Abstract

The increasing demand for alternative feed sources for livestock has evolved, owing to quest for efficient and sustainable use of resource channeled towards achieving food security. Breeding and biomass conversion of selected insects therefore, is imperative to complement existing sources. This study investigated the developmental parameters, and nutritional composition of Black soldier fly (BSF) (Hermetia illucens) larvae reared on chicken feed (CF), brewery waste (BW), food remains (FR) and fruits’ waste (FR). Proximate compositions (%) of prepupae and substrates were analyzed for dry matter (DM), crude protein (CP), ether extracts (EE), ash, fibre and mineral composition. Data were analyzed using analysis of variance (ANOVA) tests and Tukey (homoscedasticity) using SPSS statistical package. CF recorded the highest prepupal weight (0.30 g), length (2.18 cm), and shortest development time (21 days) across the different substrates. CP content was highest in prepupa fed on CF and BW at 48.93% and 44.52% respectively (p < 0.05). The ash contents and EE of the prepupae differed significantly across the different substrates. Prepupae reared on CF were low in EE and high in ash content (4.12% and 9.24%, respectively) compared to those reared on FW (13.90% and 5.24%, respectively), BW (11.23% and 10.29%, respectively) and FR (9.52% and 5.24, respectively). BSF larvae fed on different substrates exhibited different mineral accumulation patterns, with FW resulting in the largest turnover of minerals (Potassium 46.94 g/kg). The rearing of BSF larvae can be optimized on identified organic substrates into edible biomass suitable for use as an alternative protein source.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The earth’s biodiversity is under threat due to the increase in the dedication of arable land and natural resources to food production. Over the next 50 years, food demand is expected to double. is poses huge challenges to the sustainability of food production (Tilman and Clark 2014). A new tactic of food production such as sustainable insect production which adopts large improvement in recycling available resources and waste can be introduced to reduce their environmental impact and also achieve higher yields with less waste per hectare of productive land (Stamer 2015). Around 90 million tons of foods from private households, retailers and the food industry are discarded each year in the European Union alone (Stamer 2015). In Nigeria, 0.65–0.95 kg/capita of waste is produced daily, culminating to an average of 42 million tonnes of wastes generated annually (Ike et al. 2018). It is against this background that insect farming for food and feed are envisaged to mitigate the effects of some of the afore-mentioned challenges (Babarinde et al. 2020).

Insect farming is a viable new source of animal protein which can be done in high densities with small space requirements as they have a high bioconversion ratio (Oonincx and De Boer 2012). Farming of insects is important and contributes to the economic growth of developing countries as many farmers derive their sources of income from this enterprise (Naseem et al. 2020). Furthermore, many insects can be reared on waste streams, which keep the environmental footprint low and assists in recycling of refuse (Smetana et al. 2016). Insects contain high amounts of energy, protein and essential amino acids, fatty acids and micronutrients (e.g. copper, iron, zinc). (van Huis et al. 2013; Verkerk et al. 2007; Rumpold and Schlüter 2013).

Black soldier fly (BSF) (Hermetia illucens) larvae have already been used as a component of complete diets for poultry, swine, and several commercial fish species (Hale 1973; Newton et al. 1977; Sheppard et al. 2002). The results showed that breeding of BSF larvae support good growth, hence the conclusion that they can be a suitable protein source for livestock feed. At the pre-pupal stage, the larva stops feeding and empties its digestive tract. Then, the prepupae migrate to a dry and protected site. The adults do not feed and rely on the nutrients accumulated and stored during the larval stage (Sheppard et al. 2002). So far, an in-depth analysis of the nutritional value of BSF larvae reared on commercially available organic waste streams has not been reported in Nigeria. In this study, the proximate and nutrient composition of the prepupae reared on different organic waste substrates and their relationships with substrate composition were investigated.

Materials and methods

Rearing and harvesting of black soldier fly larvae

BSF eggs were purchased from Tucur BSF Farms at Ibadan, Oyo State, Nigeria. The eggs were hatched in 250 ml plastic containers containing chicken feed (broiler’s mash) mixed with distilled water (60% moisture content) in order to ensure a favorable moisture content for growth of the larvae. After five days, the first instar larvae were sieved through a 1.2 mm diameter mesh screen and sorted into the various rearing substrates and replicated for the duration of the experiment.

