Abstract

In the present work, Aspilia mossambicensis leaf extract (AMLE) and Emilia sonchifolia leaf extract (ESLE) were investigated for their corrosion inhibitive effect on Aluminium in 1 M NaOH and 1 M KOH using gravimetric and electrochemical studies. It was found that the inhibition efficiency of each of the extracts increased with increase in concentration of the inhibitors and decrease with increase in temperature. At a concentration of 1.0 g/l and temperature of 303 K after 2.75 h, AMLE and ESLE gave maximum inhibition efficiency of 79.04 and 77.00% respectively for Aluminium in KOH, and 67.10 and 73.74% respectively for Aluminium in NaOH. The equilibrium modelling of the processes reveals that Langmuir and Temkin isotherm models fitted the experimental data properly. The Gibbs free energy was found to be less negative than – 20 kJ/mol, indicating that the adsorption mechanism was spontaneous, feasible and physical adsorption process. The Electrochemical impedance data show that the increase in the concentrations of extracts decreased the double layer capacitance and simultaneously increased the charge transfer resistance, thereby increasing the inhibition efficiency. The Tafel polarization curves showed that both extracts lowered both the cathodic and anodic corrosion current densities, hence both acted as mixed—type inhibitors, without changing the mechanism of corrosion of Aluminium in the alkaline media.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Corrosion is a natural phenomenon, which can be chemical or electrochemical in nature that causes metal’s, ceramic’s and alloy’s degradation, and then make them useless for their expected utility [1, 2]. In industries, it is a serious problem which causes significant economic loss [3]. Industrial metals and alloys were often used in modern society, moreover, which played an important role in the transportation industry, construction, aerospace aviation and so on. However, corrosion was the greatest threat of all for the metals and alloys, statistically, corrosion-induced metal and alloy loss accounted for more than 30% of annual production worldwide, and the economic loss induced by corrosion per year accounted for 1–4% of the Gross National Product for these industrial countries. National Association of Corrosion Engineers (NACE) has reportedly estimated that corrosion losses in the oil and gas industry worldwide exceed $60 billion a year [46] It can be caused by the presence of water as moist in the air, bases, or acid medium, salts, liquid chemicals, aggressive metal polishes as well as hazardous gases [4]. This is because most industrial processes facilitate contact between metal and aggressive medium (Such as acid, base or salt), consequently the metal is prone to corrosion [1]. In order to prevent degradation of metals and alloys during industrial operations, various corrosion control techniques have to be employed. The most practical and efficient being the use of inhibitors [1, 3,4,5]. Corrosion inhibitors are those chemical substances which when added in small amounts to the corrosive environment, reduce the rate of metal dissolution or corrosion reaction [6]. These compounds are adsorbed on the metallic surface and block the active corrosion sites [5]. Most of the reported inhibitors are synthetic organic compounds containing heterocyclic compounds (nitrogen, sulphur, oxygen and phosphorus) with aromatic rings [3, 5]. Although these compounds have high corrosion inhibitive effect, they are expensive, toxic and harmful to both human beings and environment [1, 3, 7]. Hence there is growing interest in the use of plant extracts as corrosion inhibitors since they are readily available, inexpensive, non-toxic and environmental-friendly [1, 8]. Recently, a number of plant extracts have been investigated for corrosion inhibition. These include Plumeria rubra [3], Luffa cylindrical [9], Pongamia pinnata [7], Lignin from siam weed (Chromolaena odorata) [1], Mimosa Pudica [5], Carica papaya [10], Terminalia Catappa [11], Piper longum [12], Kalmegh [13], bark [14] etc. These plant extracts possess adequate cyclic organic phytochemicals, Nitrogen, sulphur and oxygen atoms that are responsible for their inhibition properties [15]. Emembolu, et al., [46] optimized the effect of the acid concentration, inhibitor concentration, inhibition time and temperature on the mild steel inhibition efficiency of Epiphyllum oxypetalum (EO) leaves extract in 3 M H2SO4 aggressive environment. The maximum inhibition efficiency of 82.93% was recorded at 333 K, 2.70 h and 0.055 g/L inhibitor concentration.

Previously, the authors have investigated the extract of plants, namely, Afzelia africana, Brachystegia eurycoma, Derium microcarpum, Mucuna flagellipes and Pentaclethra macrophlla shells respectively as corrosion inhibitors on Aluminium in 2.0% HCl by chemical approach and the maximum inhibition efficiencies achieved were 75, 78, 82, 78 and 79% respectively [16].

