Abstract

Lithium-rich layered oxides (LLOs), also known as Li1+xM1−xO2 or xLi2MnO3-(1–x)LiMO2 (M = Ni, Co, Mn), have been regarded as some of the highest capacity lithium cathodes and have attracted increasing attention from battery researchers and engineers in recent years. This is because LLOs possess maximum possible capacities of ~ 280 to 310 mAh g−1 with a high working potential of ~ 3.7 V (vs. Li+/Li0) and an astounding energy density of ~ 900 Wh kg−1. Despite these promising properties, these technologically important cathodes have not yet been successfully commercialized due to low initial Coulombic efficiency, poor rate capabilities and gradual capacity/voltage fade during electrochemical cycling as well as further complications from continuous structural changes during cycling. Here, researchers have concluded that these issues mainly originate from the electrochemical activation of Li2MnO3 components, which, although it provides anomalously high capacity performances, also causes associated complex anionic redox activities of O and irreversible structural and phase transformations during charging at potentials greater than 4.5 V (vs. Li+/Li0). To provide perspectives, this review will summarize various attempts made towards addressing these issues and present the connections between electrochemical properties and structural change. In addition, this review will discuss redox chemistries and mechanistic behaviours during cycling and will provide future research directions to guide the commercialization of LLOs.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Lithium-ion batteries (LIBs) have experienced major breakthroughs in battery technology since being commercialized less than 3 decades ago. Since then, LIBs have been successfully applied in electrified vehicles (EVs) and are integral to daily life, with demand for higher energy density ever increasing. The International Energy Agency reported that the number of EVs (including battery electric vehicles (BEVs) and plug-in hybrid electric vehicles (PHEVs)) surpassed 3 million in 2017, which is a 56% increase from 2016 [1] and that this is a strong driving force for breakthroughs and evolution in battery technologies, in which aside from battery costs and safety [2], long-range BEVs require higher volumetric and gravimetric energy density (i.e. 750 Wh L−1 and 350 Wh kg−1) [3].

However, cathodes in LIBs are intrinsic bottlenecks that restrict LIBs capacities and energy performances and current commercial cathode materials for BEVs and PHEVs such as LiFePO4, LiNi0.8Co0.15Al0.05O2 (NCA) and the LiNi1−x−yCoxMnyO2 (x + y < 0.5) (NCM) family [e.g. LiNi0.6Co0.2Mn0.2O2 (NCM622), LiNi0.8Co0.1Mn0.1O2 (NCM811)] exhibit gravimetric energy densities lower than 800 Wh kg−1 [4]. In addition, the overall energy density of LIBs is further reduced by battery packaging.

To address these issues, considerable research has been conducted on the optimization and design of new cathode materials with high capacities (e.g. > 200 mAh g−1) or high voltage (e.g. \(\geqslant\) 4 V vs. Li+/Li0) [5,6,7,8,9,10,11] with prospective high-voltage candidates including high-voltage spinel oxides (LiNi0.5Mn1.5O4), lithium-rich layered oxides (LLOs) (Li1+xM1−xO2, M = Ni, Co, Mn, etc.), nickel-rich layered oxides (LiNi1−xMxO2, M = Co, Mn and Al) and high-voltage sulphate-, phosphate- or silicate-based polyanionic compounds (Fig. 1). And in particular, Li1+xM1−xO2 or xLi2MnO3-(1 − x)LiMO2 (M = Ni, Co, Mn), known as LLOs, has attracted immense attention from researchers because they can deliver the highest energy density (~ 900 Wh kg−1) thus far as compared with other conventional cathode materials.

Source: Reproduced with permission from Ref. [12]

Radar plot comparing the volumetric energy density, power, cycling performance, thermal stability and costs of various high-voltage cathode materials.

The concept of LLO cathode materials originated from Thackeray et al. who investigated rock-salt-phase Li1.09Mn0.91O2 and later introduced a strategy to design new cathode materials with high capacities (> 200 mAh g−1) [13, 14]. Since then, the discharge capacity of LLOs has improved substantially, reaching above 300 mAh g−1 [15]. However, several issues still need to be addressed for LLOs before commercialization, including low initial Coulombic efficiency (ICE), capacity and voltage fade and poor rate capability [16,17,18]. And although numerous strategies have been applied to overcome these challenges, such as surface modification [19], lattice doping [20, 21] and more recently the alteration of O activities [22], the fundamental origins of the crystal structural change related to these issues, especially the voltage fade, and the mechanisms of how these changes contribute to such fading during cycling have not been elucidated clearly. Until recently, however, few studies have achieved breakthroughs in the understanding of the fundamental origin of the crystal structural changes [23,24,25,26,27,28] and most reviews have mainly focused on the structure [29], electrochemical performance [30], synthesis methods [31] or characterization technique [32] of LLO materials. Therefore, this review will comprehensively present the structure-function relationship of LLO materials along with explanations of their modifying strategy-issue connection from a fundamental perspective. In addition, this review will provide suggestions for ongoing high-energy cathode research.

2 Crystal Structures and Mechanistic Reactions

2.1 Crystal Structure

LLOs can be categorized into the xLi2MnO3-(1 − x)LiMO2 model (M stands for transition metals (TMs)) based on a two-phase model first proposed by Thackeray et al. [14, 33] and the Li(LixM1−x)O2 model based on a solid solution model with a homogeneous long-range order as proposed by Dahn et al. [34, 35]. Here, both models are widely used in the literatures, and currently, the optimal model is still a matter of debate with no agreement being reached on the definition of the original structure of LLOs [36].

For the two-phase (xLi2MnO3-(1 − x)LiMO2) model, LLOs are regarded as composites in which a monoclinic symmetry Li2MnO3 phase (space group C2/m) is structurally integrated with a trigonal symmetry LiMO2 phase (space group \(R{\overline{3}}m\)) at the atomic level [14] due to the similar O3-type layered structures of the two phases [37] with Li atom sites occupying octahedral sites in the structure with three MO6 octahedral layers (Fig. 2a, b). Here, Mn and excess Li atoms (at a Li/Mn ratio of 1:2) form the MO6 octahedral layers in the structure of the Li2MnO3 phase [37], and therefore, Li2MnO3 can be reformulated as Li(Li1/3Mn2/3)O2 [29]. Furthermore, the distances between the close-packed layers of the (001) plane in the Li2MnO3 monoclinic phase and the (003) plane in the LiMO2 trigonal phase are both ~ 4.7 Å, allowing for the compatible integration of the two phases at the atomic level [38].

Source: Reproduced with permission from Ref. [37]

Schematic of structure crystallography. a LiMO2 structure (\(R{\overline{3}}m\)), b monoclinic Li2MnO3 (C2/m), c Li/Mn atom ordering in LiM2 layer in Li2MnO3, d XRD pattern of layered 0.5Li2MnO3-0.5LiMn0.5Ni0.5O2 material.

And as a result of the high compatibility of these two phases, researchers have also proposed that the MO6 octahedral layers can contribute to a monoclinic superstructure with one LiO6 octahedron surrounded by six MnO6 octahedra to form a hexagonal LiMn6 honeycomb in the Mn-rich layer, allowing for a solid solution (Li1+xM1−xO2) model (Fig. 2c) [39] in which the cation ordering-derived superstructure can produce broad and weak peaks in the 2θ range of 20°–30° in the X-ray diffraction (XRD) patterns of LLOs (Fig. 2d).

Different synthetic methods have been suggested to be the cause of the discrepancy in the two LLO models. Based on this, Table 1 summarizes competing two-phase and single-phase models of LLOs through comparisons of experimental evidence and synthesis methods of various compounds reported in the literature in which 30% of the reported literature supports the two-phase composite model and 70% considers LLOs as a solid solution of either \(R{\overline{3}}m\) or C2/m. Here, much of the literature suggesting a phase composite model is solely based on selected characterization techniques and their conclusions do not appear to be reliable due to the structural complexity and similarity between the two phases of LLOs, and in their final analyses, a unique reference structure for the LLOs cannot be fully established because of the strong correlation to synthesis conditions and compositions.

2.2 Mechanistic Reactions of LLOs

Although the structure of LLOs is still debated, Mn-containing LLOs do possess unique mechanistic behaviours based on highly compatible intergrown structures in which it is generally accepted that the mechanistic behaviours and corresponding structural and phase evolutions are similar for all LLOs [14]. Therefore, by using the two-phase notation as a model and the composition triangle originating from Thackeray et al. [14], the mechanistic reactions of layered 0.3Li2MnO3-0.7LiMn0.5Ni0.5O2 (as an example) can be clearly described by using its typical initial two cycles and corresponding incremental capacity (dQ/dV) plots (Fig. 3a) [14, 89]. Here, upon charging to 4.4 V, Li extraction occurs with the redox couple of Ni2+/Ni4+ in the electrochemically active LiMn0.5Ni0.5O2 component based on a solid solution reaction mechanism to form 0.3Li2MnO3-0.7Mn0.5Ni0.5O2 [14, 90]. During this stage, the Li2MnO3 component is electrochemically inactive and can act as a Li reservoir to compensate for Li extraction from the active layer through Li migration from the octahedral sites in the MO6 octahedral layers to the tetrahedral sites in the Li-consuming layers, thus ensuring integrated structural stability (Fig. 3b) [14]. In addition, the existence of Li in both tetrahedral and octahedral sites in the Li-consuming layer can endow LLO materials with more interstitial Li spacing and enhance reaction kinetics. Furthermore, as charging voltage increases to above 4.4 V, a long flat plateau can be observed which can be associated with the activation process of the Li2MnO3 phase involving Li loss and O release from the monoclinic structure [39]. Here, the product obtained at the end of the charging process is a metastable MnO2 phase, implying a two-phase reaction mechanism. And upon discharge, Li can intercalate into MnO2 and MO2 lattices to form rock-salt-type LiMnO2 and LiMO2 phases, respectively [14, 22]. Overall, as described in the composition triangle (Fig. 3c) [14], the mechanistic reactions of LLO electrodes in the initial cycles can be illustrated as follows:

