Abstract

In this paper, an analytical model is developed for electrical conductivity of nanocomposites, particularly polymer/carbon nanotubes nanocomposites. This model considers the effects of aspect ratio, concentration, waviness, conductivity and percolation threshold of nanoparticles, interphase thickness, wettability between polymer and filler, tunneling distance between nanoparticles and network fraction on the conductivity. The developed model is confirmed by experimental results and parametric studies. The calculations show good agreement with the experimental data of different samples. The concentration and aspect ratio of nanoparticles directly control the conductivity. Moreover, a smaller distance between nanoparticles increases the conductivity based on the tunneling mechanism. A thick interphase also causes an increased conductivity, because the interphase regions participate in the networks and enhance the effectiveness of nanoparticles.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Electrical conductivity is one of the main properties of polymer nanocomposites, which is necessary for practical applications in electronics, sensors and electrical industries [1,2,3,4,5,6,7,8,9,10,11,12]. The combination of polymer matrix and conductive nanofillers such as carbon nanotubes (CNTs) can present high conductivity in addition to good mechanical properties, which are desirable for different applications [13,14,15,16,17,18]. The conductivity of nanocomposites needs to conductive networks in polymer matrix which form at a critical concentration as percolation threshold [19, 20]. The percolation threshold in polymer nanocomposites is correlated with several factors such as aspect ratio, orientation, dispersion, distribution, surface energy and agglomeration of fillers, mixing method and phase structure [21, 22]. The percolation threshold can be experimentally determined by the measurement of electrical conductivity at different filler concentrations.

There are many parameters, which control the electrical conductivity of polymer nanocomposites. The content, conductivity, size, orientation, waviness and wettability of nanoparticles were reported to be effective in nanocomposite conductivity [23,24,25]. The effective parameters are not independent, and it is difficult to separate the effect of each parameter on the percolation threshold and conductivity. The effects of these parameters can be studied by modeling process, which is a low-cost and effective methodology to study on general properties of nanocomposites.

Many methods were used for modeling of electrical conductivity in polymer composites such as numerical simulation, image processing, analytical and micromechanical modeling [26, 27]. However, some models include some complex parameters such as orientation angle which are not easily manageable [28]. Most available models are appropriate for microparticles and cannot consider the poor filler concentration for percolation threshold of nanocomposites [29]. The widely used model for conductivity of polymer nanocomposites is a power-law equation based on conventional percolation theory [30,31,32]. This model well agrees to the measurements of electrical conductivity of polymer nanocomposites. Similarly, some micromechanics models were developed accounting the tunneling effect, agglomeration and waviness of CNT [28, 33], but their complex and indistinct equations are not useful in practice. Accordingly, there is not a simple model, which can show the conductivity of polymer nanocomposites by the properties of conductive nanoparticles and networks.

The main drawback of available models for conductivity of polymer nanocomposites is ignoring the interphase regions around nanoparticles in nanocomposites. The interphase between polymer matrix and nanoparticles commonly forms in polymer nanocomposites, due to the extraordinary interfacial area and interactions between polymer matrix and filler [34,35,36,37,38]. The roles of interphase properties in the mechanical properties of polymer nanocomposites were well discussed [39, 40]. Also, simple micromechanics models were developed which can predict the interphase properties by the experimental results of tensile test [41, 42]. Moreover, some researchers have reported that the interphase regions can form continuous networks that cause faster percolation and bigger networks in nanocomposites which effectively improve the mechanical properties [43, 44]. However, the role of interphase areas in the electrical conductivity of nanocomposites has not been reported, well.

In this paper, an analytical model proposed by Taherian [29] is developed to describe the effects of aspect ratio, concentration, waviness, conduction and percolation threshold of nanoparticles, interphase thickness, wettability between polymer and filler, tunneling distance between nanotubes and network fraction on the electrical conductivity of polymer/CNT nanocomposites. This development is performed based on the available models and some equations, which highlight the roles of interphase and waviness in the network properties. The developed model explicitly suggests the influences of some parameters such as aspect ratio, effective concentration, conduction and percolation threshold of nanoparticles as well as tunneling distance, wettability and network fraction on the electrical conductivity of polymer nanocomposites. Moreover, the developed model implicitly expresses the roles of interphase thickness and waviness on the conductivity. The developed model is examined by the experimental results from the literature and parametric studies. The author hopes that the developed model can replace the conventional and improper models for electrical conductivity of polymer nanocomposites.

2 Theoretical analysis

Taherian [29] developed an analytical equation to predict the electrical conductivity of composites containing conductive fillers in which three effective parameters including filler conduction, filler aspect ratio and wettability between polymer and nanoparticles were considered as:

where “σ0” and “σN” are conductions of polymer and nanoparticles, “α” is filler aspect ratio, cos (θ) shows the wettability between components and roundness is a function of “α.” “A” and “B” are also adjustable parameters. Obviously, the negligible level of “σ0” can be disregarded from this model. In this study, this model is developed for conductivity of polymer/CNT nanocomposites by different effective parameters. We try to express the adjustable parameters by sensible properties of nanocomposite components.

