Abstract

This research paper delves into the simulation of the power generation analysis of a 5 MWp solar photovoltaic (PV) plant using the design and simulation tool named PVsyst. It then proceeds to contrast the performance projected by the simulation with the real generation of an installed PV plant of the same capacity. The analysis encompasses a comparison between the genuine and simulated outcomes, underscoring the dependability and appropriateness of PVsyst. Moreover, the study evaluates key performance indicators according to the standard IEC 61724. The outcomes of the study reveal a strong connection between the projected and real system yields, which underscores the reliability of PVsyst in emulating PV system performance. Furthermore, the found that real system’s PV module, inverter and system efficiency was 11.27%, 97.49% and 11.27% respectively. PVsyst estimates a higher system efficiency as 11.39% than real system. While the actual system exhibited a performance ratio of 81.02% and a capacity utilization factor of 16.05%, the simulated system showed corresponding values of 80.42% for the performance ratio and 16.54% for the capacity utilization factor. These results underscore the potential of PVsyst as a dependable instrument for evaluating and refining rooftop solar PV systems, offering valuable insights for informed decision-making in the realm of solar energy.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The development of non-conventional power resources has emerged as an effective way to protect our planet in light of the rapidly changing global energy landscape, which is characterized by dwindling conventional fossil fuel resources and a continuous rise in greenhouse gas emissions. The momentum behind renewable energy adoption is growing incessantly as a means to cater to escalating electricity demands while concurrently curbing the carbon footprint [1]. Photovoltaic (PV) energy is a constantly available, renewable source of electricity. Currently, the integration of solar energy is a focal point of research due to its unpredictable and sporadic nature [2]. The primary hurdle faced by photovoltaic generation systems pertains to the variability in weather conditions and the seamless integration with the grid. Also shading, whether it is full or partial diminishes solar PV system output, reducing energy production and efficiency, potentially causing cell damage and affecting overall performance.

In this pursuit, the Indian Ministry responsible for the promotion of Renewable Energy has significantly elevated its target to achieve 500 GW of renewable energy capacity by 2030, thereby fostering clean electrification in India [3]. To realize this objective, Ministry of Renewable Energy (MNRE) has spearheaded a range of strategic initiatives and programs. Notably, the capacity of solar installations on Andaman and Nicobar as well as Lakshadweep Islands was elevated from 40 to 50 MW on April 05, 2016, coupled with a Central Financial Assistance (CFA) totaling Rs. 192.20 crores [4]. This deliberate emphasis on solar PV energy is predominantly aimed at substituting coal-based energy generation and effecting substantial reductions in CO2 emissions.

Numerous studies have showcased the efficacy of PVsyst in accurately modeling solar energy production. Researchers have utilized PVsyst tool to analyze the solar PV systems production across diverse geographical locations, spanning varying solar irradiance levels and climatic conditions [5]. By incorporating meteorological data, PVsyst effectively replicates real-world solar panel behavior, accounting for intricate variables such as shading effects, temperature influences, and module degradation. Gusa. S. Bentouba et al [6]. He employed real operational data from the Adrar power plant situated in southern Algeria to assess the efficiency of solar PV power facilities in a hot climate zone. They showcased their simulation model to contrast the results of two simulation software tools, namely Homer Pro and RETScreen Expert. They suggested that for hot climatic regions thin film technology was preferable. Through the use of various simulation software such as RET Screen, PVSyst, and NREL SAM, Markam et al. [7] investigated the optimal slope for PV modules at six distinct locations across India to enhance its yield. Their analysis revealed that the average solar energy received at each location exceeded 5 kWh/m2/day, ranging from 5 to 6.5 kWh/m2/day. Ramanan et al. [7] primarily cantered their research on evaluating the performance of two rooftop grid-connected PV systems utilizing p-Si and CIS technologies, which were deployed in the climate of Tamil Nadu, India [8]. The PVsyst software tool was used to run the simulation for both the seasons winter and summer. The authors came to the conclusion that both PV technologies experience their highest losses during the summer. Nevertheless, it has been found that the performance ratio (PR) for both PV array technologies is slightly elevated during the winter compared to the summer period. During the winter season, the respective peak PR values are 85.19% and 93.11%. Another study forecasts performance and degradation of a 200-kW crystalline PV system at Chandigarh, India, using PVsyst simulation tool. Predicted energy generation is 292,954 kWh annually with CF, PR, and energy losses of 16.72%, 77.27%, and -26.5% respectively [9]. A study performed by Shivakumar and Sudhakar., (2017) on a 10 MW Ramagundam solar power plant performance, validated against PVsyst and PV-GIS, yields 1.96 to 5.07 h per day, an 86.12% annual performance ratio, a 17.68% capacity utilization factor, and an annual energy generation of 15,798.192 MW h [10]. This study assesses a 3 MW solar farm in Northern India, using real-time SCADA data for performance analysis, covering 2018. Key metrics include Performance Ratio (PR), Capacity Factor (CF), and energy loss, with PR at 80%, CF at 16.35%, and energy loss at 19.42%. Ambient temperature significantly influences PV performance in this region. PVSYST simulation aligns with actual results, offering guidance for solar PV applications in similar climates [11]. In their 2017 study, N. M. Kumar and colleagues undertook a comprehensive assessment to ascertain the feasibility of a 100 kWp photovoltaic (PV) system. Their findings indicated that this PV system generated an annual output of 165.38 MWh, with 161.6 MWh being injected into the grid. The system exhibited an impressive annual performance ratio of approximately 80%, while the normalized production of inverter output, equivalent to the final system yield or useful energy, amounted to 4.42 kWh/kWp/day [12].