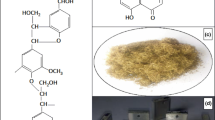

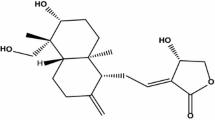

A. mossambicensis also known as the haemorrhage plant is a semi-woody herb of the genus Aspila found all over tropical Africa. It is classified among substances with low toxicity and its extract and phytochemicals were reported to have wound healing effects and exhibit strong anti-inflammatory, antimicrobial, and antioxidant activities [17]. E sonchifolia which is commonly called lilac tassel flower [18], on the other hand, is a member of sunflower family Asteraceae, it is one of the world’s worst weed and goes by many common names such as siam weed, devil weed, French weed, communist weed [19]. It is being used traditionally for treating wounds, skin infections, inflammation etc. and the leaf extract has been reported to have antioxidant, anti-inflammatory, analgesic properties [20, 21].

The above plant leaves were selected because of ease of availability, presence of water soluble active constituents, and environmental friendly/nontoxic. The main aim of this study is to evaluate the inhibition effect of AMLE and ESLE on Aluminium in 1 M NaOH and 1 M KOH solutions. The inhibition performance is examined by potentiodynamic polarization (PDP) and electrochemical impedance spectroscopy (EIS). SEM and FTIR investigations were used to validate the experimental results.

2 Experimental Methods

2.1 Materials Collection and Preparation

The aluminium metal, chemical reagents, A. mossambicensis and E.Sonchifolia plants were all sourced locally. The aluminium metal, inhibitors and regents used in this research work were prepared as previously described in [40].

2.2 Inhibitor Characterization

The inhibitors was characterized by instrumental and phytochemical analysis as described below.

2.2.1 Instrumental Characterization

2.2.1.1 Fourier Transform Infrared Spectroscopy (FTIR)

FTIR analysis was done on pure leaf samples to identify the active functional groups before the corrosion process as described in [22]. Equally the corrosion products were subjected to Fourier transform infrared spectroscopy using KBr pellet method (SHIMADZU Model IR affinity-1) as in previous study.

2.2.1.2 Scanning Electron Microscopy (SEM)

The surface morphology of the corroded coupons was analysed at Ahmadu Bello University, Zaria, using the scanning electron microscope (Manufactured by Phenom-world

Eindhoven, Netherlands) as in [22].

2.2.2 Phytochemical Analysis

The qualitative and quantitative analyses were performed on the AMLE and ESLE extracts using the chemical analysis described by [23, 24]. The extracts were analysed for the presence of alkaloids, cardiac, glycosides, flavonoids, phenolics, saponins, tannins, and phytates.

2.3 Gravimetric Measurement

Considering one factor at a time, the analysis was carried out at various temperatures of 303, 313, 323, 333, and 343 K and with various concentrations of the plant extracts. The various concentration ranges used in this work were obtained by dissolving the appropriate quantity into a given volume of the solutions as previously described in Emembolu, et al., [40]. The weighed aluminium coupons were separately immersed in 1 M NaOH and 1 M KOH solutions without and with various concentrations of the leaf extracts, respectively. At the appropriate time of 2.75 h, the coupons were taken out, immersed in acetone, scrubbed with a bristle brush under running water, dried and reweighed. The weight loss was calculated in grams as the difference between the initial weight and the weight after the removal of the corrosion product. The experimental readings were recorded. The weight loss (∆W), degree of surface coverage (Ѳ), corrosion rate (CR) and inhibition efficiency (η) were calculated using Eqs. (1), (2), (3), and (4) respectively [25].

where:

Wi and Wf are the initial and final weight of metal samples respectively;

W1 and W0 are the weight loss value in presence and absence of inhibitors respectively.

2.4 The Electrochemical Measurements

The electrochemical experiments were conducted in a three electrode corrosion cell using a VERSASTAT 300 complete dc voltammeter and corrosion system with V3 studio software for Electrochemical Impedance Spectroscopy (EIS) while the Potentiodynamic Polarization (PDP) experiments were conducted using Potentiodynamic/Galvanostat corrosion system with E-Chem software. A graphite rod was used as counter electrode and a saturated calomel electrode (SCE) as reference electrode. The latter was connected via lugging capillary. Prior to each experiment, the working electrodes used (aluminium) were polished with different grades of emery paper rinsed with distilled water and degreased with ethanol. The EIS measurements were performed in aerated and unstirred (3 M of each alkaline solutions was used) solutions at the end of 1800 s at 30 ± 1 °C. EIS measurements were made at corrosion potentials (Ecorr) over a frequency range of 100 kHz–0.1 Hz with a signal amplitude perturbation of 5 mV [26]. The inhibition efficiencies (η%) for different inhibitor concentrations were calculated from Nyquist plots using Eq. (5) below.

where Rct and Rct(inh) represents charge transfer resistance in the absence and presence of the inhibitor, respectively.

