Abstract

Edible films based on the addition of Garlic peel extract (GPE) and Aloe Vera gel (AV) into gelatin with antimicrobial properties for food packaging applications were proposed in this work. Both extracts, GPE and AV showed high total phenolic content (TPC), total flavonoids and antioxidant activity. Nine different formulations were obtained by the addition of GPE:AV in the ratios 1:1, 2:1 and 1:2 with concentrations of 1, 2 and 3 wt% to gelatin, showing films with 3 wt% of extracts with the ratio of 1:1 the best performance. Gelatin films enriched with GPE and AV retarded the growth of S. aureus and E. coli counts during the well diffusion plating technique. The addition of extracts did not significantly affect mechanical and barrier properties like water vapor transmission ratio and oxygen transmission ratio. The incorporation of these extracts into gelatin could be proposed as a potential effective packaging material for meat and poultry products by retarding the microbial growth and extending the shelf-life of these food products.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Antimicrobial packaging is an idea in active packaging that successfully infuses antimicrobial chemicals into the food packaging film material and eradicates pathogenic bacteria that harm food goods, extending the shelf life by a significant margin. The lack of interest in preservative addition and the fact that the rate of antimicrobials diffusion from packaging may be controlled are the driving forces for the interest in antimicrobial films or coatings [36]. Food packaging innovations that may shield food from the environment and serve as carriers of active chemicals include films and coatings produced from biodegradable and edible materials [3]. As an alternative to extending the shelf life and guaranteeing the safety of various foods, traditional and natural antimicrobials and other active chemicals have been integrated into edible films and coatings [25]. It has been demonstrated that using antimicrobial compounds in food packaging to reduce microbial load and target particular microorganisms results in high-quality and safe products. According to [5], improper handling and storage methods result in the loss of almost two-thirds of the food produced. This circumstance emphasizes the need to create innovative environmentally friendly solutions to reduce food waste by lengthening the shelf life of food goods as well as by discovering environment friendly ways to reuse food byproducts and waste streams [9]. In order to contribute to the circular economy concept by lowering food waste generation and preventing the unnecessary use of chemicals as additives into packaging, active packaging has emerged as a potential approach.

Aloe Vera (Aloe barbadensis) is a species of succulent plant in the Aloe genus. It is a large plant with short stems that holds water in its leaves. It is regarded as an invasive species in many parts of the world. It is a well-known medicinal herb with antibacterial and antioxidant effects. Aloe Vera (AV) gel extract has a long history of being used in food packaging [23]. These characteristics are a result of AV’s high concentration of special polysaccharides (such glucomannan and acemannan), phenolic compounds (like flavonoids and anthraquinones), organic acids, and vitamins (B1, B2, etc.) [20]. For extending the shelf life of several perishable food items, Aloe Vera gel films or coatings are particularly successful Aloe Vera gel can be combined with conventional biopolymers (proteins and polysaccharides) and lipids (emulsions) to modify the transparency, smoothness, stiffness, elasticity, water vapor permeability, and bio-functionality of films and coatings. A functional additive called AV has recently been employed in edible matrices to preserve several fruits’ postharvest qualities, including those of the mango, tomato, strawberry, and blueberry. Additionally, edible films based on alginate and AV have shown the additive's ability to create uniform films with good transparency for usage in a variety of industries (Jorge et al. 2020).

The Liliaceae family includes garlic (Allium sativum) [4]. It is consumed all around the world because of its culinary worth and medicinal qualities (Paula et al. 2022). Since the beginning of time, it has been utilized as medicine to treat a variety of human ailments [18]. It has a great flavor and a strong smell, making it a favorite component in cooking. Each clove of garlic has between 10 and 20 segments. The peel of a full garlic bulb makes up about 24% of its weight. About 800 g/kg of cloves and 250 g/kg of outer and inner husks are produced per bulb of garlic. As a result, residues made from garlic by-products could be a great biological resource that is effective and safe for the environment [14]. Allicin, an organosulfur molecule found in garlic, is well known for its antibacterial properties.

