Abstract

This paper aims to study the possibility of incorporating wood ash or waste from the ground translational pottery into the formulation of ecological bricks. The lab-scale experimental study aimed to identify the best dosage for achieving ideal mineralogical, geotechnical, thermal, and mechanical properties in brick blocks through various formulations. Thermal, physical, mineralogical, and chemical identification tests were carried out on this introduced building material to have a better knowledge of its nature. The various components were prepared at a grain size below 400 μm. The dosage of wood ash and waste from crushed pottery varied from 0 to 50% compared to the total mass of the dry mixture. The substitution of clay for 5% wood ash or 20% crushed pottery waste makes it possible to obtain ecological blocks with an increase in tensile strength by bending three points and mechanical resistance comparable to that of blocks without addition. The optimal dosage of wood ashes was found to be 5% in combination with the clay. The addition of crushed pottery waste improved the absorption of these blocks, and the highest thermal resistance values were recorded with a dosage of 20% pottery waste. By replacing 5% of the clay with wood ashes or 20% with crushed pottery waste, it was possible to produce eco-friendly blocks with an increase in thermal resistance comparable to that of traditional building materials. The experimental study conducted on the utilization of wood ash and pottery waste as secondary raw materials in the production of ecological bricks represents an effective alternative for further exploration of earthen materials as environmentally sustainable and economically viable solutions for the building sector.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

In regions of southern countries, utilizing local materials for construction and civil engineering purposes offers advantages in terms of both environmental and economic considerations. Understanding and managing the mineralogical, geotechnical, thermal, and mechanical properties of these materials are crucial tasks to ensure the effective performance and durability of structures at every stage of their construction [1, 2].

The waste management policy is part of the national strategy for sustainable development in Morocco, to enhance local materials and contribute to the reduction of construction costs and energy used for heating or cooling, pottery waste and wood ash were used to stabilize clay bricks. Then the incorporation of this waste from the manufacture of traditional pottery into clay blocks especially for local use is the best solution for the recycling of this material without affecting the environment [3,4,5].

There is a growing interest in investigating substitutes that provide improved performance attributes in addition to environmental benefits when it comes to sustainable building materials. Using clay, a common and plentiful natural material, is one of these options that seems like a good idea. However, creative approaches to improving clay’s qualities are essential if we are to realize its full potential as a building material [6].

One such tactic is stabilizing clay using materials like wood ashes or crushed leftovers from conventional pottery. This strategy is in line with the ideas of resource efficiency and the circular economy since it not only helps to enhance the mechanical and thermal qualities of clay but also tackles the problem of valorizing waste resources [7]. The characterizations of clay stabilized by these non-traditional additives in terms of mineralogical, geotechnical, thermal, and mechanical properties provide important information about the viability and functionality of these composite materials. Comprehending the modifications in composition, phase transitions, and microstructural development brought about by the incorporation of wood ashes or crushed pottery waste is crucial in clarifying the principles controlling these materials’ behavior in various environmental settings and loading scenarios [1, 8,9,10].

Furthermore, the geotechnical attributes, such as shear strength, permeability, and compaction characteristics, are crucial in deciding if stabilized clay is appropriate for a certain range of construction uses. Researchers can determine the long-term stability, durability, and structural integrity of structures made with clay-based composites by thoroughly assessing these features.

Moreover, the thermal stability of clay-stabilized materials is critical, especially when designing energy-efficient buildings [1, 8,9,10]. These composites’ thermal behavior is influenced by their thermal conductivity, heat capacity, and thermal diffusivity, which in turn affects indoor comfort levels, energy use, and the sustainability of buildings as a whole [1, 8,9,10].

As economic and technological progress unfolded, alternative materials emerged, such as cement, lime, and bitumen, known for their increased durability and resistance. These materials gained favor, especially for constructing robust infrastructures. However, given the pressing challenges posed by global warming, society has increasingly shifted towards the adoption of environmentally friendly materials that generate minimal greenhouse gas emissions. This shift in perspective has led to a renewed interest in utilizing the earth as a building material, as it aligns to employ healthier construction options [1, 8].

Soil has been utilized as a building material for centuries, gaining interest from developed countries in recent years due to its numerous health and environmental benefits. It offers various advantages over other materials in hot, dry, and temperate climates, boasting a unique composition and appealing aesthetics [9,10,11].

