Abstract

The reuse of vegetable by-products has become one main global challenge. In this study, a central composite rotate design was used to obtain the optimal conditions (extraction time, ethanol concentration and extraction temperature) for the hydroethanolic extraction of bioactive compounds from Spondias mombin L. residue. The optimized extract (35 min, 70 °C and ethanol concentration of 55%) was analyzed for yellow flavonoids, tannins, ferric reducing antioxidant power (FRAP) as well as HPLC profile of phenolic compounds. This extract had 1666.18 ± 127.56 mg GAE 100 g−1 dm of total phenolic compounds, 38.03 ± 0.49 µg mL−1 of DPPH scavenging activity (IC50) and extraction yield of 17.44 ± 0.17%. The optimized extract showed strong FRAP antioxidant activity and high content of tannins and phenolic acids. Results indicated that 2,5-dihydroxybenzoic, salicylic, 4-hydroxybenzoic acid and ellagic acids were the main components in the optimized extract. High amounts of flavonoids were also noted, highlighting rutin, catechin and myricetin hydrates. The present results show that extracts from Spondias mombin L. agro-industrial waste would be helpful to design functional food products.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The production and consumption of tropical fruits are increasing worldwide due to its nutritional values and sensorial characteristics. The Brazilian production of tropical fruits reached 602.65 thousand tonnes in 2018, corresponding to 2.52% of the entire world’s production (FAO 2018). Native fruits from the genus Spondias spp. such Spondias mombin L., also known as yellow mombin, are well accepted by consumers mostly due to their pleasant and exotic flavor. This fruit also contains a high level of ascorbic acid, carotenoids, and phenolic compounds, which contribute to its antioxidant activity (Contreras-Calderón et al. 2011). Because of these characteristics, yellow mombin is widely used in the North and Northeast of Brazil for the production of juice, popsicles, ice cream, yogurt, jam, and frozen pulp (Tiburski et al. 2011; Silva et al. 2012c).

The agro-industrial activity generates large amounts of by-products that are often discarded, causing environmental pollution and economic losses. It is estimated that 30–40% of residues (peel, stalks, seeds or seed and residual pulp) are generated during fruit processing (Nascimento Filho and Franco 2015). The reuse of vegetable waste has become one of the most challenging issue in food technology due to their potential as sources of bioactive compounds that may be used for the development of new and valuable food products. The sustainable use of agro-industrial waste can result in the production of value-added products, thus contributing to reduce environmental impacts and to boost economic growth (Sepúlveda et al. 2018).

Fruit and vegetable by-products are rich in various bioactive substances such as carotenoids, phenolic compounds, anthocyanins, flavonols, catechins, flavones, and flavanones, which have proven antioxidant activity in biological systems (Varzakas et al. 2016). For the extraction of these antioxidant compounds, several techniques are employed, such as conventional techniques, including maceration, Soxhlet, heat reflux, agitation, boiling, leaching and distillation, and more advanced techniques, such as microwave assisted extraction, extraction assisted by ultrasound, supercritical extraction and extraction of pressurized liquid (Huang et al. 2013; Krishnan and Rajan 2017; Favareto et al. 2019; Monroy et al. 2020).

Maceration is a commonly used procedure for extracting antioxidant compounds from plant materials because it is a fast, cheap, and easy to perform method (Sarraf et al. 2021). The maceration with increased temperature can promote quick extraction, improving extraction efficiency, and being suitable for thermolabile compounds (Jovanović et al. 2017; Palsikowski et al. 2020). Thus, the maceration technique can be considered adequate to maximize the solid–liquid extraction process, combining the use of temperature, short extraction time, and “green solvents” (Albuquerque et al. 2018).

Besides, studies that approach the extraction of bioactive compounds partly use some toxic organic solvent, such as acetone, chloroform, hexane, and methanol, to perform the low-pressure extractions (LPE) (such Soxhlet, maceration, ultrasound-assisted extraction (UAE), microwave-assisted extraction (MAE)) or supercritical fluid extraction (SFE) (Guindani et al. 2016; Krishnan and Rajan 2017; Santos Felix et al. 2018; Favareto et al. 2019; Fernández-Barbero et al. 2019; Paludo et al. 2019). According to Monroy et al. (2020), water and ethanol have been widely used as solvents in extraction processes, due to their low cost, low toxicity, in addition to being “green solvents” with the possibility of direct use in food and pharmaceutical products.

Palsikowski et al. (2020) reported that ethanol was considered the best solvent choice compared to hexane and ethyl acetate for the ultrasound-assisted extraction (UAE) of compounds with antioxidant activity from the leaves of B. forficata. Studies that used ethanol as extraction solvent found the highest yield of the extraction of bioactive compounds from the leaves of Duguetia furfuracea and pitanga (Favareto et al 2019; Garmus et al. 2019).

Several studies have been carried out on the extraction of antioxidant compounds from tropical fruit residues processed in Brazil such as guava, jabuticaba, grape (Casagrande et al. 2019; Fernández-Barbero et al. 2019; Lima et al. 2019; Paludo et al. 2019), and fruits from Spondias spp. In fact, many researchers have shown higher antioxidant activity in the leaves, pulp and peel of yellow mombin, umbu (Spondias tuberosa L.), and jocote (Spondias purpurea L.) (Contreras-Calderón et al. 2011; Omena et al. 2012; Tiburski et al. 2011; Silva et al. 2012a). Besides, Spondias mombin leaves are rich in phytochemicals related to wound healing and anti-inflammatory properties, being a valuable resource to the pharmaceutical industry (Silva et al. 2012a; Cabral et al. 2016). The use of these material can be useful for the prevention of free radical damage, which helps to treat herpes and diseases associated with inflammation (Tiburski et al. 2011). Therefore, by-products from the processing of exotic tropical fruits may have applicability potential and can be used as food additives such as antimicrobials, antioxidants, coloring, flavoring and thickening agents (Ayala-Zavala and González-Aguilar 2010).

Few studies have investigated the antioxidant capacity of by-products from Spondias spp. Fruits. The determination of optimum conditions for the extraction of phenolic compounds from these bioresources have also been target of little investigation although the optimization of the extraction process is essential for obtaining extracts rich in polyphenolic substances (Santos Felix et al. 2018). Considering the limited information available in the literature, a more detailed study of the mechanisms responsible for the bioactive effects of yellow mombin bagasse extract is required. Thus, the development of a practical extraction method such as maceration combined with the use of non-toxic solvent as ethanol, considered as “green solvent”, may be a viable alternative to extract antioxidant compounds from agro-industrial waste which can be possibly applied in the food, medicinal or pharmaceutical industry.

