Abstract

Maintenance planning of low volume rural road network is a challenging task due to its large length and importance to the concerned habitation. The proposed methodology is focused on developing a cost-effective maintenance plan for low volume rural Himalayan hill roads by considering the predominant distresses and factors. Maximizing overall network pavement condition rating while minimizing the budget is taken as the objective function in the optimization problem. The maintenance plan is optimized using Knapsack modified Genetic Algorithm technique developed in MATLAB. Validation of the proposed model was done by applying it to a case study of 42 low volume rural hill roads of Hamirpur district of Himachal Pradesh state in India, located in the Himalayan region. Knapsack modified GA makes maintenance planning easier by considering different scenarios of budgetary limitations varying from 0 to 100% of total need. The present model can be very helpful for pavement maintenance planners in developing an optimized cost-effective maintenance program in developing countries where budget limitation is a big concern.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Rapid economic growth demands faster and safer movement of goods and people from one place to another which is totally dependent on transportation system. Better transportation system not only saves travel time and money but also plays an important role in improving the life quality and happiness index of the people of that place. In India, roads carry about 85% of total passenger traffic and 60% freight [1]. These roads need maintenance activities to be performed time to time. It has been observed that extending the life of pavement through preventative maintenance can cut greenhouse gas emissions by up to 2% [2, 3]. Proper maintenance planning gives economic and environmental benefits to transportation agencies by cutting pavement maintenance cost up to 30%. It is helpful for road users in terms of fuel usage, tire wear, and vehicle repair and maintenance costs [4]. A complete maintenance plan consists of following steps: (a) pavement condition survey, (b) selection of maintenance technique, and (c) optimization of maintenance plan. The final step involves optimizing the plan as per the budget. A scientifically developed and optimized maintenance plan will reduce waste, ensure better utilization of resources, and will provide timely benefit to the communities. A number of decisions are to be taken by pavement maintenance planners as human judgments are subject to uncertainties [5],technical assessment of pavement is needed, and the decisions should be taken in a scientific manner.

Huge amount of budget is allocated by Indian Ministry of Roads and Transport every financial year for pavement maintenance activities. Yearly budget of 335 million USD for road and highway maintenance was allotted in 2021–22 (Including toll bridges). This is a year-over-year increase of 26% over maintenance spending in 2019–20. The maintenance budget, at 26,800 million ₹, was around 2% of the ministry's total budget. This was for a total length of 136 mm of National Highways [6] In comparison, the US government plans to spend $23.74 billion (17,00,000 million₹ which is 51 percent of its entire highway budget) on its National Highway Performance Program (NHP) in 2020–21 to improve the condition and performance of its National Highway System (roughly 0.35 million km of length) [7]. These figures depict the huge app in pavement maintenance budgets availability between developed and developing nations. This limited budget available for pavement maintenance planners to develop a maintenance plan is difficult. This lack of available maintenance planning tools and techniques has increased the demand for a systematic, easy to use, and cost-optimized maintenance plan for low volume rural roads. The significance of low volume rural (LVR) roads is extremely high in developing countries like India [8, 9]. Due to low traffic volume on these roads, their maintenance is ignored and not regularly conducted. However, due to rapid infrastructural growth in the last few decades, traffic volume has considerably increased on these roads and now they require timely maintenance for staying operational throughout the year. Maintenance of a large network of these rural roads requires planning to ensure the best use of available funds and timely repair of the needy roads [10].

2 Pavement Maintenance Planning

Development of maintenance plan for a network of roads in a region consists of 3 stages: first, conduct a pavement condition survey, second, select suitable technique for each pavement and finally prepare an optimum plan for entire road network.

2.1 Pavement Condition Survey

Pavement condition survey includes collection of pavement defect data. As the pavement age increases, the condition of pavement gets degraded due to formation of several defects on it. This degradation is due to repetitive traffic load, adverse climatic conditions, poor quality of raw materials and improper maintenance schedules [11]. Therefore, a proper assessment of pavement condition is must at suitable time intervals. Various pavement management agencies have set the different time intervals for these condition surveys at different countries. In India, As per Indian Road Congress model provisions, These condition surveys should be conducted at least once a year [12]. As these pavements are primarily bituminous, they get badly damaged during the rainy season in the months of July, August, and September. Hence, that is the best time to assess the damage and plan for remedial action. If a pavement is repaired just after the rainy season, it remains in reasonably good condition for the rest of the year. In Himalayan regions, it should be done just after the monsoon season is over because the pavement gets highly damaged after monsoon due to rain, floods, and landslides [13,14,15]. The survey can be done manually or automatically. In manual condition surveys, maintenance staff visually collects defects data by physically measuring the area and extent of each defect using measuring tapes and other instruments. There are also many advance automatic instruments which can collect these data by taking pictures or recording videos of roads. Dipstick profiler, Automated Road Image Analyzer (ARIA), rod and level survey instruments, Real System from PASCO, and California type profilometers are popular among various available automatic equipment’s [16].

