Abstract

The manufacturing industry has been facing the pressure of supply-demand and climate change around the globe. Many industry players are constantly seeking for alternative option to strike a good balance between operation and environmental performance. Despite many studies on lean and green that have been done, there is no definite definition for lean and green. This paper explores the evolution and contribution of lean manufacturing and green manufacturing. The paper’s main contribution is to focus on the application and impact of lean and green approach in the manufacturing industry. The common challenges and confusions faced by the manufacturing industry are studied. This paper identifies the similarities and benefit of both lean and green approaches, the synergy effect of lean and green, application tools, and misconception of lean and green. It allows the industries to have a better understanding on the application of tools and challenges prior to moving forward with actual implementation of the lean and green approach. This paper also identifies potential research gaps which address the need of effective lean and green implementation strategy in the industry. The need to reduce the implementation gap for lean and green approach will contribute significantly towards sustainable manufacturing.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Globalization has opened up global market opportunities for manufacturing companies around the world (Business 2018). This promotes positive global competition in supply for quality goods. The increase in global competition among the manufacturing industry has led the manufacturers to expand and source for alternative ways to improve their competitiveness. The global market has also posed challenges to the manufacturing industry with monetary fluctuation factor, political influence, economic stability, technological innovation, regulatory restructuring, and environmental pressure that have been constantly altering the competitive landscape (Issa et al. 2010). Paul et al. (2014) stated that the cost of energy and resources are constantly increasing due to rising demand and limited supply. These factors contribute significantly to operating performance and economic performance of the manufacturer directly. One of the easier methods for manufacturing industry to remain competitive is to reduce production and operation waste.

Many large manufacturers have applied the lean approach to maintain their competitiveness in the global market (Anand and Kodali 2008). The concept of lean is very popular and it has been adopted by many industries (e.g., Toyota, Ford, Boeing, etc.). There are many interpretations for the definition of lean which has resulted in confusion to identify the impact of lean (Parker 2003). The definition of lean has been elusive. Bicheno (2004) stated that lean is more of a philosophical approach than a set of tools. On the other hand, practical and project-based approaches indicate lean as a collection of waste reduction tools (Pettersen 2009). Rodríguez et al. (2017) stated that lean is an integrated socio-technical system whose main objective is to eliminate waste by concurrently reducing or minimizing supplier, customer, and internal variability. Nevertheless, the common agenda for all lean focuses on waste reduction or elimination. The lean approach provides distinctive tools, practices, and strategies that can be applied to identify possible efficient production system with fewer resource consumption and waste generation (Pettersen 2009). Lean manufacturing (LM) has been implemented in the industry since the successful implementation of the Toyota Production System (TPS) (Maynard 2013). Apart from defining LM in terms of resources, LM is defined as approach which eliminates all non-value added activity in a production process (Womack and Jones 1994).

While lean focuses on operational aspect, the environmental aspect is symbolized by green. Green represents ecological sustainability and encompasses many different concerns including waste generation and recycling, air, water and land pollution, energy usage, and efficiency (Bhattacharya et al. 2011). The European Commission has stated that the extension of the green application into other related areas such as green economy will create more value with fewer resources, by replacing them with more environmentally friendly resources wherever possible (European Commission 2015). The United Nations Environmental Program (UNEP) stated that green economy will improve human well-being and social equity, while significantly reducing environmental risk and ecological scarcities (UNEP 2011). Green economy is known as an important pathway to drive economic growth and foster the innovation of new low carbon technologies and products (Yatim et al. 2017). From the green growth perspective, the World Bank (2012) defined green growth as growth that is efficient in consumption of natural resources, minimize pollution and environmental impacts, and resilient towards natural hazards. Green growth emphasizes on global sustainability that enables the world’s poorest and most vulnerable to benefit from efficient, clean, and resilient growth. Green is also known as the new lean where industries started to move towards sustainability (Dües et al. 2013). There are different definitions across the vast green applications. It is observed that the green element mainly focuses on minimizing environmental impact and pollution by creating more value with fewer resources.

Green manufacturing (GM) has received many recognitions from literature study. Abdul-Rashid et al. (2017) claimed that GM is known as business strategy that focuses on profitability through reactive and proactive environmentally friendly operating processes. Andrew (2012) argued that GM can be perceived as “green” manufacturing and “greening” the manufacturing. “Green” manufacturing refers to an industry that uses clean technology and renewable energy while “greening” reflects on the action taken to reduce pollution and waste through minimizing usage of resources. GM approach is introduced to compensate and improve the industry performance on environment aspect. A study showed that firms embarked on green management and green innovation to improve their environmental performances and satisfy the demands of consumer to boost corporate image among regulators and public (Taylor 1992).