The recommendation of solar energy technology for producing electricity is being strengthened by data from Baqir and Channi (2022) [13]. The researchers employed the PVsyst software, yielding results such as 1266 MWh/yr of energy production and a performance ratio of 0.797 within a power factor range of 0.7–0.9. This paper showcases a simulation conducted on a 700KWp grid-connected solar power system situated in Afghanistan's Daikundi Province, and all outcomes have been thoroughly assessed. Shrivastava et al. (2021) [14] evaluated the performance of a p-si Solar Photovoltaic (SPV) plant with a capacity of 20.0 kW using PVsyst software, which was utilized to construct a grid-interactive PV plant. Drawing from the simulation results, it becomes feasible to determine the appropriate solar panel size, inverter type, and necessary load. The geographical location of the site has a big influence on the sizing procedure. The performance, losses, and precise setup of the system are represented in diagrams.

This study entails a simulation-driven evaluation of the operational efficiency of a 5 MW grid-attached SPV plant connected to the grid on the Andaman and Nicobar Islands, India. We employ the PVsyst simulation tool for this assessment and subsequently contrast it with actual operational performance. Our analysis encompasses a year-long evaluation of the system's functioning. Additionally, this research offers insights into the viability of expansive solar energy initiatives. By striving for optimum efficiency and environmental sustainability, our findings accentuate the pivotal role of accurate simulation-based assessments in guiding large-scale solar energy projects.

2 Site and system description

In 2013, National Thermal Power Corporation (NTPC) successfully inaugurated and put into operation a 5-MWp PV solar power facility in the hilly terrain of Garacharma, situated within A&N Port Blair. This geographical location is marked by coordinates 11.61° N latitude and 92.71° E longitude. Functioning as a grid injecting, ground-installed SPV plant, the plant is equipped with approximately 22,000 mono-crystalline PV modules to generate electricity. These modules, each manufactured by Hyderabad-based company Photon Energy Limited, possess a power generation capacity of 235 Wp, as detailed in Table 1. This installation stands as an exemplar of innovative renewable energy solutions, showcasing the collaborative efforts of NTPC and Photon Energy Limited to tap into the region's solar potential and contribute to sustainable power generation. Within the plant's configuration, a sum of 888 strings is distributed, encompassing 24 modules within each individual string. To facilitate the solar PV plant's functioning, a set of six SMA inverters has been employed, boasting an individual capacity of 800 kW. These inverters are designed to accommodate a 720 V DC input, which undergoes transformation within the inverter to yield a 360 V AC output. Detailed technical specifications regarding these inverters can be found in Table 2. The plant integrates a total of 96 string combiner boxes, with 16 allocated to each of the inverters. Through the utilization of transformers, the 360-V AC power is elevated to the required level for direct integration into the 33 kV utility grid (Fig. 1).

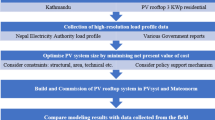

3 Methodology

A comprehensive analysis of the on-field operation of a 5 MWp SPV plant was performed through the actual operational data and the simulated data by PVsyst. A rigorous data collection process will be initiated, encompassing real-time electricity production records, environmental parameters, and solar irradiance levels. These actual performance metrics will be contrasted against the projections generated by PVsyst software, renowned for its reliability in solar energy simulations.