The larvae were fed two grams (2 g) of substrate per gram of larvae and feeding took place every two days or until their feed was finished. In accordance with European Commission (EC) Regulation No 1069/09, none of the substrates contained animal products EC (2009). Distilled water was added to the chicken feed and brewer’s mash (50 mL/100/ g of substrate) in order to guarantee an optimal moisture content for growth of the larvae.

Preparation of substrates

Four (4) different rearing substrates were evaluated for their influence on the development and proximate composition of BSF larvae: chicken feed (CF), brewery waste (BW), fruits’ waste (FW) and food remains (FR). The chicken feed (Animal Care® brand of broiler’s starter mash) was obtained from Funfas Feed Depot, Mushin, Lagos, Nigeria. Brewery waste was obtained from Nigerian Breweries Plc, Iganmu, Lagos, Nigeria. The food remains were made up of mainly rice, beans, plantain and vegetables, while fruits’ waste consisted mostly of discarded pawpaw, pineapple, orange, watermelon and banana sourced from Mavise Restaurant and various fruits’ sellers in the University of Lagos, Nigeria. The wastes were shredded into finer pieces using a Kenwood(R) grinder.

The larvae were fed two grams (2 g) of substrate per gram of larvae and feeding took place every two days. In accordance with EC Regulation No 1069/09, none of the substrates contained animal products EC (2009). Water was added to the chicken feed and brewer’s mash (50 mL/100/g of substrate) in order to guarantee an optimal moisture content for growth of the larvae.

Experimental setup

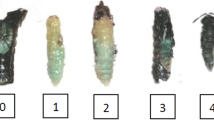

A total of 500 5- to 8-day old larvae per replicate were placed in triplicates with 300 g fresh material of each substrate type in the plastic containers (250 ml). The larvae were subjected to a feeding regime of two grams (2 g) of substrate per gram of larvae, and feeding took place every two days until the first few prepupae were sighted in each container (Diener et al. 2009). All larvae and prepupae were harvested 6 days after the first prepupae appearance, which was about 2–4 weeks after the start of the experiment. The length of time of development was recorded for each substrate, while the length and weight of five randomly selected pre-pupae from each replicate were measured and recorded. The pre-pupae were harvested by sieving through 3 mm diameter mesh screen.

The collected prepupae were washed with water and placed in sample collection tubes and stored at −20 °C in a freezer pending proximate analysis. While freeze-drying may result in less complete moisture removal compared to oven drying, this difference is minimal and freeze-drying guarantees a better preservation of nutrients (Spranghers et al. 2017). Handling of prepupae was done with forceps and 50 g of prepupae and substrate were collected manually from each replicate and placed into sample containers.

Proximate analyses

The proximate analyses consisted of analytical determinations of water (moisture), dry matter, crude protein, crude fat (ether extract), crude ash and crude fibre as described by Greenfield and Southgate (2003). Moisture content (MC) was determined by difference after freeze-drying. Dry matter was calculated by the weight difference before and after drying the sample in the oven at 100 °C for 24 h. Crude ash was determined by incineration of samples at 550 °C for 6 h. in a combustion oven. Crude protein was determined using Dumas-Gaudot et al. (2002) method, using a nitrogen-to-protein conversion factor of 6.25. Ether extract (EE), a measure of crude fat, was analyzed gravimetrically after extraction with diethyl ether using a Soxhlet system. Crude fiber content was determined using Driemeyer (2016) method. The content of soluble, insoluble and total dietary fibre in the substrates were determined using the Megazyme total dietary fibre assay procedure k-tdfr 05/12.27. This method is a simplified modification of the AACC total dietary fibre (TDF) method, 32–05.01, and the AACC soluble/insoluble dietary fibre method. These analyses were performed in duplicates and according to method reported by AOAC (2012). The proximate parameters were calculated using the following formulae:

where;

- A:

-

Weight of empty and dry crucible (g)

- B:

-

Weight of air dried test sample (g)

- C:

-

Weight of crucible and moisture free test sample (g)

where:

- A:

-

Mass of residue in crucible after drying (g)

- B:

-

Mass of residue in crucible after ashing (g)

Mineral composition

The mineral composition of the substrates and the prepupae was determined using inductively coupled plasma optical emission spectrometry (ICP-OES) (BSI 2001). The samples were incinerated until the ash grey turns red–brown and digested in diluted nitric acid (7 mol/L) British Standard Institution (2001). The extraction of iron was performed separately using aqua regia (International Organization for Standardization 2002).