Deng and Zheng [45] suggested a model for electrical conductivity of polymer/CNT nanocomposites containing random distribution of CNT above percolation threshold as:

where “\(\phi_{f}\)” is volume fraction of nanofiller and “f” is the fraction of nanoparticles which belong to network phase after percolation. This model was successfully applied to predict the electrical conductivity of polymer/CNT nanocomposites. We can conclude that the conductivity of polymer nanocomposites directly depends on “\(\phi_{f}\)” and “f” parameters. So, “A” parameter in Eq. 1 can be a function of “\(\phi_{f}\)” and “f” parameters.

Ryvkina et al. [46] also assumed that the main mechanism for electrical conductivity of polymer/CNT nanocomposites includes the electron tunneling, where electrons are transferred by tunneling effect, even though the nanotubes are not connected. The tunneling effect among the electron conduction mechanisms considers the direct contact conductance between nanofillers in close proximity. According to Landauer–Buttiker formula [47, 48], the nanoscale CNT–CNT contact resistance assumes both tunneling and direct contact resistances in nanocomposites. The Landauer formula defines a ballistic or quasi-ballistic conduction among a two-terminal configuration. Nevertheless, a full plan including transmission rates in the matrix form is essential for random geometry with many terminals. Buttiker [49] developed this generalization to describe edge transport in the quantum Hall influence, which is identified as Landauer–Buttiker formula.

Maiti et al. [50] also suggested an equation for conductivity based on tunneling distance as:

where “d” is tunneling distance between nanotubes and “D” and “E” are constant parameters. According to this equation, the conductivity of CNT nanocomposites inversely relates to the tunneling distance. As a result, “B” parameter in Eq. 1 may be a factor, which shows the tunneling distance between adjacent nanotubes in nanocomposites.

Taherian [29] also suggested the “roundness” factor as inverse aspect ratio of filler. It means that by decreasing the filler aspect ratio, the roundness grows. The roundness was defined in the range of 0–1. The aspect ratio of 1000 results in the roundness of 0, while the aspect ratio of 1 expresses the roundness of 1. Therefore, we develop an equation for roundness as:

Also, the surface energies of polymer and nanoparticles control the wettability of fillers by polymer chains which can affect the filler distribution and agglomeration [51]. So, the wettability can change the conductivity of nanocomposites. Taherian [29] proposed the role of wettability in conductivity by cos (θ) as:

where “γp,” “γf” and “γfp” are the surface energies of polymer, filler and filler/polymer interface and “θ” is wetting angle. Also, “γfp” can be defined based on the surface energies of polymer and filler as:

According to above explanations, the conductivity of nanocomposites correlates with CNT size, CNT concentration, network fraction (f), interphase thickness and tunneling distance. When the roles of these factors in the conductivity are properly considered, the developed model is obtained as:

where “z” is tunneling parameter as 1 nm. When the ranges of all parameters are considered in Eq. 7, the calculations of conductivity are much higher than the experimental data. Therefore, a factor “10−5” was added to the equation to obtain the reasonable results. Also, the conductivity inversely correlates with “B” parameter (Eq. 1). So, “B” correlates with the tunneling distance, because a large tunneling distance decreases the conductivity. However, “d” has nm unit, while “B” is a dimensionless parameter. Accordingly, “B” was considered as d/z and the tunneling parameter was considered.

This equation assumes the roles of the concentration, network fraction, aspect ratio and conduction of filler as well as the tunneling distance and wettability in the conductivity of polymer nanocomposites.

Percolation threshold for random distribution of CNT in nanocomposite was suggested based on the volume and excluded volume of nanoparticles [52] as:

where “V” and “Vex” parameters show the volume and excluded volume of particles, respectively. The excluded volume includes the volume about an object, which does not permit the center of a similar object to enter.

“V” and “Vex” parameters in polymer/CNT nanocomposites containing dispersed CNT are given [52] as:

where “R” and “l” denote the radius and length of CNT, respectively. By substituting the latter equations into Eq. 8, “\(\phi_{p}\)” is expressed as:

On the other hand, the authors in previous articles have related the “\(\phi_{p}\)” in nanocomposites to the aspect ratio of filler [53, 54]. The aspect ratio of nanoparticles is defined as:

where “2R” is the diameter of nanotubes. The researchers have presented different inverse relations between “\(\phi_{p}\)” and “α.” However, the best relation, which agrees with the levels of “\(\phi_{p}\)” derived from Eq. 11, is suggested as:

Figure 1 shows the effects of “R” and “l” parameters on the levels of “\(\phi_{p}\)” expressed by Eqs. 11 and 13 by contour plots. It is shown that the different ranges of “R” and “l” parameters show similar results for percolation threshold using Eqs. 11 and 13. A small “\(\phi_{p}\)” is obtained by thin and long nanotubes, while the worst level of “\(\phi_{p}\)” is shown by the thickest and the shortest nanotubes. Accordingly, thin and long nanotubes create desirable percolation level and “\(\phi_{p}\)” can be correlated with “α” by Eq. 13.