The extraction efficiency of antioxidant compounds from plant materials is mostly affected by extraction time, temperature, and concentration of extraction solvent. The role of each parameter in the extraction process is variable and depends on the food matrix (Xu et al. 2017). Thus, is fundamental to determine the optimal conditions for extraction in order to reduce production costs and improve product yield. The response surface methodology (RSM) is a widely used statistical tool to optimize procedures for the extraction of compounds of interest in plants and fruits since several factors can have an impact on the extraction efficiency such as concentration and type of solvent, temperature, time, etc. The RSM is a statistical method that consists of evaluating the effects of multiple factors, as well as their interactions in one or more response variables by a mathematical model, it is advantageous in terms of the reduced number of experimental tests when it is necessary to optimize a variable of answer (Casagrande et al. 2019).

Therefore, this study aimed to use the RSM to optimize the conditions for the solid–liquid extraction of the antioxidant compounds present in the yellow mombin bagasse (temperature, time, and solvent concentration) on the total phenolic compounds, antioxidant activity and extraction yield, and validate the optimization condition characterizing the optimized extract in terms of phenolic profile and antioxidant properties.

Material and methods

Solvents and reagents

The chemicals 2,2′-diphenyl-2-picrylhydrazyl hydrate (DPPH), hydroxy-2,5,7,8-tetramethylchromane-2-carboxyl acid (Trolox) and 2,4,6-tris(2-pyridyl)-s-triazine (TPTZ), methanol, acetonitrile and acetic acid were purchased from Sigma-Aldrich (São Paulo, Brazil). The standards for phenolic compounds (3,4-dihydroxybenzoic acid, 4 hydroxybenzoic acid, caffeic acid, ellagic acid, ferulic acid, gallic acid, 2,5-dihydroxybenzoic acid, salicylic acid, syringic acid, trans-cinnamic acid, p-coumaric acid, vanillic acid, myricetin, quercetin, naringenin, catechin, hesperetin and rutin) were purchased from Sigma-Aldrich (St. Louis, MO, USA). Folin–ciocalteau was obtained from Êxodo Científica (São Paulo, Brazil) and ethanol from Neon (São Paulo, Brazil). All chemicals used in the experiments were of analytical grade.

Plant material and sample characterization

Approximately 4 kg of Spondias mombin L. residue (peel, seed and residual pulp) were provided by a local fruit processing unit located in Paraiba, Brazil. Whole yellow mombin waste was oven dried at 55 °C for 24 h (Crizel et al. 2015). After dehydration, the sample was grounded using a knife mill (SL-31, Solab, Piracicaba, SP, Brazil) and stored at – 80 °C until use. Fresh and dried yellow mombin bagasse were submitted to chemical composition analysis. Moisture and ash content were analyzed by the gravimetric method according to AOAC (2005). Total lipid content was achieved using the Soxhlet procedure, and protein percentage was measured by Kjeldahl’s method according to AOAC (2005). Carbohydrate content was calculated by difference (total carbohydrates = 100 − Σ(Moisture + Ash + Lipids + Proteins). The total and reducing sugars were also determined based on the anthrone (Yemm and Willis 1954) and 3,5-dinitrosalicylic acid (DNS) methods (Miller 1959), respectively. The non-reducing sugars were calculated as the difference between total and reducing sugars. Physicochemical evaluations of acidity, pH and water activity were also performed according AOAC (2005). Acidity was determined by titration with 0.1 N NaOH. pH values were measured using a digital pH meter (iON, PHS-3E-BI, Brazil). Water activity (Aw) was quantified using an Aqualab device (4TE Decagon Devices, Inc. São Paulo, Brazil).

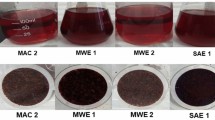

Preparation of Spondias mombin L. by-product extract

Prior to the extractions, preliminary tests were carried out (data not shown) to define the solid/liquid ratio and homogenization time of the mixture. For the extraction, 3.0 g of the dried residue was homogenized for 5 min in 30 mL of the ethanol solutions using the concentrations pre-established in the experimental design (Table 1). The mixture was then incubated in a water bath (SL-154/10-4, Solab, Piracicaba, Brazil) following the extraction time and temperature described in the experimental design matrix (Table 1). After the end of the extraction time, the crude extract was centrifuged at 8.960×g for 20 min at 10 °C (Hettich LAB TECHNOLOGY, Tuttlingen, Germany), filtered on qualitative filter paper (80 g m−2) to remove solid particles, and the ethanolic fraction was removed under vacuum (180 mbar) with a rotary evaporator at 45 °C. The volume was completed to 100 mL with distilled water and the obtained extracts were stored in dark flasks at − 80 °C until the analyses.

Experimental design

The extraction conditions were optimized for obtaining the highest antioxidant potential from Spondias mombin L. residue extract, by using a response surface methodology (RSM) with central composite rotational design (CCRD) (Table 1). Three independent variables were tested: extraction time (x1), extraction temperature (x2) and ethanol concentration (x3). The total phenolic compounds (Y1), DPPH scavenging activity (Y2) and extraction yield (Y3) were selected as the responses. The range of three independent variables presented in Table 1 was based on preliminary experiments.

The operational conditions of the experimental procedure were performed in duplicate according to the 23 central composite rotational design (CCRD) with 8 factorial points, 6 star corner points and 3 central points (Table 1), totaling 34 experimental runs. The experimental results were fitted in a second-order polynomial equation (Eq. 1), where β represents the constant regression coefficients of the model, while Y and x are the dependent and independent variable, respectively. Additional confirmation experiments were conducted to verify the validity of the statistical experimental design.

After determining the optimal extraction conditions for phenolic compounds from Spondias mombin L. residue, the optimized extract was submitted to total phenolic compounds, DPPH scavenging activity, extraction yield, yellow flavonoid, total and condensed tannins, ferric reducing antioxidant power (FRAP) and phenolic profile analyses.