The double layer capacitance (Cdl) value were obtained from the following Eq. (6) [7].

where Fmax is the Frequency at maximum Z" Value and Z" is the imaginary component of the impedance which was plotted against the Z′ (the real component) in the Nyquist plots.

For each experiment, after EIS measurement, the Potentiodynamic Polarization curves were recorded immediately by changing the electrode potential automatically from – 200 to + 200 mV with the scan rate of 2mVs−1. The linear Tafel segments of anodic and cathodic curves were extrapolated to corrosion potential (Ecorr) to obtain corrosion current densities (icorr). The η% was calculated using Eq. (7) [3].

where icorr(uninh) and icorr(inh) represents the corrosion current density value in the absence and presence of inhibitors, respectively.

3 Results and Discussion

3.1 Phytochemical Results

In nature, the presence of phytochemicals in plants were responsible for corrosion inhibition [27, 28]. Hence, the essence of the phytochemical analysis is to predict the performance of the extracts as corrosion inhibitors. The active constituents of the inhibitors donate electrons to the Al metal, which will in turn accept them to attain stability, thereby retarding further redox reaction and hence, corrosion attack on the surface of Al is thereby prevented [29]. Therefore, the presence of phytochemical constituents in any plant extracts show the corrosion potentials of such extracts to act as corrosion inhibitor. The results of the phytochemical analysis of the extracts are shown in Table 1 (both qualitative and quantitative results). The results shows the presence of alkaloids, cardiac, glycosides, flavonoids, phenolics, phytates, saponins and tannins in the extracts at various degrees. The qualitative results were denoted with symbols; +++ (highly concentrated), ++ (concentrated), + (in traces), and – (absence or too little to be observed).

3.2 Fourier Transform Infrared Spectroscopic Analysis

Close inspection of Table 2 shows the observable peaks of AMLE and ESLE (inhibitors) and corrosion products obtained from FTIR. It is evident from the inspection that AMLE and ESLE have pertinent functional groups (like C=O, O–H, and C–H stretching bands) necessary for effectual inhibition. Further examination on same Table 2, indicates that some peaks decreased or shifted while some vanished. This can be attributed to the presence of the inhibitor functional groups on the surface of the corrosion products thereby demonstrating the efficacy of the AMLE and ESLE used.

3.3 Scanning Electron Microscopy (SEM) Examination

Surface examination using SEM was carried out to understand the effect of inhibitor molecules on the surface morphology of Al. Plates 1a and 2a shows the SEM image of a polished Al surface immersed separately in aggressive alkaline (NaOH and KOH) solutions without inhibitor molecule. These micrographs shows the effects of these alkali on surface degradations resulting from pitting and erosion corrosion. Plates 1b and 2b shows SEM image of the Al surface immersed in alkaline solutions containing different concentrations of AMLE and ESLE respectively. Thus, it can be concluded that corrosion is much less in the presence of these inhibitors and the appearance of more polished surface obtained which proves its higher inhibition efficiency.

3.4 Effect of Temperature and Inhibitor Concentration on Inhibition Efficiency

In order to determine the effects of temperature and concentration of AMLE and ESLE on inhibition efficiency (η), the weight loss measurements were carried out as a function of temperature (303–343 K) and concentration of AMLE and ESLE (0.2–1.0 g/l). The inhibition efficiency was plotted against the concentration of the extracts as shown in Figs. 1, 2. It can be seen from the Figures below that the inhibition efficiencies decreases with increase in temperature but rises with progressive increase in concentrations of AMLE and ESLE respectively. The gradual rise in inhibition efficiency as well as in the concentrations of the extracts could be attributed to the increase in the fraction of aluminium surface covered by the adsorbed constituents of AMLE and ELSE respectively. This indicates that the inhibitor molecules were adsorbed on the aluminium surface and prevent the surface from further corrosion attack [30]. However, the decrease in inhibition efficiency with increase in temperature of the corrosive medium could be as a result of the partial desorption of the inhibitor from the aluminium surface at higher temperature [3] or as a result of the decomposition of the inhibitor molecules at higher temperatures [31, 32]. Also, [31] was of the opinion that the decrease in inhibition efficiency with temperature should be due to increase in the solubility of the protective films of the metal at higher temperatures, thus, increasing the susceptibility of the metal to corrosion. The decrease in inhibition efficiency with rise in temperature suggests a physical adsorption mechanism [5]. The maximum inhibition efficiency of AMLE and ESLE in KOH medium was found to be 79.04 and 77.00% respectively at 303 K at concentrations of 1.0 g/l while in NaOH solution, the maximum inhibition efficiency was found at the 303 K and 1.0 g/l to be 67.10 and 73.74% respectively. Comparatively, the result shows that AMLE has higher inhibitive property than ESLE.

