Abstract

Herein, we demonstrate a simple approach for the fabrication of MWCNT film on PVDF (polyvinylidene difluoride) membrane using vacuum filtration set-up. PVDF is a fluoropolymer with large number of applications as binder/separator in batteries and supercapacitors. In this work, a stable CNT/PVDF paper was formed. The film was then characterized by field emission scanning electron microscopy, X-ray diffractometry, and Fourier-transformed infrared spectroscopic techniques. The conductive paper was tested for super capacitor application. This study may pave a new way to make polymer-carbon nanomaterial and nanotube composite, which can have various applications in the field of strain sensors, flexible conductors, supercapacitors, and flexible batteries.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Down the line requests for the advanced flexible and stretchable energy storing devices are expanding day by day. These devices have many potential applications in wearable and convenient electronic gadgets, electronic paper, and wearable frameworks for individual media [1,2,3]. Various carbon-based materials like carbon nanotubes (CNTs), graphene, and their hybrids with other nanomaterials have shown application in various fields [4,5,6]. Especially in the field of conductive flexible materials, these materials have been coated onto a paper substrate by various methods like inkjet printing [6], airbrushing [7], sputtering [8], Meyer rod coating, spray coating, and gravure coating [9, 10]. Among flexible devices, polymer-based supercapacitors (Poly-SCs) are equipped for advantages like high performance, small size, and lightweight [11, 12]. Compared with the other energy storage devices, Poly-SCs have high power density, long life cycle, and wide range of working temperature. Flexible and binder-free electrodes with outstanding stability and conductivity are in demand. Activated carbons are most commonly utilized as electrode materials for the supercapacitor applications.

Carbon nanotubes (CNTs) have great potential to be utilized in flexible electronics due to its outstanding properties. Multi-walled carbon nanotubes (MWCNTs) have cylindrical shape and hexagonal lattice structure and have unique kind of physical [11], chemical, structural, and mechanical properties [12]. The hybrids of carbon nanotubes with graphene showed many advanced applications in flexible electronics and energy storage [13]. However, full potential of carbon nanotubes for many applications is still unharnessed [1]. MWCNTs have high aspect ratio and surface area, which can provide an advantage in loading of other nanomaterials on its surface. MWCNTs have been utilized in the field of energy storage–related applications like solar cells [1, 14], lithium-ion batteries [15], and supercapacitors [16]. Supercapacitors are mainly of two types; one is electrochemical double-layer capacitor (EDLC) and another is pseudocapacitor [1]. The EDLC depends on carbon material like graphite, graphene, SWCNT, and MWCNTs. Carbon-based nanomaterials are used for supercapacitor electrode materials resulting in high specific capacitance value. This is attributed to the high charge separation capacity of MWCNTs between the electrode and electrolyte [17]. The efficiency of a supercapacitor highly depends on the ionic conductivity of the electrolyte used [1]. Specific surface area plays an important role for electrode material to obtain high specific capacitance [18].

The present work demonstrates the fabrication and characterization of the functionalized MWCNT films by using vacuum filtration technique. Functionalization of MWCNTs was done by acid treatment. The fabricated electrodes were characterized by FESEM, X-ray diffraction, FTIR, cyclic voltammetry (supercapacitor performance), and current-voltage measurement system.

2 Materials and methods

2.1 Materials

MWCNTs with a length of 10–30 μm were purchased from Nanoshel, India. HNO3, phosphate-buffered saline (pH -7.2), N-hydroxysuccinimide, and 1-(3-dimethylaminopropyl)-3-ethyl carbodiimide hydrochloride were purchased from SRL, India and H2SO4 was purchased from Merck, India.

2.2 Functionalization of MWCNTs

MWCNT carboxyl functionalization was done by chemical method. One hundred milligrams of MWCNTs was dissolved in180 mL acid solution of H2SO4/HNO3 (3:1, v/v ratio) [19, 20] and allowed to react for 4 h. After the completion of this reaction, the sample was dissolved in deionized water and vacuum filtered through a PVDF filter paper (0.22-μm pore size).

