Abstract

The intent of this paper is to provide overview context to allow broader understanding of conventional tailings dam failure mechanisms. The research leverages global knowledge, experience, and data collection and interpretation for the safe and controlled management of the geotechnical stability of a tailings storage facility. The motivation for this review is to facilitate transparent access to tailings dam background and understanding. This paper addresses the core understanding of geotechnical failure mechanisms, and how these eventuate to instability and failure of tailings dam structures. This research focuses on foundation failure, internal erosion and piping, overtopping, seepage, seismicity, and slope instability and provides insight into what factors contribute to failure, how failure progresses due to such failure, anticipating and monitoring for the aforementioned failure modes, and designing to mitigate their risk.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

A review of all guidelines, acts, and regulation has concluded that a misalignment exists in the standard of practice for tailings dam monitoring and instrumentation, globally [8]. While acknowledging that many practitioners are well advanced in the field, the aim of this paper is to establish the baseline standard of understanding tailings dam failure types. This is expressed through the contributing factors to failure, progression of failure, ability to monitor and anticipate failure, and how to integrate these elements into the design and assessment of a structure. The consolidated information aims to fills the void of ‘you don’t know what you don’t know’, encouraging greater global collaboration in safety by extracting best practice documentation and references in a single paper.

With ongoing catastrophic mine tailings dam failures, the hindsight revelation of poor safety records, and an increasing prevalence of public scrutiny and attention of mining operations, there is an immediate call for enhanced safety provisions of tailings dams. It is estimated that each one-third century, the potential risk of tailings dam failure increases by 20-fold [35], to address increasing demands on waste volume, tailings storage facilities must be bigger, built faster, and to be longer lasting.

By understanding the extent of what could go wrong, practitioners, operators, designers, suppliers, and other various stakeholders have an opportunity to significantly improve their safety standard, beyond what the numbers and analytical procedures may suggest.

For example, the traditional factor of safety method determines the comparative ratio between the capacity of a system, against the induced loads. A performance-based assessment, on the other hand, assesses the possible deformability and strength of a soil while still satisfying the performance requirements of the structure. Hence, the intended design performance can always be checked by monitoring, integrated with finite element analyses, as well as better understanding the likelihood of potential events as captured in a risk assessment.

It is stated that the understanding of how components behave and respond under an induced load or condition change is more important than necessarily meeting specific code clauses (as specified through traditional methods). The value of performance based assessment is not in predicting performance or estimating losses, but in contributing effectively to the reduction of losses and the improvement of safety [23].

For structures such as tailings dams, the value of this method is clear: a preceding paper by the author [8] demonstrated significant, unacceptable consequences as a result of tailings dam failures that were all entirely predictable, in hindsight. It is hypothesised that a better understanding of and appreciation for the structure and the significance of failure can improve tailings dam operational practice and, in turn, safety.

2 Failure Modes

An understanding of potential failure modes is critical prior to realisation of any benefit gained through quality tailings management framework. In defining failure, Davies, Martin, and Lighthall [9] alluded to a definition by [24] in defining failure as ‘... an unacceptable difference between expected and observed performance’. In the geotechnical engineering domain, the range of influence that a ‘failure’ may have is extensive.

Although significant failures receive immense publicity and are followed by extensive investigations, the ‘same trends and lessons are available from the lesser failures’ [9]. Back analysis of failure events is invaluable in improving understanding, and hence the ability to better anticipate future events.

High level failure modes have been recognised by the International Commission on Large Dams [21], and are built on in Fig. 1. It is anticipated that considerations such as long-term and post-closure safety and failure modes (including bio-intrusion, water and wind erosion, weathering, etc.) would supplement this list for whole-of-life planning. The ICOLD Failure Cause categories are highlighted in Fig. 1 and will be retained throughout this paper.

(Part) hierarchy of failure modes (adapted from [25])

3 Type, Cause, and Behaviour

The benefit in a true understanding of different types of failure modes is undeniable: it provides a basis to reasonably action proactive measures to counter progressive deterioration at any stage of the dam’s life. This paper explores four areas in the interest of understanding any failure mode:

-

What factors contribute to this type of failure?

-

How does the mechanism of failure progress?

-

Are there any indicators that could have been observed, measured, or monitored to directly measure the development of this failure?

-

How can design counter failure?

It is vitally important to consider all three spatial dimensions, and the singular time dimension when addressing these points. Often, the extent of damage is governed by the rate and acceleration of failure. Time-dependent deterioration, increasing or decreasing flow rate, an acceleration of slope displacement, and peak ground acceleration are all concepts that must be considered in this dimension. Unfortunately, a higher rate or acceleration inevitably makes failure more challenging to anticipate. With this in mind, complacency due to minimal or no change over time is also unforgiving. ‘For any engineer to judge a dam stable for the long-term simply because it has been apparently stable for a long period of time is, without any other substantiation, a potentially catastrophic error in judgement’ [37].

3.1 Foundation Failure

Deterioration of tailings dam foundation performance and characteristics can have catastrophic flow-on effects to the remainder of the facility, regardless of the facility’s competence, stability, or contingency.

3.1.1 What Factors Contribute to Foundation Failure?

Site investigations are limited in their extent as they are often undertaken at discrete locations and targeting particular features based on the extent of information available at the time. The request for and interpretation of site investigation reports are critical, where back analysis of numerous historical failures has found indicators of the eventual cause of failure within the existing information set [21].

Characteristics that can be reasonably investigated at the design stage, and may contribute to foundation failure are:

-

Geological structures

-

Landslip surfaces

-

Fissuring in the soil/ rock

-

Presence of clayey, cohesionless, dispersive, or soft soils

-

Presence of weak and weathered layers in the foundation

-

Predicted seismic activity and flooding

-

Foundation surface inclination/ declination

-

Foundation material characteristics, including shear strength, compressibility, and permeability

Characteristics that can be difficult to investigate at the design stage but may contribute to foundation failure are identified as:

-

Sinkholes, old mine shafts, and weaknesses above active underground mine workings; and

-

Localised features, including isolated karstic voids and preferential lava flows.

Other tailings storage facility (TSF) siting considerations/ constraints include mill location, topography, hydrology, geology, hydrogeology, seismicity, environmental requirements, and local regulations.

3.1.2 How Does Failure Progress Due to Foundation Failure?

Shear strength, permeability, and settlement are dependent factors in dam performance:

Shear Strength

Failure can occur in line with Mohr-Coulomb theory [19], when the induced shear stress is greater than the resisting shear strength. Unfavourable shear strength conditions may either pre-exist or be introduced, including:

-

Poor shear strength characteristics of foundation material, subject to rotational sliding

-

Weak foundation layers may represent a plane of weakness against increasing loads on the surface

-

‘Continuous, or near continuous, weak, unfavourably oriented discontinuities in the foundation’ [17], for example:

-

(1)

Bedding surfaces

-

(2)

Bedding surface shears

-

(3)

Cleavage planes

-

(4)

Stress relief joints

-

(5)

Faults and shears

-

Pre-sheared foundation materials with low shear strength

-

Inconsistency between in situ and design values for shear strength

-

Geomembrane liners may form a plane of weakness, particularly if separating the (pervious rockfill) embankment from the foundation material [11]

-

Topography of the site and the degree of sloping foundations

-

Inadequate compaction of materials against design, at construction stage

Permeability

Impervious foundations, or those with low permeability, can experience excess pore water pressures from surface loading and TSF activity. ‘Because the immediate loading is taken by the water phase in the foundation material, there is no increase in shear strength and the rapid increase in loading can [induce foundation failure]’ [45].

