Abstract

Seismic design codes have minimal criteria and serviceability limits for the strength of structures against a selected earthquake hazard level, neglecting the structural performance during the lifetime. Life-cycle cost analysis (LCCA) includes all the expected damage costs in the lifetime of buildings in terms of all-natural hazards such as the earthquake. In addition, to create an environment-friendly structure, environmental impacts of the entire life-cycle period should be identified and evaluated. Therefore, a novel approach for the sustainable design of reinforced concrete (RC) frames is defined in terms of the life-cycle cost components and societal effects associated with environmental impacts. Expected damage costs included the structural, non-structural, and social damage costs. Environmental impacts have been estimated based on the material consumption during the lifetime due to initial production and operation periods due to repair, and then these impacts were scored. Given the nonlinear behavior of the structure under earthquake excitation, simple response functions have been generated to reduce the analysis time. In this way, the number of nonlinear dynamic analyses which is time-consuming was reduced considerably. The proposed method was used for a RC frame to achieve optimally designed structures by introducing three objective functions. The results indicated that using the proposed methodology, sustainable RC frames were obtained with low computational costs.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Structures are often damaged due to the prolonged operating lifetime, exposure to natural hazards, and degradation phenomena. When the structure is expected to be efficient for a long time, Life-cycle cost analysis (LCCA) is recognized as one of the suitable tools for the performance assessment (Lagaros 2007; Chiu et al. 2010). In addition, for designing structures, it is necessary to consider sustainability goals from a combination of one or more different economic, environmental, and social aspects (Lagaros 2007; Hossain and Gencturk 2014; Hossain 2013; Gencturk et al. 2016). However, reducing environmental impacts through optimizing energy and materials consumption is not usually considered as a design goal in building construction. Note that use of innovative methods to reduce the utilization of materials and thus a reduction in carbon impacts and future losses is required for sustainability (Hossain 2013). Most seismic codes do not pay attention to environmental issues and fail to consider the impacts and costs that a structure produces during its lifetime due to the environmental impacts. Meanwhile, environmental impacts are not corrosive environmental factors, which reduce the strength or stiffness of the structure and can be directly considered in the LCCA. Environmental impacts are generally evaluated independently through scoring.

Regarding studies on the environmental effects of structures, Kawai et al. (2005) provided a common basis for estimating emission inventory data including CO2, SOx, NOx, and particulate matter for assessing the environmental impact of a concrete structure throughout its life-cycle. Hossain and Gencturk (2014) presented a framework for assessing environmental impacts in terms of environmental damage caused by natural hazards in the future as one of the elements of structural sustainability. They developed a method for estimating the environmental factors for RC structures, where emissions were converted according to environmental impact categories by incorporating appropriate factors such as global warming potential, acidification potential, and eutrophication potential. The results indicated that low-cost low-performance design, due to utilizing less material for construction, has fewer environmental impacts in the initial and late stages of lifetime, which significantly affects the operating period. On the other hand, high-cost high-performance design (with less damage under the earthquake excitation) offers an opposite outcome. Varun et al. (2012) conducted a life-cycle environmental assessment of a building to obtain the energy consumption and greenhouse gas (GHG) emissions of the building. They found that RCC framework and steel represent the largest contributions to GHG emissions. Basbagill et al. (2013) provided a method for assessing the life cycle in the decision-making process to inform designers about the contribution of materials on environmental effects. Chou and Yeh (2015) investigated two methods of using pre-fabricated concrete and concrete in situ for a 3-story RC building in terms of carbon dioxide emissions (CO2) and related environmental costs. The main environmental effects in that study were related to those commonly used in the construction industry (such as water, electricity, and fuel). Gencturk et al. (2016) evaluated the sustainability of RC structures at different stages of the life cycle in terms of cost and duration of downtime, emissions of environmental pollutants and waste production, as well as casualties. They revealed that for a more resistant structure, financial costs and environmental impacts can be increased by two and three times, respectively. Ozcan-Deniz and Zhu (2017) added the GHG emissions to the time and cost in the multi-objective optimization to find the best solutions for transportation projects. Based on the weak positive correlation between the GHG emissions and the other objectives, they suggested future studies on other aspects including environmental impacts to enhance sustainable construction. Balasbaneh et al. (2018) evaluated the impact of different hybrid timber building constructions based on the environmental, economic and social aspects. However, results indicated that the costs for environmental effects were about 7% of total life-cycle costs and they were not always decisive.