The synergy between lean and green (L&G) approach can further enhance the operational performance through value creation and waste reduction. The combination of L&G approach has stirred up the interest of many researchers. There are many factors that drive the implementation of LM and GM that are discussed in the paper. L&G implementation has been a major industry challenge due to the lacking of industry expert. The lack of industry expert has delayed the implementation of L&G approach; this reduces the competitiveness of the industry (Cherrafi et al. 2017). The industry players rely heavily on the expert on new method and approach as there is a lack of implementation method that can be easily adopted by the industry including L&G approach. This paper reviews the principles of L&G manufacturing and their implementation methods. There is a need to review the core principles of LM and GM to develop the L&G principle as to increase the efficiency and effectiveness of operation and environmental improvement in the industry sector.

This paper covers LM principles and tools, GM principles and tools, L&G manufacturing challenges, as well as potential future research development in L&G discipline.

Lean Manufacturing

Introduction to Lean Manufacturing

Lean approach is discovered as a significant element in manufacturing since the industrial revolution. LM is commonly used to eliminate activities and procedures which do not add value to the final product (Nawanir et al. 2018). Figure 1 presents the important milestones of LM along with the development of the industrial revolution. Every important milestone in the development of LM will be reviewed to identify their contribution to LM. LM kick-started back in early 1800 by Eli Whitney during the first industrial revolution when machinery was first introduced in manufacturing (History.com 2010b). He invented the concept of interchangeable parts which allowed more unskilled workers to get involve in musket manufacturing (History.com 2010b). Musket manufacturing was a skillful task handled only by craftsman back then. Eli Whitney’s introduction of interchangeable part had successfully improved the economics of scale of the production line. The manufacturing industry focused on individual technology until the late 1890s where F.W. Taylor introduced the time study to reduce processing time (Strategosinc 2017). Time study method measures and analyzes the amount of time required by a worker to complete a task using a stopwatch (Lopetegui et al. 2014). Time study establishes a standard time for a specific process. Frank and Lilian Gilbreth then introduced Process Charting and Motion Study in 1900. Process Charting is a tool for visualizing a process to identify the area of improvement (Gilbreth 1921). The motion study method was developed to reduce the amount of motion required for a task (Lopetegui et al. 2014). Then, time study and motion study are integrated and improved as method engineering. Method engineering evaluates the involvement of human in material handling and how effective can human perform an assigned task (Industrial Timestudy Institute 2017). These innovators were considered as the initiators for the idea of waste elimination (e.g., motion and waiting) which were then reflected in the seven (7) wastes of LM.

In the early of 1910, when the second industrial revolution took place, Henry Ford integrated the elements of interchangeable parts with standard work into flow production of the assembly line (History.com 2010a). Ford production system (FPS) has made advancement in manufacturing industry by mass production of Model T, the first affordable car to the majority consumers (History.com 2010a). Buesa (2009) stated that Ford’s effort in improving the manufacturing method to increase production with lower cost had been revolutionary. Furthermore, FPS was the main factor contributing to the Allied victory of World War II where bombers were produced at the rate of one plane per hour (Garrett 2017). Ford was considered the first practitioner of LM.

After the World War II (WWII), Eiji Toyoda and Taichii Ohno visited Ford’s production complex as FPS model was one of the key factors for the victory of WWII (Strategosinc 2017). Ford’s complex was producing 8000 vehicles compared to 2500 vehicles in total that Toyota had produced per day (Maynard 2013). The visit then led to the development of TPS initiated by Taichii Ohno before the third industrial revolution. TPS was established based on two concepts, which were Jidoka and Just in Time (JIT). Jidoka is known as one of the two main pillars in TPS which is defined as “automation with a human touch”. Jidoka applies to any machine that is designed to make judgment by itself (TOYOTA 2018). JIT is known as a production method where products are created to meet demand with no surplus production or storage requirement (Rouse 2015). Taichii Ohno later introduced the “pull-flow production” which was able to generate a variety of products that could be reutilized in the process (Dekier 2012). Toyota also recognized the importance of the quality circle and the central role of inventory. Quality circle involves the participation of all employees contributing to continuous improvement of the system (Villa and Taurino 2013).

In the 1990s, James P. Womack, Daniel T. Jones, and Daniel Roos introduced LM. LM was regarded as the successor of TPS as it was an enhanced version of TPS (Dekier 2012). Kochnev (2007) revealed that TPS and LM are very similar business philosophies where TPS focuses on the principles of Toyota way and LM emphasize on continuous improvement methodology. The lean approach was defined with five principles (Table 1) and focused on eliminating seven types of waste (Table 2). The five principles are known as define value, identify value stream, create smooth value, implement pull-based production, and strive for excellence. The seven wastes of TPS and LM were defined as over-production, waiting, transport, over-process, inventory, motion, and defect.

Lean Manufacturing Principles and Tools

The development and implementation of LM have shown positive performance improvement in the manufacturing industry. The evolutions of manufacturing from the traditional method to the lean approach allow the industry to operate at a higher efficiency and competitive way. Lean is a wide context and it covers various aspects of an operation. The five key principles of LM have laid down a systematic framework to ease lean implementation. The five key principles are listed and described in Table 1. The principles of LM mainly focus on identifying the value-added and non-value-added components in a process flow. The identification and elimination of non-value-added wastes in LM will be assisted by a series of lean tools (Liker 2004).