On the other hand, ‘highly permeable foundation materials… can transmit significant flow capable of eroding material at the base of the embankment and carrying it downstream’ [42]. This erosion may result in piping, subsidence, or a reduction in shear strength, in turn compromising the stability of the overlying embankment.

In a foundation that comprises only cohesionless soils, ‘quick’ conditions exist when the critical vertical hydraulic gradient is achieved; the pore water pressure equals the submerged unit weight of the soil, and hence, effective stress is zero. Physically, the material may ‘heave’ or ‘boil’, as seen in Fig. 2.

Heave at the toe of an embankment [33]

In a foundation that comprises a low permeability, confining layer (such as clay) overlying a pervious layer (such as sand), the potential for failure exists where seepage pressures through the pervious layer exceed the overburden pressures at the downstream toe. This can cause uplift or blowout of the confining layer as seen in Fig. 3. The location of rupture may be associated with the location of maximum uplift pressure or a pre-existing defect in the foundation [42].

Uplift and/or blowout at the toe of an embankment [33]

Foundation permeability also has an influence on the phreatic surface through the embankment, as seen in Fig. 4. This may influence simplified assumptions taken in slope stability modelling.

Influence of foundation permeability on phreatic surface through the embankment [17]

Settlement

There are three primary forms of settlement [47]:

-

Compaction/ compression: applied load, removal of groundwater, or vibration reduces the pore space between soil particles. Clayey and silty soils most susceptible

-

Consolidation: Water squeezed out of the material mass due to an applied load. Clayey and silty soils most susceptible

-

Erosion: Complete removal of fine material, causing voids and instability.

Characteristics of and influences on foundation materials that have the potential to progress foundation failure include [48]:

-

Elastic and inelastic compression of the foundation due to surface loads

-

Staged settlement comprising immediate, consolidation, and creep

-

Shrinking and swelling of expansive soils;

-

Differential settlement

-

Regional subsidence or movement

The extent of settlement depends primarily on the induced stress and foundation material characteristics:

-

Young deposits such as fine grained sedimentary units exhibit high intensity of fractures and weathering [20];

-

Shrink-swell characteristics (determined by presence of minerals that absorb vast quantities of water such as smectite, montmorillonite, vermiculites, and some mixed layer minerals) should be considered alongside other properties that can encourage the natural expansiveness of a soil [28]; and

-

‘Conversely, [expansive soils] can also become very hard when dry, resulting in shrinking and cracking of the ground’ [28].

Settlement and consolidation can progress failure by destabilising overlying and embedded protection measures, tailings infrastructure, dam instrumentation, and the embankment itself.

3.1.3 Anticipating and Monitoring Foundation Failure

Visual inspection criteria for assessment of foundation conditions are outlined by Fell et al. [17]:

-

Drainage ditches clogged with vegetation

-

Dam areas, moisture on dry days

-

Flowing water: quantity, location, and clarity

-

Boils

-

Silt accumulations, deltas, and cones

A list of observations noted on failure or incident of the foundation due to piping has been recorded by Fell et al. [17] Fig. 5.

Observations during piping through the foundation [17]

It is important to monitor the relationship between pore pressures and reservoir level, particularly on first filling or at historic high reservoir levels. Instrumentation for foundation performance is recommended in Table 1.

In line with the hierarchy of controls, site foundation preparation may best be controlled through elimination (removal), substitution (replacement) or engineering control (redesign, treatment) of unfavourable conditions.

3.1.4 Design of Foundations

Detailed site investigation by experienced geologists or geotechnical personnel, in addition to tailored laboratory testing to determine foundation material parameters is deemed a necessity to assess the risk at all stages of the tailings dam life [21]. Fell et al. [17] describe foundation conditions, their influence, and possible control measures to embed at the siting and design stage, as described in Table 2.

Two predominant segments are defined for foundation preparation and clean-up requirements: the foundation beneath the bulk of the embankment (general foundation) and the foundation underneath the earthfill core (cutoff foundation) [17]. The objectives are:

-

General foundation: To provide a foundation of adequate strength by removing soft, compressible materials [17]

-

Cutoff foundation: To provide a low permeability, non-erodible foundation consistent with the foundation drain and filter design [17].

The author recommends the reader to the existing research (such as [17]) on preparation and clean-up and design detail on the zoning of foundations. The criticality of good record keeping is reiterated so that ‘those assessing the safety of the dam in the future can be informed on what was done’ [17].

3.2 Internal Erosion and Piping

Wherever water is dammed by earthen embankments, the particles are exposed to a hydraulic gradient (head loss per unit length) and seepage pressures. Seepage is typically expected and does not necessarily present as a problem so long as it is controlled, uncontaminated, and there is no associated particle migration [23]. Where the hydraulic gradient and velocity is sufficient to overcome the geometric fabric and stability of the soil structure, particles may begin to detach, move, and migrate through the embankment, foundation, or close to abutments and infrastructure.

There are different mechanisms of internal erosion, with the most common being piping. Piping describes the behaviour of the soil structure when internal erosion develops a continuous open seepage path, which acts as an unprotected and preferential flow path for seepage.

About two-thirds of internal erosion and piping failures and about half of internal erosion and piping accidents occur on first filling or in the first 5 years of operation. [17].

3.2.1 What Factors Contribute to Internal Erosion and Piping Failure?

Internal erosion initiates when an unfavourable combination of material susceptibility, stress conditions, and hydraulic load is induced at some location of the dam [42]. The factors affecting initiation are described in Fig. 6.

Factors affecting the initiation of internal erosion after USBR [42]

Guidelines for quantifying risk of different conditions are outlined in detail by USBR [42] and Fannin and Slangen [15]. USBR [42] has detailed a list of parameters of influence:

Material Properties

-

Plasticity: inversely proportional to erosion susceptibility, related to inter-particle bond strength

-

Gradation and particle size: the greater the particle size, the more energy required to move particles. Broadly graded soils with a flat tail of fines, particularly if the soil is gap-graded, are particularly susceptible to poor internal stability [42]

-

Density: a more dense soil comprises tighter particles, in which case it is harder to dislodge soil particles and initiate erosion [42]

-

Erodibility: highly influenced by plasticity and compacted moisture content

Stress Conditions

-

Influence of stress conditions on internal stability: stress conditions define whether a material experiences suffusion or suffosion. In suffusion, mass loss occurs with no change in volume and an increase in hydraulic conductivity. In suffosion, fine particles transported by seepage flow induce soil structure collapse [15]

-

Low stress zones and ‘arching’: occur in areas of severe differential settlement, potentially zones of tension

-

Flaws in the embankment and foundation: a primary mechanism for initiation of internal erosion

Hydraulic Conditions

-

Role of concentrated seepage: discontinuities, defects, or naturally pervious layers in the embankment or foundation where flows concentrate in preferential paths of least resistance. It is difficult for seepage modelling to portray these unpredicted anomalies

-

Gradients: vertical (upward) gradients can encourage heave, uplift, or blowout, and can lead to unfiltered exits or initiation of erosion [42]. Horizontal (internal) gradients through an embankment and/ or foundation are critical considerations for concentrated leak erosion, backwards erosion piping, or suffusion/suffosion.

