Abstract

Purpose

Alfalfa (Medicago sativa L.) production is adversely impacted by surface runoff and drought stress. This is particularly true for alfalfa planted in semiarid areas. Therefore, the development of erosion-tolerant management practice is crucial.

Methods

A study was carried out in a completely randomized design, with 4 treatments (3 straw biochar application rates + flat planting (FP) as control), and 3 straw biochar application rates of 0 × 104 (no biochar (NB)), 3 × 104 (single straw biochar-soil crust (SSB)) and 6 × 104 kg hm−2 (double straw biochar -soil crust (DSB)), respectively.

Results

Mean runoff efficiency in SSB was 16.58% compared to no-biochar treatment (20.14%), and in DSB was 14.57%. From 2017 to 2020, NB had the highest R2 value for the variation between runoff and rainfall and DSB had the lowest R2 value. In comparison to FP treatment, application of biochar to SSB significantly (p < 0.05) reduced runoff and increased soil water storage. The difference in soil water storage between pre-sowing and post-harvesting during alfalfa growth season increased on average by 15.69% with NB practice compared to FP, and by 11.79% and 7.58% with SSB and DSB practices, respectively. The mean weight diameter (MWD) in SSB treatment was higher than that in DSB treatment, although soil nutrients were increased in the following order: DSB > SSB > NB > FP. After post-harvest, average yields in NB, SSB, and DSB treatments were higher than those in FP treatment by 8.16%, 25.71%, and 18.31% respectively. With a mean yield of 8607 kg ha−1, SSB significantly increased alfalfa yield across all years.

Conclusion

Evidence from the four-year experiment suggested that biochar-soil crust made from a single straw significantly reduced surface runoff, increasing soil water storage, soil aggregate stability, soil nutrients, and alfalfa fodder yield. Based on our research, we advise using single straw biochar-soil crust to boost alfalfa fodder production in semi-arid regions.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The most fruitful forage legume in the world is without a doubt alfalfa (Medicago sativa L.). Due to its deep roots and high evapotranspiration rate, alfalfa may cause field soil to become desiccated (Mak-Mensah et al. 2022b). According to some studies, long-term alfalfa cultivation causes soil desiccation in arid and semi-arid regions (Huang et al. 2020). These studies linked alfalfa productivity to irrigation volume, deep root distribution, precipitation, and temperature. Ridley et al. (2001) found that alfalfa requires more water than other forage plants in Australian pasture lands and that its deep root system draws moisture from deeper soil horizons, leading to dry layers in deeper soil and long-term lower crop yields. According to Jia et al. (2009), increased soil temperature and moisture as well as the use of deep soil water are beneficial for increasing alfalfa yield and water use efficiency. Nevertheless, different crop types react differently to subsurface irrigation and controlled drainage systems. For instance, Mueller et al. (2005) highlighted that type of crop and water control level have significant impacts on amount of water needed. After several years of cultivation, alfalfa may result in decreased shallow groundwater and increased soil compaction (Petitjean et al. 2015). However, recent years have seen the use of soil improvers like biochar to prevent this.

Solid, carbon-rich material called biochar is created by pyrolyzing biomass at temperatures between 350 and 800 °C in an oxygen-limited environment (Mafiana et al. 2021). In agricultural systems, biochar has been used as a soil conditioner to improve soil water retention, soil porosity, organic content, water-nutrient availability, soil fertility, nutrient uptake, crop growth, yields, and productivity and decrease soil bulk density (Li et al. 2021; Palansooriya et al. 2019; Pradhan et al. 2022). Particularly in poor soils, biochar has enormous potential to successfully increase crop productivity. To increase productivity for various crops or vegetables, such as wheat, maize, rice, cotton, sugar beet, and tomato, biochar was applied to low-yield farmlands (Al-Wabel et al. 2018). Numerous studies demonstrated that using biochar properly increased crop growth, yields, and productivity (Farhangi-Abriz et al. 2021; Hilioti et al. 2017; Liu et al. 2020; Quilliam et al. 2012).

The differences in biochar, as well as field management practices (such as irrigation, fertilization, rotation, and cultivation), regional soil conditions, climate, and crop varieties, complicate the effects of biochar on crops (Fahad et al. 2019). As a result, it is crucial to determine how much soil water alfalfa can consume and to create specific soil water conservation techniques to manage groundwater in rain-fed areas. In this study, we hypothesize that, depending on biochar application rates, biochar may have an impact on surface runoff and soil properties. Thus, to determine the impact of biochar-soil crust on alfalfa in ridge-furrow rainwater-harvesting system, this study set out to examine the effects of biochar application rate on runoff, soil water storage, soil aggregate stability, soil nutrients, and alfalfa fodder yield. Our understanding of how addition of biochar affects surface runoff processes will be improved by the findings of this study, which are also anticipated to be crucial in helping local farmers and policymakers decide whether adding biochar is a feasible way to restore degraded croplands.

2 Materials and Methods

2.1 Experimental Site

From 2017 to 2020, the experiment was conducted at Dingxi Arid Meteorology and Ecological Environment Experimental Station of the China Meteorological Administration's Institute of Arid Meteorology (35° 33'N, 104° 35'E, 1896.7 m elevation). The site is a semi-arid area found in the Loess Plateau with an average annual temperature of 7.2 ℃, average annual frost-free period of 141 days, and average annual maximum and minimum temperatures of 25.9 °C and -13.0 °C, respectively. The annual average potential evaporation is much higher than the annual average precipitation, which is 388 mm (1445 mm). Precipitation from July to September amounted to 65% of the annual precipitation in the year. The soil bulk density was 1.09—1.36 g cm−3 in the 0–200 cm soil layer, and total nitrogen, total phosphorus, total potassium, and organic matter were 0.78, 0.77, 23.59, and 10.51 g kg−1 in the 0–40 cm soil layer, respectively. Alkali-hydrolyzed nitrogen, available phosphorus, and available potassium had respective concentrations of 54.30, 10.87, and 245 mg kg−1. The field's water capacity was 25.6%, soil pH was 7.93, and wilting water content was 6.7%. The primary cash crops in this area are maize (Zea mays), potatoes (Solanum tuberosum), and oats (Avena sativa). The farming system in this area involves one harvest per year as sainfoin (Onobrychis viciaefolia) and alfalfa (Medicago sativa) are the two primary forage plants.

