Abstract

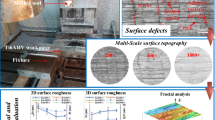

Turn-milling is a relatively new cutting process combining the both advantages of turning and milling, during which the tool and the workpiece rotate simultaneously. Due to the small axial cutting force, turn-milling is especially suitable for the machining of miniature parts. Usually, the surface quality is characterized by roughness, but the size of miniature parts is difficult to meet the requirements of the sampling length, which will have a huge influence on the characterization results. This paper introduces the box-counting method for image fractal dimension estimation to evaluate the surface quality of miniature parts during orthogonal turn-milling. The fractal dimension is an independent parameter for scale, which is not influenced by the sampling length. The effect of cutting parameters on surface quality of miniature parts during turn-milling is also studied.

Similar content being viewed by others

References

Karagüzel U, Uysal E, Budak E, Bakkal M (2015) Analytical modeling of turn-milling process geometry, kinematics and mechanics. Int J Mach Tool Manuf 91:24–33

Egashira K, Furukawa T, Yamaguchi K, Ota M (2016) Microcutting using a micro turn-milling machine. Precis Eng 44:81–86

Zhu L, Li H, Wang W (2013) Research on rotary surface topography by orthogonal turn-milling. Int J Adv Manuf Technol 69:2279–2292

Vikram KA, Ratnam C, Narayana KS (2016) Vibration diagnosis and prognostics of turn-milling operations using HSS and carbide end mill cutters. Proced Technol 23:217–224

Jiang ZD, Wang HR, Fei B (2001) Research into the application of fractal geometry in characterising machined surfaces. Int J Mach Tool Manuf 41:2179–2185

El-Sonbaty IA, Khashaba UA, Selmy AI, Ali AI (2008) Prediction of surface roughness profiles for milled surfaces using an artificial neural network and fractal geometry approach. J Mater Process Tech 200:271–278

Zhang Y, Luo Y, Wang JF, Li Z (2001) Research on the fractal of surface topography of grinding. Int J Mach Tool Manuf 41:2045–2049

Yuan CQ, Li J, Yan XP, Peng Z (2003) The use of the fractal description to characterize engineering surfaces and wear particles. Wear 255:315–326

Chen MJ, Pang QL, Wang JH, Cheng K (2008) Analysis of 3D microtopography in machined KDP crystal surfaces based on fractal and wavelet methods. Int J Mach Tool Manuf 48:905–913

Thomas TR, Rosen B-G, Amini N (1999) Fractal characterisation of the anisotropy of rough surfaces. Wear 232:41–50

Acknowledgements

This work has been supported by Natural Science Foundation of China (No. 51575050 and No. 51505034).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Niu, Z., Jiao, L., Chen, S. et al. Surface Quality Evaluation in Orthogonal Turn-Milling Based on Box-Counting Method for Image Fractal Dimension Estimation. Nanomanuf Metrol 1, 125–130 (2018). https://doi.org/10.1007/s41871-018-0015-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41871-018-0015-x