A move towards sustainable materials should stem from the realization that they are easy to produce and have a positive impact on the environment. It is necessary to reduce energy consumption during manufacturing, which is one of the natural things resources that should be taken into consideration when building [12]. Earth may be the most readily available material. An affordable option for a significant amount of time, soil-based construction has been practiced; clay blocks have been utilized as construction materials in a variety of locations, and different nations. However, concerns arise regarding the stability of these building materials due to insufficient strength, ductility, and weather resistance [13]. Improvement has been achieved through the implementation of various strategies [14–15].

Numerous studies have been conducted to enhance the energy efficiency of buildings by utilizing local materials through the incorporation of hydraulic binders such as Portland cement, plaster, clay, lime, etc., along with organic fibers [13]. In line with this objective, the present research focuses on two primary aspects [16–17].

The objective of this work is to study the mineralogical, geotechnical, thermal, and mechanical behavior of clay blocks stabilized by crushed pottery waste and wood ash as additives, and to characterize their mechanical and physical properties. This research aims to develop a novel building material with exceptional energy efficiency characteristics by combining clay with wood ashes or crushed waste from traditional pottery, resulting in a composite material that exhibits improved geotechnical, thermal, and mechanical properties. The primary goal is to stabilize the earthen materials to achieve enhanced physical performance. To achieve this, the composite material is subjected to thorough thermo-physical characterizations, including assessments of geotechnical, thermal conductivity, heat capacity, thermal diffusivity, and mechanical properties.

The objective of this research is to identify the most effective combination that provides optimal performance. It centers on the development and assessment of a highly energy-efficient building material. The first part focuses on creating a composite material that combines clay with stabilizing agents to enhance its thermal properties. The second part involves experimenting with different configurations, along with the newly developed composite material, to identify the most efficient and optimal design in terms of physical properties.

2 Materials and Methods

2.1 Samples Preparation

To valorize local clay materials and contribute to the reduction of construction costs and energy consumption for heating or cooling, waste from pottery production and wood ashes have been utilized to stabilize clay bricks. Incorporating these byproducts from traditional pottery manufacturing into clay blocks, specifically designed for local use, presents an effective solution for recycling these materials without harming the environment.

The process involved preparing various types of brick samples, followed by thermal characterization of the treated samples, including control samples. The primary objective of this study is to examine the behavior of clay blocks stabilized with crushed pottery waste and wood ashes as additives, and subsequently to characterize their thermo-physical properties.

By utilizing waste materials from pottery production and wood ashes to enhance clay bricks, the study aims to achieve several goals: promoting the use of locally available resources, contributing to cost-effective construction, and reducing energy consumption related to heating and cooling. The incorporation of these waste materials into clay blocks, tailored to meet local needs, exemplifies a sustainable approach to material reutilization and environmental conservation.

The research methodology entails the preparation of a range of brick samples, followed by subjecting them to thermal testing. Through a comparison between these treated samples and control samples, the study seeks to elucidate the behavior and thermo-physical properties of clay bricks improved with crushed pottery waste and wood ashes. The ultimate objective is to gain a comprehensive understanding of how these additives influence the thermal performance and overall characteristics of the resulting construction material.

The production of test bricks involves determining the composition of the mixtures, the material ratios, and the number of samples to be prepared. Four main series of mixtures have been defined as follows and Fig. 1:

-

Mixture M1: Clay alone.

-

Mixture M2: Clay + Crushed Pottery Waste.

-

Mixture M3: Clay + Wood Ashes.

-

Mixture M4: Clay + Crushed Pottery Waste + Wood Ashes.

The experimental tests were carried out on 7 contents of crushed pottery waste 0%, 5%, 10%, 20%, 30%, 40%, and 50% with clay and 7 contents of wood ash 0%, 5%, 10%, 20%, 30%, 40% and 50% with clay and the contents of mixing fly ash and crushed pottery, comprising also seven different mixtures, are summarized in Table 1.

Physical and thermal tests were conducted on the soil to gain a better understanding of its nature. Wood ashes obtained from furnaces were combined with clay, and the study investigated the influence of different types of wood ashes on the properties of the resulting products when combined with clay. The various constituents were prepared with a particle size smaller than 400 μm. The dosages of wood ashes and crushed pottery waste were varied from 0 to 50% relative to the total mass of the dry mixture.

