Abstract

Hydroxyapatite (HAp) is a bioceramic known for bone applications due to its physical and chemical properties similar to the human bone. In this present study, HAp nanopowder was synthesised using chemical precipitation method in the presence of polymers Joncryl61 (acrylic resin) and gelatin (biopolymer). The crystalline nature of synthesised pure and polymer-added hydroxyapatite was confirmed by powder X-ray diffraction pattern and the FTIR pattern peaks present at 604–624 cm−1 revealing the presence of phosphate phase. Morphological studies using SEM revealed the presence of rod-shaped, agglomerated rod-shaped and rod shape with small sphere dumbbell structure in pure HAp, HAp with Joncryl61 and HAp with gelatin respectively. The dielectric properties of pure and polymer-doped HAp were also examined at room temperature with frequency from 50 to 5,000,000 Hz. The dielectric constant and loss were found to be maximum when the frequency was low.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Hydroxyapatite (bone mineral) is an inorganic component and also the primary mineral component of bone matrices and hard tissues having the molecular structure of Ca10(OH)2(PO4)6. Hydroxyapatite (HAp) has an advantage of having high biocompatibility and bioactivity. It supports bone growth and osseointegration when used in orthopaedics [1, 2]. The application of HAp is useful in biocompatible material mainly depending on the purity and morphology of the powder [3,4,5]. Hydroxyapatite is widely used to repair, reconstruct and replace damaged musculoskeletal parts due to their compositional similarity to that of bone and teeth. Its properties influence the biological response of HAp implants. It can integrate with bone structures and support bone ingrowths, without breaking down or dissolving (i.e. it is bioactive). Hydroxyapatite is a thermally stable compound, decomposing at a temperature of 800–1200 °C depending on its stoichiometry ratio. HAp is combined with various types of synthetic polymer and biopolymer to generate biocomposite materials that can be used for osteoconduction in the field of orthopaedic surgery [6, 7].

Gelatin is human-made from insoluble collagen (sources include pig, cow, fish, sea urchin collagen) by hydrolysis, which provides for pre-treatment and extraction measures. It is also reported that by reducing the extraction temperature, gelatin with higher bloom index can be created, which is a measure of the stiffness of the gel (enhanced mechanical strength is attributed to higher bloom index) [8]. Gelatin has many advantages making it a suitable material for bone tissue applications. The composition of the human bone in an inorganic/organic hybrid consists of 70% (wt) apatite calcium phosphates and of 30% (wt) organic (mainly collagen). The apatite calcium phosphate of bone mineral consists of carbonate, a small amount of sodium, magnesium and other trace elements. The submicroscopic crystals of calcium phosphates in the bone look like crystal structures of synthetic HAp. HAp prepared by different ways like sol-gel, chemical precipitation, hydrothermal synthesis and combustion synthesis were reported earlier [9,10,11].

The present study is a synthesis of HAp by precipitation method in the presence of new material Joncryl61 (acrylic resin) and gelatin (biopolymer) which is used to examine the various studies on hydroxyapatite. The impact on the resulting morphology is examined. Different approaches for the incorporation of Joncryl61 and gelatin in hydroxyapatite are investigated. According to the current literature, there are no potential environmental effects due to Joncryl61. Therefore, there are no adverse ecological effects expected. This can be used further in biomedical applications, particularly for drug delivery.

Experimental methods

Material synthesis

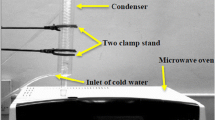

The pure HAp powders were prepared by the precipitation method. The starting material with calcium nitrate tetrahydrate (Ca(NO3)2·4H2O) and diammonium hydrogen phosphate (NH4)2HPO4 are used, and 1.67 M concentration was taken. The synthesis processes have been reported by many researchers, yet there are many challenges in synthesising pure HAp in nanosize particle range. As per literature, the same procedure was followed initially for the occurrence of the white precipitation. It was carried out by the dropwise addition of diammonium hydrogen orthophosphate solution for 3 h into calcium nitrate tetrahydrate solution then adding a little amount of ammonia solution to adjust the pH level of the reaction mixture to about 10.5. These processes were involved in a continuous stirring above room temperature at around 65 to 70 °C for 3 h. After the formation of the white precipitate, the reaction vessel can be washed 7–8 times with double distilled deionised water and dried in a hot air oven at 80 °C [12,13,14]. The similar procedure has to be followed to prepare HAp synthetically using Joncryl61 and biopolymer gelatin after sintering at 500 °C.

