Abstract

The integration of the electrochemical detection system together with microfluidic technology is an attractive choice for the construction of miniaturized components in a single platform. Microchannel networks fabricated on conductive substrates prevent environmental contaminants and require only a tiny (µL or nL) sample for electroanalysis. Microfluidics coupled electrochemical detection system is particularly advantageous compared to traditional electrochemical sensing systems due to its flexibility, rapid analysis, low fabrication costs, ease of implementation and disposability. With these electrochemical sensing platforms, biochemical assays that require complex pre-processing of biological samples can be conducted on a chip. In this review, a comprehensive overview of the basic concepts of microfluidics and its recent applications in the design of miniaturized electrochemical sensors for biosensing applications are presented.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The early diagnosis of a disease increases the possibilities for effective treatment and plays a key role in prevention strategies [1,2,3]. The presence or occurrence of biomolecules above their normal levels in human blood affects biochemical cycles and causes adverse health effects [3,4,5,6]. Therefore, rapid detection and accurate quantification of biomarkers are very essential for large-scale monitoring programs [7,8,9,10]. Monitoring the level of biomarkers in human blood serum with the help of biosensors is the only way to protect humans from adverse health effects [6, 11]. Several analytical techniques have been used to detect target analytes in human blood serum samples, including flow injection analysis, titrimetry, spectrofluorimetry, surface enhanced Raman scattering (SERS), high performance liquid chromatography (HPLC), capillary zone electrophoresis and proton nuclear magnetic resonance (1H NMR) [4,5,6, 9]. Nevertheless, these analytical methods have a high degree of specificity and sensitivity. Further, these strategies are expensive and require sophisticated laboratory instruments, sample pre-treatment and trained personnel [8, 12,13,14]. The development of an alternative protocol which minimizes the use of chemicals and expensive instruments is the need of the hour.

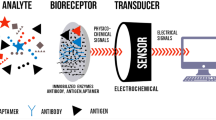

In recent years, the design of hand-held electrochemical sensing device capable of detecting target analytes in human blood serum samples received immense attention [1, 4, 5, 15]. Most of the electrochemical biosensors used in the clinical diagnosis are self-monitoring analytical devices in which working electrodes are designed by tailoring the surface of electrodes with biomolecules, such as DNA, antibodies and enzymes [1, 2, 4, 7, 16]. These electrochemical biosensors can accurately detect target analytes in human blood serum samples due to the specific interaction between target analytes and biomolecules [5, 10, 13]. In metal oxide-based electrochemical biosensor, the analytical performance can be improved by optimizing several experimental parameters including scan rate, pH, incubation time, biorecognition element loading, concentration of buffer and electrode material. The biorecognition element is immobilized on metal oxide nanomaterial, which helps to increase the electron transfer rate between the biorecognition element and the working electrode and to improve the sensitivity of an electrochemical biosensor [2, 10, 12, 13]. However, external sources are needed to mix reagents and samples (down to microliter) which limit their sensitivity. On the other hand, nanotechnology and reliability of biomicrochips have recently gained much attention in clinical diagnostics. In microfluidic biochip platforms utilizing biorecognition elements as electrocatalysts, the sizes of electrode material and immobilization section play a crucial role in enhancing the system’s sensitivity for rapid analysis. In microfluidic chip design, the immobilization section is either a particular portion of the microfluidic channel or the detection cell itself. In order to accomplish improved sensing response with low detection limit in any microfluidic biosensor, stop-flow technique is used [2, 10, 12, 13]. This method facilitates the simultaneous detection of multiple target species from a single sample by minimizing the number of preparation steps involved, reagent and sample volume and time required for the sample analysis.

Notably, the integration of micrometer-scaled fluidic channels with electrochemical biosensing platform is of current interest because of its high throughput, sensitivity, specificity and low detection limit [1, 3, 7, 11, 15, 16]. The ultimate aim of the microfluidic channel-assisted electrochemical sensing device is to restrict the movement of reagents and sample in microchannels and to design lab-on-chip devices for performing multi-process operations within a single platform [5, 11, 15]. The micrometer-scaled channels in these biosensing devices consume low volumes of reagent and sample solution. As a result, biochemical analyses can be completed rapidly and the costs associated with the production of miniaturized bioanalytical devices become cost-effcetive [5, 11, 15].

In the literature, there are only very few reviews that focus on the microfluidic device coupled electrochemical detection systems [2, 17,18,19,20,21,22,23,24]. Despite these review articles, a comprehensive overview of the different types of microfluidic systems for fabricating electrochemical sensors capable of detecting target analytes in human blood serum is not available [2, 17,18,19,20,21,22,23,24]. In this review, we present the basic concepts of microfluidics and its recent application in the design of miniaturized electrochemical sensors for biosensing applications.

2 Microfluidics

Usually, microfluidic devices are used to analyse small volumes such as aL to µL [25,26,27]. Microfluidics, a technology, essentially involves planar substrates containing microchannel network with depth (~ 10 µm), width (~ 100 µm) and length (10 mm), respectively [28,29,30]. Microfluidics finds intensive wide variety of applications [31,32,33]. Often, microfluidics is used in the design and development of microfluidic channels for electrochemical sensing of biomolecules in human blood serum [28,29,30]. Advances in microfluidics have provided strategies for the construction of lab-on-chip devices that can control microchannel fluidic transport, enabling rapid electroanalysis and allows the user to perform multi-step reactions with tiny volumes of samples and reagents [31,32,33].

Usually, the flow of fluids in engineered microfluidic devices is highly ordered and non-turbulent in nature [28,29,30]. The fluidic phenomena caused by the existence of diffusion, surface tension and viscosity are usually represented by dimensionless parameters, which include Peclet number (Eq. 1), Capillary number (Eq. 2) and Reynolds number (Eq. 3) [31,32,33].

where \(Pe\) is the Peclet number, \(Ca\) is the Capillary number, \(Re\) is the Reynolds number, \(\gamma\) is the surface tension, \(\mu\) is the dynamic fluid viscosity, \(\nu\) is the mean fluid velocity, \(l\) is a characteristic length in the system and \(\rho\) is the fluid density. In microfluidic devices, a low Peclet number can be observed only when diffusion controls convection [1, 17, 23]. Similarly, in the microfluidic system with low Capillary number, interfacial forces control viscous forces whereas, in the microfluidic system with low Reynolds number, viscous forces control inertial forces [28,29,30]. These fluidic phenomena are vital in the design of microfluidic channels for electrochemical sensors. Based on the manipulation of fluid flow through microchannel networks, microfluidic systems can be classified into four types: (1) continuous-flow-based microfluidics, (2) droplet-based microfluidics, (3) paper-based microfluidics and (4) digital microfluidics [1, 17, 23].

3 Continuous-Flow and Droplet-Based Microfluidics Coupled Electrochemical Detection System

The concept of innovative design in the fabrication of microfluidic devices originates from channel-based microfluidics [34]. So far, the channel-based microfluidics is the most extensively studied microfluidic platform in the construction of microfluidic device coupled electrochemical detection systems. Extensive research has been conducted on the translation of electrokinetic flow techniques with the help of channel-based microfluidics [35]. Channel-based microfluidics is in widespread use; however, the range of solvents and reagents used in these microchannel networks is more limited [36]. One of the main advantages of the system is that the channel-based microfluidics only requires a high-voltage–power supply, which enables them to apply different types of pressure-driven flow controlled by on-chip peristaltic pumps [37]. However, the channel-based microfluidics is particularly disadvantageous because individual reagents require external equipment to operate [38]. For example, polymethyl(siloxane) is the most widely used microchannel device material in the fabrication of microchannel networks [39].