As stated, the interphase layer surrounding CNT can speed up the formation of conductive networks in nanocomposites. The interphase regions do not affect the main volume of nanoparticles, but they increase the excluded volume [44] as:

where “t” is interphase thickness.

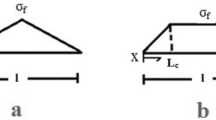

In addition, CNTs are commonly curved in nanocomposites, due to the large aspect ratio, which affects their specifications. An equivalent length as “leq” can be considered for curved nanotubes (Fig. 2). Also, the relation between the length of straight and curved CNT can be considered by a waviness parameter as:

where u = 1 demonstrates the straight CNT (no waviness), but a higher level of “u” shows more waviness which decreases the effective length.

The influence of curved nanotubes on the excluded volume beside interphase thickness can be taken into account as:

which results in an equation for percolation threshold by the roles of interphase and waviness as:

This equation was examined by the experimental results of percolation threshold in polymer/CNT nanocomposites. The predictions of percolation threshold show good agreement with the experimental data in several samples such as ultra-high-molecular-weight polyethylene/MWCNT [55], epoxy/MWCNT [56], polycarbonate/acrylonitrile butadiene styrene/MWCNT [53] and epoxy/MWCNT [31]. As a result, Eq. 17 is valuable to analyze the percolation threshold in nanocomposites supposing the interphase and waviness.

The interphase regions also increase the effectiveness of nanoparticles in the general performances of nanocomposites. The effective volume fraction of nanoparticles [28] can be defined based on interphase and waviness by:

Also, only a number of nanotubes participate in the conductive networks after percolation threshold and others are evenly dispersed in nanocomposite.

The fraction of networked CNT can be given by effective filler concentration and percolation threshold [28] as:

Furthermore, the conduction of transversely isotropic CNT changes by the waviness. Many papers indicated that the waviness weakens the conduction of CNT and suggested an inverse relation between “σN” and “u” [23, 24, 57] as:

Assuming the above parameters, the developed model based on Taherian equation can be presented for conductivity of polymer/CNT nanocomposites as:

When the aspect ratio of filler is related to percolation threshold by Eq. 13, the developed model is expressed by the effect of percolation threshold as:

which generally suggests the impacts of nanoparticles dimensions and waviness, network fraction, interphase thickness, CNT conduction, percolation threshold, tunneling distance and wettability between polymer and nanoparticles on the conductivity of polymer nanocomposites.

3 Results and discussion

The developed model can be evaluated by its predictions for electrical conductivity of polymer nanocomposites. Also, the roles of effective parameters in the conductivity of nanocomposites can be analyzed to confirm the predictability of the developed model.

3.1 Comparison between experimental and theoretical conductivities

Figure 3 exhibits the experimental data and calculations of the developed model for ultra-high-molecular-weight polyethylene/multi-walled CNT (MWCNT) (R = 8 nm, l = 8 μm, u ≈ 1.2) [55] and epoxy/MWCNT (R = 8 nm, l = 30 μm, u ≈ 1.2) [56]. CNT size for these samples was obtained from Refs. [55, 56]. Also, “u” values were approximated based on the morphological images illustrated for the samples. A good agreement between the experimental conductivity and the calculations is observed in all samples, which approves the predictability of the developed model. As a result, the developed model can approximate the electrical conductivity of polymer nanocomposites by the influences of effective parameters.

The values of “t” and “d” parameters can be also obtained by the comparison of experimental data and the predictions of the developed model. When the experimental levels of percolation threshold are applied to Eq. 11, the values of “t” can be calculated. “\(\phi_{p}\)” was reported as 0.0007 and 0.0002 for ultra-high-molecular-weight polyethylene/MWCNT [55] and epoxy/MWCNT [56] samples, respectively, by the experimental results of conductivity. When Eq. 11 is considered, the best values of “t” are estimated as 7 nm for these samples. Moreover, the “d” levels of 3 and 7 nm are obtained by the comparison between experimental conductivity of ultra-high-molecular-weight polyethylene/MWCNT [55] and epoxy/MWCNT [56] samples and the calculations of the developed model. Accordingly, the developed model can estimate the levels of interphase and tunneling distance in the nanocomposites.

3.2 Parametric studies

The effects of different parameters on the conductivity of nanocomposites are assessed based on the developed model. By this evaluation, the predictability of the developed model as well as the efficiencies of parameters in conductivity is determined.

