Abstract

Eighteen chemical kinetic mechanisms for combustion of methane/hydrogen mixtures are compared for various burning conditions. The 18 mechanisms include eight detailed mechanisms, nine reduced mechanisms, and one global mechanism. Six of the reduced mechanisms are derived in this study. In the methane/hydrogen mixture, the blending ratio of hydrogen increases from 0 to 100% by 20% point in mole fraction. Calculated ignition delay times and laminar burning velocities are compared with available experimental data over the wide ranges of pressure and equivalence ratio as variables, respectively. Ignition delay times with NO2 are also evaluated by several mechanisms to compare their prediction accuracy for NOx emission. The aim of this study is to provide information for the purpose of choice of particular kinetic mechanism to obtain accurate results at a reasonable computational cost. The results show that although the reduced reaction mechanisms developed in this study have a narrower applicable range for predicting ignition delay times with hydrogen blending, they present higher accuracy in calculating laminar burning velocities and NOx emissions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

With the increase in global energy demand and environmental concerns, search for clean and sustainable energy sources has become a major challenge [1,2,3]. Natural gas (NG), of which major component is methane (CH4), has been recognized as a promising alternative to conventional fuels due to its low carbon and sulfur emissions and abundant reserves [4, 5]. However, due to slow laminar burning velocity (LBV) of NG, NG engines suffer from issues, such as low thermal efficiency and poor lean-burn capability [6]. In addition, the carbon emissions generated by methane combustion pose obstacles to achieving carbon neutrality. The addition of hydrogen (H2) to CH4–air mixtures has been proposed as a potential solution to improve the combustion performance of NG and to reduce CO2 emissions. It can alter key combustion parameters, such as laminar flame speed, flame thickness, flammability limits, and adiabatic flame temperature [6]. However, the use of 100% hydrogen is still immature technologically and logistically, and accordingly, hydrogen-enriched natural-gas applications could be a preliminary approach to facilitate the introduction of hydrogen. For this purpose, understanding the combustion characteristics of hydrogen and methane mixtures is crucial. Gas turbine operation typically occurs at pressures around 20 atm, with flame temperatures controlled at approximately 1500K under fuel-lean conditions. Therefore, it is necessary to analyze the combustion of hydrogen, methane, and air mixtures under a wide range of conditions, spanning from atmospheric to high pressures and from fuel-lean to fuel-rich conditions.

Furthermore, methane is an interesting propellant in terms of high-performance rocket engines and reusable rockets. Because demand for rocket launch at low cost is increasing, reusable rockets can be more viable in the future. Methane, as a propellant, has the advantages of easy storage and low cost over hydrogen, high specific impulse, and fewer coking problems than kerosene [7, 8]. It is suitable for the fuel of a reusable rocket engine. In this regard, simulating and analyzing the combustion characteristics of methane under various operating pressures are also important.

A large number of experimental results for combustion of hydrogen and methane have been published, and the accuracy of these experimental results is continuously improved. For example, Chen et al. compared the laminar flame speeds of hydrogen/methane/air mixtures at different equivalence ratios under atmospheric pressure through experiments in an early study [9]. Zhang et al. measured the ignition delay time of hydr1ogen/methane/oxygen/nitrogen mixtures using a shock tube with the highest hydrogen concentration in the mixture aroud 20% [10]. Later, Zhang et al. increased the hydrogen concentration up to 80% for three pressure conditions (5, 10, and 20 atm) [11]. Recently, more experimental results on the laminar flame speed of hydrogen and methane mixtures [12,13,14], experimental and computational results on ignition delay time [3, 15, 16], and results on changes in NOx emissions after hydrogen addition have been published [17, 18].

With experimental studies, accurate simulations using computational fluid dynamics (CFD) are necessary to explain relevant combustion phenomena [19, 20]. For simulations, selecting an appropriate chemical reaction mechanism for these simulations is crucial but still challenging, as it must balance the need for short computational time with accuracy in output parameters. Additionally, a lack of communication between kinetic scientists and CFD engineers can lead to poor mechanism selection. Therefore, expert assessments of kinetic mechanism must be provided for CFD engineers to ensure that simulations incorporate the most suitable mechanisms. Zhang et al. evaluated 13 detailed kinetic mechanisms by comparing ignition delay times [21]. Ströhle et al. evaluated several detailed mechanisms for hydrogen combustion under gas turbine conditions, and they found that some of them show poor performance for the laminar flame speed at high pressures [22]. Kumar et al. also compared hydrogen–air reaction mechanisms used for unsteady shock-induced combustion devices [23]. Olm et al. have conducted comprehensive comparisons of hydrogen and syngas reaction mechanisms, identifying generally well-performing mechanisms as well as those that are only effective under specific conditions or for particular types of experiments [24, 25]. Zettervall et al. not only compared ignition delay times but also assessed four detailed mechanisms, seven reduced mechanisms, and six global mechanisms by calculating laminar burning velocities and strain rates [26]. However, these evaluations were conducted using methane rather than hydrogen–methane mixtures. The accuracy and computational efficiency of different mechanisms in simulating combustion of hydrogen–methane mixtures at various pressures and hydrogen blending ratios were not well evaluated. Currently, there are numerous available reaction models designed for high-fidelity CFD simulations, featuring a reduced number of species and elementary reactions. In most scenarios, the utilization of these reaction mechanisms presents no significant challenges. However, as pressure increases to relatively high values (20 atm) or as the hydrogen blending ratio surpasses certain thresholds (above 60%), errors in calculated results become more pronounced. Furthermore, while some reaction mechanisms yield accurate results, the absence of compiled reactions related to NOx emissions requires separate computations when applied in CFD simulations. Consequently, the creation of a reaction mechanism that encompasses NOx reactions and remains suitable for high-pressure and high-hydrogen-blending scenarios becomes imperative.