There are two types of channel-based microfluidics, namely continuous-flow and droplet-based microfluidics [34]. Channel-based microfluidics operating with low Reynolds number has been extensively applied for a wide variety of applications including intricate chemical gradients [37]. These microchannel devices are employed to combine immiscible solvents to form emulsions in microchannel networks. Within a second, the droplet-based microfluidic system can produce approximately 1000 droplets, which makes them suitable for sorting applications. The manipulation of individual droplets at high throughput has gained much attention in recent years; however, the key advantage of this technology is its throughput rather than individual droplet manipulation [39].

Usually, electrodes are patterned on a silicon or glass substrates to design a channel-based microfluidic electrochemical detection system [40]. Subsequently, a polymer-based substrate containing numerous microchannel networks is bound to the glass substrates. Conventionally, compact discs, silicon and glass substrates are commonly used in the construction of electrodes [40]. In few cases, the channel inlets contain discrete counter and reference electrodes [40].

Messina et al. [41] developed a novel continuous-flow microfluidic-based immunosensor for sensitive and selective detection of interleukin-6 in human blood serum samples in which the anti-IL-6 monoclonal antibodies immobilized on a 3-aminopropyl modified controlled-pore glass were packed in a central microchannel of the microfluidic system. Especially, microfabricated biochip from Plexiglas was equipped with gold working electrode, platinum wire counter electrode and Ag/AgCl reference electrode. This microfluidic immunosensor showed a detection limit of 0.41 pg mL−1 with a reproducibility of 6.5% RSD. The electrochemical detection system coupled with continuous-flow microfluidics has received considerable attention in the construction of miniaturized prostate specific antigen sensors due to its high sensitivity and small injection volume. For an instant, Panini et al. [42] proposed a sensitive and selective analytical method for quantifying prostate-specific antigen in human blood serum samples by coupling a continuous-flow microfluidic system with an electrochemical detector. Panini et al. [42] deposited carbon nanotubes/horseradish peroxidase/anti-tPSA on the glassy carbon electrode surface in order to fabricate GC/CNT/HRP/anti-tPSA working electrode in a microfluidic microfabricated Plexiglas biochip. Under optimized experimental conditions, the fabricated microfabricated biochip was able to detect prostate-specific antigen with a low detection limit of 0.08 µg L−1 and a reproducibility of 4.5% RSD. In another work, Lin et al. [43] reported a novel hybrid polydimethylsiloxane-glass chip for hydrogen peroxide detection. They used droplet-based microfluidic electrochemical detection system as a platform for highly sensitive and selective detection of hydrogen peroxide with a sensitivity of 1.2 A M−1 cm−2, a reproducibility of 1.1% RSD and a low limit of detection of 0.12 µM.

Glucose detection in the human blood serum with the aid of electrochemical sensors utilizing bulk electrodes is broadly discussed topic. However, there have been few studies investigating the electro-analytical performances of microfluidic chip-integrated electrochemical glucose sensor. For an instant, Gu et al. [15] reported microfluidic microfabricated chip using Pt nanoparticles as an efficient biosensing platform for the detection of glucose in human blood serum samples (see Fig. 1). The microfluidic chip was constructed based on poly(dimethylsiloxane) (PDMS) using soft lithography and comprised of a tapered tip enclosed fused-silica capillary with a Pt-black working electrode, a Pt wire counter electrode and an Ag/AgCl reference electrode. The resulting microfluidic sensor exhibited a linear response of up to 43.5 mM glucose with a reproducibility of 2.65% RSD. The impurities present on the surface of PDMS can also affect the response of microfluidic sensor. Bubendorfer et al. [44] recently reported the contamination of PDMS with residues of antimony containing photoinitiator.

Figures modified from Ref. [15] and used with permission

a Schematic illustration of the principle of concentration gradient generation. b Electrochemical sensor based on microfluidic droplets. c Electrochemical detection of glucose in a droplet. d Microphotograph of droplet concentration gradient generation module. Red dye solution was used for better observation. Scale bar 1.0 mm. e The average dispersion coefficient vs. droplet number obtained from three consecutive injections of 1 mM hydrogen peroxide. f Current responses to hydrogen peroxide produced by the enzyme reaction as a function of glucose concentration for three different enzyme concentrations 0.1, 0.5, 1.0 mg L−1. Each was measured for three repetitive injections (RSD < 5%). g The Lineweaver–Burk plot for glucose concentrations was ranging from 0.2 to 43.5 mM, resulting in a Km value of 31.06 mM. The inset shows the current response to hydrogen peroxide produced by the enzyme reaction as a function of glucose concentration. GOx: 1.0 mg L−1, glucose: 1 mM, applied potential: 0.7 V, total flow rate: 3.6 mL min−1, oil flow rate: 1.2 mL min−1, injection time: 30 s

The literature contains numerous proposals for the use of miniaturized bioanalytical devices in performing electrochemical detection on droplet-based microfluidic platforms. For example, Rattanarat et al. [14] used soft lithography technique to fabricate microfluidic microchips for the detection of 4-aminophenol in various pharmaceutical paracetamol products (see Fig. 2). The detection process was performed electrochemically with the assistance of droplet-based microfluidic electrochemical sensor. The microchannel networks were patterned to extend the aqueous microdroplets to cover all three electrodes, including carbon paste reference electrode, graphene–polyaniline modified carbon paste working electrode and carbon paste counter electrode. The fabricated microfluidic electrochemical sensor showed good linearity in the range of 50–500 µM of 4-aminophenol concentration with detection and quantification limits of 15.68 µM and 52.28 µM, respectively.

Figures modified from Ref. [14] and used with permission

a Schematic of microchannels (top) and electrode patterns (bottom). b An electrochemical batch cell (left) and a microfluidic device comprising of main channel and confined channel coupled with microband electrodes (WE working electrode, CE counter electrode, and RE reference electrode). c Comparison of cyclic voltammograms of 1 mM 4-AP obtained from the G-PANI/CPE and bare CPE at a scan rate of 0.1 Vs−1. d Cyclic voltammograms of 1 mM 4-AP at the G-PANI/CPE with various scan rates in the range of 0.01–0.2 Vs−1. e Peak currents of 4-AP as a function of the square root scan rate (ν1/2). f Square-wave voltammograms of 4-AP and PA (0–0.2 mM) at the G-PANI/CPE with the scanning potential range of −0.2 to 0.8 V vs. CPE.

Droplet-based microfluidic microchips coupled electrochemical sensors have also been extensively applied for quantitative and qualitative analysis of d-glucosamine products, especially during the manufacturing process. For example, Suea-Ngam et al. [45] fabricated an integrated platform consisting of an electrochemical d-glucosamine sensor and a droplet-based microfluidic microchip for d-glucosamine detection (see Fig. 3). The proposed microfluidic microchip was fabricated based on PDMS using soft lithography technique in which all three electrodes were inserted into the microchannels of the patterned PDMS plate. The polyaniline-gold nanoparticles-modified carbon paste was used as a working electrode and the bare screen-printed carbon paste was employed as counter and reference electrodes. The microfluidic electrochemical sensor was shown to achieve a detection limit of 0.45 mM with a sensitivity of 7.42 × 10−3 A mol−1 L cm−2.

