Abstract

Predicting labour productivity accurately in critical activities like formwork erection would enable management interventions to improve the site situations especially in the context of high-rise building construction. In this study, Artificial Neural Networks (ANNs) were employed to model and predict three categories of formwork erection activities–aluminium formwork, horizontal formwork and vertical formwork. 16 input factors were identified and a total of 19,344 data points from 42 construction sites all over India were used to train and validate the ANN models. The developed models show a high degree of accuracy in predicting the productivity on sites. The models also give major insights into the factors affecting the productivity of formwork related activities. The adverse effects of some factors like the number of workers on the site were also discussed. The study indicates the usefulness of data-driven techniques for prediction of labour productivity of formwork activities on Indian construction sites.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

India has witnessed an unprecedented pace of urbanization with 31.2% of the population staying in cities according to the 2011 census (Government of India, 2011). This pace will further accelerate in the coming years, with India being the least urbanized country among the top economies in the world and the patterns of rural–urban migration, suggesting a strong trend towards urbanization (Chandrasekhar & Sharma, 2015). The major cities in the country have witnessed tremendous growth over the last two decades due to this phenomenon (Chakraborty, 2017).

With increasing population densities to accommodate, the cities across the world have resorted to high-rise construction as a solution (Yeh & Yuen, 2011). High-rise construction brings its own challenges in terms of managing and controlling the project effectively to meet the project's objectives (Santoso, Ogunlana & Minato, 2003). In addition to the safety hazards associated with working at heights, the high-rise construction also poses challenges in terms of logistics of the shifting and erecting material to the work-front (Chin et al., 2008).

In India, with reinforced concrete as the predominant material used in construction, one of the critical challenges entail around formwork activities in high-rise construction. A high degree of resources in terms of manpower, time and cost are spent on the erection of the formwork, the removal of the formwork after the concrete is poured and the shifting of the formwork to new locations. Predicting the labour productivity in these activities will immensely help in strategizing the activities, thus leading to effective management on such projects. In the present study, an attempt is made to understand the factors affecting labour productivity in the formwork erection activities in high-rise buildings. A predictive model using ANN was developed to understand the contribution of such factors to the labour productivity. The intuitions derived from the model are discussed and the implications to both research and practise are presented in this article.

Theoretical background

Productivity is an important measure to understand the efficiency of the resources involved in a construction project, thus having a significant impact on the efficacy in completing a project on time and within budget. Productivity rates in the construction industry are the basis for accurately estimating the time and cost necessary for completing a project. Traditionally, the productivity is defined as the ratio of output to the input for any given task (Cosmetatos & Eilon, 1983).

The output is usually measured by the number of units of the particular activity which is usually linked to the payment norms on the project. The input might consist of the effort or money involved in producing the units of output. Productivity calculations can be conducted at various levels, right from the construction sector to individual activities. At any level, again multiple units may be considered, even for an individual task usually termed as total factor productivity (Hulten, 2001).

Such measures consider the factors of material, equipment and labour as inputs to a given task. While materials and equipment may involve significant amounts of money, the highest number of uncertainties exist from the labour perspective alone. Hence, labour productivity is an important measure for the construction managers, as the ratio of output by unit labour effort (usually calculated in man-days or man-hours) is an indicator of the efficiency of the manpower employed on the construction site. Thus, understanding the labour productivity is an important measure to manage and control the construction projects. Labour productivity studies are often employed on a particular activity of interest crucial for the project through construction managers’ perspective. In the context of high-rise building construction, one of the key activities involving the number of skilled manpower is the erection of formwork. Thus, understanding and modelling labour productivity in formwork related activities is deemed essential.

(Kaveh & Iranmanesh, 1998) discusses the analysis and construction of large-scale space structures using two ANN, the back-propagation neural net (BPN) and the improved counterpropagation neural net (CPN). It investigates several facets of these nets and the characteristics that impact how well each net performs. Both of which focus on structural optimization. When dealing with large-scale challenges, the upgraded CPN trains more quickly than BPN. For the identical input, the responses of the BPN and the enhanced CPN are compared.

(Kaveh et al., 2008) The energy method and the force method are integrated in the context of transmission tower optimization to create a comprehensive design and optimization strategy, obviating the necessity for time-consuming matrix inversion. The optimization procedure makes use of a genetic migration method. This approach works well for towers with a small number of pieces, but it is ineffective for the majority of towers that are encountered in practise. The entire processing load is decreased with the adoption of a neural network as an analysis tool.

