Abstract

Due to its unique electronic structure and special size effect, two-dimensional (2D) nanomaterials have shown great potential far beyond bulk materials in the field of photocatalysis. How to deeply explore the photocatalytic mechanism of 2D nanomaterials and design more efficient 2D semiconductor photocatalysts are research hotspots. This review provides a comprehensive introduction to typical 2D nanomaterials and discusses their current application status in the field of photocatalysis. The effects of material properties such as band structure, morphology, crystal face structure, crystal structure and surface defects on the photocatalytic process are discussed. The main modification methods are highlighted, including doping, noble metal deposition, heterojunction, thickness adjustment, defect engineering, and dye sensitization in 2D material systems. Finally, the future development of 2D nanomaterials is prospected. It is hoped that this paper can provide systematic and useful information for researchers engaged in the field of photocatalysis.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

With the development of science and technology, environmental pollution and energy shortage have become two major concerns of human beings. As a mild reaction, non-toxic, and reusable technology, photocatalysis can efficiently convert solar energy into chemical energy, and is considered to be one of the most forward-looking long-term solutions to global energy and environmental problems [1, 2].

As a promising technology, photocatalysis has been widely used in water treatment [3,4,5], hydrogen production by water splitting [6,7,8], CO2 reduction [9, 10], nitrogen fixation [11, 12], and organic synthesis [13, 14] (Fig. 1). Fujishima and Honda published a paper on TiO2 photoelectrochemical cells in 1972, showing that water can be decomposed into oxygen and hydrogen by visible light without any external voltage [15]. Since then, photocatalytic has come into public attention. In 1976, Carey et al. found that in the photocatalytic process of TiO2, polychlorinated biphenyl, haloalkane, etc. can be effectively photocatalytically degraded [16]. This has led to the realization that photocatalysis can provide new approaches for environmental governance. Schrauzer and Guth determined that water splitting does not require external energy except for light energy in 1977, and demonstrated that TiO2 can split water to generate H2 under ultraviolet (UV) light irradiation [17]. Nearly, 50 years of researches have also proved that photocatalytic technology can be effectively applied in environmental governance and energy conversion and has great development potential. Even studies have shown that photocatalysis can degrade almost all organic pollutants in water [18].

The principle of semiconductor photocatalyst is shown in Fig. 2: the energy band structure of semiconductor materials consists of a low-level valence band (VB) filled with electrons and a high-level conduction band (CB) that is not filled with electrons, and a gap called the forbidden band is located between the conduction band minimum (CBM) and valence band maximum (VBM). When the photocatalyst is irradiated by light with energy greater than or equal to the forbidden band width, the electrons in the VB absorb energy and transition to the CB, leaving holes in the VB, eventually forming “electron–hole pairs”, also known as “carriers”. Under the action of the space electric field, the electron–hole pairs partially migrate to the particle surface and participate in further catalytic reactions [19].

As the first semiconductor material to be applied to photocatalysis, TiO2 is a wide-bandgap semiconductor (3–3.2 eV), which can only absorb UV light with a wavelength less than 387 nm. UV light only accounts for 5% of sunlight, making TiO2 less efficient for sunlight. This makes TiO2 less than ideal in practice. At the same time, in the photocatalytic process, the high electron–hole pair recombination rate and low quantum efficiency also limit the photocatalytic activity of TiO2 [20]. Hoffmann et al. studied TiO2 in depth, and found that four processes are very important in the photocatalytic process: first, the spectral response range; second, whether the photogenerated electron holes can be effectively separated; the third is the speed at which electrons are transferred from the interior of an atom to the surface; the fourth is the strength of redox activity [21]. In order to better participate in the above four processes, the selection of semiconductor photocatalysts is the key to photocatalytic applications. High-efficiency photocatalysts must have a suitable bandgap to provide sufficient redox activity, excellent electron–hole separation ability, and visible-light response characteristics.

Aiming at these four key steps to improve the photocatalytic efficiency, two-dimensional (2D) nanomaterials have entered people’s field of vision as new photocatalysts. As shown in Fig. 3, carbon materials are used as an example to show different material structures from zero-dimensional (0D) to three-dimensional (3D) [22,23,24,25]. 2D nanomaterials refer to materials in which electrons can only move freely (plane movement) on the nano scale (1–100 nm) in two dimensions. Because of its unique thickness size and 2D structure characteristics, the intrinsic properties of the materials can be enhanced, resulting in many different properties from their corresponding 3D structures. For example, large specific surface area, porous surface with abundant reactive sites, good carrier mobility, good Young’s modulus, excellent electrical and thermal conductivity, and the advantages of easily forming new composite structures with other materials [26]. Meanwhile, this 2D structure can be assembled through spin processes or layer-by-layer, and layered artificial structures are created and designed on demand, with high flexibility in material design [27].

Reproduced with permission from Ref. [22]. Copyright 2018, Royal Society of Chemistry. Reproduced with permission from Ref. [23]. Copyright 2020, Elsevier. Reproduced with permission from Ref. [24]. Copyright 2017, ACS Publications. Reproduced with permission from Ref. [25]. Copyright 2020, Elsevier

Schematic diagram of material dimensions.

However, the practical application of 2D nanomaterials is still limited due to the easy agglomeration of powders, the small scale of preparation, and the uncontrollability. At the same time, too narrow or too wide bandgap of a single 2D nanomaterials will lead to problems such as insufficient redox capacity, narrow photoresponse range, and fast recombination of electron–hole pairs, resulting in poor photocatalytic performance. On this basis, scientists have further researched, proposed a variety of modification methods to improve the photocatalytic efficiency of 2D nanomaterials, and revealed their mechanisms. Due to the important position of 2D materials in the field of photocatalysis, some researchers have reviewed in detail the basic properties of 2D materials, the synthesis strategies of 2D materials, and the surface modification of 2D materials in recent years, providing many interesting perspectives [28,29,30,31,32,33].

Compared with previous reviews [28,29,30,31,32,33], in this review, we introduce the progress of various typical 2D materials in the field of photocatalysis in a more comprehensive and detailed manner. Unlike other reviews, which often explore the advantages of 2D materials in the field of photocatalysis from the perspective of photocatalytic processes such as light absorption, charge separation and transfer, this review discusses the influence of intrinsic characteristics of 2D materials (bandgap, morphology, facet structure, crystal structure and defects) on the photocatalytic process, revealing the advantages of 2D systems in photocatalysis. Afterwards, various modification methods (element doping, noble metal deposition, heterojunction, thickness tuning, defect engineering, and dye sensitization) are further discussed on the basis of the above-mentioned influencing factors. Finally, this review summarizes and looks forward to the main difficulties and potential solutions in the current 2D materials research, looking forward to helping readers think about the ideas of photocatalyst design.

2 Typical 2D nanomaterials

Typical 2D nanomaterials are shown in Fig. 4, which can be mainly divided into two aspects. One is graphene and its derivatives, the other is graphene-like 2D materials, such as 2D metal oxides [34, 35], hexagonal boron nitride (h-BN) [36, 37], transition metal dichalcogenides (TMDs) [38], carbonitrides [39, 40], black phosphorus (BP) [41], layered double hydroxides (LDHs) [42], 2D metal organic frameworks (MOFs) [43] and other layered materials with unique physical and chemical properties. In this section, we introduce the structure, properties, synthesis process and research progress of these materials, in order to help readers better understand the 2D material system.

2.1 Graphene and its derivatives

Since graphene was prepared by micromechanical exfoliation method [44] in 2004, it has attracted wide attention in the field of photocatalysis due to its outstanding mechanical, thermal, optical properties and appearance characteristics [45]. With the deepening of research, some new methods for preparing graphene have been proposed, such as mechanical exfoliation method, liquid phase exfoliation method (LPE), redox method, chemical vapor deposition method (CVD), and electrochemical exfoliation method. Among them, the exfoliation preparation process represented by the mechanical exfoliation method can obtain high-quality graphene, but it also has the disadvantages of small area and low yield. Although the synthesis process represented by CVD method can prepare large-area graphene, the defects generated during the growth process reduce the performance of graphene. How to combine the advantages of CVD and mechanical exfoliation is the main idea for large-scale preparation of high-quality, large-area graphene [46].

