Abstract

The present study was conducted to investigate the possibility of using iron waste along with Thiobacillus bacteria to supply soybean iron requirement in a calcareous soil. In vitro, two strains of Thiobacillus thiooxidans (T. thiooxidans) and Thiobacillus ferrooxidans (T. ferrooxidans) have been investigated for their bioleaching potential from mill scale and pyrite in in the presence and absence of sulfur. In a greenhouse experiment, the effect of iron sources (control, ferrous sulfate, mill scale, and pyrite) and bacterial inoculation (T. thiooxidans, T. ferrooxidans, and simultaneous application of two bacteria) on iron uptake by soybeans was investigated. In laboratory experiment, the effect of T. ferrooxidans on iron bioleaching from the studied iron waste was greater than T. thiooxidans. T. ferrooxidans was more effective to enhance the iron dissolution from pyrite than mill scale. The application of sulfur increased the bioleaching efficiency. In the greenhouse experiment, inoculation with T. thiooxidans caused a significant increase in shoot iron concentration of soybean compared to control only in the application of pyrite, while T. ferrooxidans significantly increased iron uptake by soybean in the application of all iron sources as well as control treatment. The highest shoot iron concentration of soybean was obtained in simultaneous application of two bacteria species. While the addition of the mineral and waste iron components did not impact on iron uptake by soybeans, soil inoculation with T. ferrooxidans and simultaneous application of T. ferrooxidans and T. thiooxidans had a significant effect on iron biofortification in soybean.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Anemia caused by iron deficiency is a major public health problem worldwide due to low quality diet, mainly lacking in animal source foods and low iron contents in foods from plant sources (García-Bañuelos et al. 2014). In other words, agricultural products are an important source of iron for humans. Although iron is generally abundant in soils, it mostly occurs in forms that are not readily available to plants. Especially phytoavailability of iron is severely restricted in calcareous soil because of high pH, low organic matter, and high carbonate contents. Therefore, the fortification of crops with iron to improve human nutrition is necessary. In this regard, biofortification is an appropriate method to fortification of agricultural products.

Biofortification is defined as a process to improve food crop’s nutritional quality through agronomic practices, conventional plant breeding, or modern biotechnology (Garg et al. 2018). In agronomic biofortification, mineral fertilizers apply to increase the concentration of nutrients in crops that may have extra effects for increasing yield (Cakmak, 2008; Adu et al. 2018).

But as mentioned above, in calcareous soils, the application of iron mineral fertilizers is usually ineffective. To overcome this problem, some strategies are used that are different in terms of efficiency and cost-effectiveness such as foliar application (Aziz et al. 2019; Niyigaba et al. 2019; Singh et al. 2018), nitrogen supply (Aciksoz et al. 2011; Singh et al. 2018), application of organic compounds and cropping systems management (Chen et al. 2019), using ammonium or sulfur containing fertilizers (Granja and Covarrubias, 2018), application of elemental sulfur (Klikocka and Marks, 2018; Bouranis et al. 2018), and using synthetic Fe chelates (Lucena, 2006) and nano iron fertilizer (Rui et al. 2016; Askary et al. 2017; Yang et al. 2020).

In this regard, the use of waste containing iron compounds such as steel industry by-products and iron ores can be cost-effective. Abbaspour et al. (2005) applied mixtures of converter sludge with sulfuric acid, organic matter, and elemental sulfur in some calcareous soils. The result showed that sludge application, especially acidified sludge, increased DTPA (diethylenetriaminepentaacetic acid) extractable Fe in soils and iron uptake by maize. The positive effect of steel converter sludge application with elemental sulfur on iron availability in calcareous soils also has been reported by Mohammadi Torkashvand (2011) and Karimian et al. (2012). Marsolek and Hagstrom (1982) showed that the application of acidified iron rich residue obtained in the process of copper extraction from copper bearing ore was effective to reduce the iron deficiency chlorosis. They stated the acidic nature of this product as an important factor in its effectiveness.

Pyrites, as a mining waste, has long been used to supply Fe for plants and S to improve soil quality (Wallace and Wallace, 1992). Castelo-Branco et al. (1999) reported that pyrite application to the calcareous soils increased nutrient availability and plant yield. Ortas et al. (2015) reported that the decrease in soil pH due to oxidation of pyrite increased the availability of phosphorus and zinc in wheat and maize cultivation. Reducing soil pH with the application of high rate of pyrite was reported by Nesheim et al. (1997).

In recent years, microbial biofortification method, as a green technology through effective microorganisms, has been raised (Khan et al. 2019; Prasanna et al. 2016). Among the beneficial microorganisms, the Thiobacillus strains, which has been used to increase bioavailability of nutrients particularly P, Fe, and Zn, can be mentioned (Besharati, 2017; Akhtar et al. 2012).

It seems that the use of iron waste along with the application of microbial biofortification technology can be more effective in increasing the availability of iron from these inexpensive compounds. The aim of this study was to investigate the effect of Thiobacillus bacteria on the availability of iron from ferrous sulfate, pyrite, and mill scale in a calcareous soil.

Mill scale is a generic term for steel-making by-products formed on the outer surface of plates, rolls, sheets, or profiles during the hot-rolling process. The total iron content of mill scale is averagely about 70% (Ndlovu et al. 2017), consisting of the mixed elemental iron and iron oxide mainly FeO (wustite), but also contain Fe2O3 (hematite), Fe3O4 (magnetite), and other oxides.

2 Materials and Methods

Mill scale and pyrite were obtained from Kabakan steel mill of Mashhad and Sarcheshmeh copper mine of Kerman, respectively. Elemental composition of these two iron compounds was determined by XRF (X-ray fluorescence) method. Laboratory-grade ferrous sulfate was obtained from Merc Co. For use in laboratory and greenhouse experiments, mill scale and pyrite were sieved to pass through 125-μm mesh sieve after crushing.

2.1 Preparing Bacterial Cells

Mesophilic Acidithiobacillus thiooxidans PTCC No: 1692 (DSM 504) and Acidithiobacillus ferrooxidans PTCC No: 1646 (DSM 583) bacteria were obtained from the Persian Type Culture Collection (PTCC) center. The medium used for cultivation and reproduction of bacteria was offered by this center.

Thiobacillus ferrooxidans (T. ferrooxidans) has been grown in liquid medium containing the following: K2HPO4 (0.4 g), MgSO4.7H2O (0.4 g), (NH4)2SO4 (0.4 g), and FeSO4.7H2O (33.3 g) per liter, and H2SO4 0.1 N was used for adjusting the pH at 1.4. The culture medium of Thiobacillus thiooxidans (T. thiooxidans) contains the following: K2HPO4 (3 g), MgCl2.6H2O (0.1 g), NH4Cl (0.1 g), CaCl2.2H2O (0.14 g), and sulfur powder (10 g) per liter with adjusting pH to 4.2. The bacteria were inoculated on rotary shaker (150 rpm) at 30 °C for 10 days. After growing, the bacterial cells were separated by centrifugation at 5000 rpm and suspended in distilled sterilized water for using in laboratory and greenhouse experiments.