Figure 4 demonstrates the roles of “\(\phi_{f}\)” and “α” factors in the conductivity of nanocomposites at average levels of R = 10 nm, l = 15 μm, u = 1.3, t = 10 nm, d = 3 nm, σN = 105 S/m, γp = 40 mN/m and γf = 45 mN/m by three-dimensional (3D) and contour plots. The maximum levels of “\(\phi_{f}\)” and “α” parameters result in the highest conductivity. As observed, σ = 5.5 S/m is obtained at \(\phi_{f}\) = 0.02 and α = 1000. However, the least conductivity is observed at the poorest levels of “\(\phi_{f}\)” and “α” parameters, where \(\phi_{f}\) = 0.005 and α = 200 calculate σ = 0.3 S/m. Therefore, “\(\phi_{f}\)” and “α” directly control the conductivity of nanocomposites which means that a high conductivity is achieved by great concentration of CNT with large aspect ratio.

As mentioned, CNTs form conductive networks in nanocomposites after percolation threshold. So, the volume fraction of nanoparticles below percolation cannot form the networks which result in the poor conductivity. When the filler concentration reaches percolation level, the networks of CNT produce a large level of electron current which is a sign of conductivity. Moreover, the higher levels of “\(\phi_{f}\)” above percolation threshold help the development of dimensions and density of network. Therefore, the conductivity shows a direct relation with nanofiller volume fraction, due to the better conductivity and networkability of CNT in nanocomposites. Additionally, reducing the particle size and increasing the filler aspect ratio make it easier to form conductive networks which reduce at percolation threshold. The effect of aspect ratio is more obvious at low filler concentrations. A high aspect ratio by long and thin nanotubes increases the ratio of surface to volume which promotes the inter-particle contacts and leads to more probability of networking. In other words, a high aspect ratio develops the properties of conductive networks which positively affect the conductivity of nanocomposites. Many reports on polymer nanocomposites have also indicated the positive influence of aspect ratio on the conductivity [58]. As a result, it is meaningful to correlate the electrical conductivity of nanocomposites with aspect ratio of filler.

Figure 5 also shows the effects of “f” and “d” parameters as the fraction of networked filler and tunneling distance on the conductivity of nanocomposites at \(\phi_{f}\) = 0.01, R = 10 nm, l = 15 μm, u = 1.3, t = 10 nm, σN = 105 S/m, γp = 40 mN/m and γf = 45 mN/m. The highest conductivity as σ = 7 S/m is observed at f = 0.5 and d = 1 nm, while the slightest conductivity as 0.37 S/m is reported at f < 0.2 and d > 5 nm. Accordingly, the conductivity is differently correlated with the fraction of percolated CNT and tunneling distance between nanotubes. A better conductivity is obtained by a higher level of percolated nanoparticles and a smaller distance between nanoparticles. On the other hand, a poor conductivity is shown when more nanoparticles cannot be involved in the networks and a far distance existed between nanotubes.

The role of “f” parameter in the conductivity of nanocomposites is reasonable, because it fixes the dimensions of conductive networks. A high level of “f” clearly displays the large number of nanotubes in the conductive networks which gives a high level of charge transportation. However, a small number of nanotubes in the networks decrease their dimensions resulting in a deprived conductivity. The direct role of network properties in the conductivity of nanocomposites was also reported in the literature [24, 57, 59], which confirms the development of this model for conductivity of polymer nanocomposites.

The conductivity of nanocomposites based on the electron tunneling mainly depends on the separation distance between CNT [46, 60]. When the separation distance of CNT is larger than a determinate range, the nanocomposite is insulated or very poor conductivity is observed, due to the absence of electron transferring. However, when CNT volume fraction increases, the conductive networks begin to form and the separate distance between CNT decreases which permits the nanotubes for electron tunneling. As a result, the distance between nanotubes is much important which controls the networking of nanoparticles and conductivity of nanocomposites. Feng and Jiang [28] indicated that the critical separation distance to form conductive networks with electrical contacts rather than physical contacts is 1.8 nm. They also indicated that the nanotubes keep this distance even after percolation threshold, due to the van der Waals attractions. Conclusively, the developed model logically predicts the effect of tunneling distance on the conductivity of nanocomposites.

The conductivity as a function of “t” and “σN” parameters is also plotted in Fig. 6 at average levels of other factors. A direct correlation is observed between the conductivity of nanocomposites and these parameters. As shown, t = 20 nm and σN = 105 S/m produce the conductivity of 18 S/m, while a poor conductivity of 0.38 S/m is reported at an average t < 8 nm and σN < 1.25 × 105 S/m. So, a thick interphase and a high conduction of CNT produce an extraordinary conductivity in nanocomposites. On the other hand, a low conductivity in nanocomposites is calculated in the case of thin interphase and poor-conductive CNT.

A thick interphase around nanoparticles accelerates the formation of conductive networks in the nanocomposites, because it extends the dimensions of CNT. Moreover, a thicker interphase participates more nanotubes in the networks which expands their size and density. Additionally, the interphase areas increase the effective volume fraction of nanoparticles in nanocomposites, due to their contributions in the general behavior of nanocomposites. Accordingly, a thicker interphase causes more positive impacts on the conductivity of nanocomposites, as suggested by the expressed equations. The positive role of interphase regions in the percolation threshold was indicated by previous researchers [43, 61], but its effects on the network properties and nanocomposite conductivity were not well studied.