Figures modified from Ref. [45] and used with permission

a A microfluidic device consisting of two PDMS layers. The top PDMS plate contains a main channel (500 mm wide and 100 mm deep) and a confined channel (50 mm wide, 100 mm deep and 1 cm long) as a detection window. The bottom PDMS plate has three parallel channels (500 mm wide and 100 mm deep) screen printed with carbon paste to be used as working, counter and reference electrodes (WE, CE and RE, respectively). The working electrode was modified with PANI and AuNPs. The distance between each electrode is 500 mm. b A well-like device with a 0.8 mm punched hole to serve as a reservoir. c, d SEM images of PANI microfibers with AuNPs. e Chronoamperometric readout of a concentration series of GlcN from 0 to 5 mM. The inset shows an example of current measurement of a droplet peak. The measurements were carried out using a total flow rate of 2.0 μL min−1 and Wf = 0.3 to generate droplets containing GlcN. The applied potential was 100 mV vs. CPE. f A hydrodynamic voltammogram of 2.5 mM GlcN.

Several recent studies have integrated electrochemical sensors with microfluidic microbiochips to improve the detection limits of dopamine and ascorbic acid for quantitative analysis of dopamine and ascorbic acid in intravenous drug samples. For example, Suea-Ngam et al. [46] reported a droplet-based microfluidic platform for chronoamperometric detection of dopamine and ascorbic acid in millimolar concentrations comprising a main channel and a confined microchannel with three screen-printed carbon paste electrodes. The experimental results exhibited that the microfluidic electrochemical sensor could detect dopamine and ascorbic acid with detection limits as low as 20 and 70 µM in the concentration ranges of 0.02–3.0 and 0.04–3.0 mM, respectively.

Many studies have shown that enzyme-modified microelectrodes are highly effective in improving the specificity of droplet-based microfluidic electrochemical devices and minimizing interferent effects. Itoh et al. [47] performed an amperometric detection of adenosine-5′-triphosphate (ATP) using a droplet-based microfluidic device in which reagent solution and extracts from fish were processed in the form of microdroplets to determine fish freshness. The microfluidic device from PDMS substrate was equipped with glycerol kinase/glycerol-3-phosphate oxidase modified Pt as a working electrode, a Pt wire as a counter electrode and Ag/AgCl as a reference electrode. The developed microfluidic electrochemical sensor could rapidly detect ATP in fish extracts within 20 s.

4 Paper-Based Microfluidics Coupled Electrochemical Detection System

Paper-based microfluidics involves manipulation of small volumes of fluids in which paper is used as a substrate to enable passive liquid transport [48,49,50,51,52,53,54,55,56]. Paper-based microfluidic devices are designed to create hydrophobic and hydrophilic patterns that allow the sample solution to move within the microchannels [48,49,50,51,52,53,54,55,56]. Several fabrication techniques have been used to create hydrophilic/hydrophobic patterns on the paper substrate, including flexographic printing, photolithography, inkjet printing and wax printing [48,49,50,51,52,53,54,55,56]. Paper-based microfluidics coupled electrochemical detection systems have received considerable attention in recent years due to their flexibility, rapid analysis, low-cost design, ease of implementation and disposability [48,49,50,51,52,53,54,55,56]. Liquid transport through microchannels in paper-based microfluidic system is particularly advantageous because it does not require any external driving force to pump liquid samples [48,49,50,51,52,53,54,55,56]. For all these reasons, the use of paper-based microfluidic electrochemical detection system as a point-of-care testing diagnostic tool has received paramount attention in the rapid and selective detection of biomarkers [48,49,50,51,52,53,54,55,56].

In most cases, pH strips use paper-based microfluidic platform for sensing applications in which the reagent changes color upon reaction with the target analyte [48,49,50,51,52,53,54,55,56]. The sensing element patterned on paper substrates includes some or all of membranes modified with (1) biomolecules-like DNA, antibodies and enzymes, and (2) nanoparticles e.g., metal nanoparticles, metal oxide nanostructures, carbon nanotubes, graphene, quantum dots, hydrogels, polymeric nanoparticles, etc. [48,49,50,51,52,53,54,55,56]. In the design and development of a paper-based microfluidic electrochemical sensor, a three-electrode system consisting of a working electrode, a counter electrode and the reference electrode is printed on the paper [48,49,50,51,52,53,54,55,56]. Such a pattern on paper substrates could replace the conventional electroanalysis using working electrodes such as gold, silver and glassy carbon [48,49,50,51,52,53,54,55,56]. The common conductive inks employed to create micropatterns on paper substrates are carbon and silver/silver chloride inks [48,49,50,51,52,53,54,55,56]. The carbon inks are extensively used in the fabrication of counter and working electrodes, whereas silver/silver chloride ink is utilized in the fabrication of reference electrode [48,49,50,51,52,53,54,55,56].

Electrochemical sensors based on paper-based microfluidic platform enhance interaction between the target analyte and the biorecognition element. Cao et al. [31] developed a paper-based microfluidic coupled electrochemical sensor using a new nanocomposite consisting of primary signal antibody, gold nanoparticles and alkaline phosphatase conjugated secondary antibody (ALP-IgG/GNPs/Ab2) for highly sensitive and selective determination of chorionic gonadotropin in human blood serum samples (see Fig. 4). Photolithography technique was utilized to fabricate paper-based microfluidic immunosensor. The fabrication of microfluidic immunosensor comprised two layers: the top and bottom layers on aldehyde-functionalized paper were screen printed with carbon and Ag/AgCl inks, respectively, utilized as working and reference electrodes. The developed microfluidic paper-based electrochemical immunosensor displayed good linearity in the range of 1 × 10−3–100 IU mL−1 of chorionic gonadotropin concentration with a detection limit of 0.36 × 10−3 U mL−1.

Figures modified from Ref. [31] and used with permission

Schematic of the processes to fabricate a paper-based microfluidic electrochemical immunosensor. a Chromatography paper was soaked in a 0.03 M KIO4 solution to make aldehyde groups. b SU-8 photoresist was poured and spread over the paper. c Photoresist-covered paper was irradiated with a UV lamp under photomask. d Hydrophilic areas were developed by rinsing with acetone and isopropyl alcohol. e Carbon working and carbon counter electrodes were screen-printed on the hydrophilic zone. f Ag/AgCl reference electrode and the connector were screen-printed on the hydrophilic zone and hydrophobic zone, respectively. g Covalently immobilize capturing antibody to aldehyde groups on hydrophilic zone of SPEs.

Despite the intense research of constructing low-cost electrochemical sensors for 17β-estradiol detection, the size of macro-working electrodes impedes the research progress of electrochemical 17β-estradiol sensors. To overcome these limitations, Wang et al. [57] fabricated paper-based microfluidic electrochemical 17β-estradiol sensor to investigate the electrocatalytic behavior of multi-walled carbon nanotubes/thionine/gold nanocomposites towards 17β-estradiol (see Fig. 5). They developed a label-free integrated microfluidic paper-based analytical device using wax printing technique for point-of-care diagnosis of 17β-estradiol. The developed microfluidic paper-based sensor exhibited good linearity in the range of 0.01–100 ng mL−1 of 17β-estradiol concentration with a detection limit of 10 pg mL−1.

Figures modified from Ref. [57] and used with permission

a Overview of the integrated paper-based electrochemical immunodevice: (1) microfluidic channel, (2) filter hole, (3) screen-printed counter electrodes, (4) screen printed reference electrodes, (5) reaction sites, (6) screen-printed working electrodes. b Picture of the integrated device and its specific size. c The modification procedure of the working electrode of paper-based immunosensor. d DPV responses to different concentrations of 17β-E2 standard solutions in 0.1 M PBS solution, pH 7.4. e Calibration curve of the microfluidic paper-based immunodevice towards 17β-E2.