2.2 Laboratory Experiment

A batch-type bioleaching experiment was performed for the investigation of iron bioleaching potential of T. thiooxidans and T. ferrooxidans from pyrite and mill scale in the presence and absence of sulfur in a completely randomized factorial design with three replications. The experimental factors included two types of iron waste (pyrite and mill scale), three bacterial treatments (control, inoculation with T. thiooxidans and T. ferrooxidans), and sulfur at two levels (0 and 10 g L−1). A total of 36 experimental units consisted of 100-mL glass Erlenmeyer flask, containing 50 mL of sterilized 9 K growth medium (pH = 7.2) and containing (NH4)2SO4 (3 g), MgSO4.7H2O (0.5 g), K2HPO4 (0.5 g), KCl (0.1 g), and Ca (NO3)2 (0.01 g) per liter that was prepared. For sulfur-containing treatments 10 g L−1 sulfur powder and for iron source treatments 8.9 g L−1 iron from pyrite or mill scale were supplied. Erlenmeyer flasks inoculated with approximately 2 mL volume of bacteria suspension containing about 107 CFU mL−1 of each species were incubated in a shaker incubator (180 rpm) at 30 °C for 15 days. McFarland’s nephelometer method (McFarland, 1907) was used to estimate the number of cells per mL. Uniformly bacterial suspension was adjusted to 0.5 McFarland standard (1.5 × 108 CFU mL−1) and then diluted 1:10 (approximately 107 CFU mL−1). The pH and iron concentration was determined in the culture medium supernatant after centrifuging at 5000 rpm for 10 min by pH meter and atomic absorption spectrometry (PG990), respectively. For measuring the concentration of iron, the samples were acidified by the appropriate addition of nitric acid and 1% nitric acid was used for dilution.

2.3 Greenhouse Experiment

In the greenhouse experiment, the effect of soil inoculation with T. thiooxidans and T. ferrooxidans bacteria on iron uptake by soybean in a calcareous soil enriched with ferrous sulfate, mill scale, and pyrite was investigated in a completely randomized factorial design with three replications. The bacterial treatments included non-inoculated soil (C), inoculation with T. thiooxidans (Tt), inoculation with T. ferrooxidans (Tf), and simultaneous inoculation of T. thiooxidans and T. ferrooxidans (Ttf). Iron treatments included control (0 mg Fe) and 10 mg Fe per kg of soil from three kinds of iron sources (ferrous sulfate, pyrite, and mill scale). A loam agricultural soil with low available Fe (1.9 mg kg−1) and 13% calcium carbonate equivalent (CCE) content was collected from 0 to 30 cm depth of the campus of Ferdowsi University of Mashhad, Razavi Khorasan province, Iran (36° 18′ 55.77″ N, 59° 31′ 34.11″ E). The soil was classified as Typic Haplocambid (Soil Survey Staff, 2010).

The electrical conductivity of saturated paste extract (ECe) and the pH of saturated paste of soil were measured 2.12 dS m−1 and 7.65, respectively. Each kilogram of the soil consisted of 0.51 g total N, 3.5 g organic C, 7.0 mg available P, 151 mg available K, and 4.48 mg available Fe. Before applying the treatments, 40 mg kg−1 of potassium sulfate, 80 mg kg−1 of calcium phosphate, 12 mg kg−1 of manganese sulfate, 20 mg kg−1 of zinc sulfate, 120 mg kg−1 of elemental sulfur powder, and 1% of composted cow manure were added to the soil. The bacterial suspension and iron treatments (10 mg Fe per kg of soil from ferrous sulfate, mill scale, and pyrite) were applied to the soil before planting. Bacterial treatments were inoculated with 30 ml of cell suspension for each pot (approximately 107 CFU mL−1). In simultaneous application of two bacteria, 15 ml per pot of each bacterial cell suspension (15 + 15) was added. Considering three replications, a total of 48 pots contained 3 kg of soil were prepared and maintained at filed capacity of moisture for a week. Due to the lack of soybean culture history in the studied soil, the soybean seeds (Katoul variety) were inoculated with native Bradyrhizobium bacteria. Ten pre-sprouted seeds were sown in each pot and then thin to 3 seedlings after germination. The pots were randomly arranged in the greenhouse under 30/22 °C temperature (day/night) and 14 h/10 h (light/dark) photoperiod and irrigated daily with deionized water to maintain the moisture at field capacity. The shoots and roots were separately collected from each pot after 60 days and rinsed with distilled water. Shoot and root dry weight was determined after drying at 65 °C. The oven-dried plant samples were crushed and passed through a 0.5-mm sieve. Dry ashing method at 500 °C was used for determination of Fe in plant material by atomic absorption spectrometry (PG990). After the plant harvesting and removing the roots, the soil of each pot air-dried, homogenized, and sieved to pass through a 2-mm mesh sieve. Soil pH in a 1:5 soil:water ratio and available Fe (Lindsay and Norvell, 1978) was determined in collected soil samples.

Analysis of variance was carried out using the MSTAT C software and significant difference between treatment means at the 5% level was determined using LSD test.

3 Results

The concentrations of chemical elements detected in mill scale and pyrite by XRF analysis are shown in Table 1. Approximately 99.5% of the mill scale contained iron oxides. Iron and sulfur content of pyrite was about 45.5% and 52%, respectively. The amounts of heavy metals in both compounds were negligible (Table 1).

3.1 Laboratory Experiment

The results showed that for both iron sources in non-inoculated treatments, the concentration of soluble iron was very low and the application of sulfur did not lead to significant increase in iron concentration (Table 2). In the application and non-application of sulfur, iron bioleaching from the studied compounds in inoculation with T. ferrooxidans (Tf) was much more than T. thiooxidans (Tt). Compared to T. thiooxidans in non-application of sulfur, T. ferrooxidans increased the concentration of soluble iron by 93.5 and 29.3 times in pyrite and mill scale treatments, respectively (Table 2). T. ferrooxidans was more effective in dissolving pyrite than mill scale. Inoculation with T. ferrooxidans in the application and non-application of sulfur increased the concentration of soluble iron by 2.29 and 5.47 times more in the pyrite treatment compared to the mill scale treatment.