Surface defects (fatty surfaces, smooth surface, streaking, and hungry surface), Cracks (all types of cracks, viz, hair-line cracks, alligator cracks), deformation (rutting, corrugations, shoving including those caused by layer slippage, shallow depressions, settlements and upheavals etc.) and Disintegration (stripping, loss of aggregates, Raveling, potholes, and edge breaking) are four categories of defects on flexible pavements. The current study is focused on the segments of low volume rural roads.

2.2 Selection of Maintenance Technique

After the assessment of the pavement condition, the next step is to evaluate the treatment alternatives that are feasible based on the categories of pavement distress. Table 1 lists best fitted surface maintenance treatments for various forms of pavement distress [17].

It should be noted that practicality does not mean affordability, as the major goal at this stage of the selection process is to figure out which treatments might work. Once the viable solutions have been identified, other factors such as climate, geography, and traffic must be made to assess their limitations. The final solutions should be the one that meets maintenance needs while remaining within budget constraints.

2.2.1 Maintenance cost and service life enhancement of various maintenance techniques

Once the possible options have been selected, cost-benefit analysis or other cost-effective measurements should be undertaken to determine which maintenance solution is best suited for the application [21]. The optimal treatment choice is one that gives the most benefit for the lowest life cycle costs whether the benefit is evaluated in terms of improved condition, extended pavement life, or even more simply the life of the treatment. Table 2 shows benefit in terms of enhancement in pavement condition rating, unit cost for different maintenance types and weightage of maintenance techniques in PCR ratings.

Each maintenance technique has its own cost and benefit features in terms of improvement of pavement life. A detailed literature survey was conducted on various maintenance techniques widely used in the field of pavement maintenance so that a proper scientific assessment of maintenance can be done for the pavements of Himalayan region. Various literatures were studied to determine the unit cost and service life of main pavement maintenance techniques used in rural hill roads [4, 18, 23,24,25,26,27,28]. Average per-unit cost of each technique differs depending on the project's location, quantity of materials used, availability of local raw materials, and weather conditions. The median value of each unit cost and service life of these literatures is taken as a reference unit cost and enhanced service life to develop our model in this study. Table 3 illustrates typical unit costs and predicted service life for various treatments.

With the help of Table 2 and Table 3, we can determine which the most suitable technique for pavement maintenance is and evaluate the total maintenance budget demand of network. Selection of best maintenance technique is done using a multi-stage selection of maintenance technique developed by Nautiyal & Sharma [17]. In developing countries like India total maintenance budget demand is not met by the government. Therefore, a limited budget makes role of a maintenance planner more crucial. The focus of planning should be on maximizing the benefits on overall network within the constrained budget.

2.2.2 Optimization of Pavement Maintenance Plan

The literature review provides a firm basis for benefit–cost evaluation, with the objective of identifying treatments that could be cost-effective for low-volume rural hill road maintenance. Table 4 shows the weightage of distress in evaluating PCR rating and enhancement after treating this distress in PCR rating [12]. Whereas Table 2 shows that if a particular maintenance technique is used then how much maximum overall PCR rating it can improve and which defects can be removed by application of a particular technique.

As shown in above Table 4, if we remove all cracks of pavement then its overall PCR value will be increased by 17.39%, similarly, the treatment of other defects i.e., raveling, potholes, patching & settlements PCR value will be increased by 13.04%,8.69%,13.04%, and 13.04% respectively. Cost-benefit optimization of the whole network needs to select the best economical treatments for various pavements that can cover maximum distress as well as gives maximum benefit in terms of improvement of PCR value of the whole network.

The maintenance strategies are optimized based on two scenarios. The first is the Necessary Funds Model (NFM), which aims to reduce the amount of maintenance funds required to keep the PCR of all pavements above a certain level. The second is the Budget Bound Model (BBM), which aims to maximize the benefits area while staying under budget constraints. The BBM is applied by making budget constraints of 10%, 30%, 50%, 80%, and 100% of the overall maintenance budget requirement. The NFM and BBM described in this study presents a thorough pavement segment repair strategy for each year of the user-defined analysis period.

The optimal solution should meet the following criteria: the total cost of maintenance for all the pavement segments taken into account is maintained to a minimum. Pavements segments are maintained above a user-defined minimum level during the analysis time. The optimization algorithm inputs are PCR values at the start of the analysis period, the threshold PCR, the age of pavement sections, the cluster to which it belongs, the maintenance options, expenses, and the accompanying increase in PCR. Using the optimization program, the maintenance treatment required for each section to keep the PCR over the threshold value is chosen from the maintenance alternatives. The PCR after treatment as well as the annual maintenance costs is determined. For each part, the PCR for the upcoming year is determined using the deterioration model for the cluster to which it belongs. The PCR after treatment, the subsequent year’s deterioration, and the treatment expenses for subsequent years are all dependent on the treatment option chosen for each year. The optimization algorithm tests several combinations of treatment methods for each pavement section.