Statistical analysis

All data were analysed using one-way analysis of variance (ANOVA) in SPSS 23.0 IBM (2015) (SPSS Inc., Chicago, IL, USA), with 95% confidence interval performed to identify statistically significant differences between developmental parameters and proximate composition. Where a significant difference was found, Tukey post-hoc test with 95% confidence interval was performed. P-values below 0.05 were considered statistically significant.

Results

Larvae bred on fruits’ waste recorded lowest mean prepupal weights (0.12 ± 0.02 g) at the same feeding rate of 2g of feed/lg of larva similar trends were also observed for the length for fruits’ waste (1.52 cm ± 0.08) and longest time (38 days) for emergence of larvae (p < 0.05). After 21 days, the first few prepupae were observed in plastic containers with chicken feed, whereas on brewery waste, it took 23 days for the first prepupae to emerge. These developmental time, were however significantly different (p < 0.05) from one another (Table 1).

Proximate composition of BSF prepupae and substrates

The dry matter (DM) content were comparable in two of the four substrates with values between 76.57 and 76.60% (Table 2). Only the food remains was substantially higher in moisture with a DM value of 82.82%. However, contents of crude protein, ash and fibre were highly variable among the substrates. The crude protein content varied from 32.97 ± 0.50 to 48.93 ± 0.61% among the substrates (Table 2). The crude protein content of the prepupae were low (32.97–44.52%) with the exception of chicken feed (48.93%) (Table 3). The food remains and fruits’ waste contained low amounts of phytic acid (12.66 and 15.53 mg/g), respectively (Table 3).

Mineral composition of black soldier fly prepupae

The four substrates demonstrated different accumulation patterns of minerals. Potassium levels were very variable ranging from 26.63 g/kg DM for those fed on brewery waste to 46.94 g/kg DM for substrate reared on food remains (Table 4). Magnesium contents were between 17.35 and 26.47 g/kg DM. The calcium content of prepupae fed brewery waste was equal to that of prepupae fed food remains (5.21%), while the calcium levels of the respective substrates were markedly different (5.18 vs. 5.42% respectively).

The values recorded for the Zinc and Copper content of both substrates and prepupae were all within a small range (0.018 to 0.18 g/kg DM) and (0.02 and 0.11 g/kg DM) respectively for larvae bred on the all the feed substates.

Discussion

The developmental parameters and nutrient composition of different organic wastes used as substrates in rearing BSF larvae to prepupae were investigated in this study. These findings are valuable to improve the mass breeding and biomass conversion of BSF larvae, complementing existing channels of adequate protein sources to meet exponential increase in human population. The high larvae body weight, development time and average biomass observed for chicken mash (CM) and brewery waste (BW) in this study can be attributed to superior nutritional content of the diets. Previous work in support of this assertion includes that of Tschirner and Simon (2015). Comparatively, chicken mash consists of a heterogeneous mixture of maize, wheat offal and concentrates. Also, the brewery waste (BW) is a mixture of spent grains and yeast cells used for grain fermentation, and proximate composition shows that it contains 44.52% crude protein, 10.29% crude fibre and higher amounts of metabolisable energy (Munguti et al. 2006), which explains its superior performance (Oonincx et al. 2015).

