Abstract

Excessive heat exposure is among the health and safety hazards that have adverse effects on the mine workers. The very nature of the underground climate makes it a convenient avenue for heat generation and accumulation from several heat sources including autocompression, equipment, and heat from strata. This study investigated the effects of clothing insulation and acclimation on the thermal comfort of mine workers who are exposed to heat in underground working environments. Several clothing ensembles have been considered to analyze the effect of the thermal resistance of clothing on the thermal comfort of workers. To investigate the impact of the clothing insulation, the thermal comfort limit of an underground miner was calculated in the form of maximum allowable exposure time for an 8-h shift. Parametric analyses were subsequently performed using an already developed thermal comfort model using MATLAB software. The results demonstrate that clothing insulation has a significant effect on the thermal comfort of mine workers. Increase in the clothing insulation decreases the maximum allowable exposure time of mine workers. This is especially true for the new and non-acclimated workers. Since acclimatized workers can tolerate a higher level of the dehydration and are capable of losing more water by sweat per shift, the maximum allowable exposure time for the acclimated workers are higher than non-acclimated workers. These analyses have shown that acclimated workers can have more continuous work per shift compared with non-acclimated workers. For example, in an environmental condition with clothing that a non-acclimated worker cannot work more than 5 h, an acclimated worker can work a full 8-h shift.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The mining industry has a workforce with varying levels of fitness, which makes it relevant to plan and protect those at the lower level threshold of fitness. Due to the nature of the job, mine workers are exposed to harsh environmental conditions that can result in occupational safety and health hazards. Among these hazards are heat exposure that has significant short-term and long-term effects on the health and safety of the workers. Furthermore, excessive heat exposure will negatively affect the performance of mine workers and the overall productivity of the mine [1]. The consequences of heat exposure include heat-related illnesses, fatigue and fainting, loss of concentration, performance reduction, and production loss [2].

Along with climate change, various sources impact the total heat load in a mine site [3,4,5]. In underground mines, the majority of the heat comes from different sources such as geothermal gradient, equipment, auto-compression, groundwater, and blasting [6]. On the surface, however, the majority of heat is in the form of solar energy.

The severity of heat on a mine worker depends on the duration and level of exposure, and the response of an individual to heat stress. The response of an individual is influenced by different factors such as age, gender, fitness, lifestyle, experiences, past medical history, and more [7].

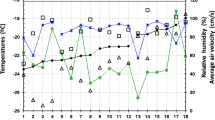

The Mine Safety and Health Administration (MSHA) has a catalog of heat-related incidents in US mines. Figure 1 represents the number of heat-related incidents in US mines between 2000 and 2017 reported by MSHA. Over 600 incidents are reported in US surface and underground mines, which are considerable. Figure 2 shows the number of heat-related incidents in different sections of mining. Considering the trend of future mines to be located underground, and for the necessity of mining deeper and deeper deposits, US underground mines are more susceptible to this problem in the future [8, 9].

MSHA published data reveals that worker’s experience is an essential factor in the number of heat-related incidents recorded. There is a reverse proportion between the number of incidents and the worker’s job experience. The more experience the workforce, the less heat-related incidents are reported. This is supported by the 67% of the heat-related incidents reported for workers with less than 5-year experience. The number of incidents decreases to 15% in the group of workers with job experiences between 5 and 10 years (Fig. 3). Also worth noting is the fact that most of the incidents occurred in the summer (i.e., 74% of the total of heat-related incidents). Figure 4 reports the effect of seasonal swings on heat-related incidents.

Total heat stress is defined as the net of the body-generated heat (metabolic heat), plus the heat derived from the environment (environmental heat), minus the heat loss from the body to the environment [10]. Environmental and metabolic heat stress will result in heat strain or physiological responses in order to reject the stored heat from the body back to the environment so that the constant core body temperature is maintained [10]. At some level of heat stress, the body mechanism is not able to keep the core temperature at the required level. Consequently, the risk of heat-related illnesses and other health and safety hazards rises [10]. The level of heat stress can be controlled by environmental factors (i.e., air temperature, air velocity, relative humidity, and radiant temperature) and also physiological factors (i.e., metabolic rate and clothing isolation) [2, 11,12,13,14].