2.2.3 Selection of Optimization Technique

There have been quite significant improvements in the field of pavement maintenance programs over the decades. Pavement maintenance programs are considered as both single objective as well as multi-objective by various researchers as per requirements. Pavement Management System (PMS) is a widely used term which takes care of the planning and implementation of the maintenance and repair of a network of roadways or other paved facilities to achieve the best possible pavement conditions [29]. In the starting phase of PMS development, pavement maintenance tools were developed solely based on single-objective optimization techniques. The significant development in the field of PMS was done using various techniques such as linear programming [30], dynamic programming [31] integer programming [32], optimal control theory [33], nonlinear programming and heuristic methods [34]. Major changes in development of PMS tool occurred when researchers understood that pavement maintenance is a very complex task that involves various criteria to be taken care of. Limiting to only one objective function makes use of many other objective functions as constraints which limit the flexibility of these major functions [35].

So, Single objective optimization-based studies were not capable to cover all criteria simultaneously. So, in early 2000, various researchers considered pavement maintenance as multi-objective and developed their model using various multi-objective optimization techniques [36]. In this era, Artificial Neural Network (ANN), Genetic Algorithm (GA), Markov chain, Fuzzy logic, became popular in PMS development. But GA is most widely accepted optimization technique among most pavement maintenance researchers [37–39]. Genetic Algorithms are robust search strategies based on the mechanics of natural selection and natural genetics [40]. These evolutionary mechanics are simple but effective. What matters in Genetic Algorithms (GA), as in all Artificial Intelligence (AI) systems, is having an effective and efficient method of representing knowledge in the computer and of converting real-world knowledge into an internal representation.

The basic idea behind Genetic Algorithms is to generate an initial pool of solutions, represented as string structures, and then to allow the solution pool to evolve toward better and better solutions through continuous copying, swapping, and modifying of partial strings in a manner similar to natural genetic evolution [38].

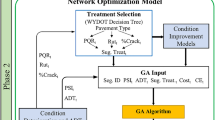

3 Methodology

3.1 Genetic Algorithm as a Maintenance Optimization Tool

The process of problem-solving with GAs is illustrated as a flow chart in Fig. 1. This procedure begins with the identification of the parameters that describe the solutions to the given problem, as well as the determination of the problem's objective function and constraints. And the final output is the optimized maintenance plan of road network.

3.1.1 Encoding of Problem

The solution of the problem needs to be encoded into genetic representation (i.e., chromosomes). Each solution in this representation has multiple genes that can be changed using the genetic operators outlined later. These genes are represented by a series of symbols that can be retrieved through various encoding methods [41]. Problem is solved using a binary encoding approach, which allows for quick computation and easy manipulation of genes [42]. Figure 2 shows the binary encoding of problem.

GA chooses a predetermined size for an initial pool of solutions, referred to as the parent pool or population. In this study, set of best fitted roads in network are selected in parent pool. The fitness function, which is determined based on the objective function and the constraints, is used to evaluate the fitness of individuals in this population.

3.1.2 Evaluation of Fitness

When it comes to cost-optimization, the fittest candidate of pavement is the one who has a lower current value of overall maintenance costs. Models for pavement performance prediction and maintenance cost are required inputs in the evaluation of candidate solutions. The parent pool is subjected to two processes to develop a new pool of solutions, referred to as the offspring pool. The objective functions and constraints that determine the fitness value of each road is shown below.

4 Objective function

4.1 Minimization of Maintenance Cost

Treatment of defective pavement segments of road network requires different maintenance costs. The pavement maintenance cost is dependent on the type of selected maintenance technique and area of degraded pavement sections. For an optimized maintenance plan, total maintenance budget requirement should be minimized. Function to minimize the total maintenance cost requirements is shown in Eq. 1 below.

Here,

n = total no of roads in network.

k = 0,1,2,3,4. (i.e., selected maintenance option).

0: no maintenance.

1: routine maintenance.

2: preventive maintenance.

3: Overlay/resurfacing,

4: major rehabilitation/reconstruction.

Ai = total area of each section in square meters.

%Pi = percentage of defective area.

Cik = cost of maintenance of section i using repair option k.

4.2 Maximization of Average Pavement Condition

Treatment of defective pavement segments will enhance the current pavement condition rating of that road, which will directly enhance the average network pavement rating. Best solution should maximize the present average network pavement condition rating. Function to maximize the average pavement condition is shown in Eq. 2 below:

Here,

qi = pavement condition rating of section i and.

n = total no of roads in network.

4.3 Constraints

As mentioned earlier the available budget allotted by road ministry in developing countries for maintenance programs can be less than budget needed to treat all roads with best maintenance options. Maintenance planners must make a maintenance plan within this allotted budget. The range of allotted budget can be any value ranging between 0 and 100% of total budget requirement. Therefore, total budget should not be more than available maintenance budget.