Therefore, the primary objective of this study is to guide in selecting reaction mechanisms for simulating the combustion of hydrogen–methane mixtures by evaluating existing and newly developed mechanisms. The secondary goal is to present reduced mechanisms developed in this study and validate their reasonability. For these purposes, the accuracy of the mechanisms is compared by calculating ignition delay times, laminar burning velocity, and NOx-related reactions under various simulation conditions ranging from low to high pressures and from 0 to 100% hydrogen blending ratios. Based on the simulation conditions and required computational time, recommendations for selecting the most appropriate mechanism are provided.

2 Methodology

2.1 Kinetic Mechanisms

This section introduces commonly adopted mechanisms with different levels of complexity, which are classified as detailed, reduced, and global mechanisms in the descending order of complexity. Eight detailed mechanisms, nine reduced mechanisms, and one global mechanism are tested here.

2.1.1 Detailed Mechanisms

Detailed kinetic mechanisms adopted here are listed in Sect. 2.1.1. Table 1. All these mechanisms are validated using a wide range of experimental data, including ignition delay times, laminar burning velocity, and ignition of the mixtures with NO2 species. As the state-of-the-art detailed mechanism, called NUIG Mech1.1 (NUIG 2020), is one of the most comprehensive mechanisms for C0–C7 species currently available. It includes 2746 species and was released by the NUI Galway research group in 2020 [27]. The same group also developed the mechanism of Aramco Mech. 2.0 (Aramco 2.0) including 502 species and was released in 2016 [28]. Aramco Mech 2.0 was built based on Aramco Mech 1.3 and has been developed to characterize the kinetic and thermochemical properties of a large number of C1–C4-based hydrocarbon and oxygenated fuels over a wide range of experimental conditions. The initial version of the NUI Galway model (NUIG 2007) consists of 118 species and 663 elementary reactions, which was published in the work of Petersen et al. in 2007 [29]. The CRECK CH4 mechanism released in 2020 was developed by the chemical reaction engineering and chemical kinetics (CRECK) laboratory to simulate the reaction and properties of C1–C3 [30]. And, a H2/CO/C1–C4 kinetic model, called USC Mech. version II (USCII), was developed by the research group of Wang et al. in 2007 [31]. This reaction model was subject to validation tests complying with reliable H2/CO/C1–C4 combustion data. Recently, Wang et al. and G. Smith at SRI international published another mechanism, called the foundational fuel chemistry model (FFCM) [32]. The FFCM can predict H2, H2/CO, CH2O, and CH4 combustion and includes 38 species and 291 steps. The combustion research group at UC San Diego developed the San Diego mechanism, which can simulate the combustion of methane or natural gas. The San Diego mechanism with nitrogen chemistry includes 68 species and 311 reactions [33]. And, the GRI 3.0 mechanism has been created by the Berkley combustion team as an updated version of GRI-Mech 2.11 [34]. It is a detailed kinetic mechanism for methane/air combustion including nitric species for NOx predictions with 53 species and 325 reactions. In this study, a fuel mixture of hydrogen and methane is considered and the aforementioned eight detailed mechanisms are adopted to simulate combustion of the mixture.

2.1.2 Path Flux Analysis Method

Path flux analysis (PFA) reduction method is applied to reduce detailed chemical kinetic mechanisms [35]. Mechanism reduction aims to identify species that are important to the target species. The production and consumption fluxes of species are used to identify the important reaction pathways. The production and consumption fluxes, PA and CA, of species A can be calculated as follows:

where vA,i is the stoichiometric coefficient of species A in the ith reaction. And \(\omega_i\) is the net reaction rate of the ith reaction, respectively. I is the total number of elementary reactions. The flux of species A related with species B can be calculated as

Here, PAB and CAB denote, respectively, the production and consumption rates of species A due to the existence of species B. For example, when two generation fluxes are considered, the interaction coefficients for production and consumption of species A via B of first generation are defined as

Using the production and consumption fluxes of the first generation, the interaction coefficients which are measures of flux ratios between A and B via a third reactant (Mi) for the second generation are defined as

The summation here includes all possible reaction paths (fluxes) relating A and B. In theory, different threshold values can be set for different interaction coefficients. For simplicity, all the interaction coefficients can be lumped together and set only one threshold value

The coefficient defined above is used to evaluate the dependence/importance of species B to species A in the PFA method. The method can be extended to more generations and consumptions. Nevertheless, with the increase of the number of generations, the computation time is proportional to the species number. A more detailed explanation of the PFA method can be found in the study conducted by Sun et al. [35].

The PFA method has been developed into an in-house code program. To facilitate the simplification of reaction mechanisms, the following steps are taken:

-

1.

Preparation of mechanism file: The detailed reaction mechanism file containing thermochemical data needs to be prepared for the mechanism that will undergo simplification.

-

2.

Database generation for mechanism reduction: The database required for mechanism reduction is generated using tools like Senkin and perfectly stirred reactor (PSR) [36, 37]. This involves simulating conditions under which the reduced mechanism will be applied, including factors like pressure, temperature, and equivalence ratios.

-

3.

Definition of target species: A set of target species is established to ensure that these selected species are retained and not eliminated during the reduction process.

-

4.

Setting threshold values or interaction coefficients: After defining the target species, threshold values or interaction coefficients are set. This step plays a crucial role in the reduction process.

-

5.

PFA method application: The PFA method is then employed to assess each species associated with the target species. If the calculated interaction coefficient is lower than the predetermined threshold value, the respective species is considered for elimination.

It's note worthy that the larger the threshold value, the smaller the reduced mechanism. This process results in a reduced reaction mechanism that retains essential combustion features while removing non-essential details.