Sulfur application had a positive effect on bioleaching efficiency and increased the percentage of Fe extraction from both studied iron compounds (Table 2). However, the addition of sulfur did not cause a remarkable increase in pyrite and mill scale dissolution in inoculated treatments with T. thiooxidans. Addition of sulfur had a great effect on increasing the iron bioleaching efficiency by T. ferrooxidans from pyrite as well as mill scale. The highest concentration of iron (6396.5 mg L−1) was observed in the presence of sulfur and T. ferrooxidans in pyrite treatment. However, the effect of sulfur application on the increase of iron bioleaching from mill scale in the presence of T. ferrooxidans was higher than pyrite. Compared to non-sulfur treated samples, in the presence of sulfur, T. ferrooxidans inoculation increased the concentration of iron by about 2.67 and 6.36 times in pyrite and mill scale, respectively. In the presence of sulfur, the percentage of iron extraction from pyrite by T. ferrooxidans was about 71.8%, while in the same treatment for mill scale, this value was 31.3%.

The results showed that Thiobacillus bacteria inoculation led a significant reduction in pH and in the application of sulfur, pH decrease was more pronounced. So that in the application of sulfur in pyrite treatment, the solution of pH reduced from 6.22 to 1.35 and 1.75 by T. thiooxidans and T. ferrooxidans, respectively. This reduction for mill scale was from 6.91 to 1.32 and 1.78 in T. thiooxidans and T. ferrooxidans treatments, respectively (Table 2).

3.2 Green House Experiment

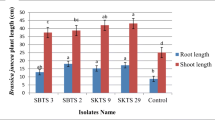

The results of greenhouse experiment showed that the application of ferrous sulfate, pyrite, and mill scale in inoculated and non-inoculated treatments had no significant effect on root dry weight and root nodulation of soybean. The effect of experimental treatments on shoot dry weight of soybean is shown in Fig. 1. Inoculation with bacteria and application of iron sources had no remarkable effect on the shoot biomass. The highest dry weight was related to ferrous sulfate treatment in the simultaneous application of two bacteria. This treatment also had the highest shoot iron concentration (Fig. 2). The simple main effect of inoculation with bacteria had a significant effect on shoot biomass of soybean. Simultaneous application of two bacteria species averagely increased the dry weight of the shoots by 12.7% compared to the non-inoculated treatments.

The effect of iron compounds (control, iron sulfate, pyrite, and mill scale) and bacterial treatments (C, no inoculation; Tt, inoculation with T. thiooxidans; Tf, inoculation with T. ferrooxidans; Ttf, inoculation with T. thiooxidans + T. ferrooxidans) on shoot dry weight of soybean. Different lowercase letters indicate significant differences between treatments (P < 0.05)

The effect of iron compounds (control, iron sulfate, pyrite, and mill scale) and bacterial treatments (C, no inoculation; Tt, inoculation with T. thiooxidans; Tf, inoculation with T. ferrooxidans; Ttf, inoculation with T. thiooxidans + T. ferrooxidans) on shoot iron concentration of soybean. Different lowercase letters indicate significant differences between treatments (P < 0.05)

Iron concentration of soybean shoots was significantly affected by experimental treatments. Based on the results, in non-inoculated treatments, application of ferrous sulfate and mill scale did not have a significant effect on the concentration of Fe in shoots of soybean, and only application of pyrite (pyrite-C) significantly increased iron concentration by 13.6% compared to non-inoculated control treatment (control-C) (Fig. 2). However, iron concentration in this treatment was not significantly different from iron concentration in iron oxide and mill scale treatments.

According to Fig. 2, inoculation with T. thiooxidans had no significant impact on increasing iron concentration except in pyrite treatment. Compared to non-inoculated control treatment (control-C), inoculation with T. thiooxidans increased the shoot iron concentration in pyrite application by 25.6%. In all iron treatments (control, ferrous sulfate, pyrite, and mill scale), inoculation with T. ferrooxidans significantly increased iron concentration. The shoot iron concentration increased by 43.9% in control treatment inoculated by T. ferrooxidans. In control treatment, this bacterium was as effective in increasing iron as the pyrite treatment (Fig. 2).

In ferrous sulfate and mill scale treatments, the concentration of Fe was significantly influenced by inoculated with T. ferrooxidans, while shoot iron concentration was not affected by the addition of pyrite in the presence of this bacterium compared to the inoculated control treatment. In fact, the effect of T. ferrooxidans on increasing shoot iron concentration in using ferrous sulfate and mill scale was greater than pyrite (Fig. 2).

The results showed that simultaneous application of both studied bacteria had a positive impact on shoot iron concentration. Simultaneous inoculation increased the shoot iron concentration by 95.9%, 54.0%, and 89.2% compared to non-inoculated treatments and 28.2%, 23.3%, and 10.4% compared to inoculated treatments with T. ferrooxidans in application of ferrous sulfate, pyrite, and mill scale, respectively. The greatest effect of inoculation with T. ferrooxidans and T. thiooxidans was observed in using ferrous sulfate and then with a significant difference in mill scale application (Fig. 2).

Due to the fact that the experimental treatments did not exert a significant influence on the dry weight of plant shoots, a similar trend was observed for iron uptake by soybean and the shoots iron concentration (Figs. 2 and 3). Except that, in the application of pyrite, inoculation with T. thiooxidans did not have a significant impact on iron uptake compared to non-inoculated treatment (Fig. 3), while iron concentration showed a significant increase (Fig. 2).

The effect of iron compounds (control, iron sulfate, pyrite, and mill scale) and bacterial treatments (C, no inoculation; Tt, inoculation with T. thiooxidans; Tf, inoculation with T. ferrooxidans; Ttf, inoculation with T. thiooxidans + T. ferrooxidans) on iron uptake by soybean. Different lowercase letters indicate significant differences between treatments (P < 0.05)

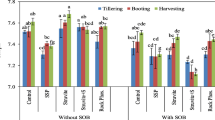

The results showed that in the control treatment, bacterial inoculation did not cause a significant increase in soil available Fe (Fig. 4), while inoculation with T. ferrooxidans and co-inoculation with T. thiooxidans and T. ferrooxidans significantly increased the uptake and concentration of iron in this treatment (Figs. 2 and 3).

The effect of iron compounds (control, iron sulfate, pyrite, and mill scale) and bacterial treatments (C, no inoculation; Tt, inoculation with T. thiooxidans; Tf, inoculation with T. ferrooxidans; Ttf, inoculation with T. thiooxidans + T. ferrooxidans) on soil available Fe. Different lowercase letters indicate significant differences between treatments (P < 0.05)

In non-inoculated treatments, application of ferrous sulfate, pyrite, and mill scale exerted no significant effect on soil available iron compared to the control (Fig. 5). Inoculation with T. thiooxidans also did not increase the availability of soil iron in the application of these iron sources. Inoculation with T. ferrooxidans in control and pyrite treatments did not cause a significant increase in soil available iron (Fig. 4), while a significant increase in the concentration and uptake of iron was observed in these treatments (Figs. 2 and 3).