Determination of total phenolic compounds (TPC) and extraction yield

TPC were determined using the Folin Ciocalteau method with modifications (Waterhouse 2002). Extracts aliquots (50 μL) were diluted in 1.950 μL of distilled water and mixed with 150 μL Folin Ciocalteau solution (2 M). After incubation for 5 min, 350 μL of 20% Na2CO3 solution was added. The mixture was then shaken and incubated for 30 min at 40 °C in a water bath. The absorbance was measured at 765 nm using an UV–Vis spectrophotometer (5100, Labnova, Santo André, Brazil). The results were calculated using a standard curve of gallic acid and expressed as mg gallic acid equivalents (GAE) per 100 g sample. The extraction yield was determined by gravimetry according to Prado et al. (2010).

DPPH scavenging activity (2,2-diphenyl-2-picrylhydrazyl)

The DPPH test of the extracts was performed according to Rufino et al. (2007). Aliquots of 0.1 mL of previously diluted extracts were mixed to 3.9 mL of methanolic DPPH solution (0.06 mM) and kept in the dark at 25 °C for 30 min. Absorbance was measured at 515 nm using methanol as a blank. The inhibition curves were prepared and IC50 values were calculated using the graph by plotting inhibition percentage against extract concentration. Results were expressed as IC50, which corresponds to the effective concentration of sample required to scavenge DPPH radical by 50%.

Yellow flavonoid content

The yellow flavonoids content was determined according to Francis (1982). The absorbance was recorded at 374 nm and the yellow flavonoid content was calculated using the Eq. 2. Results were expressed as mg yellow flavonoids per 100 g of the sample.

Total and condensed tannins content

Measurement of total tannins were performed using Folin–Ciocalteau method (Makkar et al. 1993). Results were expressed as mg of tannic acid equivalent per 100 g of sample. Condensed tannins (CT) percentage was determined using butanol-HCL test (Porter et al. 1985). Absorbance was recorded at 550 nm and the percentage of condensed tannins was calculated according to Eq. 3 (Barman et al. 2017):

Ferric reducing antioxidant power (FRAP)

The FRAP test was evaluated as described by Benzie and Strain (1999). Absorbance was read at 593 nm and the reducing power was expressed as mg Trolox Equivalent per 100 g sample and calculated based on calibration curve prepared with different concentrations of Trolox solution (2.0–27.0 μmol L−1).

Phenolic compounds profile

The profile of phenolic compounds was analyzed in quadruplicate using high performance liquid chromatography equipped with LC-20 AT safety module (Shimadzu Corporation, Japan). The separation was performed on a C18 column (SUPELCOSIL™ LC-PAH, 250 mm × 4.6 mm ID, particle size 5 μm) (Sigma-Aldrich, St. Louis, MO, USA). Chromatographic separation was performed using a gradient elution of (A) water/acetic acid 2% (v/v) and (B) acetonitrile:methanol 2:1 (v/v) described below: 90% A in 0 min, 88% A in 3 min, 85% A in 6 min, 82% A in 10 min, 80% A in 12 min, 70% A in 15 min, 65% A in 20 min, 60% A in 25 min, 50% A in 30–40 min, 75% A in 42 min and 90% A in 44 min, as described by Prasad et al. (2009) with adaptations by Meireles (2017). The flow rate was maintained at 1.0 mL min−1 and the column temperature was maintained at 40 °C with an injection volume of 20 μL. The total execution time was 50 min. Peaks of all components were detected at 280 nm. Calibration was performed by injecting the standards three times at five different concentrations (0.05, 0.1, 0.25, 0.5 and 1.0 mg mL−1). Individual phenolic compounds were identified by spectroscopic UV spectrum interpretation, retention time, and chromatographic comparison with authentic Sigma Aldrich standards. The quantification was based on detection of peak areas using LabSolutions software version 5.42 SP4 Copyright (Shimadzu Corporation) versus pre-determined calibration curves.

Statistical analysis

The results of fresh and dried Spondias mombin L. residue were compared by Student’s t test (p < 0.05). To optimize the process, the response function (Y) was used to perform the analysis of variance (ANOVA) for the regression. The desirability profile was used to find the optimal conditions of the process, using desirable condition (value 1) and undesirable condition (value 0). For phenolic compounds and extraction yield, the desirable conditions were those with the highest values for these parameters, for the DPPH scavenging activity, the desirable conditions were the lowest IC50 values. The Spearman’s test was used to determine the correlations among data obtained in the CCRD. For the optimized extract, the Pearson’s correlation test was performed for the variables phenolic compounds, DPPH scavenging activity, extraction yield, yellow flavonoids, total and condensed tannins, and Ferric reducing antioxidant power (FRAP). Pareto’s chart, response surface graphs and desirability parameters were generated for the response functions (Y1, Y2 and Y3) using Statistica software (v. 8.0 Statsoft®, Tulsa, USA).

Results and discussion

Characterization of Spondias mombin L. residues

The partial chemical composition of yellow mombin residue is described in Table 2. Fresh and dehydrated samples are composed mainly of carbohydrates and water. Compared with results on this work, higher moisture content was reported by Silva et al. (2012b) in fresh yellow mombin bagasse (83.3 g 100 g−1). Yellow mombin residues presented lipid and protein content of 4.73 and 2.01 g 100 g−1 for fresh, and 8.74 and 3.44 g 100 g−1 for dehydrated samples, respectively. These results are considerable when compared to yellow mombin pulp, which presented values of 0.26% for lipids and 0.82% for proteins according to Mattieto et al. (2010), suggesting that the peel and endocarp may contain higher amounts of lipids and proteins.

After dehydration, the yellow mombin bagasse presented higher acidity and lower pH value than the fresh sample due to the concentration of organic acids (Table 2). The acidity of dried Spondias mombin L. residue were similar to those reported by Tiburski et al. (2011) for the pulp. In fact, according to these authors, fresh and dried yellow mombin waste can be considered of low and medium acidity, respectively, suggesting that the acidity increment observed in dried residues compared to fresh samples is a good indicator of conservation. It was also observed that, although the drying process was partial, the dehydrated residue had high water activity (Aw) (0.783), which can be associated with the short time spent in the drying process. Results of Aw were very similar to the water activity found by Silva et al. (2012b) for the fresh yellow mombin bagasse.