4.3.1 Selection of Parent Population for GA

The GA's initial process, selection, is regarded as its key step since it selects the most promising chromosomes (set of roads to be selected) from the parent pool (all roads of network) and produces a mating pool (selected roads) with the same number of chromosomes. There are a variety of selection techniques that can be used, including tournament selection, roulette-wheel, and linear and exponential ranking selection [43]. The roulette wheel technique, which is a popular stochastic procedure that ties the likelihood of selection for each chromosome to its fitness value calculated earlier, was utilized to solve the current problem. In roulette wheel selection technique, the road whose fitness value is higher is that will cover the maximum area of roulette and the selection probability of that road will be higher to form initial set of two parents to generate offsprings.

4.3.2 Reproduction Stage

To increase the efficiency of GA, we need to develop new offspring pools till the criteria is reached. To establish a new offspring pool, two genetic procedures crossover and mutation are used to modify the chromosomes of the mating pool.

4.3.2.1 Crossover

To speed up the search, pairs of parent chromosomes are randomly selected with single point crossover technique, and each pair exchanges the genes of the two chromosomes at a crossing site that is also randomly determined. Figure 3 shows crossover process of the study.

4.3.2.2 Mutation

In the mutation process, parent chromosomes are chosen, and their genes are randomly changed from 0 to 1 or vice versa, with mutation probability (pm) to conduct a random search. This process inserts random changes into a small fraction of solutions to test prospective solutions that have never been chosen while avoiding the local optima trap i.e., bexplorationQ. A low mutation probability limits the possibility of discovering new solutions, whereas a high mutation probability might have a significant impact on solution convergence. Figure 4 shows the mutation process of the study.

4.4 Final Optimal Solutions

The fitness function is then applied to the resulting population, which is subsequently utilized to create a new parent population. Iteratively, the selection and evolution procedures are repeated until a predefined stopping criterion is met. The maximum number of iterations, the minimal improvement in average fitness, or both may be specified in this criterion. The solution with the highest fitness in these iterations is determined to be the optimal choice.

5 Model Validation

Validation of the developed model was done on a case study of 42 low volume hill roads in Himachal Pradesh, India. All pavements are constructed under PMGSY (Pradhan Mantri Gramin Sadak Yojna) scheme of the government of India, therefore, the quality and techniques used for the design and construction of all roads are same. All the roads considered in the case study have been constructed with bituminous pavement as the wearing course. The carriageway is single-lane 3 to 3.75 m wide depending on land availability and expected traffic. The roads are meant to connect villages with the nearby major road. These roads have become the lifeline of the rural areas giving the inhabitants access to various socio-economic facilities. These roads fall in the same district i.e., Hamirpur of Himachal Pradesh state, and the aerial distance of these is less than 30 km, therefore, there is not any significant variation in climatic conditions. Average daily traffic on these pavements is less than 1000 PCU per day therefore these are categorized as low volume roads. Study area comes into the sub-humid sub-tropical Himalayan region and the coordinates vary from 76′100 E—76′500 E to 31′200 N – 31′600 N. Temperature varies from a maximum of 40 degrees in hot summers and up to 13 degrees in cold winters. A digitized road map of the study area developed in ArcGIS is shown in Fig. 5. ArcGIS is used to store and maintain data such as: distress data, traffic data and socio-economic features, due to its unique feature of handling both spatial and non-spatial data simultaneously.

In this study, Pavement Condition Rating (PCR), Traffic volume (In terms of PCU per day), utility value (UV), and Type of connectivity are selected as four major factors for selecting and prioritizing roads for maintenance. Pavement maintenance planning is performed stepwise.

5.1 Pavement Condition Survey

Area and severity of distress in each pavement is collected by conducting manual surveys on each pavement. Cracks, potholes, patching, raveling, and rutting are five major distress found on these low volume rural roads of the network, so we have taken only these five distresses. Severity levels of each distress are determined by measuring the area and extent of distress. IRC 82 2015 guidelines are used to distinguish the severity and extent of distress.

5.1.1 Cracking

Water can infiltrate into the flexible pavements and freeze as the temperature drops. When water freezes, it expands, putting strain on surface and potentially causing cracks. The shape and cause categorize cracks into various types i.e., hair-line cracks, alligator and map cracking, longitudinal cracking, edge cracking, and reflection cracking. Cracks are also divided into Low severity cracks (1–3 mm wide), Medium severity cracks (3–6 mm wide), and High severity cracks (> 6 mm wide). The total % area of cracks in all the pavements is shown in Fig. 6 below.

5.1.2 Potholes

Potholes are bowl-shaped cavities on a bituminous surface which extends into the binder/base course caused by partial material breakdown. Potholes are categorized as Low severity potholes (25 mm deep and 200 mm wide), Medium severity potholes (25–50 mm deep and 500 mm wide), and High severity potholes (> 50 mm deep and > 500 mm wide). The total % area of Pothole in all the pavements is shown in Fig. 7 below.

