Abstract

Vanadium is one of the toxic elements that is a threat to the environment and is present in the USEPA Contaminant Candidate List (CCL); hence, the removal of the same from contaminated water is the need of the hour. The vanadium removal studies by the surface-activated T A-62(MP) resin is analyzed under a variety of chemical and physical conditions, which include vanadium concentration, resin weight, contact time, temperature, and pH of the medium. An efficient and economical procedure was found for the removal of vanadium, i.e., by using 0.1 g of surface-activated T A-62(MP) and the initial vanadium concentration of 40 mg L−1, which resulted in 97.5% vanadium removal from the solution with a contact time of 3 h; this removal percentage increased more than 99.9% when the T A-62(MP) dosage was 0.25 g. In the aqueous media with a pH range of 6.0–7.0, the sorption process resulted in the maximum removal of vanadium. T A-62(MP) was also examined using SEM with EDX, BET surface area analyzer, and FTIR spectrometer before and after vanadium adsorption. The thermodynamic parameters reveal the endothermic nature of the adsorption process. The adsorption rate increases with an increase in the temperature of the medium. The equilibrium adsorption data is well fit by the Langmuir isotherm; the linear model explains the aggregation of the solute by the adsorbent that is directly proportional to the solution concentration. These findings show that surface-activated strong base anion-exchanger T A-62(MP) can be used to remove vanadium from wastewaters and aqueous solutions effectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

People all around the world are expanding their territory, which includes industrialization and unplanned urbanization, which results in poor quality of water; here, heavy metal ions are one of the toxic categories in water contaminants and may enter the food-chain system. Many toxic heavy metal ions are drained from different industries into the environment, which has a negative impact on the environment and thus causing environmental pollution [1,2,3]. As there are various possibilities of different heavy metals entering the water system, vanadium is the main focus of many regulatory majors as it has entered the Contaminant Candidate List [4]. The Bureau of Indian Standards has established the permissible limit of vanadium in ground and surface water to be 0.2 mg L−1 [5].

In the refinery leachates, vanadium is found in its pentavalent form, V (V) [6, 7] which is considered to be carcinogenic and toxic to human beings [8]. Vanadium solubility increases with an increase in its valency; hence, vanadium in its pentavalent form [V (V)] is considered to be more toxic, and its mobility is high in aqueous media [9, 10]. Vanadium ions can cause cough, mucus membrane inflammation, anemia, and gastrointestinal disturbances in the human body when exposed to them for long periods [11]. There are several purification processes for contaminated wastewaters; some of them include ion exchange, adsorption, precipitation, phytoremediation of heavy metals [12], and advanced filtrations [13,14,15,16,17]. Others include oxidation, membrane filtration, coagulation, reverse osmosis, bioremediation, reverse osmosis, and electrochemical therapy, which are some of the applied techniques for removing metal ions [18, 19]. For vanadium ions, protonated chitosan flakes were used to remove them from aqueous solutions [4]. The removal of vanadium from aqueous solution has been reported by using activated carbon [20]. However, the process of adsorption has been implemented for the removal of heavy metals, dyes, toxic gases, and pesticides [19, 21], but there is a need for more efficient and cost-effective alternative materials which adsorb effectively [22, 23].

As there is an increase in laws, regulations and economic constraints, the development of novel cost-effective production technology with lower energy consumption and environmental impact is a major drive at the global level.

Many different materials and techniques are being used for vanadium removal from wastewaters. Adsorbents such as activated carbon and metal hydroxides on nanocomposites are being used in the removal of vanadium [24]. The adsorption capability for V (V) was studied by using surface-modified palm fruit husk [25]. For different valencies of vanadium like V (IV), highly anionic hydrogel was used for the adsorption from an aqueous solution of pH 6.5 [26]. Iron-rich sludge as a conjugate with kaolin clay has also been used as an application for vanadium removal from a solution of pH 3–7 [27]. Vanadium removal from mine water with pH 4 containing 11 mg L−1 of vanadium was removed using surface-modified (using triethanolamine and iodomethane) sawdust [28]. Studies are being carried out for surface modification of materials for which quaternary ammonium groups were grafted onto pine bark which removed maximum vanadium from a solution of pH 4 [29]. There have been studies done on the removal of vanadium by the ion exchange methods [8, 30]. A resin with cation exchange capability has also proven to have high sorption selectivity for Ni and V [31].