3.2.2 How Does Failure Progress Due To Internal Erosion and Piping?

Failure can develop in response to three general loading scenarios:

-

Static/ normal operation (poor water management)

-

Hydrologic (flood, unpredicted reservoir levels)

-

Seismic (deformation/ cracking providing initial pathway for erosion)

‘Historically, most internal erosion failures have occurred when the reservoir was within about [1 metre] of the historical maximum level or greater’ [42]. USBR [42] summarise factors that have the potential to contribute to the development of internal erosion and piping:

-

Backward erosion piping (BEP): erosion starts at the seepage exit point and erodes upstream (backwards). With distance upstream, the process generates shorter seepage paths, higher hydraulic gradients, more flow, and an increased erosion potential. Four conditions are identified as coincident characteristics of BEP [42]:

-

(1)

Flow path or source of water

-

(2)

Unprotected or unfiltered exit

-

(3)

Erodible material within the flow path

-

(4)

Continuous stable roof forms allowing the pipe to form

-

Internal migration (stoping): a void that may stope to the surface as a sinkhole, initiated due to internal instability/ suffusion or due to open defects in foundations or embedded infrastructure. The broadly graded, cohesionless soil cannot support a cavity roof, repeatedly collapsing until embankment structure is compromised

-

Concentrated leak erosion: flow concentration through a pre-existing crack, potentially caused by desiccation or differential settlement, causing erosion

-

Contact erosion: the selective erosion of fine particles in the embankment or foundation as a result of seepage flow along the contact between the two; and

-

Internal instability—suffusion and suffosion: in suffusion, mass loss occurs with no change in volume and an increase in hydraulic conductivity. In suffosion, fine particles transported by seepage flow induce soil structure collapse [15]

Unless the eroding forces are mitigated, the passage of erosion will continue and potentially enlarge. The final phase of internal erosion and piping development is the breach: an uncontrolled release of material. Four mechanisms are typically considered and can lead to crest settlement and overtopping erosion [42]:

-

Gross enlargement of a pipe or concentrated leak

-

Sloughing or unravelling of the downstream face

-

Sinkhole development

-

Slope instability

3.2.3 Anticipating and Monitoring Internal Erosion and Piping

Monitoring of seepage, either by visual surveillance, or measurement, is the most common means of identifying whether internal erosion and piping has occurred [17].

The majority of indicators that are either readily detected or have a moderate ease of detection are those that can be visually observed. These comprise leakage, muddy leakage, sinkholes, settlements, cracking, whirlpool in reservoir, increase in pore pressure, and sand boils [17]. If identifiers of erosion are visually observed, failure has likely already progressed beyond initiation and would require immediate intervention and remediation. Intervention may include [17]:

-

Sealing of eroded materials on filters/ transitions which satisfy excessive erosion criteria

-

Flow limitation by an upstream dirty rockfill zone

-

Collapse of the pipe

Unless the installed instrumentation intersects the failure plane exactly, or the erosion daylights in the slope face, internal erosion is very difficult to identify. However, this mechanism can be identified as the cause to a change in pore pressure, seepage, visual appearance, or crest settlement/ slope instability: all unique failure mechanisms discussed in this paper. When investigating the cause of these changes, thermal or geophysical methods may be employed to help detect internal degradation. Hence, proactive identification, investigation, and intervention on the parameter changes discussed can actively lower the consequence of failure.

3.2.4 Designing for Internal Erosion and Piping

Dams with properly designed and constructed filters allow an increased likelihood of intervention in the development of piping [17]. The controls against internal erosion and piping formation are closely aligned with those described for seepage. Best practices for design and construction are detailed by the US Bureau of Reclamation, US Army Corps of Engineers, The University of New South Wales, and URS [41] , and the U.S. Bureau of Reclamation (USBR) [44] . In detailing the requirement for protection against erosion and cracking, USBR [44] references Arthur Casagrande (1969):

It is not possible to prevent entirely the formation of substantial tension zones and transverse cracks in the top of the dams in the vicinity of the abutments, no matter what materials we use in the dam. Therefore, we must defend ourselves against the effects of cracks.

The issues induced by cracking are remedied by introduction of a filter at locations to protect vulnerable area. There are four main classes of filters described by [44]:

-

Class I: drainage filters. Intercept and carry away main seepage within dam and foundation. Comprising toe drains, relief wells, and drain fields

-

Class II: protective filters. Protect base material from eroding into other embankment zones and to provide some drainage function in order to control pore pressure in the dam. Comprising downstream chimneys, blankets, and transition zones

-

Class III: choke filters. Support overlying fill (base material) from moving into pervious or open work foundations. May be used under upstream impervious blankets (overlying pervious foundations), or in emergency situations such as to plug whirlpools or sinks. Comprise foundation filters and sinkhole backfill

-

Class IV: crack stoppers. Protect against cracks that occur in the embankment core, especially caused by seismic loading and/or large deformations. Comprise upstream and downstream chimneys

The author references USBR [44] for conditions that may contribute to internal erosion and piping through an embankment and potential inhibition through the use of filters.

3.3 Overtopping

Overtopping can occur from excessive inflows, malfunctioning spillway or outlet structures, insufficient spillway capacity, dam settlement, external landslide into reservoir, or by waves driven by wind running-up and overtopping the dam [49].

3.3.1 What Factors Contribute to Overtopping Failure?

Erosion resistance of the embankment material governs stability if the dam overtops. Zhang et al. [51] describe the mechanisms of surface erosion and the characterisation of soil erodibility as the basis for analysis of overtopping erosion. The author refers the reader to Zhang et al. [51] for proposed laboratory and field tests that may be utilised for assessment of soil erodibility.

Surface Erosion

Surface erosion is a physical process that occurs when water flow removes soil particles from the surface of the dam [51] .

-

Initiation mechanism of surface erosion:

-

(5)

Granular soils: Laminar (regular) surface flow attempts to drag surface particles with dominant viscous (fluid) forces alone

-

(6)

Cohesive soils: Three types of erosion are defined: pothole (clay < 30%), line (clay > 30%), and mass (steeper slope angle, clay >30%). Initiation is defined by individual particle detachment, detachment in ‘thin flakes’, and detachment in ‘chunks’ of sediment, respectively.

-

Sediment transport:

-

(7)

Bed-load transport: Transport of particles by rolling, sliding, and saltating (leaping) along the bed surface. Constitute ‘5-10% of the total sediment load’ [51]; and

-

(8)

Suspended-load transport: Transport of particles suspended in the fluid, sustained against gravity due to the upward diffusion of turbulence.

Characterisation of Soil Erodibility

-

Critical erosive shear stress: Ease of initiation of erosion in a particular material

-

Coefficient of erodibility: Soil-specific nature of erodibility encourages site-specific relationships between coefficient and soil properties:

-

(9)

For granular soils: gravitational force, grain size distribution, grain shape, and particle density

-

(10)

For cohesive soils: clay content, grain size distribution, bulk density, clay type, plasticity index, dispersion ratio, and water chemical composition

-

(11)

A higher level of compaction, greater cohesion, and optimum moisture content influence soil behaviour and hence erodibility potential

-

(12)

Briaud [6] and Briaud et al. [7] have proposed a classification of soil erodibility (Fig. 7)

Classification of soil erodibility based on flow velocity and applied shear stress against erosion rate (adapted from [6])

Failure of construction, operation, or maintenance to meet design and critical controls of the TSF has also been known to contribute to overtopping failure.

Criterion exist defining freeboard allowances for safe operation of a dam (Fig. 8 and [3]). Total freeboard represents the capacity of the dam to pass an extreme storm, comprising a combination of several contingency criteria above the maximum operating level to prevent overtopping of the dam [3].

Freeboard criterion [3]

Influential, yet less common, considerations include:

-

Wind-wave action/ wave run-up

-

Flood overtopping (flood flows, rainfall runoff, flood loadings, catchment inflow)

-

Landslide of surrounding terrain

3.3.2 How Does Failure Progress Due To Overtopping?

Pertinent findings in literature are discussed by both USBR [44] and Zhang et al. [51]:

Homogeneous Embankment Dams with Cohesionless Materials

Defined primarily by progressive surface erosion, Fig. 9 describes the breaching process of a granular embankment dam by overtopping.