The commercial glucose sensors have gradually evolved from electrochemical sensors to paper-based microfluidic electrochemical glucose sensors, as they require only tiny (µL or nL) sample for electroanalysis. For an instant, Tran et al. [58] developed a non-enzymatic glucose sensor based on single-walled carbon nanotubes (SWCNTs) electrode modified with gold nanoparticles (see Fig. 6). The SWCNT patterns fabricated on nitrocellulose membrane were used as a paper-based microfluidic platform for controlling the movement of glucose droplets. The cyclic voltammetric response of fabricated microfluidic paper-based electrochemical glucose sensor was found to be linear in the range of 0.5–10 mM with a detection limit of 148 µM and a sensitivity of 240 µA mM−1 cm−2. An interesting strategy for the impedimetric determination of interferon-gamma by Ruecha et al. [59] is reported, in which paper-based microfluidic device coupled with label-free electrochemical impedance immunosensor was used as a sensing platform. The developed paper-based microfluidic device was constructed using wax printing technique. Subsequently, the three-electrode system was fabricated by screen printing Ag/AgCl, carbon and graphene modified inks onto the hydrophilic reservoir. Polyaniline is coated on the surface of graphene screen-printed paper electrode to construct an electrochemical interferon-gamma sensor. Interestingly, the fabricated electrode is found to be linear in the 5–1000 pg mL−1 range of human interferon–gamma concentration with a detection limit of 3.4 pg mL−1.

Figures modified from Ref. [58] and used with permission

a Schematic illustration of SWCNT patterning on NC membrane. b FE-SEM images of wax-printed NC membrane before SWCNT filtration. c FE-SEM images of wax-printed NC membrane after SWCNT filtration. d FE-SEM image of SWCNT patterned NC membrane. e Optical image of SWCNT patterned NC membrane.

Recently, microfluidic paper-based alpha-fetoprotein sensors have been actively investigated. Cao et al. [60] used paper patterned with and without polymerized photoresist as a microfluidic platform. The paper-based microfluidic channels were constructed using photolithography technique and the three electrodes, including carbon counter electrode, Ag/AgCl reference electrode and graphene oxide-tetraethylene pentamine/nano-gold working electrode, were screen printed. The proposed microfluidic immunosensor exhibited wide linearity in the range of 0.01–100 ng mL−1 with a low detection limit of 0.005 ng mL−1.

Up to date, microfluidic paper-based electrochemical sensors for glucose, lactate and uric acid are commonly used in daily life and are commercially successful as portable devices. Zhao et al. [61] reported a microfluidic paper-based electrochemical biosensor array for the detection of lactate, glucose and uric acid in human blood serum samples. They utilized solid wax printing technique for fabricating microchannels on chromatographic paper. A group of three carbon microelectrodes were connected to eight microchannels for the multiplexed detection of lactate, glucose and uric acid in human blood serum samples. The microfluidic paper-based biosensor array exhibited excellent analytical performance comparable to that of existing electrochemical sensing platforms.

In recent years, many efforts have been made to enhance the sensitivity of electrochemical adenosine sensors by integrating electrochemical adenosine sensor with microfluidic paper-based microchips. Liu et al. [62] fabricated a self-powered origami paper microfluidic device and used it as a sensing probe for ultralow detection of adenosine in human blood serum samples. The proposed microfluidic paper-based device consisted of two fluidic inlets, two layers and microchannel networks bearing two screen-printed carbon electrodes, which were fabricated using wax printing technique. The resulting microfluidic electrochemical adenosine sensor exhibited a sensitivity of 0.48 µA µM−1 with a detection limit of 11.8 µM.

Electrochemical sensors coupled microfluidic paper-based systems for the monitoring heavy metal ions such as cadmium, mercury and lead have become popular in recent years, where low-cost lab-on-chip sensors have been developed to meet the challenges of environmental water monitoring. Nie et al. [63] fabricated a microfluidic paper-based electrochemical sensor to monitor heavy metal ion levels in soil and groundwater. In this instance, the device composed of three electrodes was fabricated on a piece of polyester–cellulose blend paper by screen-printing Ag/AgCl and carbon inks. Similarly, microchannel networks in the proposed microfluidic device were fabricated using the photolithography technique. The fabricated microfluidic electrochemical lead sensor displayed a sensitivity of 0.17 µA ppb−1 and a wide linear range of 5–100 ppb.

5 Digital Microfluidics Coupled Electrochemical Detection System

Digital microfluidics, an advanced microfluidic technique, enables the manipulation of discrete droplets bearing samples and reagents on a flat surface [64,65,66,67,68,69]. In most cases, digital microfluidics employs a two-plate format in which droplets are sandwiched between the top and bottom hydrophobic substrate plates [64,65,66,67,68,69]. The digital microfluidic system contains two different types of electrodes, namely driving electrodes and counter electrodes. Usually, the bottom plate consists of an array of dielectric covered driving electrodes that are commonly used to control the shape and size of droplets [64,65,66,67,68,69]. On the other hand, in top plate, the counter electrode is typically made of transparent indium-tin-oxide (ITO)-coated glass.

The electrical potential applied between dielectric covered driving electrode and counter electrode generates electrostatic force which can be used to manipulate the movement of discrete droplets [64,65,66,67,68,69]. Furthermore, splitting, merging and mixing of droplets can be performed by controlling the electrical potential between the driving and counter electrodes [64,65,66,67,68,69]. These digitized droplet actions are operated and executed with the help of a computer to perform multiple steps over a short period of time. Owing to these reasons, digital microfluidics can be used for a wide range of applications, including biomolecule analysis, chemical synthesis, chip-based diagnostics and single cell manipulation [64,65,66,67,68,69]. More specifically, in the design of digital microfluidics-assisted electrochemical sensor devices, digital microfluidics depends on electrostatic forces, which is also defined as “electrowetting” in which Laplace pressure is used as a result of asymmetric variations in the sample droplets shape [64,65,66,67,68,69].

In most cases, the digital microfluidic system has great advantages over other forms of microfluidics. For instance, digital microfluidics does not require fittings, interconnects, valves or external peristaltic pumps [64,65,66,67,68,69]. Further, manipulation of individual droplets at high throughput can be accomplished [64,65,66,67,68,69]. The throughput of digital microfluidics can be remarkably enhanced with the fabrication of devices developed formed from arrays of thin film resistors. Since there is no clogging of microchannels in digital microfluidic system, it is widely employed in the design and development of digital microfluidics coupled electrochemical detection system. Recently, digital microfluidic technique that uses magnetic forces to control solid magnetic particles has emerged as a powerful tool for controlling movements of droplets on flat surface [64,65,66,67,68,69].

Although continuous-flow, droplet and paper-based microfluidics have been successfully used by many groups, only a few groups employed digital microfluidics for electrochemical analysis due to its easy manipulation of individual droplets and low cost. Recently, Ugsornrat et al. [70] developed a miniaturized digital microfluidic electrochemical sensor by integrating electrowetting on dielectric digital microfluidic biochip with an electrochemical detector. For effective merging of sample microdroplets and buffer reagent, Ugsornrat et al. [70] constructed T-junction bearing three microelectrodes at its end. The fabricated digital microfluidic system consumes a low volume of buffer reagent and plays an active role in chemical analysis.