Concerning studies on life-cycle assessment (LCA) or sustainable design, Möller et al. (2015) developed a general optimization framework for assessing dynamic responses and reliability levels for a set of design parameters to minimize the life-cycle cost. But for estimating damage costs, it is necessary to generate a large number of nonlinear dynamic analysis. Accordingly, Möller et al. (2009) compared the three methods of general estimation, local interpolation, and artificial neural network methodology. Sakai et al. (2016) revealed that it is possible to identify the existing design methods from the viewpoint of sustainability and to incorporate a more rational and diverse concept in the design of structures. They adjusted performance requirements concerning social, economic, and environmental aspects or combined aspects. The sustainable design basically determines the structural style, materials, and construction method to satisfy such requirements. AlHamaydeh et al. (2017) investigated the impact of seismic design level on the total construction and life-cycle costs for a comprehensive assessment of buildings. They concluded that designing for higher seismicity is not always an uneconomical decision, since enhancements in the structural performance and its implications for downtime and potential life-cycle costs may be a sound decision to be taken. Note that there are some studies that have focused on the unforeseen costs such as maintenance costs over the lifetime of the structures (e.g., Foraboschi 2016a, b). While in this study, the focus is on the expected damage costs, which can be significantly altered by variations in the structural characteristics.

Overall, previous studies suggest that for the sustainable design of a structure, it is necessary to define goals which can combine environmental impacts with life-cycle costs. Accordingly, this paper presented a novel approach for the sustainable design of RC frames. Here, the structures satisfy the rules of the seismic codes as well as other goals addressing various aspects of economic, social, and environmental impacts under earthquake excitation during the life cycle of the structure. On the other hand, to calculate optimal structures, there is a need for a large number of nonlinear dynamic analyses of different structures with different combinations of concrete and reinforcement materials. Therefore, in this approach, in addition to defining new objectives, to save the analysis time and quickly obtain an optimal structure, a limited number of nonlinear dynamic analyses have been performed to generate the response functions based on the reinforcements and concrete volume.

Methodology and objective functions

General flowchart of the design

Figure 1 indicates the general flowchart of the optimum design of the RC frames in the MATLAB program. The most important components of the proposed framework include sustainable objective design functions, total life-cycle cost calculation, score calculation of the environmental impact, and generation of response functions.

Structures should have acceptable performance during the lifetime while also satisfying the rules defined in the seismic codes in terms of strength and serviceability, as presented in ACI 318-14 (2014). The main design constraint is following the minimum criteria of the design code in terms of strength and serviceability, which can be considered with other constraints such as the maximum drift. The limited value of drift is 2% and 4% for design and maximum expected hazard level of the earthquake, respectively. In a common design, the goal is to reduce initial costs by satisfying the design rules. Nevertheless, if the goal is to minimize the initial cost along the estimated damage costs during the lifetime of buildings, which are desirable for both the owners and operators. Then LCCA can be an appropriate tool. In the absence of environmental considerations, the life-cycle design may lead to unsustainable structures. To handle this issue, three design objectives are introduced further. With each of these objective functions, almost optimal structures can be developed.

Objective functions

In the common design of the structures, the goal is to reduce the structural cost. On the other hand, with the increase in initial cost, the damage costs diminished over the lifetime. For the first objective function, the following equation can be defined to balance both costs:

where \(C_{\text{TOT}}\) represents the total life-cycle cost, \(C_{\text{IN}}\) shows the initial cost, and \(C_{\text{LOS}}\) denotes the expected life-cycle damage costs. The design with the first goal will result a structure with a minimum total life-cycle cost.

For aggregation of total cost and overall environmental score, given the different dimensions of two parameters, the dimensionless function for the second objective function is introduced as Eq. (2). In this way, the environmental impact of the structure is reduced along with costs:

where \({\text{Score}}_{\text{TOT}}\) represents the total environmental score of the structure, \(C_{{{\text{TOT}},1}}\) and \({\text{Score}}_{{{\text{TOT}},1}}\) indicate the total life-cycle cost and the total environmental score of the initial structure, respectively. The total environmental score includes the initial environmental score of the structural materials and the expected environmental score of the all damaged materials of the building. According to the expert opinion and engineering judgment, the importance of the \(C_{\text{TOT}}\), the importance the \({\text{Score}}_{\text{TOT}}\) related to the environmental impacts as a major element in sustainability, and the absence of a previous study to weigh these two parameters, an equal weight was considered for both criteria.