2.2 Fabrication of Experimental Samples

2.2.1 Making the Bricks

Once all the components required for each mix had been determined, the following steps were taken to make the bricks: Adding the optimum amount of water calculated, mixing: This is done manually to ensure that the water content is evenly distributed between the components of each mix, filling the mold, and compacting and demolding and curing.

2.2.2 Curing the Bricks

This stage is also important because the final properties of the bricks, particularly their mechanical strength, are influenced by the curing conditions. The bricks were stored under the same conditions in the laboratory at a temperature of 20 ± 2 °C. The curing period was taken to be 7 days. The materials were dry-mixed until a homogeneous mixture was obtained, then mixed with water and kneaded again until the paste was completely homogenized. The mixes were homogenized by hand, a fairly important step to avoid causing cracks during the drying process. The material is then placed in the mold and compacted immediately after mixing. The mold must be carefully filled to ensure that the sample is homogeneous. A metal pestle is used to compact each layer. It should be noted that before any use of the mold and between the production of the samples,

2.2.3 Determining the Optimum Water Content

To make the bricks, and after confirming the proportions of the different materials making up the mixes, the corresponding optimum water contents must be determined. These are the main parameters influencing the properties of the studied samples. The optimum water content of the studied samples depends, among other things, on the compaction effort and the cement content used. We began by determining the studied samples. for the reference mixes M1 and M2, by plotting the dry density curves as a function of the water content.

for the mixture based on soil alone (M1), which is equal to 14%, and that for the mixture consisting of stabilized soil with wood ash and crushed pottery waste (M2), which is equal to 16%. For the other mixtures, the water content was adjusted according to the case studied.

Clay blocks were crafted and cylindrical specimens with dimensions of 5 cm in diameter and 10 cm in height were prepared. The optimal dosage for clay was determined to be 5% of wood ashes. The addition of crushed pottery waste enhanced the water absorption properties of these blocks, and the highest mechanical strengths were achieved at a dosage of 20%. Substituting 5% of the clay with wood ashes or 20% with crushed pottery waste resulted in eco-friendly blocks that exhibited increased flexural strength and compressive strengths comparable to those of blocks without additives.

2.3 Mineralogical Analysis

The mineralogical composition of the raw materials underwent analysis through X-ray diffraction (XRD) utilizing an X’Pert PRO X-ray diffractometer (PW3050/60 XRD, RIGAKU diffractometer). The XRD patterns were generated using a copper anode, operated at 30 kV and a current of 10 mA, scanning samples placed on aluminum support from 5 to 90° of inclination 20 at 45 kV and 40 mA. For a comprehensive understanding of soil morphology, scanning electron microscopy (SEM) was employed, utilizing the 4th generation of TESCAN VEGA equipped with a tungsten filament electron source [11, 18].

2.4 Particle Size by Laser Diffraction

The size and distribution of the double-sieved particle in powder may today be reliably measured using laser diffraction, which can provide a forecast of what will happen to it. Its foundation is the interaction of a large number of particles with laser light. The published Granulometry Laser ACD System model 9300 S, which could measure precise particle sizes of 0.1 to 716 μm, was the equipment utilized in this work. For our specific soil sample, this complex approach made sense because it assisted in determining both the size and the dispersion. With the use of the laser diffraction method, one can examine powder particle sizes in great detail and predict how the material will behave under various operating conditions. This method works by taking advantage of the way particles behave when exposed to laser light. For this study, we used the Granulometry Laser ACD System model 9300 S, which is known for its outstanding accuracy in separating particle sizes between 0.1 and 716 μm. This advanced technique made it possible to measure the clay sample’s particle size precisely, providing important information on the sample’s granular composition [11, 18].

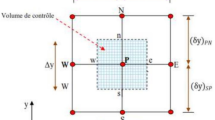

2.5 Thermal Characterization Method

The equipment employed to perform thermo-physical characterization on the samples is known as the “two-box method” or EI700 device. This apparatus allows for the concurrent determination of thermal conductivity and thermal diffusivity for solid or liquid materials. It utilizes sizeable samples, and the measurements are conducted under real operating conditions for these materials. This method remains applicable for conducting thermo-physical properties measurements on construction materials due to its inherent simplicity in operation and measurement precision that stands on par with conventional techniques like hot wire and hot disk methods [19].

The thermal conductivity measurements obtained through both methods exhibit a relative difference of less than 9%, with the precision of the methods closely aligned, ranging between 3% and 5%.