3.4.1 Effect of Temperature and Inhibitor Concentration on Corrosion Rate

The effect of temperatures and inhibitor concentrations on corrosion rates is presented in Figs. 3, 4. The Figures show that the corrosion rates increased with increase in temperature but decreased with increase in inhibitor concentrations. The increase in corrosion rates with temperatures can be accredited to rise in the average kinetic energy of the reacting molecules [33]. Also, the observed decrease in corrosion rate of aluminium with increase in concentration of the extracts is due to the inhibitive effect of the leaves extracts. This suggests that the concentrations of the extracts increases due to gradual increase in the number of adsorption constituents of the extracts onto the surface of the aluminium which creates a barrier for mass transfer and prevents further corrosion [1, 34, 35]. Similar result was reported for Mild steel in 1 M HCl using siam weed extract [1].

3.5 Adsorption Isotherm and Thermodynamic Studies

In order to understand the mechanism of corrosion inhibition, the adsorption behaviour of the inhibitor on the metal surface has to be known. For this purpose, the surface coverage (θ) and inhibitor concentration were used to ascertain the type of adsorption model at 303 K, 323 K and 343 K. The Langmuir, Frumkin and Temkin adsorption isotherms characterised by Eqs. (8), (9) and (10), respectively [3, 36,37,38] were tested.

where C is the concentration of the inhibitor, θ is the surface coverage, α is the attractive parameter between the already adsorbed inhibitors, "a" is the attractive parameter and Kads is the equilibrium constant of the adsorption.

The Kads values were deduced from the intercept lines on the C/θ axis (Fig. 5). It is related to the free energy change of adsorption (∆Gads) by Eq. (11) [1, 3, 9].

Where 55.5 is the water concentration of the solution in (mol/L), R is the universal gas constant and T, temperature in K.

The linear regression coefficients (R2) for the three isotherm models were calculated for the different alkali solutions, but only that of AMLE in KOH were presented in Table 3 and others were not presented due to lack of space. The R2 values were used to determine the most suitable model. In all the cases considered, the values of R2 approaches unity, which indicates that the adsorption of AMLE and ESLE molecules follows the Langmuir, Temkin and Frumkin adsorption isotherm models individually, which also supports the fact that the inhibition performance of AMLE and ESLE were mainly due to the adsorption processes. Although, Langmuir and Temkin isotherm data fitted the model properly but due to lack of space only Langmuir plot in Fig. 5 were presented. Again, Temkin and Langmuir isotherm models with greater R2 values best described the adsorption mechanism of AMLE and ESLE on aluminium in KOH and NaOH solutions. This implies that the monolayer coverage and homogenous distribution of the AMLE and ESLE molecules on the aluminium surface as assumed by Temkin and Langmuir equation agrees with Helal, et al., [35, 40]. Therefore, Langmuir and Temkin isotherm is more appropriate and was applied in evaluating the adsorption equilibrium constant, Kads.

The adsorption equilibrium constant, Kads and the free energy change of adsorption, ∆Gads were calculated from the intercept of the three isotherms and Eq. (11) respectively, and presented in Table 3. Generally, ∆Gads values of – 20 kJ/mol or less negative are associated with physio sorption, while those values with more negative than – 40 kJ/mol are associated with chemisorption [5]. In this study, the values all of ∆Gads obtained as can be seen from Table 3 above were all less negative than – 20 kJ/mol for the adsorption of both extracts on aluminium in KOH and NaOH. This indicates that the adsorption of AMLE and ESLE on aluminium surface in both KOH and NaOH media follow the physical adsorption mechanism. The negative value of ∆Gads indicates that the adsorption of AMLE and ELSE on aluminium surface is spontaneous and feasible. The activation of energy (Ea), enthalpy of activation (∆H) and entropy of activation (∆S) for the corrosion of aluminium were evaluated using the linearized form of Arrhenius and Transition state Eqs. (12) and (13) respectively [36].

where CR is the corrosion rate, Ea is the apparent activation energy, R is the molar gas constant, T is the absolute temperature, A is the frequency factor, N is the Avogadro’s number and h is the Plank’s constant.