Ruecha et al. [48] proposed a novel strategy for the detection of uric acid, dopamine and glucose in human blood serum samples based on a paper-based active microfluidic lab on a chip integrated with electrochemical sensors. In this instance, the microchannels in digital microfluidic lab on a chip were fabricated by paper- and printing-based modular techniques. The counter and working microelectrodes were screen-printed employing a conductive ink of carbon nanotubes while the reference microelectrode was screen-printed using a conductive ink of Ag/AgCl. Ruecha et al. [48] employed graphene-gold nanocomposites modified screen-printed electrode for the simultaneous detection of uric acid, dopamine and glucose. The electrode showed an excellent electrocatalytic activity towards uric acid, dopamine and glucose. The response is linear in the ranges 5–400 µM (UA), 1–200 µM (DA) and 0.05–6 mM (Glu) and has low detection limits of 5 µM (UA), 0.5 µM (DA) and 0.05 mM (Glu), respectively.

Extensive efforts have been put forth to design digital microfluidic electrochemical sensor system for the simultaneous determination of multi-pulmonary hypertension biomarkers. Lee et al. [71] integrated digital microfluidics with electrochemical detection system for multiple and simultaneous electrochemical detection of biomarkers associated with pulmonary hypertension, namely 8-isoprostane, low-density lipoprotein, adiponectin and fibrinogen. The proposed microfluidic electrochemical sensor consisted of five chambers which can be individually controlled employing pneumatic microvalves to control the flow movement of multiple reagents and testing samples. The resulting sensor is found to be highly sensitive and selective towards pulmonary hypertension-associated biomarkers.

Microfluidic device coupled with complementary metal oxide semiconductor (CMOS) has been designed to propose as an electrochemical imaging system [72]. The developed microfluidic device comprised 64 subarrays in which rectangular reference electrode, 64 pairs of electrodes, 128 C-shaped electrodes and rectangular counter electrode are enclosed. The outermost layer of microfluidic CMOS biosensor chip consisted of Pt, Au and Ti metal layers to maintain biological compatibility and electrical conductivity. The interdigitated micro-working electrode array coupled with microfluidic device detected changes in the release of caffeine-stimulated catecholamines from live slices of adrenal tissue with enhanced sensitivity.

Although many research groups have already proposed electrochemical potassium sensors using three electrode system, despite their originality of work, they exhibited poor sensitivity, and require sophisticated laboratory instruments, sample pre-treatment and well-trained personnel. To develop a low-cost miniaturized electrochemical potassium sensor with enhanced sensitivity, digital microfluidic device is coupled with electrochemical potassium sensor. For an instant, Farzbod et al. [9] integrated potassium selective sensor array with digital microfluidic platform on a microchip (see Fig. 7). The on-chip fabrication of microelectrodes involves three steps: (1) electroplating Ag, (2) formation of AgCl layer and (3) deposition of ion-selective membranes on microelectrodes. The fabricated digital microfluidic electrochemical sensor detected potassium ion in human blood serum samples by measuring the voltage difference across the membrane layer.

Figures modified from Ref. [9] and used with permission

On-chip ion-selective electrodes fabrication and calibration procedure. Step (1) is dispensing a droplet from Ag plating solution reservoir and transporting it to sensor electrode for electroplating Ag on patterned Au as seed layer, Step (2) is chemical oxidation of Ag layer with HCl solution using EWOD electrode for precise manipulations, Step (3) is forming a thin layer of ion-selective membrane on a sensor electrode and Step (4) is serial dilution for on-chip calibrating of the sensor.

The fabrication of digital microfluidics microchip by screen printing technique and its integration with an electrochemical sensor on a single plate substrate have been employed for ultralow detection of analytes in human blood serum samples. Ugsornrat et al. [73] coupled digital microfluidic chip with graphene–carbon screen-printed electrochemical sensor for the rapid detection of hydrogen peroxide with minimal reagent consumption. The digital microfluidic chip designed by electrowetting on dielectric consists of two parts: (1) T-junction for merging sample droplets and buffer reagent and (2) a three electrode system, including a silver/silver chloride paste reference electrode, a graphene–carbon paste counter electrode and a graphene–carbon paste working electrode. The resultant microfluidic sensor could rapidly detect hydrogen peroxide within 20 s. Another well-executed demonstration of a digital microfluidic microchip-based screen-printed electrochemical sensing platform is proposed by Ugsornrat et al. [74]. They fabricated electrowetting on dielectric microchip on single plate substrate, includes three screen-printed electrochemical detectors and a T-junction. In this, the digital microfluidic device mixed microdroplets of l-ascorbic acid and buffer reagent and the electroanalysis is performed. From the experimental results it is evident that the total analysis time, including microdroplet mixing and electroanalysis, is less than 20 s.

One of the major demerits of automation of the digital microfluidic system is the lack of synchronization. To overcome this issue, Ezra et al. [75] utilized a microprocessor-based control unit to integrate the digital microfluidic platform with the electrochemical lactate sensor. The digital microfluidic device consisted of microelectrodes, digital and discrete analog components. In this device, Ezra et al. [75] used a microfluidic multithreaded control circuit to control two solenoid valve manifolds and pressure regulators. The proposed microprocessor-based digital microfluidic system could perform multiple processes, including washing, automated sampling and electrochemical lactate sensor calibration. In another work, Karuwan et al. [67] combined electrowetting-on-dielectric digital microfluidic device with an electrochemical sensing system for quantitative analysis of iodide in real samples (see Fig. 8). The proposed microchip consisted of a T-junction for merging sample droplets and buffer reagent and a three electrode system, including Ag reference electrode, Pt counter electrode and Au working electrode, which were fabricated on glass substrate by lift-off process. The usefulness of the fabricated digital microfluidic sensor towards iodide is studied by cyclic voltammetry and the electroanalysis is completed within 12 s.

Figures modified from Ref. [67] and used with permission

a Layout of electrodes for T-junction EWOD mixer device. b Photograph of glass substrate with photoresist pattern. c Photograph of glass chip with EWOD silver electrodes, d Cross-sectional structure of EWOD chip and e Photograph of EWOD chip with three electrode system containing gold (Au) working electrode, platinum (Pt) auxiliary electrode and silver (Ag) reference electrode at the end of T-junction.

6 Conclusions and Future Perspectives

In this review, we provided a comprehensive overview of basic concepts of the microfluidic technology and developments in the fabrication of digital, continuous-flow, droplet and paper-based microfluidics for biosensing applications. And also, for each type of microfluidic electrochemical detection system, the working principles, construction, merits and demerits, basic implementation and state-of-the-art developments in the detection methods have been described in detail. Even though these microfluidic electrochemical sensors are advantageous for point-of-care testing, there are still numerous technical challenges remain to be overcome. For an instant, evaporation of droplets may cause serious issues in the manipulation of droplet movement. In addition, retention issues may also alter the sensitivity and selectivity of an electrochemical detection system, which would lead to false predictions. Moreover, during the storage process, the reagents used in the fabrication of microfluidic devices may inhibit the active sites of enzyme-modified electrodes. At present, most electrochemical sensing devices employ conventional three electrode systems. Nevertheless, they offer a high detection limit and, therefore, microfluidic-assisted electrochemical sensors are preferred.