5.1.3 Patching

Patches are formed by treating a specific region with localized distress. Application of patch reduces discomfort caused to road users by distresses. Road user discomfort can never be fully reduced. Therefore, patches are considered as distress. Patching is also categorized into three categories i.e., Low, Medium, and High severity based on the severity and extent of distress on patch. The total % area of all Patching is shown in Fig. 8 below.

5.1.4 Rutting

Rutting is a dip or groove in the pavement that runs along and parallel to the wheel path. It can be characterized by two components of the original (initial) pavement profile change, which are direct outcomes of permanent deformation such as uplift and downward deformation, and it can be described by the cause and layers in which rutting occurs. Rutting is said to be Low severity rutting (4–10 mm deep) and High severity rutting (> 10 mm deep). The total % area of Rutting in all the pavements is shown in Fig. 9 below.

5.1.5 Raveling

Raveling is the separation and dissociation of fine aggregate particles and binder from a bituminous surface over time. Fine aggregates usually wear out first, followed by coarse aggregates. Raveling usually begins at the top and works its way down, or at the edge and works its way inward. Raveling causes the surface of the pavement to become rough and jagged. Raveling is categorized as Low severity raveling, if some loss of fines is associated with an initial stage of binder wearing, Medium severity raveling when loose particles exist with some loss having binder wearing out to a rough surface, and High severity raveling when the surface is too rough with loss of aggregates. The total % area of Raveling in all pavements is shown in Fig. 10 below.

5.2 Pavement Condition Rating (PCR)

The pavement condition rating is a numerical rating (ranges between 0 and 3) assigned to each pavement and it depicts the present condition of pavement surface. “0” PCR value indicates the worst condition of pavement and “3” PCR indicates best condition of the pavement. IRC 82 2015 guidelines were used to determine the PCR value of each pavement [12]. The total area of each distress and corresponding PCR are shown in Fig. 11 below.

6 Selection of Suitable Maintenance Techniques for Each Pavement

Selection by suitable maintenance technique is done using the Multistage selection technique developed by Nautiyal and Sharma [17]. Out of 42 roads in the network, 7 roads need routine maintenance, 4 roads need preventive maintenance, 24 roads need periodic maintenance, and 4 roads need reconstruction. Estimated costs of each maintenance activity is 14433.6 ₹, 6988.938 ₹, 94,210.4 ₹, and 983,875 ₹ respectively. The exact maintenance need of each road in terms of cost and maintenance technique, as well as current average network PCR value and enhanced average PCR value, are shown in Table 5 below.

Total fund requirement for maintenance of the entire network as per the study is 1099508 ₹. Present average PCR of network is 1.79 which can be increased up to 2.59 by application of these maintenance activities. For this, we need 100% maintenance budget i.e., ₹1,099,508, but due to limited availability of maintenance budget, the maintenance plan may be optimized. The GA technique as described earlier was used to determine the optimized solutions for maintenance of the network.

6.1 Maintenance Plan Optimization Using Knapsack Modified GA

The complete pavement maintenance planning is considered as a Knapsack problem in this study. The knapsack problem is a combinatorial optimization problem that consists of the following steps: determine the quantity of each item included in a collection given a set of objects, each with a weight and value, so that the total weight is less than or equal to a certain limit and the total value is as great as possible. In our case, the selection of the maximum number of roads is done by maximizing the total average network PCR value within a fixed budget constraint. It gets its name from the dilemma that someone faces with a fixed-size knapsack while trying to load it with the most valuable stuff. The challenge frequently occurs in resource allocation, as decision-makers must choose among a set of non-divisible projects or activities while working under a strict budget or time constraint. The knapsack problem has been researched for over a century, with the earliest works reaching back to 1897. The term "knapsack problem" is derived from the early works of mathematician Tobias Dantzig (1884–1956) [44], and relates to the challenge of packing the most expensive or helpful objects without overcrowding the luggage. Pavement maintenance planning by considering the whole problem as a Knapsack problem is very useful and makes this complex task of selection and scheduling of maintenance plans easier [45, 46].

The challenge of selecting and scheduling Maintenance and rehabilitation activities during a certain planning period is formulated as a multi-dimensional 0–1 knapsack problem with M&R strategy-precedence and selection-feasibility restrictions. Binary conversion of the whole problem is done to develop a maintenance plan. If a road is selected for maintenance, then it is used as “1” and if it is not selected it is used as “0”. A combination of the Knapsack problem and Genetic algorithm was applied using MATLAB programing. The graphs between fitness value and the number of iterations for different budget constraints are shown in Fig. 12 below.

6.2 Selection of Optimum Solution

In this study finally, the use of GA and Knapsack was done to optimize pavement maintenance planning. Formulation of the optimization problem is done such that, the average network pavement condition is maximized within the allotted budget. For this, selection of a maintenance technique among the set of various available techniques is done so as it gives maximum benefit in terms of cost-saving as well as maximum enhancement in average network pavement condition rating. The algorithm is based on the mechanics of natural selection and natural genetic.