The Arrhenius plots for Al performance in AMLE were represented in Fig. 6. The values of Ea were calculated from the slope of \(LogCR\) versus 1/T and tabulated in Table 4. The values of ∆H and ∆S were equally determined from the slope and intercept of the plot of \(Log\left(\frac{CR}{T}\right)\) versus 1/T (Fig. 7) respectively and tabulated in Table 4. The positive values of ∆H indicate that the corrosion of aluminium in the alkaline media is endothermic in nature. This supports the result obtained earlier, that increase in temperature increases the corrosion rate. It was equally observed in Table 4 that the values of Ea are larger than the analogous values of ∆H, indicating that the corrosion processes might have involved a gaseous reaction [1], also the values of Ea is higher in the presence of the inhibitors than in the absence of inhibitors, indicating physical adsorption [25]. The negative values of ∆S showed that the activated complex in the rate determining step represents an association rather than a dissociation step [1, 36,37,38].

3.5.1 Electrochemical Chemical measurements

The EIS studies were done to understand the characteristics and kinetics of the electrochemical processes taking place at the aluminium/aggressive solution interface and how they were modified by AMLE and ESLE.

3.5.2 The Electrochemical Impedance Spectroscopy (EIS) Studies

Impedance measurements were made under potentiostatic conditions after 1800 s of immersion. The Nyquist plots of uninhibited and inhibited solution containing different concentrations of inhibitor molecules were performed over a frequency range from 100 kHz – 0.1 Hz and are shown in Figs. 8a, 9a, 10a, 11a. The corresponding Bode plots are shown in Figs. 8b, 9b, 10b, 11b. The resemblance in the semi-circle shapes of these diagrams throughout the experiment, shows that the progressive increase of the inhibitor molecules does not make any alteration in the corrosion mechanism. Also, Nyquist or impedance diagrams described in Figs. 8a, 9a, 10a, 11a comprises of depressed semicircles with real axis as the centre, which are typical behaviours of solid electrode which are sometimes attributed to different physical phenomenon such as roughness, inhomogeneities of the solid surfaces, impurities, grain boundaries, and distribution of surface active sites [25, 37,38,39,40]. Inspection of Table 5 shows that the values of Rct and Cdl have opposite trends at the entire concentration ranges and it may be attributed to the formation of a protective layer on the surface of the electrode. The double layer between the solution and the charged metal surface is regarded as an electrical double capacitor. The adsorption of inhibitor molecules on the Al surface leads to reductions in electrical capacity thereby displacing some ions and water molecules initially adsorbed on the metal surface [41]. The increase in the inhibitor concentrations implies that the inhibitor molecules were electrostatically adsorbed on the electrode surface due to progressive increase in the thickness of the protective layer and gradual decrease in the values of Cdl. The above statement can be expressed mathematically using Helmholtz model equation below [42].

Where d is the thickness of the protective layer, ∑ is the dielectric constant of the medium, Σ0 is the vacuum permittivity and A is the surface area of the electrode.

The increase in the peak heights (Figs. 8c, 9c, 10c, 11c respectively) presents a more capacitive response of the interface due to the presence of inhibitor molecules at the interface.

3.6 Potentiodynamic Polarization (PDP) Studies

Polarization measurements were carried out to determine the information about the interactions between the inhibitor molecules and kinetics of anodic and cathodic reactions. Potentiodynamic polarization curves for Al in the absence and presence of various concentrations of the inhibitor (AMLE and ESLE) molecules were shown in Figs. 12–13. The values of electrochemical kinetic parameters like corrosion current density (Icorr), Tafel constants (βa and βc) and others were determined by extrapolation method, and presented listed in Table 6. The corrosion inhibition efficiency (IE) was calculated using Eq. (7). The anodic reactions of corrosion in solutions occur by discharge of metal ions from the metal surface into the solution, whereas the cathodic reactions is the discharge of hydrogen ions to produce hydrogen gas or to reduce oxygen. As a result of this, inhibitors can affect either the anodic or the cathodic reaction, or both. Close examination of Figs. 12–13 indicates that the gradual increase in the inhibitors had an inhibitive effects on both anodic and cathodic branches of the polarization curves. The effects changes both the anodic and cathodic curves to lower current densities [43, 44]. This occurrence can due to the adherence of the active ingredients of the inhibitors on the metal surface. Hence, AMLE and ESLE can described as a mixed type inhibitors [40, 44]