It is well known that everyday clothing can provide physiological, physical, and psychological comfort to the wearer in a natural ambient environment [15, 16]. In hazardous environmental conditions, when the risk of exposure to occupational hazards is high, specialized protective clothing will be required in order to provide adequate protection and reduce the risk of exposure [16]. In addition to protecting workers from heat exposure, these protective clothing are also designed to protect personnel from chemical and biological agents in the environments. Ordinary protective clothes include low vapor permeability over-garment with a respirator, impermeable rubber gloves, and over-boots. These protective garments are designed to reduce the interaction of dangerous chemicals with skin and hazardous agents with the respiratory system of the body [17]. However, protective garments restrict the dry heat exchange and wet heat flux. Therefore, wearing these clothing will result in increasing the heat storage in the body, and tolerance time is decreased compared with wearing the clothing with a configuration that allows a more effective heat exchange [18, 19]. McLellan et al. [17] pointed out that for light and heavy work rates, use of protective clothes has a considerable negative impact on heat strain and tolerance time.

The physiological reaction of the human body to the heat includes acute responses such as heat-related illnesses and adaptive responses, which is the adaption of the body to heat exposure. Heat tolerance capacity of the workers specifies the level of “acceptable” heat stress. Even though there is a wide range of heat tolerance capabilities among the workers, everyone has heat stress upper limit beyond which the resultant heat strain can cause heat illness [20, 21]. Repeated exposure will lead to heat adaptation [10]. For most workers, proper repeated exposure to elevated heat stress causes physiological adaptations called acclimation. During acclimation, the body gradually becomes more efficient to afford the level of heat exposure. A higher level of heat stress can be tolerated by acclimated workers before a harmful level of heat strain.

This paper aims to discuss the effects of clothing and acclimation on the overall comfort of underground mine workers. In this paper, a thermal model is used whose input data are environmental and behavioral parameters. A series of analysis is performed in order to estimate the impact of acclimation and dehydration on the maximum allowable exposure time per 8 h of a shift for underground mine workers. Importance of acclimation and hydration is shown based on the outcomes of thermal comfort modeling.

2 Methods

Human satisfaction of the thermal environment describes thermal comfort [22]. Essentially, thermal comfort refers to a condition in which the majority of the individuals in an environment feel thermally comfortable. Thermal comfort measure is based upon the heat exchange between the human body and its environment. Generally, comfort refers to the narrow range of body temperature where the skin moisture is low, and physiological effort is minimized [22].

Sunkpal, Roghanchi & Kocsis [23] developed a model in MATLAB for the underground mine, based on the thermal comfort equation (Eq. 1). Using this equation, heat storage in the body (S) can be estimated where M (W/m2) is the metabolic rate; C, R, B, E, and K (W/m2) are respectively the heat loss due to convection, radiation, respiration, evaporation, and conduction, and W is the effective mechanical power [24, 25]. For calculating respiration heat loss, clothing insulation factor does not have direct influence. In this study, heat loss due to conduction is not considered [23].

In order to find convective heat loss, Eq. (2) should be utilized where, Tcl (K) is the external temperature of the clothing, fcl is the clothing factor (associated with the skin surface available for heat exchange), and hc (Wm−2 K−1) is the heat dissipation coefficient related to the airflow velocity [26, 27].

Radiation heat loss is calculated by Eq. (3), where ɛsk is the coefficient of skin emissivity, in which the approximate value is between 0.95 and 0.97, hr (Wm−2 K−1) linearized coefficient of heat exchange by radiation, fr correction term is equal to 0.77 [26, 28].

Evaporative heat loss is computed by Eq. (4), where ω is the skin wittedness, he (Wm−2 KPa−1) is the latent heat transfer coefficient, fec is the clothing permeability factor for vapor transfer, Psk and Pa (KPa) are the saturation partial vapor pressure at the skin temperature and in ambient air, respectively [26, 29].