(Kaveh & Bondarabady, 2004) provides a nodal numbering approach to produce a compact wavefront. Finite element meshes are mathematically modelled using element clique networks. Sloan's function is generalized to a priority function with five vectors, which is employed. The various connection characteristics of the graph models are represented by these vectors. Five coefficients are used instead of the two predefined ones in Sloan’s technique, which is based on an analysis by artificial neural networks. A straightforward evolutionary technique is used to determine the network weights.

(Khanzadi et al., 2017) By this study, a technique based on System Dynamic (SD) simulation is proposed to model labour productivity for various contractor types. A qualitative model is built using cause-and-effect feedback loops. The quantitative model is then constructed using real data from numerous genuine projects and expert opinion to establish the correlations between the various factors. The suggested SD model simulates labour productivity while taking into account all influencing factors. Two models are built and the model is tested on two different types of contractors to increase accuracy. Each contractor’s overall productivity is determined, and the impact of various parameters on labour productivity is examined.

Formwork activities in construction

Formwork activities usually consist of the assembly and erection of a temporary staging area to create a suitable platform for the concrete to be poured into desired shapes as per the design. Further, the formwork allows the concrete to take the desired shape, set and gain strength by providing support to the concrete structure. When the concrete gains sufficient strength, the formwork is removed in a prescribed systematic manner, so as not to distress the structure. Such activities will involve highly skilled labour with the necessary skills (Props materials selection, props placement scheme) to erect the formwork to the prescribed manner along with sufficient knowledge on stripping time. Such skills are also dependent on the kind of formwork system in place for a given project and the activities for the erection of formwork for vertical members like columns vary significantly from those for the erection of formwork for horizontal members like beams and slabs, in turn affecting the productivity.

On the other hand, the use of aluminium formwork in the construction industry in India is increasing day by day for high-rise buildings, in turn efficiently accelerating the process of construction with less erection time. In addition, there are a number of factors that influence labour productivity, especially in the area of high-rise building construction. The study of labour productivity has been a long-standing theme for researchers in the domain of construction. From the time-motion studies on bricklaying systems by Gilbreth (Gilbreth, 1909), the construction researchers have sought to identify the factors affecting the efficiency of operations in construction.

In the area of formwork productivity, earlier studies have focussed on various aspects. Some of the existing approaches used for the prediction of formwork labour productivity in high-rise building is described over here. Studies have focussed on learning curve effects on formwork productivity in multi-storey buildings (Jarkas, 2010b). However, the influence of site-specific and external factors on productivity after the learning curve effect was not studied in existing works. Some initial studies in this direction on formwork productivity (Smith & Hanna, 1993) were in the direction of understanding the factors influencing formwork productivity especially during the vertical formwork erection. It highlighted the influence of both measurable and non-measurable factors. Further studies focussed on the influence of buildability factors for productivity on foundations (Jarkas, 2010a).

Factors like height and climatic conditions like temperature and humidity as well as crew composition were found to be important in formwork operations (Osama, 2010). Such studies have illustrated the importance of the study of productivity as well as a glimpse of the factors that influence the formwork productivity. However, the existing literature falls short on a few fronts. One, the literature has focussed one or a few productivity-influencing factors influencing the productivity but there is a need to develop a comprehensive model to understand the moderating influence of various factors on construction formwork productivity especially in high-rise buildings. Two, different factors may influence formwork productivity for vertical formwork, horizontal formwork, and so on. Further, the use of system formworks like Aluminium-based formwork might be different from the factors influencing the productivity of normal formwork.

This would be due to the difference in the work methods for horizontal and vertical formworks and the differences in handling normal formwork with aluminium formwork. Such factors should be studied in detail to understand the impact on productivity better. Further, there is a need to analyse data from multiple construction sites to build a robust model of productivity. Hence, a robust technique or tool is essential for the prediction of productivity.

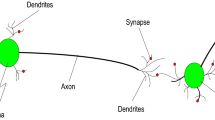

Artificial Neural Networks (ANNs) to estimate labour productivity becomes useful in this scenario. Studies (Osama, 2010; Tam et al., 2002; Zayed & Halpin, 2005) have earlier has utilized ANN in productivity studies related to various activities in construction. Artificial Neural Networks (ANNs) can be used to call various labels in neuromorphic systems or neural computing. ANN is an important application of artificial intelligence. ANN relies on a network model to predict patterns of independent variables that can cause a given outcome.