The effect of iron compounds (control, iron sulfate, pyrite, and mill scale) and bacterial treatments (C, no inoculation; Tt, inoculation with T. thiooxidans; Tf, inoculation with T. ferrooxidans; Ttf, inoculation with T. thiooxidans + T. ferrooxidans) on soil pH. Different lowercase letters indicate significant differences between treatments (P < 0.05)

In application of ferrous sulfate and mill scale, inoculation with T. ferrooxidans increased the soil available iron by 36.3 and 69.2%, respectively (Fig. 4). The highest amount of soil available Fe was observed in simultaneous inoculation of two Thiobacillus species in ferrous sulfate treatment, which was not significantly different from mill scale treatments inoculated with T. ferrooxidans and co-inoculated with T. thiooxidans and T. ferrooxidans (Fig. 4), while the concentration and uptake of iron in these three treatments were significantly different (Figs. 2 and 3).

Although the changes in soil available Fe were not entirely consistent with changes in shoot iron concentration (Figs. 2 and 4), a significant positive linear relationship (R2 = 0.87, p < 0.01) was observed between these two parameters (Fig. 6).

According to Fig. 5, T. ferrooxidans inoculation alone and mixed with T. thiooxidans decreased soil pH in all iron treatments. Soil inoculated with T. thiooxidans had no significant effect on soil pH in control, ferrous sulfate, and pyrite treatments. In application of mill scale in all bacterial treatments, soil pH significantly decreased compared to the non-inoculated control treatment. The lowest value of pH = 7.39 was observed in simultaneous application of both bacteria in using ferrous sulfate (Fig. 5). This treatment caused the highest concentration of iron in soybean shoots (Fig. 2). Although the experimental treatments had a significant influence on soil pH, the difference in pH between treatments was not remarkable and the maximum difference was 0.4 pH units. However, pH indicated a significant negative linear relationship with shoot iron concentration (R2 = 0.62, p < 0.01) and soil available Fe (R2 = 0.49, p < 0.05) (Figs. 7 and 8).

4 Discussion

4.1 Laboratory Experiment

The low concentration of iron in pyrite and mill scale treatments in non-inoculated bacterial treatments is due to the poor water solubility of these compounds. Inoculation with T. thiooxidans also had no considerable effect on iron bioleaching from pyrite and mill scale, while iron bioleaching efficiency in the application of T. ferrooxidans was remarkable. Bevilaqua et al. (2002) also reported that the oxidation of chalcopyrite by T. thiooxidans was negligible while T. ferrooxidans was quite effective. T. ferrooxidans is capable of deriving energy from the oxidation of ferrous ions. Therefore, oxidation of ferrous iron in pyrite and mill scale structure can lead to dissolution of these compounds and increase the concentration of soluble iron. Differences in chemical and physical characteristics of the studied iron compounds such as iron oxidation states, the presence of sulfur in mineral structure, particle size distribution, specific surface area, crystallization, purity grade, and interactions between bacteria and surface mineral can cause difference in their biological dissolution. The effect of T. ferrooxidans to improve the bioleaching efficiency of sulfide mineral especially pyrite has been reported in many studies (Jiang et al. 2007; Fowler et al. 1999; Rodríguez et al. 2003). While T. thiooxidans was unable to oxidize ferrous iron, both T. thiooxidans and T. ferrooxidans have a similar pathway for sulfur oxidation by utilizing molecular oxygen in aerobic condition. T. ferrooxidans can also use ferric iron to oxidize sulfur (Sugio et al. 1985; Espejo et al. 1988). The chemical and biological reaction during the bio-oxidation of pyrite is as follows (Jiang et al. 2007; Chandra and Gerson, 2010):

As shown in reactions 1, 2, and 3, the pyrite desolation is depending on the oxidation rate of ferrous ions and concentration of ferric ions. The oxidation of ferrous ions to ferric ions was catalyzed by T. ferrooxidans (Jiang et al. 2007). Biological regeneration of ferrous ions by T. ferrooxidans plays a key role in continued bio-oxidation of pyrite.

T. ferrooxidans are able to reduce ferric iron as an electron acceptor using elemental sulfur as electron donor. Presence of sulfur, oxidation state of iron, and ferric/ferrous ratio are important factors affecting the iron mineral oxidation by T. ferrooxidans (Jiang et al. 2007; Rodríguez et al. 2003). Wu et al. (2019) showed that although adding elemental sulfur to the ferrous-containing medium caused the longer logarithmic phase of T. ferrooxidans growth, the final cell density was higher than the density of bacteria in medium without sulfur. Another important factor on bio-oxidation or biological dissolution of iron compounds is interactions between bacteria cells and surface minerals. Hosseini et al. (2005) attributed the difference in pyrite and chalcopyrite dissolution to the bacterial population bound to the mineral surface. In this regard, two different mechanisms, contact and non-contact, have been proposed. In non-contact or indirect mechanism, oxidation of soluble ferrous iron occurs by free cells or planktonic bacteria and involves the ferric-ferrous cycle. While in contact or direct mechanism, there is a physical connection between bacteria and mineral surface and redox reactions occur at mineral-bacteria interphase (Rohwerder et al. 2003). Rodríguez et al. (2003) stated cooperative bioleaching strategy that both free and attached to the mineral surface microorganisms is involved in the dissolution of pyrite. Bacterial attachment to minerals is a complex process. Interactions between bacteria and surfaces are controlled by many factors including mineral surface characteristics, surface properties of the cells via extracellular polymeric substances (EPS), and features of the culture medium such as, nutrients, pH, dissolved organic carbon, and type of bacteria. Extracellular polymeric substances (EPS) play a major role in bacterial attachment to the mineral surface (Sand and Gehrke 2006). The different substances in the bacterial culture medium affect the composition, functional groups, and the amount of EPS (Sharma et al. 2003; Devasia et al. 1993). Gehrke et al. (1998) reported that EPS from T. ferrooxidans mainly contain sugars in the presence of iron (II) sulfate while in the presence of sulfur, the major components were lipids. Therefore, it seems that addition of sulfur to the culture medium can affect the composition and amount of EPS and consequently the number of bacteria adhesions to mineral surfaces. In addition to the role of EPS in the electrostatic attachment of cell minerals, the importance of Fe (III) in EPS as a sulfide oxidizing agent at the cell-pyrite interface to enhance pyrite dissolution has been reported by Mitsunobu et al. (2016). Rapid attachment of both Acidithiobacillus ferrooxidans and Acidithiobacillus thiooxidans bacteria to the pyrite surface was reported by Liu et al. (2011). Fowler et al. (1999) stated that the bacteria with increasing pH at the mineral surface enhance the solubility of pyrite.