The basic structure of graphene is a honeycomb-shaped planar film formed by sp2 hybridization of carbon atoms, and its derivatives are graphene oxide (GO) and reduced graphene oxide (rGO). Due to its zero bandgap, graphene has excellent electrical conductivity, and has a wide spectral absorption range, including visible light and long-wave infrared, even to terahertz frequencies. At the same time, the special single-atom-layer planar structure enables it to have a high light transmittance (~ 97.7%), which can be combined with other catalysts without affecting the light absorption capacity of the photocatalyst. The theoretical specific surface area of graphene is as high as 2,630 m2·g−1, which can provide more redox active sites [47]. However, the zero bandgap of graphene also makes its redox reaction ability poor, which is not conducive to the photocatalytic reaction. Therefore, researchers often combine it with other wide-bandgap photocatalytic materials to form composites with excellent photocatalytic properties, thereby exerting the excellent optoelectronic properties of graphene. Zhang et al. prepared graphene/ZnO composites (GR/ZnO) by ball milling and LPE [48]. The bandgap test results show that the bandgap of the GR/ZnO is narrowed to 3.10 eV compared with pure ZnO. Under simulated sunlight irradiation, GR/ZnO exhibited significantly enhanced photocatalytic activity, which was 6 times higher than that of pure ZnO (Fig. 5). This study shows that the addition of graphene can effectively narrow the bandgap and improve the photocatalytic performance. Huang et al. composited flake BiFeO3 with graphene via a simple hydrothermal method. The composite material has excellent visible-light response, and the photocatalytic performance is greatly improved [49]. Zhang et al. prepared MoS2/N-doped graphene composites, which constituted a Z-scheme photocatalytic system composed by two narrow-bandgap semiconductors [50]. Its transformed bandgap extends the photoresponse to 1,550 nm, enabling the composite to effectively degrade NH3 under near-infrared irradiation. Although graphene can hardly be applied to photocatalysis independently due to the zero bandgap, Yang et al. found that coating a single layer of graphene on a metal co-catalyst can form a photocatalyst that can be applied to photocatalytic overall water splitting (POWS) [51]. Studies have shown that graphene plays an important role in suppressing the reverse action of H2 and O2. Importantly, among various types of graphene, γ-graphene (GY) is regarded as the graphene with the highest stability and semiconducting properties. It has a suitable optical bandgap (2.3 eV) and can be well applied in the field of photocatalysis [52]. Wu et al. prepared TiO2/MoSe2/GY ternary nanocomposites. GY acts as an electron collector and hole transfer channel, effectively separating photogenerated carriers [53].

Reproduced with permission from Ref. [48].Copyright 2021, Elsevier

a Schematic diagram of the preparation of GR/ZnO. b Ultraviolet–visible absorption spectra (UV–Vis absorption spectra) of ZnO–Polyvinyl alcohol (PVA) and GR/ZnO. c Light energy relationship diagram of ZnO–PVA and GR/ZnO. d Rate diagram of degradation of methylene blue (MB) and rhodamine B (RhB) by GR/ZnO under simulated sunlight, and e pseudo-first order kinetic curve.

More studies have shown that functionalized graphene-based analogs, such as GO, may be potential materials for photocatalysts, because the band structure of GO is related to its oxidation degree, its bandgap can be regulated during the preparation process [54, 55]. Yeh et al. used the modified Hummers method to prepare GO with a bandgap of 2.4–4.3 eV, and the results showed that it can be used as a photocatalytic catalyst for water splitting [56]. Under ultraviolet or visible-light irradiation, 20% Methanol aqueous solution and pure water can stably generate H2.

2.2 Graphene-like 2D materials

Graphene-like 2D materials are a general term for 2D single-layer or few-layer structural materials. There are many types of graphene-like materials, which exhibit superior surface properties compared with bulk materials due to their unique layered structure.

2.2.1 Metal oxides

In the past 4 decades, many metal oxides such as TiO2 [57, 58], ZnO [59, 60], SnO2 [61, 62], WO3 [63, 64], and Fe2O3 [65, 66] have been extensively studied as photocatalysts. Due to the obvious advantages of 2D materials in the field of photocatalysis compared with bulk materials, the research of metal oxide nanosheets is also widely carried out. Taking TiO2 as an example, the preparation methods of metal oxide nanomaterials mainly include CVD, sol–gel method, hydrothermal method, pulse laser deposition method (PLD) and sputtering method. Among them, the hydrothermal method is the most common method for preparing 2D TiO2 nanosheets, and PLD and laser sputtering method are commonly used to prepare thinner TiO2 films. Other methods are commonly used to prepare lower dimensional forms such as TiO2 nanorods and nanospheres. It is notable that by controlling the reaction temperature during CVD, different states of TiO2 from nanotubes to thin films can be obtained [67].

The 2D nanosheets of TiO2 are exfoliated from layered titanates and exhibit similar semiconductor properties to rutile and anatase TiO2. However, due to the reduced grain size, the bandgap of TiO2 nanosheets is slightly larger (~ 3.8 eV), which is larger than that of anatase TiO2 (~ 3.2 eV). This will lead to a decrease in the photoresponse range, which is not conducive to the photocatalytic reaction [68]. Studies have shown that photocatalytic performance of TiO2 nanosheets can be further improved by modifying it by doping or carrying a narrow-bandgap photocatalyst. Such as Liu et al. prepared transition metal modified TiO2 nanosheets by microwave-assisted hydrothermal method [69]. It is revealed that the addition of transition metals effectively narrows the bandgap of TiO2 (Fig. 6a). Through UV–Vis absorption spectra, it can be seen that TiO2 with transition metals has better visible-light absorption than pure TiO2 (Fig. 6b). The results of photoluminescence spectra (PL spectra) (Fig. 6c) show that the addition of transition metals reduces the intensity of TiO2, especially Cu/TiO2. The decrease in intensity indicates faster carrier transfer, which corresponds to the optimal photocatalytic nitrogen fixation performance of Cu/TiO2. Chen et al. prepared TiO2 nanosheets/NiO nanorods composites by a hydrothermal method (Fig. 6d) [58]. TiO2/NiO photocatalyst showed good MB degradation activity and hydrogen production efficiency under visible light, which were 12 times and 10 times that of TiO2 nanosheets. This is due to the construction of its p–n heterojunctions, which enhances interfacial charge transfer and light absorption (Fig. 6e). At present, TiO2-based nanocomposites have been studied in many fields such as sewage treatment, medical treatment, hydrogen energy, and CO2 reduction. It is worth pointing out that in the field of anti-cancer, TiO2 will have great potential due to its good biocompatibility and low toxicity.

Reproduced with permission from Ref. [69]. Copyright 2020, Royal Society of Chemistry. d The schematic diagram of the synthesis processes of TiO2/NiO. e The schematic diagram of the photocatalytic mechanism of TiO2/NiO. Reproduced with permission from Ref. [58] Copyright 2020, Elsevier. Degradation curves of MB by MnO2/Fe3O4 at different pH values f in the dark and g with UV−Vis light, h the speculated reaction principle of MnO2/Fe3O4 and MB under different pH values. Reproduced with permission from Ref. [71]. Copyright 2014, ACS Publications

a UV–Vis absorption spectra of transition metal modified TiO2 nanosheets. b The bandgap evaluation of transition metal modified TiO2 nanosheets. c PL spectra of transition metal modified TiO2 nanosheets.

In addition to TiO2, the nanoscale research on other traditional metal oxide catalysts has also achieved success. Wang et al. prepared oxygen-rich vacancy-defective ZnO nanosheets with tunable Brunauer–Emmett–Teller (BET) surface area [70]. The analysis showed that the oxygen-rich vacancies enhanced the visible-light absorption of the ZnO nanosheets, and the increase in the surface oxygen vacancy concentration was positively correlated with the BET surface area. Compared with ZnO with fewer oxygen defects, the rate of RhB degradation by oxygen-enriched ZnO under visible light is increased by about 11 times. Zhang et al. prepared MnO2/Fe3O4 nanocomposites [71]. The results show that the MnO2/Fe3O4 nanocomposite exhibits excellent photocatalytic performance and high stability when degrading MB under UV–Vis light (Fig. 6f, g). In addition to the light factor, the photocatalytic performance of MnO2/Fe3O4 also varied with pH, which was due to the different surface charge states at different pH (Fig. 6h). In addition, tests have shown that the MnO2/Fe3O4 nanocomposite is ferromagnetic and can be effectively separated by an external magnetic field, enabling reuse and being more environmentally friendly.

2.2.2 h-BN

h-BN is a graphene-like hexagonal structure formed by covalently connecting N atoms and B atoms in equal proportions. It has a honeycomb lattice structure similar to graphene, so it is called “white graphite” and has excellent physical properties and surface atomic flatness [72, 73]. Since h-BN is an insulator with a bandgap of 6 eV and lacks dangling bonds on the surface, h-BN was studied as an ideal substrate and insulating layer for other 2D materials in the early stages of research [74]. As the research progressed, it was found that the bandgap of h-BN is very sensitive to size, thickness and defects. Meanwhile, h-BN has a high specific surface area and excellent conductivity [75]. Moreover, although h-BN is an insulator, its (002) crystal plane has abundant active sites, which can effectively participate in the photocatalytic process [76]. The above advantages have led researchers to explore the application of h-BN in photocatalysis. Currently, the mainstream methods for preparing h-BN include mechanical exfoliation, solvothermal, CVD, and molecular beam epitaxy (MBE). Due to the advantages of high quality and large scale, CVD has become the main preparation method of h-BN. At the same time, CVD also has excellent performance for the preparation of h-BN heterostructures [77].