3.7 Corrosion Mechanism

The standard electrode potential of Al demonstrates that Al is thermodynamically reactive. The Pourbaix diagram for Aluminium-water system designates Aluminium as being thermodynamically stable within the pH range of 5.0–8.5. This can be attributed to the fact, that Aluminium forms protective oxide film on the surface (stable) which prevents it from further attack against the harsh environment (passivity) [45]. The effect of AMLE and ESLE on the corrosion rate of Al in 1 M NaOH and 1 M KOH were studied using Tafel polarization technique. The decrease in corrosion rate occurs by shifting the anodic curves to more positive potentials and cathodic curves to more negative potentials, and to the lower values of corrosion current densities Figs. 12–13. However, the dissolution of Aluminium in alkaline environments occurs through different stages of successive addition of surface hydroxyl species resulting in the dissolution of Al (OH)3 in the presence of surface oxide film. The overall reaction occurring in the corrosion of aluminium in the alkaline solution involves anodic (15), (16), (17), (18), and cathodic (19) reactions as presented below [13, 45]

The cathodic reaction on the film covered electrode surface is the reduction of water [15]:

4 Conclusion

The capacity of AMLE and ESLE as green inhibitors has been assessed in this research using the weight loss and electrochemical methods. The extracts showed good inhibition characteristics on Aluminium in 1M KOH and 1M NaOH solutions. The inhibition efficiency improved with increasing inhibitor concentrations and decreased with increasing temperature. The adsorption of the extracts on Aluminium was found to follow the Langmuir isotherm and Temkin models. The value of ∆Gads estimated from the adsorption isotherms suggested that the adsorption mechanism of AMLE and ESLE on Aluminium is spontaneous, feasible and follow physical adsorption mechanism. The potentiodynamic polarization curve indicate that both leaf extracts act as mixed-type inhibitors and does not change the mechanism of corrosion. The weight loss and electrochemical studies showed that the extracts are efficient corrosion inhibitors for Aluminium in the alkaline media.

Data Availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

Abbreviations

- C:

-

Inhibitor concentration

- SEM:

-

Scanning Electron Microscopy

- FTIR:

-

Fourier Transform Infrared Spectroscopy

- C dl :

-

Double-layer capacitance

- CS:

-

Electrochemical work station

- E corr :

-

Corrosion potential

- i corr :

-

Corrosion current density

- R 2 :

-

Coefficient of determination

- R ct:

-

Charge transfer resistance

- R s :

-

Solution resistance

- D:

-

AMLE, A. mossambicensis leaf extract

- F:

-

ESLE, E. sonchifolia leaf extract

- β a and β c :

-

Tafel anodic and cathodic constants respectively

- E a :

-

Activation of energy

- ∆H :

-

Enthalpy of activation

- ∆S :

-

Entropy of activation

- ∆G :

-

Free energy of adsorption

References

Nwosu FO, Muzakir MM (2016) Thermodynamic and adsorption studies of corrosion inhibition of mild steel using lignin from Siam weed (Chromolaena odorata) in acid medium. J Mater Sci 7:1663–1673

Hariom KH, Pradeep H, Bala A (2016) Corrosion inhibition of mild steel by using hexylamine as corrosion inhibitor in acidic medium. Der Pharma Chemica 8:268–278

Pradeep Kumar CB, Mohana KN (2013) Adsorption and Thermodynamic characteristics of Plumeria rubra plant extract on mild steel corrosion in industrial water medium. Int Res J Pure Appl Chem 3(4):330–346

Nwabanne JT, Okafor VN (2012) Adsorption and thermodynamics study of the inhibition of corrosion of mild steel in H2SO4 medium using Vernonia amygdalina. J Mine Mater Character Eng 11:885–890

Sumita A, Nikhila G (2018) Adsorption and thermodynamic study of Mimosa pudica on Mild steel in 2M H2SO4. Int J ChemTech Res 11(3):129–139

Sastri VS (1998) Corrosion Inhibitors: Principles and applications. Wiley, New York

Bhuvancowari TK, Vasantha VS, Jeyaprabha C (2018) Pongamia Pinnata as a Green Corrosion Inhibitor for Mild Steel in 1N Sulphuric Acid Medium. Retrived August, 13 2020 from https://springerlink.bibliotecabuap.elogim.com/COntent/pdf/https://doi.org/10.1007/s12633-017-9673-3.pdf