A depiction of the EI700 device in conjunction with the Fluke 2686 A data acquisition system is illustrated in Fig. 2. The device is comprised of two separate boxes: one dedicated to measuring thermal conductivity and the other focused on assessing thermal diffusivity.

2.6 Mechanical Characterization

2.6.1 Compressive Strength Test

The clay blocks are made of cylindrical test specimens measuring 5 cm in diameter and 10 cm in height. The optimal dosage of wood ash for clay was determined to be 5%. The addition of crushed pottery waste promotes better absorption of these blocks and maximum mechanical strengths are recorded for the dosage of 20%. The assessment of sample compressive strength was conducted using a specific test method. Cylindrical samples underwent compression until failure using the INSTRON 3396 hydraulic press (Fig. 3). The application of a continuous deflection of 1 mm/min served as the load. While the test simultaneously recorded both loads and displacements. Subsequently, the data derived from the sample sizes facilitated the creation of a stress-strain curve [11, 18].

The value of the compressive strength is given by the following equation:

Eq. 1

Rc:

Compressive strength of blocks in (MPa);

F:

Maximum load supported by the two half blocks (KN);

S:

Average surface area of test faces in cm2.

2.6.2 Indirect Tensile Strength Tests

The Indirect tensile strength test, also known as The Brazilian indirect tensile strength test, is a popular technique for evaluating the tensile characteristics of rock and concrete. This test has also been used to assess the soil’s tensile strength. In this test, a compressive force is applied to a cylindrical soil specimen measuring 30 cm in length and 60 cm in diameter that is horizontally positioned using two rigid plates that are opposed to each other (Fig. 4). Tensile stress is produced perpendicular to the applied compressive force along the plane that separates the two plates. As the test goes on, the compressive force is increased until failure happens along this plane. After that, tensile stress is computed along the loaded diameter under the assumption of linear elasticity [11, 18].

The tensile strength by splitting bricks is given by the following equation:

Eq. 2

Rt:

Tensile strength of bricks in Mega Pascal (MPa).

F:

Maximum load supported by the two semi-bricks in kN.

l:

Width of the brick in centimeters (cm).

h:

Brick thickness in centimeters (cm).

3 Results and Discussion

3.1 Mineralogical Characterizations of the Studied Building Material

3.1.1 MEB-EDX of Soil

The SEM image depicted in Fig. 5, provided an intricate portrayal of the soil sample’s microstructure, revealing a mix of particles varying in diameter. This heterogeneous composition, comprising both small and large particles, holds significance in influencing the physical and chemical attributes of the soil. Further, EDX analysis substantiated the presence of oxygen, aluminum, and silicon as predominant elements, with oxygen dominating the sample’s atomic composition at 55%. The detection of potassium, aluminum, and silicon hints at potential feldspar mineral content, commonly abundant in these elements. Subsequent X-ray diffraction (XRD) analysis corroborated the existence of feldspar minerals, possibly stemming from albite, a prevalent feldspar mineral encountered in various rock types. The scanning electron microscope (SEM) image as illustrated in Fig. 5, offers a detailed insight into the microstructure of the soil sample. It unveils a complex arrangement of particles exhibiting variations in diameter. This heterogeneous composition, encompassing both diminutive and sizable particles, plays a pivotal role in shaping the physical and chemical characteristics of the soil.

3.1.2 X-Ray Diffraction

The mineralogical characteristics of soil significantly influence its physical and geotechnical attributes, subsequently impacting the thermomechanical behavior and microstructure of final composite and building products. Analysis of the soil’s phase composition reveals distinct properties indicative of prevalent minerals. In Fig. 6, the X-ray diffraction patterns of the raw soil powder, captured within the 2θ range of 5–90 °, offer insights into the distribution of crystal phases. Predominantly, the soil features a phyllosilicate group consisting prominently of muscovite, kaolinite, and albite [2, 20], along with notable peaks associated with quartz.

3.2 Geotechnical Characterizations of the Soil

Figure 7 illustrates the particle size distribution of the soil under study, primarily composed of 20% clay fraction, 65% silt, and 15% sand, conforming to the granular fraction distribution specified by standard NF EN ISO14688-1, 2017 [21]. The Atterberg limit test revealed a liquid limit (LL) of 67%, a plastic limit (PL) of 45%, and a plasticity index (PI) of 22%, indicating intermediate plasticity of the material. In addition, the density of solid particles in the soil is 1.45 g/cm³. Based on NF P94-068 criteria, the methylene blue value of 2.67 indicates that the soil composition is somewhere in between silty and clayey. These findings align with the Atterberg limit test outcomes and the soil’s particle size distribution, as summarized in Table 2.