As expected, the carbohydrate content increased after dehydration from 26.68 to 69.24 g 100 g−1. An increase in the content of total sugars (from 4.19 to 8.80 g 100 g−1), reducing sugars (from 1.40 to 3.15 g 100 g−1) and non-reducing sugars (2.79 for 5.65 g 100 g−1) was also noted (Table 2). The total soluble sugars content for the fresh residue was close to the results reported by Amariz et al. (2018) in yellow mombin bagasse.

Optimization of the extraction of antioxidant compounds

Table 3 shows the mean values of response variables in all conditions proposed in the factorial design. Assay 7 (90 min, 60 °C and 30% of ethanol) and 12 (60 min, 70 °C and 55% of ethanol) showed the best responses for phenolic compounds (1013.88 and 970.72 mg GAE 100 g−1), antioxidant activity (42.60 and 34.31 IC50 μg mL−1) and extraction yield (17.08 and 16.93%), while assays 13 (60 min, 45 °C and 13% ethanol) and 14 (60 min, 45 °C and 97% ethanol) showed the lowest values for these variables (760.04 and 856.34 mg GAE 100 g−1 for phenolic compounds, 179.35 and 103.92 IC50 μg mL−1, and 15.92 and 12.53% for extraction yield). Considering the extraction time factor, it is possible to consider that the point of imminence for the conditions of higher extraction corresponds to assay 12.

According to the factorial design, it was possible to verify by means of the Pareto's chart (Fig. 1) that the ethanol concentration was the factor of greatest influence on the content of phenolic compounds, antioxidant activity (quadratic) and extraction yield (linear) of obtained extracts, being directly proportional to the antioxidant activity and inversely proportional to phenolic compounds and yield. As observed in the Pareto’s chart, the ethanol concentration showed great influence on the response variables, and this variation directly reflected the antioxidant activity of the extract. The lowest antioxidant activity values were observed in the assays that used the highest (97%) and lowest (13%) concentrations of ethanol (assays 13 and 14), while those using the center point concentration (55%) showed the highest antioxidant activity values (Table 3).

The extraction time and temperature directly influenced the phenolic content and extraction yield in the linear model. Time × extraction temperature interactions were also significant (p < 0.05), with inversely proportional effects on phenolic compounds’ content and extraction yield. The extraction temperature × ethanol concentration interaction resulted in reduction in the extraction process of phenolic compounds but promoted an increase in antioxidant activity. On the other hand, the extraction time × ethanol concentration interaction is directly proportional to the increase of the antioxidant activity of extracts. According to Albuquerque et al. (2018), time, temperature and solvent proportion are variables of interest for the extraction of nutritional or bioactive compounds from vegetable materials in maceration extraction systems.

The adjustments of mathematical models of the optimization process of response variables (Y1, Y2 and Y3) were performed through ANOVA in the regression model. Only significant effects were considered, as shown in the Pareto’s chart (Fig. 1), and the significance of models were analyzed by the F test. In the ANOVA performed for the content of phenolic compounds, antioxidant activity and extraction yield, R2 values were equal to 0.6871, 0.896 and 0.9586, respectively. According to the F test, the calculated F values for phenolic compounds, antioxidant activity and extraction yield were 17.87, 66.51 and 173.12, respectively, being higher than tabulated F under the study conditions (Ftab = 2.34 for phenolic compounds and antioxidant activity and Ftab = 2.25 for extraction yield), suggesting that the models for these parameters are significant (p < 0.05) and predictive.

Therefore, Eqs. 4, 5 and 6 represent the proposed second-order polynomial model to experimental data, containing only statistically significant terms:

Spearman’s correlation (Table 4) showed that all significant correlations were negative, and the phenolic compounds (Y1) showed a moderate negative correlation (p < 0.001 and rs = − 0.483) with IC50 (Y2). A strong negative correlation (p < 0.001 and rs = − 0.650) was found between antioxidant activity and extraction yield (Y3). These results suggest that phenolic compounds were the main substances responsible for the antioxidant capacity of the extracts.

From Eqs. 3–5, response surfaces were generated (Fig. 2). The three independent variables promoted a greater impact on the extraction of phenolic compounds (Fig. 2A–C), as observed through the analysis of the Pareto’s chart (Fig. 1). Evaluating the three response surfaces, it was possible to observe the optimal regions (Y1 close to 1050 mg 100 g−1 of the sample) when the x1, x2 and x3 was respectively between 100 and 110 min of maceration, 60 and 70 °C and 50 and 70% ethanol. The values obtained in all tests were higher than those observed by Santos Felix et al. (2018), who evaluated the use of Doehlert matrix and mix designs to optimize the extraction of antioxidant compounds from yellow mombin bagasse. Omena et al. (2012) obtained higher contents of phenolic compounds when evaluating the antioxidant potential of umbu and jocote (2022 and 2547 mg GAE 100 g−1).

For the antioxidant activity (Fig. 2D–F), as well as in phenolic compounds, the extraction time and temperature promoted small changes in IC50 values (Y2). The higher antioxidant potential (IC50 close to 20 μg mL−1 of extract) was observed in extracts obtained at a temperature range of 55 to 75 °C and an ethanol concentration range of 40 to 65%. The results obtained for antioxidant activity were higher than those observed by Satpathy et al. (2011) in Spondias pinnata K. extracts and by Silva et al. (2012a) in leaves of Spondias mombin and Spondias tuberosa, showing that extracts obtained from yellow mombin residue displayed high antioxidant activity against the DPPH radical.

The extraction yield (Fig. 2G–I) showed an optimum region (yield close to 17%) when subjected to extraction between 40–80 min, with temperatures of 40 and 70 °C and ethanol concentration between 30 and 60%. The extraction yield values were higher than those reported by Omena et al. (2012) evaluating, respectively, the antioxidant extraction yield of umbu and jocote peel (11.3 and 5.9%) and seeds (5.6 and 1.4%). These results are an important parameter in determining the technical and economic viability of the processes (Palsikowski et al. 2020).

All independent variables caused variations in response variables. The extraction time was the factor that had lower impact in the studied variables. This can be attributed to the possible saturation of the extraction solution. The balance between the concentrations of solutes of the bagasse in the solution is obtained after a certain time, since the behavior over time of the extraction process is explained by Fick's diffusion law. Thus, after some time, an increase in extraction time causes only a small increase in compounds concentration. Alternatively, it can be attributed to the fact that relatively longer extraction times can promote increased phenolic oxidation (Chirinos et al. 2007; Silva et al. 2007).