2.2 Biochar

The Engineering Research Center of Biochar of Zhejiang Province produced the rice straw biochar used in this experiment at a pyrolysis temperature of 500 °C. The physical and chemical characteristics of rice straw biochar are displayed in Table 1.

2.3 Experimental Design

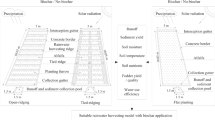

2.3.1 Runoff Experimental Design

Alfalfa production experimental plots were built close to the runoff experimental plots. In this experiment, the design was completely randomized with three treatments and three application rates of rice straw biochar (Fig. 1). The three straw biochar application rates were, 0 × 104 (no biochar), 3 × 104 (single straw biochar-soil crust), and 6 × 104 kg hm−2 (double straw biochar-soil crust). A biochar-soil mixture with a thickness of 10–15 mm was created by evenly mixing wet soil (with soil water content of 14–19%) with biochar in a volume ratio of 1:1. The mixture was then evenly spread on the surface of rain harvesting ridges. From exposure to rain, wind, and sunlight, the mixture developed into a biochar-soil crust. The ridge was defined as having a hemispherical shape, with dimensions of 10 m in length, 0.45 m in width, 0.2 m in height, and an angle of 34° to 45° between its surface and the horizontal plane. Prefabricated plates with height and thickness of 10 cm and 2 cm were placed around the ridge and smooth asphalt with 0.2 cm thickness was laid at the bottom of the catchment tank to prevent runoff overflow and reduce runoff infiltration loss. Every two rainfall harvesting ridges had a 1.5 m wide runoff observation area installed between them. Each rainwater collection ridge's low point serves as the foundation for the runoff collection tank, which is 1.5 m deep. The runoff collection tank is placed in a 100 L plastic bucket and a 32 mm inner diameter plastic hose was used to connect the inlet of the plastic bucket to the two sides of the lower end of the rainwater collection ridge. The runoff produced by the collecting ridge flows into the plastic bucket during a rainfall event. The plastic hose and sediment in the plastic bucket are cleaned to make room for subsequent runoff collection after the runoff in the bucket has been measured.

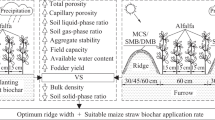

2.3.2 Alfalfa Production Experimental Design

For the ridge-furrow rainwater harvesting plot, parallel ridges were mulched with biochar-soil crust, while furrows were not mulched for alfalfa (Gannong No. 3) production. The experimental design was completely randomized with 4 treatments (3 straw biochar application rates + flat planting (FP) as control), and the 3 straw biochar application rates were 0 × 104 (no biochar (NB)), 3 × 104 (single straw biochar-soil crust (SSB)) and 6 × 104 kg hm−2 (double straw biochar-soil crust (DSB)), respectively. The ridge-furrow rainwater harvesting plots for NB, SSB, and DSB were made up of 4 ridges and 3 furrows. In the alfalfa production experiment, the ridge's length, width, height, and other characteristics were the same as in the runoff experiment. The furrow measured 10 m in length and 0.6 m in width. The effective planting ditch has a surface area of 18 m2 (3 furrows, each 10 m long and 0.6 m wide). The effective planting area for the flat planting (FP) plot was equal to the plot's area, which in this case was 36 m2 (10 m long by 3.6 m wide). Until alfalfa started to spread across furrows, the soil surface of the furrow was left uncovered. Seven days before sowing, manually compacted soil or a soil-biochar mixture was heaped.

2.4 Field Management

The experimental site was manually plowed and experimental plots were demarcated and divided from March 20 to April 3, 2017. To prevent the wind from blowing away biochar from the fields, a rainwater harvesting ridge was constructed with in situ wet soil (soil water content of 14 to 19%) before biochar and soil mixture was evenly distributed on the ridge surface. After manually patting the biochar-soil mixture with a shovel, it was soaked by rain and allowed to dry naturally to form a structural biochar-soil crust. Alfalfa planting was completed on April 4, 2017, in strips with 22.5 kg hm−2 of seed being sown, at a depth of 2–4 cm, and with a row spacing of 15 cm. Four alfalfa rows were sown in each furrow and twelve alfalfa rows were sown in each NB, SSB, and DSB plot (3 furrows). There were 25 alfalfa seeding rows in FP plots (no water harvesting ridges). During alfalfa growth period, no irrigation, herbicide nor insecticide spraying was done. Hand weeding was carried out every 20 days.

2.5 Sampling and Measurements

2.5.1 Rainfall and Runoff

From 2017 to 2020, rainfall and runoff were recorded during alfalfa growing seasons. The automatic siphon rain gauge (WS-STD1, UK) which was 60 m away from the experimental location was used to measure precipitation. Three manual rain gauges (RS485, China) were installed simultaneously to prevent accidental rain gauge damage and rainfall leakage. There was a three meters separation of the experimental field from the rain gauge. Every time it rained, the runoff amount collected in a 100 L plastic bucket was weighed. The following formula was used to determine the runoff coefficient (RC) of ridges used to collect rainwater:

where Rv is the runoff collection volume (m3), Rf is the rainfall amount (m), and Ac is the projected area (m2) of the ridge.