The comparative analysis will encompass various aspects such as daily, monthly, and yearly energy generation profiles, efficiency ratios, and performance indicators based on IEC 61724 [15] as shown in Fig. 2. This research methodology aims to yield valuable insights into the precision and limitations of PVsyst software in estimating the performance of real-world solar PV systems.

4 Result and discussion

The primary hurdle faced by photovoltaic generation systems pertains to the variability in weather parameters like solar radiation, temperature, wind speed, rainfall, and humidity [16]. Also shading, whether it is full or partial diminishes solar PV system output, reducing energy production and efficiency, potentially causing cell damage and affecting overall performance [17]. A comprehensive analysis of these factors holds paramount importance for precisely evaluating the performance of PV systems. The effective functionality of a solar PV module on the field is notably impacted by solar radiation, a pivotal meteorological parameter [18]. As depicted in Fig. 3, the monthly average daily solar radiation, drawn from both real-world recorded data and PVsyst-generated data, demonstrates this influence. The pyranometer registered the highest solar radiation of 6.88 kWh/m2/d in March, while PVsyst projected 6.31 kWh/m2/d in April. Conversely, the lowest solar radiation recorded by the sensor was 4.15 kWh/m2/d in November, and PVsyst yielded a slightly lower figure of 4.03 kWh/m2/d in August.

Figure 4 illustrates the monthly mean daily actual and simulated ambient temperature alongside cell temperature. A linear correlation persists between cell and ambient temperatures, with cell temperature rising proportionally to ambient temperature increments [19]. The minimal recorded real average temperature occurred at 12.50°C during September, mirroring the PVsyst-derived 26.12°C value for the same period. Notably, the highest average daily real and simulated ambient temperatures manifested as 32.08°C and 27.87°C, sequenced in March and May, respectively. In terms of cell temperature, fluctuations were observed. For the actual system, daily averages ranged from 38.40°C in July to 51.58°C in March. Similarly, the simulated system exhibited cell temperature oscillations from 40.24°C in June to 51.85°C in March. These temperature dynamics underscore the interplay between ambient conditions and cell temperature, ultimately impacting the operational characteristics of the PV system.

The array's performance relies on a range of climatic elements including temperature, solar radiation, dust accumulation, humidity, and wind conditions. Notably, temperature stands out as a direct influencer of the array's efficiency [20]. Illustrated in Fig. 5, the annual average monthly efficiencies of modules, inverters, and the entire system are presented using both real-world and simulated data. Based on actual data, the lowest module efficiency, at 7.81%, was observed in October. In terms of inverter and system efficiency, the nadirs were 96.14% and 7.65%, occurring in June and October, respectively. Conversely, employing simulated data, the least efficiencies for module, inverter, and system were 11.22%, 98.30%, and 11.05% in March, June, and March, respectively. The pinnacles of actual module, inverter, and system efficiency reached 13.26%, 98.56%, and 12.99% in December, March, and December, respectively. In the simulated scenario, the peaks were slightly lower: 11.85%, 98.50%, and 11.65% in June, January, and June. This emphasizes that inverter efficiency is a pivotal determinant in the functioning of a Solar Photovoltaic (SPV) system.

Illustrated in Fig. 6 is the fluctuation in the mean monthly reference, array, and ultimate yield of a photovoltaic system, as determined by both empirical data and predictions from PVsyst. The reference yield, computed for the actual system, demonstrates a range of 3.68 h/day to 5.68 h/day, while the PVsyst simulation anticipates a span from 3.95 h/day to 6.48 h/day. Likewise, employing real-world data, the highest array yield as 5.52 h/day materialized in March, juxtaposed with the lowest 2.88 h/day in January. In contrast, as foreseen by PVsyst's simulation, the minimum array yield is projected to be approximately 3.28 h/day in July, with the pinnacle as 5.13 h/day occurring in March. Regarding the ultimate yield of the system, evaluations grounded in actual data and PVsyst's projections fluctuate from 2.81 h/day in January to 5.44 h/day in March, and from 3.23 h/day in July to 5.05 h/day, respectively. The annual values of different yields calculated for both actual data and PVsyst's estimations, stand at 4.92 h/d, 4.08 h/day, and 3.98 h/day, and 5.20 h/day, 4.24 h/day, and 4.17 h/day, respectively.