2.1.3 Reduced and Global Mechanisms

In the present study, the target species are methane, hydrogen, oxygen, nitrogen, and their intermediate species produced in the reaction. The ranges of pressure, temperature, and equivalence ratio for mechanism reduction are from 1 to 20 atm, from 1000 to 2000 K, and from 0.5 to 1, respectively. It is important to emphasize that during the process of mechanism reduction, important species, elementary reactions, and their corresponding rate constants and coefficients have been retained. No modifications have been made to rate constants to artificially align the calculated results more closely with experimental data.

Reduced mechanisms are named according to the number of species, as shown in Table 2. Mechanism Nos. 1–4 and 6–7 are developed in the present study. The reduced mechanism No. 1, called SP282, contains 282 species. It is reduced from NUIG 2020 and kept all species related to reactions of methane and hydrogen as much as possible. The reduced mechanism No. 2, SP58, contains 58 species and it reduced the species number as much as possible while ensuring that the calculation results are consistent with the detailed mechanism NUIG 2020. Both SP282 and SP58 contain reaction mechanisms related to NOx chemistry. The No. 6, SP41, is obtained after removing the NOx chemical mechanism included in SP58. By combining the NOx mechanism of GRI 3.0 with SP41, the mechanism No. 3, NOx56, are developed. Another detailed mechanism, Aramco 2.0, is also used to generate the reduced mechanism, resulting in the mechanism No. 7, SP33. The SP33 does not include the NOx mechanism. By adding the NOx mechanism of GRI 3.0 to SP33, the reduced mechanism No. 4, NOx50, is generated. It is important to make clear that the thermal data for non-NOx reaction species in NOx56 and NOx50 are sourced from NUIG 2020 and Aramco 2.0, respectively, while the thermal data for species related to NOx reactions are sourced from GRI 3.0. In conclusion, reduced mechanisms Nos. 1–4 contain NOx mechanism, but Nos. 6 and 7 do not. The No. 5, USC50, was developed by D. Sharma et al. through the reduction of USCII, and it also does not include reactions related to NOx [38].

The mechanism Nos. 8–10 are obtained from previous studies for comparison. The No. 8, DRM22, and No. 9, DRM19, [39, 40] were reduced from GRI 1.2 [41] using a reduction method proposed by Wang and Frenklach [42]. The DRM22 predicts high-temperature ignition delay times up to 10 atm and laminar flame properties up to 20 atm. Deviations from the original mechanism GRI 1.2 are between 1 and 10% with the largest deviation at high pressures. The DRM19 shows a larger deviation from the reference mechanism, in particular, for fuel-rich conditions. An widely used mechanism for methane/air combustion is the mechanism with 16 species and 35 irreversible reactions proposed by Smooke and Giovangigli (SG35) in 1991 [43] and constructed by selection of reactions from detailed reaction mechanisms available at that time. The mechanism was developed to model laminar flames and has been used in numerous published CFD modeling studies [44].

Global mechanisms result from crude simplification and are tuned to give accurate estimations of heat release, laminar flame propagation, fuel breakdown, and production of major species within a limited range of conditions [26]. A 4-step mechanism developed by Jones and Lindstedt, called JL, was extensively used in CFD simulations. In this study, its optimized version, called JLANN, developed by an artificial neural network (ANN) is adopted for a comparative study [45, 46]. The JLANN is obtained by ANN searching for the optimal reaction parameters that lead to the results matching those from GRI-Mech 3.0, the detailed mechanism for burning methane in a plug flow reactor [46].

2.2 Collection of Experimental Data

The mechanisms are evaluated by comparison with available experimental data. The ignition delay time (IDT), laminar burning velocity (LBV), and ignition delay time with NO2 are selected as the validation targets. Experimental data are collected from reliable literature data to cover a range of conditions [11, 13, 26, 47,48,49]. They are selected by considering the fuel type, the hydrogen blending ratio, the range of operating pressure and temperature, and the equivalence ratio. For evaluation of IDTs and LBVs, the hydrogen blending ratio increases from 0 to 100% by 20% point. The operating temperature increases from 1000 to 2000 K at three operating pressures, 5, 10, and 20 atm in the case of evaluation of IDTs. Effects of hydrogen blending ratios and equivalence ratios are examined at 1 atm and temperature near 300 K for evaluation of LBVs. IDTs of the fuel with NO2 are calculated to compare the accuracy of prediction of the mechanisms involving the NOx steps in the aspect of the NOx prediction. Three different pressures and the temperature range from 900 to 1900 K are considered. All of the experimental data and conditions are summarized in Table 3.

2.3 Details on Modeling

The hydrogen blending ratio (\(n_{{\text{H}}_2 }\)) is defined as the mole percentage of hydrogen in the CH4/H2 mixtures. It is calculated by the equation

where \(n_{{\text{H}}_2 }\) denotes hydrogen blending ratio, \(X_{{\text{H}}_2 }\) hydrogen mole fraction in the mixture, and \(X_{{\text{CH}}_4 }\) methane mole fraction in the mixture.

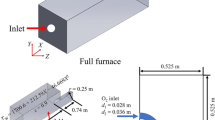

A comprehensive software package [50] is used to simulate laminar premixed flames and ignition delays. Ignition in a closed homogeneous reactor is modeled using a constant volume approach with an energy equation solved. The ignition delay time is determined by the instant when time derivative of temperature, dT/dt, has its maximum. The experimental results used for comparison in this study are obtained from the previous study [11]. In the previous study, pressure generated by the reflected shock wave in the shock tube increased at a rate of 4%/ms after 1.5 ms due to the facility-dependent boundary layer effect. Therefore, when calculating the ignition delay in the present study, the same increase rate of pressure is set after 1.5 ms.