Since the polymer matrices are approximately insulated, the CNT conduction mainly controls the conductivity of polymer nanocomposites. By increasing in the CNT conduction, the conductivity of nanocomposites linearly improves and a better maximum conductivity is obtained by more conductive CNT [29]. The main reason for this occurrence can be expressed by the large difference between the conductions of polymers and CNT which highlights the role of CNT conduction in the conductivity of whole nanocomposite. In view of that, the developed model correctly suggests that the CNT conduction linearly affects the conductivity of produced nanocomposites.

The roles of surface energies of polymer and filler on the conductivity of nanocomposites are depicted in Fig. 7 at average levels of other parameters. The best conductivity is observed at the highest and the least surface energies of polymer and nanoparticles, respectively, while the conductivity decreases by poor “γp” and maximum “γf.” However, it is found that these parameters cannot significantly change the conductivity of nanocomposites. As observed, σ = 2.25 S/m is obtained at γp = 50 mN/m and γf = 30 mN/m, but low conductivity of about 2 S/m is exhibited at γp = 20 mN/m and γf = 60 mN/m. As a result, polymers with high surface energy and low surface energy nanofillers produce the nanocomposites with high conductivity.

The surface tensions of polymer matrix and nanoparticles regulate the wettability of filler by polymer which affects the filler distribution and agglomeration. A high wettability facilitates the surrounding of filler by polymer chains which inhibits the direct contacts between nanoparticles and weakens the conductivity of nanocomposite [29]. In addition, a lower wettability leads to more agglomeration of nanoparticles in the matrix which is appropriate for electrical conductivity, because the conductive networks are formed by weak distribution of nanoparticles [29]. So, a low wettability is suitable for the formation of filler networks and improvement of electrical conductivity of nanocomposites. The wettability between polymer and nanofiller is shown by cos (θ) parameter in Eq. 5. Since higher differences between the surface energies of polymer and nanoparticles as well as the great surface energy of polymer and poor surface energy of filler produce worse wetting of filler by polymer matrix, the developed model correctly exhibits the correlations between the conductivity of nanocomposites and the surfaces energies of polymer and filler.

Figure 8 also demonstrates the conductivity of nanocomposites as a function of “\(\phi_{p}\)”and “\(\phi_{\text{eff}}\)” parameters at average values of other variables. A desirable conductivity of 3.5 S/m is estimated at \(\phi_{p}\) = 0.001 and \(\phi_{\text{eff}}\) = 0.08, whereas σ = 0.1 S/m is calculated at \(\phi_{p}\) = 0.005 and \(\phi_{\text{eff}}\) = 0.02. Therefore, the smallest and the highest levels of “\(\phi_{p}\)” and “\(\phi_{\text{eff}}\)” parameters result in the best conductivity representing that low percolation threshold and numerous effective nanoparticles can considerably grow the conductivity of nanocomposites.

The dependences of conductivity of nanocomposite on “\(\phi_{p}\)”and “\(\phi_{\text{eff}}\)” parameters based on Eq. 22 at average values of u = 1.3, d = 3 nm, σN = 105 S/m, γp = 40 mN/m and γf = 45 mN/m via a 3D and b contour plots

The percolation threshold shows the least volume fraction of nanoparticles which can form the conductive networks. Beside this, the percolation threshold controls the fraction of nanotubes which creates the networks based on Eq. 19. As a result, the roles of “\(\phi_{p}\)” in the networks formation and their properties are not deniable which affect the conductivity of nanocomposites. All experimental and modeling studies have indicated that a lower percolation threshold is more desirable for conductivity of nanocomposites [28, 58]. Therefore, it is proper to express an inverse relation between the conductivity of nanocomposites and percolation threshold, as suggested by the developed model.

On the other hand, a more level of “\(\phi_{\text{eff}}\)” parameter shows the further efficiencies of nanoparticles and interphase in the conductivity of nanocomposites. According to Eq. 20, a high “\(\phi_{\text{eff}}\)” is obtained by thin and long nanotubes, thick interphase and less waviness. All these ranges are required to produce effective conductive networks capable to significantly improve the conductivity of nanocomposites. Therefore, the role of “\(\phi_{\text{eff}}\)” parameter as a function of filler and interphase specifications in the conductivity of nanocomposites is well given by the developed model.