In practical photocatalytic applications, due to the wide bandgap of h-BN, it is necessary to modify h-BN by defect engineering, doping or building a heterojunction structure to realize its application in the field of catalysis [78,79,80]. It is found that combining wide-bandgap h-BN with zero-bandgap graphene into an in-plane heterostructure is an effective approach to design efficient photocatalysts. Bevilacqua et al. used density functional theory (DFT) to study the stability and optical properties of monolayer h-BN when doped with graphene [81]. The results show that graphene (h-BNC) doped with wide-bandgap h-BN nanodomains exhibits a non-zero gap, and the width of its bandgap is related to the number of BN nanodomains. Therefore, by doping h-BN with graphene, the h-BNC that can respond to visible light can be obtained, which is a promising photocatalytic material. Besides graphene, h-BN can also be combined with other 2D materials to form photocatalysts. Li et al. constructed TiO2/h-BN composite photocatalysts with TiO2 nanosheets and h-BN nanosheets by a solvothermal method. The photocatalyst has greatly improved the degradation efficiency of rhodamine B, which is 6.9 times that of commercial TiO2 [82]. Wang et al. prepared a composite photocatalyst of h-BN and g-C3N4 quantum dots. Due to the large specific surface area and good electron-harvesting properties of h-BN, h-BN/g-C3N4 has excellent photocatalytic performance [83].

2.2.3 Transitional metal dichalcogenides (TMDs)

TMDs are compounds composed of transition metal elements and chalcogen elements (S, Se or Te). The basic expression of TMDs is MX2, where M is a transition metal and X is a chalcogen (Fig. 7a). The layers of TMDs are connected by weak van der Waals forces, which can be easily peeled from the bulk phase to a single sheet [38]. As Fig. 7b shows, depending on the coordination of elements and the stacking order of the lamellae, TMDs can form a variety of crystalline polytypes: 1T, 2H, and 1T’ [84], exhibiting different electronic properties from metals to semiconductors [85, 86]. TMDs exhibit excellent electronic, optical, and physicochemical properties, which mainly have the advantages of high electrical conductivity, narrow bandgap, abundant active sites, abundant earth reserves, and low cost [87,88,89]. At the same time, it is found that the theoretical catalytic performance of TMDs is second only to the noble metal Pt and some transition metals, which has great research value [90, 91].

Reproduced with permission from Ref. [84]. Copyright 2023, John Wiley and Sons. c Evolution of the band structure of 2H‑MoS2 calculated for samples of decreasing thickness. Reproduced with permission from Ref. [96]. Copyright 2017, Springer Nature. d Schematic diagram of direct band gap and indirect band gap. Reproduced with permission from Ref. [97]. Copyright 2020, ACS Publications. e Scanning electron microscope image of U-CN/MoS2-3. f Histograms of hydrogen production for different ratios of U-CN/MoS2. g Heterojunction mechanism of U-CN/MoS2 photocatalyst. Reproduced with permission from Ref. [106]. Copyright 2019, Elsevier

a Composition of TMDs. b Schematic models of different phases of TMDs.

Most TMDs materials have typical bandgap tunable properties, such as MoS2 [92], MoSe2 [93], WSe2 [94] and WS2 [95]. According to DFT, as shown in Fig. 7c, the band structure of 2H-MoS2 will evolve as it decreases from bulk layer to monolayer [96]. As the thickness decreases, the positions of VB and CB change, from an indirect bandgap semiconductor to a direct bandgap semiconductor. The difference between the two bandgaps is shown in Fig. 7d [97]. At present, the main methods for preparing 2D TMDs include mechanical exfoliation, LPE, CVD, and wet chemical synthesis. The above traditional methods have been widely used in the preparation of various TMDs materials. Yang et al. reviewed the preparation methods of TMDs materials in detail [84]. It is noteworthy that the electrochemical Li-ion intercalation method has been creatively proposed in recent years. This method can produce atomically thin TMDs nanosheets on a large scale and with high yield, and has been widely applied to the preparation of various TMDs materials [98].

As the most representative material among TMDs materials, MoS2 is a hexagonal layered crystal structure, and each unit is a “sandwich” structure of S-Mo-S. The common crystal forms are 1T, 2H and 3R, of which the 2H crystal form is the most stable. Although some studies have revealed that the metal phase 1T-MoS2 exhibits better photocatalytic performance, the research on 2H-MoS2 catalysts is still the mainstream due to the requirement of stability in practical applications [99,100,101]. The bandgap of bulk MoS2 is too small, only 1.2 eV, which cannot provide sufficient oxidation/reduction potential to activate the photocatalytic process. The single-layer MoS2, due to the conversion of indirect bandgap to direct bandgap, has an increased forbidden band width to about 1.96 eV, which can be used as a photocatalyst [102, 103]. However, due to its still narrow bandgap, the oxidizing ability is weaker when used alone. The edge potentials of the CB and VB of MoS2 are higher than those of most photosensitive semiconductors, and the potential difference between the CB of MoS2 and other semiconductor materials can promote the transfer of electrons to MoS2, thereby effectively separating the carriers. At the same time, MoS2 can be used as a substitute for noble metals in the hydrogen evolution reaction and become a co-catalyst for the hydrogen evolution reaction [104, 105]. Therefore, MoS2 is generally used as a co-catalyst or carrying other semiconductor photocatalytic materials to form a heterojunction to improve the photocatalytic performance. Li et al. prepared ultrathin C3N4/MoS2 heterojunction photocatalysts (U-CN/MoS2) [106]. The results show that the photocatalyst activity is significantly improved after MoS2 is supported on C3N4 to form a heterojunction (Fig. 7e). The best photocatalytic hydrogen production efficiency can reach 385.04 μmol·h−1·g−1 (Fig. 7f). The photocatalytic mechanism of U-CN/MoS2 is shown in Fig. 7g. When U-CN/MoS2 is illuminated, the electrons on VB of both materials are excited to CB. Under the action of the heterojunction, the electrons on the CB of U-CN are transferred to the CB of MoS2, and the holes on the VB of MoS2 are transferred to the VB of U-CN at the same time. This process realizes the effective separation of electrons and holes, which promotes the improvement of photocatalytic activity.

In addition to MoS2, other TMDs materials have also shown excellent performance in the field of photocatalysis. Kou et al. grew TiO2 on MoSe2 nanosheets [107]. Under visible light, the hydrogen production rate of MoSe2/TiO2 is much higher than that of pure MoSe2 and TiO2. The study shows that the increase in the hydrogen production rate is attributed to the MoSe2 promoting the absorption of visible light and the high charge separation efficiency of the MoSe2/TiO2 interface. Zhang et al. synthesized WSe2 nanosheets with a thickness of 0.7 nm by a colloidal method [108]. The results show that the synthesized WSe2 nanosheets can efficiently catalyze the aerobic coupling reaction of amines and imines under visible-light irradiation, verifying the possibility of TMDs being applied in various catalytic processes.

2.2.4 Graphitic carbon nitride (g-C3N4)

As a semiconductor material, the catalytic hydrogen evolution performance of g-C3N4 was not discovered until 2008 by Wang et al. and it is the first non-metal organic semiconductor photocatalytic material with visible-light response in the field of photocatalysis with a suitable bandgap (2.7 eV) [109]. Since bulk g-C3N4 is formed by stacking 2D structures, g-C3N4 nanosheets can be obtained by exfoliating bulk g-C3N4. Studies have shown that the photocatalytic performance of g-C3N4 nanosheets is significantly improved compared with that of bulk g-C3N4, and are only composed of C and N elements, which will not cause metal pollution and are environmentally friendly [110]. The main methods for preparing bulk g-C3N4 include thermal polycondensation, hydrothermal method, template method and ball milling method. Among them, the preparation of g-C3N4 by thermal polycondensation of nitrogen-rich precursors is the most commonly used [111]. However, g-C3N4 prepared by this method is rich in defects due to incomplete deamination during calcination. Relatively speaking, the template method can effectively regulate the structural characteristics such as porosity and specific surface area of g-C3N4 through appropriate templates. However, the residual template will have a great impact on the photocatalytic performance of g-C3N4, and it also has a more cumbersome process. In response to the above problems, the researchers considered improving the structural defects by pretreatment of the nitrogen-rich precursor before calcination. If the precursor is treated with acid, the van der Waals force between the layers is weakened, which is beneficial to obtain thinner g-C3N4 sheets [112].