2.5.2 Physical Properties of Straw Biochar-Soil Crust

The aggregate characteristics, bulk density, and total porosity of biochar-soil crust quadrats were measured after the final runoff experiment in 2020. Three, 0.16 m2 (40 cm × 40 cm) biochar-soil crust quadrats were selected and measured from each rain harvesting ridge surface. The dry and wet sieving techniques were used to analyze the composition of crust soil aggregates. A 100 g sample of air-dried soil was manually sieved on a column of five sieves, measuring 5, 2, 1, 0.5, and 0.25 mm. Handshaking was used to shake the stack horizontally for two minutes at a rate of 30 strokes per minute and each aggregate-size fraction's weight percentage was calculated. Wet-sieved composite soil samples were created by proportionally blending all dry aggregate fractions. To release trapped air from the aggregates, exactly 50 g of soil that had been combined during the aforementioned steps was placed on the first sieve of the same set and gently moistened for 10 min. The sieve was moved vertically at a speed of 30 strokes per minute for 5 min to separate the aggregates larger than 5 mm. The remaining soil fractions on the sieves were then separately collected, dried in the oven, and weighed to obtain a constant mass. The mean weight diameter (MWD), and geometric mean diameter (GMD) were calculated as follows (Adekiya et al. 2020; Mondal et al. 2020):

where di is the average diameter of the openings of two consecutive sieves; wi is the weight ratio of aggregates remaining on the i th sieve, and wT is the cumulative weight of all aggregate-size fractions. The dry weight of the crust was divided by its volume to get its bulk density (BD g cm−3). To stabilize and seal the crust surface, an adhesive spray was applied to the samples of dry, undisturbed crust. After that, samples of the dry, undisturbed crust were submerged in water in a graduated cylinder to measure displacement (volume). The total porosity of the crusted soil (TP, %) was determined using the formula (1-BD/PD) × 100, where PD stands for particle density (g cm−3), which was set to 2.65 g cm−3.

2.5.3 Soil Moisture

The soil moisture was measured before alfalfa green-up stage, one day after each cutting, and one day after an effective rainfall (rainfall of less than 5 mm) (Fig. 2a, b, c, and d). The measured profiles had a depth of 0 to 200 cm. The soil was stratified every 10 cm for soil depths of 0 to 20 cm after which at every 20 cm, nine layers were created for the 20–200 cm soil depth. By drying, the water content of the soil profile was determined. By using a 100 cm3 (volume) cylinder with three replications, soil bulk density was calculated. Stratification, depth, and water content in the soil profile were used to calculate soil bulk density. The following formula was used to calculate soil water storage of 0–200 cm (Yang et al. 2020):

where θ is the soil profile water content (%) of each layer, BD is the soil bulk density of each layer (g cm−3), H is the soil depth of each layer (cm), and 10 is the coefficient.

2.5.4 Soil Nutrient

To determine soil nutrients and properties, soil samples from all studied treatments were taken at a depth of 0–40 cm after the last cutting. An Auto Analyzer 3 TOC analyzer was used to measure organic matter (SEAL Analytical, Norderstedt, Germany). An automatic Kjeldahl apparatus (Kjeltec 8400, Foss, Denmark) was used to measure soil total nitrogen content. With a 0.5 mol L−1 NaHCO3 extraction, soil-available phosphorus was measured using a spectrophotometer (Mapada Corporation, China). The soil-available potassium content was measured using a flame photometer and determined using the CH3COONH4 extraction method.

2.5.5 Fodder Yield

All plots were harvested when alfalfa reached its senescence and first flowering stage. Manual harvesting of alfalfa was conducted two times in 2017 and three times each in 2018, 2019, and 2020. Instantaneously, the harvested alfalfa was weighed. To determine fodder yield, a sample of 3–4 kg of freshly harvested alfalfa was dried in an oven at 105 °C for 1 h and then at 75 °C for at least 72 h.

2.5.6 Statistical Analysis

Using one-way Tukey test analysis of variance and compared means, the treatment effects were calculated. The SPSS (Version 22) Statistics program was used to process all the data.

3 Results

3.1 Runoff

Average runoff efficiency in the field decreased with biochar application over time during alfalfa production. Mean runoff efficiency in single straw biochar-soil crust (SSB) was 16.58% compared to no-biochar treatment (20.14%), and was 14.57% in double straw biochar-soil crust (DSB). With R2 = 0.926 in NB and R2 = 0.8011 in DSB, the proportion of variation between runoff and rainfall from 2017 to 2020 was highest in NB (Fig. 3a, b, c, and d). This suggests that, in comparison to NB treatment, DSB treatment is less effective at preventing floods, which may ultimately result in runoff. This shows that using double straw biochar and soil crust in ridge-furrow rainwater harvesting systems is ineffective for water conservation in rain-fed agriculture.

3.2 Soil Aggregate Stability

Compared to soil in the DSB treatment, straw biochar-soil crust in the SSB treatment had a higher average > 5 mm water-stable soil aggregate content (> 5.42%) (Table 2). This outcome showed that the biochar-soil crust made from a single straw effectively encouraged the aggregation of small particles into larger particles. However, DSB had the highest value of 6.24% compared to NB (4.26%) and SSB (5.97%) treatments in the 2–1 mm water-stable soil aggregate content. The aggregate content of the 1–0.25 mm water-stable soil showed a similar trend. In particular, SSB treatment's mean weight diameter (MWD) was larger than DSB treatment's. High MWD values typically indicate greater erosion resistance and are desired to stop erosion or lessen soil crusting.

3.3 Soil Water Dynamics

Figure 4a, b, c, and d display the amount of soil water stored in the 0–200 cm soil profile of the various treatments at harvest each year. In comparison to SSB, DSB, and the control (FP), no biochar (NB) treatment preserved more soil moisture. The difference in soil water storage between pre-sowing and post-harvesting during alfalfa growth season increased on average by 15.69% with NB practice compared to FP, and by 11.79% and 7.58% with SSB and DSB practices, respectively. With no biochar treatment, four peak values were seen at the post-harvesting stage, while FP recorded the lowest value on July 29, 2019. The soil water storage in the control varied from 217.34 to 399.89 mm throughout the entire experiment. These findings demonstrate that ridge-furrow systems with a single straw biochar-soil crust can improve soil water availability for alfalfa growth under dry conditions.