The rate of sweat production is indicated with multiplying SW by 0.6726, e.g., 1 W/m = 1.4868 gh−1 m−2 [8, 23]. The maximum sweat rate production (SWreq) which is the function of metabolic rate (M in Watt) can be computed by the Eqs. (5) and (6) for non-acclimated and acclimated workers [30].

The maximum allowable exposure time (Tmax) is evaluated in Eq. (7) based on the maximum tolerable dehydration (Dmax) for 1 working day, where SW is the sweat production rate. This limitation of exposure time is calculated for an average subject based on maximum water loss (dehydration) of 7.5% of the body mass, it has to be decreased by 33% in order to protect 95% of the miner population [23, 30].

Sunkpal et al. [23] assumed that the thermal resistance of the clothing is constant and equal to 0.093 m2 °CW−1 and the maximum tolerable dehydration (Dmax) is equal to 3900 Whg/m2. This model was employed to calculate the maximum allowable exposure time at different air temperatures, assuming a relative humidity of 80% and air velocity equal to 1.5 m/s for different clothing thermal resistances. In this study, the maximum allowable exposure time is considered the threshold limit value. Furthermore, a metabolic rate of 200–350 W/m2 was considered moderate work intensity levels in a fully mechanized underground mine. Radiant temperature was assumed to be equal to ambient air temperature in underground mines due to strong flow condition [31]. The highest tolerable values of required sweat rate suggested by ISO 7933 [32] for acclimated and non-acclimated workers were used. The highest tolerable values of required sweat rate suggested by ISO 7933 (2004) [32] for acclimated and non-acclimated workers were used.

Table 1 displays thermal comfort model parameters and Table 2 demonstrates the clothing categories and their relevant insulation values adapted from [10]. The TLV is evaluated based on the maximum dehydration (Dmax). Based on ISO 7933 [33], the level of risk for acclimated and non-acclimated workers was categorized to danger and warning (alarm) levels. The warning level is when there is no risk related to the worker’s activities, and they are in good health, and the danger level is when the workers could be already at risk. This study considered four levels of dehydration as demonstrated in Table 3 to estimate the maximum allowable exposure time of the workers.

3 Results

3.1 The Effect of Clothing Insulation on the Thermal Comfort of Miners

Several scenarios were studied to identify the effect of the thermal resistance of clothing on the thermal comfort of workers in underground mine working areas. For this purpose, the maximum allowable exposure time (TLV exposure time) for a shift of 8 h in different ambient air temperatures was analyzed. The maximum allowable exposure time was plotted as a function of ambient air temperature (Fig. 5). The results of the simulation indicate that the allowable exposure time will decrease by increasing the thermal resistance factor. Although it was expected that the high clothing insulation would decrease the allowable exposure time, one can quantify the maximum allowable exposure time based on the environmental factors and the level of activities. Tables 4, 5, 6, and 7 show the results of this analysis at the air temperatures of 0, 10, 20, and 30 °C and metabolic rate of 200, 250, 300, and 350 W/m2. For instance, at Dmax equal to 3900 Whm−2 g, the allowable exposure time at Rcl = 0.11 m2°CW−1 and Rcl = 0.186 m2°CW−1 is less than 8 h and 5 h, respectively. It is obvious that the human body can tolerate higher temperatures at lower metabolic rates with the same clothing insulation.

3.2 The Effect of Acclimation on the Thermal Comfort of Miners

In order to identify the effect of the acclimation on the thermal comfort of the individuals, maximum allowable exposure time of the acclimation and non-acclimation workers was determined. Acclimated and non-acclimated workers can be differentiated by different maximum dehydration levels. Figure 6 shows the maximum allowable exposure times at the metabolic rate of 250 W/m2 for the warning and danger dehydration levels. Tables 8 and 9 summarize the maximum allowable exposure times for acclimated and non-acclimated workers at air ambient temperature of 20 °C and 30 °C, respectively. These analyses show that for similar clothing insulation, acclimated workers have higher maximum allowable exposure time. For example, at Rcl = 0.11 m2°CW−1 and Ta = 20 °C, a non-acclimated worker cannot work more than 5 h, while an acclimated worker can work a full 8-h shift. Furthermore, at the same environmental condition, at danger level of dehydration, the TLV is less than 7 h for non-acclimated workers, while it is 8 h for acclimated workers. Therefore, acclimated workers have more maximum allowable exposure time in the same environment and metabolic rate due to greater maximum dehydration level.