The photocatalytic activity of pure-phase g-C3N4 still needs to be improved due to the limitations of low quantum rate, fast recombination of photogenerated carriers, and insufficient response to visible light above 460 nm [113]. Generally, the photocatalytic activity of g-C3N4 can be enhanced by modification methods such as doping, noble metal deposition, and construction of heterojunctions. Peng et al. synthesized a ternary composite photocatalyst CdS/Au/g-C3N4 [114]. Due to the deposition of CdS and Au on the surface of g-C3N4, two different structures, CdS–g-C3N4 and CdS@Au-g-C3N4, were formed (Fig. 8a, b). Meanwhile, there is a strong interaction between the three components, so compared with the binary composites CdS/g-C3N4, Au/g-C3N4 and pure g-C3N4, the photocatalytic activity of CdS/Au/g-C3N4 for RhB degradation was significantly enhanced under visible-light irradiation. Zhang et al. prepared Mn-adsorbed g-C3N4 [115]. The change in electronic structure caused by the stable bond between Mn and N atoms makes the photocatalytic performance of Mn-adsorbed g-C3N4 three times that of pristine g-C3N4. Cao et al. introduced nitrogen vacancies (NVs) into n-type g-C3N4 to construct a p-n heterojunction, which significantly improved the photocatalytic degradation activity of g-C3N4 [116]. Introducing appropriate functional groups into the g-C3N4 framework is also an effective strategy to enhance the photocatalytic activity. Wang et al. designed a simple KOH-assisted sealing heating process to tune the electronic structure of g-C3N4 [117]. The introduction of cyano groups increases the charge carrier density of g-C3N4, reduces the surface transfer resistance, promotes charge separation and transfer, and improves the photocatalytic hydrogen production performance.

Reproduced with permission from Ref. [114]. Copyright 2016, Royal Society of Chemistry

a CdS–g-C3N4 heterojunction. b CdS@Au–g-C3N4 heterojunction.

2.2.5 2D elemental material

2D elemental materials include 2D main group elements and 2D transition metals. In the field of catalysis, BP is one of the most concerned 2D elemental materials. BP is an allotrope of phosphorus with a monolayer pleated honeycomb structure. It was first extracted from white phosphorus in 1,914 under high pressure and moderate temperature (200 ℃), showing high density and good conductivity [118]. However, the high-pressure conditions of this method limit the development of this method. In 2007, a simple method for preparing BP by catalyzing red phosphorus was proposed, which further promoted the practical application of BP [119]. The current mainstream methods for preparing BP mainly include “top-down” methods such as mechanical exfoliation, LPE, and electrochemical exfoliation. BP is highly sensitive to substrates, so the “bottom-up” preparation of BP remains a challenge [120]. BP nanosheets have a flexible and tunable bandgap (0.3–2.0 eV), which increases with the decrease of the number of layers, 2D ultrathin structure and large specific surface area. These features can enhance the adsorption of photocatalysts, increase the number of active sites, and effectively improve the catalytic performance [121, 122]. At present, the latest research published in Nature has revealed a significant change in the shape of the VB of BP when it receives light radiation, which will provide a solid theoretical basis for its further application in many fields such as catalysis [123]. The narrow bandgap of BP enables it to absorb a large amount of visible light and even near-infrared light, but at the same time, it does not have enough driving force to participate in the photoreaction. Another limitation of BP is that it is unstable in the atmospheric environment, and usually requires the deposition of a coating on the surface to improve its stability [124]. Although monolayer BP has excellent theoretical photocatalytic activity, few experiments have proved the photocatalytic performance of pure BP, and researchers often combine it with other materials. It was not until 2017 that Zhu et al. prepared BP nanosheets with a size of 300–500 nm by ball milling [125]. The hydrogen evolution rate was 512 μmol·h−1·g−1, which was superior to g-C3N4.

In addition to BP, bismuth (Bi), a group V element, is also a popular element 2D material, which has the characteristics of metal and semiconductor. Bi-based semiconductor photocatalysts have been widely used in the field of catalysis due to their unique electronic, optical, magnetic, and structural properties. Unlike metal oxides such as TiO2, the VB of Bi is formed by the hybridization of Bi 6s and O 2p orbitals, which effectively shortens the semiconductor band gap and is more conducive to the absorption of visible light [28]. At present, researchers have synthesized many Bi-based photocatalysts, such as bismuth oxide (Bi2O3), bismuth oxyhalide (BiaObXc, where X = Cl, Br or I), and Bi-based polymetallic salts (BiVO4, Bi2WO6, and Bi2MoO6, etc.). By adjusting the parameters to prepare Bi-based photocatalysts with ultrathin structures, materials with more excellent photocatalytic properties will be obtained. Its main preparation methods include exfoliation, solvothermal, colloidal synthesis, and CVD growth [126].

In addition to 2D Bi-based materials, the bismuthene exfoliated from bulk bismuth also has excellent 2D ultrathin structures. However, due to the diamond structure of bulk Bi, the layers may not be completely connected by weak van der Waals force, so it is difficult to prepare bismuthene by traditional mechanical exfoliation and ultrasonic exfoliation. Generally, it is prepared by other methods such as high-temperature hydrothermal and LPE [127]. Yu et al. successfully prepared Bi-nanobelts (~ 20 nm) through high-temperature hydrothermal synthesis [128]. Yang et al. designed a method for preparing bismuthene by sulfuric acid intercalation exfoliation, and finally successfully exfoliated bulk Bi into thin bismuthene materials [129]. Hussain et al. used a simple mechanical route to successfully prepare Bi-nanosheets (~ 2 nm) on highly polished silicon substrates by hot pressing [130]. Sun et al. prepared bismuthene nanosheets by LPE. They ground crystalline Bi for 5 h, then dispersed and centrifuged, and finally successfully prepared bismuthene nanosheets with a thickness of about 4 nm [131].

2.2.6 MOFs and covalent organic frameworks (COFs)

MOFs are a class of 2D materials composed of metal ions or metal clusters and organic ligand molecules. Due to their tunable metal centers and functionalizable ligands, MOFs can have diverse basic building blocks, monodisperse metal sites and organic ligands, and thus can form crystal structures with different space groups. At the same time, MOFs also have a periodic arrangement structure, a precisely controlled pore structure, and a high specific surface area. Compared with bulk materials, 2D MOFs nanosheets have more unsaturated coordination bonds and active centers, and have better catalytic performance [132, 133]. Due to the variability of the crystal structure of 2D MOFs, the electronic structure of MOFs can be adjusted by the construction of vacancies, which can cause atomic arrangement distortion, charge density redistribution, and generate a large number of active sites. Zou et al. constructed MOFs with abundant vacancies by pyrolyzing specific functional groups [134]. The results showed that the MOFs maintained the framework structure and more active sites were exposed. The electronic structure is optimized to facilitate the uniform formation of site angles along the defect interface. After fusion of metal phosphides with defective MOFs, they exhibit low overpotentials and long-term oxygen evolution reaction (OER) stability. The excellent electrochemical performance is mainly attributed to vacancies, which enlarge the electrochemically active surface area and accelerate the charge-transfer rate. On the other hand, due to their functionalizable ligands, MOFs can also improve light absorption properties by introducing large conjugated ligands, dual ligands and other ligand engineering methods. Degaga et al. investigated the structure–property relationship of pristine and functionalized zinc benzene-1,3,5-tricarboxylate (Zn-BTC) MOFs using DFT [135]. Figure 9a shows different Zn-BTC MOFs unit-cells constituted from the coordinatively saturated and unsaturated secondary building unit (SBU) and the organic linker BTC for pristine, amino-functionalized (–NH2), and cyano-functionalized (–CN) MOFs. Density of state (DOS) calculations revealed the variation of VBM and CBM of the Zn-BTC constituted from the coordinatively unsaturated SBU(Zn-BTCU)and their relative relationship with the Fermi level (Fig. 9b). Figure 9c shows the relative positions of VBM and CBM of pristine and functionalized Zn-BTCU MOFs. It is not difficult to see, the –NH2 can lead to an upward shift of the band edge, and the –CN leads to a shift of the band edge in the opposite direction, which narrows the bandgap and tunes the light absorption properties. This variation is due to the inhomogeneous distribution of N 2p and C 2p states at the band edge introduced by functionalizations.