2.3 Preparation of the electrode

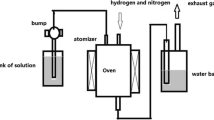

Eighty milligrams of acid-oxidized MWCNTs (1 mg/mL) was dissolved in 80 mL of deionized water. Forty milliliters of this solution was filtered by vacuum filtration through PVDF membrane (pore size 0.22 μm). Acid oxidized-MWCNT film on PVDF membrane was treated with 20 mL of EDC (25 mM)/NHS (12.5 mM) solution in filtration funnel without applying vacuum. The filtrate is passed through the membrane 4 times without vacuum. Afterwards, 1 mL of tri-ethylene-tetra-amine was allowed to react with the MWCNT/PVDF film. As a result of this process, amine-functionalized MWCNT film on PVDF (amine-FMWCNT/PVDF film) was obtained. Forty milliliters of remaining acid-oxidized carbon nanotubes was added to the membrane in the same filtration funnel followed by the addition of 20 mL of EDC/NHS. The filtrate was allowed to pass through the membrane repeatedly for four times for complete attachment of carbon nanotubes followed by washing with DI water and hot air drying. Schematic of the process is displayed in Fig. 1.

3 Results and discussion

3.1 X-ray Diffractometry

X-ray diffraction (XRD) was used to study the interplanar dividing and structure of MWCNTs. The diffractograms have been recorded using Rigaku Minifles-600 X-ray diffractometer using Cu Kα as characteristic wavelength (1.54 Å) at an operating voltage of 40 kV. XRD pattern was recorded with 2θ scan range from 20–70°. Figure 2 demonstrated the XRD spectra of amine-functionalized MWCNT/PVDF film. The XRD pattern of amine-functionalized MWCNT/PVDF film prepared by vacuum filtration assembly shows major diffraction peak at 2θ = 24.16° (Fig. 2), which corresponds to interplaner spacing of 0.36 nm. The interplanar spacing has been calculated by Bragg’s law:

where the crystal plane is (002) for corresponding angle of 24.16° as compared with normal graphite, 2θ = 26.5°; this peak shows a downward shift, which indicates the increase in interlayer spacing [21].

3.2 FTIR spectroscopy

FTIR study was carried out on Shimadzu IR affinity 1S at a range from 400 to 4000 cm−1 for both amine-functionalized and acid-oxidized MWCNTs (Fig. 3). Acid-oxidized MWCNT nanotubes show absorption peak at 1732 cm−1 attributing to C=O bond stretching vibrations of –COOH functional groups grafted on the surface of nanotubes, whereas in case of amine-functionalized MWCNTs (amine-FMWCNTs), peaks were observed at 1013, 1632, and 3320 cm−1 corresponding to stretching vibrations of C–O, N–H, and N–H bonds respectively (Fig. 3).

3.3 Microstructural properties

Field emission scanning electron microscope (FESEM) is utilized to examine the morphology of amide bond–interlinked MWCNT film (Fig. 4). The figure clearly indicates the embedment of nanotubes in the pores of PVDF membrane as well as the crosslinking of the MWCNTs.

3.4 Electrochemical performance study

The electrochemical performance of the amine-FMWCNT/PVDF film was studied by cyclic voltammetry and galvanostatic charge-discharge (CV-CD) measurement using Metrohm Autolab potentiostat (Fig. 5). We have used Ag/AgCl as reference electrode and platinum wire as counter electrode, and the prepared film (cross-linked MWCNT/PVDF film) was used as working electrode. 1M H2SO4 solution was used as electrolyte. Figure 5 a shows the CV response curve of the film. Primarily, we studied the electrochemical performance of the prepared film at 10 mV/s scan rate in 1 M H2SO4 (Fig. 5a). Specific capacitance can be calculated by surface area of the curve [22, 23]. Further, we carried out a detailed study of CNT-based electrodes at different scan rates, i.e., 10 mV/s, 20 mV/s, 30 mV/s, 50 mV/s, and 100 mV/s (Fig. 5b). The potential window for CV analysis was kept from − 0.1 V to 0.6 V. It can be clearly seen that a lower scan rate gives high current value. Charge-discharge curve of different scan rates is shown in Fig. 5c. Specific capacitance Cs of the fabricated electrodes was calculated using the following equation (1).