The chemical reactions are

Characterisation

Powder X-ray diffraction

PXRD is carried out for structural identification of the pure HAp and polymer-added HAp using a Bruker D8-Advance X-ray diffractometer with 2.2-kW Cu anode, ceramic X-ray tube, Ni filter and a high-efficiency linear detector of Lynx eye type operated in integration mode. The patterns are scanned with a 2θ range from 20° to 80° with a step size of 0.01 and 46.55 measuring time per step. The average crystallite size was determined using the Debye-Scherer formula

where D is the crystallite size of the material, λ is the wavelength of X-ray, β is the broadening of diffraction line (FWHM) and θ is the angle of diffraction.

Fourier transform of infrared spectroscopy

A PerkinElmer FTIR spectrophotometer is used to determine the functional groups by scanning the HAp sample at the range of 400–4000 cm−1. The powder was made into pellets of KBr, and the spectrum was recorded. Resolution used was 4 cm−1, and the number of scans used was 32 and each scan takes 1 s [15, 16].

Scanning electron microscope

The structure and surface morphology of the sample was studied using a HITACHI S2600N-type scanning electron microscope operated at 10.00 kV in a vacuum. SEM images of the synthesised hydroxyapatite powder are shown in Fig. 3. For elemental analysis, the electron microscope was equipped with energy-dispersive X-ray attachment (EDXA value). The morphology was studied using an optical microscope.

Dielectric measurement

The dielectric constant and loss for pure and polymer-doped HAp were investigated at room temperature (35° and 40 °C) over a frequency range of 50 to 5,000,000 Hz using the HIOKI 3532-50LCR HiTESTER meter. The dielectric constant was measured using

where C is the sample capacitance, εo is the permittivity of free space, A is the area and t is the thickness [16].

Results and discussion

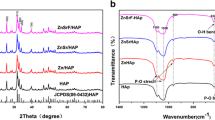

Figure 1 shows the variation of intensity of diffracted X-rays as a function of 2θ. The powder XRD phase identification is performed by using JCPDS standard. The presence of the characteristics of HAp peaks at 25.86, 31.708, 32.07, 32.96, 34.04 and 39.81 is represented in Fig. 1(a) which confirms the hexagonal structure of HAp [17]. PXRD spectra of all samples of pure HAp (a) and HAp with Joncryl61 (b) show similar phases of pure HAp and HAp with gelatin with the characteristic peak shift towards left [18, 19] at 25.04, 31.35, 31.5, 32.04, 33.59 and 38.66 as shown in Fig. 1(c). The crystals were identified by PXRD and compared with JCPDS standards. The value of a = 4.41, b = 4.41, and c = 5.83, if a is equal to b and not equal to c; the lattice will be primitive lattice confirmed with powder X. The average crystallite size of hydroxyapatite and polymer-doped hydroxyapatite shows the range from 20 to 32 nm approximately obtained using Eq. 2. The incorporation of Joncryl61 and gelatin with HAp could increase the crystallite size. The average crystallite size increases for HAp with Joncryl61 and HAp with gelatin because β and D are reciprocally related as the greater the broadening, the smaller the crystallite size and vice versa. Peak broadening is a little higher for pure HAp when compared to that of HAp with Joncryl61 and HAp with gelatin. So the average crystallite size is increased. Table 1 shows the average crystallite size of pure HAp and HAp with Joncryl61 and HAp with gelatin. The average crystallite size is based on the corresponding high reflection 2 theta values shown in Table 2. The average of those Xs (nm) values gives an average crystallite size. In Fig. 2(a), the peak shows that there are fewer water molecules during sintering of the OH molecules due to evaporation. This peak is mainly due to OH stretching vibration in HAp at 3586.48 cm−1. In Fig. 2(b, c), the peaks observed around 3589.33 and 3580.95 cm−1 are typical stretching vibration modes confirming the presence of hydroxyl ion [OH−] in the apatite lattice and the small broad peak at 1096.38 to 1020.95 cm−1; 1099.42 cm−1 is associated with the stretching modes of the P–O bonds of HAp. The bands around 3439 and 1643.98 cm−1 are due to absorbed water during the synthesis process [20]. The double peak at (a) 604.19 and 560.76 cm−1, (b) 605.71 and 558.476 cm−1 and (c) 624.76 and 553.14 cm−1 are due to bending modes of P–O bonds in phosphate groups. Thus, the presence of the PO43- group in pure HAp and polymer-mixed HAp is almost confirmed from IR studies.