Reproduced with permission from Ref. [135]. Copyright 2019, Royal Society of Chemistry

a Multiple structures of Zn-BTC (Zn3(BTC)2) MOFs combined with different ligands. b DOS calculation of Zn-BTCU MOFs with unsaturated SBU. c Relative positions of the VBM and CBM of pristine and functionalized Zn-BTCU MOFs. (PDOS: partial density of states)

Notably, not all MOFs are suitable for photocatalytic water splitting. MOFs suitable for photocatalytic decomposition should satisfy three requirements: (1) low bandgap energy and suitable band edges, (2) water-stability, and (3) high conjugation backbone [136]. Meanwhile, the stability of MOFs in practical applications is related to the bonding strength between metal clusters and organic ligands. At present, the mainstream MOFs materials used in the field of photocatalysis are: Zeolitic imidazolate framework -67 (ZIF-67) [137, 138], Materials of Institut Lavoisier -125 (MIL-125) [139, 140], University of Oslo -66 (UIO-66) [141, 142], etc.

Since MOFs have strict requirements on the reaction environment, COFs have been proposed as their alternative materials. COFs are porous crystalline materials composed of organic units composed of light elements (C, N, B, etc.) covalently linked. They have the same low density and high specific surface area and are easy to functionalize as MOFs [143]. The design principle of COFs is to use covalent or non-covalent bonds to integrate structural units to form an extended structure in the internal space of the material. Since covalent bonds can be designed in advance, COFs have the conditions for directional design of pore structures, and various functional groups such as alkyl, phenyl, fullerene, acid, amine, organic groups can be integrated into the pore structure of COFs, thereby realizing rich functional applications [144]. Fuerte-Diez et al. prepared novel covalent triazine frameworks (CTFs) containing phenyl-extended naphthalene units [145]. This metal-free heterogeneous photocatalyst exhibits high chemical stability for selective aerobic oxidation and dehydrogenation cross-coupling reactions of sulfides under visible-light irradiation.

2.2.7 LDHs

LDHs, also known as hydrotalcite-like compounds, are a kind of 2D nanomaterials with a chemical composition of \({{[\mathrm{M}}_{1-x}^{2}{\mathrm{M}}_{x}^{3+}{\left(\mathrm{OH}\right)}_{2}]}^{x+}{({\mathrm{A}}^{n-})}_{x/n}\cdot {\mathrm{mH}}_{2}\mathrm{O}\), where M2+ and M3+ represent divalent and trivalent metal cations, respectively (such as Mg2+ and Al3+ and transition metal elements, Fe2+, Co2+, Ni2+, Zn2+, Cr3+, Fe3+, etc.), and An− represent interlayer anions(such as NO3−, CO32− and SO42−) [146, 147]. The structures of LDHs are shown in Fig. 10. Due to the diversity of cations and interlayer anions, LDHs have large interlayer spacing, so they are easy to exfoliate, and easy to combine with other materials to achieve specific functional designs. LDHs can be produced naturally or synthesized in the laboratory. At present, the main methods for preparing LDHs include co-precipitation, urea hydrolysis, ion exchange, hydrothermal and electrodeposition. The co-precipitation method is the most important preparation method of LDHs. By adjusting the pH values, temperature, solution concentration and precipitation time during the precipitation process, the control of the nucleation process of LDH materials can be realized [148]. The hydrothermal method is also often used in the preparation of LDHs materials. Compared with the co-precipitation method, the synthesized LDHs have the advantages of large area, good crystallinity, uniform shape and fine particles [149]. At the same time, the LDHs prepared by the hydrothermal method have a narrower bandgap (~ 2.6 eV) and structural advantages, which can be better used in photocatalysis [150].

Reproduced with permission from Ref. [147]. Copyright 2019, John Wiley and Sons

Schematic diagram of the structure of LDH.

At present, LDHs have shown great potential in the fields of supercapacitors, secondary batteries and catalysis. By regulating the M2+ and M3+ cations, the energy bandgap of LDHs ranges from 2.0 to 3.4 eV, which can improve the absorption of visible light, and generally does not introduce additional carrier recombination centers. The chemical composition of the inorganic compound layer and the intercalation layer of LDHs is highly tunable, which can effectively control the position of the catalytic active site, the activation mode of the photocatalytic reaction and the product selectivity. With the decrease of the number of LDHs layers, the thickness decreases continuously, which shortens the migration paths of photogenerated electrons and holes, and can effectively inhibit the recombination of photogenerated electrons and holes [151]. Li et al. briefly introduced the influence of the structural features of LDHs on the photocatalytic process and clarified the flexible and tunable properties of LDHs [152]. Based on the structural tunability of LDHs, researchers have carried out many studies on their ion composition. Starukh et al. prepared Zn-Al LDHs [153]. The results show that the photocatalytic activity of Zn-Al-LDHs for MB degradation under UV light originates from the existence of ZnO phase, and the content of ZnO can be adjusted by changing the Zn/Al ratio and heating temperature. Thus, its photocatalytic activity can be regulated. In addition to adjusting the composition of metal ions, Su et al.’s study showed that ZnAl-LDHs with different anions showed different photocatalytic nitrogen reduction activities, which means that the performance of LDHs can also be adjusted by adjusting the interlayer anions [154].

2.2.8 MXenes

MXenes are a new type of ultrathin 2D nanomaterials with great application potential, which contain a large number of transition metal carbides and carbonitrides. MXenes were discovered and synthesized by Gogotsi’s group and Barsoum’s group in 2011 [155]. Unlike graphene and phosphorene, which have natural 3D precursors of graphite and BP, respectively, MXenes have no direct 3D precursors in nature. In contrast, MXenes multilayer flakes are usually produced by selective removal of the A layer in the MAX phase [156]. The specific process is to use selective etching to etch the A atomic layer in the MAX phase to weaken the bonding between the layers, and then peel off the single-layer nanosheets by intercalation peeling or ultrasonic-assisted liquid phase peeling, and stably dispersed in a specific solvent [157,158,159]. Since the precursor of this new ultrathin 2D material comes from the MAX phase of the ternary layered ceramic material and exhibits properties similar to graphene, after unifying the names of the MAX phase and graphene, the newly discovered materials are named MXenes [160]. The general formula of the MAX phase is Mn+1AXn, where “M” refers to an early transition metal, “A” refers to a main group element, “X” means C or N, and n = 1–4. Compared with the single-atom structure of graphene and the metallic bond between C–C, the M and X atoms of MXenes, and the covalent bond between M and X, make MXenes more stable and more diverse than graphene [161]. The general formula of MXenes after removing the A layer is Mn+1XnTx, where T represents the surface functional groups (–O, –OH and –F), and x is the number of surface functional groups. Studies have shown that surface functional groups are related to the electronic state of MXenes. MXenes without functional groups exhibit metallic properties, while it with functional groups exhibit semiconducting properties, making it more widely used [162].

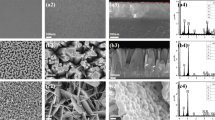

The most widely used preparation method for MXenes is wet chemical etching, and fluorine-containing compounds such as hydrofluoric acid were first used for etching. Later, with the research on fluorine-free etching methods, electrochemical etching methods, alkali etching methods, and molten salt etching methods were also proposed one after another. Generally speaking, the MXenes obtained by etching have a stacked accordion morphology (Fig. 11a), and further intercalation and exfoliation are required to obtain single-layer MXenes [163]. At present, the main peeling methods are ultrasonic exfoliation method, mechanical exfoliation method, intercalation exfoliation method and so on. Wei et al. reviewed the etching methods and layering methods of MXenes, and discussed their advantages and disadvantages [164].

Reproduced with permission from Ref. [163]. Copyright 2022, ACS Publications. b Structural diagrams of the four kinds of MXenes. Reproduced with permission from Ref. [165]. Copyright 2022, Elsevier. c The charge-transfer process in the Ti3C2/TiO2 system. Reproduced with permission from Ref. [166]. Copyright 2020, Elsevier. d Schematic diagram of the reaction mechanism of 2D-Bi2MoO6@2D-Mxene. (NSs: nanosheets) Reproduced with permission from Ref. [169]. Copyright 2020 Elsevier

a Field emission scanning electron microcopy images of bulk Ti3AlC2 and Ti3AlC2 after HF treatment.