Soil water storage at furrow bottoms in 0–200 cm soil depth in 2017 (a), 2018 (b), 2019(c), and 2020 (d). Means within a column labeled with the same letters within each group are not significantly different at the 5% level (one-way Tukey test’s Analysis of variance). FP = flat planting; NB = no biochar; SSB = single straw biochar application; DSB = double straw biochar application

3.4 Soil Nutrient Dynamics

During alfalfa cultivation seasons, soil biochar crust increased soil nutrient availability (Fig. 5a, b, c, and d). Following harvest in 2020, the SOC in NB, SSB, and DSB plots was, respectively, 5.47%, 7.83%, and 13.62% higher than SOC in FP plots. In NB, SSB, and DSB, the amount of total nitrogen in the soil increased by 5.29%, 21.18%, and 23.24%, respectively. Application of biochar-soil crust increased soil available P in NB by 6.73%, SSB by 22.71%, and DSB by 26.79% when compared to FP. Soil available K increased in NB, SSB, and DSB plots by 6.71%, 14.89%, and 24.48%, respectively. Soil nutrients increased in the following order: DSB > SSB > NB > FP.

Organic matter (a), total nitrogen (b), available phosphorus (c), and available potassium (d) at furrow bottoms in 0–40 cm soil depth. Means within a column labeled with the same letters within each group are not significantly different at the 5% level (one-way Tukey test’s Analysis of variance). FP = flat planting; NB = no biochar; SSB = single straw biochar application; DSB = double straw biochar application

3.5 Alfalfa Yield Performance

In terms of improving alfalfa yield in 2020, DSB performed the best among various treatment types (10,505 kg ha−1) (Table 3). With a mean yield of 8607 kg ha−1, SSB significantly increased alfalfa yield across all years. During the growing seasons, alfalfa yield increased by 3241 to 10,505 kg per hectare. Following harvest, the average yields in NB, SSB, and DSB treatments increased by 8.16%, 25.71%, and 18.31% in comparison to FP treatment. This increase may be attributed to ridge-furrow treatments' adequate nutrient conservation and suitable soil watering practices. One explanation could be the ability of biochar application in furrows to keep soil moisture.

4 Discussion

Surface runoff could be reduced by increasing soil infiltration or water holding capacity (decreasing saturation overland flow) of the topsoil (Sadeghi et al. 2021). According to results of this study, adding biochar to soil generally reduced surface runoff and soil loss, which is in line with those of earlier studies (Sadeghi et al. 2021), which reported that soil loss and runoff were reduced by 82% and 98%, and 356% and 46% in conditions where biochar was applied 48 and 24 h before rainfall events, respectively. Indeed, this positive impact of biochar application on reducing soil loss and runoff could be the result of strong interactive effects of soil texture, particle size distribution, and soil structure on enhancing the stability of soil particles (Ahmadi et al. 2020). Although the impact varied depending on precise biochar application rates employed. A thorough analysis revealed that the advantages of biochar in reducing surface runoff gradually diminished as application rates increased. Li et al. (2019) reported that the incorporation of biochar into the soil significantly reduced soil loss by 64% and 50% at 5% and 2.5% application rates, respectively. Similarly, Li et al. (2017) indicated that biochar application could significantly reduce soil loss contents by 35% to 90% under an extreme rainfall event in degraded soil. They also reported that enhancement of soil strength might be the major factor in decreasing soil loss in the biochar-amended soil. This implies biochar application leads to improved soil aggregation and ultimately to an increase in soil water infiltration capacity as reported by Jien and Wang (2013).

An improvement in soil water properties after biochar addition can be attributed to an indirect effect due to increased soil aggregation (Abrol et al. 2016). Soil aggregation refers to the arrangement and binding of soil particles to form secondary units (linked also to pore formation), which influence water movement. According to Nugraha et al. (2022), biochar addition to soil increases soil aggregate stability, which is in line with the results of this study. Soil aggregate stability improves hydraulic conductivity and soil water retention. However, biochar can affect the content and stability of soil aggregates by interacting with soil organic carbon, minerals, and microorganisms (Huo et al. 2017). According to Esmaeelnejad et al. (2016), the improvement of soil aggregate stability in topsoil following biochar application can increase soil anti-erodibility by enhancing intrinsic soil properties, which is consistent with our findings. There is widespread knowledge of the stability of adding biochar to soil, and the mean residence time has been extrapolated over hundreds of years or even thousands of years (Kätterer et al. 2019; Obia et al. 2019). Due to extremely low biochar loss from chemical decomposition, the long-term impact of biochar application rates on surface runoff can be sustained. However, biochar is susceptible to structural fracturing at lower strains than the original biomass, and aging (weathering) reduces its mechanical strength (Li et al. 2019). Consequently, after being incorporated into soil for a long time, biochar cannot maintain its original physical size (Spokas et al. 2014). These characteristics suggest that the effect of biochar on surface runoff is more complex and unpredictable than the biochar application rate, which may have led to the biochar application rate's higher contribution rate.

The modification of soil structural properties by biochar addition has a direct effect on soil water storage and mobility. Similar to what happened in this experiment, single straw biochar markedly raised soil water storage over four years during alfalfa growing seasons. The study by Zhang et al. (2013), which looked at how biochar amendment affected soil water potential during wheat growing season, showed that biochar tended to increase soil water potential in the B4.5 treatment while tending to decrease it in the B9.0 treatment. They deduced that the distinct increase in soil temperature caused by higher amount of biochar, and increased soil water evaporation, may be responsible for the reduction in soil water potential in B9.0. Since water is generally stored and held in biochar pores, an increase in biochar porosity could lead to an increase in soil nutrients. Soil water storage however varied depending on rainfall, soil evaporation, and crop growth requirements (Wu et al. 2017).