In the present study, an effort has been made to efficiently extract vanadium from aqueous media using an eco-friendly process, ion exchange resins. Commercially available resin T A-62(MP) was used for the removal of vanadium from an aqueous solution. The vanadium removal studies by the surface-activated T A-62(MP) resin was analyzed under a variety of chemical and physical conditions. Based on the above measurements, further studies were carried out for surface-activated T A-62(MP) in batch tests in the removal of vanadium from aqueous media. The effects of vanadium concentration at an initial stage, pH of the medium, contact time, and adsorption equilibrium were analyzed. Adsorption data obtained was checked with Langmuir and Freundlich adsorption isotherms for their efficacy.

2 Materials and methods

Ion exchange studies of vanadium were done by using de-mineralized water free from carbon dioxide. The chemicals required for the experiment were of AR grade. Vanadium solution was prepared using divanadium pentoxide (AR) to get a vanadium concentration of 40 mg L−1 (V solution). The commercially available T A-62(MP) resin was procured from Thermax Ltd., India.

The detailed properties and calculated properties of T A-62(MP) have been shown in Table 1. The general structure of the strong base anion exchange resin has been depicted in Fig. 1. The T A-62(MP) was surface activated by alternatively using dilute sodium hydroxide solution and dilute hydrochloric acid solution, finally the T A-62(MP) was washed with de-mineralized water to remove excess hydrochloric acid and then dried at 303 K temperature.

The experiment for ion exchange studies was done by shaking 40 mL of varying concentrations of V solution and a definite quantity of resin Tulsion A-62(MP) in a thermostatic water bath shaker at 303 K, 313 K, and 323 K temperatures until equilibrium was reached.

The adsorption studies were made with 40 mL of V solution and varying resin quantity kept for stirring at 160 rpm in an orbital shaker (Glassco, 12 stations) for 3 h.

These parameters chosen are efficient and economical as shown in Fig. 5; here, only 0.1 g of T A62 (MP) removed 97.5% of vanadium from 40 mg L−1 of vanadium solution.

Equilibrium distribution coefficient is calculated [32] using Eq. (1).

Here qe represents metal ions adsorbed (mg g−1) at equilibrium, and Ce denotes the metal ion equilibrium concentration (mg L−1).

Vanadium recovery factors (% R) are calculated using the Eq. (2):

where Ca is vanadium concentration adsorbed on the T A-62(MP) (mg L−1) and Co is the vanadium concentration (mg L−1) at the beginning of the process.

3 Analysis

ICP-OES (PerkinElmer, Optima) was used to measure vanadium concentration, and wavelengths were selected by the standard method (USEPA Method 200.7). The calibration was carried out by using 1, 2, and 5 mg L−1 standards from Merck’s Certipur ICP multi-element standard solution, and samples were analyzed through ICP-OES with QC standard check after every 10 samples. Also BET surface area (Quantachrome, NOVA), SEM with EDX (HITACHI, SU), and FTIR (Thermo Scientific, Nicolet) scan of the T A-62(MP) were done before and after the adsorption of vanadium.

4 Results and discussion

4.1 Effect of pH

T A-62(MP) highest uptake capacity can be determined by the variation of pH of the medium. Vanadium adsorption by the T A-62(MP) was investigated at pH values ranging from 1 to 12, and the parameters like temperature, contact time, initial concentration, and resin dosage were kept constant. From Fig. 2, one can infer that for T A-62(MP), the percent removal of vanadium was 97.5%, which was highest in the 6.0 to 7.0 pH range. The removal was maximum at this pH due to the stable acidic pH maintained by the amine group protonation, and the ion exchange process can be explained by the following exchange reaction in the pH range 6–7, where the RCl represents the T A-62(MP) in the chloride form:

Here, in the V solution of 6–7 pH, the vanadium removal percentage is highest due to the presence of HV10O285− in the majority, which displaces the chloride ions present on the adsorption site of T A-62(MP) as shown in Eq. (3).