The breach initiation phase (phases 1 and 2; Fig. 9a) is the process, whereby overtopping flow erodes material from the downstream face and crest, until the erosion connects with the upstream face and begins to accelerate overtopping flows [51]. Proposed stages of initiation are summarised as follows:

-

(13)

Overtopping occurs

-

(14)

Slope erosion starts

-

(15)

Continuous erosion likely, surface slips induced

-

(16)

Gradual development of a breach channel by continuous erosion is accelerated through isolated occurrences of lateral erosion

The breach development phase (phases 3 to 7; Fig. 9b) defines the process becoming rapid once the scour reaches the upstream edge of the dam crest. Failure develops by slope flattening, breach opening, and downstream slope erosion.

Homogeneous Embankment Dams with Cohesive Materials

Defined primarily by headcut erosion, Fig. 10 describes the breaching process of a cohesive embankment dam by overtopping.

In the breach initiation phase (phases 1 to 4; Fig. 10a), the cohesive nature of the materials could result in near-vertical side slopes of the breach [51]. Proposed stages of initiation are summarised as follows:

-

(17)

Initial overtopping flow progresses surficial erosion on the downstream surface, with preferential erosion developing a series of cascading overfalls [51];

-

(18)

A headcut (or stepped headcuts) develops from the overfall at the downstream face due to tensile or shear failure on the over-steepened slope

-

(19)

The cascading overfalls combine into a large overfall

-

(20)

Breach flow concentrates pressure and associated erosive forces on the toe of the slope, creating a reverse roller (Fig. 10c), in turn deepening the erosive effect of the large overfall and undercutting the toe of the slope [51]

-

(21)

As this process continues, headcut erosion retreat accelerates [51]

-

(22)

The breach is widened gradually due to the washing away of unstable side slopes

-

(23)

The headcut reaches the upstream crest

The breach development phase (phases 5 to 7; Fig. 10b) occurs rapidly once the headcut reaches the upstream crest. Failure develops by breach enlargement both in depth and laterally and stops only once overtopping levels are depleted or the downstream elevation increases.

3.3.3 Anticipating and Monitoring Overtopping

In anticipating and monitoring overtopping, water management is deemed the critical control.

In accordance with the roles and responsibilities outlined in an effective tailings management plan, direct observations will assist in early detection of faults or abnormalities against anticipated conditions. Such include [1]:

-

Position and size of the decant pond and observations relating to freeboard requirements

-

Status of leak detection systems

-

Status of secondary containment systems

-

Status of automatic flow measurement and fault alarms

-

Condition of pump and pipeline systems

Throughout daily operation, it is also important to monitor the weather, wave action, and filling rate.

The initial breach location is often difficult, if not impossible, to predict prior to failure. Usually associated with a weak point on the dam crest or downstream slope, the initiation location can be influenced by a number of factors, including:

-

Poor compaction quality of embankment material during construction

-

Unsuitable materials used in embankment construction

-

Presence of internal weak points or discontinuities

-

Pre-existing damage to the embankment crest or slope

3.3.4 Designing for Overtopping

Complexity of the breach formation process is increased based on tailings dam embankment composition and as a result of altered erosion processes of or around elements such as surface protection measures, a concrete floodwall on the crest, or a clay core.

[3] detail a flow sheet for tailings dam spillway and storage design (Fig. 11). Considerations to be integrated into the design for tailings storage capacity and water management include:

Flow sheet for tailings dam spillway and storage design (adapted from [3])

Risk Assessment

-

Environmental implications of any release

-

Timing of construction: primarily, avoid the wet season and consider the duration of earthworks required

-

Physical climate

-

Political climate

-

Importance of maintaining continuous production

Regional

-

Minimum wet season water storage allowance

-

Minimum extreme storage allowance

-

Freeboard allowances (Fig. 8)

-

Design flood for spillway design

-

Hydrological setting, including site catchment, water inflow/outflow, and characteristic rainfall and flood events [1]

-

Stream management and catchment diversions

Operational

-

Excess capacity contingency: ‘at least six months excess capacity remaining at the time the next stage of storage capacity is expected to be available’ [3]

-

Impoundments and their retaining dams need to be able to accommodate extreme hydrologic events, typically dependent on the consequence of failure of the structure

-

Some minimum allowance for decant storage

-

Tailings water balance modelling [1]

Fig. 11 indicates provision for the design of a spillway only when the dam spill consequence category is very low, or negligible. In the traditional case, due to a restriction on the discharge of tailings material, tailings dams do not integrate conventional spillway facilities, but rather rely on service spillways/decanting systems, or ‘emergency’/auxiliary spillways. Overtopping protection can be considered as an auxiliary spillway, albeit in recognition of the limitations of the approach [16, 18].

3.4 Seepage

The liquid component of tailings waste comprises dissolved salts, heavy metals, and other residual chemicals from the mineralogical processes [17]. There is substantial environmental and ecological risk in the connectivity of contaminated liquid tailings (liquor) to surrounding surface water and groundwater. Seepage can influence downstream communities and ecologies to varying degrees, dependent on the degree of concentration, and the amount of liquor release, to which regulatory restrictions also apply. Seepage also has the potential to reduce geotechnical stability.

3.4.1 What Factors Contribute to Seepage Failure?

There are a number of factors that have the potential to induce fluctuation of the phreatic surface and the associated pore water pressures in the embankment, including (from [3, 17, 24]):

-

Elevation difference between decant pond and surrounding ground

-

Reservoir level

-

Rainfall

-

Highly pervious zones

-

Development of cracks in the impervious core

-

Deterioration or cracking of liners and grout curtains

-

Drainage from consolidating slimes

-

Thawing of ice

-

Height of embankment and degree of dissipation by consolidation of pore pressures induced by the embankment

-

Dynamic loading

3.4.2 How Does Failure Progress Due To Seepage?

Seepage through tailings embankments can give rise to instability through three primary mechanisms [24]:

-

Piping: See Section 3.6

-

Slope instability and heaving: an increased pore pressure in the embankment or foundation of a tailings dam can cause downstream slope instability

-

Excess water losses: occur when the embankment or foundation is pervious. Connectivity of contaminated seepage water to surrounding surface and groundwater presents substantial environmental and ecological risks.

3.4.3 Anticipating and Monitoring Seepage

‘Seepage data is one of the best indicators of dam performance’ [17], making monitoring of seepage an essential part of any tailings management strategy.

A number of the key measurement parameters specifically related to seepage are identified by Fell et al. [17] as:

-

Seepage flow measurements

-

Pore pressure measurements

-

Measurement of reservoir water level and rainfall

-

Seepage water temperature

-

Seepage water chemistry and pH

-

Seepage water turbidity measurement

Complementary visual indicators of seepage in the tailings impoundment may include [17]:

-

Quantity, location, and clarity of seepage discharge water, which may indicate piping of the embankment or foundation

-

Overgrowth or wet terrain vegetation on dam and within 15 m beyond toe of dam, indicating excessive moisture, or seasonal and pond level changes

-

Wet patches, change in local moisture on dam embankment

-

Damp areas around conduits, outlet works, and pumps

Seepage flow and pore pressure measurements can also be instrumented, primarily through use of a range of different piezometers. Monitoring any change over time of these instruments can give information for use in assessment of unexpected pore pressures which may be a precursor to different failure mechanisms like internal erosion and piping, foundation heave, or slope instability [17]. The location of each piezometer in the network is critical in obtaining meaningful results, noting [17] :

-

Installing piezometers in the foundations under and downstream of the dam, monitoring for change. Instrumentation in zones of different materials, hence different pore pressure regimes, is also favoured (see Fig. 12)

-

For ‘blow-out’ and ‘heave’ in foundations, piezometric conditions are important to understand below lower permeability layers which act to confine the seepage flow