Several reports on the impact of biochar on soil total N in field and laboratory settings have already been published (Beck et al. 2011; Turan et al. 2018a). According to Jones et al. (2012) and Alburquerque et al. (2014), the N content of the amended soils was higher than that of the control as demonstrated in this current study. According to Borchard et al. (2014), soils amended with 45 t ha−1 of slow-pyrolyzed hardwood biochar, gasified hardwood biochar, or flash-pyrolyzed softwood biochar had significantly higher total N content. Numerous studies have demonstrated that adding biochar to soil can significantly increase its nutrient content (Lehmann et al. 2011; Arif et al. 2015; Ojeda et al. 2015). This is partially because of the direct addition of nutrients, like P and K, and partially because runoff and leaching have decreased (Laird et al. 2010; Enders et al. 2012). In this study, soils amended with biochar, particularly in DSB, had significantly higher available P and K contents than control soils. This is in line with research by Lai et al. (2013), which found that woodchip biochar increased the amount of K that was readily available in soils that were typically in Taiwan but had no discernible impact on crop yield. Biochar's nutrient composition is largely influenced by the feedstock and pyrolysis conditions (Egamberdieva et al. 2019). Similarly, Güereña et al. (2013) found that applying biochar to the soil increased plant K uptake in addition to increasing K availability in the soil. Although biochar can provide some nutrients when used as a fertilizer, its use as a soil conditioner can help plants use their nutrients more effectively (Peng et al. 2011; Turan et al. 2018b). Additionally, the porous nature of biochar can increase nutrient availability by improving water balance and water retention (Major et al. 2010). As a result, DSB rather than SSB might be a better nutrient supplement for soils.

According to Mak-Mensah et al. (2021), there is evidence that applying biochar to agricultural fields may increase crop yield, which is consistent with this study. As an illustration, Zhang et al. (2012) discovered that biochar addition significantly increased rice yield, increasing it by 10% in the first cycle and by 9.5–29% in the following cycle. However, adding biochar to acidic soils boosts crop yield, but not always in the case of calcareous soils (Palansooriya et al. 2019). For instance, in a greenhouse experiment, the application of 20 t ha−1 cow manure biochar significantly increased maize yields in sandy acid soil (Musa et al. 2019). However, the response to biochar in calcarosol amended with fertilizer varied depending on the crop; biochar increased soybean biomass but decreased wheat and radish biomass (Van Zwieten et al. 2010). In Colombian savanna Oxisol, wood biochar amendment at a single dose of 20 t ha−1 resulted in no change in maize yield in the first year but showed significant increases in the following three years, according to Major et al. (2010). Farmland biochar amendment increases crop productivity by enhancing soil quality (Jien and Wang 2013; Agbna et al. 2017). In this current study, biochar treatment led to higher grain and straw yields. Previous studies have noted similar effects of biochar application on P and K availability (Yamato et al. 2006; Turan 2022). Mekuria et al. (2014) discovered that rice husk biochar can boost crop yields from cold, waterlogged paddies and dry matter accumulation there, primarily by enhancing the root growth environment and encouraging the uptake of N, P, and K by plant tissues. The reported negative impact of biochar on grain yield for crops at relatively P-rich sites may have been brought on by a reduction in N availability as a result of biochar application (Asai et al. 2009; Turan 2021).

5 Conclusion

In this work, the impact of biochar and ridge-furrow rainwater harvesting on alfalfa cultivation was examined. The application of single straw biochar, soil crust, and ridge-furrow rainwater harvesting together had the greatest impact on alfalfa crop yield and had a favorable effect on several soil characteristics, leading to an improvement in soil quality. When single straw biochar-soil crust was applied, yield increased, which implied that biochar can increase nutrient availability. Although this study was a success, certain limitations need to be addressed in future research. Future research should focus on how different alfalfa varieties respond to ridging, single straw biochar, and soil crust amendment. Based on these findings, it is recommended that the use of single straw biochar in furrows together with ridge-furrow rainwater harvesting is promoted and expanded, particularly in smallholder agriculture to increase yield and nutritional value of alfalfa fodder in semi-arid areas on a large scale.

Data Availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Abrol V, Ben-Hur M, Verheijen FGA, Keizer JJ, Martins MAS, Tenaw H, Tchehansky L, Graber ER (2016) Biochar effects on soil water infiltration and erosion under seal formation conditions: rainfall simulation experiment. J Soils Sediments 16:2709–2719. https://doi.org/10.1007/s11368-016-1448-8

Adekiya AO, Agbede TM, Olayanju A, Ejue WS, Adekanye TA, Adenusi TT, Ayeni JF (2020) Effect of Biochar on Soil Properties, Soil Loss, and Cocoyam Yield on a Tropical Sandy Loam Alfisol. Sci World J 2020: https://doi.org/10.1155/2020/9391630

Agbna GHD, Dongli S, Zhipeng L, Elshaikh NA, Guangcheng S, Timm LC (2017) Effects of deficit irrigation and biochar addition on the growth, yield, and quality of tomato. Sci Hortic (amsterdam) 222:90–101. https://doi.org/10.1016/j.scienta.2017.05.004

Alburquerque JA, Calero JM, Barrón V, Torrent J, del Campillo MC, Gallardo A, Villar R (2014) Effects of biochars produced from different feedstocks on soil properties and sunflower growth. J Plant Nutr Soil Sci 177:16–25. https://doi.org/10.1002/jpln.201200652