4 Discussion

The degree of clothing insulation can have a great effect on the level of heat exchange between the body and the environment and may restrict the convective transfer and interfere with the body’s capacity to lose heat by sweat evaporation. However, clothing can decrease the radiant heat from surrounding surfaces to the body [34]. Clothing thermal resistance (Rcl) describes the insulation level between body and environment [12]. Clothing insulation can be estimated from the tables in the ISO 9920 standard for each level of clothing insulation [14]. Clothing area factor (Fcl) is calculated from the insulation of the entire ensemble (Icl) and radiation heat transfer coefficient (hr) and convective heat transfer coefficient (hc) [14]. Generally, four kinds of insulation exist: the total insulation that involves air and clothing, the effective insulation which only considers clothing, intrinsic or basic insulation in which increasing the exchange area is considered, and the resultant insulation from which human activity and sweating are taken into consideration [14].

Since underground miners are required to wear the appropriate clothing combination and personal protective equipment (PPE), it is important to determine the effect of clothing insulation on the comfort of underground miners. Based on the thermal comfort model, clothing can significantly change the tolerance of the individual to heat exposure. These results demonstrate that increase in insulation factor of clothing will lead to the reduction of maximum allowable exposure time for the workers. With increasing in air ambient temperature and same insulation factor of the clothing, TLV exposure time is decreasing, which means that at harsh environmental condition, appropriate clothing should be provided along with more break per a shift of work.

When workers are exposed to the hot work environment, their body starts to show signs of discomfort, such as elevated heart rates and core temperatures, nausea or headache, and other symptoms of heat exhaustion [35,36,37,38]. As a result of repeated exposure to heat, principal physiological adaptation will occur [10]. Heat tolerance capacity of the workers specifies the level of heat stress. Even though there is a wide range of heat tolerance capabilities among workers, everyone has a heat stress tolerance limit that if exceeded will result in heat strain and subsequently cause heat-related incidents [20, 21]. With acclimation, the body gradually becomes more efficient to accommodate the hot environment. Higher heat stress can be tolerated by acclimated workers before a harmful level of heat strain. Acclimation has these useful physiological adaptations [10, 39, 40]:

-

efficient sweating system

-

stabilization of the circulation

-

working at lower core temperature and heart rate

-

higher skin blood flow at a given core temperature

Full heat acclimation is the result of the daily short exposures to heat in the working area. It does not seem necessary to be in a hot environment for 24 h; in fact, such excessive exposure is difficult for non-acclimated individuals to compensate for the whole amount of water they lost by sweat. The minimum time of exposure to heat is 2 h per day [38]. The level of acclimation depends on physical fitness and previous experience of exposure to heat [38, 39]. With acclimation sweat rate will increase, so it is necessary to replace the water lost [38, 41]. Absence from work for a week or more reduces the acclimation level and can usually be reestablished in 2–3 days upon return to the hot environment [42, 43]. Recent studies demonstrate that several heat-related incidents occur due to lack of acclimation program by the employers [10, 44]. According to the National Institute for Occupational Safety and Health (NIOSH), a sudden increase in environmental parameters can increase the risk of heat-related illnesses even when the workers are acclimated.

Heat transfer through clothing or conversely clothing insulation, depends mainly on the air that is trapped in the clothing. If the clothing contains any sort of material that offers a hold to layers of air, then it provides insulation. The insulation of a clothing ensemble depends to a large extent on the design of the clothing. A number of layers, apertures, fit, and distribution of insulation over the body and exposed skin are design parameters, which affect the insulation of the clothing. Some material properties such as air permeability, reflectivity, and coatings are important as well. It is crucial to look at the importance of clothing as a key factor of thermal comfort in case of heat exposure [15].