Structures obtained from the first and second objective functions may result in a very high initial cost but very low expected damage costs, or a very low initial but very high expected damage costs; the first case is not desirable for the owners while the latter does not favor the consumers. For this reason, in some studies (Mitropoulou et al. 2011; Fragiadakis and Lagaros 2011), minimizing both initial and expected damage costs was introduced as a multi-objective optimization. Here, to overcome this issue, the third objective function was introduced. Therefore, damage and initial cost, as well as their related environmental scores, are added up as dimensionless functions due to the importance of the initial cost for owners. By defining Eq. (3), convergence of the objective function to the options with a high initial cost and low damage cost and vice versa is avoided. Another advantage of this function is that environmental impacts have been considered dimensionless at different phase like the cost parameters:

where \({\text{Score}}_{\text{IN}}\) shows the initial environmental score, \({\text{Score}}_{\text{LOS}}\) denotes the expected environmental score of the structure in the operating stage, \({\text{Score}}_{{{\text{IN,}}1}}\) indicates the initial environmental score, and \({\text{Score}}_{{{\text{LOS,}}1}}\) refers to the expected environmental score of the initial structure in the operating stage. As mentioned earlier, the weight coefficients are assumed to be the same.

Life-cycle cost analysis

The stages of life-cycle cost estimation involve calculating the initial cost of construction of the structure, the cost of the structural and non-structural elements, and incremental nonlinear dynamic analysis (IDA) of the structure. Then, the expected damage cost of the structure over its lifetime is calculated under different earthquake intensities, after which fragility curves are produced for damage indicators. Finally, the total cost at the end of the operating period is estimated. The damage costs are calculated based on different hazard levels. Table 1 presents the seismic hazard level and basic performance objective for new buildings. BSE-2N hazard level has a 2% occurrence probability in 50 years, while BSE-1N hazard level is two-thirds that of the BSE-2N (ASCE 41-17 2017). Concerning the risk category, the current study frames are assumed as category II.

The engineering parameters of the various elements obtained from the structural analysis were used for generating the fragility curves. For a member, at a particular earthquake magnitude, the probability of reaching or exceeding the breakdown level j for the ith engineering parameter is obtained as following:

where \(P\left[ {{\text{DS}}_{ij} | {\text{edp}}_{i} } \right]\) is the probability of exceedance of damage state (DS) from the jth parameter conditioned on the ith engineering demand parameter (EDP), and \(p[{\text{edp}}_{i} |{\text{im}}]\) shows the probability density of the EDPi for a given IM.

Each of the total cost parameters is related to floor acceleration or inter-story drift ratio (abbreviation: drift). The relationship between the total life-cycle cost (CTOT) of a structure over a period of time when the lifetime of a new structure or the remaining lifetime of a restored structure can be expressed as a function of the time and vector of design variables is as Eq. (5) (Wen and Kang 2001):

where CIN represents the initial cost of a new or retrofitted structure, CLS denotes the limit state-dependent cost, s shows the design vector corresponding to the design loads, resistance, and material properties, and t reflects the time period. The CLS parameter, associated with the expected cost of repair and return of the structure to the level of operation after an earthquake, involves repair costs (Cdam), cost of contents damage (Ccon), cost of renting a place (Cren), cost of place income (Cinc), as well as cost of injuries (Cinj) and fatalities (Cfat). The life-cycle cost of a structure is an important parameter for engineers and the structure’s owner. The life-cycle cost is calculated from the following equation (Wen and Kang 2001):

where \(C_{0}\) is the initial cost of construction, t shows the lifetime of the structure, λ represents the annual inflation rate, N is the total number of scenarios, \(P_{i}\) denotes the probability of constructing the structure at the level of i due to the occurrence of the earthquake, and \(C_{i}\) is the cost of part of the initial cost of the structure. The probability of a demand exceeding a certain value, δ, is expressed as the following equation:

where \(\varPhi [ \cdot ]\) is standard normal cumulative distribution, \(\lambda_{\text{D}}\) shows the natural logarithm of the mean earthquake demand as the magnitude of the earthquake, and \(\beta_{\text{D}}\) indicates the standard deviation of the normal distribution of the desired earthquake demand. Uncertainty in capacity (\(\beta_{\text{C}}\)) is due to modeling errors, lack of knowledge, and variations in material properties.

Möller et al. (2015) divided the final costs into three categories:

where \(C_{0} (x_{\text{d}} )\) is the construction cost; \(C_{\text{d}} (x_{\text{d}} )\) and \(C_{\text{s}} (x_{\text{d}} )\) represent the cost of repairs and the social costs due to earthquake occurrence, respectively.

In the current study, based on the actual costs of the buildings constructed in Iran with administrative use, structural costs and social costs have been considered. The lifetime of the structure is assumed 50 years, the downtime of the entire structure is assumed 18 months, and the average annual interest rate is assumed 10%.