Temperature significantly affected the extraction of phenolic compounds, and consequently antioxidant activity and extraction yield. This effect was more important at intermediate concentrations, between 40 and 70%. In other conditions it is possible that phenolic compounds may have been degraded with increasing temperature. At the highest temperatures (50 and 70 °C), the rupture of the cell wall of the yellow mombin bagasse may occur, as a result of weakened interactions and reduced affinity of the solid with the solute, as well as the increase in the solubility and diffusivity of phenolic compounds, improving mass transfer. It may also promote the reduction of viscosity and density of the medium, facilitating the penetration of the solvent in the sample and accelerating the extraction process (Krishnan and Rajan 2017; Lazar et al. 2016; Maran et al. 2017).

As phenolic compounds are composed of several classes of substances with antioxidant potential, each class can interact in a way with the solvent used in the extraction. The variation of solvent (ethanol) concentration in water contributed to the creation of a moderately polar medium, which promoted the potentiation of polyphenol extraction from Spondias mombin L. residues (Chirinos et al. 2007; Mokrani and Madani 2016). This result shows that due to the increase in the polarity of the extracting solvent, the extraction yield increases, indicating that the increase in the concentration of water in ethanol provides the increases the extraction yield. Possibly, phenolic compounds present in the yellow mombin bagasse possess stronger affinity for intermediate polarity solvents.

The use of solvents in conjunction with high temperatures may allow a greater solvation of the target compounds present in the matrix, promoting the increase in diffusion rates. Consequently, it may reduce the extraction time and solvent consumption (Mustafa and Turner 2011; Okiyama et al. 2018). Thus, the results of phenolic compounds, antioxidant activity and extraction yield may be related to the solvent polarity and solubility of polyphenols present in yellow mombin bagasse. It shows that ethanol concentration from 40 to 70% is indicated for the efficient extraction of polyphenolic compounds from Spondias mombin L. residues, resulting in high antioxidant potential of the extract.

In the desirability function (Fig. 3), only the extraction time showed different values (35 min) from those observed in experimental assays. The extraction temperature and ethanol concentration were 70 °C and 55%, respectively. The conditions estimated by the desirability function indicated optimum values for phenolic compounds, DPPH scavenging activity and extraction yield of 1.051.56 mg GAE 100 g−1, 24.62 μg mL−1 extract and 17.42%, respectively. The optimization value was very close to 1 (0.9646). This is a satisfactory value since each independent variable can display different measurement scales, hence the optimization of multiple responses at the same time is a challenge.

Model fitting

According to the optimum conditions obtained from the desirability of antioxidant compounds extraction, Eqs. 3–5 indicated that the optimal condition for the extraction of antioxidant compounds from yellow mombin bagasse was 35 min of extraction at 70 °C using 55% ethanol in distilled water. The estimated content of phenolic compounds, antioxidant activity and extraction yield were 1051.56 mg GAE 100 g−1 of sample, 24.62 μg mL−1 of extract and 17.42%, respectively. For validation of the mathematical model, the results obtained from the extracts prepared under the desirability conditions were compared with estimated values. Observed values of phenolic compounds (1666.18 ± 127.56 mg GAE 100 g−1) and antioxidant activity (38.03 ± 0.49 μg mL−1) were consistent with predicted values calculated by the model, yet, significantly different (p < 0.05). For the extraction yield, however, average value of 17.44 ± 0.17% was observed. This obtained results is not significantly different from value predicted by the model (p > 0.05), enabling the validation of the proposed model. The results showed the difficulty of developing an optimal method to extract antioxidant compounds present in yellow mombin residue when working with three response variables at the same time.

Characterization of the optimized extract

The optimized extract showed high content of total tannins (835.12 ± 63.57 mg TAE 100 g−1 sample), with 41.78 ± 1.29% corresponding to condensed tannins. Tannins display several biological properties, such as antioxidant, antitumor, antimutagenic, antiviral, antibacterial and hemostatic activities (Okuda and Ito 2011). Condensed tannins or proanthocyanidins are composed of catechin, epicatechin and gallic acid esters, which may be associated with a wide range of potential human health benefits (De-Faria et al. 2012).

The optimized extract also presented 31.22 ± 0.81 mg of yellow flavonoids per 100 g of sample. Rufino et al. (2010) observed contents of yellow flavonoids equal to 7.1 ± 0.7 and 6.9 ± 1.7 mg 100 g−1 of fresh sample in yellow mombin and umbu fruits, respectively. These results show that dehydrated yellow mombin bagasse presents approximately 4.5 times more flavonoids than fresh fruits. This is an important finding since yellow flavonoids have beneficial health properties, acting as nutraceuticals and antioxidants (Tapas et al. 2008; Silva et al. 2012c).

Regarding the ferric reducing antioxidant power (FRAP), the extract obtained under optimum conditions presented FRAP value equal to 98.54 ± 4.37 μmol TE g−1 of the sample. The extract presented high FRAP values compared to results reported by Omena et al. (2012) for jocote and umbu peel (16.20 ± 1.05 and 4.98 ± 0.21 μmol TEAC g−1) and seeds (13.73 ± 0.53 and 5.46 ± 0.08 μmol TE g−1), respectively. Fernandes et al. (2016) reported lower FRAP values in 5 plant extracts (mustard, saffron, mint, ginger and fennel) compared to results observed in this experiment. According to the FRAP value, yellow mombin bagasse extract can be classified with good ferric reducing capacity (Fernandes et al. 2016).

For the optimized extract, no significant correlation of phenolic compounds, antioxidant activity (DPPH and FRAP) was observed with any of the other variables evaluated (p > 0.01 and p > 0.05, respectively). However, it is observed that phenolic compounds and condensed tannins were the most important phenol groups for the antioxidant activity (DPPH), and tannins (total and condensed) are the most important groups for the FRAP activity (Table 5). A strong significant Pearson’s correlation of extraction yield and total tannins (p < 0.001 and r = − 0.995) was observed. Yellow flavonoids and condensed tannins were also found to have strong significant correlation (p < 0.05 and r = − 0.974). The negative extract yield and total tannins correlation may be due to ethanol concentration used in the extractor solution. It can also be attributed to the degree of polymerization of the extracted tannins since their solubility vary among different solvents (Khoddami et al. 2013). The negative effect of yellow flavonoids on condensed tannins can possibly be attributed to flavones and flavonols. These are the main chromophores responsible for yellow coloring, characteristic of flavonoids while condensed tannins are oligomers or polymers of flavan-3-ols units (such as catechin and epicatechin monomers) (Shadkami et al. 2009; Deveoglu and Karadag 2019). Thus, condensed tannins may have influenced the absorption of UV light during the analysis of yellow flavonoids increasing their value.