The possibility of removing vanadium ions at pHs below 4.0 decreases rapidly due to the formation of V3+, HVO2+, and VO2+ [4]. V+3; V+4 and V+5 are the stable oxidation states of vanadium. Here, V+5, the most common oxidation state, has greater solubility under oxic conditions. At lower pH, the T A-62(MP) did not adsorb vanadium; this is because vanadium exists dominantly in the form of VO2+ at low pH (Fig. 3) and the anion exchange resins cannot adsorb cationic species; also the pH values at the lower side indicate adsorption, which is lesser due to the exchange competition between hydrogen ions and vanadate ions for bonding regions. The adsorption capacity decreases gradually above pH 7.0 for T A-62(MP) due to an increase in the hydroxyl ions. [33,34,35].

Forms of vanadium existing in aqueous solution [33]

The ion exchange process and the possible mechanism for the vanadium removal using surface-activated T A-62(MP) can be explained by the below equations under specific pH (Table 2).

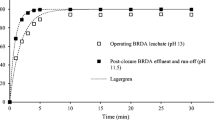

4.2 Effect of interaction time

The kinetics of adsorption gives a clear picture of the uptake of ions which governs the contact time of the adsorption process. The adsorption processes were carried out in a temperature-regulated water bath shaker with 0.1 g of T A-62(MP) beads in 40 mL of V solution to determine the kinetic parameters of vanadium adsorption on the T A-62(MP) beads. Throughout the experimental time, continuous 160 rpm shaking is carried out. Inductively coupled plasma optical emission spectrometry is used to calculate the amount of vanadium that remains in each sample after adsorption at various time intervals. Figure 4 illustrates that the adsorption of vanadium increases as the equilibration time increases. Within 15 min, the T A-62(MP) can remove approximately 70% of vanadium. At 180 min, 97.5% of vanadium has been removed. The percentage of vanadium removal was increased rapidly up to 180 min before reaching equilibrium, suggesting monolayer coverage of vanadium on the resin surface. The mechanism of vanadium removal by T A-62(MP) resin was governed by electrostatic adsorption. Because of the large number of adsorption sites available on the resin matrix, the removal percentage of vanadium was fast at first. Since the active sites on the resin matrix were saturated after equilibration, increasing the interaction period had no effect on vanadium adsorption.

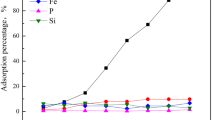

4.3 Resin dosage effect

Equilibrium capacity tests on the resin T A-62(MP) were carried out with a concentration of 40 mg L−1 and varying the amount of resin from 0.020 to 0.140 g and equilibrating for 3 h at 6.5 pH. Figure 5 illustrates that the necessary resin dosage for optimum uptake of vanadium is 0.1 g, above which the percent removal does not improve significantly [36, 37]. It is possible to infer that raising the adsorbent dose improves removal efficiency, while there was a decrease in adsorption density, which can be explained by the fact that certain adsorption sites during the adsorption phase remain unsaturated. Experiments show that the removal of vanadium increases as the quantity of resin increases since the amount of available sites increases.

4.4 Vanadium concentration effect

The effect of the different concentration ranges of vanadium on T A-62(MP) is investigated. V solution concentrations were taken from 30 to 100 mg L−1. Figure 6 shows that as the initial concentration of the adsorbate in an aqueous medium increases at a constant temperature at 303 K, the removal of vanadium decreases. This is because at first, the resin matrix has the most active sites available for adsorption, and as the concentration of vanadium ions rises, the resin matrix becomes saturated with vanadium. This reduces the amount of vanadium uptake.

4.5 Adsorption isotherms

The sorption mechanism is a fascinating topic for predicting metal partitioning between a solution and a solid. Metal adsorption by various adsorbents can be defined using the Langmuir and Freundlich isotherms [38, 39]. At constant temperature, these isotherms link metal uptake (qe) to the adsorbates’ equilibrium concentration (Ce). These models are defined in broader terms below.

Langmuir isotherm equation can be as follows:

The Langmuir constants As (mol g−1) and Kb (l mol−1) are related to ion exchange capacity and adsorption energy, respectively.