4 Conclusions

An analytical model was developed for electrical conductivity of polymer nanocomposites based on Taherian approach considering the main effects of aspect ratio, concentration, waviness, conduction and percolation threshold of nanoparticles, interphase thickness, wettability, tunneling distance and network fraction. The developed model was examined by experimental results and parametric analysis. Good agreement between the experimental data and the calculations is observed which validates the predictability of the developed model. Moreover, the developed model can approximate the interphase thickness and tunneling distance by experimental results. The concentration and aspect ratio of nanoparticles directly change the conductivity of nanocomposites, because they affect the nanotubes contacts and network probability. Additionally, a better conductivity is obtained by a higher level of percolated nanoparticles, which produces a larger network. Also, a smaller distance between nanoparticles causes more desirable conductivity, due to the tunneling effect. A thick interphase yields an extraordinary conductivity in nanocomposites, because it well contributes to the effective filler fraction and network level. The high conduction of CNT also manages the conductivity of polymer nanocomposites, because polymers are commonly insulated. Moreover, a high conductivity is observed at great and low surface energies of polymer and nanoparticles, respectively, because they suggest a low wettability between polymer and filler. However, it is shown that these parameters cannot significantly control the conductivity of nanocomposites. The smallest and the highest levels of “\(\phi_{p}\)” and “\(\phi_{\text{eff}}\)” parameters also result in the finest conductivity, because “\(\phi_{p}\)” affects the fraction of networked filler and “\(\phi_{\text{eff}}\)” shows the efficiencies of nanoparticles and interphase in the conductivity.

References

Power AC, Gorey B, Chandra S, Chapman J (2018) Carbon nanomaterials and their application to electrochemical sensors: a review. Nanotechnol Rev 7(1):19–41

Zare Y, Rhee KY (2018) Expression of normal stress difference and relaxation modulus for ternary nanocomposites containing biodegradable polymers and carbon nanotubes by storage and loss modulus data. Compos Part B Eng 158:162–168

Kim H-S, Jung Y, Kim S (2017) Capacitance behaviors of conducting polymer-coated graphene nanosheets composite electrodes containing multi-walled carbon nanotubes as additives. Carbon Lett 23:63–68

Kim KJ, Huh M-Y, Kim W-S, Song J-H, Lee HS, Kim J-Y et al (2018) The effect of carbon nanotube diameter on the electrical, thermal, and mechanical properties of polymer composites. Carbon Lett 26:95–101

Noh YJ, Kim HS, Kim SY (2012) Improved electrical conductivity of a carbon nanotube mat composite prepared by in situ polymerization and compression molding with compression pressure. Carbon Lett 13(4):243–247

Liu J, Jin B, Meng L-Y, Lee K-H (2018) Synthesis of polypyrrole-based nitrogen-containing porous carbon nanotubes for CO2 adsorption. Carbon Lett 28(1):111–115

Zare Y, Rhee KY (2017) Prediction of tensile modulus in polymer nanocomposites containing carbon nanotubes (CNT) above percolation threshold by modification of conventional model. Curr Appl Phys 17(6):873–879

Zare Y, Garmabi H, Rhee KY (2018) Structural and phase separation characterization of poly (lactic acid)/poly (ethylene oxide)/carbon nanotube nanocomposites by rheological examinations. Compos B Eng 144:1–10

Rostami A, Vahdati M, Alimoradi Y, Karimi M, Nazockdast H (2018) Rheology provides insight into flow induced nano-structural breakdown and its recovery effect on crystallization of single and hybrid carbon nanofiller filled poly (lactic acid). Polymer 134:143–154

Rostami A, Vahdati M, Nazockdast H (2018) Unraveling the localization behavior of MWCNTs in binary polymer blends using thermodynamics and viscoelastic approaches. Polym Compos 39(7):2356–2367

Salahandish R, Ghaffarinejad A, Naghib SM, Niyazi A, Majidzadeh-A K, Janmaleki M et al (2019) Sandwich-structured nanoparticles-grafted functionalized graphene based 3D nanocomposites for high-performance biosensors to detect ascorbic acid biomolecule. Sci Rep 9(1):1226

Gooneh-Farahani S, Naimi-Jamal MR, Naghib SM (2019) Stimuli-responsive graphene-incorporated multifunctional chitosan for drug delivery applications: a review. Exp Opin Drug Deliv 16:79–99

Naghib SM (2019) Two dimensional functionalized methacrylated graphene oxide nanosheets as simple and inexpensive electrodes for biosensing applications. Micro Nano Lett 14:462–465

Roy S, Petrova RS, Mitra S (2018) Effect of carbon nanotube (CNT) functionalization in epoxy-CNT composites. Nanotechnol Rev 7(6):475–485

Zhang P, Yi W, Xu H, Gao C, Hou J, Jin W et al (2018) Supramolecular interactions of poly [(9,9-dioctylfluorenyl-2, 7-diyl)-co-thiophene] with single-walled carbon nanotubes. Nanotechnol Rev 7:487–495

Salahandish R, Ghaffarinejad A, Omidinia E, Zargartalebi H, Majidzadeh-A K, Naghib SM et al (2018) Label-free ultrasensitive detection of breast cancer miRNA-21 biomarker employing electrochemical nano-genosensor based on sandwiched AgNPs in PANI and N-doped graphene. Biosens Bioelectron 120:129–136