The following are the three major obstacles that the conventional techniques failed to address: (1) difficulty in commercializing liquid polymer (i.e., PDMS), (2) complex control systems and (3) non-standard user interfaces. However, 3D printing appears to be the solution to these issues. It is very cost effective for making microbiochips. Numeroous components have been designed to address the needs of microfluidics. However, till date, 3D printing could not achieve expected outcome as that of PDMS manufacturing. Although hydrogels such as polyethylene glycol clearly show promise in this area, biocompatibility needs to be resolved with techniques like stereolithography and multi-jet modeling. It is possible that as the 3D printing technology advances, almost all the other methods involved in the manufacturing of microfluidic devices will be replaced. Furthermore, the customized device manufacturing ability and simple scale-up can possibly popularize 3D printing as one of the most preferred commercial manufacturing methods.

Despite interesting advancements in the field of electrochemical biosensor, the application of microfluidic biochips as biosensors still has many obstacles, particularly for point of care diagnosis in resource-limited environments. For instance, several microfluidic biochips often use complex detection methods and necessitate expensive external devices and thereby the use of these biosensors is inappropriate for in vivo and in vitro diagnostic applications in low-resource environments. Recently, a wide variety of add-ons and apps have enabled smartphones to execute complex functions for personal health monitoring. There are several reports in the literature on the use of powerful smartphones for point-of-care and field diagnosis. The integration of microfluidic sensors with smartphone technology could improve the performance of detection system with respect to specificity and sensitivity. We believe that microfluidic platforms integrated with electrochemical detectors is important for the scientific advancements of bio/chemical sensors in the near future.

References

Materón EM, Lima RS, Joshi N, Shimizu FM, Oliveira ON. Chapter 13—graphene-containing microfluidic and chip-based sensor devices for biomolecules. In: Pandikumar A, Rameshkumar P, editors. Graphene-based electrochem. Elsevier: Oxford; 2019. p. 321–36. https://doi.org/10.1016/B978-0-12-815394-9.00013-3.

Liao Z, Wang J, Zhang P, Zhang Y, Miao Y, Gao S, et al. Recent advances in microfluidic chip integrated electronic biosensors for multiplexed detection. Biosens Bioelectron. 2018;121:272–80. https://doi.org/10.1016/j.bios.2018.08.061.

Hamzah HH, Shafiee SA, Abdalla A, Patel BA. 3D printable conductive materials for the fabrication of electrochemical sensors: a mini review. Electrochem Commun. 2018;96:27–31. https://doi.org/10.1016/j.elecom.2018.09.006.

Perrier R, Pirog A, Jaffredo M, Gaitan J, Catargi B, Renaud S, et al. Bioelectronic organ-based sensor for microfluidic real-time analysis of the demand in insulin. Biosens Bioelectron. 2018;117:253–9. https://doi.org/10.1016/j.bios.2018.06.015.

Liu Z, Jin M, Cao J, Niu R, Li P, Zhou G, et al. Electrochemical sensor integrated microfluidic device for sensitive and simultaneous quantification of dopamine and 5-hydroxytryptamine. Sens Actuators B Chem. 2018;273:873–83. https://doi.org/10.1016/j.snb.2018.06.123.

Lu L, Gunasekaran S. Dual-channel ITO-microfluidic electrochemical immunosensor for simultaneous detection of two mycotoxins. Talanta. 2018;1:5. https://doi.org/10.1016/j.talanta.2018.10.091.

Pursey JP, Chen Y, Stulz E, Park MK, Kongsuphol P. Microfluidic electrochemical multiplex detection of bladder cancer DNA markers. Sens Actuators B Chem. 2017;251:34–9. https://doi.org/10.1016/j.snb.2017.05.006.

Ali MA, Jiang H, Mahal NK, Weber RJ, Kumar R, Castellano MJ, et al. Microfluidic impedimetric sensor for soil nitrate detection using graphene oxide and conductive nanofibers enabled sensing interface. Sens Actuators B Chem. 2017;239:1289–99. https://doi.org/10.1016/j.snb.2016.09.101.

Farzbod A, Moon H. Integration of reconfigurable potentiometric electrochemical sensors into a digital microfluidic platform. Biosens Bioelectron. 2018;106:37–42. https://doi.org/10.1016/j.bios.2018.01.048.

Hwang D-W, Lee S, Seo M, Chung TD. Recent advances in electrochemical non-enzymatic glucose sensors—a review. Anal Chim Acta. 2018;1033:1–34. https://doi.org/10.1016/j.aca.2018.05.051.

Kaur G, Tomar M, Gupta V. Development of a microfluidic electrochemical biosensor: prospect for point-of-care cholesterol monitoring. Sens Actuators B Chem. 2018;261:460–6. https://doi.org/10.1016/j.snb.2018.01.144.

Lima HRS, da Silva JS, de Oliveira Farias EA, Teixeira PRS, Eiras C, Nunes LCC. Electrochemical sensors and biosensors for the analysis of antineoplastic drugs. Biosens Bioelectron. 2018;108:27–37. https://doi.org/10.1016/j.bios.2018.02.034.

Cardoso RM, Mendonça DMH, Silva WP, Silva MNT, Nossol E, da Silva RAB, et al. 3D printing for electroanalysis: from multiuse electrochemical cells to sensors. Anal Chim Acta. 2018;1033:49–57. https://doi.org/10.1016/j.aca.2018.06.021.

Rattanarat P, Suea-Ngam A, Ruecha N, Siangproh W, Henry CS, Srisa-Art M, et al. Graphene-polyaniline modified electrochemical droplet-based microfluidic sensor for high-throughput determination of 4-aminophenol. Anal Chim Acta. 2016;925:51–60. https://doi.org/10.1016/j.aca.2016.03.010.

Gu S, Lu Y, Ding Y, Li L, Song H, Wang J, et al. A droplet-based microfluidic electrochemical sensor using platinum-black microelectrode and its application in high sensitive glucose sensing. Biosens Bioelectron. 2014;55:106–12. https://doi.org/10.1016/j.bios.2013.12.002.

Hong SA, Kim Y-J, Kim SJ, Yang S. Electrochemical detection of methylated DNA on a microfluidic chip with nanoelectrokinetic pre-concentration. Biosens Bioelectron. 2018;107:103–10. https://doi.org/10.1016/j.bios.2018.01.067.

Kudr J, Zitka O, Klimanek M, Vrba R, Adam V. Microfluidic electrochemical devices for pollution analysis—a review. Sens Actuators B Chem. 2017;246:578–90. https://doi.org/10.1016/j.snb.2017.02.052.

Nasseri B, Soleimani N, Rabiee N, Kalbasi A, Karimi M, Hamblin MR. Point-of-care microfluidic devices for pathogen detection. Biosens Bioelectron. 2018;117:112–28. https://doi.org/10.1016/j.bios.2018.05.050.

Pol R, Céspedes F, Gabriel D, Baeza M. Microfluidic lab-on-a-chip platforms for environmental monitoring. Trends Anal Chem. 2017;95:62–8. https://doi.org/10.1016/j.trac.2017.08.001.

Xu D, Huang X, Guo J, Ma X. Automatic smartphone-based microfluidic biosensor system at the point of care. Biosens Bioelectron. 2018;110:78–88. https://doi.org/10.1016/j.bios.2018.03.018.

Hervás M, López MA, Escarpa A. Electrochemical immunosensing on board microfluidic chip platforms. Trends Anal Chem. 2012;31:109–28. https://doi.org/10.1016/j.trac.2011.06.020.

Reverté L, Prieto-Simón B, Campàs M. New advances in electrochemical biosensors for the detection of toxins: nanomaterials, magnetic beads and microfluidics systems: a review. Anal Chim Acta. 2016;908:8–21. https://doi.org/10.1016/j.aca.2015.11.050.