As agricultural trash, garlic peel is often disposed of in landfills or burned. Incinerating waste results in the emission of a variety of air pollutants including particulate matter, greenhouse gases, volatile organic compounds, etc. [28]. Vitamins A, C, and E as well as a variety of antioxidants are abundant in garlic peel. The presence of organosulfurs and different aliphatic sulfurides gives the peels antibacterial action. Allicin and ajoene are the two main antibacterial organosulfur chemicals found in garlic [17]. Allicin is the major compound that contributes to antimicrobial activity [31]. All of these factors combine to make garlic peel a fantastic byproduct. Simple methods can be used to extract the peel from garlic. According to Fortunata et al. [6], ethanolic extraction of garlic peel extract revealed good retention of antioxidant and antibacterial components.

Materials and Methods

Materials

Garlic peel, Aloe Vera leaf, Ethanol, Distilled water, Folin–Ciocalteu reagent (0.1 N). Na2CO3 (0.05% w/v), NaNO2 (1.5% w/v), AlCl3 (3% w/v), NaOH (1 N).

Preparation of Aloe Vera Gel Extract

Aloe Vera gel was prepared by removing the leaf base and spines. 2 cm of the white part of the leaf base, 5–6 cm of the leaf top and the sharp spines along the margins were removed [2]. The pulp was manually separated from the inner fillet. This pulp was subjected to a grinding process and was further centrifuged at 5000 rpm for 30 min to remove the suspended solids [21]. The colorless supernatant was filtrated under vacuum, freeze-dried and stored at − 4 °C.

Preparation of Garlic Peel Extract

Garlic peels (GP) were collected from the garlic processing centre. The collected GP was dried using two different ways, sun dried for 6 days and oven dried at 60 °C for 4 h. Dried GP was then powdered using a blender. GP powder was stored for further use [10]. For aqueous extraction, the extraction was done with an ultrasonicator [16] with ultrasonic power 1800 W and frequency range 20–25 kHz, samples of 1-g fine GP powder were mixed with distilled water at ratios of 1:15, 1:20, and 1:25 (w/v) and extraction temperatures of 30 °C, 35 °C, and 40 °C for 20, 30, and 40 min.

Characterization of the Extracts

Total Phenolic Compounds

The evaluation of total phenolic compounds was conducted using the approach described by Ochoa et al. [24]. In a nutshell, 1 mL of extract was combined with 1 mL of 0.1 N Folin-Ciocalteu reagent. After the mixture had stood for 3 min, 1 mL of a Na2CO3 solution (0.05% w/v) was added. The mixture was incubated for one hour in a dark area at room temperature. A UV–Vis spectrophotometer was used to measure the absorbance at 765 nm while using distilled water as a reference. Using a Gallic acid standard curve, the results were reported as milligrams of gallic acid equivalents (GAE) per gram of dry sample (dm).

Total Flavonoids

The analysis of total flavonoids (TF) was conducted using the approach suggested by Carlos et al. (2016). The mixture was then combined with 1 mL of NaNO2 (1.5% w/v) and allowed to stand for 5 min. 0.5 mL of NaOH (1 N) and 1 mL of AlCl3 (3% w/v) were added and stirred for 1 min. A UV–Vis spectrophotometer was used to read the absorbance at 415 nm after the combination had been incubated for 1 min while using distilled water as a blank. Using a quercetin standard curve, results were represented as mg of quercetin per g of sample.

Antioxidant Activity

A variety of extract concentrations were combined with 1 mL of 0.004% DPPH solution and left to stand for 30 min at room temperature in the dark. In order to test antioxidant capacity, a UV–Vis spectrophotometer was used at 517 nm.The following equation was used to calculate the inhibition ratio (%) [40].

The inhibition ratio (%) was obtained from the following equation

where A1 is the absorbance of the addition of ethanol instead of testing sample and A2 is the absorbance of testing sample solution.