Here, the process of Li+ extraction (Eq. 2) along with O evolution during Li2MnO3 activation in the first cycle [16, 25, 54, 91, 92] is a one-off reaction behaviour that is not only linked with initial irreversibility but also linked with the highly anomalous reversible capacity involving the anionic redox species, O, which can coordinate with metal ions (i.e. Mn, Ni or Li) or form peroxo-like O n−2 species [39]. In their study, Koga et al. [93] proposed that all cations were in the oxidation state of +4 after charging and recovered to their normal state after discharging, implying that TM cation redox cannot fully explain the observed extra capacity. Here, the researchers concluded that lattice oxygen could undergo reversible redox reactions within the bulk and that irreversible O loss occurred at the surface [94]. Furthermore, researchers have conducted theoretical and experimental studies and have reported that the anionic redox reactions of O anions can not only lead to extra capacity, but also affect the mechanistic behaviour and electrochemical performance of LLOs [22, 95]. In addition, Armstrong et al. [54] were the first to track oxygen evolution using in situ differential electrochemical mass spectrometry (DEMS) and powder neutron diffraction (NPD). Here, the researchers demonstrated that O2 was released from LLOs during charging and suggested that this surface oxygen loss can lead to structural changes, with Li from octahedral sites migrating into Li layers and creating vacancies which were subsequently occupied by TM ions, simulating the formation of metastable rock-salt MnO2. In later studies, Hy et al. [91] used in situ surface-enhanced Raman spectroscopy (SERS) to confirm the formation of a Li2O phase and Muhammad et al. [96] reported significant drops in the O content in a 0.4Li2MnO3-0.6LiMn0.5Ni0.5O2 electrode during the first charge (190–280 mAh g−1) (e.g. 4.4–4.7 V) (Fig. 3d). Here, the decomposition of conventional electrolyte solutions can also occur, especially at high-voltage operations (> 4.4 V).

Source: a Reproduced with permission from Ref. [89]. b, c Reproduced with permission from Ref. [14]. d Reproduced with permission from Ref. [96]

Typical voltage profiles and dQ/dV plots (inset) of 0.3Li2MnO3-0.7LiMn0.5Ni0.5O2 electrode. b Compositional phase diagram illustrating the electrochemical reaction pathways at different voltages in LLO electrodes. c Schematic of diffusion from octahedral sites to tetrahedral sites. d Oxygen content in 0.4Li2MnO3–0.6LiMn0.5Ni0.5O2 electrode during the first cycle.

In general, the mechanistic behaviours of LLOs are complex and are closely related to performance. However, significant research is required to elucidate these behaviours. In addition, although researchers have reported that anionic oxygen redox reactions and oxygen evolution give rise to the extra capacity in LLOs, the relationship between these two oxygen activities is not fully understood. However, the phase evolution and electrochemical performance of LLOs are obviously linked to the activities associated with the Li2MnO3 activation process. Overall, the precise understanding of high-voltage (> 4.4 V) mechanisms and corresponding effects on electrochemical performance is attainable through a combination of advanced characterization tools to explain bulk and surface reactions of LLOs.

3 Challenges and Strategies

To address the challenging issues of LLOs (i.e. low ICE, capacity and voltage fade and poor rate capability), it is vital to understand the origin of such issues, which are closely connected to underlying mechanistic reactions and structural/chemical evolutions. Here, many methods have been attempted by researchers, and surface modifications and lattice doping have been reported to be useful. In this review, various surface modifications and lattice doping strategies for LLOs are summarized, along with corresponding effects on the issues of low ICE, capacity/voltage fade and poor rate capability (Tables 2, 3).

3.1 Low Initial Coulombic Efficiency (ICE)

3.1.1 The Origins of Low ICE

All LLOs suffer from low ICE, which is unfavourable in real-world applications [16, 28, 54, 73, 97]. For example, Wu et al. [98] reported that LLOs generally suffered from an initial capacity loss in the range of 60–120 mAh g−1, implying an ICE of ~ 65% to 83%, based on a systematic investigation of surface modifications on LLOs. Similarly, Rozier et al. [29] reported an ICE of 25% for a Li1.2Ni0.2Mn0.6O2 electrode (Fig. 4a), Thackeray et al. [89] reported an ICE of 81.3% for a 0.3Li2MnO3-0.7LiMn0.5Ni0.5O2 electrode and West et al. [99] reported an ICE of 27% for a Li1.2Ni0.175Mn0.52O2 electrode, indicating that ICEs vary with LLO composition.

Source: a, b Reproduced with permission from Ref. [28]

First charge-discharge characteristics and dQ/dV plots. b Gas evolution rates of Li1.2Ni0.2Mn0.6O2 electrode.

Mechanistically, the mechanisms for these low ICEs or the initial irreversible capacity loss are typically a combination of irreversible Li and O loss from the LLO lattice in conjunction with possible electrolyte decomposition at high voltage (Eq. 2) [15, 28, 100, 101]. For example, Kang et al. [102] reported that acid treatment can be applied to 0.5Li2MnO3-0.5LiNi0.44Co0.25Mn0.31O2 to remove Li2O from the Li2MnO3 component before cycling and can greatly improve ICE. And although this approach is not considered to be fully successful because the acid-leached samples demonstrated worse cycling performances and rate capabilities as compared with pristine samples, this approach does confirm the origin of low ICE and can guide researchers. Furthermore, researchers also proposed a combination of LLOs with Li receptor oxides such as V2O5 [103] and MnO2 [104], which can act as intercalation hosts to “catch” isolated Li+ for reinsertion back into the layered lattice after the initial charge, to improve ICE. Alternatively, Xu et al. [28] used in situ DEMS to characterize two LLOs (Li1.2Ni0.2Mn0.6O2 and Mn-free Li1.2Ni0.2Ru0.6O2) by monitoring gas (O2 and CO2) evolutions at 4.5 V during the first charge and suggested that O2 evolution only contributed to less than half of the total capacity loss, whereas non-volatile electrolyte decomposition played a major role in this context (Fig. 4b). However, from the perspective of this review, low ICE mainly arises from the loss of Li and O because high ICE values (90%–95%) can be achieved through O activity (anionic redox) modifications and Li diffusion enhancements without targeting electrolyte decomposition/passivation [101, 105].

3.1.2 Efforts to Improve ICE

3.1.2.1 Particle Size Control

The use of nanocomposites and nanometre-thick coatings has proved to dramatically impact electronic and ionic conduction pathway optimizations [106, 107], which are closely related to the Coulombic efficiency (CE) of LIB electrode materials. And because nanoparticles typically possess higher surface areas that are directly exposed to electrolytes, there are higher rates of side reactions. Therefore, it is important to keep primary particle sizes at an appropriate scale for LLOs [108, 109]. This was demonstrated by Li et al. [110] and Yabuuchi et al. [111], both of whom claimed that particle size can greatly affect LLO structural evolutions and electrochemical properties. In the study by Li et al. [110], the researchers compared the charge-discharge profiles of LLO electrodes with large and small particle sizes at different cycles and their corresponding structural evolutions during cycling using in situ XRD (Fig. 5a, b) and reported that the large-particle LLO exhibited a two-phase reaction mechanism, whereas the small-particle LLO exhibited no phase separation upon charging to above 4.5 V (Fig. 5a, b). Here, the researchers suggested that O loss occurred throughout the bulk of small-particle LLO, whereas O loss only occurred on the surface of large-particle LLO, resulting in smaller capacity loss and higher ICE for the large-particle LLO. Despite these results, this study sacrificed the completeness of the reactions and the deliverable capacity to increase the ICE and cycling performance of the LLOs and did not show a solid improvement to the ICE. Nevertheless, there is no doubt that particle size can affect LLOs through its effects on structural evolution during cycling [108,109,110,111].

Source: Reproduced with permission from Ref. [110]

Cell voltage as a function of capacity and selected in situ individual diffraction patterns during the first cycle of a large-particle and b small-particle LLOs. The cells were tested in a potential window of 2.0–4.8 V versus Li/Li+ at a current of C/100.

3.1.2.2 Surface Modification

Because O loss occurs at the electrode/electrolyte interface and is accompanied by various side reactions [110, 112,113,114], surface modification has become one of the most effective approaches to improve ICE, in which surface modifications can act as a protective layer or a source of surface structure modification to positively influence ICE. For example, Wu et al. [98] investigated ICE based on a series of protective coatings on LLOs (Fig. 6a, b) and reported that the coated samples, in particular those with Al2O3 and AlPO4 coatings, exhibited higher ICE and discharge capacities than pristine samples. In another study, Sun et al. [59] reported that a thin AlF3 coating can effectively enhance the electrochemical performance of Li(Li0.19Ni0.16Co0.08Mn0.57)O2 (Fig. 6c) and hypothesized that the improvement can be attributed to the transformation of the Li2MnO3 component to a spinel phase resulting from the effects of Li chemical leaching by the AlF3 layer. Here, the researchers suggested that the coating-induced changes to the original structure/composition can alter mechanistic behaviours and vary O activities during O evolution and Li2MnO3 activation, thus reducing Li and O loss and improving ICE. Furthermore, the researchers also hypothesized that this improvement arose from the increased retention of oxide ion vacancies in the lattice after the initial charge, particularly in the Al2O3- and AlPO4-modified samples. Overall, a wide range of materials, including other oxides and electron and ion conductive materials, have been employed as coatings to improve the ICE of different LLOs.