Jane IIM, Uzoma OT, Egblefu AV, Ugochukwu U (2012) Corrosion Inhibition behaviour of Emilia sonchifolia leaves extract as a green corrosion inhibitor for mild steel in hydrochloric acid medium. Int J Basic Appl Chem Sci 2:48–58

Ogunleye OO, Arikoola AO, Eletta OA, Agbede OO, Osho YA, Morakinyo AF, Hamed JOM (2020) Green Corrosion Inhibition and Adsorption Characteristics of Luffa Cylindrica Leaf Extract on Mild Steel in Hydrochloric Acid Environment. Retrieved August, 13 2020 from https://www.ncbi.nlm.nih.gov/pmc/articlco/PMC6970177/pdf/main.pdf

Kasuga B, Park E, Machunda RL (2018) Inhibition of aluminium corrosion using Carica papaya leaves extract in sulphuric acid. J Miner Mater Character Eng 6:142–148

Madu N et al (2019) Corrosion inhibition efficiency of Terminalia Catappa Leaves extract on stainless steel in hydrochloric acid. J Phys: Conf Ser. https://doi.org/10.1088/1742-6596/1378/2/022092

Singh A, Ahamad I, Mumtaz A (2016) Quraishi Piper longum extract as green corrosion inhibitor for aluminium in NaOH solution. Arab J Chem 9:S1584–S1589

Namrata et al (2017) Electrochemical approach of Kalmegh leaf extract on the corrosion behavior of aluminium alloy in alkaline solution. Int J Ind Chem 8:75–82

Namrata et al (2017) Corrosion inhibition performance of different bark extracts on aluminum in alkaline solution. J Assoc Arab Univ Basic Appl Sci 22(1):38–44. https://doi.org/10.1016/j.jaubas.2015.12.003

Helen II, Rahim AA, Saad B, Saleh MI, Bothi RP (2014) Aquilaria Crassna leaves extracts – a green corrosion inhibitor for mild steel in 1.0M HCL medium. Int J Electrochem Sci 9:830–846

Emembolu et al (2020) Seed shells as active and nontoxic corrosion inhibitors for aluminum in aggressive acid environment. World News Nat Sci 31:120–137

Komakech R, Matsabisa MG, Kang Y (2020) The Wound Healing Potential of Aspillia Africana (Pers.). Retrieved September 9 from http://downloads.hindawi.COm/journals/ecam/2019/7957860.pdf

Vaisakh MN, Pandey A (2012) The invasive weed with healing propertico: a review on Chromolaena odorata. Int J Pharm Sci and Research 3(1):80–83

Demet ÖZKIR (2021) The role of Lavandula sp. extract for effective inhibiting the mild steel corrosion in the hydrochloric acid solution. Int Chem Technol 5(2):125–132. https://doi.org/10.32571/ijct.943385

Miralrio A, Vázquez AE (2020) Plant extracts as green corrosion inhibitors for different metal surfaces and corrosive media: a review. Processes 8(8):942. https://doi.org/10.3390/pr8080942

Emembolu et al (2020) Evaluation of the corrosion inhibitory effect of Napoleonaea imperalis leaf extract on mild steel in 1.3 M H2SO4 medium. J Bio Tribo Corros 6(128):1–15. https://doi.org/10.1007/s40735-020-00422-2

Mayuri PN (2012) Screening of Ailanthus Excelsa Roxb for secondary metabolites. J Curr Pharm Res 10(1):19–219

Marcano L, Hasenawa D (1991) Analysis of phytochemicals in leaves and seeds. Agron J 83:445–452

Olugbade T, Lu J (2019) Characterization of the corrosion of nanostructured 17–4 PH stainless steel by surface mechanical attrition treatment (SMAT). Anal Lett 52(16):2454–2471

Emembolu LN, Onukwuli OD (2019) Effect of Dialium guineense extracts on the corrosion inhibition of aluminum in alkaline solutions. J Mater Environ Sci 10(6):495–509

Singh A, Ebenso EE, Quraishi MA (2012) Corrosion inhibition of carbon steel in HCl solution by some plant extracts. Int J Corros. https://doi.org/10.1155/2012/89430

Odusote et al (2020) The inhibitive action of Plukenetia conophora plant extract on corrosion of Al-Zn-Cu alloy in different acidic media. Int Rev Appl Sci Eng 11(3):269–279