Antimicrobial Activity of the Extracts

The antibacterial activity of the extracts were evaluated using the agar diffusion method [26]. Gram positive and Gram negative common bacterial strains associated with food spoiling in refrigerators, S. aureus and E. coli, were employed [13]. On Muller Hinton agar plates, 0.1 mL of inoculums containing roughly 105 CFU mL 1 of the examined bacteria was applied. After 24 h of incubation at 37 °C, the inhibition zone’s diameter (mm) surrounding the film disc (1.0 cm2) was measured. Tetracycline served as the control. Each sample was tested three times.

Preparation of Gelatin Film

Gelatin (8 wt%) [8] was dispersed in distilled water at 35 °C and placed in a magnetic stirrer at 1000 rpm for 20 mins. Glycerol (30 wt%) was added and dispersed for 10 min under the same conditions. Varying concentration with varying ratios of extracts were added and stirred for 10 mins. Finally the mixture was dried in petri dishes in a climate chamber [30]. Gelatin Film with Antimicrobial Agent (AM) concentration 1%, 2%, 3% with varying AM ratios (Garlic peel extract: Aloe Vera gel extract) of 1:1, 1:2, 2:1 were prepared.

Characterization of Edible Film

Visual Appearance and Thickness

The thickness of films were measured using a Micrometer. Each film sample was measured at five random positions. Colour of the film was determined by using a colorimeter [29]. Gloss was measured by shining a known amount of light at a surface at a specific angle and measuring the amount of reflected light [39]. A gloss meter was used to find the gloss of the edible film.

Mechanical Properties

Utilizing a tensile stress testing machine with a cross head speed of 10 mm/min, the tensile properties of the edible films, including tensile strength (TS) and percent elongation at break (Eb), were assessed [41]. Dimension of the specimens were 8 cm length and 2 cm width, 3 distinct blends with various extract concentrations in gelatin were examined.

Barrier Properties

Water vapor permeability (WVP) was determined by using the WVTR tester (Water vapor transmission rate tester). Oxygen transmission rate (OTR) tests were carried out with an OTR analyzer [24]. WVTR and OTR rates were determined from the graphs obtained.

Antimicrobial Activity

The antibacterial activity of the produced films was evaluated using the agar diffusion method [26]. Gram positive and Gram negative common bacterial strains associated with food spoiling in refrigerators, S. aureus and E. coli were employed. On Muller Hinton agar plates, 0.1 mL of inoculums containing roughly 105 CFU mL-1 of the examined bacteria was applied. After 24 h of incubation at 37 °C, the inhibition zone's diameter (mm) around the film disc’s (1 1 cm2) surface area was measured. Gelatin served as the control. Each sample was tested three times.

Results and Discussion

Extraction of Garlic Peel

Ultrasound extraction gives maximum yield with very fine garlic peel powder [19]. The yield percentage was 82.23%.

Characterization of Extracts

Total Phenolic Compounds and Total Flavonoids

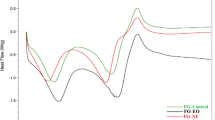

The TPC value for Aloe Aera gel extract was found to be 30.15 μg GAE/ml. where as total phenolic compound value for garlic peel extract was found to be 32.47 μg GAE/ml. The total flavonoids of GPE was found to be higher than Aloe Vera extract. Total flavonoid content of GPE was 18.13 μg of quercetin/mL and it was 0.503 μg of Catechin/mL for Aloe Vera extract. According to various writers, a number of factors, including variety, pre- and post-harvest treatment, and storage, can alter the bioactive components of different fruits and other crops. The most crucial factors are extraction condition and quantification [12] (Figs. 1, 2, Table 1).

Antioxidant Activity of Extracts

IC 50 value obtained from the graph were 768.26 µg/ml of garlic peel extract and 498.63 µg/ml of Aloe Vera gel extract. The phenolic chemicals in garlic peel, particularly the phenyl propanoids, may be strongly associated with this antioxidant effect had already been discovered and investigated [11]. According to the results of the experiments, the antioxidant activity appears to be inversely related to the total phenolic compound [15]. As shown in Table 2, the Radical Scavenging Activity is connected to the capacity to scavenge DPPH radicals, was used to express the antioxidant activity of the Aloe Vera powder.The IC50 value is a parameter used to measure the antioxidant activity of test samples. It is calculated as the concentration of antioxidants needed to decrease the initial DPPH concentration by 50%. Thus, the lower IC50 value the higher antioxidant activity (Fig. 3, Tables 2, 3).