Initial charge-discharge profiles of a 0.6Li(Li1/3Mn2/3)O2-0.4Li(Mn1/3Ni1/3Co1/3)O2 and b 0.6Li(Li1/3Mn2/3)O2-0.4Li(Mn1/6Ni1/6Co2/3)O2 with various coatings and F doping. c Initial charge-discharge curves of pristine and AlF3-modified Li(Li0.19Ni0.16Co0.08Mn0.57)O2 electrodes. d Initial charge-discharge profiles of Li(Li0.2Mn0.54Ni0.13Co0.13)O2, V2O5-modified samples and V2O5.

3.1.2.3 Lattice Doping

In addition to surface modification, lattice doping with cationic and anionic ions has also been introduced to improve ICE for LLOs [21, 115]. For example, Qing et al. [116] employed gradient Na+ doping to boost the kinetics of LLOs using a molten salt method (Fig. 7a) and reported the Na-doped LLO not only exhibited a higher ICE (87 vs. 63%), but also a higher discharge capacity (286 vs. 228 mAh g−1) during testing at 25 mA g−1 in the range of 2.0–4.7 V (Fig. 7b, c). Here, the researchers attributed the noticeably better electrochemical performance of the doped LLO to the pinning effect of Na ions towards the stabilization of the LLO structure and the consequent improvements in electronic and ionic conductivities. In another study, Zhao et al. [117] employed gradient PO43− doping and developed a spinel-like hierarchical structure on LLOs composed of a PO 34 -enriched spinel-like surface and a PO 34 -doped LLO core (Fig. 7d). Here, the optimal modified sample showed an enhanced ICE of 86% as compared with 72% for the pristine sample, indicating faster Li + diffusion and reduced irreversible Li2O due to the increased PO43− polyanions (Fig. 7e).

Source: a–c Reproduced with permission from Ref. [116]. d, e Reproduced with permission from Ref. [117]

a Schematic of gradient surface Na+ doping in LLOs and the initial charge-discharge profiles of b pristine and c Na-doped LLOs. d, e Schematic of gradient polyanion doping in LLOs and the first charge-discharge curves of pristine and PO43−-doped LLOs.

Researchers have also reported the use of cationic and anionic ions as dopants in LLO lattices and reported that the performance effects were varied. For example, Pang et al. [51] reported that anionic doping with F− can promote larger lattice sizes and stimulate faster Li diffusions, whereas cationic doping with Cr3+ can enhance structural stabilities but sacrifice capacity through reduced redox centres and therefore suggested that co-doping can be a viable strategy to combine the benefits of various dopants to achieve optimal electrochemical performances. Overall, by regulating the loss of Li and O in LLOs, ICE can be improved, in which particle size control, surface coating and lattice doping prove to be useful in the reconstruction of surface structures, leading to possible stabilization of bulk structures, and are therefore feasible strategies.

3.2 Capacity and Voltage Fade

The capacity and voltage fade in LLOs, especially sustained average voltage, decreases during electrochemical cycling, significantly lowers energy efficiency and complicates corresponding battery management systems. Therefore, capacity and voltage fade has been thoroughly studied to achieve a better fundamental understanding. And because capacity fade is often coupled with voltage fade in LLOs, they will be reviewed simultaneously.

3.2.1 The Origins of Capacity and Voltage Fade

Capacity and voltage fade is a key issue in the practical application of LLOs and has been extensively investigated. Here, fading is believed to be caused by (1) TM/Li migration/layered-spinel transition/O redox, (2) the valence drop of TM ions and (3) porogenic behaviours or cracking, and all of these are closely linked to each other [48, 52, 97, 177].

3.2.1.1 TM/Li Migration/Layered-Spinel Transition/O Redox

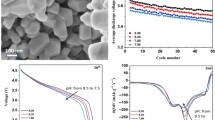

TM migration is an intrinsic feature of the electrochemical process in LLOs which causes an increase in trapped TM ions in interstitial tetrahedral sites, and cation migration from a TM slab to a Li slab is closely associated with the layered-spinel transition and the formation of spinel-like structures and is known to be associated with voltage fade [178,179,180,181,182,183]. In one study, Dogan et al. [184] used 6Li magic angle spinning (MAS) nuclear magnetic resonance (NMR) spectroscopy to confirm that TM migration in LLOs was a limited reversible process that could cause gradual decay of LLO capacity and voltage during cycling. Moreover, recent studies have also shown that there is a close coupling between TM migration and the anion redox reactions of O [27, 97, 181, 185, 186] and this was further supported by first-principles calculations (Fig. 8) [23]. In a further study, Kleiner et al. [177] experimentally demonstrated that the host structure of Li1.17Ni0.19Co0.10Mn0.54O2 could undergo an irreversible transition metal-ion migration during long-term cycling (Fig. 9a), resulting in a high capacity drop (50 mAh g−1) between the initial two cycles and ~ 0.4 mAh g−1 drop per cycle in the following cycles (Fig. 9b). In another study, Zheng et al. [72] combined aberration-corrected scanning transmission electron microscopy (AC-STEM) with electron energy loss spectroscopy (EELS) to probe the structural changes in Li(Li0.2Ni0.2Mn0.6)O2 during cycling (Fig. 9c) and revealed that the layered structure experienced phase transformations, including a defect spinel-like structure and a disordered rock-salt structure. Finally, Yan et al. [187] combined STEM with density functional theory (DFT) calculations to investigate the structural evolution of Li1.2Ni0.2Mn0.6O2 during cycling and concluded that the successive phase transitions of C2/m, I41 and spinel occurred after extended cycling (Fig. 9d, e). And based on these results, it is clear that TM migration, layered-spinel transition and O redox are closely connected to each other and contribute to the capacity and voltage decay of LLOs.

Source: a–c Reproduced with permission from Ref. [23]

Electronic structure related to cation migration. a Plot of the O fractional oxidation state and the migrated TM fraction as a function of capacity. b Projected density of states (pDOS) for TMs and two-coordinate (O(1)) and three-coordinate (O(2)) oxygen environments in the pristine delithiated state (top) and after Mn (middle) and Ni (bottom) migration into octahedral sites in the Li layer. c Schematic of the reorganization of the electronic structure resulting from TM migration.

Source: a, b Reproduced with permission from Ref. [177]. c–e Reproduced with permission from Ref. [187]

Difference Fourier maps of the ab plane of discharged LLOs after the first cycle. b Mean specific capacity of LLOs in pouch cells upon cycling. c Schematic of cycling-induced surface layer evolution. d, e [101] and [010] zone axis STEM-HAADF images and fast Fourier transformation (FFT) image of LLO electrodes after 45 cycles.

3.2.1.2 Valence Drops of TM Ions During Cycling

Alternatively, Hu et al. [25] achieved better fundamental understandings of voltage fade and suggested that the origin of voltage fade may arise not only from changes in TM migration and O redox activity, but also from the valence drop process of TM ions as induced by O release based on structural changes in Li1.2Ni0.15Co0.1Mn0.55O2. Here, the researchers noticed that lower-voltage Mn3+/Mn4+ and Co2+/Co3+ redox couples became major contributors to capacity in extended cycling, which was directly linked to voltage fade (Fig. 10a), and that the shift of redox couples from O and Ni to Mn and Co had dramatic influences on voltage profiles (Fig. 10b, c). This finding was also supported by other researchers. For example, Zheng et al. [48] examined the structural changes of Li(Li0.2Ni0.2Mn0.6)O2 electrodes and ascribed the capacity fading to the irreversible formation of Mn2+ species from the disproportionate reaction of Mn3+ (Fig. 11), in which Mn2+ species dissolved in the electrolyte and the number of redox centres in the LLOs was permanently reduced.

Source: a–c Reproduced with permission from Ref. [25]

Evolution of redox couples in Li1.2Ni0.15Co0.1Mn0.55O2 upon cycling. a Contribution towards the discharge capacity of Ni, Co, Mn and O redox at various cycles. b Effects of electronic structure change on the Fermi level. c Diagram of the correlation between redox couple and energy level of each element.

Source: Reproduced with permission from Ref. [48]

Schematic of corrosion/fragmentation-related capacity/voltage fade upon electrochemical cycling in Li(Li0.2Ni0.2Mn0.6)O2.

3.2.1.3 Porogenic Behaviours and Cracking Issues

In addition to Mn2+ dissolution, particle fragmentation of LLO particles can be induced by spinel grain formations (Fig. 11). In addition, the formation of cracks or porogenic behaviours on the surface or in the bulk of LLO materials has also been proposed and is directly related to high strain and high-voltage cycling [185, 188]. For example, Chen et al. [97] used operando neutron powder diffraction and transmission X-ray microscopy methods to reveal that generated cracks, possibly occurring alongside the two-phase and Li2MnO3 reactions during the charge process (Fig. 12a), accounted for capacity fade, and suggested that controlling phase separation and O evolution can prevent capacity fade in LLOs. Similarly, Liu et al. [74] found that layered-spinel transition was an irreversible behaviour that occurred not only on the surface, but also in the internal bulk structure of Li1.2Ni0.13Mn0.54Co0.13O2 during cycling (Fig. 12b) and can induce surface cracking and bulk fragmentation. Here, the researchers suggested that surface degradation and drastic bulk evolution were the main degradation mechanisms and were the sources of the rapid failure of their LLO electrodes. In addition, by using in situ Bragg coherent diffractive imaging (BCDI) techniques, Singer et al. [26] directly captured structural evolution during cycling in primary particles and observed large quantities of dislocations and grain boundary movements, inducing strains between the grains and causing particle cracking in LLO electrodes (Fig. 12c). Overall, all these results suggest that porogenic behaviours and cracking issues are intrinsic properties of typical LLOs.