LM approach mainly focuses on improving the productivity of the operation through value creation by reducing seven wastes from an operation. Table 2 provides a detailed explanation of the seven wastes commonly encountered in LM.

To improve the effectiveness of the lean approach, many LM tools have been developed to assist the industry to achieve lean. Lean tool (Table 3) selection is highly critical to building the industry’s confidence to implement the lean practice. Some of the lean tools exist in different names and overlap with other tools, for example, process mapping is also known as value stream mapping. Mourtzis et al. (2016) suggested that lean tools can be applied to every enterprise worldwide with appropriate modifications. However, misapplication of lean tools might cause additional resource wastage. To ease tools selection, Pavnaskar et al. (2003) proposed a classification scheme that matches the lean tools to the waste that needs to be eliminated. The scheme established a relationship between the LM tools and waste that leads the users to the selection of appropriate lean tools. Simona and Cristina (2015) reviewed fifteen (15) lean tools and concluded that an organization required years with experience lean mentor to observe significant results. The dependency on experienced lean mentor to implement and produce operational results from the lean approach requires time and lack of empowerment to the employee. Pavnaskar et al. (2003) classification scheme will be able to empower production employee to take initiative to identify and apply appropriate lean tools to gain maximum production output.

The successful implementation of LM approach and tools has shown positive results in operating performance such as 50% or greater increase in capacity with current facilities, 50% improvement in quality, 60% reduction in cycle time and etc. (Zimmer 2000). Enaghani et al. (2009) stated that lean is a culture for quality improvement that should be cultivated in the employee. Czabke (2007) claimed that LM aims to create a smooth, high-quality, and well-organized operation that can produce customer-demanded product on time with minimum waste. LM has also shown to have a significant impact on cost performance and waste reduction has to be carried out to improve the competitiveness of the manufacturing plant (McGrath 2007).

Systematic Implementation of Lean Manufacturing

Generally, LM strives to improve an existing operation’s productivity by eliminating non-value-added product. Table 3 explains the essential lean tools that are normally used by an organization. Despite the benefits brought by the successful implementation of lean approach, there are some challenges in implementing the LM approach. Some lean tools tend to have the same intention for value creation, and they are complementing each other. For instance, value stream mapping, bottlenecking analysis, Gemba analysis, and continuous flow tools can be used to complement block diagram to achieve better value. Despite the existence of various lean tools, lack of proper guidance in matching the suitable lean tools with targeted non-value-added stream can be resource consuming. The development and creation of more lean tools will create confusion in lean tools selection prior to implementation.

In normal application, many lean practitioners use combination of individual lean tools to form combination method such as Sig-Sigma and Agile. However, sustainable-focused work has received minimal attention despite Six-Sigma being one of the reliable tools in improving operational performance (Erdil et al. 2018). Garza-Reyes (2015b) developed a conceptual model to integrate lean, Six Sigma, and Green concept using DMAIC cycle that can be implemented together with lean Six-Sigma tools. Besides, Tortorella et al. (2016) mentioned that the successful implementation of LM is highly dependent on the predominant culture within an organization. Tortorella et al. (2016) associated the implementation of LM in an organization’s leadership to have an influence on follower’s attitude and behavior. A study had been carried out by Kumar et al. (2015) to evaluate the carriers, enablers, and critical success factors that are critical to be identified to ensure successful implementation of an integrated model. The study revealed that human resources and management appeared to be the top-ranked critical success factor. Castillo-Pérez et al. (2018) also discovered that human factor was the key to ensure successful implementation of LM approach. A systematic implementation system of LM will require a top-down approach within the organization. In other words, empowerment of employee and lean approach implementation strategy should be taken into consideration carefully by an organization to ensure successful implementation of LM.

Green Manufacturing

Introduction to Green Manufacturing

Global warming has triggered the public concern where people are giving more attention to the environment. The lean improvement of operational performances in the manufacturing industry has shown a lack of consideration for environmental performance. GM is widely known as sustainable manufacturing, refers to the business strategy that focuses on profitability through reactive and proactive environmentally friendly operating processes (Abdul-Rashid et al. 2017).

GM is mainly initiated in the early 1990s with the emerging of eco-innovation (Sezen and Çankaya 2013). The eco-innovation is known as production method which is novel to the organization which results in reduction of environmental risk and other negative impact of resources used (Kemp and Pearson 2008). Many researchers have been working to explore the potential of green approach in the industry. GM is regarded as an environmental and economical-driven approach to minimize waste stream through process design, consumption of products, and materials (Maruthi and Rashmi 2015). According to Mittal and Sangwan (2014), GM approach helps to achieve better economy significantly without compromising the environment. Mohnty and Deshmukh (1998) defined green productivity as all activities that decrease wastes. They highlighted that the potential of green productivity can have on the overall manufacturing performance. Handfield et al. (1997) conducted a case study on industry environmentally friendly best practice then discovered that environmental caution and practice should be implemented in all value chain to make green approach successful. The International Standard Organization (ISO) published the first Environmental Management System (EMS) standard internationally which is known as ISO14001 (Agan et al. 2013). EMS system acts as a continuous improvement tool to provide a systematic method to manage an organization’s environmental-related matters (ISO 2015). EMS can act as a tool to implement GM.

