocyanin, and Phycoerythrin. Braz. J. Chem. Eng. (2024). https://doi.org/10.1007/s43153-023-00428-6

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43153-023-00428-6