Sources: a Reproduced with permission from Ref. [97], b Reproduced with permission from Ref. [74]. c Reproduced with permission from Ref. [26]

Summary of the changes related to electrochemistry and morphology in Li2MnO3·LiMO2 electrodes during cycling based on a combination of operando NPD and TXM results. b Schematic of the structural evolution of Li1.2Ni0.13Mn0.54Co0.13O2 electrodes during electrochemical cycling. c Changes in the displacement field along q in a plane in LLO nanoparticles during charge and the strain along the (001) direction (perpendicular to the layers) inside the LLO nanoparticles calculated from 3D displacement fields.

Alternatively, researchers have also reported that the release of O in the irreversible process of O redox activity can result in bulk/surface cracking [61, 97, 189] and can contribute to LLO capacity/voltage fade. In addition, researchers have also reported that pores can form within bulk structures through nucleating vacancies which can worsen LLO cracking issues in which nucleating vacancies are thought to be formed through the release of O during charging and exposed through the pathways of O diffusion [25]. Overall, deeper fundamental understandings of the capacity and voltage fade of LLOs need to be achieved with direct detection and quantification of TM and oxygen activities through operando techniques such as in situ neutron powder diffraction, X-ray absorption spectroscopy and Raman spectroscopy. And in particular, correlations between fundamental reaction mechanisms and structure-property relationships are needed for further improvement.

3.2.2 Strategies to Suppress Voltage Fade

To mitigate capacity and voltage fade, electrolyte and binder modulation, surface modification and lattice doping are the most commonly used strategies.

3.2.2.1 Electrolyte and Binder Modulation

Aside from intrinsic mechanistic issues, the instability and possible decomposition of conventional electrolytes can also affect the capacity and voltage fade of LLOs due to the need for high-voltage charging (> 4.7 V). Because of this, conventional electrolytes and binders cannot meet the demands of high-voltage operations for LLOs; therefore, optional solvents (e.g. ionic liquids [190], suberonitrile [191]) and additives (e.g. tris(pentafluorophenyl) borane (TPFPB) [192], lithium bis(oxalate) borate (LiBOB) [193], dimethyl phenylphosphonite (DMPP) [194], lithium difluoro(oxalate)borate (LiDFOB) [195, 196], triethyl phosphite (TEP) [197], tris(trimethylsilyl)borate (TMSB) [198, 199], (trimethylsilyl)methanesulphonate (TMSOMs) [199], 1,3,6-hexanetricarbonitrile [200], tripropylborate (TPB) [201], phenyl vinyl sulphone (PVS) [200], tris(2,2,2-trifluoroethyl) phosphite (TTFP) [202], tri(hexafluoro-iso-propyl)phosphate (HFiP) [203]) have been frequently applied to achieve better electrolyte stability at such high working voltages. Here, most additives can improve capacity retention and even discharge voltage fade by forming protective solid electrolyte interphase (SEI) films on cathode surfaces to prevent direct contact between cathode surfaces and electrolytes. For example, Zheng et al. [192] reported that TPFPB as an anion receptor can be used as an electrolyte additive in Li(Li0.2Ni0.2Mn0.6)O2 to effectively improve capacity retention and reduce voltage fade through the capture of oxygen species generated during Li2MnO3 activation. In another example, Nayak et al. [193] reported that LiBOB as an electrolyte additive could slow down Li2MnO3 activation and that the subsequent structural stabilization could restrict layered-spinel transition in Li1.2Mn0.56Ni0.16Co0.08O2. In addition, various binders other than the commonly used polyvinylidene fluoride (PVDF) have been found to able to enhance LLO electrochemical performances [63, 204]. For example, Zhang et al. [205] used sodium carboxymethyl cellulose (CMC) as a binder in Li1.2Ni0.13Co0.13Mn0.54O2 and reported excellent suppression of voltage fade (Fig. 13), revealing that the CMC binder could not only prevent the detachment of electrode materials from the current collector, but also possibly introduce Na+ doping through an ion exchange process during discharge.

Source: a–d Reproduced with permission from Ref. [205]

Mid-point discharge voltage fade curves of LLOs and b–d voltage profiles of LLOs with 10 wt% PVDF, PAN and CMC binders.

3.2.2.2 Surface Modification

As for surface modifications, they can not only protect, but also enhance electronic/ionic conductivities and alter mechanistic behaviours of LLOs in terms of capacity and voltage fade. For example, Liu et al. [206] modified Li1.17Ni0.17Co0.17Mn0.5O2 with a hybrid surface coating layer composed of Mg2+ pillars and Li-Mg-PO4 (Fig. 14a) and reported significantly enhanced cycling performances (capacity of 180 mAh g−1 after 250 cycles at 60 °C) and average discharge voltage retention of 88.7% after extended cycling (Fig. 14b-c). In another example, Prakasha et al. [157] used Li2ZrO3, a well-known ion conductor, as a coating layer for LLOs to promote the migration of Li+ and resist the diffusion of Mn2+ and reported greatly suppressed layered-spinel transitions and voltage fade during cycling. Similarly, Wu et al. [150] modified Li(Li0.2Fe0.1Ni0.15Mn0.55)O2 with an AlPO4 coating and reported that the coating reduced side reactions between the electrolyte and the electrode surface, decreased O vacancy mobility and promoted Li diffusion, leading to improved LLO electrochemical performances. In a further example, Kim et al. [207] modified the surface structure of LLOs to form a Li2MnO3-like coating on the surface and reported that the Li2MnO3-like layer possessed high atomic-level structural compatibility and exhibited a seamless surface–bulk connection with the core LLO structure. In addition, the researchers reported that compared with other coating materials, their Li2MnO3-like coating not only provided facile Li diffusion, but also suppressed layered-spinel transition, hence ameliorating the voltage fade problem of LLOs (Fig. 15a–c), in which the suppression of the layered-spinel transition was attributed to the unique atomic coordination of Li/Ni mitigating TM mixing (Fig. 15d).

Source: a-c Reproduced with permission from Ref. [206]

Schematic of Li1.17Ni0.17Co0.17Mn0.5O2 particles with surface modification. b, c Charge-discharge curves of bare and surface-modified LLOs at various cycles.

Source: a–d Reproduced with permission from Ref. [207]

Surface crystal structure of LLOs and the effects of surface modification: a pristine sample, b with conventional surface coating and c with unique surface modifications in which Ni is located between Mn layers. d Schematic of the effects of surface modification.

3.2.2.3 Lattice Doping

Lattice doping is the most common approach used by researchers to reduce voltage fading through the blocking of TM migration and the stabilization of LLO structures [208, 209]. For example, Nayak et al. [50] replaced Mn ions with Al3+ ions in Li1.2Ni0.16Mn0.56Co0.08O2 and reported that the doped sample demonstrated noticeably reduced capacities and voltage fade and that this effect increased with Al doping amounts (Fig. 16). Here, Raman spectroscopy results suggested that Al doping can stabilize the layered structure during the charge-discharge process in LLOs. In another example, Yu et al. [210] introduced Ti4+ doping into an LLO structure to investigate its effects towards LLO voltage fade suppression and reported that Ti4+ doping can prevent the migration of Mn ions and therefore stabilize the layer structure. Furthermore, in addition to TM site doping, Li site doping with alkali cations (such as Na+ and K+) [116, 164] and O site doping with F− [115, 211] have also been investigated by researchers with promising results.

Source: a–d Reproduced with permission from Ref. [50]

Charge-discharge curves of LLOs: a Li1.2Ni0.16Mn0.56Co0.08O2, b Li1.2Ni0.16Mn0.54Al0.02Co0.08O2, c Li1.2Ni0.16Mn0.51Al0.05Co0.08O2 and d Li1.2Ni0.16Mn0.48Al0.08Co0.08O2.

Overall, it is generally accepted that oxygen activities play an important role in the suppression of capacity and voltage fade in LLOs. And although lattice doping and the control of synthesis conditions have been shown to affect oxygen activities, more precise control has yet to achieve and a deep understanding into this control is lacking. More importantly, more cost-effective methods for the large-scale synthesis of optimal LLOs in full cells are required for real-world applications.

3.3 Poor Rate Capability

The rate capability of an electrode is an important parameter in application for high-power applications such as EVs. In LLOs, rate performance is linked to Li diffusion kinetics within crystal structures and interfacial charge transfer reactions [55].

3.3.1 The Origins of Poor Rate Capability

LLOs suffer from structural instabilities (TM migration and lattice dislocation) and complex O activities during cycling and therefore hinder Li diffusion, resulting in poor rate capabilities. Here, rate capability is determined by the Li mobility within cells, and for LLOs, the Li2MnO3 component with the C2/m monoclinic structure possesses relatively low Li diffusion kinetics as compared with other layered oxides [55, 212]. In a study, Zheng et al. [55] used galvanostatic intermittent titration technique (GITT) to confirm that the sluggish Li diffusion kinetics in Li2MnO3 and MnO2 components was the rate-determining factor of Li(Li0.2Ni0.2Mn0.6)O2 and limited the discharge capacity of LLOs at high rates. Similar results have also been reported in literature [31, 213, 214]. Furthermore, although the activation of Li2MnO3 in LLOs is the origin of their anomalously high capacities and energy densities, it also causes surface structure transformations, which can increase interfacial resistances, impede Li diffusion kinetics and induce poor rate capabilities [18, 215, 216]. In addition, the oxidation of organic electrolytes at high voltage can induce the formation of undesirable surface passivation layers, which block Li diffusion and contribute to poor rate capabilities.