Ansari MIH, Hassan S, Qurashi A, Khanday FA. Microfluidic-integrated DNA nanobiosensors. Biosens Bioelectron. 2016;85:247–60. https://doi.org/10.1016/j.bios.2016.05.009.

Fu L-M, Wang Y-N. Detection methods and applications of microfluidic paper-based analytical devices. Trends Anal Chem. 2018;107:196–211. https://doi.org/10.1016/j.trac.2018.08.018.

Triroj N, Jaroenapibal P, Beresford R. Gas-assisted focused ion beam fabrication of gold nanoelectrode arrays in electron-beam evaporated alumina films for microfluidic electrochemical sensors. Sens Actuators B Chem. 2013;187:455–60. https://doi.org/10.1016/j.snb.2013.01.049.

Shiba S, Yoshioka K, Kato D, Ishihara S, Anzai H, Saito N, et al. Electrochemical microfluidic devices for evaluation of drug metabolism. J Electroanal Chem. 2016;779:86–91. https://doi.org/10.1016/j.jelechem.2016.04.043.

Akhtar MH, Hussain KK, Gurudatt NG, Shim Y-B. Detection of Ca2+-induced acetylcholine released from leukemic T-cells using an amperometric microfluidic sensor. Biosens Bioelectron. 2017;98:364–70. https://doi.org/10.1016/j.bios.2017.07.003.

Ko E, Tran V-K, Geng Y, Chung WS, Park CH, Kim MK, et al. Continuous electrochemical detection of hydrogen peroxide by Au–Ag bimetallic nanoparticles in microfluidic devices. J Electroanal Chem. 2017;792:72–8. https://doi.org/10.1016/j.jelechem.2017.03.027.

Watanabe T, Shibano S, Maeda H, Sugitani A, Katayama M, Matsumoto Y, et al. Fabrication of a microfluidic device with boron-doped diamond electrodes for electrochemical analysis. Electrochim Acta. 2016;197:159–66. https://doi.org/10.1016/j.electacta.2015.11.035.

Sharma PS, Iskierko Z, Noworyta K, Cieplak M, Borowicz P, Lisowski W, et al. Synthesis and application of a “plastic antibody” in electrochemical microfluidic platform for oxytocin determination. Biosens Bioelectron. 2018;100:251–8. https://doi.org/10.1016/j.bios.2017.09.009.

Cao L, Fang C, Zeng R, Zhao X, Jiang Y, Chen Z. Paper-based microfluidic devices for electrochemical immunofiltration analysis of human chorionic gonadotropin. Biosens Bioelectron. 2017;92:87–94. https://doi.org/10.1016/j.bios.2017.02.002.

Kim J, Elsnab J, Gehrke C, Li J, Gale BK. Microfluidic integrated multi-walled carbon nanotube (MWCNT) sensor for electrochemical nucleic acid concentration measurement. Sens Actuators B Chem. 2013;185:370–6. https://doi.org/10.1016/j.snb.2013.05.018.

Jiang H, Jiang D, Zhu P, Pi F, Ji J, Sun C, et al. A novel mast cell co-culture microfluidic chip for the electrochemical evaluation of food allergen. Biosens Bioelectron. 2016;83:126–33. https://doi.org/10.1016/j.bios.2016.04.028.

Cecchini MP, Hong J, Lim C, Choo J, Albrecht T, deMello AJ, et al. Ultrafast surface enhanced resonance raman scattering detection in droplet-based microfluidic systems. Anal Chem. 2011;83:3076–81. https://doi.org/10.1021/ac103329b.

Srinivasan V, Pamula VK, Fair RB. Droplet-based microfluidic lab-on-a-chip for glucose detection. Anal Chim Acta. 2004;507:145–50. https://doi.org/10.1016/j.aca.2003.12.030.

Han Z, Li W, Huang Y, Zheng B. Measuring rapid enzymatic kinetics by electrochemical method in droplet-based microfluidic devices with pneumatic valves. Anal Chem. 2009;81:5840–5. https://doi.org/10.1021/ac900811y.

Casadevall I, Solvas X, Demello A. Droplet microfluidics: recent developments and future applications. Chem Commun. 2011;47:1936–42. https://doi.org/10.1039/c0cc02474k.

Baker CA, Duong CT, Grimley A, Roper MG. Recent advances in microfluidic detection systems. Bioanalysis. 2009;1:967–75. https://doi.org/10.4155/bio.09.86.

Su F, Fair RB. Microfluidics-based biochips: technology issues, implementation platforms, and design-automation challenges. IEEE Trans Comput Des Integr CIRCUITS Syst. 2006;25:1–14. https://doi.org/10.1109/TCAD.2005.855956.

Rackus DG, Shamsi MH, Wheeler AR. Electrochemistry, biosensors and microfluidics: a convergence of fields. Chem Soc Rev. 2015;44:5320–40. https://doi.org/10.1039/c4cs00369a.

Messina GA, Panini NV, Martinez NA, Raba J. Microfluidic immunosensor design for the quantification of interleukin-6 in human serum samples. Anal Biochem. 2008;380:262–7. https://doi.org/10.1016/j.ab.2008.05.055.

Panini NV, Messina GA, Salinas E, Fernández H, Raba J. Integrated microfluidic systems with an immunosensor modified with carbon nanotubes for detection of prostate specific antigen (PSA) in human serum samples. Biosens Bioelectron. 2008;23:1145–51. https://doi.org/10.1016/j.bios.2007.11.003.

Lin X, Hu X, Bai Z, He Q, Chen H, Yan Y, et al. A microfluidic chip capable of switching W/O droplets to vertical laminar flow for electrochemical detection of droplet contents. Anal Chim Acta. 2014;828:70–9. https://doi.org/10.1016/j.aca.2014.04.023.

Bubendorfer AJ, Ingham B, Kennedy JV, Arnold WM. Contamination of PDMS microchannels by lithographic molds. Lab Chip. 2013;13:4312–6. https://doi.org/10.1039/C3LC50641J.

Suea-Ngam A, Rattanarat P, Wongravee K, Chailapakul O, Srisa-Art M. Droplet-based glucosamine sensor using gold nanoparticles and polyaniline-modified electrode. Talanta. 2016;158:134–41. https://doi.org/10.1016/j.talanta.2016.05.052.

Suea-Ngam A, Rattanarat P, Chailapakul O, Srisa-Art M. Electrochemical droplet-based microfluidics using chip-based carbon paste electrodes for high-throughput analysis in pharmaceutical applications. Anal Chim Acta. 2015;883:45–54. https://doi.org/10.1016/j.aca.2015.03.008.

Itoh D, Sassa F, Nishi T, Kani Y, Murata M, Suzuki H. Droplet-based microfluidic sensing system for rapid fish freshness determination. Sens Actuators B Chem. 2012;171–172:619–26. https://doi.org/10.1016/j.snb.2012.05.043.

Ruecha N, Lee J, Chae H, Cheong H, Soum V, Preechakasedkit P, et al. Paper-based digital microfluidic chip for multiple electrochemical assay operated by a wireless portable control system. Adv Mater Technol. 2017;2:1–8. https://doi.org/10.1002/admt.201600267.

Wu Y, Xue P, Hui KM, Kang Y. A paper-based microfluidic electrochemical immunodevice integrated with amplification-by-polymerization for the ultrasensitive multiplexed detection of cancer biomarkers. Biosens Bioelectron. 2014;52:180–7. https://doi.org/10.1016/j.bios.2013.08.039.