Al-Wabel MI, Hussain Q, Usman ARA, Ahmad M, Abduljabbar A, Sallam AS, Ok YS (2018) Impact of biochar properties on soil conditions and agricultural sustainability: A review. L Degrad Dev 29:2124–2161. https://doi.org/10.1002/ldr.2829

Arif M, Jalal F, Jan MT, Muhammad D, Quilliam RS (2015) Incorporation of Biochar and Legumes into the Summer Gap: Improving Productivity of Cereal-Based Cropping Systems in Pakistan. Agroecol Sustain Food Syst 39:391–398. https://doi.org/10.1080/21683565.2014.996696

Asai H, Samson BK, Stephan HM, Songyikhangsuthor K, Homma K, Kiyono Y, Inoue Y, Shiraiwa T, Horie T (2009) Biochar amendment techniques for upland rice production in Northern Laos. 1. Soil physical properties, leaf SPAD and grain yield. F Crop Res 111:81–84. https://doi.org/10.1016/j.fcr.2008.10.008

Beck DA, Johnson GR, Spolek GA (2011) Amending greenroof soil with biochar to affect runoff water quantity and quality. Environ Pollut 159:2111–2118. https://doi.org/10.1016/j.envpol.2011.01.022

Borchard N, Siemens J, Ladd B, Möller A, Amelung W (2014) Application of biochars to sandy and silty soil failed to increase maize yield under common agricultural practice. Soil Tillage Res 144:184–194. https://doi.org/10.1016/j.still.2014.07.016

Egamberdieva D, Li L, Ma H, Wirth S, Bellingrath-Kimura SD (2019) Soil amendment with different maize biochars improves chickpea growth under different moisture levels by improving symbiotic performance with mesorhizobium ciceri and soil biochemical properties to varying degrees. Front Microbiol 10:1–14. https://doi.org/10.3389/fmicb.2019.02423

Enders A, Hanley K, Whitman T, Joseph S, Lehmann J (2012) Characterization of biochars to evaluate recalcitrance and agronomic performance. Bioresour Technol 114:644–653. https://doi.org/10.1016/j.biortech.2012.03.022

Esmaeelnejad L, Shorafa M, Gorji M, Hosseini SM (2016) Enhancement of physical and hydrological properties of a sandy loam soil via application of different biochar particle sizes during incubation period. Spanish J Agric Res 14. https://doi.org/10.5424/sjar/2016142-9190

Fahad S, Ullah A, Ali U, Ali E, Saud S, Hakeem KR, Alharby H, Sabagh AE, Barutcular C, Kamran M, Turan V (2019) Drought tolerance in plantsrole of phytohormones and scavenging system of ROS. InPlant Tolerance to Environmental Stress. CRC Press, pp 103–114

Farhangi-Abriz S, Torabian S, Qin R, Noulas C, Lu Y, Gao S (2021) Biochar effects on yield of cereal and legume crops using meta-analysis. Sci Total Environ 775:145869. https://doi.org/10.1016/j.scitotenv.2021.145869

Güereña D, Lehmann J, Hanley K, Enders A, Hyland C, Riha S (2013) Nitrogen dynamics following field application of biochar in a temperate North American maize-based production system. Plant Soil 365:239–254. https://doi.org/10.1007/s11104-012-1383-4

Hilioti Z, Michailof CM, Valasiadis D, Iliopoulou EF, Koidou V, Lappas AA (2017) Characterization of castor plant-derived biochars and their effects as soil amendments on seedlings. Biomass Bioenerg 105:96–106. https://doi.org/10.1016/j.biombioe.2017.06.022

Huang R, Gao X, Wang F, Xu G, Long Y, Wang C, Wang Z, Gao M (2020) Effects of biochar incorporation and fertilization on nitrogen and phosphorus losses through surface and subsurface flow in sloping farmland of Entisol. Agric Ecosyst Environ 300:106988. https://doi.org/10.1016/j.agee.2020.106988

Huo L, Pang H, Zhao Y, Wang J, Lu C, Li Y (2017) Buried straw layer plus plastic mulching improves soil organic carbon fractions in an arid saline soil from Northwest China. Soil Tillage Res 165. https://doi.org/10.1016/j.still.2016.09.006

Jia Y, Li FM, Zhang Z-H, Wang XL, Guo R, Siddique KHM (2009) Productivity and water use of alfalfa and subsequent crops in the semiarid Loess Plateau with different stand ages of alfalfa and crop sequences. F Crop Res 114:58–65. https://doi.org/10.1016/j.fcr.2009.07.004

Jien SH, Wang CS (2013) Effects of biochar on soil properties and erosion potential in a highly weathered soil. CATENA 110:225–233. https://doi.org/10.1016/j.catena.2013.06.021

Jones DL, Rousk J, Edwards-Jones G, DeLuca TH, Murphy DV (2012) Biochar-mediated changes in soil quality and plant growth in a three-year field trial. Soil Biol Biochem 45:113–124. https://doi.org/10.1016/j.soilbio.2011.10.012

Kätterer T, Roobroeck D, Andrén O, Kimutai G, Karltun E, Kirchmann H, Nyberg G, Vanlauwe B, Röing de Nowina K (2019) Biochar addition persistently increased soil fertility and yields in maize-soybean rotations over 10 years in sub-humid regions of Kenya. F Crop Res 235:18–26. https://doi.org/10.1016/j.fcr.2019.02.015

Lai WY, Lai CM, Ke GR, Chung RS, Chen CT, Cheng CH, Pai CW, Chen SY, Chen CC (2013) The effects of woodchip biochar application on crop yield, carbon sequestration and greenhouse gas emissions from soils planted with rice or leaf beet. J Taiwan Inst Chem Eng 44:1039–1044. https://doi.org/10.1016/j.jtice.2013.06.028

Laird DA, Fleming P, Davis DD, Horton R, Wang B, Karlen DL (2010) Impact of biochar amendments on the quality of a typical Midwestern agricultural soil. Geoderma 158:443–449. https://doi.org/10.1016/j.geoderma.2010.05.013