According to studies conducted by researchers including Möller et al (2015), Mitropoulou et al. (2011), and Ahadi and Razi-Ardakani (2015) and regarding the rental rates, income, medical costs, and issues such as wergild in Iran, the costs associated with the social aspects are presented as Table 2. In addition to the aforementioned references, engineering judgment was used.

Summing up the FEMA 227 (1992), ATC 13 (1985), and the study conducted by Mitropoulou et al. (2011), the loss levels for estimating the damage caused by the earthquake during the lifetime of the structure are reported in Table 3.

In this paper, all the constructional costs such as operational cost were included. In addition, regarding other studies (Mitropoulou et al. 2011; Fragiadakis and Lagaros 2011, Hossain and Gencturk 2014), since the end-of-life cost and its occurrence probability (collapse probability) over the lifetime of the structure are ignorable, the end-of-life cost was excluded.

Generate response functions

To develop the optimal structure, due to the significant range of cross-sectional and reinforcement variables, a large number of analyses are required. To overcome this issue, response functions can be used. Initially, the incremental dynamic analysis (IDA) provides different damage indices for different ground accelerations of the hazard curve, but these damage indices do not match the limits defined in the damage tables. Therefore, in the first step, it is necessary to correlate damage limits with earthquake excitation accelerations by a suggested exponential function.

In the second step, since the nonlinear time history analysis of RC frames with different combinations of reinforcing and concrete materials is too time-consuming and costly, given the design objectives, the generated simple functions are based on the analysis of a limited number of designed structures. These functions are used to quickly estimate the values of initial costs, damage cost, and environmental scores in terms of different magnitudes of reinforcements and concrete volume.

The initial structure is designed in line with the seismic design codes with the design ratio of 1.0. Then, 10 other over-designed structures are selected while adhering to the permissible limits of reinforcements and concrete. Over-design is a design that exceeds the usual standard and minimum requirement. After calculating the response functions based on these structures and obtaining the optimal structure with the defined design objectives, the obtained structure is analyzed whose results are compared with the values of the response functions and with the design rules in the seismic design code. If the structure does not satisfy the rules of the code, the structure will be strengthened until it is acceptable. In this case, and in a case where the difference of the compared response functions is greater than 5%, the obtained structure is added to the set of over-designed structures, where the two-step process is repeated until it finally stops and the optimal structure is achieved.

Life-cycle assessment of environmental impacts

Identification of environmental impacts

A structure during its lifetime has various effects on the environment from the stage of production of materials and construction to the end of the life and destruction, involving the operation phase. Regarding the environmental impacts of pollutants, one can mention the potential of global warming, acidification, eutrophication, and toxicity. In this regard, the research by some organizations such as EPA (Wallace 1987) could be used to score the environmental impacts. The lower the environmental score, the better the structure’s environmental performance will be (Kumar and Gardoni 2014).

The “Environmental Problems” approach has been developed to assess the environmental impacts of various products and processes in the Society of Environmental Toxicology and Chemistry (SETAC), which involves a two-stage process as follows (Fava et al. 1993; Guinée 2002):

Classifying inputs which are relevant to a specific environmental impact (Lippiatt 2007).

Determining the potential contribution of each category to environmental impacts and determining the index weight for each group, representing its contribution to environmental pollution (Lippiatt 2007; Hossain and Gencturk 2014).

According to the Building for Environmental and Economic Sustainability (BEES) report (Lippiatt 2007), environmental impacts include global warming, acidification potential, eutrophication potential, fossil fuel depletion, habitat alteration, criteria air pollutants, human health, smog formation potential, ozone depletion, and ecological toxicity.

Global warming refers to the potential of greenhouse gases emissions absorbing solar radiation in the atmosphere, causing elevation of the earth temperature (Lippiatt 2007). Acidification potential is due to acidic compounds, generally sulfur and nitrogen emitting from fossil fuels and biomass combustion (Lippiatt 2007). Eutrophication potential refers to the entrance of nutrients such as nitrogen and phosphorus into water, causing unusual changes in water quality and reduction of biological diversity (Lippiatt 2007).

Fossil fuel depletion refers to the consumption and reduction of fossil fuels, resulting in degradation and decline of resources and climate change. Habitat alteration indicates the potential of land use change by humans, causing damage to the threatened and endangered species (Lippiatt 2007).

Criteria air pollutants refer to six pollutants including carbon monoxide, lead, ground-level ozone, nitrogen dioxide, particulate matter, and sulfur dioxide produced from many activities including combustion, vehicle use, power generation, as well as crushing and mixing operations (Lippiatt 2007).

Smog formation potential refers to the formation of photochemical smog caused by the reaction of air emissions from industry and transportation with sunlight under certain climatic conditions. Smog has harmful effects on human health and vegetation (Lippiatt 2007).