ANNs are powerful tools and have been used extensively in various fields of research in construction management. For example, ANNs have been used in understanding the disputed change orders in construction (Chen & Hsu, 2007). ANNs were also used in the risk analysis like contractor default (Al-Sobiei et al., 2005). ANNs were also widely employed in the domain of productivity measurement and prediction. Some studies utilized ANNs in understanding the productivity of construction equipment. For example, Tam et al. (2002) estimated the productivity of excavation equipment using ANNs.

Similarly, ANNs were employed in understanding the productivity of particular activities like pile driving (e.g., Zayed & Halpin, 2005). Such research has shown the importance of ANN as an efficient tool especially in productivity research, suitable for understanding tough patterns and the learning capabilities with data would ensure better predictive capabilities. In the present article, the ANN was used to model the labour productivity of various activities related to formwork erections in high-rise building construction. Thus, the main objective of the present study is to develop a predictive model of labour productivity in various activities related to formwork erection in high-rise building construction. Specifically, a back-propagation feed-forward ANN is trained to model and predict the productivity for three categories namely Aluminium, horizontal and vertical formwork erection activities in high-rise building construction.

Research methodology

In this study, to attain the issues in labour productivity an improved algorithm is proposed. A back-propagation feed-forward ANNs (BPF-ANNT) is proposed with one hidden layer. Moreover, the hyperbolic tangent sigmoid function is used as a transfer function other than the normally used transfer functions like sigmoid. The hyperbolic tangent sigmoid function is better than sigmoid activation function. Hyperbolic tangent sigmoid function is also referred as tanh. Since sigmoid activation or transfer function only considers variables between 0 and 1. But the hyperbolic tangent sigmoid function considers variables between − 1 and 1. Hence by this transfer function the negative inputs will also be mapped. Also, the zero inputs will also be mapped in the perfect zero location. Moreover, the hyperbolic tangent sigmoid function fits the feed-forward networks.

The proposed method has been used to predict productivity in aluminium, horizontal and vertical formwork erection activities in high-rise building construction. To this end, the literature review and a brief survey were conducted to understand the factors affecting labour productivity as inputs to the ANN. Accordingly, 16 input factors were identified for the study. The data pertaining to these 16 factors and the productivity observed on the site was calculated over 6 months’ time. Next, the ANN model was developed in the r statistical programming language. The data were split into 80–20 training and validation/test data sets, and the ANN model was trained and validated on the data. The following sections describe these steps in detail.

The proposed ANN is trained by back-propagation algorithm with feed-forward network other than the normally used simulated annealing technique. The mathematical expression of the hyperbolic tangent sigmoid function is equated as (1)

where \({\text{fac}}\) defines the number of input factors used in the network. Within the proposed only one hidden layer is used. Accuracy in the test set will decline if the number of hidden layers is increased beyond the required number of layers. The proposed network will overfit to the training set as a result. It is because it will only be able to generalize to previously unknown data after learning the training set of data. And since only one hidden layer is used in the proposed network overfitting does not occurs. The output unit predicts the probability of formwork labour productivity prediction.

By being trained on examples of input–output pairs, the feed forward back-propagation neural network can learn a function for mapping inputs to outputs. The entire square of the output, as determined by the network, is minimized using the back-propagation neural network. It uses a declining slope algorithm. Additionally, neural networks using back-propagation neural network benefit from faster learning. In feed-forward networks, the neurons can have any transfer function that the designer chooses to employ (Babu, 2013).

Input variables used in the study

A literature review in the area of factors affecting the productivity followed by a brief survey with the 225 field engineers across India was conducted to understand the factors affecting the productivity for formwork erection in high-rise buildings. Based on this, a total of 16 independent variables were identified for the study. The variables so identified along with the scheme of measurement employed in the current study are presented in Table 1.

Data collection and preparation

The data pertaining to the 16 variables and the observed productivity in three different activities–aluminium formwork, horizontal formwork and vertical formwork erection was collected from 42 construction sites over a period of 6 months. A total of 19,344 data points were collected from the sites during this period for the three activities. The collected data was then randomly split into training and validation/test sets for each of the three activities using an 80–20 split. The number of data points used in training and validation for the different activities like Aluminium, horizontal and vertical is given in Table 2.

Development and validation of ANN model

A Back Propagation Neural Network is selected in this research. The ANN model has an input layer for the 16 variables identified. One hidden layer was developed to transform the input variables. The output layer consisted of a hyperbolic tangent sigmoid function which also introduces non-linearity in the predicted output in relation to the input variables. The data was trained for the three activities using neural network code developed in the R programming language. The models so trained are presented below.