Since its discovery in 2011, researchers have predicted more than 100 possible MXenes compositions through theoretical calculations, of which more than 40 MXenes have been successfully prepared experimentally. As shown in Fig. 11b, in addition to the most studied M3X2Tx system, three typical MXenes systems have also been synthesized: M2XTx, M4X3Tx, and M5X4Tx. Among them, the research based on Ti3C2 is the most extensive [165]. The 2D planar topology endows MXenes nanosheets with a large surface area, and its layered structure makes it easy to carry other materials to form nanocomposite photocatalysts, enhance light absorption, and obtain better photocatalytic performance. Since the excellent synergy between TiO2 and MXenes can effectively improve the electrical conductivity, electron mobility, and carrier separation efficiency of the system, the TiO2/MXenes system has been extensively studied. Chen et al. synthesized Ti3C2/TiO2 nanosheets with HF as auxiliary agent [166]. The Schottky barrier at the interface of Ti3C2/TiO2 effectively hinders the electron backflow of TiO2 (Fig. 11c). At the same time, the (001) crystal face of TiO2 with higher catalytic activity is exposed by using HF as an auxiliary agent, which improves the photocatalytic activity of Ti3C2/TiO2 nanosheets. Ti3C2/TiO2 composite photocatalysts can also be successfully prepared by in-situ oxidation or self-assembly [167, 168]. In addition to composites with TiO2, MXenes materials have also been extensively studied in other composite systems. Zuo et al. prepared layered 2D-Bi2MoO6@2D-MXene nanocomposites [169]. The photocatalytic activity of the composites for water splitting is 7.9 times higher than that of pristine Bi2MoO6. The analysis showed that there are two reasons for the enhanced photocatalytic activity. On the one hand, the composite structure inhibits the agglomeration of Bi2MoO6 nanosheets and increases its specific surface area, and on the other hand, the formed Schottky heterojunction can promote charge transport and hinder carrier recombination (Fig. 11d). Liu et al. successfully prepared a 2D/2D Schottky junction of Ti3C2/g-C3N4 by ultrasonic irradiation, which accelerated the charge separation [170]. g-C3N4 loaded with Ti3C2 exhibited excellent photocatalytic activity in nitrogen fixation, CO2 reduction and degradation.

3 Main factors affecting photocatalysis

In general, photocatalytic material properties and photocatalytic reaction conditions are the two main factors affecting the photocatalytic performance. This paper mainly discusses the influencing factors of the material itself, such as energy band structure, morphology, and crystal face, and further explains the unique influence of these influencing factors in the 2D nanomaterial system.

3.1 Band structure of photocatalysts

In the photocatalytic process, the core reaction process is: when light is irradiated on the photocatalyst, the catalyst absorbs light energy to generate electrons (e−) with reducing ability and holes (h+) with oxidative ability. e− and h+ further react with the system to generate free radicals, which reduce or oxidize substances in the environment such as H2O, pollutants, heavy metal ions, and CO2. This process is closely related to the energy band structure of the photocatalyst. On the one hand, the positions of the semiconductor photocatalysts CB and VB determine their redox capacity, that is, the more negative CB, the stronger the reduction capacity; the more positive VB, the stronger the oxidation capacity. In other words, the wider the forbidden band of the semiconductor photocatalyst, the stronger is its redox capacity [171]. On the other hand, the photoresponse range of semiconductor photocatalysts is also related to its forbidden bandwidth, as shown in Eq. (1):

Eg is the forbidden bandwidth of the semiconductor, and λ is the wavelength. The narrower the forbidden bandwidth, the wider the light absorption range, and the easier it is to be excited by light. According to this equation, the visible-light response range of the semiconductor photocatalytic material can be roughly estimated. The wavelength of 400–700 nm is the visible range. According to Eq. (1), the semiconductor photocatalyst that can respond to visible light has a bandgap range of about 1.77–3.1 eV. Therefore, in order to better respond to the visible-light range and improve the practical application potential of the photocatalyst, the bandgap of the photocatalyst should be selected in 3.1 eV or less.

Hydrogen production from water splitting is one of the main applications of photocatalytic technology. The water splitting process is closely related to the energy band of the photocatalyst. Figure 12 is a schematic diagram of the energy of photocatalytic water splitting when pH = 0. Protons are reduced by e− in CB to generate hydrogen, while h+ left in VB oxidizes water molecules to oxygen. In order to realize the whole water splitting reaction, two points must be satisfied: (i) the CBM is more negative than the reduction potential (0 eV) of H+ to H2, (ii) the VBM is larger than the oxidation potential of H2O to O2 (+ 1.23 eV). To satisfy the above two conditions, the minimum theoretical bandgap for driving water splitting is 1.23 eV. In theory, the bandgap of the semiconductor photocatalyst should be designed between 1.23 and 3.1 eV to ensure visible-light activity while overcoming the energy consumption of the water splitting reaction. In fact, some additional kinetic overpotentials are likely to be required to drive the electron transfer process in practical applications, and hydrogen evolution reaction (HER) and OER at reasonable reaction rates, semiconductors with bandgaps less than 1.6 eV will be limited by it [97]. At present, common semiconductors used for photocatalytic hydrogen production include TiO2, ZnO, transition metal compounds (such as ZrO2, CdS, and WO3) and composite oxides with a layered perovskite structure. Since the energy band of 2D materials is very sensitive to external effects, it is an important research direction for photocatalysts to peel off traditional bulk semiconductor materials to prepare 2D materials.

Starting from the basic principles of photocatalysis, it can be known that the regulation of the bandgap is an extremely important modification method in photocatalysis. Many influencing factors and modification methods in photocatalysis basically change the bandgap of semiconductor catalysts, thereby changing the photocatalytic performance. Based on the semiconductor properties, its photocatalytic performance can be altered by tuning the VB, CB, and simultaneous tuning of the two. The methods for adjusting the bandgap of semiconductor materials include: thickness adjustment, element doping, heterojunction, external electric field, and strain engineering. Among them, for 2D materials with a layered structure, thickness adjustment is a very important mean of regulation, and many studies have proved that the bandgap change is strongly correlated with the thickness. We will go into more details in Sect. 4.

3.2 Catalyst morphology

The effect of material morphology on its properties is significant. In addition to the inherent morphology of the material, the catalysts can also design hollow structures [172], core–shell structures [173] and interlayer layered structures [174], showing flower-like [175], spherical [176] and other morphologies. The acquisition of different morphologies depends on their preparation methods, reaction times, and temperatures. Lu et al. synthesized CeO2 materials with different morphologies by hydrothermal method and template method and have good applications in biological sterilization [177]. Figure 13a shows the transmission electron microscope (TEM) images of CeO2 nanorods (NRs), nanocubes (NCs), nanosheets (NSs), hollow spheres (HSs), and mesoporous CeO2 (m-CeO2). Based on the area of the X-ray photoelectron spectroscopy (XPS) pattern, it is calculated that the CeO2 nanorods have a higher concentration of Ce3+ and oxygen vacancies (Fig. 13b–d). Benefiting from this feature, CeO2 nanorods have the most excellent tetracycline (TC) degradation performance (Fig. 13e, f). Free radical trapping experiments reveal that h+ and superoxide radicals (·O2−) play a major role in the degradation of TC (Fig. 13g). Liu et al. prepared TiO2 with different morphologies (porous structure, flower-like nanospheres, and granular) by solvothermal method [178]. TiO2 with a porous structure exhibits better catalytic activity due to the unsaturated coordinated Ti atoms and the highest concentration of oxygen vacancies, as well as the good adsorption properties brought about by the high specific surface area and low pore size. The above experiments show that it is necessary to study the different morphologies of the same material. The difference in morphology will create different surface states, showing different surface defects, adsorption properties, specific surface area, etc.

Reproduced with permission from Ref. [177]. Copyright 2023, Elsevier

a The TEM images of CeO2 with different morphology. XPS spectra of synthesized CeO2 samples, b Ce 3d, c O1s. d The Ce3+/Oads concentrations of CeO2 with different morphologies. e The reaction kinetic curves of TC degraded by CeO2 sample. f The kinetic rate constant TC degraded by CeO2 sample. g The free radical trapping experiments of CeO2 NRs. (BQ: benzoquinone. AO: ammonium oxalate. IPA: isopropanol)

Due to the flexible and adjustable structure of 2D materials, the design of their morphology is easier than that of bulk materials. The commonly used methods are hydrothermal method and template method. The hydrothermal method can effectively prepare photocatalysts with different morphologies by changing the reaction conditions and reagents. The template method can design a more complicated specific shape through template induction.