GM focuses on a closed-loop operation involving recycling and recuperation practices to reduce waste, capturing the residual value of products while implementing green technologies and optimized logistics for pollution prevention (Ferguson and Toktay 2009). Sezen and Çankaya (2013) showed that GM can cause growth in economics, environmental, and social performances through waste and cost reduction. Taylor (1992) investigation shows that firms embarked on green management and green innovation are able to improve environmental performance while satisfying demand of consumers to boost corporate image among regulators and the public. The demand for manufacturing is expected to increase in the future while improvements in the energy-efficient manufacturing process will become an essential element for any industry (Nukman et al. 2017). Paul et al. (2014) emphasized that the cost of energy and resources are constantly increasing due to its rising demand and limited supply. The manufacturing industries are exploring for alternatives to strike a balance for the operation cost to remain competitive. They are also exploring ways to improve production performance while achieving healthy environmental performance.

Green Manufacturing Principles and Tools

In order to achieve a healthy environmental performance in manufacturing, there is a need to establish the proper approach to achieve GM. Anastas and Zimmerman (2003) proposed the 12 Principles of Green Engineering (Table 4) as the guidelines for process design. They have also stressed that evaluation for input and output of energy and material should be non-hazardous inherently and product lifecycle as well. Helu and Dornfeld (2012) then suggested a simplified framework that consists of five principles of GM. The five principles of GM from Helu and Dornfeld (2012) are illustrated in Table 5. In the second principle of Helu and Dornfeld (2012), the “vertical” refers to systems at any one level of details from the enterprise down to the process; the “horizontal” refers to systems at any one level of detail. Helu and Dornfeld (2012) have covered and simplified the principles that Anastas and Zimmerman (2003) proposed. The main intention for both principles emphasizes the evaluation of the manufacturing process based on product lifecycle and resources. Both proposals also exhibit a strong emphasis on energy and environmental emission issue that can be taken into consideration in green approach.

Lele (2009) shows the main product lifecycle design elements such as design, procure, manufacture, packing and distribution, product end of life, and re-manufacturing, to be incorporated with GM approach. Vila et al. (2015) have expanded the product lifecycle element proposed by Lele (2009) into a more detail framework by looking into the method, tools, and knowledge in lifecycle design. However, Vila et al. (2015) also categorized and proposed a framework with three major sections such as design development, manufacturing, and services. In the manufacturing context of Lele (2009) and Vila et al. (2015), the framework focuses on resource management, production control, production, assembly, and storage package. As far as GM is concerned, a design of sustainable manufacturing, utilization of green energy, and new technology that can improve environmental performance should be taken into consideration (Vila et al. 2015). It is discovered that 80% of the economic, social, and environmental impact is determined during product or process design (Kim and Kara 2012). Thus, design of environment (DfE) is introduced to include green element into process design. Generally, DfE identifies and designs the product based on the environmental impact of a product throughout the lifecycle of the product (Eibel and Joanneum 2014). The lifecycle assessment (LCA) of a product is relatively important at the initial design stage (Ma et al. 2012). LCA analyzes the potential environmental impact throughout the entire lifecycle of a product from raw material, production, use, and disposal. The relationship between LCA and DfE is closely related to reducing the environmental emission or waste. Paul et al. (2014) mentioned the importance of LCA in evaluating the product which leads to environmental pollution.

Other than DfE and LCA for the product, energy consumption plays a significant role in manufacturing. Green technology is no longer a new term to researchers and the industrialist. Green technology is known as the usage of science in the environment to preserve the resource and environment to control negative impact from human activity (Ishak et al. 2017). Energy efficient technology such as photovoltaic, co-generation, biogas, etc. can improve the green aspect of a factory (Paul et al. 2014). Yong (2014) stated that green technologies have achieved certain technological maturity but still occupied comparatively low market share. Yong (2014) also mentioned that changes are required at the technology level, system perspective, paradigm shift, and system knowledge level to achieve GM. From DfE and LCA of the product of a process, screening method can be used to evaluate new technologies that can eliminate or reduce pollution (Reich-Weiser et al. 2010). Green technology can bring positive impact to energy management and optimization performance in the factory. For instance, gas turbine co-generation system is able to reduce the operation cost without compromising the exhaust emission.