Figure 3a shows SEM descriptions of HAp powder from the morphology of particles, and there is a distribution of small particles with a rod-shaped morphology [21]. The surface morphology is found to be plain rod-shaped with the dense surface. Figure 3b shows that rod-shaped morphology with some dumbbell and some small spherical structure is found. Figure 3c shows large agglomerates consist of fine particles with rod-shaped structures that are close together. The presence and percentage variations of compositional elements of (a) pure HAp, (b) HAp with Joncryl61 and (c) HAp with gelatin are shown in Fig. 3 EDXA spectrum. Figure 4 shows the morphology of (a) pure HAp, (b) HAp with Joncryl61 and (c) HAp with gelatin using an optical microscope. From the morphology of particles, there is identified distribution of small particles and some agglomerates in all the structures. These agglomerates consist of fine particles that are close together. The surface morphology of pure HAp is found to be bright with the solid surface, and some pores, HAp with Joncryl61, show a spherical structure with fewer agglomerates found and HAp with gelatin shows more agglomeration with the thick surface at some areas. Figure 5a, b shows the frequency dependence of the dielectric constant and dielectric loss of pure and polymer-doped HAp nanocomposites at room temperature (35 and 40 °C). Initially, the dielectric constant is maximum at low frequency. Consequently, the dielectric constant is small for pure HAp (a) when compared to that of polymer-doped HAp (b) and (c). Frequency increases with a decrease in dielectric constant whereas at high frequency, the variation of dielectric constant is small. The electrical conductivity of the HAp nanocomposites was analysed at two different temperatures. Dielectric constant and loss decrease due to the relaxation process. Similarly, in Fig. 5b, the dielectric loss slowly decreases with increase in frequency. The dielectric loss was initially high at low frequency whereas at high frequency, dielectric loss decreases gradually. The decrease in constant and loss with an increase in frequency is due to the absorption of water.

Conclusion

Hydroxyapatite was successfully synthesised by the precipitation method. Powder XRD spectra reveal that all the samples have pure phase and its average crystallite size is in the range of 20–32 nm. PXRD spectra of all samples for pure HAp and HAp with Joncryl61 show similar phases of pure HAp and HAp with gelatin showing some characteristic peaks shifting left. FTIR peaks present around 604–624 cm−1 confirm the phase of the phosphate group in HAp. Morphological structure changes were found in SEM; rod-shaped, rod-shaped with a small sphere dumbbell and agglomerated rod-shaped structures were observed in pure HAp, Joncryl61-mixed HAp and gelatin-mixed HAp respectively. The morphology with the plain and dense surface with small pores was observed in pure HAp with some small spheres with agglomeration at certain surfaces; rod shape with more agglomeration sphere was detected using an optical microscope. The dielectric properties of all samples were studied at room temperature. The dielectric constant and loss for A, B, C are maximum for low frequency and gradually decrease for high frequency.

References

Zhou, H., Lee, J.: Nanoscale hydroxyapatite particles for bone tissue engineering. Acta Biomater. 7(7), 2769–2781 (2011)

Jiao, Y., Lu, Y.P., Xiao, G.Y., Xu, W.H., Zhu, R.F.: Preparation and characterization of hollow hydroxyapatite microspheres by the centrifugal spray drying method. Powder Technol. 217, 581–584 (2012)

Del Real, R.P., Wolke, J.G.C., Vallet-Regı, M., Jansen, J.A.: A new method to produce macropores in calcium phosphate cement. Biomaterials. 23(17), 3673–3680 (2002)

Tahriri, M., Solati-Hashjin, M., Eslami, H.: Synthesis and characterisation of hydroxyapatite nanocrystals via chemical precipitation technique. Iran. J. Pharm. Res. 4(2), 127–134 (2008)

Ramli, R.A., Adnan, R., Bakar, M.A., Masudi, S.A.M.: Synthesis and characterisation of pure nanoporous hydroxyapatite. J. Phys. Sci. 22(1), 20–37 (2011)