Figure 7 illustrates the mean monthly losses within the solar PV system, encompassing both system losses (LS) and capture losses (LC), as observed in actual operations and as projected by PVsyst’s simulations. The computed system losses, stemming from real-world and PVsyst data, exhibit a yearly range of 0.06 h/d to 0.13 h/d and 0.05 h/d to 0.08 h/d, respectively. The highest capture losses (LC) for the actual system, observed in March, reached 2.18 h/d due to elevated cell temperatures. These losses demonstrate an upward trend alongside rising cell temperatures, with the nadir of 0.23 h/d transpiring in December. As depicted in Fig. 7, PVsyst's predictions showcase capture losses fluctuating between 0.66 and 1.35 h/d. The average monthly capture losses for both the real-world and simulated systems were measured at 0.84–0.96 h/d, in comparison to a lower 0.10–0.07 h/d for system losses.

The PR stands as a crucial metric illuminating the real-world efficacy of a solar PV system. Figure 8 intricately portrays the monthly PR values, offering a comparative lens through both actual on-field performance and the predictive prowess of PVsyst simulations.

The calculated PR values reveal their fluctuating nature, capturing the intricacies of solar energy conversion. The real-world PR spans from 54.72 to 92.92%, showcasing the variance inherent in daily and seasonal operational conditions. In the domain of simulations, PVsyst crafts a narrower PR spectrum, ranging from 77.90% to 82.30%, reaffirming its role as a valuable predictive tool. Annual PR averages, further contextualizing system efficiency, come to the fore. For the actual installation, the average PR settles at 81.02%, signifying the system's adeptness at converting sunlight into usable energy. The simulated counterpart, projecting its own capabilities, yields an average PR of 80.42%. These figures collectively underscore the intricate interplay of factors influencing PR and emphasize the value of efficient energy conversion in ensuring optimal solar PV system performance.

In India, the capacity utilization factor (CUF) generally hovers between 16 and 20% [21]. The calculated CUF values, derived from both the actual system performance and the predictive power of PVsyst, exhibit a dynamic range spanning 11.26% to 20.61% and 11.64% to 21.30%, respectively, across the year. As illustrated in Fig. 9, the nadir of CUF emerged from the real system, recording 11.26% in July, mirrored closely by PVsyst's prediction of 11.64% in the same month. In contrast, the zenith of CUF materialized in December, with the actual system achieving a remarkable 20.61%, while PVsyst forecasted an even higher 21.30%. The annual mean CUF values for the PV system and PVsyst projections stand at 16.05% and 16.54%, respectively, encapsulating the overall energy-generation efficiency and utilization of the solar installation.

5 Discussion and comparison with other work

Our research focuses on comparing the performance of a 5 MWp SPV plant using the PVsyst simulation tool. There are existing studies that evaluate the performance of PV plants using PVsyst as a simulation tool for real-world PV system performance. In a study, the performance of a 1 MWp solar PV plant on an educational institute's rooftops in Andhra Pradesh, India, was assessed. Real-time monitoring and simulations using three tools were conducted over 12 months. The plant generated 1325.42 MWh annually, with simulations ranging from 118 to 170 MWh per month. PV Syst demonstrated the best energy yields. The plant's performance ratio was approximately 88%, covering roughly 20% of the campus's annual energy consumption [22]. Malvoni et al., (2017) analyzed a 960 kWp PV system in southern Italy over 43 months, evaluating energy yields, losses, and efficiency. They compared it to PV plants in various climates for degradation rate. Using SAM and PV Syst, they compared actual performance, finding SAM underestimated by 3.0% and PV Syst by 3.3%, with PV Syst generally performing better [23]. Another study delves into the feasibility of establishing a fully solar PV-powered academic campus at MANIT in Bhopal, India, proposing a 5 MW solar PV plant based on MANIT's energy consumption. The performance of the solar campus is assessed using PVSyst and SAM software, projecting an annual electricity generation of 8000 MWh and a reduction of 73,318.0 metric tons of carbon emissions. The study concludes that the project demonstrates both technical and financial viability, potentially yielding annual earnings ranging from INR 55,341,788 to INR 938,894,000 over a 25-year period. Furthermore, it has the capacity to offset 173,318.0 metric tons of CO2 emissions [24]. The real performance of 186 kWp ground-mounted solar PV system at Amity University, Gurugram, India, compared to the predicted one obtained with PVSyst and system advisor model. Annual solar insolation averaged 5550–700 W/m2, with a mean temperature of 28.4 °C in 2018. The system achieved a yearly mean performance ratio of 0.827, a capacity utilization factor of 0.178, and an energy production agreement with predictions within a 1.34% uncertainty [25]. A study performed to assess the real and simulated performance using PVSyst and SolarGIS tools for 23.92 MWp solar PV plant in El Bayadh, Algeria, over 36 months (March 2017–February 2020). Findings show strong alignment between real and predicted data, a notable correlation (0.91) between module temperature and performance ratio [26].