Evaluating the phenolic profile of the optimized extract, it was possible to identify 18 compounds. Some compounds have not been identified (Fig. 4). The extract showed high concentrations of phenolic acids (652.84 ± 72.37 mg 100 g−1 dm) and 12 compounds belonging to this class were found (Table 6). Phenolic acids are a group of compounds that exhibit high antioxidant activity, which is positively correlated to the number of hydroxyl groups attached to aromatic rings (Bogucka-Kocka et al. 2016). Among the acids found in the optimized extract, 2,5-dihydroxybenzoic acid (gentisic acid) (259.84 ± 22.29 mg 100 g−1 dm), salicylic (113.49 ± 12.48 mg 100 g−1 dm), 4-hydroxybenzoic acid (79.99 ± 10.44 mg 100 g−1 dm) and ellagic (46.93 ± 6.99 mg 100 g−1 dm) acids stand out, which are important compounds in the pharmaceutical area.

Moreover, hydroxycinnamic acids (p-coumaric, ferulic and caffeic) were found, which constitutes another important group of antioxidant compounds. These substances present high antioxidant potential, with caffeic acid being the highest in antioxidant potential and p-coumaric acid the lowest in potential among the three (Andreasen et al. 2001). Dutra et al. (2017) observed similar phenolic acids’ profile to that of this study in jocote and umbu (fruit and pulp), and reported higher levels of 2,5-dihydroxybenzoic (gentisic) and 3,4-dihydroxybenzoic (protocatechuic) acids.

The extract obtained in the optimized conditions also had considerable amounts of flavonoids (281.03 ± 58.85 mg 100 g−1 dm), with 6 compounds of this class. Among these, rutin (156.26 ± 23.38 mg 100 g−1 dm), catechin (66.90 ± 3.60 mg 100 g−1 dm) and myricetin (33.95 ± 6.55 mg 100 g−1 dm) can be highlighted. Moreover, other flavonoids such as quercetin, hesperetin and naringenin were also found. The rutin and quercetin contents found in yellow mombin residue extract were similar to those reported by Dutra et al. (2017) for jocote and umbu (fruit and pulp).

Conclusions

The optimal conditions for the extraction of antioxidant compounds were extraction time of 35 min, 70 °C and 55% ethanol solution. Although the content of phenolic compounds and antioxidant activity are higher than values predicted by the experimental model, it could be concluded that the results obtained in the validation test were satisfactory, since they allowed obtaining extract from Spondias mombin L. pulp residue with high antioxidant power and a diversified phenolic profile, highlighting 2,5-dihydroxybenzoic and salicylic acids, hydroxycinnamic acids, in addition to considerable amounts of flavonoids such as rutin and catechin which are responsible for providing antioxidant potential to yellow mombin extract. Due to the variety of compounds with antioxidant potential found in the extract, the low environmental risk and reduced toxicity of ethanol, it could be concluded that the Spondias mombin L. by-product extract has the potential to be applied in the food and pharmaceutical industry.

References

Albuquerque BR, Prieto MA, Vazquez JA, Barreiro MF, Barros L, Ferreira ICFR (2018) Recovery of bioactive compounds from Arbutus unedo L. fruits: comparative optimization study of maceration/microwave/ultrasound extraction techniques. Food Res Int 109:455–471

Amariz A, Lima MAC, Alves RE (2018) Quality and antioxidant potential of byproducts from refining of fruit pulp. Food Sci Technol 38:203–209

Andreasen MF, Landbo AK, Christensen LP, Hansen Å, Meyer AS (2001) Antioxidant effects of phenolic rye (Secale cereale L.) extracts, monomeric hydroxycinnamates, and ferulic acid dehydrodimers on human low-density lipoproteins. J Agric Food Chem 49:4090–4096

AOAC (2005) Official methods of analysis, 18th edn. Association of Official Analytical Chemists, Washington, DC, USA

Ayala-Zavala JF, González-Aguilar GA (2010) Use of additives to preserve the quality of fresh-cut fruits and vegetables. In: Martin-Belloso O, Fortuny RS (eds) Advances in fresh-cut fruits and vegetables processing, 1st edn. CRC Press, Boca Raton, pp 231–254

Barman K, Dubey DK, Tandon M, Thirumeignanam D, Rai SN (2017) Tannin estimation. http://pt.scribd.com/doc/43638556/6506867-Tannin-Assay. Accessed 16 Oct 2017

Benzie IFF, Strain JJ (1999) Ferric reducing/antioxidant power assay: direct measure of total antioxidant activity of biological fluids and modified version for simultaneous measurement of total antioxidant power and ascorbic acid concentration. Method Enzymol 299:15–27

Bogucka-Kocka A, Zidorn C, Kasprzycka M, Szymczak G, Szewczyk K (2016) Phenolic acid content, antioxidant and cytotoxic activities of four Kalanchoë species. Saudi J Biol Sci 25:622–630

Cabral B, Siqueira SEM, Bitencourt MAO, Lima MCJS, Lima AK, Ortmann CF, Chaves VC, Fernandes-Pedrosa MF, Rocha HAO, Scortecci KC, Reginatto FH, Giordani RB, Zucolotto SM (2016) Phytochemical study and anti-inflammatory and antioxidant potential of Spondias mombin leaves. Braz J Pharmacogn 26:304–311

Casagrande M, Zanela J, Pereira D, Lima VA, Oldoni TLC, Carpes ST (2019) Optimization of the extraction of antioxidant phenolic compounds from grape pomace using response surface methodology. J Food Meas Charact 13:1120–1129

Chirinos R, Rogez H, Campos D, Pedreschi R, Larondelle Y (2007) Optimization of extraction conditions of antioxidant phenolic compounds from mashua (Tropaeolum tuberosum Ruíz & Pavón) tubers. Sep Purif Technol 55:217–225

Contreras-Calderón J, Calderón-Jaimes L, Guerra-Hernández E, García-Villanova B (2011) Antioxidant capacity, phenolic content and vitamin C in pulp, peel and seed from 24 exotic fruits from Colombia. Food Res Int 44:2047–2053