Lehmann J, Rillig MC, Thies J, Masiello CA, Hockaday WC, Crowley D (2011) Biochar effects on soil biota - A review. Soil Biol Biochem 43:1812–1836. https://doi.org/10.1016/j.soilbio.2011.04.022

Li Y, Zhang F, Yang M, Zhang J, Xie Y (2019) Impacts of biochar application rates and particle sizes on runoff and soil loss in small cultivated loess plots under simulated rainfall. Sci Total Environ 649:1403–1413. https://doi.org/10.1016/j.scitotenv.2018.08.415

Li L, Zhang YJ, Novak A, Yang Y, Wang J (2021) Role of biochar in improving sandy soil water retention and resilience to drought. Water (Switzerland) 13. https://doi.org/10.3390/w13040407

Liu D, Feng Z, Zhu H, Yu L, Yang K, Yu S, Zhang Y, Guo W (2020) Effects of corn straw biochar application on soybean growth and alkaline soil properties. BioResources 15:1463–1481. https://doi.org/10.15376/biores.15.1.1463-1481

Mafiana MO, Dodkins IR, Dirisu CG, Li SW (2021) Use of Biochar for Limiting the Pathway of Exposure and Reducing the Risk of Heavy Metal Contamination from Mines. Water Air Soil Pollut 232. https://doi.org/10.1007/s11270-021-05004-7

Major J, Rondon M, Molina D, Riha SJ, Lehmann J (2010) Maize yield and nutrition during 4 years after biochar application to a Colombian savanna oxisol. Plant Soil 333:117–128. https://doi.org/10.1007/s11104-010-0327-0

Mak-Mensah E, Obour PB, Essel E, Wang Q, Ahiakpa JK (2021) Influence of plastic film mulch with biochar application on crop yield, evapotranspiration, and water use efficiency in northern China: A meta-analysis. PeerJ 9:e10967. https://doi.org/10.7717/peerj.10967

Mak-Mensah E, Yeboah FK, Obour PB, Usman S, Essel E, Bakpa EP, Zhang D, Zhou X, Wang X, Zhao X, Zhao W, Wang Q, Adingo S, Ahiakpa JK (2022a) Integration of ridge and furrow rainwater harvesting systems and soil amendments improve crop yield under semi-arid conditions. Paddy Water Environ. https://doi.org/10.1007/s10333-022-00900-y

Mak-Mensah E, Zhang D, Zhou X, Zhao X, Wang X, Zhao W, Wang Q, Ahiakpa JK (2022b) Effect of Co-application of Ridge-Furrow Rainwater Harvesting and Mulching on Fodder Yield, Quality, and Soil Desiccation in Alfalfa (Medicago sativa) Production. J Soil Sci Plant Nutr. https://doi.org/10.1007/s42729-022-00829-5

Mekuria W, Noble A, Sengtaheuanghoung O, Hoanh CT, Bossio D, Sipaseuth N, McCartney M, Langan S (2014) Organic and Clay-Based Soil Amendments Increase Maize Yield, Total Nutrient Uptake, and Soil Properties in Lao PDR. Agroecol Sustain Food Syst 38:936–961. https://doi.org/10.1080/21683565.2014.917144

Mondal S, Naik SK, Haris AA, Mishra JS, Mukherjee J, Rao KK, Bhatt BP (2020) Effect of conservation tillage and rice-based cropping systems on soil aggregation characteristics and carbon dynamics in Eastern Indo-Gangetic Plain. Paddy Water Environ 18:573–586. https://doi.org/10.1007/s10333-020-00802-x

Mueller L, Behrendt A, Schalitz G, Schindler U (2005) Above ground biomass and water use efficiency of crops at shallow water tables in a temperate climate. Agric Water Manag 75:117–136. https://doi.org/10.1016/j.agwat.2004.12.006

Musa FB, Jayeoba FM, Olayiwola VA, Adekunle EA, Abiodun FO (2019) Residual Effect of Organic Manure (Biochar and Cowdung) on the Growth of Pterocarpus osun. Curr J Appl Sci Technol 37:1–6. https://doi.org/10.9734/cjast/2019/v37i530336

Nugraha SS, Sartohadi J, Nurudin M (2022) Field-Based Biochar, Pumice, and Mycorrhizae Application on Dryland Agriculture in Reducing Soil Erosion. Appl Environ Soil Sci 2022. https://doi.org/10.1155/2022/1775330

Obia A, Martinsen V, Cornelissen G, Børresen T, Smebye AB, Munera-Echeverri JL, Mulder J (2019) Biochar application to soil for increased resilience of agroecosystems to climate change in Eastern and Southern Africa. Agriculture and Ecosystem Resilience in Sub Saharan Africa: Livelihood Pathways Under Changing Climate 129–144. https://doi.org/10.1007/978-3-030-12974-3-6

Ojeda G, Mattana S, Àvila A, Alcañiz JM, Volkmann M, Bachmann J (2015) Are soil-water functions affected by biochar application? Geoderma 249–250:1–11. https://doi.org/10.1016/j.geoderma.2015.02.014

Palansooriya KN, Ok YS, Awad YM, Lee SS, Sung JK, Koutsospyros A, Moon DH (2019) Impacts of biochar application on upland agriculture: A review. J Environ Manage 234:52–64. https://doi.org/10.1016/j.jenvman.2018.12.085

Peng X, Ye LL, Wang CH, Zhou H, Sun B (2011) Temperature- and duration-dependent rice straw-derived biochar: Characteristics and its effects on soil properties of an Ultisol in southern China. Soil Tillage Res 112:159–166. https://doi.org/10.1016/j.still.2011.01.002