According to Diener et al. (2009), the preference for a substrate at different instars may be related to the structure of the raw material. This could have accounted for the high larval growth rate response for chicken feed and brewery waste, within 21 and 23 days respectively. The fine particle size, coupled with nutrient composition are perhaps the basis for recommending special starter diets in insect production systems (Oonincx et al. 2015). On the other hand, fruits’ waste (FW) showed poor performance as rearing substrate for BSF larvae. Documented proximate analysis of banana peels which is a component of fruits’ waste shows that they contain crude protein of 7.2–8.6%, crude lipids (7.9% - 8.5%), crude fiber (11.3%), nitrogen free extracts (53.8% - 62.7%), and ash (7.8%–10.9%) irrespective of variety or locality of collection of banana (Munguti et al. 2006). The poor performance of the substrate can therefore be attributed to its low crude protein to carbon content ratio and high crude fiber content (Tschirner and Simon 2015). The low protein content may have adversely affected both the larval growth rate and the total prepupal yield while high dietary fibre is known to cause poor growth as it causes delayed feeding, reduced feed intake, digestibility and nutrient utilization (Tomberlin et al. 2009).

The crude protein content of the prepupae from different substrates generally reflected the nutrient content of the substrates used. In addition, the observed protein content of the biomass produced from all the tested substrates ranged from 32.97 to 48.93% which is slightly higher than the range (33 to 41%) reported by Marwa et al. (2019). This is due to the fact that the larvae were reared on almost the same range of same feed substrate (food remains and brewery waste) with exception of chicken feed and fruits’ waste, harvested at the same stage (prepupae) and processed by the same method. These values are sufficient to recommend the use of the larval product as protein source in the animal feed industry (Liu et al. 2008) and can replace fishmeal and soybean meal in conventional livestock feeds (Bosch et al. 2019).

The link between composition and diet suggests the possibility of rearing BSF larvae on specialized substrates in order to customize resultant biomass nutrient content to meet needs of targeted animals (St-Hilaire et al. 2007). All the substrates in this study yielded prepupae having high fat and variable crude protein contents. This shows that BSF larvae are efficient at bioconversion and valorization process as they are able to convert low nutrient substrates into high value biomass with sufficient nutrient quantities. In addition to CP, other nutritional components of livestock feed can greatly enhance the quality of animal production, including several minerals and vitamins such as calcium, magnesium, phosphorus, copper, cobalt and vitamins A or D). For example, calcium and phosphorous play important roles in physiological functions of animals including muscle mass reductions, neuro-signaling, enzymatic activity, metabolic reactions, construction of proteins, maintenance of osmotic and acidic-alkaline equilibria and construction of membranes (Ewing and Charlton 2007).

With reference to bone and egg formation in layer hens, calcium in particular plays a crucial role as it contributes to more than 90% of the mineral matrix. Therefore, deficiencies in calcium and phosphorus can result in bone loss, growth retardation and abnormal posture (Hafeez et al. 2015). The range of calcium concentrations reported in this study (5.21 to 12.85%) was higher than that (1.7 to 3.2%) in Marwa et al. (2019). Potassium levels in BSF prepupae from our experiments were high compared to the levels reported in Marwa et al. (2019). The prepupal contents of other minerals with importance for animal feed, such as copper, potassium and manganese, appear to be unaffected by rearing substrate type. Moreover, phosphorus levels are in compliance with the requirements of pigs (NRC 2012.; and poultry (CVB 2012). In this regard, edible insects with abundant minerals are likely to reduce the consumption of dairy, meat and animal protein products (Van Huis et al. 2013; Oonincx et al. 2015).

The variability in the range of values of mineral content of BSF larvae can be ascribed to the impact of the rearing substrate using these prepupae could have some shortcomings. This may be an issue for concern especially in feed formulations for young animals like piglets. High feed calcium levels may increase the stomach pH, increasing the risk of bacterial infection (Lawlor et al. 2005). Moreover, extracting fat from the prepupae would increase the mineral content of black soldier fly larvae.

Conclusion

Black soldier fly (Hermetia illucens) larvae has the potential to convert organic waste streams to high quality protein, reduce pollution and complement increasingly expensive protein sources used in livestock diet formulation. The nutritional composition of BSF larvae varied according to different rearing substrates. The quality of this resource would be constant in terms of crude protein content depending on the type of substrate the larvae were offered which is suitable for use in animal feed production. The biomass, breeding and nutritional profile of black soldier fly larvae reared on different organic waste streams can be employed for inclusion in feed rations for animal feed.

Based on these findings, it is necessary to evaluate nutritional components of BSF fed on other categories of organic wastes during its various life stages. One of these is evaluation of the fatty acid content which could facilitate more accurate use of larvae in feed production. This will help to establish a database of eligible substrates for BSF larvae production and develop economically feasible inclusion levels in animal feeds.