Melnyk et al. (2001) proposed a conventional material requirement planning system (MRP) that includes environmental concern into material planning. The MRP system provides a better understanding of potential waste stream generated from an operation in both quantitative and financial term. Hui et al. (2002) suggested a network analytic model to evaluate environmental hazards in manufacturing; it focuses on analyzing the impact produced by different types of manufacturing waste. Krishnan et al. (2004) developed environmental value system analysis tools that assess the environmental performance through a “bottom-up” analysis approach. The bottom-up approach enables flexibility in the analysis required by the client. Van Berkel (2010) discovered that industrial symbiosis allows an industry to substitute high-quality resources (raw material and energy source) with lower quality substitute (waste). The substitution process will involve conversion, substitution, and avoidance steps. The conversion step is involved with the collection of waste material from a symbiosis partner’s waste which is suitable to act as a feedstock or energy source that can be transported to the site. The substitution steps use alternative feedstock and require process adjustment to compensate for alternative feedstock input. The final step emphasizes the reduction or the elimination of waste that is generated and can harm the environment.

Drivers for Green Manufacturing

GM shows identical waste reduction initiative with LM. Therefore, Hines (2009) proposed to align green waste with lean waste to close the gap between L&G approach. Verrier et al. (2016) have also laid out the correlation between lean waste and green waste and proposed them to be incorporated together as one to further improve the operation performance. The green wastes are greenhouse gases (GHG), eutrophication, excessive resource usage, excessive power usage, pollution, rubbish, excessive water usage, and poor health and safety.

In this work, an interview was conducted with several companies (i.e., palm oil refineries, rubber processing facility, and pharmaceutical company) on green technology and discovered a few important factors that can potentially delay the implementation of the green approach. The interviewed companies were the active manufacturing industries that contribute to South East Asia (SEA) economy. One of the main reasons is that the management is not aware of the potential or possibility to improve the efficiency of the factory operators. The lack of expertise in the factory results in the delay of the green implementations. Some of the engineers stated that only no or low-cost improvement can be done in the factory (Cheng, personal communication, Jan 20, 2018). Cheng (2018) also mentioned that the management is not confident with high-cost investment technology as they do not have experience and capable employee who can lead the project; payback on investment also plays a significant role to convince the management. Green technology and financial scheme appear to be manufacturing industry’s concern. The market tends to focus on individual or smaller component of energy efficient equipment where it only contributes to a potential improvement of 2–5% (UNIDO 2010). It is observed that a particular discipline of manufacturing industry will be actively engaged in green technology when one successfully initiated and implement the technology.

According to International Energy Outlook (2016), the industry sector is consuming 54% of the world total delivered energy. Besides that, BP. (2018) indicates the global primary energy consumption has increased by 2.2% in 2017. Energy generation has been one of the major contributors to global warming as coal or fossil fuel is used as fuel. Generally, the main driving force will be from the external driver such as legislation, corporate image, peer pressure, and tax incentive. Álvarez-Gil et al. (2007) discovered that significant influence of stakeholders such as supplier, customer, government agency, non-governmental organization (NGO), and shareholder on the organization in terms of power, legitimacy, and urgency towards GM. Government regulation plays a crucial role in promoting and advocating the industry towards achieving GM (Zhu et al. 2005). In order to promote the green initiative, the government has offered tax inventive for the company in green practice such as investment tax allowance (MIDA 2017). Government support in providing green project funding and incentive to the industry will further thrust the implementation and confident of the user for GM (MDV 2013). The Japanese government has shown strong commitment and initiatives in green approach. Japan has implemented the Joint Crediting Mechanism (JCM) to facilitate the implementation of low-carbon technology and system in some developing countries (JCM 2017). Figure 2 illustrates a simplified flow of JCM structure. In exchange, Japan will benefit from the total GHG emission reduction or removal that will contribute to Japan’s emission reduction target (Japan 2017). Green technology will not only reduce environmental pollution but also helps to reduce operation cost. Green technology such as cogeneration or tri-generation is considered that can increase energy generation efficiency of the facility. Andiappan and Ng (2016) have proposed a systematic approach to tri-generation system selection that will assist industry players to improve their energy performance.

Japan’s Joint Credit Mechanism Scheme with developing countries (JCM 2017)

Nowadays, clients are more educated and aware of climate change. Carter and Jennings (2002) discovered that customer pressure is influencing the company to incorporate GM. A study also showed that customers are frequently pressuring and demanding the manufacturer (Hall 2001). The demand of clients on GM also relates to competitor pressure. Company also realized that corporate image can be improved through environmental-related corporate social responsibility (Maloni and Brown 2006). There are many green tools and methods that aid the company to achieve green. ISO-certified company will have to maintain the certification by continuously practicing green approach. A study showed that ISO 14001 certified companies are 40% likely to assess their suppliers’ environmental performances and 50% likely to require their suppliers to undertake specific environmental practices (Maloni and Brown 2006).

Researchers have discovered that GM focuses mainly on environmental pollution, manufacturing energy efficient and waste management (Rehman and Shrivastava 2013). Many countries around the world have put priority on GM; technologies and incentives are available in the market. It is discovered that GM emphasizes the reduction of resources, energy, and environmental emission of a company. In reality, some manufacturing industries are implementing green approach in their operations without realizing.