The budget allotted for road maintenance may be less than total need. Therefore, we must optimize our maintenance plan as per the allotted budget. It can be any number ranging from 0 to 100% of total budget requirement as per the availability of funds allotted by road ministry. Therefore, in this study, we have optimized our maintenance plan for 100%, 80%, 50%, 30%, and 10% of budget allotment. Within these budget constraints, we must develop our maintenance plan so that we can maximize our average network PCR value. The optimized maintenance plan is shown in Table 6 below.

7 Results and Conclusions

This study proposes the use of GA, Knapsack, and multi-stage selection of maintenance techniques to develop a scientific decision-making model for pavement maintenance planning. Formulation of an optimization problem is done such that it maximizes the average network pavement condition within the allotted budget. For this, selection of a maintenance technique among the set of various available techniques is done so as it gives maximum benefit in terms of cost-saving as well as maximum enhancement in average network pavement condition rating. The algorithm is based on the mechanics of natural selection and natural genetics. GA is simple but effective. What matters in GA, as in all Artificial Intelligence systems, is having an effective and efficient method of representing knowledge in the computer and converting real-world knowledge into an internal representation.

The model was applied to a case study of 42 rural hill roads. The results of case study show a significant advantage in terms of maximizing network pavement condition within available budget. Within a limited budget, the results of Knapsack Modified GA are very efficient in handling the complex task of pavement maintenance planning. The result of study concludes that, if we have full 100% budget allotment and prescribed technique given by the model are applied then we can enhance the average network PCR rating by 44.69% (i.e., 2.59 from 1.79). Similarly for 80%, 50%, 30%, and 10% budget allotment, PCR rating can be enhanced by 41.63%, 35.41%, 32.5% and 23.07% respectively. Maximum pavement maintenance budget demand as per the results of our model is 1099508 ₹ which can enhance our previous average network PCR rating from 1.79 to 2.59. Pavement maintenance planners need to take optimized cost-effective decisions which maximize enhancement of the average rating of network with allotted budget constraints. So, with different budget levels, this model was analyzed, and most cost-beneficial optimal plans are developed. Within the budgets limit of 80%, 50%, 30%, and 10% the planners can only select 41, 38, 37, and 33 roads out of total 42 roads. Maximum budget utilized is 750004.05₹, 548,531.43₹, 328,606.43₹, and 103,980.53₹ and enhancement in average network PCR rating up to 2.53, 2.42, 2.37, and 2.20 respectively.

The proposed methodology will be very helpful for pavement maintenance planners to plan their maintenance schedule in a scientific manner. It has incorporated all the challenges of maintenance planning in rural hill roads and makes the complex task of maintenance planning easier and more scientific. Future studies can compare the present study with some other conventional stochastic optimization techniques or neuro-dynamic programming to enhance the quality of the model. The case study has been used only to demonstrate the functionalities of the proposed methodology. The steps in the methodology can be followed in any other region/country and a similar maintenance plan can be developed using available software tools. The minor differences in data collection, specific major pavement defects, available pavement treatment techniques, budget allocation for optimization, etc. may be suitably adjusted during the maintenance planning.

References

World Bank, India Transportation, (2011). https://www.worldbank.org/en/news/feature/2011/09/23/india-transportation (accessed March 8, 2022).

A. Nautiyal, S. Sharma, A model to compute service life of rural roads using present pavement condition and pavement age, Compusoft. 8 (2019).

Han, B., Ling, J., & Zhao, H. (2016). Environmental Impacts of Different Maintenance and Rehabilitation Strategies for Asphalt Pavement. Transportation Research Congress 2016: Innovations in Transportation Research Infrastructure. https://doi.org/10.1061/9780784481240.033

Huang, M., Dong, Q., Ni, F., & Wang, L. (2021). LCA and LCCA based multi-objective optimization of pavement maintenance. Journal of Cleaner Production, 283, 124583. https://doi.org/10.1016/J.JCLEPRO.2020.124583

Nautiyal, A., & Sharma, S. (2021). Scientific approach using AHP to prioritize low volume rural roads for pavement maintenance. Journal of Quality in Maintenance Engineering. https://doi.org/10.1108/JQME-12-2019-0111/FULL/PDF

MORTH, Annual report 2020–21 Bhartmala road to prosperity, NEW DELHI, 2021. https://morth.nic.in/sites/default/files/Annual Report - 2021 (English)_compressed.pdf (accessed May 9, 2022).

FHWA, FHWA FY 2019 Budget, Federal Highway Administration, Washington, D.C., 2019. https://www.fhwa.dot.gov/cfo/fhwa-fy-2019-cj-final.pdf (accessed March 8, 2022).