The electrochemical performance of the amine-FMWCNT/PVDF film. a Cyclic voltammetry (CV) curves of amine-FMWCNT/PVDF film at the scan rate of 10 mV/s. b Cyclic voltammetry curve for various scan rates. c Charge-discharge curve of different scan rates. d Relation between different scan rates and specific capacitance

I is the current (A) which shows by area under the curve found from cyclic voltammogram, m is the mass of deposited films in grams, and S is the scan rate in millivolts per second.

In this study, it is clearly seen that at various scan rates, Cs values were 24.2 F/g, 23.4 F/g, 21.6 F/g, 19.5 F/g, and 16.4 for the 10 mV/s, 20 mV/s, 30 mV/s, 50 mV/s, and 100 mV/s respectively (Fig. 5d). From the above study, it is clear that the highest specific capacitance (Cs) was calculated by a low scan rate at 10 mV/s. The results were favorable for the electrochemical energy storage using flexible MWCNT/PVDF electrode.

4 Conclusion

In this study, we have prepared a covalently cross-linked network of carbon nanotubes on PVDF membrane. The covalent bonding was confirmed by FTIR spectroscopy. Morphological studies carried out by FESEM microscopy indicated the embedment of CNTs in PVDF membrane pores and crosslinking of the nanotubes. Explicit capacitance of the film was determined utilizing cyclic voltammetry. Higher Cs is obtained at low scan rates.

References

A. You, M. A. Y. Be, and I. In, MWCNTs-PANi nanocomposite films prepared by AC-EPD technique and its potential for enhance supercapacitor electrode. AIP Conf Proc vol. 1875, no.1, pp. 020008, 2017

B. F. Bøguin and K. Szostak, A Self-supporting electrode for Supercapacitors prepared by one-step pyrolysis of carbon nanotube / Polyacrylonitrile blends, Adv. Mater., vol. 17, no. (19), pp. 2380–2384, 2005

S.A. Bansal, A.P. Singh, A. Kumar, S. Kumar, N. Kumar, J.K. Goswamy, Improved mechanical performance of bisphenol-a graphene-oxide nanocomposites. J. Compos. Mater. 52(16), 2179–2188 (2018)

S.A. Bansal, A.P. Singh, S. Kumar, Reinforcing graphene oxide nano particles to enhance viscoelastic performance of epoxy nano-composites. J. Nanosci. Nanotechnol. 18, 1–7 (2018)

S.A. Bansal, A.P. Singh, S. Kumar, High strain rate behavior of epoxy graphene oxide nanocomposites. Int. J. Appl. Mech. 10(07), 1850072 (2018)

L. Yang, S. Member, A. Rida, S. Member, R. Vyas, RFID tag and RF structures on a paper substrate using inkjet-printing technology. IEEE Trans Microwave Theory Tech 55(12), 2894–2901 (2007)

A. Asadpoordarvish, A. Sandström, C. Larsen, R. Bollström, M. Toivakka, R. Österbacka, L. Edman, Light-emitting paper. Adv Funct Mater 25(21), 3238–3245 (2015)

M. Hsieh, C. Kim, M. Nogi, K. Suganuma, Electrically conductive lines on cellulose nanopaper for flexible electrical devices. Nanoscale 5, 9289–9295 (2013)

A. Yu, Victor Chabot and Jiujun Zhang (Fundamentals and Applications, CRC Press, Electrochemical Supercapacitors for Energy Storage and Delivery, 2017)