-

For landslide piezometric conditions, pore pressure on the slide plane is critical yet difficult to intercept. However, trending phreatic elevations can be monitored

-

For jointed and sheared rock, several piezometers should be installed, intercepting the discontinuities that groundwater flows along [17]

-

Three elements are introduced in any scheme: observation well standpipes, pressure piezometers, and standpipe piezometers [27]

-

Piezometer placement downstream and upstream of a cutoff or drain can give an indication of the hydraulic gradient behaviour

-

Caution should be taken when installing piezometers in the core of new dams or in existing dams, both with the potential to create defects on install

Section showing idealised pore pressure monitoring scheme in an upstream tailings dam (adapted from [27])

Chemical analysis can be a useful guide to the source of seepage water, for example [17]:

-

A comparison of ions in the reservoir water and seepage may indicate leaching of cement from grout curtains, or oxidation of sulphides within the foundation or within the embankment materials

-

Biological analysis can indicate the source relative to the depth in the reservoir

-

The age of the water as indicated by analysis of tritium can indicate its sources as rainwater or groundwater

The monitoring of tailings dams should include surface water and groundwater quality sampling both upstream and downstream of the facility to check against agreed trigger levels [1]. Parameters that are monitored either through continuous sensors or in-field analysis include:

-

Water level

-

pH

-

Total dissolved solids

-

Turbidity

-

Temperature

-

Dissolved oxygen

-

Conductivity

-

Heavy metals

Technology and geophysics represent new developments in geotechnical application. While not anticipated to replace more conventional seepage measurements and regular inspections, some techniques are listed as [17]:

-

Self-potential: detects natural or ‘spontaneous’ voltages in ground materials as generated by chemical, thermal or hydraulic processes

-

Electrical resistivity: utilises direct currents or low frequency alternating currents to investigate the electrical properties of the subsurface

-

Ground penetrating radar (GPR): transmits and receives electromagnetic waves to generate imagery of the shallow surface profile [32]

-

Electromagnetic (EM) profiling: measures the lateral variation of ground conductivity by inducing an alternating current at a transmitter, which interacts proportional to ground conductivity and reports to the receiver

-

Thermal monitoring: temperature measurements provide an indirect measurement of the presence and behaviour of seepage flow [17]

Each method benefits from a comparison against baseline readings.

3.4.4 Designing for Seepage

Australian National Committee on Large Dams [2] identify key seepage principles during the design and operation phases as ‘maximisation of solar drying, minimisation of water content of tailings, and minimising the volume (and areal extent) of ponded water’. Vick (1990) notes that even with complex lining systems, full prevention of seepage from a tailings facility is unlikely to be achievable. [14]. Two overlying systems are employed in tailings dam design to mitigate seepage concerns [14]:

-

Barrier systems (seepage reduction): retain or resist the flow of seepage to outside the tailings impoundment, comprising cutoff walls, upstream blankets, liners or embankment barriers

-

Collection systems (seepage control): intercept and safely focus the seepage as it leaves the tailings storage facility, comprising embankment toe drains, extraction wells, or ditch systems

FEMA [16] proposes typical design elements in an embankment dam which contribute to seepage control systems, as seen in Fig. 13.

Typical embankment design elements found in a central core design [16]

-

Impervious blanket: Extends the seepage path and increases the head loss zone for dams on pervious foundations when a cutoff under the dam is impractical. Upstream blankets are integrated into the core of the dam

-

Riprap and bedding: Riprap protects the upstream slope of the dam against erosion caused by reservoir wave action. Bedding under riprap protects against particle movement of the protected zone after reservoir drawdown

-

Transition zone: On the interior side of the upstream or downstream shells. Upstream transition zones can also function as seismic crack stoppers

-

Impervious core: Impervious/ low permeability soil that acts as a water barrier

-

Cutoff trench: To rock or other low permeability strata that is integrated with the overlying core

-

Cutoff wall: Vertical water barrier in rock, also known as a grout curtain. Fills all fractures, joints, and other openings in the rock to prevent seepage flow

-

Chimney drain: Collects seepage coming through the chimney filter and delivers it to the blanket drain

-

Chimney filter: Protects the core from internal erosion and piping

-

Blanket drain: Provides hydrostatic pressure relief for pervious foundations, outlet for seepage collected in the chimney, and protects against particle movement in soil foundations

-

Toe drain: Collects water from the blanket drain as well as any foundation seepage and safely conveys it away from the embankment

-

Relief well: Collects seepage water in the foundation that cannot be collected by toe drains due to overlying impervious layers. Typically used to reduce artesian foundation pressures in confined layers

-

Drainage ditch: Open trench downstream of the dam that collects seepage water. Most effective when extending into a pervious layer

The seepage control elements required for any particular embankment design depend on site conditions, availability of materials, loading conditions, and economics [16]. To determine the most appropriate control measures, the designer must understand the behaviour of seepage through the embankment and/or foundation. Fell et al. [17] acknowledge parameters involved in the assessment of seepage potential as:

-

Permeability of tailings. The tailings are commonly part of the seepage path and in many cases control the seepage rates

-

Permeability of the soil and rock underlying and surrounding the storage. This understanding will demand greater complexity for sites where the flow paths extend beyond the storage area

-

Modelling of the seepage, which may involve several section models and/ or a plan model

Seepage assessment at the design stage is necessary in order to [2]:

-

Define pore pressures/ phreatic surfaces for use in stability analysis

-

Evaluate restrictions on the rate of rise, if any

-

Determine potential impacts of seepage on the receiving environment

-

Allow design of drainage and collection systems

The key parameter for seepage analysis is the material saturated hydraulic conductivity [2]. It is essential to capture the variation of hydraulic conductivity in different in situ environments.

The risk of seepage has generated interest in dewatering of tailings, as classified in Fig. 14. By lowering the water content of delivered tailings, the potential seepage can be reduced [14]. Under the correct and educated considerations, the theory states that with less moisture: seepage losses, groundwater contamination, costs, and stability are all improved.

Classification of tailings by degree of dewatering [12]

3.5 Seismicity

Seismicity induces dynamic loading that is short-term, cyclic, and occurs in both horizontal and vertical directions [17]. This motion has the potential to destabilise the tailings dam embankment, propagate internal cracking, or induce pore pressure increase and hence encourage liquefaction in different materials.

3.5.1 What Factors Contribute to Seismic Failure?

Earthquakes are the most common source of seismicity, where the magnitude of damage caused by an event depends on [17]:

-

The seismicity of the area

-

Foundation materials and topographic conditions at the dam site

-

The type and construction of the dam

-

The water level in the reservoir at the time of the earthquake

-

The liquefaction potential of the tailings material [26]

One could be optimistic about the value of education and resilience in earthquake design, where failure of tailings dams due to seismic liquefaction have reduced in seismic-susceptible Chile ‘from 14% in pre-2000 cases to zero in post-2000 cases: the 2010 Chilean earthquake of magnitude 8.8 did not cause any failure’ [4].

Global Seismicity Trends

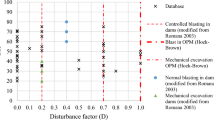

Fig. 15 displays a spatial comparison between 203,186 earthquakes of magnitude four or greater from 1898 through to 2003, and a by-country scale number of recorded tailings dam failures due to seismicity. Although earthquakes are most common at tectonic plate boundaries, approximately 2% (4063 events, [34]) of all earthquakes occur in intra-plate regions. The core reason that intra-plate earthquakes occur has not yet been established. Research into this is deemed important, as the level of seismic preparedness, monitoring, and retrofitting is minimal in unaccustomed regions, potentially causing significant damage.