Rejani, V. U., Sunitha, V., Mathew, S., & Veeraragavan, A. (2021). A network level pavement maintenance optimisation approach deploying GAMS. International Journal of Pavement Research and Technology, 2021, 1–13. https://doi.org/10.1007/S42947-021-00058-6

Business Standard, 70% Indians live in rural areas: Census | Business Standard News, Press Trust India. (2013). https://www.business-standard.com/article/economy-policy/70-indians-live-in-rural-areas-census-111071500171_1.html (accessed March 7, 2022).

Chundi, V., Raju, S., Waim, A. R., & Swain, S. S. (2021). Priority ranking of road pavements for maintenance using analytical hierarchy process and VIKOR method. Innovative Infrastructure Solutions, 71, 1–17. https://doi.org/10.1007/S41062-021-00633-7

Nautiyal, A., & Sharma, S. (2022). Methods and factors of prioritizing roads for maintenance: a review for sustainable flexible pavement maintenance program. Innovative Infrastructure Solutions. https://doi.org/10.1007/S41062-022-00771-6

IRC:82–2015, Indian Roads Congress Code of Practice for Maintenance of Bituminous Road Surface, First revision, Indian Road Congress, New Delhi, India, 2015.

IRC:130–2020, Guidelines for Road Asset Management System, Indian Road Congress, New Delhi, India, 2020.

IRC:64–1990, Guidelines for Capacity of Roads in Rural Areas , First edit, Indian Road Congress, New Delhi, India, 1990.

IRC:SP:20–2002, Rural Road Manual, SpecialEdition20 ed., Indian Road Congress, New Delhi India, 2002.

N. Attoh-Okine, O. Adarkwa, Pavement Condition Surveys-Overview of Current Practices, DuPont HallNewark, Delaware 19716, 2013.

Nautiyal, A., & Sharma, S. (2021). Condition Based Maintenance Planning of low volume rural roads using GIS. Journal of Cleaner Production, 312, 127649. https://doi.org/10.1016/J.JCLEPRO.2021.127649

Wang, Y., Wang, G., Asce, M., & Mastin, N. (2012). Costs and effectiveness of flexible pavement treatments: experience and evidence. Journal of Performance of Constructed Facilities, 26, 516–525. https://doi.org/10.1061/(ASCE)CF.1943-5509.0000253

Ouma, Y. O., Opudo, J., & Nyambenya, S. (2015). Comparison of fuzzy AHP and fuzzy TOPSIS for road pavement maintenance prioritization: Methodological Exposition and Case Study. Advances in Civil Engineering. https://doi.org/10.1155/2015/140189

U. Uknowledge, D.J. Michels, Pavement Condition Index and Cost of Ownership Analysis on Preventative Maintenance Projects in Kentucky, Theses Diss. Eng. (2017). https://doi.org/10.13023/ETD.2017.084.

Torres-Machi, C., Pellicer, E., Yepes, V., & Chamorro, A. (2017). Towards a sustainable optimization of pavement maintenance programs under budgetary restrictions. Journal of Cleaner Production, 148, 90–102. https://doi.org/10.1016/J.JCLEPRO.2017.01.100

HPPWD, Govt of Himachal Pradesh Rural Roads Maintenance Policy 2015, Shimla , 2015.

Chen, X., Zhu, H., Dong, Q., & Huang, B. (2017). Optimal thresholds for pavement preventive maintenance treatments using LTPP data. Journal of Transportation Engineering, Part A: Systems, 143, 04017018. https://doi.org/10.1061/JTEPBS.0000044

Q. Dong, B. Huang, Cost-Effectiveness Evaluation of Pavement Maintenance Treatments by OPTime, Paving Mater. Pavement Anal 2010. https://doi.org/10.1061/41104%28377%2955

Torres-Machí, C., Chamorro, A., Pellicer, E., Yepes, V., & Videla, C. (2015). Sustainable pavement management: integrating economic, technical, and environmental aspects in decision making, Transp. Res. Transportation Research Record: Journal of the Transportation Research Board, 2523, 56–63. https://doi.org/10.3141/2523-07

Yao, L., Dong, Q., Fujian Ni, J., Jiang, Xianrong Lu, & Du, Y. (2019). Effectiveness and cost-effectiveness evaluation of pavement treatments using life-cycle cost analysis. Journal of Transportation Engineering, Part B: Pavements, 145(2), 04019006. https://doi.org/10.1061/JPEODX.0000106

Yepes, V., Torres-Machi, C., Chamorro, A., & Pellicer, E. (2016). Optimal pavement maintenance programs based on a hybrid greedy randomized adaptive search procedure algorithm. Vilnius Gedim Tech Univ, 22, 540–550. https://doi.org/10.3846/13923730.2015.1120770

Zhou, B., Zhang, C., Tsai, J., Guo, X., & Zhou, X. (2013). Asphalt pavement maintenance technologies evaluation model based on “economic-benefit” index, procedia - Soc. Behavioral Science, 96, 2115–2122. https://doi.org/10.1016/J.SBSPRO.2013.08.238

Marcelino, P., de Lurdes Antunes, M., Fortunato, E., & Gomes, M. C. (2021). Machine learning approach for pavement performance prediction. International Journal of Pavement Engineering, 22, 341–354. https://doi.org/10.1080/10298436.2019.1609673

R.L. Lytton, From Ranking to True Optimization, Moderators Report., in: Irst North Am. Pavement Manag. Conf. Toronto, CANADA, Toronto, 1985.