The dataset for the sorption process of vanadium by the T A-62(MP) is processed using the Langmuir equation in its linear form. As shown in Fig. 7 for the resin T A-62(MP), the linear model explains that the aggregation of a solute by the adsorbent is directly proportional to the concentration of the solution. The equilibrium adsorption data is well fit by the Langmuir isotherm. The results show that, under the studied conditions, the resin has a higher capacity and affinity for removing vanadium from solutions.

Freundlich isotherm describes the vanadium adsorption on T A-62(MP) resin. It defines the relationship between the amount of adsorbed metal per unit mass of adsorbent and the equilibrium metal concentration (Ce). Freundlich isotherm in its most basic context is:

Here, x represents the quantity of adsorbed metal, Ce represents the equilibrium concentration, m represents the quantity of adsorbent, and n and k represent the strength of adsorption and adsorption capacity, respectively. The equation is written in a logarithmic form as:

The relationship between the resin’s adsorption potential and vanadium concentration at equilibrium is investigated using the Freundlich equation (Fig. 8). Table 3 lists the measurements of the Freundlich and Langmuir isotherms. In addition, n which is Freundlich constant indicates greater interaction between T A-62(MP) and vanadium in the range of 1–10. For the T A-62(MP), the Freundlich constant (n) is found to be 3.20. A dimensionless parameter known as the separation factor [40, 41] can be used to analyze the Langmuir equation, as shown.

Here, the Langmuir constant is Kb, and the initial concentration of vanadium is Co (mg L−1). The adsorption on T A-62(MP) is found to be favorable since 0 < RL < 1 (Table 3).

4.6 Characterization of the Tulsion A-62(MP) before and after vanadium adsorption

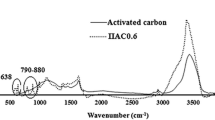

Scanning electron microscopic (SEM) of T A-62(MP) shows the surface of the T A-62(MP) before (Fig. 9a) and after vanadium adsorption (Fig. 9b), giving a picture of the crust of vanadium on the surface of T A-62(MP). Figure 9c depicts the pore surface of the T A-62(MP), while Fig. 9d shows the pore surface covered by vanadium, which is also detected in the point and shoot method (Fig. 10). In addition, the specific surface area (SSA) of T A-62(MP) was 21.5 m2g−1, and after adsorption of vanadium, it was found to be 23 m2g−1 which shows that SSA had increased due to vanadium adsorption; this might be because the vanadium has its own surface area and has contributed to the increase. Meanwhile, after the adsorption process, 1.94% wt. V2O5 was found in the elemental composition of T A-62(MP) by point and shoot method in SEM–EDX (Fig. 10) which indicates that vanadium had been adsorbed throughout the surface of the T A-62(MP). Figure 11 illustrates the Fourier transform infrared (FTIR) spectra of as is T A-62(MP) and after adsorption of V on T A-62(MP). The FTIR spectrum of the exchanger (Fig. 11) revealed that a wide peak at about 3428 cm−1 is of the hydroxyl group’s O–H stretching vibration [42]. Peaks at 3015, 2924, and 2856 cm−1, on the other hand, refer to the C-H stretching of the aromatic ring of the polystyrene divinylbenzene matrix of the resin [43]. Furthermore, a major peak at 1458 cm−1 is due to CH2 bending of the quaternary ammonium functional group [38]. The FTIR spectrum of T A-62(MP) taken after the adsorption studies shows a band at 1119 cm−1, which reveals the presence of V = O bonds. This confirms the presence of vanadium on the T A-62(MP) (Table 4).

4.7 Study of thermodynamic parameters

The Van’t Hoff equation can be applied to study thermodynamic parameters and it is given by Eq. (8) [44].

The change in enthalpy ΔH0 and change in entropy ΔS0 of the adsorption process were determined from the slope and intercept of plot ln Kd vs. 1/T.

The Gibbs free energy ΔG0 is calculated by using Eq. (9):

Table 5 represents thermodynamic data generated for the adsorption study; the negative ΔG0 value indicates that the adsorption of vanadium on T A-62 (MP) is feasible and spontaneous. The positive ΔH0 value suggests the endothermic nature of the adsorption process. The positive ΔS0 value indicates the increase in randomness at the solid-solute interface during the adsorption of vanadium.