Agrawal, K., Singh, G., Puri, D., Prakash, S.: Synthesis and characterisation of hydroxyapatite powder by a sol-gel method for biomedical application. J. Miner. Mater. Charact. Eng. 10(08), 727 (2011)

Eslami, H., Tahriri, M., Bakhshi, F.: Synthesis and characterization of nanocrystalline hydroxyapatite obtained by the wet chemical technique. Mater. Sci. Pol. 28(1), 5–13 (2010)

Selestina, G., Vanja, K.: Collagen- vs gelatine-based biomaterials and their biocompatibility: review and perspectives. In: Pignatello, R. (ed.) Biomaterials applications for nanomedicine, pp. 17–53. INTECH Open Access Publisher (2011). https://doi.org/10.5772/24118

Fathi, M.H., Hanifi, A.: Evaluation and characterization of nanostructure hydroxyapatite powder prepared by the simple sol-gel method. Mater. Lett. 61(18), 3978–3983 (2007)

Kim, I.S., Kumta, P.N.: Sol-gel synthesis and characterization of nanostructured hydroxyapatite powder. Mater. Sci. Eng. B. 111(2), 232–236 (2004)

Mobasherpour, I., Heshajin, M.S., Kazemzadeh, A., Zakeri, M.: Synthesis of nanocrystalline hydroxyapatite by using precipitation method. J. Alloys Compd. 430(1), 330–333 (2007)

Chung, J. H., Kim, Y. K., Kim, K. H., Kwon, T. Y., Vaezmomeni, S. Z., Samiei, M., ... & Akbarzadeh, A. Synthesis, characterisation, biocompatibility of hydroxyapatite–natural polymers nanocomposites for dentistry applications. Artif. Cells Nanomed. Biotechnol. 44(1), 277–284 (2016)

Anitha, P., Pandya, H.M.: Comprehensive review of preparation methodologies of nano-hydroxyapatite. J. Environ. Nanotechnol. 3(1), 101–121 (2013)

Palanivelu, R., Kumar, A.R.: Synthesis, characterisation, in vitro antiproliferative and hemolytic activity of hydroxyapatite. Spectrochim. Acta A Mol. Biomol. Spectrosc. 127, 434–438 (2014)

Chavan, P.N., Bahir, M.M., Mene, R.U., Mahabole, M.P., Khairnar, R.S.: Study of nanobiomaterial hydroxyapatite in simulated body fluid: formation and growth of apatite. Mater. Sci. Eng. B. 168(1), 224–230 (2010)

Ragu, A., & Sakthivel, P. Synthesis and Characterization of Nano Hydroxyapatite with Polymethyl methacrylate Nanocomposites for Bone Tissue Regeneration. International Journal of Science and Research (IJSR) 3(11), 2282–2285 (2014)

Matković, T., Matković, P., Malina, J.: Effects of Ni and Mo on the microstructure and some other properties of Co–Cr dental alloys. J. Alloys Compd. 366(1), 293–297 (2004)

Sivakumar, M., Rao, K.P.: Preparation, characterisation and in vitro release of gentamicin from coralline hydroxyapatite–gelatin composite microspheres. Biomaterials. 23(15), 3175–3181 (2002)

Chang, M.C., Ko, C.C., Douglas, W.H.: Preparation of the hydroxyapatite-gelatin nanocomposite. Biomaterials. 24(17), 2853–2862 (2003)

Lett, J.A., Sundareswari, M., Ravichandran, K.: Porous hydroxyapatite scaffolds for orthopaedic and dental applications-the role of binders. Mater. Today 3(6), 1672–1677 (2016)

Kolanthai, E., Ganesan, K., Epple, M., Kalkura, S.N.: Synthesis of nanosized hydroxyapatite/agarose powders for bone filler and drug delivery application. Mater. Today Commun. 8, 31–40 (2016)

Acknowledgements

The authors excitedly recognised VIT University for providing support and excellent research facilities.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shalini, B., Kumar, A.R. Effect of Joncryl61 and gelatin in the formation of hydroxyapatite nanocomposite. J Aust Ceram Soc 55, 229–234 (2019). https://doi.org/10.1007/s41779-018-0227-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41779-018-0227-y