Although, safety plays a big part in choosing the appropriate clothing for workers such as wearing of hard hat, gloves, and long sleeves, in high heat load climates, it is recommended to provide protective clothing such as cooling vests and cooling garments, as discussed before. It is important to look at the appropriate protective clothing that can support the health and safety of the workers in different occupational hazards as well as heat exposure. In severe environmental conditions, many considerations should be taken into account in order to optimize the cooling garments of the mine workers. These factors include temperature, humidity levels, weight, compatibility with safety regulations, and efficiency of the garment. Currently, no cooling technology is practically compatible with the condition of deep underground mines [45,46,47]. The combination of two or more cooling garments may be a solution to protect the underground workers in severe environmental conditions.

Heat acclimation plays a big role in the body’s physiological responses and ability to cope with heat exposure. Heat acclimation is a broad term that can be defined as a series of adaptations that occur in response to heat stress in a controlled environment over the course of 7–14 days. In either case, the positive adjustment that occurs include reductions in heart rate, body temperature, skin temperature, and perceive exertion and improve in sweat rate, sweat onset, heart function, blood distribution, and pressure, salt loss in sweat and urine, and overall ability to perform in the heat. Therefore, it is important to acclimate workers before exposure to heat based on the past history of working environmental conditions. It is recommended to have an acclimation plan for both acclimated and non-acclimated workers. Since acclimated workers have a higher level of dehydration and capable of losing more water by sweat per shift, the maximum allowable exposure time for the acclimated workers are greater than non-acclimated. These analyses have shown that acclimated workers in danger level can have more continuous work per shift compared with non-acclimated workers in the same condition.

5 Conclusion

Clothing insulation factor has a significant effect on the thermal comfort of mine workers. This study analyzed the effects of changing the insulation factor of the clothing, dehydration level, and acclimation on the thermal comfort of the workers in an underground mine. The criterion in this study was the maximum allowable exposure time of the workers per 8 h of a shift. Increase in the clothing insulation decreases the maximum allowable exposure time of the workers. Maximum dehydration level has a significant effect on the maximum allowable exposure time. Increase in dehydration level causes allowable exposure time to increase. Since acclimated workers can tolerate a higher level of the dehydration and capable of losing more water by sweat per shift, the maximum allowable exposure time for the acclimated workers is higher than non-acclimated workers. These analyses have shown that acclimated workers can have more continuous work per shift compared with non-acclimated workers.

References

Roghanchi P, Kocsis KC (2018) Challenges in selecting an appropriate heat stress index to protect workers in hot and humid underground mines. Saf Health Work 9(1):10–16

Roghanchi P (2017) Managing and controlling the thermal environment in underground metal mines. Doctoral Dissertation, University of Nevada, Reno

Hanna EG, Kjellstrom T, Bennett C, Dear K (2011) Climate change and rising heat: population health implications for working people in Australia. Asia Pacific Journal of Public Health 23:14S–26S

Kjellstrom T, Lemke B, Hyatt O, Otto M (2014) Climate change and occupational health: a south African perspective. S Afr Med J 104(8):586

Song X, Wang S, Hu Y, Yue M, Zhang T, Liu Y, Tian J, Shang K (2017) Impact of ambient temperature on morbidity and mortality: an overview of reviews. Sci Total Environ 586:241–254

Maurya T, Karena K, Vardhan H, Aruna M, Raj MG (2015) Potential sources of heat in underground mines–a review. Procedia Earth and Planetary Science 11:463–468

Talebi E, Roghanchi P, Abbasi B (2019) Heat management in mining industry: personal risk factors, mitigation practices, and industry actions. In: 17th North American mine ventilation symposium, Madiseh A, Sasmito A, Hassani F, Stachulak J, eds. Montreal, QC, Canada

Roghanchi P, Kocsis KC, Sunkpal M (2016) Sensitivity analysis of the effect of airflow velocity on the thermal comfort in underground mines. Journal of Sustainable Mining 15(4):175–180. https://doi.org/10.1016/j.jsm.2017.03.005