Crizel TM, Rios AO, Thys RCS, Flôres SH (2015) Effects of orange by-product fiber incorporation on the functional and technological properties of pasta. Food Sci Technol 35:546–551

De-Faria FM, Almeida ACA, Luiz-Ferreira A, Dunder RJ, Takayama C, Da Silva MS, Da Silva MA, Vilegas W, Rozza AL, Pellizzon CH, Toma W, Souza-Brito ARM (2012) Mechanisms of action underlying the gastric antiulcer activity of the Rhizophora mangle L. J Ethnopharmacol 139:234–243

Deveoglu O, Karadag R (2019) A review on the flavonoids—a dye source. Int J Adv Eng Pure Sci 31:188–200

Dutra RLT, Dantas AM, Marques DA, Batista JDF, Meireles BRLA, Cordeiro ÂMTM, Magnani M, Borges GSC (2017) Bioaccessibility and antioxidant activity of phenolic compounds in frozen pulps of Brazilian exotic fruits exposed to simulated gastrointestinal conditions. Food Res Int 100:650–657

FAO (2018) FAOSTAT domains, crops: In: FOOD and Agriculture Organization. http://www.fao.org/faostat/en/#data/QC. Accessed 29 Jun 2020

Favareto R, Teixeira MB, Soares FAL, Belisário CM, Cabral JF, Silva EA, Moia TA, Cardoso-Filho L (2019) Extraction of bioactive compounds of leaves of Duguetia furfuracea (Annonaceae) using green and organic solvents. Braz J Chem Eng 36:549–556

Fernandes RPP, Trindade MA, Tonin FG, Lima CG, Pugine SMP, Munekata PES, Lorenzo JM, De Melo MP (2016) Evaluation of antioxidant capacity of 13 plant extracts by three different methods: cluster analyses applied for selection of the natural extracts with higher antioxidant capacity to replace synthetic antioxidant in lamb burgers. J Food Sci Technol 53:451–460

Fernández-Barbero G, Ponedo C, Espada-Bellodo E, Ferreoro-González M, Carrera C, Palma M, García-Barroso C (2019) Optimization of ultrasound-assisted extraction of bioactive compounds from jabuticaba (Myrciaria cauliflora) fruit through a Box-Behnken experimental design. Food Sci Technol 39:1018–1029

Francis FJ (1982) Analysis of anthocyanins. In: Markakis P (ed) Anthocyanins as food colors, 1st edn. Academic Press, New York, pp 181–207

Garmus TT, Kopf SFM, Paula JT et al (2019) Ethanolic and hydroalcoholic extracts of pitanga leaves (Eugenia uniflora L.) and their fractionation by supercritical technology. Braz J Chem Eng 36:1041–1051

Guindani C, Podestá R, Block JM, Rossi MJ, Mezzomo N, Ferreira SRS (2016) Valorization of chia (Salvia hispanica) seed cake by means of supercritical fluid extraction. J Supercrit Fluids 112:67–75

Huang HW, Hsu CP, Yang BB, Wang CY (2013) Advances in the extraction of natural ingredients by high pressure extraction technology. Trends Food Sci Technol 33(1):54–62

Jovanović AA, Đorđević VB, Zdunić GM et al (2017) Optimization of the extraction process of polyphenols from Thymus serpyllum L. herb using maceration, heat- and ultrasound-assisted techniques. Sep Purif Technol 179:369–380

Khoddami A, Wilkes M, Roberts T (2013) Techniques for analysis of plant phenolic compounds. Molecules 18:2328–2375

Krishnan RY, Rajan KS (2017) Influence of microwave irradiation on kinetics and thermodynamics of extraction of flavonoids from Phyllanthus emblica. Braz J Chem Eng 34:885–899

Lazar L, Talmaciu AI, Volf I, Popa VI (2016) Kinetic modeling of the ultrasound-assisted extraction of polyphenols from Picea abies bark. Ultrason Sonochem 32:191–197

Lima R S, Ferreira SRS, Vitali L, Block JM (2019) May the superfruit red guava and its processing waste be a potential ingredient in functional foods? Food Res Int 115:451–459

Makkar HPS, Blümmel M, Borowy NK, Becker K (1993) Gravimetric determination of tannins and their correlations with chemical and protein precipitation methods. J Sci Food Agric 61:161–165

Maran JP, Manikandan S, Vigna Nivetha C, Dinesh R (2017) Ultrasound assisted extraction of bioactive compounds from Nephelium lappaceum L. fruit peel using central composite face centered response surface design. Arab J Chem 10:S1145–S1157

Mattieto R A, Lopes AS, Menezes HC (2010) Physical and physicochemical characterization of caja fruit (Spondias mombin L.) and its pulp, obtained using two types of extractor. Braz J Food Technol 13:156–164

Meireles BRLA (2017) Nutritional and antioxidant potential of the fruit of the catolé (Syagrus cearensis). Federal University of Paraiba, João Pessoa

Miller GL (1959) Use of dinitrosaiicyiic acid reagent for determination of reducing sugar. Anal Chem 31:426–428

Mokrani A, Madani K (2016) Effect of solvent, time and temperature on the extraction of phenolic compounds and antioxidant capacity of peach (Prunus persica L.) fruit. Sep Purif Technol 162:68–76

Monroy YM, Rodrigues RAF, Sartoratto A, Cabral FA (2020) Purple corn (Zea mays L.) pericarp hydroalcoholic extracts obtained by conventional processes at atmospheric pressure and by processes at high pressure. Braz J Chem Eng 37:237–248

Mustafa A, Turner C (2011) Pressurized liquid extraction as a green approach in food and herbal plants extraction: a review. Anal Chim Acta 703:8–18

Nascimento Filho WB, Franco CR (2015) Potential assessment of waste produced through the agro-industrial processing in Brazil. Rev Virtual Quím 7:1968–1987

Okiyama DCG, Soares ID, Cuevas MS, Crevelin EJ, Moraes LAB, Melo MP, Oliveira AL, Rodrigues CEC (2018) Pressurized liquid extraction of flavanols and alkaloids from cocoa bean shell using ethanol as solvent. Food Res Int 114:20–29