ANN model for aluminium formwork

The ANN model developed for Aluminium formwork (Fig. 1) and the corresponding weights of the predicted equation generated by ANN after training is given below.

The corresponding equations for the aluminium formwork productivity in high-rise building construction are given by Eqs. 2 and 3.

ANN model for horizontal formwork

The ANN model developed for horizontal formwork (Fig. 2) and the corresponding weights of the predicted equation generated by ANN after training is given below.

The corresponding equations for the aluminium formwork productivity in high-rise building construction are given by Eqs. 4 and 5.

ANN model for vertical formwork

The ANN model developed for vertical formwork (Fig. 3) and the corresponding weights of the predicted equation generated by ANN after training are given below.

The corresponding equations for the vertical formwork productivity in high-rise building construction are given by Eqs. 6 and 7.

Validity of the developed ANN models

The developed ANN models are then validated against the validation/test data to validate the applicability of the models on construction sites. The validity is tested using 2 major measures namely Mean Absolute Predicted Error (MAPE) and Pearson coefficient of correlation (R). The corresponding measures of Average Accuracy percentage (AAP, related to MAPE) and coefficient of determination (R2 related to R) was also presented for completeness. The parameters are calculated using the following Eqs. 8, 9 and 10.

Table 3 below presents the calculated parameters (from Figs. 4, 5, 6) for the three kinds of formwork activities taken up in this study. As shown in the Table 3, all the parameters indicate that a high degree of prediction accuracy was achieved by the developed models on the validation/test sets thus confirming the validity of the developed models.

The proposed BPF-ANNt algorithm is compared with some other works like ANN without back-propagation algorithm and ANN without back-propagation algorithm with sigmoid transfer function. These exiting works are implemented. From Table 3 it is evident that the proposed algorithm has less error with high accuracy and higher degree of determination when compared with existing methods. It is for all the three framework like Aluminium framework, horizontal framework and vertical framework.

Discussions

The developed ANN models for the three major categories provided good insights into understanding the factors affecting productivity on the high-rise construction projects. First, for the aluminium formwork activities, Height of the structure, Wind speed, Site Logistics, Lift of the structure, have the most significant effect on labour productivity. Similarly, for the horizontal formwork, Age, Experience, Lift of the structure, Weight of the panel, have the most significant effect on the productivity of formwork fixing. Finally, for the vertical formwork, Weight of panel, Size of the panel, Ambient temperature, and Site Safety conditions have the most significant effect on the formwork fixing productivity. All the l6 factors have some form of influence on labour productivity. Further, some factors have a negative impact on the productivity of the sites. Consistently, the number of labour present on the site has a negative impact on labour productivity on the site. This finding is in line with the site conditions usually encountered in high-rise building construction where availability of work front is a major issue. The increase in the number of labour increases the congestion on the site and also imposes additional constraints on the availability of crane to shift requisite material and other logistic issues. Thus, increasing the number of labour might increase the output on a construction site, however, may have an adverse impact of output per labour on the site as well, thus increasing the overall cost of the project. Similarly, weather conditions impose an adverse effect on the productivity, as the work happens at a height and the weather imposes constraints on the visibility of the material shifting, the ease of shifting etc. Thus, the ANN models developed to capture these nuances observed by the sites in general and past literature as well.

Conclusions and future work

The study illustrates the usefulness of ANN as a tool in predicting the labour productivity related to formwork activities in high-rise building construction. The developed ANN models make use of 16 input factors and demonstrated a high level of accuracy in predicting labour productivity corresponding to three formwork related activity categories. Such ANN models, apart from their predictive ability also generate useful managerial insights about understanding the dynamics related to the factors and its influence on labour productivity. Few such factors were discussed in this article.

With the advent of faster computing powers with relatively affordable costs and the ease of collection of data from sites using mobile phones, the study presents a case of value for the construction industry to adopt data-driven management techniques and tools to better manage construction projects. Use of machine learning and artificial intelligence tools like ANN would help us further understand the complex field of construction management and process information in a useful manner to take timely interventions on the project to deliver quality on the project objectives within time and budget in a safe manner. The proposed method produced a good formwork labour productivity prediction. The effectiveness of the proposed method is checked with some existing algorithms. By comparison it is proved that the proposed method has less error rate and high accuracy with high productivity of 99%.