Petitjean C, Hénault C, Perrin AS, Pontet C, Metay A, Bernoux M, Jehanno T, Viard A, Roggy JC (2015) Soil N2O emissions in French Guiana after the conversion of tropical forest to agriculture with the chop-and-mulch method. Agric Ecosyst Environ 208:64–74. https://doi.org/10.1016/j.agee.2015.04.004

Pradhan S, Mackey HR, Al-Ansari TA, McKay G (2022) Biochar from food waste: a sustainable amendment to reduce water stress and improve the growth of chickpea plants. Biomass Convers. Biorefinery

Quilliam RS, Marsden KA, Gertler C, Rousk J, DeLuca TH, Jones DL (2012) Nutrient dynamics, microbial growth and weed emergence in biochar amended soil are influenced by time since application and reapplication rate. Agric Ecosyst Environ 158:192–199. https://doi.org/10.1016/j.agee.2012.06.011

Ridley AM, Christy B, Dunin FX, Haines PJ, Wilson KF, Ellington A (2001) Lucerne in crop rotations on the Riverine Plains 1. The soil water balance. Aust J Agric Res 52:263–277. https://doi.org/10.1071/AR99165

Sadeghi SH, Hazbavi Z, Kiani-Harchegani M, Younesi H, Sadeghi P, Angulo-Jaramillo R, Lassabatere L (2021) The hydrologic behavior of Loess and Marl soils in response to biochar and polyacrylamide mulching under laboratory rainfall simulation conditions. J Hydrol 592:125620. https://doi.org/10.1016/j.jhydrol.2020.125620

Spokas KA, Novak JM, Masiello CA, Johnson MG, Colosky EC, Ippolito JA, Trigo C (2014) Physical Disintegration of Biochar: An Overlooked Process. Environ Sci Technol Lett 1:326–332. https://doi.org/10.1021/ez500199t

Turan V (2019) Confident performance of chitosan and pistachio shell biochar in reducing Ni bioavailability in soil and plant plus improving the soil enzymatic activities, antioxidant defense system, and nutritional quality of lettuce. Ecotoxicol Environ Saf 183:109594. https://doi.org/10.1016/j.ecoenv.2019.109594

Turan V (2021) Arbuscular mycorrhizal fungi and pistachio husk biochar combination reduces Ni distribution in mungbean plants and improves plant antioxidants and soil enzymes. Physiol Plant 173:418–429. https://doi.org/10.1111/ppl.13490

Turan V (2022) Calcite in combination with olive pulp biochar reduces Ni mobility in soil and its distribution in chili plants. Int J Phytoremediation 24:166–176. https://doi.org/10.1080/15226514.2021.1929826

Turan V, Khan SA, Mahmood-ur-Rahman IM, Ramzani PMA, Fatima M (2018a) Promoting the productivity and quality of brinjal aligned with heavy metals immobilization in a wastewater irrigated heavy metal polluted soil with biochar and chitosan. Ecotoxicol Environ Saf 161:409–419. https://doi.org/10.1016/j.ecoenv.2018.05.082

Turan V, Ramzani PMA, Ali Q, Abbas F, Iqbal M, Irum A, Khan W ud D (2018b) Alleviation of nickel toxicity and an improvement in zinc bioavailability in sunflower seed with chitosan and biochar application in pH adjusted nickel contaminated soil. Arch Agron Soil Sci 64:1053–1067. https://doi.org/10.1080/03650340.2017.1410542

Van Zwieten L, Kimber S, Morris S, Chan KY, Downie A, Rust J, Joseph S, Cowie A (2010) Effects of biochar from slow pyrolysis of papermill waste on agronomic performance and soil fertility. Plant Soil 327:235–246. https://doi.org/10.1007/s11104-009-0050-x

Wu GQ, Liu HL, Feng RJ, Wang CM, Du YY (2017) Silicon ameliorates the adverse effects of salt stress on sainfoin (Onobrychis viciaefolia) seedlings. Plant, Soil Environ 63:545–551. https://doi.org/10.17221/665/2017-PSE

Yamato M, Okimori Y, Wibowo IF, Anshori S, Ogawa M (2006) Effects of the application of charred bark of Acacia mangium on the yield of maize, cowpea and peanut, and soil chemical properties in South Sumatra, Indonesia. Soil Sci Plant Nutr 52:489–495. https://doi.org/10.1111/j.1747-0765.2006.00065.x

Yang Y, Du W, Cui Z, Lei S, Lei T, Lv J (2020) Effects of plastic film mulching on soil water use efficiency and wheat yield in the Loess Plateau of China. Arid L Res Manag 0:1–14. https://doi.org/10.1080/15324982.2020.1738593

Zhang A, Bian R, Pan G, Cui L, Hussain Q, Li L, Zheng J, Zheng J, Zhang X, Han X, Yu X (2012) Effects of biochar amendment on soil quality, crop yield, and greenhouse gas emission in a Chinese rice paddy: A field study of 2 consecutive rice growing cycles. F Crop Res 127:153–160. https://doi.org/10.1016/j.fcr.2011.11.020

Zhang Q, Wang Y, Wu Y, Wang X, Du Z, Liu X, Song J (2013) Effects of Biochar Amendment on Soil Thermal Conductivity, Reflectance, and Temperature. Soil Sci Soc Am J 77:1478–1487. https://doi.org/10.2136/sssaj2012.0180

Acknowledgements

This research was funded by the National Natural Science Foundation of China (42061050) and the Natural Science Foundation of Gansu Province, China (22JR5RA849).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing Interests

The authors declare there are no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhao, X., Wang, Q., Zhou, X. et al. Effects of Ridge-Furrow Rainwater Harvesting with Biochar-Soil Crust Mulching on Soil Properties, Nutrients, and Alfalfa Fodder Yield in a Semiarid Agroecosystem. J Soil Sci Plant Nutr 23, 3137–3148 (2023). https://doi.org/10.1007/s42729-023-01316-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42729-023-01316-1