When discussing the difference in morphology of 2D materials, the discussion of specific surface area is necessary. Generally speaking, the larger the specific surface area, the better the adsorption performance of the photocatalyst and the more active sites, so the catalytic performance is also better. In particular, the inherent layered structure of 2D nanomaterials can naturally lead to a large specific surface area, so that most of the active centers are exposed on the surface [179]. Du et al. prepared nanomesh B/O co-doped graphitic carbon nitride (BO-C3N4 nanomesh) [180]. The hydrogen production rate of BO-C3N4 nanomesh under visible-light irradiation is nearly 28 times higher than that of bulk g-C3N4. This is due to the unique 2D porous nanomesh structure, which enables BO-C3N4 to obtain a surface area of up to 160.58 m2·g−1. Liu et al. constructed a porous SnO2 precursor with obvious photocatalytic activity [181]. Then, using In2O3 as a sensitizer to increase the specific surface area of the porous SnO2 matrix, the specific surface area of the porous SnO2 was increased by 3 times, and the photocatalytic performance was 1.94 times that of the original porous SnO2.

However, some scholars hold different views. Some studies have pointed out that the photocatalytic activity of the material may not be related to the specific surface area. Li et al. synthesized graphitic carbon nitride with low specific surface area by silica template method, and its photocatalytic activity was improved compared with the high specific surface area graphitic carbon nitride synthesized by traditional method [182]. Studies have shown that this is because the synthesized low specific surface area graphitic carbon nitride has more free electrons and a lower recombination rate of carriers. In contrast, the size of the specific surface area is not the main factor affecting the photocatalytic performance.

The above studies show that it is a feasible method to improve the photocatalytic performance by changing the morphology of the catalyst and increasing its specific surface area. However, it cannot be simply assumed that the specific surface area of the material must be positively correlated with the improvement of the photocatalytic performance. The changes in the catalytic process at the microscopic level caused by the specific surface area should be further explored, which in turn guides the design of catalyst morphology and structure.

3.3 The structure of crystal face

Photocatalytic reactions generally occur on the surface of photocatalysts, so the reaction process is closely related to the surface atomic structure [183]. Since different crystal faces of photocatalysts naturally have different atomic arrangements, they can further affect key steps in photocatalytic reactions such as adsorption, desorption, and electron transfer processes. The research on TiO2 single crystal surface regulation published by Yang et al. in 2008 is the most representative work on semiconductor crystal surface regulation [184]. Its research found that the concentration of F ions can precisely control the exposure ratio of (001) crystal planes, significantly reduce the surface activation energy of (001) crystal planes, and promote the growth of (001) crystal planes. This work demonstrates the feasibility of finely tuned crystal planes. Subsequent studies have shown that by adjusting the concentration of specific ions, changing the pH values, adding surfactants, etc., specific crystal faces can be effectively exposed to further improve the photocatalytic performance of the system. Nowadays, facet engineering has become a common means of photocatalyst regulation. At present, the active crystal planes of some typical 2D materials have been identified, such as Li et al. synthesized WO3 thin films with different exposure ratio (002) planes by a simple hydrothermal method [185]. The proportion of each crystal plane of different WO3 samples was calculated by X-ray diffraction (XRD) spectrum (Fig. 14a), and the layer spacing corresponding to (002) crystal plane was also observed in TEM spectrum (Fig. 14b). Through a series of characterizations such as current density–voltage curve (J–V curve) (Fig. 14c), electrochemical impedance spectroscopy (EIS) (Fig. 14d) and Mott–Schottky plots (M–S plots) (Fig. 14e), it was found that with the increase of the (002) plane exposure rate, the separation of photogenerated carriers was promoted and the photoelectrochemical (PEC) performance was improved. Hu et al. prepared MoS2 nanosheets with higher activity (100) surface concentration at lower pH values, and the photocatalytic performance was effectively improved [186]. CdS with exposed (002) crystal faces also showed better performance in catalyzing hydrogen evolution [187]. The regulation of specific crystal planes can also control the thickness of 2D materials. Guan et al. used polyvinyl pyrrolidone (PVP) as an active agent to synthesize ultrathin BiOCl nanosheets with a thickness of 2.7 nm, while the thickness of BiOCl nanosheets without PVP was 30 nm [188]. The generation of ultrathin nanosheets is due to the deposition of PVP on the bottom and top (001) planes, preventing the growth of the longitudinal planes (Fig. 14f). TEM images and atomic force microscopy (AFM) revealed its crystal planes and thickness (Fig. 14g, h). Ultrathin BiOCl nanosheets show superior RhB degradation activity (Fig. 14i). Figure 14j, k reveals the distribution of defects in the samples, triple Bi3+ oxygen vacancy dominates in ultrathin BiOCl nanosheets, while isolated Bi vacancies dominates in BiOCl nanoplates.

Reproduced with permission from Ref. [185]. Copyright 2023, Elsevier. f Schematic illustration of the crystal orientation of the nanosheet. g The high resolution transmission electron microscopy (HRTEM) images of the ultrathin BiOCl nanosheet. h The atomic force microscopic image of the ultrathin BiOCl nanosheet. i The RhB degradation curve. j The positron annihilation spectroscopy. k The positron lifetime spectrum. Reproduced with permission from Ref. [188]. Copyright 2013, ACS Publications

a XRD patterns and calculated crystal facet ratios of different WO3 samples. b The TEM image of WO3-S4. c The J–V curve of different WO3 samples. d The EIS of different WO3 samples. e The M–S plots of different WO3 samples.

Compared with traditional materials, 2D materials require more complex crystal facet engineering due to their 2D anisotropic growth and thermodynamic factors. In general, there are two factors influencing the formation of specific crystal planes: thermodynamic and kinetic driving forces. From a thermodynamic point of view, the material facets exposed to the lowest surface energy will eventually be preserved. Kinetically, the slowest growing facets will eventually be preserved. Therefore, how to find a balance between the minimum energy exposure surface and the minimum total area is the challenge that the crystal plane engineering of 2D materials needs to face. In other words, researchers need to think about how to expose specific crystal faces while maintaining the ultrathin atomic thickness unique to 2D materials [189].

3.4 Crystal structure

The same material has different crystal structures due to different atomic arrangements. Different crystal structures have different forbidden bandwidths, so they will show different catalytic properties. The choice of crystal structure of photocatalytic materials is also an important factor to improve their catalytic properties. Taking TiO2 as an example, TiO2 has three crystal structures: anatase, rutile and brookite. Among them, the most common structures are anatase and rutile. The forbidden bandwidths of anatase-type TiO2 and rutile-type TiO2 are 3.2 eV and 3.0 eV, respectively, so anatase-type TiO2 has stronger redox ability. At the same time, anatase TiO2 has a larger specific surface area, more lattice defects, and higher separation efficiency of electron–hole pairs, thus possessing stronger photocatalytic performance [190]. MoS2 is a typical material with different crystal structures leading to different photocatalytic properties. 1T-MoS2 brings better photocatalytic performance than 2H-MoS2 due to the significantly lower charge-transfer resistance. Meanwhile, the active sites of 1T-MoS2 are distributed in a large number in the plane, rather than in the edge zone as in 2H-MoS2. However, since the 1T phase is not stable enough in nature, it will spontaneously transform into the 2H phase. How to utilize the 1T phase with better catalytic performance is one of the research focuses of MoS2 catalytic application. At present, intercalation of alkali metal ions, heteroatom doping and laser beam irradiation are considered to be effective methods for phase modulation [191]. Among them, the hydrazine hydrate-induced phase transition method is a simple and effective method. Li et al. regulated and synthesized a stable 1T-MoS2 phase by hydrazine hydrate without obvious transformation within 3 months, and its conductivity was 700 times that of 2H-MoS2 [192]. Jia et al. easily adjusted the ratio of 1T phase to 2H phase of MoS2 by simply adjusting the amount of hydrazine hydrate, and the obtained MoS2 had a small Tafel slope with 56.6 mV·dec−1 [101]. However, the current research on the photocatalytic performance of 1T-MoS2 has not yet obtained satisfactory results. 1T-MoS2 is usually used as a co-catalyst in photocatalysis to enhance the photocatalytic performance, which benefits from its metallicity. Liu et al. prepared a 1T/2H-MoS2 mixed phase loaded TiO2 nanorod system by a hydrothermal method [193]. The system exhibited excellent performance in the photocatalytic hydrogen evolution process. Mixed phase MoS2 exhibits better co-catalyst performance than Pt. Through Perdew–Burke–Ernzerhof (PBE) calculation (Fig. 15), it can be seen that due to the embedding of 1T-MoS2 layer, the mixed phase MoS2 exhibits conductor characteristics, which is helpful for the catalytic hydrogen evolution reaction on TiO2.

Reproduced with permission from Ref. [193]. Copyright 2019, Elsevier

PBE calculated band structures of a 2H-MoS2, b 1T-MoS2, and c mixed phase MoS2.