The depletion of the ozone layer due to the emission of chlorofluorocarbons (CFCs) and other harmful gases causes more harmful short-wave radiation reaching the earth surface, resulting in changes in ecosystems, adverse effects on agricultural productivity, as well as climate and harmful human health effects. Meanwhile, ecological toxicity measures the ability of a chemical released into the environment to damage the human health and ecosystems (Lippiatt 2007).

Environmental score

In this study, the impacts and scores are determined using SimaPro 8.2.3.0 software and studies conducted by Bare (2011), and a report from entitled BEES (Lippiatt 2007). The BEES research project (Lippiatt 2007) proposed converting environmental impacts to the environmental scores. According to the mentioned references, the environmental effects of various pollutants are determined which are produced by various materials and processes. The environmental impacts including the amount of pollutants associated with all utilized materials in the building are determined per unit of mass, volume, and ton-kilometer (for transportation). The estimated amounts of environmental impacts of each of the main structural materials are presented in Table 4.

Finally, the environmental impacts are expressed in terms of the environmental scores. Accordingly, the environmental impacts are normalized with predetermined index values and then converted to the score. To obtain an environmental score, weight factors are selected based on long-term and short-term effects on the environment. With this regard, two similar projects were compared whereby the decision process was facilitated. Based on the SimaPro 8.2.3.0 software, the extent of environmental impacts was estimated, and from the Lippiatt (2007), the default index values were extracted. The contribution of each of these effects to the environmental scores is presented in Table 5 (Lippiatt 2007). In addition, Table 5 reports the single score of each of the main structural materials of RC frames, including reinforcements and concrete. Comparing the emission values in both the material production and construction phases demonstrates that the end-of-life environmental impact is ignorable.

The environmental impacts and related scores of non-structural materials can be estimated in the same way. These materials are indicated in Table 6. The environmental effects associated with the non-structural materials are constant among the design options. However, since the damage to structures are not constant under probable earthquake hazards, so the environmental effects associated with structural and non-structural materials along the life cycle of structures are variable. Table 7 shows the environmental single score of each non-structural material. Note that the environmental scores of concrete and reinforcements of the joists have been calculated individually.

Numerical study

Numerical modeling

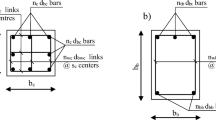

The proposed flowchart is used for an intermediate RC moment-resistant frame of 4 stories and 3 bays. Each story has 108 m2 area. The initial structure is designed based on the seismic regulations of ASCE07-16 (2016) and ACI 318-14 (2014). The typical geometry of the frame is displayed in Fig. 2. The original frames are developed by increasing the design earthquake coefficient compared to the initial structure up to two times. In addition, the section area, reinforcement details, and the design ratios of the 10 original RC frames are shown in Table 8. Further, the specification of the materials utilized in the building is in accordance with Table 6. The tensile strength of the reinforcements and the compressive strength of the concrete have been assumed to be 400 MPa and 25 MPa, respectively. The attempts were made to establish the strong-columns and weak-beams condition for the original structures. In addition, the cyclic behavior and the deterioration hysteresis curves are consistent with the cyclic behavior of the concrete structures of intermediate ductility.

Execution costs are estimated by metering the material usage and construction operations, according to the price list of Iran in 2018. The cost of contents has been assumed to be about 260 USD per square meter.

Seismic hazard function

Based on Gutenberg–Richter recurrence, seismic hazard curve is logarithmic. The annual exceedance probability function of the peak ground accelerations (PGA) is assumed to be in the form of the following equation:

where a and b are the coefficients obtained from linear transmission in the semi-logarithmic environment of hazard curve and \(P\left( {{\text{PGA}}_{i} } \right)\) is the annual exceedance probability for the \({\text{PGA}}_{i}\).

Earthquake accelerograms

Table 9 presents the selected 14 natural earthquake ground motions of soil type C with the magnitude between 6 and 7.5. These accelerograms have been scaled according to ASCE07-16 (2016).

For nonlinear dynamic time history analysis of structures, OpenSEES (McKenna and Fenves 2006) was used. This open source software is object-oriented software for simulation of earthquake engineering which is supported by the PEER Center.

Generating IDA reverse functions

The maximum drift of the nonlinear time history dynamic analysis is estimated for each PGA and each accelerogram. For example, for the initial RC frame, PGA with drift has been plotted in Fig. 3. Based on the trend of changes in this figure, Eq. (10) can be an appropriate exponential function between the PGA and the maximum floor drift:

where a1 and a2 are constant coefficients which are different for each structure and each earthquake accelerogram. The average sum of squared errors (SSE) of Eq. (10) for drift calculations is less than 2%, indicating that the functions towel match the data obtained from the nonlinear dynamic analysis. The annual exceedance probability of drift of the initial structure under all accelerograms has been plotted in Fig. 4. The probability values associated with each drift are obtained through combining Eqs. (9) and (10). Figures 3 and 4 depict the correspondence of the results of these functions.