Data availability

Available.

References

Association of Official Analytical Chemists (AOAC) International (2012) Official methods of analysis of AOAC international, 17th edn. Arlington, pp 25–42

Babarinde SA, Mvumi BM, Babarinde GO, Manditsera FA, Akande TO, Adepoju AA (2020) Insects in food and feed systems in sub-Saharan Africa: the untapped potentials. Int J Trop Insect Sci. https://doi.org/10.1007/s42690-020-00305-6

Bosch G, van Zanten HH, Zamprogna A, Veenenbos M, Meijer NP, van der Fels-Klerx HJ, van Loon JJA (2019) Conversion of organic resources by black soldier fly larvae: legislation, efficiency and environmental impact. J Clean Prod 222:355–363

British Standards Institution (BSI) (2001) EN 13652:2001, Soil improvers and growing media. Extraction of water soluble nutrients and elements. BSI, London, pp 12–24

CVB, Tabellenboek Veevoeding (2012) voedernormen landbouwhuisdieren en voederwaarde veevoeders. Productschap Diervoeder, The Hague. pp 85

Diener S, Zurbrugg C, Tockner K (2009) Conversion of organic material by black soldier fly larvae: establishing optimal feeding rates. Waste Manag Res 27:603–610. https://doi.org/10.1177/0734242X0910383

Driemeyer H (2016) Evaluation of black soldier fly (Hermetia illucens) larvae as an alternative protein source in pig creep diets in relation to production, blood and manure microbiology parameters. Dissertation, University of Stellenbosch

Dumas-Gaudot E, Pozo MJ, Cordier C, Gianinazzi S, Barea JM, Azcón-Aguilar C (2002) Localized versus systemic effect of arbuscular mycorrhizal fungi on defence responses to Phytophthora infection in tomato plants. J Exp Bot 53(368):525–534

European Commission, Commission Regulation (EC) (2009) No. 152/2009 of 27 January 2009 laying down the methods of sampling and analysis for the official control of feed establishes the sampling method and the methods of analysis of feed for control purposes. Off J Eur Union 54:177

Ewing WN, Charlton SJ (2007) The minerals directory: your easy to use guide on minerals in animal nutrition. Context Products Ltd. 2nd edn 5a–5f; 19a

Greenfield H, Southgate DAT (2003) Food composition data. Production management and use, vol 2, 2nd edn. Food and Agriculture Organization of the United Nations, Rome, pp 17–19

Hafeez AM, Anneluise R, Isabelle RI, Goodarzi BF et al (2015) Implication of milling methods, thermal treatment, and particle size of feed in layers on mineral digestibility and retention of minerals in egg contents. Poult Sci J, p 94

Hale OM (1973) Dried Hermetia illucens larvae (Diptera: Stratiomyidae) as a feed additive for poultry. J GA Entomol Soc 8:16–20

IBM Corp. Released (2015) IBM SPSS statistics for windows, version 23.0. IBM Corp, Armonk

Ike C, Christian E, Sandra C, Nik D (2018) Solid waste Management in Nigeria: problems, prospects, and policies. J Solid Waste Technol Manag 44:163–172. https://doi.org/10.5276/JSWTM.2018.163

International Organization for Standardization (2002) ISO 15587–1:2002, 2002 Water quality – Digestion for the determination of selected elements in water – Part 1: Aqua regia digestion. ISO, Geneva, pp 56–72

Lawlor P, Lynch P, Caffrey P et al (2005) Measurements of the acid-binding capacity of ingredients used in pig diets. Irish Vet J 58:447–452

Liu Q, Tomberlin JK, Brady JA, Sanford MR, Yu Z (2008) Black soldier Fly (Diptera: Stratiomyidae) larvae reduce Escherichia coli in dairy manure. Environ Entomol 37:1525–1530

Marwa S, Isaac M, Fathiya MK, Chrysantus MT et al. (2019) The nutritive value of black soldier fly larvae reared on common organic waste streams in Kenya. Sci Rep: 13 https://doi.org/10.1038/s41598-019-46603-z