3.3.2 Strategies for Improving Rate Performance

Various successful methods have been reported in the enhancement of LLO rate performances, and in this review, various enhancement strategies will be presented to assist with understanding and discussion.

3.3.2.1 Surface Modification

Surface modification is still one of the most effective approaches to improve rate capability, and many studies have shown that solid electrolytes and ion conductive coating materials can improve the interfacial stability and rate capability of LLOs as compared with other surface coating materials that possess low Li conductivity and electronic conductivity and can block Li transport channels. Researchers have reported that carbon and other electronic conductive coating materials on LLOs can exhibit superior rate performance, mainly due to their high electronic conductivities and reduced charge transfer resistances [137,138,139,140,141,142,143,144,145, 217] and that surface coating with ionic conductive AlPO4 can retain O vacancies and stabilize electrode/electrolyte interface side reactions due to the high stability of AlPO4 (stemming from the high electronegativity of polyanions with Al ions) [150]. For example, Ahn et al. [155] reported that nanoscaled Zr-abundant nanolayers grown along the (20\( \bar{2} \))m plane which are along the Li diffusion facets can exhibit a capacity of ~ 110 mAh g−1 even at a high rate of 30 C in which Zr can prevent the segregation of TM ions along the (20\( \bar{2} \))m plane and was believed to influence the electrochemical performance. In addition, the researchers also suggested that this surface modification can induce O vacancies in the surface regions. Normally, cation-disordered structures impede Li diffusion [4, 206]; however, this study suggests the unexpected formation of percolation networks with facile Li transport in Li-disordered rock-salt structures [218, 219]. Based on this, surface modification can not only refer to coatings for protection and higher conductivity, but also refer to the pre-activation of Li2MnO3, surface structure tuning and surface gradient doping through pre-cycling treatments.

Pre-cycling treatments on LLO surfaces have been shown to improve rate performance, and surface treatments with H2SO4 [220], AlF3 [221, 222], NH4H2PO4 [117], (NH4)2HPO4 [223], Na2S2O8 [224, 225], (NH4)2SO4 [226] and NH4HF2 [227] have been used to activate Li2MnO3 components and induce the formation of the spinel-like phase on the surface, which enhance Li diffusion (Fig. 17). For example, Wu et al. [228] pre-treated LLOs with Mn(Ac)2 to achieve an encapsulating layer and annealed the samples to achieve a heterostructured spinel layer with three-dimensional (3D) Li diffusion channels that facilitated rapid Li diffusion and reported that the treated cathode exhibited improved cycling stability and rate capability (Fig. 18).

Source: Reproduced with permission from Ref. [117]

Spinel-like formations after surface treatment in LLOs.

Source: a–d Reproduced with permission from Ref. [228]

HRTEM images of treated and untreated samples with spinel heterostructure surfaces.

Aside from activating Li2MnO3 with acidic species and facilitating fast Li diffusion channels, surface treatments with polyaniline [229], Super P [230], hydrazine [231] and reduced graphene oxide (rGO) [180] have all been shown to be able to prevent layered-spinel transitions in LLOs through limiting the formation of Li and O vacancies at the surface and thereby preventing induced structural instability in these materials. For example, Zhang et al. [232] introduced surface nitridation to Li(Li0.17Ni0.25Mn0.58)O2 through sintering in NH4OH atmosphere at 400 °C and reported that the nitrogen introduction improved interfacial stability and Li diffusion. Here, the researchers reported that the improved rate capability (164.7 mAh g−1 discharge capacity at 5 C rate) can be associated with the presence of surface nitrogen; however, explanations and findings related to the effects of surface nitridation are obscure. Furthermore, surface morphology tuning is also a possible approach to enhance the rate capability of LLOs. For example, Qing et al. [116] adopted a surface doping strategy to achieve surface gradient Na+ doping by soaking LLOs in molten NaCl before heat treatment. Here, the researchers reported that some of the Li+ layers were occupied by Na+, resulting in a pinning effect that stabilized the structure and improved Li+ diffusion kinetics.

In addition, Ding et al. [64] investigated gradient surface doping using Si/Sn in which the interplanar spacings of the TM ions were expanded as Sn/Si atoms were doped into the lattice of LLO near the crystal surface and reported that such doping can result in structural stabilization and enhanced cycling performances in which the rate capability of their LLO was improved by improving Li+ diffusion through the enlargement of the interslab spacing of the TM layer. A similar gradient doping approach was conducted by Zhao et al. [117] in which polyanion doping resulted in a surface spinel transformation similar to that in acid treatments, which enhanced ionic and electronic conductivities through electrode surfaces and improved rate kinetics. Here, the researchers reported that a Mn-depleted surface layer can limit HF acid attacks and Mn dissolution and improve the stability of the electrode/electrolyte interface. In addition, these researchers also reported that PO43− doping can restrain TM-ion migration because the smaller vP cations tend to occupy tetrahedral interstitial sites. In another study, Liu et al. [118] also reported that surface doping with Nb5+ and other heavy element ions such as Ti4+ and Zr4+ can improve LLO capacity retention rates and rate capability. Here, the researchers suggested that these elements possess stronger bonds to oxygen as compared with Mn–O bonds and can limit oxygen evolution through surface oxygen deactivation and that doped Nb5+, Ti4+ and Zr4+ ions can enter the surface Li layers to inactivate Mn4+ ions and retain them in the TM layers, thus retarding migration and phase transformation. Surface gradient doping strategies have also been reported to improve LLO cycling stability and rate capabilities through the stabilization of LLO structures during electrochemical cycling. For example, Hu et al. [25] recently had suggested that AlF3 coatings can thermally stabilize LLO surface structures and restrict O release, thereby limiting structural instability and impedance build-up at the interface caused by electrolyte decomposition.

The surface coating of LLO cathode materials is an effective method to enhance rate performances through the passivation of electrode surfaces during cycling, the enhancement of LLO surface electronic and ionic conductivities and the ability to act as a protective barrier. Here, surface coating layers can act as protective layers to suppress side reactions, reduce interfacial resistances and stabilize interfaces, and some surface coatings can stabilize structural stability of LLO by partially removing Li2O or enhance structural stability by limiting O release. Researchers also reported that the effectiveness of the surface coating approach depends on the thickness, uniformity, stability (thermal and mechanical), electronic and ionic conductivity of the coating layer and that these parameters are linked to the type of coating materials and methods adopted. For example, Qiu et al. [15] introduced O vacancies into the surface of LLOs through the interfacial modification of LLO surfaces using gas-solid interface reactions (GSIR) between LLOs and CO2 gas. Here, the researchers reported that the induced O vacancies at the LLO surface suppressed O evolution and limited electrolyte decomposition due to the highly reactive O species (Fig. 19a–e). In addition, the researchers also reported that the presence of O vacancies destabilized the tetrahedral sites, which reduced the chance of Li atoms becoming trapped in the tetrahedral sites, impeding Li diffusion and affecting rate performances and capacity.

Source: a–c Reproduced with permission from Ref. [15]

Schematic of the site stability and Li migration barrier under conditions of no oxygen vacancy and oxygen vacancies at different site vertexes. Schematic of LLOs b without induced oxygen vacancies and c with surface oxygen vacancies before and after initial charging.

The surface of electrode materials can also influence the electrode/electrolyte contact, the reactivity of particles and the surface reactions and reactivity, and researchers suggest that hierarchical nanostructures with exposed (110), (100) and (010) planes with better Li intercalation kinetics can demonstrate improved rate capabilities [233, 234]. For example, Xia et al. [139] fabricated a layered-spinel carbon heterostructure using the carbothermal reduction method and reported significantly enhanced rate performances. Here, the researchers suggested that the high-capacity Li-rich core with the spinel interlayer and the outside carbon-coated shell took advantage of the 3D Li+ diffusion channels favoured by the spinel interlayer and demonstrated improved electrical conductivity due to the nanocarbon coating layer, in which a capacity of > 120 mAh g−1 even at 20 C was obtained. In another example, Li et al. [235] synthesized a core-shell structure with a Ni-rich material as the core and a Mn-rich material as the shell and reported that the Ni-rich core contributed to high energy densities and the Mn-rich shell hindered electrolyte oxidation. A similar heterogeneous design was also adopted to enhance the rate capability of LLOs in other studies and was reported to also possess high capacity inner cores and structurally stable outer shells [236, 237]. Overall, all these presented strategies aim at limiting voltage fade and have achieved improved rate performances as well because the origin of both issues is related to O activities in LLOs.

3.3.2.2 Lattice Doping

Lattice doping with alkali metals such as Na+ [163, 208], K+ [164, 165] and Mg2+ [166] with large ionic radii has proved to enhance LLO rate performances. For example, Zheng et al. [165] synthesized K-doped Li1.212K0.02Mn0.615Ni0.154O2 which exhibited enhanced rate performances and suggested that K+ can restrict TM-ion migration and accompanying spinel formation in subsequent cycles. In another example, Yu et al. [166] doped Mg2+ ions into Li1.5(Mn0.75Ni0.25)O2+δ and reported stronger Mg–O bonds as compared with Li–O bonds, allowing for the suppression of irreversible Li extraction and subsequent oxygen loss. As a result, this Mg-doped cathode exhibited good capacity retention of 94% even after 200 cycles at 0.5 C and 92% after 100 cycles if cycled at 5 C. Overall, improvements in rate performance through lattice doping can be mainly attributed to the stabilization of LLO crystal structures through the suppression of O evolution and accompanying phase transitions in subsequent cycles. Here, large dopant elements can hinder TM-ion migration and promote lattice expansion, favouring Li diffusion kinetics. In addition, researchers reported that the partial substitution of Ti4+ ions into Li sites of the Li2MnO3 component can create Li vacancies and increase interlayer spacing, allowing for better Li diffusion kinetics [171] and that doping with anions such as F− can improve rate kinetics in which F− doping into O sites can result in larger crystal lattices and improved Li diffusion [51] along with restricted spinel-phase transformation [238]. Furthermore, 4d TMs such as Sn [170], Ru [174], Nb [175], Y [169], Zr [172] and Sb [63], and 5d metals such as W [176] have also been used as dopants in LLOs and have shown improved cycling stability and rate capabilities. Here, the observed enhanced electrochemical performances can mainly be attributed to reduced O loss due to strong 4d–O and 5d–O bonds as compared with 3d–O bonds. Moreover, researchers suggest that the strengthening of M–O covalent bonds can promote reversible anionic redox instead of irreversible O loss that results from the breaking of M–O bonds [239].