The proposed approach produces reasonable wavefronts. In future its applications to priority functions with more graph parameters will be expanded. Also in future some parameters may also undergo some optimization techniques.

Data availability statement

The authors declare that there is no data associated with the manuscript.

References

Al-Sobiei, O. S., Arditi, D., & Polat, G. (2005). Predicting the risk of contractor default in Saudi Arabia utilizing artificial neural network (ANN) and genetic algorithm (GA) techniques. Construction Management and Economics, 23(4), 423–430.

Babu, G. A., Bhukya, S. N., & Kumar, R. S. (2013). Feed forward network with back propagation algorithm for detection of breast cancer. In 2013 8th International Conference on Computer Science & Education, IEEE, 181–185

Chakraborty, J. (2017). An unequal process of urbanisation. Economic and Political Weekly, 52(9), 90–94.

Chandrasekhar, S., & Sharma, A. (2015). Urbanization and spatial patterns of internal migration in India. Spatial Demography, Springer International Publishing, 3(2), 63–89.

Chen, J. H., & Hsu, S. C. (2007). Hybrid ANN-CBR model for disputed change orders in construction projects. Automation in Construction, 17(1), 56–64.

Chin, S., Yoon, S., Choi, C., & Cho, C. (2008). RFID+ 4 D CAD for progress management of structural steel works in high-rise buildings. Journal of Computing in Civil Engineering, 22(2), 74–89.

Cosmetatos, G. P., & Eilon, S. (1983). Effects of productivity definition and measurement on performance evaluation. European Journal of Operational Research, 14(1), 31–35.

Gilbreth, F. B. (1909). Bricklaying system (pp. 413–416). MC Clark Publishing Company.

Government of India. (2011). India Census 2011, Office of Registrar General and Census Commissioner India, Ministry of Home Affairs, Government of India. New Delhi, Available at: http://www.censusindia.gov.in/2011census/population_enumeration.html, Accessed 24 Apr 2019

Hulten, C. R. (2001). Total factor productivity: a short biography. In New developments in productivity analysis, University of Chicago Press. pp. 1–54.

Jarkas, A. M. (2010a). Buildability factors influencing formwork labour productivity of isolated foundations. Journal of Engineering Design and Technology, 8(3), 274–285.

Jarkas, A. M. (2010b). The impacts of buildability factors on formwork labour productivity of columns. Journal of Civil Engineering and Management, 16(4), 471–483.

Kaveh, A., & Bondarabady, H. R. (2004). Wavefront reduction using graphs, neural networks and genetic algorithm. International Journal for Numerical Methods in Engineering, 60(11), 1803–1815.

Kaveh, A., Gholipour, Y., & Rahami, H. (2008). Optimal design of transmission towers using genetic algorithm and neural networks. International Journal of Space Structures, 23(1), 1–19.

Kaveh, A., & Iranmanesh, A. (1998). Comparative study of backpropagation and improved counterpropagation neural nets in structural analysis and optimization. International Journal of Space Structures, 13(4), 177–185.

Khanzadi, M., Kaveh, A., Alipour, M., & Khanmohammadi, R. (2017). Assessment of labor productivity in construction projects using system dynamic approach. Scientia Iranica, 24(6), 2684–2695.

Osama, M. (2010). Analysis of labour productivity of formwork operations in building construction. Construction Innovation, 10(3), 286–303.

San Santoso, D., Ogunlana, S. O., & Minato, T. (2003). Assessment of risks in high rise building construction in Jakarta. Engineering, Construction and Architectural Management, 10(1), 43–55.

Smith, G. R., & Hanna, A. S. (1993). Factors influencing formwork productivity. Canadian Journal of Civil Engineering, 20(1), 144–153.

Tam, C. M., Tong, T. K. L., & Tse, S. L. (2002). Artificial neural networks model for predicting excavator productivity. Engineering, Construction and Architectural Management, 9(5/6), 446–452.

Yeh, A. G., & Yuen, B. (2011). Introduction: High-rise living in asian cities (pp. 1–8). Springer.

Zayed, T. M., & Halpin, D. W. (2005). Pile construction productivity assessment. Journal of Construction Engineering and Management, 131(6), 705–714.

Funding

This research received no external funding.

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bhilwade, V., Delhi, V.S.K., Nanthagopalan, P. et al. Predicting labour productivity for formwork activities in high-rise building construction: a case study. Asian J Civ Eng 24, 959–968 (2023). https://doi.org/10.1007/s42107-022-00545-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42107-022-00545-6