For 2D nanomaterial photocatalysts, the crystal structure is also a significant influencing factor in their photocatalytic applications. Due to the strong correlation between the geometric properties and performance of 2D nanomaterials, by controlling the thickness of 2D nanomaterials, the crystal structure can be adjusted, so that different bandgap widths, electronic properties, etc. can be obtained on the same material. Huang et al. selectively destroyed the hydrogen bonds between g-C3N4 layers to adjust the crystal structure of g-C3N4, and obtained layer plane ordered porous carbon nitride (LOP-CN) [194]. The photocatalytic hydrogen production performance of LOP-CN is 7.4 times that of pristine g-C3N4. Studies have shown that the improvement of photocatalytic performance is due to the long-range atomic order layer plane brought by the new crystal structure, which improves the diffusion length of electrons in the plane, thereby enhancing the charge separation ability. Meanwhile, the broken interlayer hydrogen bonds lead to the formation of a large number of slit holes, providing more active sites.

3.5 Catalyst defect

Defects in materials can generally be divided into intrinsic defects, electron defects and hole defects, and the intrinsic defects are mainly caused by the deviation of the stoichiometric ratio of the material itself. Material defects can affect photocatalysts in several ways. On the one hand, it affects the band structure of the catalyst. Defects will introduce new energy levels in the energy band structure of semiconductor photocatalysts, thereby shortening the forbidden band width and enhancing the absorption ability of visible light. On the other hand, due to the existence of defects, the adsorption of H2O and O2 is enhanced, which can further generate a large number of active free radicals, thereby improving the photocatalytic performance. At the same time, the defects can serve as electron-trapping centers, which are beneficial to the separation of electron–hole pairs and improve the photocatalytic performance [195]. In conclusion, the purposeful introduction of defects can enhance the performance of photocatalysts. Due to the reduction of its thickness, the local atomic structure of 2D nanomaterials is significantly different from that of bulk materials, such as coordination number, bond length, bond angle, and surface atomic disorder, so it is easy to form more surface defects [196]. Therefore, for 2D nanomaterials, it is necessary to study the effect of surface defects on the photocatalytic performance. As an effective modification method for photocatalysts, defect engineering has been extensively studied, and the details will be further introduced in Sect. 4.5 of this paper.

4 Main modification methods and their mechanisms

4.1 Elemental doping

Most of the semiconductor photocatalysts are n-type semiconductors, and they all have a special energy band structure different from that of metals or insulating substances: there is a forbidden band between the VB and the CB. The relationship between the light absorption wavelength range of the semiconductor and the bandgap can be expressed by the above-mentioned Eq. (1)

The absorption wavelength range of commonly used wide-bandgap semiconductors are mostly in the ultraviolet region. For example, TiO2 is a typical material that can only respond to ultraviolet light due to the wide bandgap. Since light absorption is an important process in photocatalytic reactions, the widening of the visible-light response range is of great significance for the practical application of photocatalytic technology. By shortening the bandgap, the photoresponse range can be effectively broadened. Studies have shown that by doping metal or non-metal elements, the bandgap of the photocatalyst can be effectively adjusted, its energy band structure can be changed, and the photoresponse range of the catalyst can be broadened [197]. At the same time, the introduction of impurity elements can also effectively enhance the concentration of carriers. As effective electron acceptors, metal ions can become photogenerated electron capture sites and hinder the recombination of electron holes [198]. In conclusion, doping can improve the photocatalytic performance of materials in multiple dimensions. Next, the mechanism of metal element doping and non-metal element doping will be introduced in detail to understand the role of doping in bandgap regulation.

The doping of metal elements has been studied for a long time and is more mature. The main principle is to change the light absorption range by the introduction of impurity energy levels. Figure 16a, b is schematic diagrams of metal element doping. The introduction of donor level and acceptor level enables electrons not only to be excited from the VB to the CB, but also to transition from donor level to the CB, or from the VB to acceptor level. The change in the forbidden bandgap allows semiconductors to absorb visible light. The type of element and the position of doping are the factors that affect the catalytic activity. Common metal atom dopings include Fe [199], Ni [200], Mn [201], Ag [202], Au [203], and Pt [204]. Tonda et al. prepared Fe-doped g-C3N4 nanosheets, which had a 7 times higher degradation rate of RhB than bulk g-C3N4 [205]. Shah et al. prepared Mn-doped BiFeO3 nanofilms (Mn-BFO) [206]. The oxygen evolution activity of Mn-BFO under visible-light irradiation is significantly improved compared to pure BFO. Bandgap studies show that the bandgap of Mn-BFO can be tuned from 2.1 to 1.36 eV by changing the doping amount of Mn, thereby broadening its optical response range. Qin et al. prepared Ag-doped g-C3N4 [207]. Under visible-light irradiation, Ag-g-C3N4 exhibits good photocatalytic hydrogen evolution activity, and the highest hydrogen evolution rate is 3.62 times that of the pure phase.

The doping of non-metallic elements can also change the energy band structure, but unlike metallic elements, it does not introduce new energy levels, but shortens the energy band. The specific process is shown in Fig. 16c. Common non-metallic elements used for doping are N, B, O, P, S, etc. The doping of non-metal elements compared to metallic elements can well avoid the effect of thermochemical instability on the photocatalytic activity. Thus, doping method with non-metal elements is more widely used. For example, the reason for the better photocatalytic performance of N-doped TiO2 can be simply explained as follows: N-doping forms a state in the bandgap that can absorb visible light, and N-doping induces oxygen vacancies, thereby enhancing the photocatalytic performance [208]. Wang et al. prepared S-doped g-C3N4 (Fig. 17a) [209]. By doping element S, the bandgap of g-C3N4 is narrowed from 2.7 to 2.63 eV (Fig. 17b), the photoresponse range is broadened to 475 nm, and the photocatalytic reduction of CO2 shows more outstanding performance. Kong et al. prepared N-doped ZnO/g-C3N4 composites [210]. Compared with pure g-C3N4, ZnO and composite ZnO/g-C3N4, N-ZnO/g-C3N4 degrades MB and phenol better under visible-light irradiation. The studies showed that one of the reasons for the improvement of photocatalytic performance is the change of the energy band structure and the improvement in stability brought by doping N.

Reproduced with permission from Ref. [209]. Copyright 2015, Elsevier. c The Tauc plots of different samples. d Photo-induced temperature rise rates of different samples. e The electron paramagnetic resonance (EPR) spectra of 2,2,6,6-tetramethylpiperidinyl (TEMP-1O2) for Co1Zn19-ZIF. f The EPR spectra of 5,5-dimethyl-1-pyrroline N-oxide (DMPO-O2-) for Co1Zn19-ZIF. Reproduced with permission from Ref. [214]. Copyright 2023, Elsevier

a Unit cell of pure C3N4 and sulfur-doped C3N4. b Schematic diagram of the band structures of pure g-C3N4 (left) and S-doped g-C3N4 (right). (BCB: bottom of CB. TVB: top of VB)

In summary, it can be seen that element doping is an effective mean to narrow the bandgap of photocatalysts, and the narrowed bandgap can broaden the visible-light absorption range. In addition to metal doping and non-metal doping, co-doping is also widely used as a doping method, and the synergistic effect between two different elements also has a profound impact on the performance of semiconductor catalysts [203, 211]. Currently, there is no research on controllable bandgap narrowing, and the bandgap change caused by element doping is still an unquantifiable thing.

Usually, doping is achieved by introducing dopants containing corresponding elements during the preparation process or post-treatment process of the semiconductor material precursor. Dopants can be liquid, solid or gaseous. Taking N element doping as an example, the common doping method is hydrothermal method using ammonia solution (such as formamide and ammonia water), calcination of precursors containing nitrogen elements, or nitriding materials in NH3 atmosphere. The element type, element position, doping concentration and doping solubility are the main influencing factors in the doping process. The doping solubility refers to the solubility of the dopant in the host material. In general, solubility is limited due to interactions between elements. Even the maximum solubility sometimes fails to achieve effective photocatalytic performance. In addition to selecting elements with higher solubility, appropriate post-treatments such as annealing, pressurization, and thermal cycling can also increase doping solubility [212, 213]. However, the current solubility enhancement methods have problems such as cumbersome process and unclear mechanism, which need to be further explored and discussed. It is worth looking forward to that, compared with bulk surface doping, 2D nanomaterials have the characteristic of thin thickness. The doping process of 2D materials requires only a small diffusion depth to form uniform doping, which is more conducive to adjusting the electronic structure, light absorption and improving photocatalytic activity, and can significantly change its physicochemical properties. In general, doping alone cannot effectively improve the visible-light response, and the defects caused by doping may also become the recombination sites of electrons and holes, which has a negative effect on the photocatalytic performance. The direction to solve this problem is to explore the mechanism of doping more deeply through the combination of various characterization methods and computational simulations.