5 Conclusions

The surface-activated T A-62(MP) ion exchange resin having a quaternary ammonium functional group has been found to be the capable polymeric substance that can be used for the removal of vanadium from polluted water. Here, the studies on T A-62(MP) suggest that this surface-activated resin efficiently removes vanadium from aqueous solutions in the pH range of 6.0 to 7.0, and the efficiency increases with an increase in resin dosage, as 0.25 g of surface-activated T A-62(MP) removed more than 99.9% of 40 mg L−1. Vanadium and the thermodynamic study conclude that as the temperature of the solution increases, vanadium removal percentage increases showing endothermic nature of the adsorption process. Adsorption kinetics is influenced by resin dosage and vanadium concentration. Equilibrium data followed the Freundlich and Langmuir isotherms. Here, the Freundlich constant (n) is found to be 3.20, which suggests greater interaction between the T A-62(MP) and vanadium ions. The non-dimensional separation factor is a strong predictor of vanadium adsorption (RL). Surface-activated T A-62(MP) was found to be a capable material for the removal of vanadium from aqueous solutions.

Availability of data and material

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

Code availability

Not applicable.

Abbreviations

- T A-62(MP):

-

Tulsion A-62 (macroporous)

- qe :

-

Quantity of adsorbate adsorbed at the time of equilibrium (mg g−1)

- Qo :

-

Langmuir constant (Langmuir adsorption capacity) (mg g−1)

- Co :

-

Adsorbate initial concentration (mg L−1)

- Ce :

-

Adsorbate concentration at equilibrium time (mg L−1)

- SSA:

-

Specific surface area

- RL :

-

Equilibrium parameter

References

B. Volesky, Detoxification of metal-bearing effluents: biosorption for the next century. Hydrometallurgy 59, 203–216 (2001)

A. Bhatnagar, A.K. Minocha, D. Pudasainee, H.K. Chung, S.H. Kim, H.S. Kim, G. Lee, B. Min, B.H. Jeon, Vanadium removal from water by waste metal sludge and cement immobilization. Chem. Eng. J. 144, 197–204 (2008)

M. Dehghani, Assessment of heavy metals concentration in water and sediments international wetland of Khuran Straits. J. Sci. Res. Environ. Sci. 3, 180–188 (2015)

A. Padilla-Rodríguez, J.A. Hernández-Viezcas, J.R. Peralta-Videa, J.L. Gardea-Torresdey, O. Perales-Pérez, F.R. Román-Velázquez, Synthesis of protonated chitosan flakes for the removal of vanadium (III, IV and V) oxyanions from aqueous solutions. Microchem. J. 118, 1–11 (2015)

Bureau of Indian Standards, Discharge limits of the effluents. New Delhi: IS, p 2490 (1981)

I.T. Burke, W.M. Mayes, C.L. Peacock, A.P. Brown, A.P. Jarvis, K. Gruiz, Speciation of arsenic, chromium, and vanadium in red mud samples from the Ajka spill site. Hungary. Envi. Sci. & Tech. 46, 3085–3092 (2012)

I.T. Burke, C.L. Peacock, C.L. Lockwood, D.I. Stewart, R.J.G. Mortimer, M.B. Ward, P. Renforth, K. Gruiz, W.M. Mayes, Behavior of aluminum, arsenic, and vanadium during the neutralization of red mud leachate by HCl, gypsum, or seawater. Environ. Sci. Technol. 47, 6527–6535 (2013)

H.I. Gomes, A. Jones, M. Rogerson, I.T. Burke, W.M. Mayes, Vanadium removal and recovery from bauxite residue leachates by ion exchange. Environ Sci Pollut Res 23, 23034–23042 (2016)

L. Hao, B. Zhang, C. Tian, Y. Liu, C. Shi, M. Cheng, C. Feng, Enhanced microbial reduction of vanadium (V) in groundwater with bioelectricity from microbial fuel cells. J. Power Sources 287, 43–49 (2015)

Y. Jiang, B. Zhang, C. He, J. Shi, A.G.L. Borthwick, X. Huang, Synchronous microbial vanadium (V) reduction and denitrification in ground water using hydrogen as the sole electron donor. Water Res. 141, 289–296 (2018)