The above studies demonstrate the accuracy and reliability of PVsyst as a simulation tool for assessing PV plant performance. These studies span different locations and capacities, including kilowatt to megawatt level plants in all over the globe. In each case, PVsyst consistently provided reliable estimations and closely matched real-world performance data, affirming its credibility as a dependable tool for evaluating solar PV systems.

6 Conclusion

This study is centered around the simulation of solar PV utilisation in Andaman, India, and encompasses a comprehensive and comparative analysis. Employing the PVsyst software as the primary tool, the investigation aims to establish a highly efficient PV plant for electricity production. The capabilities of PVsyst in predicting critical electricity generation factors are notably valuable. The simulated average performance ratio (PR) of 80.42% slightly less that of the actual PV system, which stands at 81.02%, primarily due to a higher yield. Similarly, the real plant's CUF was 16.05%, while the simulated CUF reaches 16.54%.

The results demonstrate that the actual system performance closely aligns with the PVsyst simulations, validating the software's efficacy in predicting energy generation patterns. The future scope of this research lies in advancing the accuracy of PVsyst simulations and refining models for solar PV system performance under diverse climatic conditions. Further exploration should focus on incorporating advanced technologies and maintenance strategies to optimize large-scale solar energy projects. Investigation into the impact of evolving solar technologies on real-world efficiency will be crucial. Additionally, the study paves the way for ongoing research to contribute to meeting ambitious renewable energy targets and addressing environmental concerns on a global scale, emphasizing the pivotal role of accurate simulation-based assessments in guiding the implementation of future large-scale solar energy initiatives.

Data availability

All essential data is encompassed in the article. No additional data availability statement is required.

References

Suman S, Jasrotia R, Singh SP (2023) A MCDM-based framework for selection of photovoltaic cell technology using novel information measure under Pythagorean fuzzy environment. Int J Inf Technol. https://doi.org/10.1007/S41870-023-01525-Y

El Bourakadi D, Ramadan H, Yahyaouy A, Boumhidi J (2023) A novel solar power prediction model based on stacked BiLSTM deep learning and improved extreme learning machine. Int J Inf Technol. https://doi.org/10.1007/s41870-022-01118-1

Kumar Yadav S, Manoj Kumar N, Ghosh A, Bajpai U, Chopra SS (2022) Assessment of soiling impacts and cleaning frequencies of a rooftop BAPV system in composite climates of India. Sol Energy 242:119–129. https://doi.org/10.1016/J.SOLENER.2022.07.022

Annual Report 2018–19. https://mnre.gov.in/img/documents/uploads/file_f-1608040317211.pdf (Accessed 1 Mar 2023).

Kumar NM, Sudhakar K, Samykano M (2017) Techno-economic analysis of 1 MWp grid connected solar PV plant in Malaysia. Int J Ambient Energy 40(4):434–443. https://doi.org/10.1080/01430750.2017.1410226

Bentouba S, Bourouis M, Zioui N, Pirashanthan A, Velauthapillai D (2021) Performance assessment of a 20 MW photovoltaic power plant in a hot climate using real data and simulation tools. Energy Rep. https://doi.org/10.1016/j.egyr.2021.10.082

Markam K, Sudhakar K, Bhopal M (2016) Estimation of optimal tilt angle for solar photovoltaic installations in India. Int Res J Eng Technol 3(5):2735–2741

Ramanan P, KalidasaMurugavel K, Karthick A, Sudhakar K (2020) Performance evaluation of building-integrated photovoltaic systems for residential buildings in southern India. Build Serv Eng Res Technol. https://doi.org/10.1177/0143624419881740

Kumar NM, Gupta RP, Mathew M, Jayakumar A, Singh NK (2019) Performance, energy loss, and degradation prediction of roof-integrated crystalline solar PV system installed in Northern India. Case Stud Therm Eng 13:100409. https://doi.org/10.1016/J.CSITE.2019.100409

Kumar BS, Sudhakar K (2015) Performance evaluation of 10 MW grid connected solar photovoltaic power plant in India. Energy Rep 1:184–192. https://doi.org/10.1016/J.EGYR.2015.10.001