Lean and Green Manufacturing

Both lean approach and green approach have shown similar objectives towards minimization of non-value-added product; they form stronger commitment in operational performance when incorporated simultaneously. The development of L&G manufacturing approach has been in the industry and academic since the past decade (Verrier et al. 2016). L&G manufacturing is the current paradigm of manufacturing industry. Garza-Reyes (2015a) highlighted the misunderstanding in L&G, where L&G is referred to as the lean environment, instead of relating lean to a green environment.

LM and GM have been proven to be an effective approach to improve global market competition. LM and GM approaches are powerful tools that can improve production efficiency and global competition. LM and GM show similarity; both approaches indicate a strong commitment to efficiency-driven practice and zero waste (Dües et al. 2013). Hajmohammad et al. (2013) conducted a study on developing an extensive application for LM that helps organizations to incorporate rethinking capability in their processes with waste reduction in mind which can be transferable to GM. Both LM and GM have a similar positive effect on operational and environmental performances (Galeazzo et al. 2014).

According to Vachon and Klassen (2006), some researchers argued that LM has a positive environmental impact on environmental performance. Sawhney et al. (2007) further discovered that factories that operate with lean principles have greater ability to reduce environmental pollutant. Factories that introduce LM practice to seek for continuous improvement in their productions have positive influence and effect towards higher efficiency and better environmental performance (Galeazzo et al. 2014). Chiarini (2014) indicated the implementation of lean tools such as 5S, single-minute exchange die (SMED), TPM will improve environmental performance. A study conducted in Boeing’s LM program resulted in reduced environmental waste as process efficiency and quality improved (EPA 2000). However, the LM study did not specifically address environmental waste as a main subject in the study.

Some authors claimed that GM allows the production facilities to perform better. Jabbour et al. (2013) concluded that the implementation of the environmental program (ISO14001) can have positive impact on various areas of organization performance. According to Melnyk et al. (2002), GM has a positive influence on the operation to create the synergy between environmental management and operational performance. Dües et al. (2013) stated that lean is a catalyst to implement green in manufacturing company and green may help in return to maintain best practice in lean. Bergmiller and McCright (2009a) have developed a parallel L&G model where implementation of the green approach may lead to lean effects as well. Generally, L&G approach complements each other and enhances the efficiency and effectiveness of operation outcome as compared to the individual approach. Hallam and Contreras (2016) stated that L&G manufacturing shares the same objectives in enhancing performance, product quality, and time to reduce operation cost while creating values. This indicates the relationship and interconnection between L&G in the manufacturing system (Bergmiller and McCright 2009b).

Dües et al. (2013) indicated the overlapping of L&G according to series of common attributes such as people and organization, waste and waste reduction method, lead time reduction, supply chain relationship, key performance index (KPI), and common tools and practices. Figure 3 shows the relationship and overlapping of L&G. It is explained that although both the lean approach and green approach share common attributes, they are defined differently. Figure 3 also reflects the main commonality in the objectives of both approaches in waste elimination. It is observed that the purpose of lean is to maximize profit through cost reduction while green is to reduce environmental risks and impacts while improving the ecological efficiency of organization. Practice indicated in Fig. 3 has reflected different objectives between the lean approach and green approach. Lean practice ensures high resource utilization rate by frequently replenishing required item while green practice reduces replenish frequency to reduce environmental pollution. Dües et al. (2013) discovered that although the lean approach and green approach have a different objective in waste elimination, they do target the same type of waste. Verrier et al. (2016) also performed a study to layout the relationship between lean waste and green waste to be incorporated as one to further enhance the operational performance in the area of waste reduction. This shows the symbiosis characteristic between L&G.

Relationship between lean and green approaches (Dües et al. 2013)

Challenges in Implementing Lean and Green (L&G) Manufacturing Approach

Many tools have been developed for the L&G approach, but there is a lack of development of the measurement method and model for a specific process (Garza-Reyes 2015a). Garza-Reyes (2015a) found that production, manufacturing, and industrial system attracts 27% of the L&G researchers’ attention for development. There are limited approaches that integrate L&G to merge their fundamental principles (Pampanelli et al. 2014). The current approaches show similarities in terms of management, implementation technique, and expected result. Carvalho et al. (2010) developed a conceptual model to measure the relationship between L&G practice performance. Top down management commitment is the key to implementation of L&G manufacturing (Asif et al. 2013). Kurdve et al. (2014) also discovered that the lack of organizational responsibility and ownership of the L&G approaches are the major hurdles towards successful implementation. The implementation of L&G is highly dependent on an organization’s commitment (Asif et al. 2013). From the strategy and direction of the organization, L&G approach will be used as an execution direction for improvement.

Verrier et al. (2016) have developed an L&G model to correlate both L&G method and waste. The lack of L&G expertise in the industry has always been the challenge in the manufacturing industry. To enhance the implementation of L&G approach in the industry, a systematic approach should be implemented to support and allow the employee to understand the benefit of L&G. Florida (1996) conducted a study on advanced management practice and discovered that techniques (e.g., management commitment, new process technology, innovative product design, and supply chain management) are closely associated with L&G manufacturing system. The facility that organized under the principles of LM exhibits improved environmental performance (Florida 1996). However, there is an implementation gap during implementation stage on which element shall lead L&G approach. Simons and Mason (2003) conducted a study on L&G and concluded that both L&G have many in common in the way resources are being used and focus on maximizing the efficiency to reduce waste.