The average PGA in terms of drift for all accelerograms of the initial RC frame has been presented in Fig. 5. Assuming a normal inverse cumulative distribution function for the occurrence probability of accelerations greater than 84%, the drift and corresponding PGA values for earthquake accelerogram have been presented in Fig. 6.

These analyses are repeated for each RC frame in the design process, where the annual exceedance probability of drift is obtained. Based on these charts, the exceedance probability of each drift limit, defined in Table 3, has been calculated. Similar to the calculations performed for the drift, the exceedance probability from the maximum acceleration of floors is also calculated.

At this stage, Eq. (11) is estimated for each accelerogram for the maximum floor acceleration. The results of maximum floor acceleration in terms of PGA for the initial RC frame are demonstrated in Fig. 7. In addition, the annual exceedance probability of the maximum floor acceleration of the initial RC frame is presented in Fig. 8.

As with displacement, Figs. 6 and 7 reveal that the computational functions are also consistent with the results for acceleration. Similarly, the annual exceedance probability of acceleration of each RC frame has been obtained as Fig. 9. Further, the exceedance probability of each floor acceleration limit, defined in Table 3, has been calculated based on this chart.

Generation of the cost functions

Cost functions are generated from the results of analyzing the original RC frames. As such, initially the relationships between the maximum floor acceleration plus the drift and the concrete volume as well as the reinforcements are obtained. Afterwards, the direct relationships of damage costs in terms of concrete volume and reinforcements are obtained. Table 10 summarizes the best-fitted relationships, and Fig. 10 indicates some samples of the fitted curves.

Regarding the variables in the cost functions, the effect of the cross-section area of the structures in the drift response under the severe earthquakes and the effect of the reinforcements in the maximum floor acceleration response are negligible. Therefore, the drift and maximum floor acceleration equations are generated in terms of the reinforcement and concrete, respectively. The reason is that the drift response in the nonlinear behavior of structures is dependent on the structural strength capacity and the maximum floor acceleration response is dependent on the stiffness of the structure. On the other hand, changes in the drift response of the structure under the PGA of the design earthquake hazard level are trivial, because in over-designed structures the reinforcements and cross-section areas are simultaneously changed. Therefore, drift function was generated in terms of the PGA of the maximum considered earthquake (MCE). It was assumed that the changes in the reinforcements and cross-section area are uniform concerning the initial structure. The loss costs dependent on the drift were the structural damage costs and social costs as mentioned in Table 2, and the loss cost dependent on the maximum acceleration of floors were non-structural damage.

Results and discussions

As the designed structures should be in accordance with the design codes, the considered constraints are made as Eqs. (12) and (13), to avoid the development of weak structures:

By these constraints, it is possible to limit the maximum drift of the structures under the PGA of the design hazard level to 2%. Table 11 presents the properties of the initial structure in the first row as well as properties of other developed RC frames for different design objectives.

The RC frame, which is achieved by the first objective (F1), has the lowest total life-cycle cost including the initial cost and expected damage costs during the lifetime. The cross-section areas of this RC frame are similar to the A7 scenario, while its reinforcements are the average of the A7 and A8 scenarios. In this case, the total life-cycle cost is about 9% less than that of the initial structure. With the increase in the initial cost, the drift and consequently, the expected damage cost decreased. Therefore, there is a balance between the initial cost and the expected damage cost.

In the second and third objectives, the optimally designed structure had a lower initial cost than the RC frame resulted from the first objective. In these RC frames, due to the great effect of the reinforcements on the environmental score, the mass of the reinforcements diminished to the minimum value (A1 scenario), while its cross-section areas were approximately equal to the cross-section areas of the A7 scenario. Therefore, it was observed that the extent of drifts and expected life-cycle damage costs were less than the score reduction. The results indicated that the structure developed for the second objective function, was the same structure for the third objective function.

Since the behavior of the RC structures is nonlinear under extreme seismic loads, there is no direct relationship between increasing the initial cost and reducing the expected life-cycle damage costs. Consequently, there is no direct relationship between the increase in the score for the construction stage and the reduction of the damage-related score. Further, two separate parameters (acceleration of the floors and inter-story drift ratio) are effective in damage determination. On the other hand, if the proportions in the third optimization function are calculated for the optimum structures obtained from different functions, no direct trend will be obtained in the changes. Thus, the similarity of the structures obtained from the objective functions F2 and F3 was coincidental.