V. Dogan, S. Aydin, Vanadium (V) removal by adsorption onto activated carbon derived from starch industry waste sludge. Sep. Sci. Technol. 49, 1407–1415 (2014)

S. Muthusaravanan, N. Sivarajasekar, J.S. Vivek, T. Paramasivan, M.U. Naushad, J. Prakashmaran, V. Gayathri, O.K. Al-Duaij, Phytoremediation of heavy metals: mechanisms, methods, and enhancements. Environ. Chem. Lett. 16, 1339–1359 (2018)

S.E. Bailey, T.J. Olin, R.M. Bricka, D.D. Adrian, A review of potentially low-cost sorbents for heavy metals. Water Res. 33, 2469–2479 (1999)

H. Sharifpour, N. Javid, M. Malakootian, Investigation of single-walled carbon nanotubes in removal of Penicillin G (Benzyl penicillin sodium) from aqueous environments. Desalin. Water Treat. 124, 248–255 (2018)

N. Javid, Z. Honarmandrad, M. Malakootian, Ciprofloxacin removal from aqueous solutions by ozonation with calcium peroxide. Desalin. Water Treat. 174, 178–185 (2020)

M. Malakootian, H. Mahdizadeh, A. Nasiri, F. Mirzaienia, M. Hajhoseini, N. Amirmahani, Investigation of the efficiency of microbial desalination cell in removal of arsenic from aqueous solutions. Desalination 438, 19–23 (2018)

A.H. Mahvi, M. Malakootian, M.R. Heidari, Comparison of polyaluminum silicate chloride and electrocoagulation process, in natural organic matter removal from surface water in Ghochan, Iran. J. Water Chem. Technol. 33, 377–385 (2011)

F. Fu, Q. Wang, Removal of heavy metal ions from wastewaters: a review. J. Environ. Manage. 92, 407–418 (2011)

A. Ihsanullah, A.M. Abbas, T. Al-Amer, M.J. Laoui, M.S. Al-Marri, M. Nasser, M. Khraisheh, Ali Atieh, Heavy metal removal from aqueous solution by advanced carbon nanotubes: critical review of adsorption applications. Sep. Purif. Technol. 157, 141–161 (2016)

C. Namasivayam, D. Sangeetha, Removal and recovery of vanadium (V) by adsorption onto ZnCl2 activated carbon: kinetics and isotherms. Adsorption 12, 103–117 (2006)

M.M. Meimand, N. Javid, M. Malakootian, Adsorption of sulfur dioxide on clinoptilolite/nano iron oxide and natural clinoptilolite. Health Scope 8 (2019)

E. Erdem, N. Karapinar, R. Donat, The removal of heavy metal cations by natural zeolites. J. Colloid Interface Sci. 280, 309–314 (2004)

M.S. El-Geundi, Pore diffusion model for the adsorption of basic dyestuffs onto natural clay in batch adsorbers. Adsorpt. Sci. Technol. 9, 109–120 (1993)

H. Sharififard, M. Soleimani, Performance comparison of activated carbon and ferric oxide-hydroxide-activated carbon nanocomposite as vanadium (V) ion adsorbents. RSC Adv. 5, 80650–80660 (2015)

M.J.V. Thamilarasi, P. Anilkumar, C. Theivarasu, M.V. Sureshkumar, Removal of vanadium from wastewater using surface-modified lignocellulosic material. Environ Sci Pollut Res 25, 26182–26191 (2018)

S. Jana, J. Ray, D. Jana, B. Mondal, S.K. Bhanja, T. Tripathy, Removal of vanadium (IV) from water solution by sulfated Katira gum-cl-poly (acrylic acid) hydrogel. Colloids Surf. A 566, 70–83 (2019)

A. Belloa, T. Leiviskäa, R. Zhanga, J. Tanskanena, P. Maziarzb, J. Matusikb, A. Bhatnagarc, Synthesis of zerovalent iron from water treatment residue as a conjugate with kaolin and its application for vanadium removal. J. of Hazardous Materials 374, 372–381 (2019)

H. Gogoi, R. Zhang, J. Matusik, T. Leiviska, J. Ramo, J. Tanskanen, Vanadium removal by cationized sawdust produced through iodomethane quaternization of triethanolamine grafted raw material. Chemosphere 278, 130445 (2021)