Nnanna LA, Obasi VU, Nwadiuko OC, Majeh KI, Ekekwe ND, Udensi SC (2012) Inhibition by Newbouldia Levis leaf extract on the corrosion of aluminium in HCL and H2SO4 solutions. Arch Appl SCi Res 4:207–217

Rammananda SM (2013) A green approach: a corrosion inhibition of mild steel by Adhatoda vasica plant extract in 0.5M H2SO4. J Mater Environ Sci 4(1):119–126

Manimegalai SM (2015) Thermodynamic and adsorption studies for corrosion inhibition of mild steel in aqueous media by Sargasam swartzii (Brown algae). J Mater Environ Sci 6(6):1629–1637

Akinbulumo OA, Adejobi OJ, Odekanle EL (2020) Thermodynamics and adsorption sturdy of the corrosion inhibition of mild steel by Euphorbia heterophylla L. extract in 1.5M HCL. Materials 5:100074

Philip YJN, Buchwcohaija J, Mwakalesi A (2016) Corrosion inhibition of amino pentadecylphenols (APPS) derived from cashew nut shell liquid on mild steel in acidic medium. Mater Sci and Appl 7:386–402

Emembolu LN, Onukwuli OD (2020) Inhibitive effect and adsorption study of Chromolena odorata and Aspillia africana as corrosion inhibition of zinc in 1MH2SO4 solution. J Engr Appli Sci 16(1):108–116

Helal NH, El-Rabiee MM, Abd El-Hafez GM, Badawya WA (2008) Environmentally safe corrosion inhibition of Pb in aqueous solutions. J Alloy Compd 45(6):372–378

Meroufel B, Benali O, Bangahia M, Benmousa Y, Zenasnni MA (2013) Adsorptive removal of anionic dye from aqueous solution by Algerian kaolini: characteristics studies. J Mater Environ Sci 3(4):482–491

Emembolu LN, Onukwuli OD (2019) Corrosion inhibitive efficacy of natural plant extracts on zinc in 0.5MHCl Solution. Pharm Chem J 6(2):62–70

Al-Mhyawi SR (2014) Inhibition of mild steel corrosion using Juniperus plants as green inhibitor. Afr J Pure Appl Chem 8(1):9–22

Olugbade TO, Omoniyi OO, Omiyale BO (2022) Electrochemical properties of heat-treated Al alloy A6061–T6 in 0.5 M H2SO4 solution. J Inst Eng (India): Ser D 103:141–147

Loveth et al (2021) Electrochemical and statistical study of the inhibition effect of T. conophorum leaf extract on aluminum corrosion in acidic medium. Saf Extrem Environ. https://doi.org/10.1007/s42797-021-00040-2

Sam et al (2017) Corrosion inhibition properties of 1, 2, 4-Hetrocyclic systems: electrochemical, theoretical and Monte Carlo simulation studies. Egypt J Pet 26(3):721–732

Al-Miery et al (2018) Electrochemical studies of novel corrosion inhibitor for mild steel in 1 M hydrochloric acid. Results Phys 9:978–981

Idouhi et al (2018) Electrochemical studies of Monoterpenic Thiosemicarbazones as corrosion inhibitor for steel in 1 M HCl. Int J Corros. https://doi.org/10.1155/201/9212705

Daanace et al (2020) Electrochemical and quantum chemical studies on corrosion inhibition performance of 2,2’-(2-Hydroxyethylimino)bis[N-(alphaalpha-dimethylphenethyl)-N-methylacetamide] on mild steel corrosion in 1M HCl Solution. Mater Res. https://doi.org/10.1590/1980-5373-mr-2018-0610

Yadav et al (2016) Corrosion inhibition performance of pyranopyrazole derivatives for mild steel in HCl solution: gravimetric, electrochemical and DFT studies. J Mol Liq 216:78–86. https://doi.org/10.1016/j.molliq.2015.12.106

Zhanga Q et al (2022) Green and high-efficiency corrosion inhibitors for metals: a review. J Adhes Sci Technol. https://doi.org/10.1080/01694243.2022.2082746

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Onyenanu, C.N., Emembolu, L.N. & Ejiofor, C.C. Corrosion Inhibition Potentials of A. mossambicensis and E. sonchifolia Leaves' Extracts on Aluminium in Alkaline Media: Insights from Gravimetric and Electrochemical Studies. Chemistry Africa 6, 999–1014 (2023). https://doi.org/10.1007/s42250-022-00531-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42250-022-00531-0