Conclusions

LCCA was employed for assessing the performance of structures over their lifetime from a wide range of economic and social aspects. In addition, environmental effects of the life-cycle period were evaluated. Accordingly, this paper focused on the LCCA and societal effects associated with environmental impacts, where a new approach was presented for sustainable design of RC structures. In this approach, in addition to the strength criteria, the environmental effects and damage costs of the structures over their life cycle were also taken into account. Hence, through three defined design objectives and generated response functions, in addition to satisfying the rules of the codes, sustainable structures were developed throughout their lifetime. Response functions in terms of the consumed materials were used to reduce the computationally expensive nonlinear dynamic analyses, which proved to be very effective.

The environmental impacts that were dealt with in this study included global warming potential, acidification, eutrophication, fossil fuel depletion, habitat alteration, water consumption, air pollution, smog formation, ecological toxicity, ozone depletion, and human health. The results for a case study can be summarized as follows:

Using the introduced methodology, with a low computational cost, more sustainable RC frames were obtained compared to the initial RC frame. The obtained RC frame with the first objective function had a total life-cycle cost 9% lower than that of the initial RC frame. The RC frame obtained with the second and third objective functions (the same RC frame was obtained) has had 4% and 5% lower total life cycle cost and total environmental impact score as compared with the initial RC frame, respectively.

The expected life-cycle damage cost of the investigated RC frames was much greater than the initial cost. Therefore, when the structure was designed to minimize the total life-cycle cost, a balance between initial cost and damage cost of the life cycle was established by increasing the initial cost. In this case, the initial cost increased by about 5759$, while the damage cost diminished by about 10,090$.

The contribution of the reinforcements to the environmental score was high. Therefore, in cases where various parameters were added in the form of dimensionless factors, a RC frame with low reinforcements relative to the optimum structure of the first objective function was concluded. In this case, the reinforcement was the minimum (reinforcement of the A1 scenario). However, the cross-section areas of the obtained structure were greater than those of the initial structure. Specifically, the initial cost increased by about 3725$, while the damage cost dropped by about 5607$ relative to the initial structure. In addition, the total environmental score was reduced.

In terms of environmental impacts, according to the second and third objectives, although the total life-cycle cost was enhanced by 5.5%, the environmental score was lessened by 22%.

References

ACI318-14. (2014). Building code requirements for structural concrete and commentary. Farmington Hills, MI: American Concrete Institute (ACI). https://doi.org/10.14359/51706926.

Ahadi, M., & Razi-Ardakani, H. (2015). Estimating the cost of road traffic accidents in Iran using human capital method. International Journal of Transportation Engineering,2(3), 163–178. https://doi.org/10.22119/IJTE.2015.9601.

AlHamaydeh, M., Aly, N., & Galal, K. (2017). Seismic response and life-cycle cost of reinforced concrete special structural wall buildings in Dubai, UAE. Structural Concrete,19(3), 771–782. https://doi.org/10.1002/suco.201600177.

Ancheta, T. D., Darragh, R. B., Stewart, J. P., Seyhan, E., Silva, W. J., Chiou, B. S., et al. (2013). Peer NGA-West2 database.

ASCE 41. (2017). Seismic rehabilitation of existing buildings. Reston, VA: American Society of Civil Engineers.

ASCE/SEI7-16. (2016). Minimum design loads for buildings and other structures. Reston, VA: American Society of Civil Engineers/Structural Engineering Institute.

ATC-13. (1985). Applied ATC-13: Earthquake damage evaluation data for California. Redwood City, CA: Applied Technology Council (ATC).

Balasbaneh, A. T., Marsono, A. K. B., & Khaleghi, S. J. (2018). Sustainability choice of different hybrid timber structure for low medium cost single-story residential building: Environmental, economic and social assessment. Journal of Building Engineering,20, 235–247.

Bare, J. (2011). TRACI 2.0: The tool for the reduction and assessment of chemical and other environmental impacts 2.0. Clean Technologies and Environmental Policy,13(5), 687–696.

Basbagill, J., Flager, F., Lepech, M., & Fischer, M. (2013). Application of life-cycle assessment to early stage building design for reduced embodied environmental impacts. Building and Environment,60, 81–92.

Chiu, C. K., Noguchi, T., & Kanematsu, M. (2010). Effects of maintenance strategies on the life-cycle performance and cost of a deteriorating RC building with high-seismic hazard. Journal of Advanced Concrete Technology,8(2), 157–170.

Chou, J. S., & Yeh, K. C. (2015). Life cycle carbon dioxide emissions simulation and environmental cost analysis for building construction. Journal of Cleaner production,101, 137–147.