3.3 Thermal Characterizations of the Studied Building Material

Several formulations and tests were carried out for the measurements of thermal performances for the studied building material (Table 2). The obtained results are summarized in Table 3. Measurements were repeated three times to estimate the measurement error.

Numerous tests were conducted to assess the thermal performance of the studied material under various experimental configurations.

3.4 Mechanical Characterizations of the Studied Building Material

3.4.1 Compressive Strength

To understand the synergistic impacts of fly ash and crushed pottery, the compressive strength of clay was extensively investigated. First, the impact of fly ash on the compressive strength of clay was thoroughly investigated using fly ash concentrations ranging from 5 to 50%. The initial compressive strength of pure clay was 3.01 MPa, and when fly ash was added, the compressive strength gradually decreased. Significantly, a peak with a compressive strength of 2.85 MPa was recorded at 20% fly ash concentration, and this was followed by a decline. On the other hand, the effect of crushed pottery on the compressive strength of clay was carefully evaluated. With an increase in pottery content, the analysis showed a declining trend in compressive strength, with the initial compressive strength of 2.81 MPa at 5% crushed pottery falling to 1.67 MPa at 50%. After that, a thorough analysis was carried out by combining fly ash and crushed pottery at the preset ratios shown in Table 4. The resulting data demonstrate how crucial the additives working together in increasing the compressive strength of clay. It was found that a combination of 20% fly ash and 30% crushed pottery produced the best results, with a remarkable compressive strength of 3.52 MPa. This comprehensive investigation offers some information about the complex interactions between fly ash, crushed pottery, and clay, using their combined effectiveness in raising compressive strength and making a substantial contribution to the advancement of sustainable construction materials.

3.4.2 Tensile Strength Test

As seen in Table 5, an extensive examination of the effects of fly ash and crushed pottery additions was part of the research into the tensile strength of clay. First, the impact of fly ash at different concentrations (from 5 to 50%) on the tensile strength of clay was carefully investigated. In comparison to the tensile strength of pure clay, which was 0.48 MPa, the results showed a significant fall in tensile strength, from 0.41 MPa at 5% fly ash content to 0.18 MPa at 50%. Comparable results were seen when crushed pottery was added, with tensile strength dropping from 0.44 MPa at 5% pottery content to 0.22 MPa at 50%. Promising results were obtained from a subsequent experiment with mixed additives. When the two additions were combined, the tensile strength increased and peaked at 30% fly ash and 30% crushed pottery concentration, with an ideal tensile strength of 0.65 MPa. However, other combinations showed a decrease in tensile strength; nevertheless, these values remained superior to the tensile strength of pure clay. This thorough investigation illustrates the delicate balance that must be maintained between fly ash and crushed pottery to increase the tensile strength of clay, offering important information for the creation of durable and sustainable building materials.

4 Conclusion

In conclusion, a thorough examination of the soil’s ability to withstand mechanical, mineralogical, and geotechnical stresses provides us with a multifaceted understanding of the soil’s properties. The microstructure of the soil was found to be highly complex in the MEB-EDX investigation, with a wide range of particle types, including a significant presence of feldspar crystals. The elemental makeup of the material comprises (oxygen (44.03%), aluminum (25%), and silicon (16.65%)), with indications of potassium. which is corroborated by XRD research. The presence of dominating components including oxygen, aluminum, and silicon as well as suggestions of potassium, aluminum, and silicon; suggests an extensive feldspar mineral presence, supports by XRD. The soil ‘s complex mineral composition is further emphasized by the presence of phyllosilicates such as muscovite, kaolinite, and albite, alongside quartz. From a geotechnical perspective, the soil’s particle distribution was found to be 20% clay, 65% silt, and 15% sand, aligning with accepted practices. Intermediate plasticity was revealed by Atterberg limit testing, placing the soil’s density between silty and clayey compositions. The similar patterns in the compressive and tensile strength tests demonstrate the importance of different clay compositions in addition to fly ash and broken pottery. Interestingly, increasing clay ratios always resulted in increased compressive strengths, but increasing fly ash and broken pottery concentrations were associated with decreasing compressive strengths. A blend of fly ash and crushed pottery produced the best results; the ratio of fly ash to crushed pottery was 20% for compressive strength. Similar to this, using 30% of fly ash and 30% of crushed pottery produced the best results for tensile strength. These results illustrates the value of precisely blended materials to improve the mechanical qualities of building materials, highlighting the complementary effects of fly ash and crushed pottery.