The synergy between L&G can impact the operation and environmental performance through effective management strategy with the proper aiding tools. There are lean tools such as Hoshin Kanri, Gemba, KPI and etc. to help the organization to strategize the lean effect on the employee. In the lean context of operations, tools such as total productive maintenance (TPM) and root cause analysis are critical to ensure smooth operation. On the green aspect, energy consumption can be easily reduced through optimization and integration approach. An effective energy management system will reflect directly on the total operation cost reduction in every facilities. Potential energy saving opportunities can be identified through energy management responses. Furthermore, the appropriate lean tools (e.g., kanban, 5S, PDCA and etc.) can be used to establish continuous improvement practice. Besides that, environmental emission will be monitored and improved through operation and technology improvement. Both L&G elements are interrelated and they have positive synergy to further enhance manufacturing performance. The manufacturing industry is driven by market demand; thus, the industry needs to be able to adapt quickly and adopt new technologies and performance boosting approaches to improve its performance.

Cherrafi et al. (2017) pointed out a list of important challenges in the implementation of L&G as shown in Table 6. Based on Table 6, four (4) mitigation methods are suggested to improve the implementation of L&G. The first mitigation action is to develop a green economy to positively affect L&G implementation (Loiseau et al. 2016). Cherrafi et al. (2017) emphasized the importance of promoting education and training method for the top management to ensure their commitments and understanding to implement L&G. Industry collaborations among NGOs and academics can be formulated to develop workshop and internship program to promote L&G among industry practitioners and students. Strong government support and commitment form the third mitigation method (Cherrafi et al. 2017). Many industry players are bound by fund constraint in implementing a newer approach in their facilities, strong government policies will lead to easier access to funding through the financial institute. The fourth mitigation method proposes proper implementation of data collection and performance measurement system (Cherrafi et al. 2017). This allows the organization to identify problems and evaluate the effectiveness of action plan in a proper manner. Cherrafi et al. (2017) also mentioned that recruiting qualified and competent person to implement and improve L&G is also a challenge to the organization.

Based on the literature review, there is a lack of a systematic framework and analytic model to guide the manufacturing industralist towards L&G manufacturing. The need to fullfill this research gap is significant in improving the operational and environmental performances of the industry. This research will address the solution to the research gap with the proposed L&G framework.

Future Work

The importance to achieve global goods demand without compromising the performance of environmental ecological system has been aware by many industry players. The industry revolution has posed great techno-economical challenge for the industry players in adopting advance technology to remain sustainable in the market. The rise of digitalization has led to a new paradigm in manufacturing which is known as industrial revolution 4.0. Industry 4.0 has massively influenced the latest industry development especially in smart factories, smart products, and smart services that are embedded with Internet of Thing (IoT) (Stock and Seliger 2016). Industry 4.0 combines the production system technology with intelligent production process to create new technology wave that fundamentally transforms the industry value chain, production value chain, and business model (Zhong et al. 2017).

Recently, many researchers have developed guidelines for manufacturing factory to practice L&G. Data collection analytic is a key process to improve the manufacturing industry performance. Operation data can be used as analytical tools to improve production yield, quality assurance, and efficiency of the process (Columbus 2014). Zhong et al. (2017) also stated that for existing industry players to adapt to Industry 4.0, various smart sensors, adaptive decision-making model, advance model, intelligent devices, and data analytics are unavoidable. This would incur a huge amount of investment cost to the industry players. There is a huge gap between actual implementation of Industry 4.0 element and confident of industry players, especially dealing with large investment cost and competition from the global market.

Figure 4 presents the proposed L&G process flow for future modeling work to fill the implementation gap of Industry 4.0 where the simulation outcome can help to build industry players’ confidence at lower investment cost. The approach towards Industry 4.0 is highly dependent on actual data collection through factory instrumentation. The data will be analyzed to allow continuous process improvement to enhance production efficiency (Qin 2014). The proposed L&G process flow provides a lower cost method for industry players to adapt and appreciate continuous process improvement prior to venturing into Industry 4.0 which will incur higher investment cost.

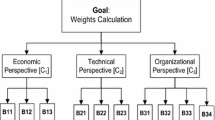

An L&G framework has been proposed to be incorporated in “data collection with L&G checklist” as shown in Fig. 5. The proposed L&G framework mainly consists of five major components such as manpower, money, machine, material, and environment. 5me (2018) model focuses on lean such as man, material, machine, methods, and money but it does not take into consideration of green method. The proposed L&G framework modifies 5me (2018) with the incorporation of green element. Leong et al. (2018) stated that “manpower” plays an important role in the manufacturing industry. In order to adapt to new manufacturing technology and strategy, organization has to create a positive environment to allow the workforce to adapt rapidly. On top of that, retaining and improving employee capability is critical to ensure organization competitiveness globally. As for “money”, Jason (2016) has carried out a study to show the relationship between cost saving, efficiency, and sustainability. Money factor is also a direct indication or performance index to an organization. Moving on to “machine”, most of the manufacturing players depend on machinery to produce goods. The optimization of machinery performance will not only improve production efficiency, it will create a continuous improvement environment for employee to strive for better performance (Leong et al. 2018). The component “material” covers the aspect of resources where raw and output products, logistic and storage, and quality of material are taken into consideration. Lastly, “environment” is included to represent the green aspect of the framework. The importance of decision making by an organization without including environmental factors can contribute severely to global warming and climate change. Therefore, these five major components are proposed to be included in the L&G framework.