Antimicrobial activity of extracts

Highest inhibition zones for S. aureus and E. coli were detected for antimicrobial agents with ratio (1:1). Given the high TPC and antioxidant activity values obtained in this study, it is possible that the presence of polyphenols and other antioxidants in AV and GPE were responsible for this antibacterial activity. Allicin present in garlic peel extract would be the key element in antibacterial activity, On the other hand, the acemannan present in AV had been reported to be also responsible for antibacterial activity [22].

From Table 4 Inhibition zone obtained was maximum for GPE: AV in the ratio 1:1. Maximum inhibition zone for S. aureus was 13 mm for both 1:1 and 2:1 ratios of GPE:AV and for E. coli was found to be 20 mm in well diffusion method.

Characterization of Edible Film

Visual Appearance, Thickness

The majority of the films displayed good visual transparency and uniformity, which are desirable qualities for applications involving food packaging. Average thickness value for the films was found to be 0.255 mm. Gelatin film thickness values were not significantly different, indicating that the inclusion of AV and GPE did not significantly alter the film forming process (Sui et al., 2017). Gelatin thickness values were not significantly different, indicating that the inclusion of AV and GPE did not significantly alter the film forming process [27].

Mechanical Properties-Tensile Strength

Tensile stress for Edible gelatin film 1%, 2%, and 3% of antimicrobial agents with varying ratios of 1:1, 2:1, and 1:2 were analyzed using a tensile stress tester [41]. From Table 5, it is found that the highest elongation percentage of 186.61 was obtained for film with AM agent 2% (2:1) while the Maximum force 14.629 Mpa was withstand by the film with AM agent 3% (2:1). From the overall results, it can be concluded that the tensile strength has improved with addition of antimicrobial agents. And thus the stretchability of the film is increased by increasing its suitability to become sausage casing.

Barrier Properties

Water vapor permeability (WVP) was determined by using the WVTR tester (Water vapor transmission rate tester). Oxygen transmission rate (OTR) tests were carried out with an OTR analyzer [24]. Gelatin is hydrophilic in nature, due to the presence of polar amino acids and large number of hydroxyl groups (-OH). Addition of Antimicrobial agents has slightly increased the WVTR of the film but addition of AM agents increased Oxygen transfer ratios of the films, but the changes are influenced by the ratios or concentrations of antimicrobial agent. From Table 5, the highest water vapor transmission ratio was found in gelatin film with antimicrobial agent 3% (2:1) and the lowest water vapor transmission ratio was found in control gelatin film. The highest Oxygen transmission ratio was obtained for gelatin film with antimicrobial agent 3% (1:2) and the lowest oxygen transmission ratio was obtained for control gelatin film.

Antimicrobial Activity of Gelatin Films

In interaction with the two strains of bacteria under study, Edible gelatin films’ antibacterial efficacy varied noticeably. Highest inhibition zones for S. aureus and E. coli were detected for gelatin film with AM agent 3% (1:1), respectively, as opposed to the control gelatin film, which did not manifest any inhibitory zone as would be expected [1]. Given the high TPC and antioxidant activity values obtained in this study, it is possible that the presence of polyphenols and other antioxidants in AV and GPE were responsible for this antibacterial activity. Allicin present in garlic peel extract would be the key element in antibacterial activity, On the other hand, the acemannan present in AV had been reported to be also responsible for antibacterial activity [22]. These antioxidants have the ability to produce the precipitation of cell membrane proteins or have non-specific interactions with them [33] (Fig. 4).

From Table 6, the inhibition zone obtained was maximum for AM film with 3% (1:1) Am agent concentration. Maximum inhibition zone for S. aureus was 15 mm and for E. coli was found to be 17 mm in well diffusion method.