B.C. Liu, F. Li, L. Ma, H. Cheng, Advanced materials for energy storage. Adv. Mater. 22(8), 28–62 (2010)

R. Souad et al., Microporous activated carbon electrode derived from date stone without use of binder for capacitive deionization application. Mater. Res. Bull. 111, 342–349 (2018)

S.A. Bansal et al., Synergistic effect of graphene and carbon nanotubes on mechanical and thermal performance of polystyrene. Mater Res Express 5(7), 075602 (2018)

K. Xia, H. Zhan, Y. Gu, Graphene and carbon nanotube hybrid structure : A review. Procedia IUTAM 21, 94–101 (2017)

N. Cheng et al., Multi-walled carbon nanotubes act as charge transport channel to boost the efficiency of hole transport material free perovskite solar cells. J. Power Sources 332, 24–29 (2016)

L.G. Bulusheva et al., Fabrication of free-standing aligned multiwalled carbon nanotube array for Li-ion batteries. J. Power Sources 311, 42–48 (2016)

D. Ma, J. Cai, X. Wu, H. Xu, Y. Tian, H. Zhao, Supercapacitor electrode materials treatment of multiwall carbon nanotubes based on the modified hummers method for supercapacitor electrode materials. J Renewable and Sustainable Energy 8, 01410 (2016)

L. Dong, W. Xue, D. Jinxing, Z. Chenglong, G. Jinshan, L. Peng, Crosslinked carbon nanotubes/Polyaniline composites as a Pseudocapacitive material with high cycling stability. Nanomaterials 5, 1034–1047 (2015)

C. Fu, H. Zhou, R. Liu, Z. Huang, J. Chen, Y. Kuang, Supercapacitor based on electropolymerized polythiophene and multi-walled carbon nanotubes composites. Mater. Chem. Phys. 132(2–3), 596–600 (2012)

S. Kumar, I. Kaur, K. Dharamvir, L.M. Bharadwaj, Controlling the density and site of attachment of gold nanoparticles onto the surface of carbon nanotubes. J. Colloid Interface Sci. 369(1), 23–27 (2012)

S. Kumar, H. Kaur, H. Kaur, Magnetic field-guided orientation of carbon nanotubes through their conjugation with magnetic nanoparticles. J. Mater. Sci. 47, 1489–1496 (2012)

H. Misak, R. Asmatulu, Functionalization of carbon nanotube yarn by acid treatment. International Journal of Smart and Nano Materials 5(1), 34–43 (2016)

K. Pradeeswari, A. Venkatesan, P. Pandi, K. Karthik, K.V.H. Krishna, R.M. Kumar, Study on the electrochemical performance of ZnO nanoparticles synthesized via non-aqueous sol-gel route for supercapacitor applications study on the electrochemical performance of ZnO nanoparticles synthesized via nonaqueous sol-gel route for supercapacitor applications. Materials Research Express 6(10) (2019). https://doi.org/10.1088/2053-1591/ab3cae

A. Hübler et al., Printed paper photovoltaic cells. Adv Energy Mater 1(6), 1018–1022 (2011)

Acknowledgments

The authors thank the University Grants Commission, New Delhi, India for Rajiv Gandhi National Junior Research Fellowship. Suresh Kumar would like to thank the Department of Science and technology, Science and Engineering Research Board (SERB), New Delhi, India for the ECRA research grant. The authors are thankful to the Department of Physics, Panjab University, Chandigarh, for XRD measurements. Parveen Kumar thanks the director of CSIR-CSIO for providing necessary infrastructure facility and acknowledges the Department of Science and Technology for INSPIRE faculty award.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Twinkle, Kaur, M., Gowsamy, J.K. et al. Synthesis and characterization of CNT/PVDF paper for electronic and energy storage applications. emergent mater. 3, 181–185 (2020). https://doi.org/10.1007/s42247-020-00074-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42247-020-00074-5