Fava, J., Consoli, F., Denison, R., Dickson, K., Mohin, T., & Vigon, B. (1993). A conceptual framework for life cycle impact assessment, workshop report society of environmental toxicology and chemistry (SETAC). Pensacola: Foundation for Environmental Education.

FEMA-227. (1992). A benefit-cost model for the seismic rehabilitation of buildings. Washington, DC: Federal Emergency Management Agency, Building Seismic Safety Council.

Foraboschi, P. (2016a). The central role played by structural design in enabling the construction of buildings that advanced and revolutionized architecture. Construction and Building Materials,114, 956–976.

Foraboschi, P. (2016b). Versatility of steel in correcting construction deficiencies and in seismic retrofitting of RC buildings. Journal of Building Engineering,8, 107–122.

Fragiadakis, M., & Lagaros, N. D. (2011). An overview to structural seismic design optimisation frameworks. Computers & Structures,89(11–12), 1155–1165.

Gencturk, B., Hossain, K., & Lahourpour, S. (2016). Life cycle sustainability assessment of RC buildings in seismic regions. Engineering Structures,110, 347–362.

Guinée, J. B. (2002). Handbook on life cycle assessment operational guide to the ISO standards. The International Journal of Life Cycle Assessment,7(5), 311.

Hossain, K. A. (2013). Structural optimization and life-cycle sustainability assessment of reinforced concrete buildings in seismic regions (Doctoral dissertation).

Hossain, K. A., & Gencturk, B. (2014). Life-cycle environmental impact assessment of reinforced concrete buildings subjected to natural hazards. Journal of Architectural Engineering,22(4), A4014001.

Kawai, K., Sugiyama, T., Kobayashi, K., & Sano, S. (2005). Inventory data and case studies for environmental performance evaluation of concrete structure construction. Journal of Advanced Concrete Technology,3(3), 435–456.

Kumar, R., & Gardoni, P. (2014). Renewal theory-based life-cycle analysis of deteriorating engineering systems. Structural Safety,50, 94–102.

Lagaros, N. D. (2007). Life-cycle cost analysis of design practices for RC framed structures. Bulletin of Earthquake Engineering,5(3), 425–442.

Lippiatt, B. (2007). BEES 4.0: Building for environmental and economic sustainability technical manual and user guide. Gaithersburg, MD: National Institute of Standards and Technology (NISTIR).

McKenna, F., & Fenves, G. L. (2006). Opensees 2.4.0. Computer software. UC Berkeley, Berkeley, CA. http://opensees.berkeley.edu.

Mitropoulou, C. C., Lagaros, N. D., & Papadrakakis, M. (2011). Life-cycle cost assessment of optimally designed reinforced concrete buildings under seismic actions. Reliability Engineering & System Safety,96(10), 1311–1331.

Möller, O., Foschi, R. O., Ascheri, J. P., Rubinstein, M., & Grossman, S. (2015). Optimization for performance-based design under seismic demands, including social costs. Earthquake Engineering and Engineering Vibration,14(2), 315–328.

Möller, O., Foschi, R. O., Rubinstein, M., & Quiroz, L. (2009). Seismic structural reliability using different nonlinear dynamic response surface approximations. Structural Safety,31(5), 432–442.

Ozcan-Deniz, G., & Zhu, Y. (2017). Multi-objective optimization of greenhouse gas emissions in highway construction projects. Sustainable Cities and Society,28, 162–171.

Sakai, K., Shibata, T., Kasuga, A., & Nakamura, H. (2016). Sustainability design of concrete structures. Structural Concrete,17(6), 1114–1124.

Varun, Aashish Sharma, Shree, Venu, & Nautiyal, Himanshu. (2012). Life cycle environmental assessment of an educational building in Northern India: A case study. Sustainable Cities and Society.,4, 22–28.

Wallace, L. A. (1987). Total exposure assessment methodology (TEAM) study: summary and analysis. Volume 1 (No. PB-88-100060/XAB; EPA-600/6-87/002A). Environmental Protection Agency, Washington, DC (USA). Office of Acid Deposition, Environmental Monitoring, and Quality Assurance.

Wen, Y. K., & Kang, Y. J. (2001). Minimum building life-cycle cost design criteria. I: Methodology. Journal of Structural Engineering,127(3), 330–337.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all the authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nouri, A., Asadi, P. & Taheriyoun, M. Life-cycle sustainability design of RC frames under the seismic loads. Asian J Civ Eng 21, 293–310 (2020). https://doi.org/10.1007/s42107-019-00199-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42107-019-00199-x