3.3.2.3 Particle Morphology Control and Other Strategies for LLO Rate Enhancements

Architectures of nanosized LLOs that provide shorter Li diffusion pathways and more exposed surface sites for lithium intercalation/deintercalation can also enhance LLO rate capabilities [63, 240]. Here, the morphology of LLO plays a critical role in electrochemical performance in which hierarchial nanostructures with exposed (110), (100) and (010) planes favour Li intercalation kinetics, and LLOs possessing hierarchial porous structures can exhibit enhanced rate performances [233, 241,242,243,244]. Researchers also report that the formation of undesirable surface passivation layers due to organic electrolyte oxidation at higher voltage can cause poor rate capabilities due to increased Li diffusion resistances at the electrode/electrolyte interface [229, 245, 246]. In one study, Ming et al. [243] synthesized LLO nanoplates with built-in spinel/rock-salt tunnels (OAN-ST) that exhibited highly exposed (010) planes and reported that the resulting cathode exhibited enhanced capacity retention rates (92% after 100 cycles at 1 C), delivering high discharge capacities and ICE. Here the researchers attributed the performance enhancements to enhanced Li diffusion and intercalation kinetics as well as structural reinforcements through the accommodation of volume change during electrochemical cycling due to the peculiar structural design. In another study, Lin et al. [245] reported that other than the formation of surface passivation layers, progressive structural transitions can occur at the LLO surface depending on the crystal orientation and can result in impedance build-up and affect Li diffusion kinetics.

One reason for poor rate capability and irreversible capacity fading in LLOs is the formation of undesirable SEI layers (e.g. Li2CO3, LiF) on cathode surfaces, which can generate resistance to Li diffusion, and O species extracted during the Li2MnO3 activation process can oxidize organic solvents and result in the formation of this surface passivation layer at the cathode/electrolyte interphase [247]. In addition, at higher voltages above 4.6 V, carbonate-based electrolytes can decompose and contribute to SEI layer formations as well. Based on this, researchers have reported that electrolyte additives such as TPFPB [192], tris(2,2,2-trifluoro ethyl)phosphite [202] and LiBOB [193] can be useful to improve LLO rate capability by forming protective films at the cathode surface without impeding Li diffusion or by preventing undesirable parasitic reactions at the cathode/electrolyte interphase and therefore avoid the formation of undesirable surface passivating layers. For example, TPFPB with B atoms located at the centre has been found to be effective in the capture of active oxygen species and thus can limit side reactions at the interphase and assist in the dissolution of by-products of these parasitic reactions [192]. Alternatively, LiBOB is an electrolyte additive that can slow down Li2MnO3 activation and although studies report poor performances and an initial discharge capacity of only 215 mAh g−1, cycling stability and rate performances can be enhanced with less discharge voltage fade [193]. However, the mechanisms behind the stabilization achieved by this additive have not yet been elucidated. Furthermore, with its stable chemical structure, PVS as an electrolyte additive can form a stable and ion conductive film on cathode surfaces to improve the capacity and rate performance of Li(Li0.2Mn0.54Ni0.13Co0.13)O2 [248]. Lastly, lithium difluoro(oxolato)borate (LiODFB) can also be employed as an electrolyte additive in full cells with Li1.17Ni0.17Mn0.5Co0.17O2 cathodes and graphite anodes to achieve better rate capabilities due to the improved electronic and ionic conductivities of the SEI layer at the anode surface and the alleviated metal-ion dissolution of the cathode surface [249].

Overall, lattice changes and phase transformations originating from the activation process of Li2MnO3 are the major causes of poor rate capability; therefore, the optimization of the TM content and stabilization of TM lattices, especially Mn, are potential strategies to improve LLO rate capabilities.

4 Summary and Future Perspectives

Lithium-rich layered oxides (LLOs) possess high energy densities and are ideal for large-scale energy storage applications such as EVs and PHEVs. However, intrinsic weaknesses such as low initial Coulombic efficiency (ICE), severe capacity/voltage fade and poor rate capabilities impede further application. Therefore, in this review, fundamental origins of these issues and corresponding solutions are summarized along with opinions and perspectives.

Since the introduction of LLOs by Thackeray et al. in 1993, their electrochemical performances have continuously improved. And although the practical capacity of LLOs has reached ~ 330 mAh g−1 and many breakthroughs have been achieved, challenging issues remain and are closely connected with Li2MnO3 activation as well as the subsequent O release and evolution and the corresponding atomic (transition metal/cation migrations, mechanistic evolutions and valence drop cation redox reactions) and macroscopic (porogenic behaviours, surface cracking and pulverization) responses. To address these, commonly used strategies that have proved to be useful include particle size control, electrolyte and binder formulations, surface modifications and lattice doping. Although these strategies can partially mitigate some issues posed by LLOs, intrinsic issues that limit practical application have not been fully resolved. Here, many recent studies on LLOs have been able to find the root causes of these issues with the aid of advanced characterization techniques, but more efforts are needed to obtain reliable conclusions and solutions. This is because none of these studies have been able to deliver clear and conclusive results regarding the fundamental origins of the challenges, especially the voltage fade, as well as the fact that many of the proposed solutions, such as surface modification, involve additional costs. Overall, an ICE greater than 90% for LLOs is required for communalization, and to achieve this, more intensive full-cell studies need to be conducted. In addition, volumetric energy densities of LLOs need to be improved through the improvement of LLO tap densities through the exploration of facile routes for low-cost large-scale synthesis.

Overall, an in-depth understanding of the correlation between O redox reactions and O release with respect to how it is affected by local structures is required and a promising and challenging approach is to create more triggering anionic redox reactions while lowering O release in which a noteworthy example is the use of electroactive cations such as Ru while maintaining strong d-sp hybridization to harvest additional capacity from \( {\text{O}}^{2 - } \mathop \to \limits^{{}} {\text{O}}_{2}^{2 - } \) redox. In addition, new cutting-edge probing techniques need to be developed to investigate redox origins such as the direct measurement of O activities in LLOs during lithiation/delithiation to provide clearer and more precise pictures of mechanistic behaviours along with currently available characterization tools and approaches. And from a material design perspective, achieving coupled cationic and anionic redox processes can be a good solution, in which the fast kinetics of cationic redox reactions can act as redox mediators for sluggish anionic processes. Overall, there has been clear progress in the commercialization of LLOs; however, intrinsic challenges remain for practical application. To address these challenges, this review has presented many promising strategies in the hope that LLOs will eventually become optimized enough to meet the demands of commercial and industrial applications.

References

Bunsen, T., Cazzola, P., Gorner, M., et al.: Global EV Outlook 2018: towards cross-modal electrification. International Energy Agency, Paris (2018)

Li, M., Lu, J., Chen, Z., et al.: 30 Years of lithium-ion batteries. Adv. Mater. 30, 1800561 (2018)

Howell, D., Duong, T.Q., Faguy, P.W., et al.: FY 2016 annual progress report for advanced batteries. In: Energy Efficiency & Renewable Energy, U.S. Department of Energy, Washington, DC (2017)

Liu, W., Oh, P., Liu, X., et al.: Nickel-rich layered lithium transition-metal oxide for high-energy lithium-ion batteries. Angew. Chem. Int. Edit. 54, 4440–4457 (2015)

Julien, C., Mauger, A.: Review of 5-V electrodes for Li-ion batteries: Status and trends. Ionics 19, 951–988 (2013)

Hu, M., Pang, X., Zhou, Z.: Recent progress in high-voltage lithium ion batteries. J. Power Sources 237, 229–242 (2013)

Xu, B., Qian, D., Wang, Z., et al.: Recent progress in cathode materials research for advanced lithium ion batteries. Mater. Sci. Eng. R-Rep. 73, 51–65 (2012)

Ellis, B.L., Lee, K.T., Nazar, L.F.: Positive electrode materials for Li-ion and Li-batteries. Chem. Mater. 22, 691–714 (2010)

Choi, J.W., Aurbach, D.: Promise and reality of post-lithium-ion batteries with high energy densities. Nat. Rev. Mater. 1, 16013 (2016)

Croguennec, L., Palacin, M.R.: Recent achievements on inorganic electrode materials for lithium-ion batteries. J. Am. Chem. Soc. 137, 3140–3156 (2015)

Kraytsberg, A., Ein-Eli, Y.: Higher, stronger, better… A review of 5 volt cathode materials for advanced lithium-ion batteries. Adv. Energy Mater. 2, 922–939 (2012)

Li, W., Song, B., Manthiram, A.: High-voltage positive electrode materials for lithium-ion batteries. Chem. Soc. Rev. 46, 3006–3059 (2017)

Rossouw, M.H., Liles, D.C., Thackeray, M.M.: Synthesis and structural characterization of a novel layered lithium manganese oxide, Li0.36Mn0.91O2, and its lithiated derivative, Li1.09Mn0.91O2. J. Solid State Chem. 104, 464-466 (1993)