Salahandish R, Ghaffarinejad A, Naghib SM, Majidzadeh-A K, Zargartalebi H, Sanati-Nezhad A (2018) Nano-biosensor for highly sensitive detection of HER2 positive breast cancer. Biosens Bioelectron 117:104–111

Naseer B, Srivastava G, Qadri OS, Faridi SA, Islam R, Younis K (2018) Importance and health hazards of nanoparticles used in the food industry. Nanotechnol Rev 7:623–641

Zha X-J, Li T, Bao R-Y, Bai L, Liu Z-Y, Yang W et al (2017) Constructing a special ‘sosatie’structure to finely dispersing MWCNT for enhanced electrical conductivity, ultra-high dielectric performance and toughness of iPP/OBC/MWCNT nanocomposites. Compos Sci Technol 139:17–25

Herceg TM, Yoon S-H, Abidin MSZ, Greenhalgh ES, Bismarck A, Shaffer MS (2016) Thermosetting nanocomposites with high carbon nanotube loadings processed by a scalable powder based method. Compos Sci Technol 127:62–70

Pourfayaz F, Khodadadi AA, Jafari S-H, Mortazavi Y, Khonakdar HA (2014) Ultra-low electrical and rheological percolation thresholds in PMMA/plasma-functionalized CNTs nanocomposites. Polym Plast Technol Eng 53:1450–1455

Grunlan JC, Mehrabi AR, Bannon MV, Bahr JL (2004) Water-based single-walled-nanotube-filled polymer composite with an exceptionally low percolation threshold. Adv Mater 16(2):150–153

Razavi R, Zare Y, Rhee KY (2017) A two-step model for the tunneling conductivity of polymer carbon nanotube nanocomposites assuming the conduction of interphase regions. RSC Adv 7(79):50225–50233

Liu Z, Peng W, Zare Y, Hui D, Rhee KY (2018) Predicting the electrical conductivity in polymer carbon nanotube nanocomposites based on the volume fractions and resistances of the nanoparticle, interphase, and tunneling regions in conductive networks. RSC Adv 8(34):19001–19010

Zare Y, Rhee KY (2018) A power model to predict the electrical conductivity of CNT reinforced nanocomposites by considering interphase, networks and tunneling condition. Compos Part B Eng 155:11–18

Pal R (2008) On the Lewis-Nielsen model for thermal/electrical conductivity of composites. Compos A Appl Sci Manuf 39(5):718–726

Krupa I, Novák I, Chodák I (2004) Electrically and thermally conductive polyethylene/graphite composites and their mechanical properties. Synth Met 145(2):245–252

Feng C, Jiang L (2013) Micromechanics modeling of the electrical conductivity of carbon nanotube (CNT)–polymer nanocomposites. Compos A Appl Sci Manuf 47:143–149

Taherian R (2016) Experimental and analytical model for the electrical conductivity of polymer-based nanocomposites. Compos Sci Technol 123:17–31

Clingerman ML, King JA, Schulz KH, Meyers JD (2002) Evaluation of electrical conductivity models for conductive polymer composites. J Appl Polym Sci 83(6):1341–1356

Chang L, Friedrich K, Ye L, Toro P (2009) Evaluation and visualization of the percolating networks in multi-wall carbon nanotube/epoxy composites. J Mater Sci 44(15):4003–4012

Kara S, Arda E, Dolastir F, Pekcan Ö (2010) Electrical and optical percolations of polystyrene latex–multiwalled carbon nanotube composites. J Colloid Interface Sci 344(2):395–401

Takeda T, Shindo Y, Kuronuma Y, Narita F (2011) Modeling and characterization of the electrical conductivity of carbon nanotube-based polymer composites. Polymer 52(17):3852–3856

Zare Y, Rhee KY (2017) Dependence of Z parameter for tensile strength of multi-layered interphase in polymer nanocomposites to material and interphase properties. Nanoscale Res Lett 12(1):42

Zare Y, Fasihi M, Rhee KY (2017) Efficiency of stress transfer between polymer matrix and nanoplatelets in clay/polymer nanocomposites. Appl Clay Sci 143:265–272

Ma X, Zare Y, Rhee KY (2017) A two-step methodology to study the influence of aggregation/agglomeration of nanoparticles on Young’s Modulus of polymer nanocomposites. Nanoscale Res Lett 12(1):621

Amraei J, Jam JE, Arab B, Firouz-Abadi RD (2018) Modeling the interphase region in carbon nanotube-reinforced polymer nanocomposites. Polym Compos 40:E1219–E1234

Shokrieh MM, Rafiee R (2010) On the tensile behavior of an embedded carbon nanotube in polymer matrix with non-bonded interphase region. Compos Struct 92(3):647–652

Nikfar N, Zare Y, Rhee KY (2018) Dependence of mechanical performances of polymer/carbon nanotubes nanocomposites on percolation threshold. Phys B Condens Matter 533:69–75