Laminar flames are simulated using the premixed-flame model with adaptive grids, where solution gradient and curvature are set to 0.02 and 0.03, respectively. It resulted in grid-independent solutions for all mechanisms [26]. To calculate the LBVs, the equivalence ratio, \(\varphi\), covers from fuel-lean (\(\varphi\) = 0.6) to fuel-rich (\(\varphi\) = 1.4) conditions along with a specified initial inlet temperature of 300 K. In the present work, the “multi-component transport” is chosen, because it can accurately predict the laminar burning velocities [51]. In addition, a thermal diffusion coefficient, called the Soret effect, is included, which is significant for light species, such as H and H2. Details on the different approaches to transport model can be found in the literature [50]. One should keep in mind that transport treatment becomes increasingly significant as the diameter of species decreases and, therefore, larger deviations is expected for hydrogen flames [26].

The agreement between experimental data and calculation results is evaluated using the following parameter:

where N is the number of data points, and Num. and Exp. are numerical and experimental results, respectively. For example, when the ignition delay time is calculated as temperature increases at 5 atm with a hydrogen blending ratio of 0%, N will be the number of temperature points. To clearly compare the errors across all cases, the discrepancy is normalized by the minimum in all the cases. The critical threshold for evaluating the accuracy of computational results with various reaction mechanisms is set to be 15%. The value of 15% was determined based on a comprehensive comparison of all calculation results. This value can help to distinguish between the detailed and reduced mechanisms and can also do between various reaction mechanisms based on their computational results.

3 Results and Discussion

3.1 Ignition Delay Time

Ignition delays of lean methane–hydrogen mixtures (equivalence ratio of 0.5) with hydrogen fractions from 0 to 100% are compared in the temperature range from 1000 to 2000 K and the pressure range from 5 to 20 atm. All the reaction mechanisms listed in Tables 1 and 2 are adopted in the calculation. Since the trend of ignition delay is consistent at all pressures, the calculation results at 5 atm are chosen as an example for this comparative study, as shown in Fig. 1. It is seen that the ignition delays decrease with increasing \(n_{{\text{H}}_2 }\) due to high reactivity, high diffusion, and low auto-ignition temperature of H2. The results calculated with the detailed reaction mechanisms of NUIG 2020 and FFCM are presented in Fig. 1a. It is found that both reaction mechanisms show a good agreement with experimental results for all the hydrogen blending ratios. The calculation results of the other detailed reaction mechanisms can be checked in Fig. 1b–d. With the increase of \(n_{{\text{H}}_2 }\), the error increases even if the results are calculated by a detailed mechanism. When the \(n_{{\text{H}}_2 }\) is 100%, it can be clearly seen that the calculation errors of GRI 3.0 are relatively large. The calculation results of the reduced reaction mechanisms are not shown here and their discrepancies will be compared with the detailed reaction mechanism in a later section.

Figure 2 shows the discrepancy between calculated ignition delays and experimental results for all the reaction mechanisms as pressure and \(n_{{\text{H}}_2 }\) increase. Each discrepancy value was obtained by comparing the calculated ignition delay results with experimental data in the temperature range of 1000–2000 K. Figure 2a shows that at relatively low pressures (5 atm), the detailed reaction mechanism provides higher calculation accuracy compared to the reduced mechanism. As \(n_{{\text{H}}_2 }\) increases from 0 to 100%, only the detailed reaction mechanisms of Aramco2.0 and GRI 3.0 exhibit discrepancies above 15% under certain conditions. However, in the reduced mechanisms, SP33 and NOx50 show a discrepancy of 18% starting from a blending ratio of 40%, which gradually increases to 50% as \(n_{{\text{H}}_2 }\) increases up to 100%. The discrepancies for SP282, SP58, NOx56, and SP41 also exceed 15% when \(n_{{\text{H}}_2 }\) reaches 100%. The DRM19 and DRM22 published in previous studies also show a high discrepancy when \(n_{{\text{H}}_2 }\) is 100%; however, their discrepancy is relatively low when \(n_{{\text{H}}_2 }\) increases up to 80%. As the pressure increases to 10 atm and shown in Fig. 2b, the calculated discrepancies exceed 15% at smaller blending ratios. For example, at a blending ratio of 80%, the calculated discrepancy for GRI 3.0 is 21%, which is higher than the 9% discrepancy at 5 atm. Also, the discrepancies of SP282, SP58, NOx50, and SP41 exceed 15% when \(n_{{\text{H}}_2 }\) is 60%. As the pressure is increased to 20 atm, the discrepancy of the reduced mechanism further increases, starting from \(n_{{\text{H}}_2 }\) of 40%. Additionally, the detailed reaction mechanisms also show discrepancies approaching 15% at the blending ratio of 80%. Consequently, the operational range of the reaction mechanisms to accurately calculate the IDT becomes narrower with pressure. The results for SG35 and JLANN are not presented in Fig. 2 due to their inability to provide reasonable results for ignition delay time calculations.

3.2 Laminar Burning Velocity

Figure 3 shows the errors between the calculated and experimental results of laminar burning velocity at 1 atm and 300 K as an example. It demonstrates how the laminar burning velocity varies with the equivalence ratio and \(n_{{\text{H}}_2 }\). The equivalence ratio ranges from 0.6 to 1.8 with a step size of 0.1, while \(n_{{\text{H}}_2 }\) increases from 0 to 100% with a step size of 20%. From Fig. 3a, it can be observed that the laminar burning velocity first increases and then decreases as the equivalence ratio increases. Furthermore, as \(n_{{\text{H}}_2 }\) increases, the equivalence ratio corresponding to the maximum laminar burning velocity also gradually increases. This trend is the most evident at \(n_{{\text{H}}_2 }\) of 100%, where the laminar burning velocity continues to increase even when the equivalence ratio is increased to 1.8. As predicted, if the equivalence ratio continues to increase, the laminar burning velocity will gradually decrease, which has been already shown in the previous studies [48]. Figure 3b–d shows the zoomed-in results for hydrogen blending ratios of 0%, 60%, and 100%, respectively. It is seen that the calculated results by all detailed reaction mechanisms are relatively accurate when the hydrogen blending ratio is 0% or 100%. However, when \(n_{{\text{H}}_2 }\) is 60%, the error is relatively large, as will be shown in more detail in the following paragraph. It should be noted that in this study, the laminar burning velocity is compared at four pressure conditions of 1, 5, 10, and 20 atm for pure methane. Although the results are not displayed in Fig. 3, the errors between the calculated and experimental results will be shown later.