References

Boumhaout M, Boukhattem L, Nouh FA, Hamdi H, Benhamou B (2013) Int Energy efficiency in buildings: Thermophysical characterization of building materials, in: Renew. Sustain. Energy Conf., IEEE, 2013: pp. 391–395

M’lahfi B, Amegouz D, Qandil ME (2020) A new approach for the mandatory application of the thermal regulation of construction (RTCM) in the future Moroccan buildings. SN Appl Sci 2:1–16

Chu Z, Li Q, Zhou A, Zhang W, Huang W, Wang J (2023) Strategy formulation path towards zero-waste of municipal solid waste: a case study from Shanghai. J Clean Prod 418:138091

Magutu P.O., Mbeche I.M., Nyamwange O, Mwove M.N., Ndubai R.E., Nyaanga R.O. (2010) Formulation and implementation of operation strategies used in solid waste management: case study of City Council of Nairobi. J Afr Res Bus Technol 2010:c1–21

Salemane MG, Luyt AS (2006) Thermal and mechanical properties of polypropylene–wood powder composites. J Appl Polym Sci 100:4173–4180

Nehdi ML (2014) Clay in cement-based materials: critical overview of state-of-the-art. Constr Build Mater J 51:372–382 0950– 0618,

NGAYAKAMO, Blasius et ONWUALU, Azikiwe Peter (2022). Recent advances in green processing technologies for valorisation of eggshell waste for sustainable construction materials. Heliyon, 8

Minke G (2013) Building with earth. Birkhäuser

Smil V (2013) Making the modern world: materials and dematerialization. Wiley

Brevik EC, Hartemink AE (2010) Early soil knowledge and the birth and development of soil science. CATENA 83:23–33

Oubani M, Bouferra R, Essaleh M, Bouchehma A, Bourial A, Melhaoui M, Essaleh L (2023) Developing sustainable building materials using local Soil Reinforced with Alkali-treated and untreated Alfa Fiber: a characterization study of Thermal and Mechanical properties. Chem Afr 1–16

DUFLOU, Joost R, John SUTHERLAND, David WDORNFELD et al (2012) Towards energy and resource efficient manufacturing: a processes and systems approach. CIRP Ann 61:587–609

Omer AM (2008) Energy, environment and sustainable development. Renew Sustain Energy Rev 12:2265–2300

Spiegel R, Meadows D (2010) Green building materials: a guide to product selection and specification. Wiley

Schroeder H (2016) Sustainable building with earth. Springer

Valentini F, Morandini F, Bergamo M, Dorigato A (2020) Development of eco-sustainable plasters with thermal energy storage capability. J Appl Phys 128

Bumanis G, Vitola L, Pundiene I, Sinka M, Bajare D (2020) Gypsum, Geopolymers, and starch—alternative binders for bio-based building materials: a review and life-cycle assessment. Sustainability 12:5666

Muralidharan A (2023) Detection of secondary phase in nmc811 (OH) 2 precursor using x-ray powder diffraction and raman spectroscopy

Boumhaout M, Boukhattem L, Hamdi H, Benhamou B (2017) Thermomechanical characterization of a bio-composite building material: Mortar reinforced with date palm fibers mesh. Constr Build Mater 135:241–250

The Canadian Mineralogist 2019;; 57 (1): 47–64. doi: https://doi.org/10.3749/canmin.1800036

NF EN ISO 14688- 1:2017 Geotechnical reconnaissance and testing Soil identification and classification AFNOR 2017

Funding

Not applicable.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethical Approval

Not applicable.

Informed Consent

Not applicable.

Conflict of Interest

Not applicable.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bajji, S., Oubani, M., Bammou, Fe. et al. Mineralogical, Geotechnical, Thermal and Mechanical Characterizations of an Energy-Efficient Building Material: Clay Stabilized by Wood Ashes or Crushed Waste from Traditional Pottery. Chemistry Africa 7, 3981–3992 (2024). https://doi.org/10.1007/s42250-024-00988-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42250-024-00988-1