Razavi R, Zare Y, Rhee KY (2018) A model for tensile strength of polymer/carbon nanotubes nanocomposites assuming the percolation of interphase regions. Colloid Surf A 538:148–154

Zare Y, Rhee KY (2017) Multistep modeling of Young’s modulus in polymer/clay nanocomposites assuming the intercalation/exfoliation of clay layers and the interphase between polymer matrix and nanoparticles. Compos A Appl Sci Manuf 102:137–144

Zare Y, Rhee KY (2017) A two-step technique for tensile strength of montmorillonite/polymer nanocomposites assuming filler morphology and interphase properties. Appl Clay Sci 150:42–46

Qiao R, Brinson LC (2009) Simulation of interphase percolation and gradients in polymer nanocomposites. Compos Sci Technol 69(3):491–499

Baxter SC, Robinson CT (2011) Pseudo-percolation: critical volume fractions and mechanical percolation in polymer nanocomposites. Compos Sci Technol 71(10):1273–1279

Deng F, Zheng Q-S (2008) An analytical model of effective electrical conductivity of carbon nanotube composites. Appl Phys Lett 92(7):071902

Ryvkina N, Tchmutin I, Vilčáková J, Pelíšková M, Sáha P (2005) The deformation behavior of conductivity in composites where charge carrier transport is by tunneling: theoretical modeling and experimental results. Synth Met 148(2):141–146

Tuovinen R, Perfetto E, Stefanucci G, Van Leeuwen R (2014) Time-dependent Landauer–Büttiker formula: application to transient dynamics in graphene nanoribbons. Phys Rev B. 89(8):085131

Büttiker M (1986) Four-terminal phase-coherent conductance. Phys Rev Lett 57(14):1761

Büttiker M (1988) Absence of backscattering in the quantum Hall effect in multiprobe conductors. Phys Rev B 38(14):9375

Maiti S, Suin S, Shrivastava NK, Khatua B (2013) Low percolation threshold in polycarbonate/multiwalled carbon nanotubes nanocomposites through melt blending with poly (butylene terephthalate). J Appl Polym Sci 130(1):543–553

Rittigstein P, Torkelson JM (2006) Polymer–nanoparticle interfacial interactions in polymer nanocomposites: confinement effects on glass transition temperature and suppression of physical aging. J Polym Sci Part B Polym Phys 44(20):2935–2943

Berhan L, Sastry A (2007) Modeling percolation in high-aspect-ratio fiber systems. I. Soft-core versus hard-core models. Phys Rev E 75(4):041120

Maiti S, Shrivastava NK, Khatua B (2013) Reduction of percolation threshold through double percolation in melt-blended polycarbonate/acrylonitrile butadiene styrene/multiwall carbon nanotubes elastomer nanocomposites. Polym Compos 34(4):570–579

Zare Y (2017) An approach to study the roles of percolation threshold and interphase in tensile modulus of polymer/clay nanocomposites. J Colloid Interface Sci 486:249–254

Lisunova M, Mamunya YP, Lebovka N, Melezhyk A (2007) Percolation behaviour of ultrahigh molecular weight polyethylene/multi-walled carbon nanotubes composites. Eur Polym J 43(3):949–958

Kim YJ, Shin TS, Do Choi H, Kwon JH, Chung Y-C, Yoon HG (2005) Electrical conductivity of chemically modified multiwalled carbon nanotube/epoxy composites. Carbon 43(1):23–30

Zare Y, Rhee KY (2017) A simple methodology to predict the tunneling conductivity of polymer/CNT nanocomposites by the roles of tunneling distance, interphase and CNT waviness. RSC Adv 7(55):34912–34921

Li J, Ma PC, Chow WS, To CK, Tang BZ, Kim JK (2007) Correlations between percolation threshold, dispersion state, and aspect ratio of carbon nanotubes. Adv Funct Mater 17(16):3207–3215

Zare Y, Rhee KY (2019) Simplification and development of McLachlan model for electrical conductivity of polymer carbon nanotubes nanocomposites assuming the networking of interphase regions. Compos B Eng 156:64–71

Hu N, Karube Y, Yan C, Masuda Z, Fukunaga H (2008) Tunneling effect in a polymer/carbon nanotube nanocomposite strain sensor. Acta Mater 56(13):2929–2936

Shin H, Yang S, Choi J, Chang S, Cho M (2015) Effect of interphase percolation on mechanical behavior of nanoparticle-reinforced polymer nanocomposite with filler agglomeration: a multiscale approach. Chem Phys Lett 635:80–85

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zare, Y., Mišković-Stanković, V. & Rhee, K.Y. Effects of interphase regions and tunneling distance on the electrical conductivity of polymer carbon nanotubes nanocomposites. Carbon Lett. 29, 567–577 (2019). https://doi.org/10.1007/s42823-019-00051-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42823-019-00051-x