The discrepancy comparison of laminar burning velocity is shown in Fig. 4. Figure 4a displays the errors between calculated results and experimental data at different pressures for the 100% methane. At 1 atm, only the reduced mechanism, SG35, and the global mechanism, JLANN, have large errors, while the errors of the other detailed reaction mechanisms are less than 10%. When the pressure increases to 5 atm, except for CRECK, the errors of the other detailed reaction mechanisms increase over 15%. Due to long calculation times, complete results for NUIG 2020 and Aramco2.0 were not obtained. However, the reduced mechanisms of SP33, SP41, SP58, NOx50, and NOx56 derived from the two detailed mechanisms show small errors, even at high pressures of 10 and 20 atm. This indicates that the original detailed reaction mechanisms NUIG 2020 and Aramco 2.0 should be also accurate. Figure 4b shows the discrepancy between calculated results and experimental data as \(n_{{\text{H}}_2 }\) increases from 0 to 100% at 1 atm. It is seen that all the detailed reaction mechanisms give accurate results. Only the detailed reaction mechanism of NUIG 2007 and the five reduced reaction mechanisms developed in this study have slightly larger discrepancy, but the errors do not exceed 15%. In contrast to the results with pressure variation, DRM19 and DRM22 give good results for all hydrogen mixture fractions. Both the reduced mechanism of SG35 and the global mechanism of JLANN showed relatively large discrepancies in predicting ignition delay times and laminar burning velocities. The laminar burning velocities is not calculated by using NUIG 2020 here, because it requires a significant amount of computational time. The results from NUIG 2020 can be predicted from that of NUIG 2007, as both share the same reaction mechanisms for methane and hydrogen.

3.3 Ignition Delay Time with NO2

Next, the calculation discrepancy of reaction mechanisms containing NOx in terms of ignition delay time of hydrogen–oxygen mixtures containing NO2 is examined. NO2 of 1600 ppm is added to the hydrogen–oxygen mixture, and argon is used as a diluent gas. Ignition delay times calculated using six reaction mechanisms are compared at three pressures of 1.6, 13, and 33 atm. The six reaction mechanisms are GRI 3.0, San Diego, and four reduced mechanisms containing NOx developed in this study, i.e., SP282, SP58, NOx56, and NOx50. The experimental results used for a comparative study are from the literature [47]. From Fig. 5a, it is seen that the calculation results of SP282, which has the most species, are quite accurate, especially at high pressure. When comparing the results at each pressure separately, Fig. 5 shows that the mechanism, SP58, which is also reduced from NUIG 2020, has similar calculation results to those of SP282 at all pressures. On the other hand, the other four mechanisms show significant errors.

a Errors between calculated ignition delay time with NO2 and experimental data at various pressures using the reduced mechanism, SP282. Comparison of experimental data and predicted results by San Diegio, GRI 3.0, SP282, SP58, NOx56, and NOx50 at the pressure of b 1.3 atm, c 13 atm, and d 33 atm. Symbols: experimental data; lines: calculated data in this work

The comparison of the results calculated by each mechanism and experimental data is presented in Fig. 6. It is seen that the performance of the reduced mechanisms developed in this study is excellent when it comes to NOx-related calculations with the average error of only 1% at 33 atm. On the other hand, the other two mechanisms developed in this study and the two widely used mechanisms have relatively larger errors. The NOx-related reactions selected for the development of NOx50 and NOx56 are all from GRI 3.0, while a large part of the NOx-related reactions in San Diego is the same as those in GRI 3.0. This result also indicates that the NOx-related reactions in GRI 3.0 and San Diego are not sufficient in simulating pressure dependence accurately.

3.4 Computational Time

Finally, computational time of each mechanism is compared. The calculations are conducted using 32 CPU cores with a clock frequency of 3.5 GHz. All the results are normalized by the computational time of GRI 3.0. As shown in Fig. 7, the required time for both ignition delay time and laminar flame speed calculations is positively correlated with the number of species in the reaction mechanism. Figure 7a shows the required time for computing 30 ignition delay times using different mechanisms, with a required time of 3.7 s with GRI 3.0. The detailed reaction mechanism of NUIG 2020 requires 15,588 times longer than the computational time of GRI 3.0, while the computational times of the other mechanisms developed in this study are similar to that of GRI 3.0, except for SP282, which required 15.5 times longer than the computational time of GRI 3.0. Figure 7b shows the required time for computing one data of laminar flame speed, with a required time of 34.4 s for GRI 3.0. The required time of NUIG 2020 is 46,125 times longer than that of GRI 3.0. This is also the reason why calculation of the laminar flame speed using NUIG 2020 was not conducted. It is due to its excessively long computational time. These results indicate that when selecting a reaction mechanism, both accuracy and computational time should be taken into account. It is recommended that a mechanism with the shortest computational time within an acceptable range of error is selected.

4 Summary of Numerical Errors or Discrepancies

All the above calculation results are summarized and presented in Tables 4 and 5. Table 4 shows the results calculated by the detailed chemical mechanisms. While pressure and hydrogen blending ratio are variable, the ignition delay time results calculated by detailed mechanisms are quite accurate (with an error of less than 15%). Only Aramco 2.0, GRI 3.0, and San Diego exhibit higher errors at some high pressures or high-hydrogen-blending ratios. The mechanisms of NUIG 2007, USC II, and San Diego show significant errors in calculating laminar burning velocity at 5 atm and 10 atm. In most cases, a detailed reaction mechanism can be used to calculate and simulate combustion of methane and hydrogen mixture. The selection should be made reasonably based on the required computational time and whether NOx needs to be considered or not.