Conclusion

The extraction and analysis of Aloe Vera gel and garlic peel was successfully performed to obtain active edible films with antimicrobial properties against S. aureus and E. coli. Analysis of GP and AV shown that GPE and AV were effective antioxidants and have antimicrobial properties against S. aureus and E. coli. So these two extracts can be used as antimicrobial agent in the gelatin based edible films and it can be used for the extension of shelf-life of different food products. In conclusion, this project underlines the optimization of extraction and analysis of AV inner gel and garlic peel extract, development of gelatin based edible antimicrobial films and characterization of the edible film. The main motive of the study was reducing the use of synthetic additives and contributing to the circular economy concept by reducing food wastes.

Data Availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Adzitey F, Agbolosu A & Udoka UJ (2019) Antibacterial effect of Aloe Vera Gel extract on Escherichia coli and Salmonella enterica isolated from the gastrointestinal tract of guinea fowls. World Vet J 9(3):166–173. www.wvj.science-line.com

Assefa GY, Admassu SE (2013) Antimicrobial activity, physicochemical and mechanical properties of aloe (Aloe debrana) based packaging films. Br J Appl Sci Technol 3:1257–1275

Birania S, Kumar S, Kumar N, Attkan AK, Panghal A, Rohilla P, Kumar R (2022) Advances in development of biodegradable food packaging material from agricultural and agro-industry waste. J Food Process Eng. https://doi.org/10.1111/jfpe.13930. (John Wiley and Sons Inc.)

Carreón-Delgado DF, Hernández-Montesinos IY, Rivera-Hernández KN, del Sugeyrol Villa-Ramírez M, Ochoa-Velasco CE, Ramírez-López C (2023) Evaluation of pretreatments and extraction conditions on the antifungal and antioxidant effects of garlic (Allium sativum) peel extracts. Plants. https://doi.org/10.3390/plants12010217

Fasihnia SH, Peighambardoust SH, Peighambardoust SJ, Oromiehie A (2018) Development of novel active polypropylene based packaging films containing different concentrations of Sorbic acid. Food Pack Shelf Life. https://doi.org/10.1016/j.fpsl.2018.10.001

Fortunata SA, Rahmawati D, Andika D (2019) Evaluation of phytochemical activities of aqueous and ethanolic garlic peel extract. J Funct Food Nutraceutical 1(1):41–46. https://doi.org/10.33555/jffn.v1i1.20

Gómez I, Janardhanan R, Ibañez FC, Beriain MJ (2020) The effects of processing and preservation technologies on meat quality: sensory and nutritional aspects. Foods 9:1416

Gomez-Estaca J, Montero P, Fernandez-Martin F, Aleman A, Gomez-Guillen MC (2009) Physical and chemical properties of tuna-skin and bovine-hide gelatin films with added aqueous oregano and rosemary extracts. Food Hydrocolloids 23:1334–1341

Gupta N, Mahur BK, Izrayeel AMD, Ahuja A, Rastogi VK (2022) Biomass conversion of agricultural waste residues for different applications: a comprehensive review. Environ Sci Pollut Res 29(49):73622–73647. https://doi.org/10.1007/s11356-022-22802-6. (Springer Science and Business Media Deutschland GmbH)

Hajiuon B (2014) Effects of garlic (Allium sativum L.) hydroalcoholic extract on estrogen, progesterone and testosterone levels in rats exposed to cell phone radiation. Zahedan J Res Med Sci 16(12):20–25

Ichikawa M, Ryu K, Yoshida J, Ide N, Kodera Y, Sasaoka T, Rosen RT (2003) Identification of six phenylpropanoids from garlic skin as major antioxidants. J Agric Food Chem 51(25):7313–7317

Jattar-Santiago KY, Ramírez-López C, Hernández-Carranza P, Avila-Sosa R, Ruiz-López II, Ochoa-Velasco CE (2022) Effect of extraction conditions on the antioxidant compounds from habanero pepper (Capsicum chinense) and its potential use as antimicrobial. J Food Process Preserv 46(4):e16427