Carvalhal RF, Simão Kfouri M, de Oliveira Piazetta MH, Gobbi AL, Kubota LT. Electrochemical detection in a paper-based separation device. Anal Chem. 2010;82:1162–5. https://doi.org/10.1021/ac902647r.

Santhiago M, Kubota LT. A new approach for paper-based analytical devices with electrochemical detection based on graphite pencil electrodes. Sens Actuators B Chem. 2013;177:224–30. https://doi.org/10.1016/j.snb.2012.11.002.

Cate DM, Adkins JA, Mettakoonpitak J, Henry CS. Recent developments in paper-based microfluidic devices. Anal Chem. 2015;87:19–41. https://doi.org/10.1021/ac503968p.

Nie Z, Deiss F, Liu X, Akbulut O, Whitesides GM. Integration of paper-based microfluidic devices with commercial electrochemical readers. Lab Chip. 2010;10:3163–9. https://doi.org/10.1039/c0lc00237b.

Noiphung J, Songjaroen T, Dungchai W, Henry CS, Chailapakul O, Laiwattanapaisal W. Electrochemical detection of glucose from whole blood using paper-based microfluidic devices. Anal Chim Acta. 2013;788:39–45. https://doi.org/10.1016/j.aca.2013.06.021.

Dungchai W, Chailapakul O, Henry CS. Electrochemical detection for paper-based microfluidics. Anal Chem. 2009;81:5821–6. https://doi.org/10.1021/ac9007573.

Delaney JL, Hogan CF, Tian J, Shen W. Electrogenerated chemiluminescence detection in paper-based microfluidic sensors. Anal Chem. 2011;83:1300–6. https://doi.org/10.1021/ac102392t.

Wang Y, Luo J, Liu J, Li X, Kong Z, Jin H, et al. Electrochemical integrated paper-based immunosensor modified with multi-walled carbon nanotubes nanocomposites for point-of-care testing of 17β-estradiol. Biosens Bioelectron. 2018;107:47–53. https://doi.org/10.1016/j.bios.2018.02.012.

Tran VK, Ko E, Geng Y, Kim MK, Jin GH, Son SE, et al. Micro-patterning of single-walled carbon nanotubes and its surface modification with gold nanoparticles for electrochemical paper-based non-enzymatic glucose sensor. J Electroanal Chem. 2018;826:29–37. https://doi.org/10.1016/j.jelechem.2018.08.013.

Ruecha N, Shin K, Chailapakul O, Rodthongkum N. Label-free paper-based electrochemical impedance immunosensor for human interferon gamma detection. Sens Actuators B Chem. 2019;279:298–304. https://doi.org/10.1016/j.snb.2018.10.024.

Cao L, Fang C, Zeng R, Zhao X, Zhao F, Jiang Y, et al. A disposable paper-based microfluidic immunosensor based on reduced graphene oxide-tetraethylene pentamine/Au nanocomposite decorated carbon screen-printed electrodes. Sens Actuators B Chem. 2017;252:44–54. https://doi.org/10.1016/j.snb.2017.05.148.

Zhao C, Thuo MM, Liu X. Erratum: A microfluidic paper-based electrochemical biosensor array for multiplexed detection of metabolic biomarkers (Science and Technology of Advanced Materials (2013) 14 (054402)). Sci Technol Adv Mater. 2013;2015:16. https://doi.org/10.1088/1468-6996/16/4/049501.

Liu H, Xiang Y, Lu Y, Crooks RM. Aptamer-based origami paper analytical device for electrochemical detection of adenosine. Angew Chem Int Ed. 2012;51:6925–8. https://doi.org/10.1002/anie.201202929.

Nie Z, Nijhuis CA, Gong J, Chen X, Kumachev A, Martinez AW, et al. Electrochemical sensing in paper-based microfluidic devices. Lab Chip. 2010;10:477–83. https://doi.org/10.1039/b917150a.

Malic L, Brassard D, Veres T, Tabrizian M. Integration and detection of biochemical assays in digital microfluidic LOC devices. Lab Chip. 2010;10:418–31. https://doi.org/10.1039/b917668c.

Choi K, Ng AHC, Fobel R, Wheeler AR. Digital microfluidics. Annu Rev Anal Chem. 2012;5:413–40. https://doi.org/10.1146/annurev-anchem-062011-143028.

Sista R, Hua Z, Thwar P, Sudarsan A, Srinivasan V, Eckhardt A, et al. Development of a digital microfluidic platform for point of care testing. Lab Chip. 2008;8:2091–104. https://doi.org/10.1039/b814922d.

Karuwan C, Sukthang K, Wisitsoraat A, Phokharatkul D, Patthanasettakul V, Wechsatol W, et al. Electrochemical detection on electrowetting-on-dielectric digital microfluidic chip. Talanta. 2011;84:1384–9. https://doi.org/10.1016/j.talanta.2011.03.073.

Shamsi MH, Choi K, Ng AHC, Wheeler AR. A digital microfluidic electrochemical immunoassay. Lab Chip. 2014;14:547–54. https://doi.org/10.1039/c3lc51063h.

Kwakye S, Goral VN, Baeumner AJ. Electrochemical microfluidic biosensor for nucleic acid detection with integrated minipotentiostat. Biosens Bioelectron. 2006;21:2217–23. https://doi.org/10.1016/j.bios.2005.11.017.

Ugsornrat K, Maturos T, Pogfai T, Tuantranont A. Design, fabrication, experimental study, and test electrochemical detector with EWOD for chemical analysis. IFMBE Proc. 2014;43:853–6. https://doi.org/10.1007/978-3-319-02913-9_220.

Lee GH, Lee JK, Kim JH, Choi HS, Kim J, Lee SH, et al. Single microfluidic electrochemical sensor system for simultaneous multi-pulmonary hypertension biomarker analyses. Sci Rep. 2017;7:1–8. https://doi.org/10.1038/s41598-017-06144-9.

Tedjo W, Nejad JE, Feeny R, Yang L, Henry CS, Tobet S, et al. Electrochemical biosensor system using a CMOS microelectrode array provides high spatially and temporally resolved images. Biosens Bioelectron. 2018;114:78–88. https://doi.org/10.1016/j.bios.2018.04.009.

Ugsornrat K, Maturos T, Pasakon P, Karuwan C, Sriprachuabwong C, Pogfai T, et al. Graphene digital microfluidics microchip. ECTI-CON 2017–2017 14th International conference on electrical engineering/electronics, computer, telecommunications and information technology, 2017, pp 489–92. https://doi.org/10.1109/ecticon.2017.8096281.

Ugsornrat K, Maturos T, Pasakon P, Karuwan C, Pogfai T, Wisitsoraat A, et al. Screen printed electrochemical detector combine with digital microfluidic microchip. 2016 13th International Conference on Electrical Engineering/Electronics, Computer, Telecommunications and Information Technology, ECTI-CON 2016, 2016, pp 1–5. https://doi.org/10.1109/ecticon.2016.7561296.

Ezra E, Maor I, Bavli D, Shalom I, Levy G, Prill S, et al. Microprocessor-based integration of microfluidic control for the implementation of automated sensor monitoring and multithreaded optimization algorithms. Biomed Microdev. 2015;17:1–9. https://doi.org/10.1007/s10544-015-9989-y.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Nesakumar, N., Kesavan, S., Li, CZ. et al. Microfluidic Electrochemical Devices for Biosensing. J. Anal. Test. 3, 3–18 (2019). https://doi.org/10.1007/s41664-019-0083-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41664-019-0083-y