Webber RCW, Franz RM, Marx WM, Schutte PC (2003) A review of local and international heat stress indices, standards and limits with reference to ultra-deep mining. Journal of the South African Institute of Mining and Metallurgy 103(5):313–324 https://www.saimm.co.za/Journal/v103n05p313.pdf%0, https://hdl.handle.net/10520/AJA0038223X_2862

Jacklitsc B, Williams WJ, Musolin K, Coca A, Kim J, Turner N (2016) Criteria for a recommended standard: occupational exposure to heat and hot environments. National Institute for Occupational Safety and Health (NIOSH). https://www.cdc.gov/niosh/docs/2016-106/pdfs/2016-106.pdf?id=10.26616/NIOSHPUB2016106

Graveling R, Morris L, Graves R (1988) Working in hot conditions in mining: a literature review. Institute of Occupational Medicine, Ergonomic Branch

Sunkpal MN (2015) Assessing thermal comfort in deep underground mines. Dissertation, University of Nevada, Reno. https://scholarworks.unr.edu/bitstream/handle/11714/2651/Sunkpal_unr_0139M_11926.pdf?sequence=1&isAllowed=y

Macpherson RK (1962) The assessment of the thermal environment. A review. Occupational and Environmental Medicine 19(3):151–164. https://doi.org/10.1136/oem.19.3.151

Djongyang N, Tchinda R, Njomo D (2010) Thermal comfort: a review paper. Renew Sust Energ Rev 14(9):2626–2640

Lotens WA (2011) Heat exchange through plastics. Encyclopaedia of Occupational Health and Safety. http://www.iloencyclopaedia.org/part-vi-16255/heat-and-cold/76-42-heat-and-cold/heat-exchange-through-clothing

Song G, Mandal S, Rossi RT (2016) Thermal protective clothing for firefighters. Woodhead Publishing. https://books.google.com/books?hl=en&lr=&id=kXe0CwAAQBAJ&oi=fnd&pg=PP1&dq=Thermal+protective+clothing+for+firefighters&ots=oZFzltanmN&sig=pyK3n5065BFbZprVABrMqt1KdPg#v=onepage&q=Thermal protective clothing for firefighters&f=false

McLellan TM, Pope JI, Cain JB, Cheung SS (1996) Effects of metabolic rate and ambient vapour pressure on heat strain in protective clothing. Eur J Appl Physiol Occup Physiol 74(6):518–527

Givoni B, Goldman RF (1972) Predicting rectal temperature response to work, environment, and clothing. J Appl Physiol 32(6):812–822

Carter BJ, Cammermeyer M (1985) Emergence of real casualties during simulated chemical warfare training under high heat conditions. Mil Med 150(12):657–665

ISO 7243 (1989) Hot environments - estimation of the heat stress on working man, based on the WBGT-index (Wet bulb globe temperature)

Occupational Safety and Health Administration (OSHA) (2017) Heat Stress. https://www.osha.gov/dts/osta/otm/otm_iii/otm_iii_4.html

ASHRAE Handbook-Fundamentals (1997) American society of heating, Refrigerating and Air-Conditioning Engineers

Sunkpal M, Roghanchi P, Kocsis KC (2018) A method to protect mine workers in hot and humid environments. Saf Health Work 9(2):149–158

McPherson MJ (1993) Subsurface ventilation and environmental engineering. Chapman and Hall, London

Fanger PO (1970) Thermal comfort. Analysis and Application in Environment Engineering

Larry K (1970) Encyclopaedia of occupational health and safety. In: Jacques M (ed) The Physical Basis of Work in Heat, 4th edn. Internationational Labour Office, Wellington

Mairiaux P, Malchaire J, Candas V (1987) Prediction of mean skin temperature in warm environments. Eur J Appl Physiol Occup Physiol 56(6):686–692

Wacławik J, Branny M (2004) Nummerical modelling of heat exchange between a human body and the environment. Arch Min Sci 49(2):223–251 https://www.infona.pl/resource/bwmeta1.element.baztech-article-BWA5-0001-0016/tab/summary