Munguti JM, Liti DM, Waidbacher H et al (2006) Proximate composition of selected potential feedstuffs for Nile tilapia (Oreochromis niloticus Linnaeus) production in Kenya. 1:128–137

Naseem R, Majeed W, Rana N, Koch EBA, Naseem MR (2020) Entomophagy: an innovative nutritional and economic navigational tool in race of food security. Int J Trop Insect Sci. https://doi.org/10.1007/s42690-020-00284-8

National Research Council (NRC) (2012) Nutrient Requirements of Swine, 11th revised edn. National Academy Press, Washington, DC, p 38

Newton G, Booram C, Barker R, Hale O (1977) Dried Hermetia illucens larvae meal as a supplement for swine. J Anim Sci 44:395–400

Oonincx DG, De Boer IJ (2012) Environmental impact of the production of mealworms as a protein source for humans—a life cycle assessment. PLoS One 7:11–45

Oonincx DG, van Broekhoven S, van Huis A, van Loon JA (2015) Feed conversion, survival and development, and composition of four insect species on diets composed of food by-products. PLoS One. https://doi.org/10.1371/journal.pone.0144601

Rumpold BA, Schlüter OK (2013) Potential and challenges of insects as an innovative source for food and feed production. Innov Food Sci Emerg Technol 17:1–11

Sheppard DC, Tomberlin JK, Joyce JA, Kiser BC, Sumner SM (2002) Rearing methods for the black soldier fly (diptera : Stratiomyidae). J Med Entomol 39:695–698

Smetana S, Palanisamy M, Mathys A, Heinz V (2016) Sustainability of insect use for feed and food: life cycle assessment perspective. J Clean Prod 137:741–751

Spranghers T, Ottoboni M, Klootwijk C, Ovyn A, Deboosere S, de Meulenaer B, Michiels J, Eeckhout M, de Clercq P, de Smet S (2017) Nutritional composition of black soldier fly (Hermetia illucens) prepupae reared on different organic waste substrates. J Sci Food Agric 97:2594–2600. https://doi.org/10.1002/jsfa.8081

Stamer A (2015) Insect proteins — a new source for animal feed. Sci Soc 16:676–680. https://doi.org/10.15252/embr.201540528

St-Hilaire S, Sheppard C, Tomberlin JK, Irving S, Newton L, McGuire MA, Mosley EE, Hardy RW, Sealey W (2007) Fly prepupae as a feedstuff for rainbow trout, Oncorhynchus mykiss. J World Aquacult Soc 38:59–67

Tilman D, Clark M (2014) Global diets link environmental sustainability and human health. Nat. 515:518–522

Tomberlin JK, Adler PH, Myers HM (2009) Development of the black soldier fly (Diptera: Stratiomyidae) in relation to temperature. Environ Entomol 38:930–934. https://doi.org/10.1603/022.038.0347

Tschirner M, Simon A (2015) Influence of different growing substrates and processing on the nutrient composition of black soldier fly larvae destined for animal feed. J Insects as Food Feed 1:249–259

Van Huis A, Van Itterbeeck J, Klunder H et al (2013) Edible insects: future prospects for food and feed security. FAO Forestry Paper no. 171. Food and Agriculture Organization of the United Nations (FAO), Rome, pp. 187 Available at: http://www.fao.org/docrep/018/i3253e/i3253e.pdf. Accessed 12 Jun 2019

Verkerk MC, Tramper J, Van Trijp JC, Martens DE (2007) Insect cells for human food. Biotechnol Adv 25:198–202

Acknowledgements

We thank Mr. Adetuberu and members of staff of Tucur farms Ibadan for availing us the opportunity to use their facility and offering us other forms of support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethics approval and consent to participate

Not Applicable.

Consent for publication

Not Applicable.

Code availability

Not Applicable.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Adebayo, H.A., Kemabonta, K.A., Ogbogu, S.S. et al. Comparative assessment of developmental parameters, proximate analysis and mineral compositions of black soldier fly (Hermetia illucens) prepupae reared on organic waste substrates. Int J Trop Insect Sci 41, 1953–1959 (2021). https://doi.org/10.1007/s42690-020-00404-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42690-020-00404-4