Map showing earthquakes by magnitude since 1898 (adapted from [22]) against recorded tailings dam failures due to seismicity

Local Stress

When characterising a site, the stress orientation and magnitude of earth stresses can be aligned with site geomorphology to assist in anticipation of potential risk. The Seismology Research Centre [39] provides a generic example, where:

-

Dams are usually built in valleys

-

Valleys exist because active erosion is taking place

-

Active erosion implies there has been recent uplift

-

Under compressional tectonic force, reverse or thrust faults produce uplift

-

Reverse or thrust faults dip under the upthrown block; therefore,

-

Many dams have an active fault dipping under them.

Induced Seismicity

Although less frequent than the natural process, ‘man-made earthquakes’ have been empirically proven to be caused by mining and exploration activity. Sources of ‘man-made earthquakes’, aligned with their influence on Coulomb parameters, include [31]:

Decrease in normal stress

-

Changes in tectonic forces caused by underground mining and the associated groundwater reduction

-

Rock burst in active and inactive underground mines

-

Oil and gas extraction

Increase in pore pressure:

-

Fluid injection and hydraulic fracturing

-

Pore pressure increase in active faults (as a result of seepage, monsoons, or induced)

Increase in shear stress:

-

Reservoir-induced earthquakes (not driven by the load of the reservoir, but rather ‘the increased pore water pressure in faults, leading to a reduction in shear strength over already stressed faults’ [17]).

Material Suitability

Analysis of foundation materials is conducted to determine their susceptibility to seismic induced failure. On either static or dynamic liquefaction of saturated or partially saturated soils, the stiffness and shear strength of a material is significantly reduced due to rapid increases in loading. The loading reflects an increase in shear stress, accompanied by the inability for resulting pore pressures to drain or dissipate in sufficient time. The increased pore pressure then exceeds the contact pressure between the soil grains, disrupting the soil structure and causing it to ‘flow’. When referencing the liquefaction characteristics of tailings, Davies, Mcroberts, and Martin [10] identify that material will have one of four characteristics:

-

Brittle strain softening (full liquefaction with the potential for limitless deformation)—contractant behaviour upon shear up to the steady-state condition

-

Limited strain softening (limited liquefaction with limited deformation)—some initial contraction followed by dilation of the tailings skeleton

-

Ductile behaviour with undrained shearing but no significant degree of strain softening (no liquefaction)

-

Strain hardening (no appreciable liquefaction or deformation)—essentially pure dilation.

Divisions defined by strain thresholds are often specified, relative to ‘changes in cyclic stress-strain behaviour, stiffness degradation, pore pressure generation, post-cyclic strength, and microscale processes’ [13].

The author references literature for strain and stress losses, and transitional behaviour for different materials in Boulanger and Idriss [5], and the challenges in estimating undrained strengths of materials on interaction with shear-induced pore pressures in Davies, Martin, and Lighthall [9].

Four material states of plasticity and their response to seismic loading are conceptualised by Vucetic [46] and presented systematically in Table 3.

Cemented, highly sensitive, and other ‘special soils’ are not included

3.5.2 How Does Failure Progress Due To Seismicity?

Seismicity can affect different components of a tailings dam, to varying degrees, including [17]:

-

Settlement and longitudinal and transverse cracking of the embankment, particularly near the crest of the dam—reduced freeboard, increased potential for overtopping

-

Internal erosion and piping may develop in cracks—seepage and slope stability

-

Liquefaction or loss of shear strength due to increase in pore pressures in the embankment and its foundations

To greater detail, seismic loading may result in [17]:

-

Instability of the upstream and downstream slopes of the dam and large deformations

-

Differential settlements and cracking due to active faults passing through the dam foundation

-

Development of open cracks [into deep circular sliding], or opening of previously closed joints in the foundation, close to the core-foundation contact

-

Differential movement between the embankment, abutments, and spillway structures leading to transverse cracks

-

Damage to outlet works passing through the embankment and differential settlements leading to cracking

-

Central core zone of rockfill dam exposed at the crest due to settlement and drug of surrounding shells, causing decrease in lateral constraint and opening of cracks [29]

3.5.3 Anticipating and Monitoring Seismicity

It is difficult to predict seismic activity because the two most important factors, the state of stress and the rock strength at earthquake depths, cannot be measured directly [39]. As such, seismic monitoring of a dam generally serves to assess expected versus actual performance of the dam during a seismic event [38].

Earthquake ground vibration is monitored over a wide range of scales, including global, regional, local, and microseismic using either surface or downhole instruments [18]. At the larger scales, seismometers are employed, while when addressing earthquakes at a smaller scale but higher resolution, microseismic monitoring is used.

Against source characteristics and propagation path of waves, local site conditions are suggested to be the most influential factor on engineering problems [36]. Local site conditions have a strong influence on the maximum amplitude, frequency, and duration of seismic waves. Event-specific seismic factors to consider include the Annual Exceedance Probability (AEP), and Design Earthquakes (Operating Basis Earthquake (OBE) and Maximum Design Earthquake (MDE)).

3.5.4 Designing for Seismicity

Fell et al. [17] describe the concept of ‘defensive design’ of embankment design for earthquakes. Industry best practice is described by [17]:

-

Provide ample freeboard, above normal operating levels, to allow for settlement, slumping, or fault movements which displace the crest

-

Use well designed and constructed filters downstream of the earthfill core to control erosion. To ensure effectiveness in the event of large dam settlements, likely associated with transverse cracking, filters should extend the full height of the embankment

-

Provide ample drainage zones to allow for discharge of flow through possible cracks in the core. Ensure that at least part of the downstream zone is free draining, or that extra discharge capacity is provided in the vertical and horizontal drains

-

Avoid, densify, drain, or remove potentially liquefiable materials in the foundation or in the embankment

-

Avoid founding the dam on strain weakening clay soils, completed weathered rock, or weak rock with the potential to strain weaken

-

The foundation under the core should so far as practicable be shaped to avoid sharp changes in profile across the valley, to discourage differential settlement and the associated cracking

Further, the author refers the reader to Fell et al. [17] for a number of minor measures that may also be taken into consideration.

It is noted that these measures are not necessarily applicable in assessment of existing dams, where an upgrade may be required if unsuitable conditions are present. Appropriate remedial measures and ground improvement options are described and referenced, as also described in Fell et al. [17]. The ANCOLD [3] flow sheet for seismic stability analysis is observed in Fig. 16.

Flow sheet for seismic stability analysis [3]

3.6 Slope Instability

Fundamental to many areas of geotechnical engineering, slope stability is the governing consideration in initial and iterative embankment designs. Monitoring of a tailings dam embankment slope is valuable in early identification of instability and can easily be cross-checked using multiple methods if monitoring results appear inconsistent [17].

3.6.1 What Factors Contribute to Slope Instability Failure?

Assessing the likelihood of slope instability requires consideration of the extent of potential soil behaviours and the influence of time and rate of loading on these behaviours [43]. Material characteristics deemed as the core to slope stability design and analysis comprise [43]:

-

Shear strength selection: potential influences of ‘sample disturbance, variability in borrow materials, possible variations in compaction water content and density of fill materials, anisotropy, loading rate, creep effects, and possibly partial drainage’ [40]

-

Critical state soil mechanics: ‘soils loaded under shear reach a critical density/ void ratio where there is no further change in shear stress and no further change in volume’ [43]. Normally to lightly over-consolidated soils typically contract, while dense to highly over-consolidated soils typically dilate. On contracting, normally to lightly over-consolidated soils generate excess pore pressures and undrained strengths are likely governing. Conversely, dilative soils generate negative pore pressures and, unless pore pressures still do not dissipate more quickly than loading applied (demanding complex assessment), are likely to be governed by drained, long-term conditions

-

Undrained strength (Fig. 17): Fine grained soils that are loaded faster than excess pore pressures can dissipate are assigned undrained shear strengths [43]. Typically, this occurs at end of construction, flooding and reservoir rise, and very rapid loading such as during seismicity

Typical undrained shear strain curves [43]

-

Drained strength (Fig. 18): Higher permeability materials such as sands and gravels are expected to drain and hence dissipate any excess pore pressures near instantaneously. In clays, loading must be slow enough to allow dissipation and hence consider a non-transient (steady state) seepage condition

Generalised drained stress strain curves [43]

-

Pore water pressures and associated strengths: Increased pore pressure within slopes results in an increased total stress. Further, the degree of saturation of different materials can cause the material to behave differently: the most common case is the difference between dry and saturated material states; and

-

Loading conditions: Various loading and analysis conditions should be analysed.