Table 5 summarizes the results of reduced reaction mechanisms. Compared with the detailed reaction mechanism, the reduced reaction mechanism generally exhibits larger calculation errors in predicting ignition delay times at pressures above 10 atm and hydrogen mixing ratios above 40%. In terms of calculation of laminar burning velocities, the six reduced reaction mechanisms developed in this study show high accuracy, with discrepancies below 15%. It is worth noting that the reduced mechanisms of SP282 and SP58 show higher accuracy than GRI 3.0 and San Diego in calculating reactions of NOx emissions. However, the computational times are longer by about 15.5 times and 1.5 times compared to GRI 3.0, respectively. Furthermore, across all pressure and hydrogen blending ratio ranges, the reduced mechanism USC50 demonstrates a similar high level of accuracy as observed with the detailed mechanism USCII.

5 Conclusions

Various chemical kinetic mechanisms for burning of methane/hydrogen mixtures are tested for various burning conditions. The numerical results show that the widely used GRI-Mech 3.0 works well when the pressure is less than 10 atm and the blending ratio is less than 60%. If the simulation is performed above 10 atm and the blending ratio exceeds 60%, a detailed reaction mechanism with more species, such as San Diego mechanism, should be adopted, although longer computational time is required. If calculation of NOx emissions is not considered, the FFCM is a good choice under various operating conditions. The reduced mechanism of SP58 has higher accuracy in calculating NOx emission, but the computational time is 1.5 times longer than that of GRI 3.0. In the range of 1–20 atm, the laminar burning velocity of methane calculated using the reduced reaction mechanism developed in this study is more accurate than those calculated using the detailed mechanisms San Diego, GRI 3.0, and USC II.

When selecting a reaction mechanism, it is important to consider the reaction characteristics depending on the simulation purpose. For example, ignition delay time is more important for study of ignition in high-speed propulsion, while more consideration is needed for laminar burning velocity when simulating hydrogen combustion in a gas turbine combustor. Additionally, it is necessary to check the required computation time. In studying pollutant emissions, the accuracy of NOx-related reaction calculations is also critical.

In future works, the reduced reaction mechanisms will be applied to CFD simulations and compared with the existing detailed mechanisms. This comparison aims to validate the accuracy of the reduced reaction mechanisms in simulating methane and hydrogen combustion.

Abbreviations

- dt :

-

Time difference

- dT :

-

Temperature difference

- \(n_{{\text{H}}_2 }\) :

-

Hydrogen blending ratio

- N :

-

Number of data points

- \(X_{{\text{H}}_2 }\) :

-

Hydrogen mole fraction

- \(X_{{\text{CH}}_4 }\) :

-

Methane mole fraction

- ANN:

-

Artificial neural network

- CFD:

-

Computational fluid dynamics

- IDT:

-

Ignition delay time

- LBV:

-

Laminar burning velocity

- NG:

-

Natural gas

- Num.:

-

Numerical

- Exp.:

-

Experimental

- PFA:

-

Path flux analysis

- SP:

-

Species

References

Yuze S, Tao C, Shahsavari M, Dakun S, Xiaofeng S, Dan Z, Bing W (2021) RANS simulations on combustion and emission characteristics of a premixed NH3/H2 swirling flame with reduced chemical kinetic model. Chin J Aeronaut 34:17–27. https://doi.org/10.1016/j.cja.2020.11.017

Ni S, Zhao D, You Y, Huang Y, Wang B, Su Y (2021) NOx emission and energy conversion efficiency studies on ammonia-powered micro-combustor with ring-shaped ribs in fuel-rich combustion. J Clean Prod 320:128901. https://doi.org/10.1016/j.jclepro.2021.128901

Han HS, Han KR, Wang Y, Kim CJ, Sohn CH, Nam C (2022) Effects of natural-gas blending on ignition delay and pollutant emission of diesel fuel for the condition of homogenous charge compression ignition engine. Fuel 328:125280. https://doi.org/10.1016/j.fuel.2022.125280

Zhang B, Li Y, Liu H (2021) Ignition behavior and the onset of quasi-detonation in methane-oxygen using different end wall reflectors. Aerosp Sci Technol 116:106873. https://doi.org/10.1016/j.ast.2021.106873

Shokri M, Ebrahimi A (2018) Heat transfer aspects of regenerative-cooling in methane-based propulsion systems. Aerosp Sci Technol 82:412–424. https://doi.org/10.1016/j.ast.2018.09.025

Wang X, Fu J, Xie M, Liu Q, Liu J (2022) Numerical investigation of laminar burning velocity for methane–hydrogen–air mixtures at wider boundary conditions. Aerosp Sci Technol 121:107393. https://doi.org/10.1016/j.ast.2022.107393

Liang Y, Liu W (2018) Review and prospect of LOX/Methane rocket engine systems. Aero Weaponry 4:21–27. https://doi.org/10.19297/j.cnki.41-1228/tj.2018.04.002

Gascoin N, Gillard P, Bernard S, Bouchez M (2008) Characterisation of coking activity during supercritical hydrocarbon pyrolysis. Fuel Process Technol 89:1416–1428. https://doi.org/10.1016/j.fuproc.2008.07.004

Dong C, Zhou Q, Zhang X, Zhao Q, Xu T, Se H (2010) Experimental study on the laminar flame speed of hydrogen/natural gas/air mixtures. Front Chem Eng China 4:417–422. https://doi.org/10.1007/s11705-010-0515-8

Zhang Y, Huang Z, Wei L, Niu S (2011) Experimental and kinetic study on ignition delay times of methane/hydrogen/oxygen/nitrogen mixtures by shock tube. Chin Sci Bull 56:2853–2861. https://doi.org/10.1007/s11434-011-4635-4