Zuhaib M, Khan HA, Rihan M (2021) Performance analysis of a utility-scale grid integrated solar farm considering physical and environmental factors. J Inst Eng Ser B. https://doi.org/10.1007/s40031-020-00500-6

Kumar NM, Kumar MR, Rejoice PR, Mathew M (2017) Performance analysis of 100 kWp grid connected Si-poly photovoltaic system using PVsyst simulation tool. Energy Procedia. https://doi.org/10.1016/j.egypro.2017.05.121

Baqir M, Kaur HC (2022) Analysis and design of solar PV system using Pvsyst software. Mater Today: Proc. https://doi.org/10.1016/j.matpr.2021.09.029

Shrivastava A, Sharma R, Kumar Saxena M, Shanmugasundaram V, LalRinawa M, Ankit (2023) Solar energy capacity assessment and performance evaluation of a standalone PV system using PVSYST. Mater Today Proc. https://doi.org/10.1016/j.matpr.2021.07.258

Ayompe LM, Duffy A, McCormack SJ, Conlon M (2011) Measured performance of a 1.72 kW rooftop grid connected photovoltaic system in Ireland. Energy Conversat Manag 52(2):816–825. https://doi.org/10.1016/J.ENCONMAN.2010.08.007

Manisha PG (2021) The survey of MPPT under non-uniform atmospheric conditions for the photovoltaic generation systems. Int J Inf Technol. https://doi.org/10.1007/s41870-020-00591-w

Sreedhar R, Chandrasekar P, Karunanithi K, Vijayakumar SC, Raja SP (2022) Design and validation of a single-phase buck–boost inverter with Grey Wolf optimization algorithm under partial shaded conditions. Int J Inf Technol. https://doi.org/10.1007/s41870-022-00948-3

Singh P, Ravindra NM (2012) Temperature dependence of solar cell performance—an analysis. Sol Energy Mater Sol Cells 101:36–45. https://doi.org/10.1016/J.SOLMAT.2012.02.019

Chakraborty V, Yadav SK, Bajpai U (2021) Thermal regulation of solar photovoltaic modules by incorporating phase change materials to enhance the yield. Lect Notes Electr Eng 616:341–350. https://doi.org/10.1007/978-981-16-1978-6_30

Kumar NM et al (2020) Operational performance of on-grid solar photovoltaic system integrated into pre-fabricated portable cabin buildings in warm and temperate climates. Energy Sustain Dev 57:109–118. https://doi.org/10.1016/j.esd.2020.05.008

Srivastava R, Tiwari AN, Giri VK (2020) An overview on performance of PV plants commissioned at different places in the world. Energy Sustain Dev 54:51–59. https://doi.org/10.1016/J.ESD.2019.10.004

Thotakura S, Kondamudi SC (2022) Operating temperature prediction and comparison for rooftop PV arrays in coastal climates of India. Environ Sci Pollut Res 29(29):43532–43545. https://doi.org/10.1007/S11356-022-20068-6/FIGURES/10

Malvoni M, Leggieri A (2017) Long term performance, losses and efficiency analysis of a 960 kWP photovoltaic system in the Mediterranean climate. Energy Convers Manag. https://doi.org/10.1016/j.enconman.2017.04.075

Baitule AS, Sudhakar K (2017) Solar powered green campus: a simulation study. Int J Low-Carbon Technol. https://doi.org/10.1093/ijlct/ctx011

Arora R, Arora R, Sridhara SN (2022) Performance assessment of 186 kWp grid interactive solar photovoltaic plant in Northern India. Int J Ambient Energy. https://doi.org/10.1080/01430750.2019.1630312

Dahmoun MEH, Bekkouche B, Sudhakar K, Guezgouz M, Chenafi A, Chaouch A (2021) Performance evaluation and analysis of grid-tied large scale PV plant in Algeria. Energy Sustain Dev. https://doi.org/10.1016/j.esd.2021.02.004

Acknowledgements

The researchers express their gratitude to Mr. C.H. Kiran Kumar, Senior Manager at NTPC, A&N Port Blair Island, Government of India, for granting permission to utilize the facilities to carry out the study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mishra, P.R., Rathore, S. & Jain, V. PVSyst enabled real time evaluation of grid connected solar photovoltaic system. Int. j. inf. tecnol. 16, 745–752 (2024). https://doi.org/10.1007/s41870-023-01677-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41870-023-01677-x