-

External influences causing increased shear stress: Removal of support (change in slope angle, unloading, subsidence), surcharge (loading, dam raises), transitory earth stresses (earthquakes, vibrations/ blasts), lateral pressure (freezing of water in cracks, organic intrusions); or

-

Internal influences causing decreased shear strength: Weathering (disintegration, decomposition), or water regime change (increased pore pressure, drawdown).

3.6.2 How Does Failure Progress Due To Slope Instability?

Unsatisfactory slope performance for tailings dams can develop by [40]:

Shear failure: Sliding of a portion of the embankment along a discrete surface, relative to its adjacent mass.

-

Rotational (circular) slides: Conventional assumption in stability analysis. Shear movements may occur across zones of appreciable thickness

-

Translational slides: Planar sliding along the interface between stratum of differing stiffness

-

Compound failure: A combination of the two sliding mechanisms, where a circular slip surface encounters stiff stratum and the failure surface occurs along the interface, as opposed to cutting through

Surface sloughing: A surficial portion of the embankment shears and moves downstream [40]

Excessive deformation/settlement/subsidence: Consolidation of the foundation may result in a displacement of particles and dislodging of a uniformly constructed slope, in turn potentially impacting the integrity of the slope. The rate of deformation is more influential than magnitude, on stability

Creep: Continuous mass deformation and/ or the progression of numerous small scale slides. Slow, long lasting, and difficult to recover

3.6.3 Anticipating and Monitoring Slope Instability

Natural events represent slope instability triggers and encourage increased monitoring due to associated water inflows, seismicity, or environmental damage. Historical monitoring of each dam is crucial, as unexpected variation from this may indicate a cause for concern.

Direct observation of the tailings dam embankment, or surrounding slopes, can aid in prediction of slope instability. Parameters may include [17, 30]:

-

Cracking in the crest or slope face

-

Settlement of the crest

-

Sinkholes

-

Saturated ground in areas that were previously dry

-

Damaged infrastructure and foundations

-

Misaligned fence lines

-

Change in downstream water levels or water quality

-

Sudden decrease in water levels

-

Unusual sounds, such as trees cracking or rock collisions may indicate moving debris on surrounding slopes [30]

In addition to, or perhaps prompted by visual observation, instrumentation can be utilised on a variety of different scales to assess and predict slope instability. Potential methods are described in Table 4. For many instrumentation types, technology has provided the opportunity to automate and remotely collect monitoring data. Real-time, accessible information hold vast benefit in monitoring practice.

3.6.4 Designing for Slope Instability

Evaluation of slope stability requires [40]:

-

Establish design or loading conditions to which the slope may be subjected during its life

-

Performing analyses of stability for each of these conditions. Four conditions must be considered:

-

(24)

During and at the end of construction

-

(25)

Steady state seepage

-

(26)

Sudden drawdown

-

(27)

Seismic

Soil stability analysis techniques are generally classified into either limiting analysis approach (upper and lower bound), limit equilibrium approach (factor of safety), or displacement based approach (finite element, boundary element, and discrete element). While the possibilities of manually calculating slope stability through slice methods or otherwise exists, modern proprietary software is commonly adopted to improve the speed and accuracy of slope stability model generation.

For static analyses (load conditions 1–3), the strength envelopes are governed by drained and undrained conditions (and effective and total stresses, respectively). Material implications for shear strength are described in Table 5 (adapted from [40], Table 2-1 ‘Shear Strengths and Pore Pressures for Static Design Conditions’). For dynamic analyses, the potential magnitude of earthquake and manmade earthquakes are the main consideration, as described in Seismicity.

4 Conclusion

The author reiterates the value in training and understanding of all levels of employee for routine visual inspection, where the multitude of competent eyes, familiar with the environment, is undeniably an invaluable asset in assessment of change, deterioration, and indicators of failure.

Familiarisation with tailings dam behaviour and characteristics fundamentals, and establishing a basis of the risks that apply to each unique site is undeniably essential. Knowledge and information sharing provides opportunity for designers, operators, researchers, and suppliers to reach out and learn from different regions and practitioners, tailoring the information gained in the interest of safety on their own site/s. For example, the improvements and adaptation that Chile has made in designing against seismicity presents a network of global leaders in the area. For benefit to be realised, reliance on practitioners to be more open and available with their data is critical. If an event occurred that was avoided due to efficient monitoring, document and share the case study. If an unpredicted event occurred, industry culture needs to focus on learning and ensuring that this does not happen again. As Davies, Martin, and Lighthall [9] identified, there have been no unexplained tailings failure events. Sharing this knowledge then not only demands an understanding of what occurred, it presents a database of events to prevent future incidents, advances design practices, and overall reduces the risk associated with mine tailings dam, oil sand tailings ponds, and other earthen dam industries.

Data Availability

Not applicable.

References

Australian Government Department of Industry Tourism and Resources (2007) Tailings management: Leading Practice Sustainable Development Program for the Mining Industry. Canberra. Viewed 16 March 2017. https://www.industry.gov.au/data-and-publications/leading-practice-handbook-tailings-management

Australian National Committee on Large Dams (ANCOLD) (2003) Guidelines on dam safety management.

Australian National Committee on Large Dams (ANCOLD) (2012) Guidelines on tailings dams – planning design, construction, operation, and closure.

Azam S, Li Q (2010) Tailings dam failures: a review of the last 100 years. In: Geotechnical News: Waste GEOtechnics, pp 50–53

Boulanger RW, Idriss IM (2006) Liquefaction susceptibility criteria for silts and clays. J Geotech Geoenviron 132(11):1413–1426

Briaud JL (2008) Case histories in soil and rock erosion: Woodrow Wilson Bridge, Brazos River Meander, Normandy Cliffs, and New Orleans Levees. J Geotech Geoenviron 134(10):1425–1447

Briaud JL, Chen HC, Govindasamy AV, Storesund R (2008) Levee erosion by overtopping in the New Orleans during the Katrina Hurricane. J Geotech Geoenviron 134(5):618–632

Clarkson L, Williams D (2019) Critical review of tailings dam monitoring best practice. Int J Min Reclam Environ. https://doi.org/10.1080/17480930.2019.1625172

Davies, M, Martin, D & Lighthall, P (2002a) Mine tailings dams - when things go wrong

Davies M, Mcroberts E, Martin T (2002) Static liquefaction of tailings – fundamentals and case histories.

Davies MP, Lighthall PC, Rice S, Martin TE (2002b) Design of tailings dams and impoundments. In: Proceedings of the Tailings and Mine Waste Practices. SME, Phoenix

Davies MP, Rice S (2001) An alternative to conventional tailings management – “dry stack” filtered tailings. In: Proceedings of Tailings and Mine Waste 2001, Fort Collins, pp 411–420

Díaz-Rodrigues, López-Molina (2008) Strain thresholds in soil dynamics. In: Proceedings of the 14th World Conference on Earthquake Engineering, Beijing

Engels J (2016) Water management considerations for conventional storage, viewed 16 March 2017, http://www.tailings.info/technical/water.htm

Fannin RJ, Slangen P (2014) On the distinct phenomena of suffusion and suffosion. Géotechnique 4(4):289–294

Federal Emergency Management Agency (FEMA) (2014) Technical manual: overtopping protection alternatives for dams.