Zhang Y, Huang Z, Wei L, Zhang J, Law CK (2012) Experimental and modeling study on ignition delays of lean mixtures of methane, hydrogen, oxygen, and argon at elevated pressures. Combust Flame 159:918–931. https://doi.org/10.1016/j.combustflame.2011.09.010

Han W, Dai P, Gou X, Chen Z (2020) A review of laminar flame speeds of hydrogen and syngas measured from propagating spherical flames. Appl Energy Combust Sci 1–4:100008. https://doi.org/10.1016/j.jaecs.2020.100008

Zhang Y, Fu J, Shu J, Xie M, Liu J (2020) A chemical kinetic investigation of laminar premixed burning characteristics for methane-hydrogen-air mixtures at elevated pressures. J Taiwan Inst Chem Eng 111:141–154. https://doi.org/10.1016/j.jtice.2020.04.013

Mitu M, Razus D, Schroeder V (2021) Laminar burning velocities of hydrogen-blended methane–air and natural gas–air mixtures, calculated from the early stage of p(t) records in a spherical vessel. Energies 14:7556. https://doi.org/10.3390/en14227556

Shu B, Vallabhuni SK, He X, Issayev G, Moshammer K, Farooq A, Fernandes RX (2019) A shock tube and modeling study on the autoignition properties of ammonia at intermediate temperatures. Proc Combust Inst 37:205–211. https://doi.org/10.1016/j.proci.2018.07.074

Han HS, Sohn CH, Han J, Jeong B (2021) Measurement of combustion properties and ignition delay time of high performance alternative aviation fuels. Fuel 303:121243. https://doi.org/10.1016/j.fuel.2021.121243

de Persis S, Idir M, Molet J, Pillier L (2019) Effect of hydrogen addition on NOx formation in high-pressure counter-flow premixed CH4/air flames. Int J Hydrogen Energy 44:23484–23502. https://doi.org/10.1016/j.ijhydene.2019.07.002

Park S (2021) Hydrogen addition effect on NO formation in methane/air lean-premixed flames at elevated pressure. Int J Hydrogen Energy 46:25712–25725. https://doi.org/10.1016/j.ijhydene.2021.05.101

Wang Y, Sohn CH, Bae J, Yoon Y (2021) Prediction of combustion instability by combining transfer functions in a model rocket combustor. Aerosp Sci Technol 119:107202. https://doi.org/10.1016/j.ast.2021.107202

Wang Y, Cho CH, Du J, Sohn CH (2022) Effects of recess length on combustion instability in a model chamber with a gas-centered swirl coaxial injector. Aerosp Sci Technol 130:107911. https://doi.org/10.1016/j.ast.2022.107911

Zhang P, Zsély IG, Samu V, Nagy T, Turányi T (2021) Comparison of methane combustion mechanisms using shock tube and rapid compression machine ignition delay time measurements. Energy Fuels 35:12329–12351. https://doi.org/10.1021/acs.energyfuels.0c04277

Ströhle J, Myhrvold T (2007) An evaluation of detailed reaction mechanisms for hydrogen combustion under gas turbine conditions. Int J Hydrogen Energy 32:125–135. https://doi.org/10.1016/j.ijhydene.2006.04.005

Kumar PP, Kim K-S, Oh S, Choi J-Y (2015) Numerical comparison of hydrogen-air reaction mechanisms for unsteady shock-induced combustion applications. J Mech Sci Technol 29:893–898. https://doi.org/10.1007/s12206-015-0202-2

Olm C, Zsély IG, Pálvölgyi R, Varga T, Nagy T, Curran HJ, Turányi T (2014) Comparison of the performance of several recent hydrogen combustion mechanisms. Combust Flame 161:2219–2234. https://doi.org/10.1016/j.combustflame.2014.03.006

Olm C, Zsély IG, Varga T, Curran HJ, Turányi T (2015) Comparison of the performance of several recent syngas combustion mechanisms. Combust Flame 162:1793–1812. https://doi.org/10.1016/j.combustflame.2014.12.001

Zettervall N, Fureby C, Nilsson EJK (2021) Evaluation of chemical kinetic mechanisms for methane combustion: a review from a CFD perspective. Fuels 2:210–240. https://doi.org/10.3390/fuels2020013

Wu Y, Panigrahy S, Sahu AB, Bariki C, Beeckmann J, Liang J, Mohamed AA, Dong S, Tang C, Pitsch H (2021) Understanding the antagonistic effect of methanol as a component in surrogate fuel models: a case study of methanol/n-heptane mixtures. Combust Flame 226:229–242. https://doi.org/10.1016/j.combustflame.2020.12.006

Zhou C-W, Li Y, O’connor E, Somers KP, Thion S, Keesee C, Mathieu O, Petersen EL, DeVerter TA, Oehlschlaeger MA (2016) A comprehensive experimental and modeling study of isobutene oxidation. Combust Flame 167:353–379. https://doi.org/10.1016/j.combustflame.2016.01.021

Petersen EL, Kalitan DM, Simmons S, Bourque G, Curran HJ, Simmie JM (2007) Methane/propane oxidation at high pressures: experimental and detailed chemical kinetic modeling. Proc Combust Inst 31:447–454. https://doi.org/10.1016/j.proci.2006.08.034

Song Y, Marrodán L, Vin N, Herbinet O, Assaf E, Fittschen C, Stagni A, Faravelli T, Alzueta MU, Battin-Leclerc F (2019) The sensitizing effects of NO2 and NO on methane low temperature oxidation in a jet stirred reactor. Proc Combust Inst 37:667–675. https://doi.org/10.1016/j.proci.2018.06.115

Wang H, You X, Joshi AV, Davis SG, Laskin A, Egolfopoulos F, Law CK (2007) USC Mech Version II. High-temperature combustion reaction model of H2/CO/C1-C4 compounds. http://ignis.usc.edu/USC_Mech_II.htm