Okuda T, Ito H (2011) Tannins of constant structure in medicinal and food plants-hydrolyzable tannins and polyphenols related to tannins. Molecules 16:2191–2217

Omena CMB, Valentim IB, Guedes G S, Rabelo LA, Mano CM, Bechara EJH, Sawaya ACHF, Trevisan MTS, Costa JG, Ferreira RCS, Sant’Ana AEG, Goulart MOF (2012) Antioxidant, anti-acetylcholinesterase and cytotoxic activities of ethanol extracts of peel, pulp and seeds of exotic Brazilian fruits. Food Res Int 49:334–344

Palsikowski PA, Besen LM, Klein EJ, Silva C, Silva EA (2020) Optimization of ultrasound-assisted extraction of bioactive compounds from B. forficata subsp. Pruinosa. Can J Chem Eng 98:2214–2226

Paludo M, Colombo R, Teixeira J, Hermosín-Gutiérrez I, Ballus C, Godoy H (2019) Optimizing the extraction of anthocyanins from the skin and phenolic compounds from the seed of jabuticaba fruits (Myrciaria jabuticaba (Vell.) O. Berg) with ternary mixture experimental designs. J Braz Chem Soc 30:1506–1514

Porter LJ, Hrstich LN, Chan BG (1985) The conversion of procyanidins and prodelphinidins to cyanidin and delphinidin. Phytochemistry 25:223–230

Prado ACP, Aragão AM, Fett R, Block JM (2010) Phenolic compounds and antioxidant activity of pecan [Carya illinoinensis (Wangenh.) C. Koch] shell extracts. Braz J Food Technol 12:323–332

Prasad KN, Yang B, Yang S, Chen Y, Zhao M, Ashraf M, Jiang Y (2009) Identification of phenolic compounds and appraisal of antioxidant and antityrosinase activities from litchi (Litchi sinensis Sonn) seeds. Food Chem 116:1–7

Rufino MSM, Alves RE, Brito ES, Morais SM, Sampaio CG, Jiménez JP, Saura-Calixto FD (2007) Scientific method: determination of total antioxidant activity in fruits by capturing the free radical DPPH. Comunicado Técnico Online. EMBRAPA Available at https://www.infoteca.cnptia.embrapa.br/bitstream/doc/426953/1/Cot127.pdf. Accessed 30 Dec 2021

Rufino MSM, Alves RE, Brito ES, Pérez-Jiménez J, Saura-Calixto F, Mancini-Filho J (2010) Bioactive compounds and antioxidant capacities of 18 non-traditional tropical fruits from Brazil. Food Chem 121:996–1002

Santos Felix AC, Novaes CG, Pires Rocha M, Barreto GE, Do Nascimento BB, Giraldez Alvarez LD (2018) Mixture design and doehlert matrix for the optimization of the extraction of phenolic compounds from Spondias mombin L apple bagasse agroindustrial residues. Front Chem 5:116

Sarraf M, Beig-babaei A, Naji-Tabasi S (2021) Optimizing extraction of berberine and antioxidant compounds from barberry by maceration and pulsed electric field-assisted methods. J Berry Res 11:133–149

Satpathy G, Tyagi YK, Gupta RK (2011) Preliminary evaluation of nutraceutical and therapeutic potential of raw Spondias pinnata K., an exotic fruit of India. Food Res Int 44:2076–2087

Sepúlveda L, Romaní A, Aguilar CN, Teixeira J (2018) Valorization of pineapple waste for the extraction of bioactive compounds and glycosides using autohydrolysis. Innov Food Sci Emerg Technol 47:38–45

Shadkami F, Estevez S, Helleur R (2009) Analysis of catechins and condensed tannins by thermally assisted hydrolysis/methylation-GC/MS and by a novel two step methylation. J Anal Appl Pyrolysis 85:54–65

Silva E, Rogez H, Larondelle Y (2007) Optimization of extraction of phenolics from Inga edulis leaves using response surface methodology. Sep Purif Technol 55:381–387

Silva ARA, Morais SM, Marques MMM, Oliveira DF, Barros CC, Almeida RR, Vieira ÍGP, Guedes MIF (2012a) Chemical composition, antioxidant and antibacterial activities of two Spondias species from Northeastern Brazil. Pharm Biol 50:740–746

Silva AS, Oliveira EL, Santos ES, Oliveira JA (2012b) Characterization and drying of caja bagasse (Spondias mombin L.) in a tray dryer using a factorial planning. Rev Bras Frutic 34:239–247

Silva FVG, Silva S M, Silva GC, Mendonça RMN, Alves RE, Dantas AL (2012c) Bioactive compounds and antioxidant activity in fruits of clone and ungrafted genotypes of yellow mombin tree. Food Sci Technol 32:685–691

Tapas A, Sakarkar D, Kakde R (2008) Flavonoids as nutraceuticals: a review. Trop J Pharm Res 7:1089–1099

Tiburski JH, Rosenthal A, Deliza R, Godoy RLO, Pacheco S (2011) Nutritional properties of yellow mombin (Spondias mombin L.) pulp. Food Res Int 44:2326–2331

Varzakas T, Zakynthinos G, Verpoort F (2016) Plant food residues as a source of nutraceuticals and functional foods. Foods 5:88

Waterhouse AL (2002) Determination of total phenolics. In: Current protocols in food analytical chemistry. Wiley, Hoboken, pp I111–I118

Xu DP, Li Y, Meng X, Zhou T, Zhou Y, Zheng J, Zhang JJ, Li HB (2017) Natural antioxidants in foods and medicinal plants: extraction, assessment and resources. Int J Mol Sci 18(1):96. https://doi.org/10.3390/ijms18010096

Yemm EW, Willis AJ (1954) The estimation of carbohydrates in plant extracts by anthrone. Biochem J 57:508–514. https://doi.org/10.1016/j.seppur.2007.01.008

Acknowledgements

The authors would like to thank “Tropical Polpas de Frutas” Company for the donation of the study material. Finally, the authors declare that the present study was financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior-Brasil (CAPES)-Finance Code 001.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

de Santana Neto, D.C., Ferreira, V.C.d., Araújo, Í.B.d. et al. Solid–liquid extraction of bioactive compounds from Spondias mombin L. by-products: optimization and identification of phenolic profile. Braz. J. Chem. Eng. 39, 511–525 (2022). https://doi.org/10.1007/s43153-021-00209-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s43153-021-00209-z