Fell R, MacGregor P, Stapledon D, Bell G, Foster M (2015) Geotechnical engineering of dams¸ 2nd edn. CRC Press/ Balkema, The Netherlands

Gibson G, Sandiford M (2013) Seismicity and induced earthquakes. Office of the NSW Chief Scientist and Engineer.

Holtz RD, Kovacs WD (1981) An introduction to geotechnical engineering. Prentice Hall, Englewood Cliffs, New Jersey

Huzjak RJ, Prochaska AB (2012) Bedrock settlement beneath a large embankment dam. In: Proceedings of the Biennial Geotechnical Seminar 2012. American Society of Civil Engineers

ICOLD (2001) Tailings dams. Transport. Placement. Decantation. Review and recommendations. International Commission on Large Dams. Bulletin 101.

IDV Solutions (2012) Earthquakes since 1898, viewed 12 February 2017, http://uxblog.idvsolutions.com/2012/06/earthquakes-since-1898.html

Jantzer I (2009) Critical hydraulic gradients in tailings dams: Comparison to natural analogies, Licentiate Thesis, Luleå University of Technology, Sweden.

Klohn EJ (1979) Seepage control for tailings dams. In: Tailings and waste disposal-seepage, contamination, regulations, and control, British Columbia, Canada

Leonards GA (1982) Investigation of failures. Sixteenth Terzaghi Lecture. ASCE J Geotech Eng 108(Number GT2, February):224–283

Liang JZ, Elias D (2010) Seismic evaluation of tailings storage facility. Australian Earthquake Engineering Society, Perth

Martin TE (2002) Characterisation of pore pressure conditions in upstream tailings dams.

Mokhtari M, Dehghani M (2012) Swell-shrink behavior of expansive soils, damage and control. Electron J Geotech Eng (EJGE) 17:2673–2682

Narita K (2000) Design and construction of embankment dams. Aichi Institute of Technology, Toyota

Nelson SA (2013) EENS 3050: slope stability, triggering events, mass movement hazards, Online Course Notes, Tulane University, Louisiana, United States.

Oancea D (2007) Man-made earthquakes, viewed 12 February 2017, http://technology.infomine.com/articles/1/887/earthquake.geothermal.energy/man-made.earthquakes.aspx

Olson Engineering (2005) Geophysical methods, viewed 19 March 2017 http://www.olsonengineering.com/methods/geophysical-methods.html

Pabst MW, Engemoen WO, Hanneman DL, Redlinger CG, Scott GA (2012) Heave, uplift, and piping at the toe of embankment dams: A new perspective. In: Proc., Dam Safety 2012. ASDSO, Denver

Richardson E (2016) Plate tectonics and intra-plate earthquakes, viewed 12 February 2017, https://www.e-education.psu.edu/earth501/content/p4_p4.html

Robertson AM (2015) FMEA risk analysis: failure modes and effects analysis. PowerPoint slides.

Shoji Y, Tanii K, Kamiyama M (2004) The duration and amplitude characteristics of earthquake ground motions with emphasis on local site effects. In: Proceedings of the 13th World Conference on Earthquake Engineering, Vancouver B.C, Canada

Szymanski MB, Davies MP (2004) Tailings dam design criteria and safety evaluations at closure, In: Proceedings of the British Columbia Reclamation Symposium 2004, British Columbia.

Task Committee on Instrumentation and Monitoring Dam Performance (2000) Guidelines for instrumentation and measurements for monitoring dam performance. Reston, Va. American Society of Civil Engineers.

The Seismology Research Centre (n.d.) Dams & earthquakes, ESS Earth Sciences, viewed 21 April 2018, http://www.src.com.au/earthquakes/seismology-101/dams-earthquakes/

U.S. Army Corps of Engineers (USACE) (2003) Slope stability, in Engineer manuals. EM 1110-2-1902. Washington, D.C.

U.S. Bureau of Reclamation, U.S. Army Corps of Engineers, University of New South Wales, and URS (2008), Risk analysis for dam safety – a unified method for estimating probabilities of failure of embankment dams by internal erosion and piping guidance document, Version D, Issue 2

U.S. Bureau of Reclamation (USBR) (2015) Internal erosion risks for embankments and foundations, in Best practice and risk methodology, Security, Safety, and Law Enforcement Office – Dam Safety.

U.S. Bureau of Reclamation (USBR) (2015b) Embankment slope instability, in Best practice and risk methodology, Security, Safety, and Law Enforcement Office – Dam Safety.

U.S. Department of Interior Bureau of Reclamation (USBR) (2011) Design standards no. 13: chapter 5 – protective filters, DS-13(5)-9.

U.S. Environmental Protection Agency (US EPA) (1994) Design and evaluation of tailings dams, technical report code EPA 530-R-94. US EPA, Washington, DC

Vucetic M (1992) Soil properties and seismic response. In: Proceedings of the 10th World Conference of Earthquake Engineering, Rotterdam, Netherlands, pp 1199–1204

Woodward J (2005) An introduction to geotechnical processes. Spon Press, New York, New York.

Yuen STS (n.d.) Introduction to foundation engineering, The University of Melbourne, viewed 10 April 2017, http://people.eng.unimelb.edu.au/stsy/geomechanics_text/Ch13_foundatn.pdf

ZagonJolli M (2007) Dam break modelling, risk assessment and uncertainty analysis for flood mitigation, PhD thesis, Delft University of Technology, the Netherlands.

Zhao G (2016) Breach growth in cohesive embankments due to overtopping. Delft Academic Press, Delft

Zhang L, Peng M, Chang D, Xu Y (2016) Dam failure mechanisms and risk assessment, 1st edn. John Wiley & Sons, Singapore

Acknowledgements

The authors would like to recognise The University of Queensland and the Geotechnical Engineering Centre for the opportunity to explore this field and dedicate best efforts forward to empower others to achieve their potential in tailings dam safety. The authors would like to acknowledge GroundProbe for their technical and financial contributions to this Doctor of Philosophy and for upholding a genuine interest in safety over commercials. GroundProbe provided financial support for the conduct of the research, which supported the research through facilitation of international collaboration with the geotechnical community of practice, enhancing the perspectives and understanding as expressed in this research. The authors would like to acknowledge The Mining and Geotechnical community that the authors have made a network with as part of this work, particularly those involved in Tailings and Mine Waste 2017, and Slope Stability 2018, as well as from The University of Queensland and the Australian Government, for their influential and wide perspectives on global practice and how safety can be improved. The author would also like to recognise those that support unconditionally, irrespective of the degree of involvement in this work. Such positive attitudes and perspectives are interpersonal fuel to driving value in the technical setting.

Funding

This research was supported by GroundProbe, through a PhD grant awarded to the primary author, Luke Clarkson.

Author information

Authors and Affiliations

Contributions

In alignment with the Contributor Roles Taxonomy (CRediT) methodology:

Luke Clarkson: conceptualisation, methodology, data curation, investigation, writing—original draft, verification, writing—review and editing

David Williams: project administration, supervision

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that there is no conflict of interest.

Code Availability

Not applicable.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Clarkson, L., Williams, D. An Overview of Conventional Tailings Dam Geotechnical Failure Mechanisms. Mining, Metallurgy & Exploration 38, 1305–1328 (2021). https://doi.org/10.1007/s42461-021-00381-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42461-021-00381-3