Significant reduction in pH values were observed in inoculated treatments with Thiobacillus bacteria and the application of sulfur caused a further reduction. Thiobacillus bacteria can reduce pH in sulfur-containing minerals such as pyrite with oxidizing sulfur to sulfuric acid. Addition of elemental sulfur can lead to further reduction of pH. T. ferrooxidans also oxidize ferrous iron to ferric iron and chemical hydration of ferric iron produces additional hydrogen ions. Reduction of pH in mill scale treatment by T. thiooxidans can be the result of iron hydrolysis due to partial biochemical dissolution of this mineral. In T. thiooxidans inoculated treatments, a remarkable decrease in pH was observed. However, T. thiooxidans activity did not cause a significant increase in iron solubility, which indicates that the acidification of solution did not have a remarkable effect on dissolution of studied iron-containing minerals.

4.2 Green House Experiment

Some studies reported significant increase in plant growth after using different iron compounds (Tiwari et al. 1982; Purakayastha et al. 1998; Dubey and Mondal 1994; Bayat and Kaya 1998; Ortas et al. 2015; Tozsin, and Arol 2015). It seems that in this study, nodulation success by Bradyrhizobium and increasing soil fertility by adding sulfur and manure are the reasons for low impact of iron treatments on the shoot dry weight. Argaw et al. (2015) also reported that a non-significant effect of directly supplied of FeSO4 (0 and 4 mg Fe kg−1 soil) to the soil on nodulation and shoot biomass of soybean. They stated that genotype, high soil native N, and symbiotic effectiveness might be the cause of the ineffectiveness of iron application. Heitholt et al. (2003) also indicated that the application of FeSO4 (0, 3, 10, 30, and 100 ppm Fe) had no effect on soybean biomass.

Without bacterial inoculation, the application of ferrous sulfate and mill scale had no impact on iron uptake by soybean compared to the control treatment. Probably, the use of pyrite as an energy source by chemoautotrophic bacteria such as soil native Thiobacillus species has been the reason for a significant increase of iron uptake and concentration only in pyrite treatment. Shenker and Chen (2005) stated that high soil pH, the presence of carbonates especially high calcium carbonate content, and high buffering capacity cause inefficiency or low efficiency of using iron mineral fertilizers such as ferrous sulfate on iron uptake by plants in calcareous soils. Although Mohammadi Torkashvand (2011) reported that the use of converter slag significantly increased shoot dry matter and Fe uptake by maize, the use of high amounts of converter slag (above 2%) seems to be the reason for increasing iron uptake by plant in this study. Wang and Cai (2006) showed that the application of steel slag at rates of 10 and 20 g kg−1 increased corn dry matter yield and Fe uptake and extractable Fe in a calcareous soil. Wallace and Wallace (1992) reported that application of large amounts of pyrite can be used as useful fertilizers and soil amendments in crop production on alkaline calcareous soils by using ways to increase the oxidation rate. Joseph et al. (2014) reported that pyrite amendment alone and along with T. ferrooxidans improved yields and nutrient uptake in canola and wheat in a sulfur-deficient alkaline soil.

Based on the results, inoculation with T. thiooxidans only in the application of pyrite increased the concentration of iron in the plant. Oxidation of structural sulfur in this mineral is probably the reason for increasing its dissolution and consequently increasing the availability of iron, while T. ferrooxidans inoculation increased iron uptake by soybean in application of all studied iron sources as well as control treatment. In fact, without the use of any iron source, the effect of T. ferrooxidans on soybean iron uptake in the control treatment was significant. In this regard, T. ferrooxidans can be applied as biofertilizers to increase Fe uptake by plant in calcareous soils.

Low efficacy of T. thiooxidans compared to T. ferrooxidans was also observed in the laboratory experiment, and this bacterium did not have a remarkable effect on the solubility of pyrite and mill scale. In a soil bioleaching experiment, Ko et al. (2013) reported that the application of T. ferrooxidans generated lower soil pH and higher amount of Fe3+ than T. thiooxidans.

The effect of T. ferrooxidans on increasing iron uptake in using ferrous sulfate and mill scale was greater than pyrite application. These results were inconsistent with the results of the laboratory section that T. ferrooxidans was more effective on pyrite dissolution than mill scale. The result is difficult to explain on the presented stage of experiments, although the impact of complex soil environment compared to controlled laboratory conditions may be the reason for the difference. Wallace and Wallace (1992) demonstrated that oxidation of pyrite in soil includes both chemical and biological processes and is affected by origin and crystallinity, particle size and purity of pyrite, and soil parameter such as pH, temperature, microbial activity, organic matter, and presence of phosphate. Pyrite oxidation processes under simulated calcareous soil conditions was studied by Lara et al. (2015). They reported that after the initial dissolution, meta stable siderite (FeCO3)-like compound and subsequent jarosite and ferric oxyhydroxide were formed in pyrite surface depending on the surface acid condition reached in the systems. The formation of these secondary compounds was found to play a significant role in pyrite weathering.

Simultaneous soil inoculation with T. ferrooxidans and T. thiooxidans showed a synergistic effect on increasing iron uptake by soybean in all three studied iron sources. Liu et al. (2011) reported that the mixed culture of T. ferrooxidans and T. thiooxidans was more effective in pyrite solubilization than T. ferrooxidans. In addition, the effectiveness of simultaneous application of T. ferrooxidans and T. thiooxidans on metal bioleaching has been reported in some studies (Wang et al. 2009; Nguyen et al, 2015).

Soil pH is considered a major soil variable affecting iron availability. Due to the fact that calcium carbonate in calcareous soils causes a very high pH buffer capacity, the low pH changes in the experimental treatments were expected, although the addition of organic matter and sulfur to the studied soil before planting could be another reason for the low pH changes between the different treatments.

Simultaneous inoculation with T. thiooxidans and T. ferrooxidans had the greatest impact on soil available Fe as well as the shoot iron concentration and iron uptake by soybean. However, changes in soil iron alone were not sufficient to interpret changes in concentration and uptake of iron. This may be attributed to the rhizosphere effect. The effect of Thiobacillus bacteria on iron solubility may be limited to the rhizosphere area. Interactions between microbes and plant roots in rhizosphere can improve Fe availability by redox, complexation, and acidification processes (Colombo et al. 2014; Rengel 2015). Assuming that the effect of experimental treatments in the rhizosphere was greater than bulk soil, inoculation of seeds with bacteria may have similar results compared to soil inoculation, which should be considered. Bayat and Kaya (1998) stated that under field conditions, increasing wheat grain yield up to 25% due to application of pyrite may be as a result of decreased rhizosphere pH and as a consequence of increasing pyrite solubility. Awad et al. (2011) revealed that in soil inoculation with Thiobacillus, first the pH decreased and then increased over time and at the end of the growing period, the soil pH changes from 7.8 to 7.5. A decrease in soil pH from 7.2 to 7.0 has also been reported by Anandham et al. (2007).