Tao Y, Smith GP, Wang H (2018) Critical kinetic uncertainties in modeling hydrogen/carbon monoxide, methane, methanol, formaldehyde, and ethylene combustion. Combust Flame 195:18–29. https://doi.org/10.1016/j.combustflame.2018.02.006

San Diego Mechanism web page MaAECR, University of California at San Diego (2016) Chemical-Kinetic Mechanisms for Combustion Applications. http://combustion.ucsd.edu

Smith GP, Golden DM, Frenklach M, Moriarty NW, Eiteneer B, Goldenberg M, Bowman CT, Hanson RK, Song S, Gardiner WC Jr., Lissianski VV, Qin Z (2000) GRI-Mech 3.0. http://combustion.berkeley.edu/gri-mech/version30/text30.html

Sun W, Chen Z, Gou X, Ju Y (2010) A path flux analysis method for the reduction of detailed chemical kinetic mechanisms. Combust Flame 157:1298–1307. https://doi.org/10.1016/j.combustflame.2010.03.006

Glarborg P, Kee RJ, Grcar JF, Miller JA (1986) PSR: A FORTRAN program for modeling well-stirred reactors. Sandia National Laboratories, Livermore

Lutz AE, Kee RJ, Miller JA (1988) SENKIN: A FORTRAN program for predicting homogeneous gas phase chemical kinetics with sensitivity analysis. Sandia National Labs, Livermore

Sharma D, Mahapatra S, Garnayak S, Arghode VK, Bandopadhyay A, Dash SK, Reddy VM (2020) Development of the reduced chemical kinetic mechanism for combustion of H2/CO/C1–C4 hydrocarbons. Energy Fuels 35:718–742. https://doi.org/10.1021/acs.energyfuels.0c02968

Kazakov A, Frenklach M (1995) DRM22. http://combustion.berkeley.edu/drm/

Kazakov A, Frenklach M (1995) DRM19. http://combustion.berkeley.edu/drm/

Frenklach M, Wang H, Goldenberg M, Smith G, Golden D, Bowman C, Hanson R, Gardiner W, Lissianski V, Frenklach M (1995) An optimized detailed chemical reaction mechanism for methane combustion. GRI-Mech, Berkeley, CA, Report No. GRI-95/0058

Wang H, Frenklach M (1991) Detailed reduction of reaction mechanisms for flame modeling. Combust Flame 87:365–370. https://doi.org/10.1016/0010-2180(91)90120-Z

Smoke MD, Giovangigli V (1991) Formulation of the premixed and nonpremixed test problems. In: Smoke MD (ed) Reduced kinetic mechanisms and asymptotic approximations for methane-air flames, 1st edn. Springer, pp 1–28

Bulat G, Fedina E, Fureby C, Meier W, Stopper U (2015) Reacting flow in an industrial gas turbine combustor: LES and experimental analysis. Proc Combust Inst 35:3175–3183. https://doi.org/10.1016/j.proci.2014.05.015

Jones W, Lindstedt R (1988) Global reaction schemes for hydrocarbon combustion. Combust Flame 73:233–249. https://doi.org/10.1016/0010-2180(88)90021-1

Si J, Wang G, Li P, Mi J (2020) Optimization of the global reaction mechanism for MILD combustion of methane using artificial neural network. Energy Fuels 34:3805–3815. https://doi.org/10.1021/acs.energyfuels.9b04413

Mathieu O, Levacque A, Petersen EL (2013) Effects of NO2 addition on hydrogen ignition behind reflected shock waves. Proc Combust Inst 34:633–640. https://doi.org/10.1016/j.proci.2012.05.067

Teng F (2014) The effect of hydrogen concentration on the flame stability and laminar burning velocity of hydrogen–hydrocarbon–carbon dioxide mixtures. University of Sheffield, Sheffield

Amirante R, Distaso E, Tamburrano P, Reitz RD (2017) Laminar flame speed correlations for methane, ethane, propane and their mixtures, and natural gas and gasoline for spark-ignition engine simulations. Int J Engine Res 18:951–970. https://doi.org/10.1177/1468087417720018

ANSYS Chemkin-Pro: Release 2022 R1. ANSYS, Inc., Canonsburg

Hughes K, Turányi T, Clague A, Pilling M (2001) Development and testing of a comprehensive chemical mechanism for the oxidation of methane. Int J Chem Kinet 33:513–538. https://doi.org/10.1002/kin.1048

Acknowledgements

This work was supported by Korea Institute of Energy Technology Evaluation and Planning (KETEP) grant funded by the Korea government (MOTIE) (20206710100030, Development of Eco-friendly GT Combustor for 300MWe-class High-efficiency Power Generation with 50% Hydrogen Co-firing).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix A: Errors between predicted results and experimental data

Appendix A: Errors between predicted results and experimental data

The errors between predicted results and experimental data not depicted in Figs. 1, 3, and 5 are shown in this appendix section.

1.1 A.1 Ignition Delay Time

The comparison between the predicted ignition delay times and experimental results for the hydrogen blending ratio ranging from 0 to 100% at an equivalence ratio of 0.5, and pressures of 5 atm, 10 atm, and 20 atm is presented in Figs.

8,

9, and

10, respectively.

1.2 A.2 Laminar Burning Velocity

The comparison between the predicted laminar burning velocities and experimental data for the hydrogen blending ratio ranging from 0 to 100% at equivalence ratios of 0.6–1.8, and pressures of 1 atm is presented in Fig.

11. The comparison between the predicted results and experimental data for 100% methane combustion at equivalence ratios of 0.6–1.8 and 1 atm is shown in Fig.

12.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, Y., Han, H.S. & Sohn, C.H. A Comparative Study of Chemical-Kinetic Mechanisms for Combustion of Methane/Hydrogen/Air Mixtures. Int. J. Aeronaut. Space Sci. 25, 519–539 (2024). https://doi.org/10.1007/s42405-023-00671-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42405-023-00671-8