Johnson M, Olaleye O, Kolawole O (2016) Antimicrobial and antioxidant properties of aqueous garlic (Allium sativum) extract against Staphylococcus aureus and Pseudomonas aeruginosa. Br Microbiol Res J 14(1):1–11. https://doi.org/10.9734/bmrj/2016/24095

Kim G-H, Duan Y, Lee S-C, Kim S (2016) Assessment of antioxidant activity of garlic (Allium sativum L.) peels by various extraction solvents. J Korean Oil Chem Soc. https://doi.org/10.1292/jkocs.2016.33.1.204

Kujala T, Pihlaja K, Vuorela H, Vuorela P (2000) Antimicrobial effects of Finnish plant extracts containing flavonoids and other phenolic compounds. Int J Food Microbiol 56:3–12

Kumar K, Srivastav S, Sharanagat VS (2021) Ultrasound assisted extraction (UAE) of bioactive compounds from fruit and vegetable processing by-products: a review. Ultrason Sonochem 70:105325. https://doi.org/10.1016/j.ultsonch.2020.105325. (Epub 2020 Sep 1)

Lanzotti V, Scala F, Bonanomi G (2014) Compounds from Allium species with cytotoxic and antimicrobial activity. Phytochem Rev 13(4):769–791. https://doi.org/10.1007/s11101-014-9366-0. (Kluwer Academic Publishers)

Lau BH, Ide N (2001) Garlic compounds minimize intracellular oxidative stress and inhibit nuclear factor-κB activation. J Nutr 131(3):1020S-1026S

Liaqat A, Zahoor T, Atif Randhawa M, Shahid M (2019) Characterization and antimicrobial potential of bioactive components of sonicated extract from garlic (Allium sativum) against foodborne pathogens. J Food Process Preserv. https://doi.org/10.1111/jfpp.13936

Liu C, Cui Y, Pi F, Cheng Y, Guo Y, Qian H (2019) Extraction, purification, structural characteristics, biological activities and pharmacological applications of Acemannan, a polysaccharide from Aloe Vera: a review. Molecules 24(8):1554. https://doi.org/10.3390/molecules24081554

Majumder R, Parida P, Paul S, Basak P (2020) In vitro and in silico study of Aloe Vera leaf extract against human breast cancer. Nat Prod Res 34(16):2363–2366

Martínez-Romero D, Alburquerque N, Valverde JM, Guillén F, Castillo S, Valero D, Serrano M (2006) Postharvest sweet cherry quality and safety maintenance by Aloe Vera treatment: a new edible coating. Postharvest Biol Technol 39:93–100

Mohsen R, Elham F, Hamid-Reza A, Sedigheh A (2017) E_ect of Gelatin-based edible coatings incorporated with Aloe Vera and black and green tea extracts on the shelf life of fresh-cut oranges. J Food Qual 1:9764650

Ochoa-Velasco CE, Valadez-Blanco R, Salas-Coronado R, Sustaita-Rivera F, Hernández-Carlos B, García-Ortega S, Santos-Sánchez NF (2016) Effect of nitrogen fertilization and Bacillus licheniformis biofertilizer addition on the antioxidants compounds and antioxidant activity of greenhouse cultivated tomato fruits (Solanum lycopersicum L. var. Sheva). Sci Hortic 201:338–345

Paidari S, Zamindar N, Tahergorabi R, Kargar M, Ezzati S, Shirani N, Musavi SH (2021) Edible coating and films as promising packaging: a mini review. J Food Measure Characteriz 15(5):4205–4214. https://doi.org/10.1007/s11694-021-00979-7

Pelissari FM, Grossmann MVE, Yamashita F, Pineda EAG (2009) Antimicrobial, mechanical, and barrier properties of cassava starch—chitosan films incorporated with oregano essential oil. J Agric Food Chem 57:7499–7504