Gagge A (1981) Rational temperature indices of thermal comfort. In: Studies in environmental science. Elsevier, Amsterdam, pp 79–98. https://doi.org/10.1016/S0166-1116(08)71082-3

Malchaire J, Kampmann B, Havenith G, Mehnert P, Gebhardt HJ (2000) Criteria for estimating acceptable exposure times in hot working environments: a review. Int Arch Occup Environ Health 73(4):215–220

Wang S, Ren T, Zhang T, Liang Y, Xu Z (2012) Hot environment- estimation of thermal comfort in deep underground mines. In: 12th Coal Operators’ Conference, University of Wollongong. pp 241–9 https://ro.uow.edu.au/cgi/viewcontent.cgi?referer=https://www.google.com/&httpsredir=1&article=2073&context=coal

ISO 7933 (2004) Ergonomics of the thermal environment - analytical determination and interpretation of heat stress using calculation of the predicted heat strain

ISO 7933 (1989) Hot environments - analytical determination and interpretation of thermal stress using calculation of required sweat rate

Department of Industry and Resources (1997) Management and Prevention of Heat Stress. https://www.dmp.wa.gov.au/Documents/Safety/MSH_G_ManagementAndPreventionOfHeatStress.pdf

Leithead C, Lind A (1964) Heat stress and heat disorders. London Cassell

WHO Scientific Group (1969) Health factors involved in working under conditions of heat stress. Geneva. https://apps.who.int/iris/handle/10665/40716

Hancock PA (1982) Task categorization and the limits of human performance in extreme heat. Aviat Space Environ Med

Sawka M, Wenger C, Montain S, Kolka M, Bettencourt B, Flinn S, et al (2003) Heat stress control and heat casualty management. https://www.dir.ca.gov/oshsb/documents/Heat_illness_prevention_tbmed507.pdf

Tian Z, Zhu N, Zheng G, Wei H (2011) Experimental study on physiological and psychological effects of heat acclimatization in extreme hot environments. Build Environ 46(10):2033–2041

Tipton MJ, Pandolf K, Sawka M, Werner J, Tylor N (2008) Physiological responses and adaptations to hot and cold environments. In: Taylor N, Groeller H, McLennan P (eds) Physiological bases of human performance during work and exercise. Churchill Livingstone, London, pp 379–400

Navy Environmental Health Center (2007) Prevention and treatment of heat and cold stress injury. Portsmouth, Virginia. http://www.public.navy.mil/surfor/Documents/6260_6A_NMCPHC_TM.pdf

Lind AR, Bass DE (1963) Optimal exposure time for development of acclimatization to heat. Federation Proceedings, pp 704–708. https://www.ncbi.nlm.nih.gov/pubmed/13930724

Wyndham CH (1973) The physiology of exercise under heat stress. Annu Rev Physiol 35(1):193–220

Arbury S, Jacklitsch B, Farquah O, Hodgson M, Lamson G, Martin H, Profitt A (2014) Heat illness and death among workers—United States, 2012–2013. MMWR. Morbidity and mortality weekly report 63(31):661

Hartman HL, Mutmansky JM, Ramani R, Wang YJ (2012) Mine ventilation and air conditioning, 3rd edn. Wiley, New York https://www.worldcat.org/title/mine-ventilation-and-air-conditioning/oclc/827207860

Piekarski C (1995) Climatic stress in coal mining in Germany: occupational health aspects. Ergonomics 38(1):23–35

Al Sayed C, Vinches L, Hallé S (2016) Towards optimizing a personal cooling garment for hot and humid deep mining conditions. Open J Optim 5(01):35

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Talebi, E., Sunkpal, M., Sharizadeh, T. et al. The Effects of Clothing Insulation and Acclimation on the Thermal Comfort of Underground Mine Workers. Mining, Metallurgy & Exploration 37, 1827–1836 (2020). https://doi.org/10.1007/s42461-020-00208-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42461-020-00208-7