Although in this study the effect of pyrite and mill scale application on the accumulation of heavy metals in plant and soil was not investigated, the effect of long-term use of these compounds on soil and plant contamination should be considered.

5 Conclusion

Microbial biofortification with application of effective microorganisms can be well used as a sustainable and economical way to address plant nutrient deficiencies. In the current study, the application of iron waste along with Thiobacillus bacteria exhibited effectiveness in increasing iron concentration in soybean shoots in a calcareous soil under greenhouse conditions. The results showed that Thiobacillus ferrooxidans was more effective than Thiobacillus thiooxidans on uptake of iron by soybean in the application of ferrous sulfate, mill scale, and pyrite. Simultaneous application of Thiobacillus ferrooxidans and Thiobacillus thiooxidans had a synergistic effect on the iron concentration of the plant. Based on the results, the use of iron waste along with Thiobacillus bacteria can be considered an agronomic biofortification method in plant iron nutrition in calcareous soils.

References

Abbaspour A, Kalbasi M, Shariatmadari H (2005) Effect of steel converter sludge as iron fertilizer and soil amendment in some calcareous soils. J Plant Nutr 27:377–394. https://doi.org/10.1081/PLN-120027661

Aciksoz S, Yazici A, Ozturk L, Cakmak I (2011) Biofortification of wheat with iron through soil and foliar application of nitrogen and iron fertilizers. Plant Soil 349:215–225. https://doi.org/10.1007/s11104-011-0863-2

Adu MO, Asare PA, Yawson DO, Nyarko MA, Osei-Agyeman K (2018) Agronomic biofortification of selected underutilized Solanaceae vegetables for improved dietary intake of potassium (K) in Ghana. Heliyon 4:1–30. https://doi.org/10.1016/j.heliyon.2018.e00750

Akhtar MS, Babel S, Yadav BK, Yadav RS, Panwar J (2012) Potentiality of Thiobacillus in agricultural system. Adv Sci Eng Med 4:77–80. https://doi.org/10.1166/asem.2012.1123

Anandham R, Sridar R, Nalayini P, Poonguzhali S, Madhaiyan M, Tongmin S (2007) Potential for plant growth promotion in groundnut (Arachis hypogaea L.) cv. ALR-2 by co-inoculation of sulfur-oxidizing bacteria and Rhizobium. Microbiol Res 162:139–153. https://doi.org/10.1016/j.micres.2006.02.005

Argaw A, Mekonnen E, Muleta D (2015) Agronomic efficiency of N of common bean (Phaseolus vulgaris L.) in some representative soils of Eastern Ethiopia. Cogent Food Agric 1:1–15. https://doi.org/10.1080/23311932.2015.1074790

Askary M, Amirjani MR, Saberi T (2017) Comparison of the effects of nano-iron fertilizer with iron-chelate on growth parameters and some biochemical properties of Catharanthus roseus. J Plant Nutr 40:974–982. https://doi.org/10.1080/01904167.2016.1262399

NM Awad AA Abd El-Kader M Attia AK Alva 2011 Effects of nitrogen fertilization and soil inoculation of sulfur-oxidizing or nitrogen-fixing bacteria on onion plant growth and yield Int J Agron 1–6 https://doi.org/10.1155/2011/316856

Aziz MZ, Yaseen M, Abbas T, Naveed M, Mustafa A, Hamid Y, Saeed Q, Ming-gang XU (2019) Foliar application of micronutrients enhances crop stand, yield and the biofortification essential for human health of different wheat cultivars. J Integr Agric 18:1369–1378. https://doi.org/10.1016/S2095-3119(18)62095-7

O Bayat Z Kaya (1998) The use of pyrite from a zinc processing plant as a fertilizer in calcareous soils. 1998 2nd International Symposium on Mine Environmental Engineering 29–31 July Brunel University England https://doi.org/10.1080/01904167.2014.957392

Besharati H (2017) Effects of sulfur application and Thiobacillus inoculation on soil nutrient availability, wheat yield and plant nutrient concentration in calcareous soils with different calcium carbonate content. J Plant Nutr 40:447–456. https://doi.org/10.1080/01904167.2016.1245326

Bevilaqua D, Leite ALLC, Garcia O, Tuovinen OH (2002) Oxidation of chalcopyrite by Acidithiobacillus ferrooxidans and Acidithiobacillus thiooxidans in shake flasks. Process Biochem 38:587–592. https://doi.org/10.1016/S0032-9592(02)00169-3

Bouranis DL, Chorianopoulou SN, Margetis M, Saridis GI, Sigalas PP (2018) Effect of elemental sulfur as fertilizer ingredient on the mobilization of iron from the iron pools of a calcareous soil cultivated with Durum wheat and the crop’s iron and sulfur nutrition. Agriculture 8:1–17. https://doi.org/10.3390/agriculture8020020

Cakmak I (2008) Enrichment of cereal grains with zinc: agronomic or genetic biofortification? Plant Soil 302:1–17. https://doi.org/10.1007/s11104-007-9466-3

MA Castelo-Branco A Oliveira F Pereira Pires S Dias LM Fernandes VE Silva JM, Santos J, Magalhaes I, Ramalho Ribeiro J, Moreira O, Gama J, 1999 Potential use of pyrite as an amendment for calcareous soil J Geochem Explor 66 363 367 https://doi.org/10.1016/S0375-6742(99)00026-6

Chandra AP, Gerson AR (2010) The mechanisms of pyrite oxidation and leaching: a fundamental perspective. Surf Sci Rep 65:293–315. https://doi.org/10.1016/j.surfrep.2010.08.003

Chen X, Wei X, Hao M, Zhao J (2019) Changes in soil iron fractions and availability in the loess belt of northern China after 28 years of continuous cultivation and fertilization. Pedosphere 29:123–131. https://doi.org/10.1016/S1002-0160(17)60331-X

Colombo C, Palumbo G, He JZ, Pinton R, Cesco S (2014) Review on iron availability in soil: interaction of Fe minerals, plants, and microbes. J Soils Sediments 14:538–548. https://doi.org/10.1007/s11368-013-0814-z

Devasia P, Natarajan K, Sathyanarayana D, Rao GR (1993) Surface chemistry of Thiobacillus ferrooxidans relevant to adhesion on mineral surfaces. Appl Environ Microbiol 59:4051–4055. https://doi.org/10.1128/aem.59.12.4051-4055.1993