Pereira R, Tojeira A, Vaz DC, Mendes A, Bártolo P (2011) Preparation and characterization of films based on alginate and aloe Vera. Int J Polym Anal Charact 16:449–464

Prati P, Henrique CM, de Souza AS, da Silva VSN, Pacheco MTB (2014) Evaluation of allicin stability in processed garlic of different cultivars. Food Sci Technol (Campinas) 34(3):623–628. https://doi.org/10.1590/1678-457x.6397

Ragain JC (2016) A review of color science in dentistry: colorimetry and color space. J Dent Oral Disord Ther 4(1):1–5. https://doi.org/10.15226/jdodt.2016.00148

Ramos M, Valdés A, Beltrán A, Garrigós M (2016) Gelatin-based films and coatings for food packaging applications. Coatings 6(4):41. https://doi.org/10.3390/coatings6040041

Rybak ME, Calvey EM, Harnly JM (2004) Quantitative determination of Allicin in Garlic: supercritical fluid extraction and standard addition of Alliin. J Agric Food Chem 52(4):682–687. https://doi.org/10.1021/jf034853x.com269-279.[CrossRef]

dos Santos PCM, da Silva LMR, Magalhaes FEA, Cunha FET, Ferreira MJG, de Figueiredo EAT (2022) Garlic (Allium sativum L.) peel extracts: from industrial by-product to food additive. Appl Food Res 2(2):100186. https://doi.org/10.1016/j.afres.2022.100186

Sogvar OB, Koushesh Saba M, Emamifar A (2016) Aloe Vera and ascorbic acid coatings maintain postharvest quality and reduce microbial load of strawberry fruit. Postharvest Biol Technol 114:29–35

Sui Chin S, Han Lyn F, Nur Hanani ZA (2017) Effect of Aloe Vera (Aloe barbadensis Miller) gel on the physical and functional properties of fish gelatin films as active packaging. Food Packag Shelf Life 12:128–134. https://doi.org/10.1016/j.fpsl.2017.04

Uçak I (2019) Physicochemical and antimicrobial effects of gelatin-based edible films incorporated with garlic peel extract on the rainbow trout fillets. Prog Nutr 21(1):232–240

Uçak İ, Yerlikaya P, Khalily R & Abuibaid AKM (2019) Effects of gelatin edible films containing onion peel extract on the quality of rainbow trout fillets. Eurasian J Food Sci Technol 3(2):40–48

Valdés A, Mellinas AC, Ramos M, Garrigós MC, Jiménez A (2014) Natural additives and agricultural wastes in biopolymer formulations for food packaging. Front Chem. https://doi.org/10.3389/fchem.2014.00006. (Frontiers Media S. A.)

Valdés A, Ramos M, Sanahuja A, Garrigós MC (2014) Characterization and degradation characteristics of poly("-caprolactone)-based composites reinforced with almond skin residues. Polym Degrad Stab 108:269–279

Weber C, Spiehl D, Dörsam E (2021) Comparing gloss meters for gloss measurements on metallic embellishments from the printing industry. https://doi.org/10.14622/Advances_47_2021

Xiao F, Xu T, Lu B, Liu R (2020) Guidelines for antioxidant assays for food components. Food Front 1(1):60–69. https://doi.org/10.1002/fft2.10. (John Wiley and Sons Inc)

Zaman H, Khan M, Khan R (2012) Studies on the thermo-mechanical properties of gelatin based films using 2-hydroxyethyl methacrylate by gamma radiation. Open J Compos Mater 2(1):15–21. https://doi.org/10.4236/ojcm.2012.21003

Funding

Not applicable.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Ethical Approval

Not applicable.

Consent to Participate/Publication

All the authors are aware of the submission of this manuscript to this journal.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

MP, D.R., NV, K. & M, S. Preparation and Characterization of Gelatin Based Antimicrobial Edible Films Incorporated with Aloe Vera Gel and Garlic Peel Extract. J Package Technol Res 8, 121–128 (2024). https://doi.org/10.1007/s41783-024-00166-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41783-024-00166-1