Thackeray, M.M., Kang, S.H., Johnson, C.S., et al.: Li2MnO3-stabilized LiMO2 (M = Mn, Ni, Co) electrodes for lithium-ion batteries. J. Mater. Chem. 17, 3112–3125 (2007)

Qiu, B., Zhang, M., Wu, L., et al.: Gas–solid interfacial modification of oxygen activity in layered oxide cathodes for lithium-ion batteries. Nat. Commun. 7, 12108 (2016)

Lu, Z., Dahn, J.R.: Understanding the anomalous capacity of Li/Li [NixLi(1/3−2x/3)Mn(2/3− x/3)]O2 cells using in situ X-ray diffraction and electrochemical studies. J. Electrochem. Soc. 149, A815–A822 (2002)

Croy, J., Kang, S.H., Balasubramanian, M., et al.: Li2MnO3-based composite cathodes for lithium batteries: a novel synthesis approach and new structures. Electrochem. Commun. 13, 1063–1066 (2011)

Yu, X., Lyu, Y., Gu, L., et al.: Understanding the rate capability of high-energy-density Li-rich layered Li1.2Ni0.15Co0.1Mn0.55O2 cathode materials. Adv. Energy Mater. 4, 1300950 (2014)

Kalluri, S., Yoon, M., Jo, M., et al.: Feasibility of cathode surface coating technology for high-energy lithium-ion and beyond-lithium-ion batteries. Adv. Mater. 29, 1605807 (2017)

Wang, Y., Yang, Z., Qian, Y., et al.: New insights into improving rate performance of lithium-rich cathode material. Adv. Mater. 27, 3915–3920 (2015)

Zhang, X.D., Shi, J.L., Liang, J.Y., et al.: Structurally modulated Li-rich cathode materials through cooperative cation doping and anion hybridization. Sci. China Chem. 60, 1554–1560 (2017)

Assat, G., Tarascon, J.M.: Fundamental understanding and practical challenges of anionic redox activity in Li-ion batteries. Nat. Energy 3, 373 (2018)

Gent, W.E., Lim, K., Liang, Y., et al.: Coupling between oxygen redox and cation migration explains unusual electrochemistry in lithium-rich layered oxides. Nat. Commun. 8, 2091 (2017)

Assat, G., Foix, D., Delacourt, C., et al.: Fundamental interplay between anionic/cationic redox governing the kinetics and thermodynamics of lithium-rich cathodes. Nat. Commun. 8, 2219 (2017)

Hu, E., Yu, X., Lin, R., et al.: Evolution of redox couples in Li-and Mn-rich cathode materials and mitigation of voltage fade by reducing oxygen release. Nature Energy 3, 690 (2018)

Singer, A., Zhang, M., Hy, S., et al.: Nucleation of dislocations and their dynamics in layered oxide cathode materials during battery charging. Nat. Energy 3, 641–647 (2018)

Myeong, S., Cho, W., Jin, W., et al.: Understanding voltage decay in lithium-excess layered cathode materials through oxygen-centred structural arrangement. Nat. Commun. 9, 3285 (2018)

Xu, J., Sun, M., Qiao, R., et al.: Elucidating anionic oxygen activity in lithium-rich layered oxides. Nat. Commun. 9, 947 (2018)

Rozier, P., Tarascon, J.M.: Li-rich layered oxide cathodes for next-generation Li-ion batteries: chances and challenges. J. Electrochem. Soc. 162, A2490–A2499 (2015)

Thackeray, M., Croy, J., Lee, E., et al.: The quest for manganese-rich electrodes for lithium batteries: strategic design and electrochemical behavior. Sustain. Energy Fuels 2, 1375–1397 (2018)

Nayak, P.K., Erickson, E.M., Schipper, F., et al.: Review on challenges and recent advances in the electrochemical performance of high capacity Li-and Mn-rich cathode materials for Li-ion batteries. Adv. Energy Mater. 8, 1702397 (2018)

Hu, E., Wang, X., Yu, X., et al.: Probing the complexities of structural changes in layered oxide cathode materials for Li-ion batteries during fast charge-discharge cycling and heating. Acc. Chem. Res. 51, 290–298 (2018)

Thackeray, M.M., Johnson, C.S., Vaughey, J.T., et al.: Advances in manganese-oxide ‘composite’ electrodes for lithium-ion batteries. J. Mater. Chem. 15, 2257–2267 (2005)

Lu, Z., Beaulieu, L., Donaberger, R., et al.: Synthesis, structure, and electrochemical behavior of Li[NixLi1/3−2x/3Mn2/3−x/3]O2. J. Electrochem. Soc. 149, A778–A791 (2002)

Lu, Z., Chen, Z., Dahn, J.R.: Lack of cation clustering in Li[NixLi1/3−2x/3Mn2/3−x/3]O2 (0 < x \(\leqslant\) 1/2) and Li[CrxLi(1−x)/3Mn(2−2x)/3]O2 (0 < x < 1). Chem. Mater. 15, 3214–3220 (2003)

Li, X., Qiao, Y., Guo, S., et al.: Direct visualization of the reversible O2−/O− redox process in Li-rich cathode materials. Adv. Mater. 30, 1705197 (2018)

Hong, J., Gwon, H., Jung, S.K., et al.: Review—lithium-excess layered cathodes for lithium rechargeable batteries. J. Electrochem. Soc. 162, A2447–A2467 (2015)

Yu, H., Ishikawa, R., So, Y.G., et al.: Direct atomic-resolution observation of two phases in the Li1.2Mn0.567Ni0.166Co0.067O2 cathode material for lithium-ion batteries. Angew. Chem. Int. Edit. 125, 6085–6089 (2013)

Radin, M.D., Hy, S., Sina, M., et al.: Narrowing the gap between theoretical and practical capacities in Li-ion layered oxide cathode materials. Adv. Energy Mater. 7, 1602888 (2017)

Mohanty, D., Huq, A., Payzant, E.A., et al.: Neutron diffraction and magnetic susceptibility studies on a high-voltage Li1.2Mn0.55Ni0.15Co0.10O2 lithium ion battery cathode: insight into the crystal structure. Chem. Mater. 25, 4064–4070 (2013)

Wang, D., Belharouak, I., Zhang, X., et al.: Insights into the phase formation mechanism of [0.5Li2MnO3·0.5LiNi0.5Mn0.5O2] battery materials. J. Electrochem. Soc. 161, A1–A5 (2014)

Boulineau, A., Simonin, L., Colin, J.F., et al.: Evolutions of Li1.2Mn0.61Ni0.18Mg0.01O2 during the initial charge/discharge cycle studied by advanced electron microscopy. Chem. Mater. 24, 3558–3566 (2012)

Cho, S.W., Kim, G.O., Ryu, K.S.: Sulfur anion doping and surface modification with LiNiPO4 of a Li[Co0.1Ni0.15Li0.2Mn0.55]O2 cathode material for Li-ion batteries. Solid State Ion. 206, 84–90 (2012)

Gummow, R.J., Sharma, N., Feng, R., et al.: High performance composite lithium-rich nickel manganese oxide cathodes for lithium-ion batteries. J. Electrochem. Soc. 160, A1856–A1862 (2013)

Devaraj, A., Gu, M., Colby, R., et al.: Visualizing nanoscale 3D compositional fluctuation of lithium in advanced lithium-ion battery cathodes. Nat. Commun. 6, 8014 (2015)

Bareño, J., Balasubramanian, M., Kang, S.H., et al.: Long-range and local structure in the layered oxide Li1.2Co0.4Mn0.4O2. Chem. Mater. 23, 2039–2050 (2011)

McCalla, E., Lowartz, C.M., Brown, C.R., et al.: Formation of layered-layered composites in the Li–Co–Mn oxide pseudoternary system during slow cooling. Chem. Mater. 25, 912–918 (2013)

Zheng, J., Gu, M., Xiao, J., et al.: Corrosion/fragmentation of layered composite cathode and related capacity/voltage fading during cycling process. Nano Lett. 13, 3824–3830 (2013)

Zheng, J., Gu, M., Xiao, J., et al.: Functioning mechanism of AlF3 coating on the Li-and Mn-rich cathode materials. Chem. Mater. 26, 6320–6327 (2014)

Nayak, P.K., Grinblat, J., Levi, M., et al.: Al doping for mitigating the capacity fading and voltage decay of layered Li and Mn-rich cathodes for Li-ion batteries. Adv. Energy Mater. 6, 1502398 (2016)

Pang, W.K., Lin, H.F., Peterson, V.K., et al.: Effects of fluorine and chromium doping on the performance of lithium-rich Li1+xMO2 (M = Ni, Mn, Co) positive electrodes. Chem. Mater. 29, 10299–10311 (2017)

Gu, M., Genc, A., Belharouak, I., et al.: Nanoscale phase separation, cation ordering, and surface chemistry in pristine Li1.2Ni0.2Mn0.6O2 for Li-ion batteries. Chem. Mater. 25, 2319–2326 (2013)

Lei, C.H., Bareño, J., Wen, J.G., et al.: Local structure and composition studies of Li1.2Ni0.2Mn0.6O2 by analytical electron microscopy. J. Power Sour. 178, 422–433 (2008)

Armstrong, A.R., Holzapfel, M., Novák, P., et al.: Demonstrating oxygen loss and associated structural reorganization in the lithium battery cathode Li[Ni0.2Li0.2Mn0.6]O2. J. Am. Chem. Soc. 128, 8694–8698 (2006)