N. Li, W. Xie, R. Haas, A new application of Markov modeling and dynamic programming in pavement management, in: Proc., 2nd Int. Conf. Road Airf. Pavement Technol., 1995: pp. 683–691.

T.F. Fwa, R. Shanmugam, Fuzzy logic technique for pavement condition rating and maintenance-needs assessment, in: 4th Int. Conf. Manag. Pavements , 1998.

Camahan, J. V., Davis, W. J., Shahin, M. Y., Keane, P. L., & Wu, M. I. (1987). Optimal maintenance decisions for pavement management. Journal of Transportation Engineering, 113, 554–572. https://doi.org/10.1061/(ASCE)0733-947X(1987)113:5(554)

OECD, Organization for economic cooperation and development , pavement manag. Syst. (1987).

Fwa, T. F., Chan, W. T., & Hoque, K. Z. (2000). Multiobjective optimization for pavement maintenance programming. Journal of Transportation Engineering, 126, 367–374. https://doi.org/10.1061/(ASCE)0733-947X(2000)126:5(367)

Picado-Santos, L., Ferreira, A., Antunes, A., Carvalheira, C., Santos, B., Bicho, M., Quadrado, I., & Silvestre, S. (2004). Pavement management system for Lisbon. Proceedings of the Institution of Civil Engineers: Municipal Engineer, 157, 157–165. https://doi.org/10.1680/MUEN.2004.157.3.157/ASSET/IMAGES/SMALL/MUEN157-157-F8.GIF

Ferreira, A., De Picado-Santos, L., Wu, Z., & Flintsch, G. (2011). Selection of pavement performance models for use in the Portuguese PMS. International Journal of Pavement Engineering, 12, 87–97. https://doi.org/10.1080/10298436.2010.506538

Fwa, T. F., Tan, C. Y., & Chan, W. T. (1994). Road-maintenance planning using genetic algorithms II: Analysis. Journal of Transportation Engineering, 120, 710–722. https://doi.org/10.1061/(ASCE)0733-947X(1994)120:5(710)

C. Yang, R. Remenyte-Prescott, J.D. Andrews, (2015) Pavement maintenance scheduling using genetic algorithms. International Journal of Performability Engineering 11.

Goldberg DE., Genetic Algorithms in Search, Optimization and Machine Learning, S.I. Addism Wesley Longman (1989).

M. Gen, R. Chen, Genetic Algorithms (Engineering Design and Automation), (2001).

Miyamoto, A., Kawamura, K., & Nakamura, H. (2000). Bridge Management System and Maintenance Optimization for Existing Bridges. Computer-Aided Civil and Infrastructure Engineering, 15, 45–55. https://doi.org/10.1111/0885-9507.00170

E.K.P. Chong, H. Stanislaw, An introduction to optimization, 4th ed., John Wiley & Sons, Inc., Hoboken, New Jersey, 2014. http://www.lewissoft.com/pdf/INTRO_OPT.pdf (accessed March 7, 2022).

Stephenson, W. (1931). Number—the language of science. by Tobias Dantzig. London: George Allen & Unwin Ltd, 1930. Large crown 8vo Pp 260 Price 10s. Journal of Mental Science, 77, 843–843. https://doi.org/10.1192/BJP.77.319.843

Gao, L., & Zhang, Z. (2013). Management of Pavement Maintenance, Rehabilitation, and Reconstruction through Network Partition: Transp. Transportation Research Record: Journal of the Transportation Research Board, 2366, 59–63. https://doi.org/10.3141/2366-07

Yoo, J., & Garcia-Diaz, A. (2008). Cost-effective selection and multi-period scheduling of pavement maintenance and rehabilitation strategies. Engineering Optimization, 40, 205–222. https://doi.org/10.1080/03052150701686937

Acknowledgements

The work presented in this paper was supported by State Council for Science, Technology & Environment (SCSTE), through financial support to carry out this research. The author would like to thank pavement maintenance planners of PMGSY and Himachal Pradesh Public Works Department (HPPWD) road maintenance engineers for their valuable expert advice and guidance.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no conflict of interest.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Nautiyal, A., Sharma, S. Cost-Optimized Approach for Pavement Maintenance Planning of Low Volume Rural Roads: A Case Study in Himalayan Region. Int. J. Pavement Res. Technol. 17, 335–352 (2024). https://doi.org/10.1007/s42947-022-00239-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42947-022-00239-x