Dubey SK, Mondal RC (1994) Effect of amendments and saline irrigation water on soil properties and yields of rice and wheat in a highly sodic soil. J Agric Sci 122:351–357. https://doi.org/10.1017/S0021859600067277

Espejo RT, Escobar B, Jedlicki E, Badilla-Ohlbaum UP, R, (1988) Oxidation of ferrous iron and elemental sulfur by Thiobacillus ferrooxidans. Appl Environ Microbiol 54:1694–1699. https://doi.org/10.1128/aem.54.7.1694-1699.1988

Fowler TA, Holmes PR, Crundwell FK (1999) Mechanism of pyrite dissolution in the presence of Thiobacillus ferrooxidans. Appl Environ Microbiol 65:2987–2993. https://doi.org/10.1128/AEM.65.7.2987-2993.1999

García-Bañuelos ML, Sida-Arreola JP, Sánchez E (2014) Biofortification-promising approach to increasing the content of iron and zinc in staple food crops. J Elem 19:865–888. https://doi.org/10.1007/s42106-020-00100-w

Garg M, Sharma N, Sharma S, Kapoor P, Kumar A, Chundari V, Arora P (2018) Breeding crops generated by breeding, agronomy, and transgenic approaches are improving lives of millions of people around the world. Front Nutr 5:1–33. https://doi.org/10.3389/fnut.2018.00012

Gehrke T, Telegdi J, Thierry D, Sand W (1998) Importance of extracellular polymeric substances from Thiobacillus ferrooxidans for bioleaching. Appl Environ Microbiol 64:2743–2747. https://doi.org/10.1128/AEM.64.7.2743-2747.1998

Granja F, Covarrubias JI (2018) Evaluation of acidifying nitrogen fertilizers in avocado trees with iron deficiency symptoms. J Soil Sci Plant Nutr 18:157–172. https://doi.org/10.4067/S0718-95162018005000702

Heitholt JJ, Sloan JJ, MacKown CT, Cabrera RI (2003) Soybean growth on calcareous soil as affected by three iron sources. J Plant Nutr 26:935–948. https://doi.org/10.1081/PLN-120018575

Hosseini T, Kolahdoozan M, Tabatabaei Y, Oliazadeh M, Noaparast M, Eslami A, Manafi Z, Alfantazi A (2005) Bioflotation of Sarcheshmeh copper ore using Thiobacillus ferrooxidans bacteria. Miner Eng 18:371–374. https://doi.org/10.1016/j.mineng.2004.06.005

Jiang L, Zhou HY, Peng XT (2007) Bio-oxidation of pyrite, chalcopyrite and pyrrhotite by Acidithiobacillus ferrooxidans. Chin Sci Bull 52:2702–2714. https://doi.org/10.1007/s11434-007-0352-4

Joseph AR, Kavimandan SK, Tilak KV, Nain L (2014) Response of canola and wheat to amendment of pyrite and sulphur-oxidizing bacteria in soil. Arch Agron Soil Sci 60: 367–375. /https://doi.org/10.1080/03650340.2013.799275

Karimian N, Kalbasi M, Hajrasuliha S (2012) Effect of converter sludge, and its mixtures with organic matter, elemental sulfur and sulfuric acid on availability of iron, phosphorus and manganese of 3 calcareous soils from central Iran. Afr J Agric Res 7:568–576. https://doi.org/10.5897/AJAR11.1484

Khan A, Singh J, Upadhayay VK, Singh AV, Shah S (2019) Microbial biofortification: a green technology through plant growth promoting microorganisms. In: Shah S, Venkatramanan V, Prasad R. (eds.) Sustain Green Technol Environ Manage Springer, Singapore. https://doi.org/10.1007/978-981-13-2772-8_13

Klikocka H, Marks M (2018) Sulfur and nitrogen fertilization as a potential means of agronomic biofortification to improve the content and uptake of microelements in spring wheat grain DM. J Chem 2018:1–20. https://doi.org/10.1155/2018/9326820

Ko MS, Park HS, Kim KW, Lee JU (2013) The role of Acidithiobacillus ferrooxidans and Acidithiobacillus thiooxidans in arsenic bioleaching from soil. Environ Geochem Health 35:727–733. https://doi.org/10.1007/s10653-013-9530-2

Lara RH, Mallet M, Monroy MG, Dossot M, Gonzalez MA, Cruz R (2015) An experimental study of iron sulfides weathering under simulated calcareous soil conditions. Environ Earth Sci 73:1849–1869. https://doi.org/10.1007/s12665-014-3540-y

Lindsay WL, Norvell WA (1978) Development of a DTPA soil test for zinc, iron, manganese and copper. Soil Sci Soc Am J 42:421–428. https://doi.org/10.2136/sssaj1978.03615995004200030009x

Liu H, Gu G, Xu Y (2011) Surface properties of pyrite in the course of bioleaching by pure culture of Acidithiobacillus ferrooxidans and a mixed culture of Acidithiobacillus ferrooxidans and Acidithiobacillus thiooxidans. Hydrometallurgy 108:143–148. https://doi.org/10.1016/j.hydromet.2011.03.010

Lucena JJ (2006) Synthetic iron chelates to correct iron deficiency in plants. In: Barton L L, Abadia J. (eds.) Iron nutrition in plants and rhizospheric microorganisms. Springer, Dordrecht. https://doi.org/10.1007/1-4020-4743-6_5

Marsolek MD, Hagstrom GR (1982) Acidified mining residue for correction of iron chlorosis on calcareous soils. J Plant Nutr 5:941–948. https://doi.org/10.1080/01904168209363024

McFarland J (1907) Nephelometer: an instrument for media used for estimating the number of bacteria in suspensions used for calculating the opsonic index and for vaccines. J Am Med Assoc 14: 1176–1178. Cited in: Dalynn Biologicals (2012) McFarland standard-for in vitro use only- Catalogue No. TM50-TM60. www.dalynn.com/dyn/ck_assets/files/tech/TM53.pdf

MitSunobu S, Zhu M, Takeichi Y, Ohigashi T, Suga H, Makita H, Sakata M, Ono K, Mase K, Takahashi Y (2016) Direct detection of Fe (II) in extracellular polymeric substances (EPS) at the mineral-microbe interface in bacterial pyrite leaching. Microbes Environ 31:63–69. https://doi.org/10.1264/jsme2.ME15137

Mohammadi Torkashvand A (2011) Effect of steel converter slag as iron fertilizer in some calcareous soils. Acta Agric Scand B 61:14–22. https://doi.org/10.1080/09064710903410031