Zheng, J., Shi, W., Gu, M., et al.: Electrochemical kinetics and performance of layered composite cathode material Li[Li0.2Ni0.2Mn0.6]O2. J. Electrochem. Soc. 160, A2212–A2219 (2013)

Kikkawa, J., Akita, T., Tabuchi, M., et al.: Coexistence of layered and cubic rocksalt structures with a common oxygen sublattice in Li1.2Mn0.4Fe0.4O2 particles: a transmission electron microscopy study. J. Appl. Phys. 103, 104911 (2008)

Jacob, C., Jian, J., Zhu, Y., et al.: A new approach to investigate Li2MnO3 and Li(Ni0.5Mn0.3Co0.2)O2 mixed phase cathode materials. J. Mater. Chem. A 2, 2283–2289 (2014)

Shi, J.L., Zhang, J.N., He, M., et al.: Mitigating voltage decay of Li-rich cathode material via increasing Ni content for lithium-Ion batteries. ACS Appl. Mater. Interfaces 8, 20138–20146 (2016)

Sun, Y.K., Lee, M.J., Yoon, C.S., et al.: The role of AlF3 coatings in improving electrochemical cycling of Li-enriched nickel-manganese oxide electrodes for Li-ion batteries. Adv. Mater. 24, 1192–1196 (2012)

Zhang, S., Gu, H., Tang, T., et al.: Insight into the synergistic effect mechanism between the Li2MO3 phase and the LiMO2 phase (M = Ni Co, and Mn) in Li- and Mn-rich layered oxide cathode materials. Electrochim. Acta 266, 66–77 (2018)

Ito, A., Li, D., Sato, Y., et al.: Cyclic deterioration and its improvement for Li-rich layered cathode material Li[Ni0.17Li0.2Co0.07Mn0.56]O2. J. Power Sources 195, 567–573 (2010)

Shojan, J., Chitturi, V.R., Soler, J., et al.: High energy xLi2MnO3–(1-x)LiNi2/3Co1/6Mn1/6O2 composite cathode for advanced Li-ion batteries. J. Power Sources 274, 440–450 (2015)

Yu, R., Zhang, Z., Jamil, S., et al.: Effects of nanofiber architecture and antimony doping on the performance of lithium-rich layered oxides: enhancing lithium diffusivity and lattice oxygen stability. ACS Appl. Mater. Interfaces 10, 16561–16571 (2018)

Ding, F., Li, J., Deng, F., et al.: Surface heterostructure induced by PrPO4 modification in Li12[Mn0.54Ni0.13Co0.13]O2 cathode material for high-performance lithium-ion batteries with mitigating voltage decay. ACS Appl. Mater. Interfaces 9, 27936–27945 (2017)

Ghanty, C., Basu, R.N., Majumder, S.B.: Performance of wet chemical synthesized xLi2MnO3-(1-x)Li(Mn0.375Ni0.375Co0.25)O2 (0.0 \(\leqslant\) x \(\leqslant\) 1.0) integrated cathode for lithium rechargeable battery. J. Electrochem. Soc. 159, A1125–A1134 (2012)

Nomura, F., Liu, Y., Tanabe, T., et al.: Elucidation of key factors of water-resistance of Li-rich solid-solution layered oxide cathode materials applicable to a water-based cathode preparation process for Li-ion battery. Electrochim. Acta 283, 478–487 (2018)

Bréger, J., Jiang, M., Dupré, N., et al.: High-resolution X-ray diffraction, DIFFaX, NMR and first principles study of disorder in the Li2MnO3-Li[Ni1/2Mn1/2]O2 solid solution. J. Solid State Chem. 178, 2575–2585 (2005)

Jarvis, K.A., Deng, Z., Allard, L.F., et al.: Atomic structure of a lithium-rich layered oxide material for lithium-ion batteries: evidence of a solid solution. Chem. Mater. 23, 3614–3621 (2011)

Shukla, A.K., Ramasse, Q.M., Ophus, C., et al.: Unravelling structural ambiguities in lithium-and manganese-rich transition metal oxides. Nat. Commun. 6, 8711 (2015)

Zheng, J., Gu, M., Genc, A., et al.: Mitigating voltage fade in cathode materials by improving the atomic level uniformity of elemental distribution. Nano Lett. 14, 2628–2635 (2014)

Komatsu, H., Minato, T., Matsunaga, T., et al.: Site-selective analysis of nickel-substituted Li-rich layered material: migration and role of transition metal at charging and discharging. J. Phys. Chem. C 122, 20099–20107 (2018)

Zheng, J., Xu, P., Gu, M., et al.: Structural and chemical evolution of Li-and Mn-rich layered cathode material. Chem. Mater. 27, 1381–1390 (2015)

Ozawa, K., Nakao, Y., Mochiku, T., et al.: Electrochemical characteristics of layered Li1.95Mn0.9Co0.15O3 (C2/m) as a lithium-battery cathode. J. Electrochem. Soc. 159, A300–A304 (2012)

Liu, H., Harris, K.J., Jiang, M., et al.: Unraveling the rapid performance decay of layered high-energy cathodes: from nanoscale degradation to drastic bulk evolution. ACS Nano 12, 2708–2718 (2018)

Wang, J.X.: Structure and delithiation/lithiation of the lithium-rich layered oxide Li[Li0.23Ni0.15Mn0.62]O2 as cathode material. Int. J. Electrochem. Sci. 12, 8095–8105 (2017)

Pimenta, V., Sathiya, M., Batuk, D., et al.: Synthesis of Li-rich NMC: a comprehensive study. Chem. Mater. 29, 9923–9936 (2017)

Fujii, H., Ozawa, K., Mochiku, T.: Electron diffraction and high-resolution electron microscopy studies on layered Li2−δ(Mn1−xCox)1+δO3. J. Solid State Chem. 203, 345–352 (2013)

Nomura, F., Tanabe, T., Gunji, T., et al.: Effect of the cooling process on the structure and charge/discharge cycling performance in Li[Li0.20Mn0.58Ni0.18Co0.04]O2 Li-rich solid-solution layered oxide cathode materials for Li-ion battery. ECS Trans. 85, 1497–1505 (2018)

Koga, H., Croguennec, L., Mannessiez, P., et al.: Li1.20Mn0.54Co0.13Ni0.13O2 with different particle sizes as attractive positive electrode materials for lithium-ion batteries: insights into their structure. J. Phys. Chem. C 116, 13497–13506 (2012)

Numata, K., Sakaki, C., Yamanaka, S.: Synthesis and characterization of layer structured solid solutions in the system of LiCoO2-Li2MnO3. Solid State Ion. 117, 257–263 (1999)

Yoon, W.-S., Iannopollo, S., Grey, C.P., et al.: Local structure and cation ordering in O3 lithium nickel manganese oxides with stoichiometry Li[NixMn(2−x)/3Li(1−2x)/3]O2 NMR studies and first principles calculations. Electrochem. Solid-State Lett. 7, A167–A171 (2004)

Meng, Y.S., Ceder, G., Grey, C.P., et al.: Cation ordering in layered O3 Li[NixLi1/3−2x/3Mn2/3−x/3]O2 (0 \(\leqslant\) x \(\leqslant\) 1/2) compounds. Chem. Mater. 17, 2386–2394 (2005)

Genevois, C., Koga, H., Croguennec, L., et al.: Insight into the atomic structure of cycled lithium-rich layered oxide Li1.20Mn0.54Co0.13Ni0.13O2 using HAADF STEM and electron nanodiffraction. J. Phys. Chem. C 119, 75–83 (2014)

Sun, Y., Shiosaki, Y., Xia, Y., et al.: The preparation and electrochemical performance of solid solutions LiCoO2–Li2MnO3 as cathode materials for lithium ion batteries. J. Power Sources 159, 1353–1359 (2006)

West, W.C., Soler, J., Smart, M.C., et al.: Electrochemical behavior of layered solid solution Li2MnO3-LiMO2 (M = Ni, Mn, Co) Li-ion cathodes with and without alumina coatings. J. Electrochem. Soc. 158, A883–A889 (2011)

Ohzuku, T., Nagayama, M., Tsuji, K., et al.: High-capacity lithium insertion materials of lithium nickel manganese oxides for advanced lithium-ion batteries: toward rechargeable capacity more than 300 mAh g−1. J. Mater. Chem. 21, 10179–10188 (2011)

Singh, G., Thomas, R., Kumar, A., et al.: Electrochemical behavior of Cr-doped composite Li2MnO3-LiMn0.5Ni0.5O2 cathode materials. J. Electrochem. Soc. 159, A410–A420 (2012)

Nomura, F., Liu, Y., Tanabe, T., et al.: Optimization of calcination temperature in preparation of a high capacity Li-rich solid-solution Li[Li0.2Ni0.18Co0.03Mn0.58]O2 material and its cathode performance in lithium ion battery. Electrochim. Acta 269, 321–330 (2018)

Thackeray, M., Kang, S.H., Johnson, C., et al.: Comments on the structural complexity of lithium-rich Li1+ xM1−xO2 electrodes (M = Mn, Ni, Co) for lithium batteries. Electrochem. Commun. 8, 1531–1538 (2006)

Pan, H., Zhang, S., Chen, J., et al.: Li- and Mn-rich layered oxide cathode materials for lithium-ion batteries: a review from fundamentals to research progress and applications. Mol. Syst. Des. Eng. 3, 748–803 (2018)

Hy, S., Felix, F., Rick, J., et al.: Direct In situ observation of Li2O evolution on Li-Rich high-capacity cathode material, Li[NixLi(1–2x)/3Mn(2–x)/3]O2 (0 \(\leqslant\) x \(\leqslant\) 0.5). J. Am. Chem. Soc. 136, 999–1007 (2014)