R. Zhang, T. Leiviskä, Surface modification of pine bark with quaternary ammonium groups and its use for vanadium removal. Chem. Eng. J. 385, 123967 (2020)

Y. Yang, Hong-Yi Li, Min-Min Lin, B. Xie, Batch studies for removing vanadium (V) and chromium (VI) from aqueous solution using anion exchange resin. Rare Metal Technol. 291–298 (2018)

Z.A. Al-Jasera, M.F. Hamodab, Removal of nickel and vanadium from desalination brines by ion-exchange resins. Desalin. Water Treat. 157, 148–156 (2019)

E. Pehlivan, T. Altun, Ion-exchange of Pb2+, Cu2+, Zn2+, Cd2+, and Ni2+ ions from aqueous solution by Lewatit CNP 80. J. Hazard. Mater. 140, 299–307 (2007)

W. Li, Y. Zhang, T. Liu, J. Huang, Y. Wang, Comparison of ion exchange and solvent extraction in recovering vanadium from sulfuric acid leach solutions of stone coal. Hydrometallurgy 132, 1–7 (2013)

A. Ayuso, G. Sanchez, X. Querol, Purification of metal electroplating wastewaters using zeolites. Water Res. 37, 4855–4862 (2003)

P.S. Koujalagi, S.V. Divekar, R.M. Kulkarni, Adsorption studies of hexavalent chromium on weak base macroporous anion exchanger Tulsion A 2X(MP) in water and organic solvent mixed media. Asian J. Chem. 30, 1083–1087 (2018)

S. Rengaraj, K.H. Yeon, S.Y. Kang, J.U. Lee, K.W. Kim, S.H. Moon, Studies on adsorptive removal of Co(II), Cr(III), and Ni(II) by IRN77 cation-exchange resin. J. Hazard. Mater. B92, 185–198 (2002)

S. Rengaraj, S.H. Moon, Kinetics of adsorption of Co (II) removal from water and wastewater by ion exchange resins. Water Res. 36, 1783–1793 (2002)

K. Bedoui, I. Bekri-Abbes, E. Srasra, Removal of cadmium (II) from aqueous solution using pure smectite and Lewatite S 100: the effect of time and metal concentration. Desalination 223, 269–273 (2008)

Q. Yu, P. Kaewsarn, Binary adsorption of copper (II) and cadmium (II) from aqueous by biomass of marine alga Durvillaea potatorum. Sep. Sci. Technol. 34, 1595–1606 (1999)

S.K. Sahu, P. Meshram, B.D. Pandey, V. Kumar, T.R. Mankhand, Removal of chromium (III) by cation exchange resin, Indion-790 for tannery waste treatment. Hydrometallurgy 99, 170–174 (2009)

P.K. Malik, Dye removal from wastewater using activated carbon developed from sawdust: adsorption equilibrium and kinetics. J. Hazard. Mater. 113, 81–88 (2004)

S. Ghosh, K.J. Dhole, M.K. Tripathy, R. Kumar, R.S. Sharma, FTIR spectroscopy in the characterization of the mixture of nuclear grade cation and anion exchange resins. J. Radioanal. Nuclear Chem. 304, 917–923 (2015)

S.M. Alshehri, M. Naushad, T. Ahamad, Z.A. Alothman, A. Aldalbahi, Synthesis, characterization of curcumin based eco-friendly antimicrobial bio-adsorbent for the removal of phenol from aqueous medium. Chem. Eng. J. 254, 181–189 (2014)

B. Singha, S.K. Das, Biosorption of Cr (VI) ions from aqueous solutions: kinetics, equilibrium, thermodynamics and desorption studies. Colloids Surf. B. Biointerfaces 84, 221–232 (2011)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest/Competing interests

The authors declare no competing interests.

Rights and permissions

About this article

Cite this article

Gurjar, V.R., Koujalagi, P.S., Revankar, H.N. et al. Adsorptive removal of vanadium from aqueous media by ion exchange resin. emergent mater. 5, 1543–1551 (2022). https://doi.org/10.1007/s42247-021-00251-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42247-021-00251-0