S Ndlovu GS Simate E Matinde 2017 Waste production and utilization in the metal extraction industry Taylor and Francis, CRC Press https://doi.org/10.1201/9781315153896

Nesheim L, Gautneb H, Myhr K (1997) Plant uptake of sulphur and trace elements from pyrite applied on grassland. Acta Agric Scand B 47:135–141. https://doi.org/10.1080/09064719709362453

Nguyen VK, Lee MH, Park HJ, Lee JU (2015) Bioleaching of arsenic and heavy metals from mine tailings by pure and mixed cultures of Acidithiobacillus spp. J Ind Eng Chem 21:451–458. https://doi.org/10.1016/j.jiec.2014.03.004

Niyigaba E, Twizerimana A, Mugenzi I, Ngnadong WA, Ye YP, Wu BM, Hai JB (2019) Winter wheat grain quality, zinc and iron concentration affected by a combined foliar spray of zinc and iron fertilizers. Agronomy 9:1–18. https://doi.org/10.3390/agronomy9050250

Ortas I, Kaya Z, Ercan S (2015) Effect of pyrite application on wheat-maize growth and nutrient uptake under diverse soil conditions. J Plant Nutr 38:295–309. https://doi.org/10.1080/01904167.2014.957392

Prasanna R, Nain L, Rana A, Shivay YS (2016) Biofortification with microorganisms: present status and future challenges. In: Singh U, Praharaj C, Singh S, Singh N. (eds.) Biofortification of food crops. Springer, New Delhi. https://doi.org/10.1007/978-81-322-2716-8

Purakayastha TJ, Singh CS, Chhonkar PK (1998) Growth and iron nutrition of broccoli (Brassica oleracea L. var. italic Plenck), grown in a Typic Ustochrept, as influenced by vesicular-arbuscular mycorrhizal fungi in the presence of pyrite and farmyard manure. Biol Fertil Soil 27:35–38. https://doi.org/10.1007/s003740050396

Rengel Z (2015) Availability of Mn, Zn and Fe in the rhizosphere. J Soil Sci Plant Nutr 15:397–409. https://doi.org/10.4067/S0718-95162015005000036

Rodríguez Y, Ballester A, Blázquez M, González F, Muñoz J (2003) New information on the pyrite bioleaching mechanism at low and high temperature. Hydrometallurgy 71:37–46. https://doi.org/10.1016/S0304-386X(03)00172-5

Rohwerder T, Gehrke T, Kinzler K, Sand W (2003) Bioleaching review part A: Progress in bioleaching: fundamentals and mechanisms of bacterial metal sulfide oxidation. Appl Microbiol Biotechnol 63:239–248. https://doi.org/10.1007/s00253-003-1448-7

Rui M, Ma C, Hao Y, Guo J, Rui Y, Tang X, Zhao Q, Fan X, Zhang Z, Hou T, Zhu S (2016) Iron oxide nanoparticles as a potential iron fertilizer for peanut (Arachis hypogaea). Front Plant Sci 7:815. https://doi.org/10.3389/fpls.2016.00815

Sand W, Gehrke T (2006) Extracellular polymeric substances mediate bioleaching/biocorrosion via interfacial processes involving iron (III) ions and acidophilic bacteria. Res Microbiol 157:49–56. https://doi.org/10.1016/j.resmic.2005.07.012

Sharma P, Das A, Rao KH, Forssberg K (2003) Surface characterization of Acidithiobacillus ferrooxidans cells grown under different conditions. Hydrometallurgy 71:285–292. https://doi.org/10.1016/S0304-386X(03)00167-1

Shenker M, Chen Y (2005) Increasing iron availability to crops: fertilizers, organo-fertilizers, and biological approaches. Soil Sci Plant Nutr 51:1–17. https://doi.org/10.1111/j.1747-0765.2005.tb00001.x

Singh BR, Timsina YN, Lind OC, Cagno S, Janssens K (2018) Zinc and iron concentration as affected by nitrogen fertilization and their localization in wheat grain. Front Plant Sci 9:307. https://doi.org/10.3389/fpls.2018.00307

Soil Survey Staff (2010) Keys to soil taxonomy, 11th edn. Lincoln, USDA. National Resources Conservation Service. National Soil Survey Center

Sugio T, Domatsu C, Munakata O, Tano T, Imai K (1985) Role of a ferric ion-reducing system in sulfur oxidation of Thiobacillus ferrooxidans. Appl Environ Microbiol 49:1401–1406. https://doi.org/10.1128/AEM.49.6.1401-1406.1985

Tiwari KN, Pathak AN, Upadhyay GP (1982) Effect of sedimentary pyrites and Zn application on yield, Zn and ca nutrition of rice and wheat crops and on amelioration of saline sodic soil. J Agric Sci 99:411–416. https://doi.org/10.1017/S0021859600030203

Tozsin G, Arol AI (2015) Pyritic tailings as a source of plant micronutrients in calcareous soils. Comm. Soil Sci. Plant Anal 46: 1473–1481. https://doi.org/10.1080/00103624.2015.1043446

Wallace A, Wallace GA (1992) Factors influencing oxidation of iron pyrite in soil. J Plant Nutr 15:1579–1587. https://doi.org/10.1080/01904169209364423

Wang J, Bai J, Xu J, Liang B (2009) Bioleaching of metals from printed wire boards by Acidithiobacillus ferrooxidans and Acidithiobacillus thiooxidans and their mixture. J Hazard Mater 172:1100–1105. https://doi.org/10.1016/j.jhazmat.2009.07.102

Wang X, Cai QS (2006) Steel slag as an iron fertilizer for corn growth and soil improvement in a pot experiment. Pedosphere 16:519–524. https://doi.org/10.1016/S1002-0160(06)60083-0

Wu L, Yang B, Wang X, Wu B, He W, Gan M, Qiu G, Wang J (2019) Effects of single and mixed energy sources on intracellular nanoparticles synthesized by Acidithiobacillus ferrooxidans. Minerals 9:163. https://doi.org/10.3390/min9030163

Yang X, Alidoust D, Wang C (2020) Effects of iron oxide nanoparticles on the mineral composition and growth of soybean (Glycine max L.) plants. Acta Physiol Plant 42: 128. https://doi.org/10.1007/s11738-020-03104-1

Funding

This study was funded by Ferdowsi University of Mashhad with grant number 3/38839.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Daliran, T., Halajnia, A. & Lakzian, A. Thiobacillus Bacteria-Enhanced Iron Biofortification of Soybean in a Calcareous Soil Enriched with Ferrous Sulfate, Mill Scale, and Pyrite. J Soil Sci Plant Nutr 22, 2221–2234 (2022). https://doi.org/10.1007/s42729-022-00804-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42729-022-00804-0