The five major components will act as a check and balance model to guide and assist the industry players during L&G implementation. This will not only accelerate the implementation of L&G but also allow an organization to have a clear direction during decision making. Moreover, the direction of the model is to create a multiple-criteria decision making (MCDM) tool that can assist an organization to make the right decision based on their operational behavior.

This framework will help to fill this implementation gap as the simulation is one of the technologies that contribute to Industry 4.0. Crahmaliuc (2018) expected that global engineering simulation software will rise by 12.4% per annum from 2014 to 2022 due to increasing demand for integrated analysis and development of process automation. Hong et al. (2016) performed a study on various modeling techniques for sustainable biomass supply chain that can be used to optimize and locate bottleneck point for system improvement. This can be used as a reference for future model development on optimization and debottlenecking approach. Rojko (2017) revealed that Industry 4.0 is able to reduce production, logistics, and quality management cost by a minimum of 10%. However, it is discovered that there is a lack of attention of green element in Industry 4.0 from literature reviews. The proposed L&G framework will include five major components such as manpower, machine, material, money, and environment that will cover both operational and environmental aspects. The framework intends to solve the barrier to promote L&G in the industry. An actual industry case study that will be evaluated with the proposed L&G improves the operating performance of the facility as future research work. The intention of the framework is to fill the implementation gap and assist the industry players towards Industry 4.0 by implementing L&G approach in their production systems.

Conclusion

The fundamentals of lean aspect and green aspect have been studied as the foundation to understand the application of both aspects. The synergy of L&G approach has shown a better effect that will benefit operational and environmental performances. This paper offers an overview of principles of L&G, application tools, potential barriers, and common challenges faced by the industry. The study shows that there is a lack of policy support and commitment from the government as well as industry players in implementing the L&G approach. Top-down commitment from the organization is one of the major contributors to succeed in L&G approach implementation. The potential barriers have been identified; however, actual implementation has been ineffective mainly due to lack of competent personnel. This paper has also identified the research gap between the potential barrier and implementation method. An L&G framework model has been proposed to fill the research gap to overcome problems during the implementation of the L&G approach. The L&G model focuses on manpower, machine, material, money, and environmental as the main components of the model. The proposed model is expected to fill the research gap by performing simulation studies to improve the implementation rate of the L&G method. This paper also intends to provide the industrialists with a better understanding of L&G and help them to strategize an effective way to improve the sustainability of their facilities. This study will motivate and encourage industry players towards L&G manufacturing and to catch up with Industry 4.0.

Abbreviations

- DfE:

-

Design for environment

- FPS:

-

Ford Production System

- GM:

-

Green manufacturing

- IoT:

-

Internet of things

- ISO:

-

International Standard Organization

- JCM:

-

Joint Credit Mechanism

- JIT:

-

Just in time

- L&G:

-

Lean and green

- LCA:

-

Lifecycle analysis

- LM:

-

Lean manufacturing

- MCDM:

-

Multiple-criteria decision making

- NGO:

-

Non-governmental organization

- SMED:

-

Single-minute exchange die

- TPS:

-

Toyota Production System

- UNEP:

-

United Nations Environmental Program

- WWII:

-

World War II

References

5me (2018) RUN Faster – 5ME Cryogenic Machining. [online] Available at: http://5me.com/ [Accessed 10 Jul. 2018]

Abdul-Rashid SH, Sakundarini N, Raja Ghazilla RA, Thurasamy R (2017) The impact of sustainable manufacturing practices on sustainability performance: empirical evidence from Malaysia. International Journal of Operations & Production Management 37(2):182–204

Agan Y, Acar M, Borodin A (2013) Drivers of environmental processes and their impact on performance: a study of Turkish SMEs. Journal of Cleaner Production 51:23–33

Álvarez-Gil MJ, Berrone P, Husillos FJ, Lado N (2007) Reverse logistics, stakeholders' influence, organizational slack, and managers' posture. Journal of Business Research 60:463–473

Anand G, Kodali R (2008) Selection of lean manufacturing systems using the PROMETHEE. Journal of Modelling in Management 3(1):40–70

Anastas P, Zimmerman J (2003) Peer reviewed: design through the 12 principles of green engineering. Environmental Science & Technology 37(5):94A–101A

Andiappan V, Ng D (2016) Synthesis of tri-generation systems: technology selection, sizing and redundancy allocation based on operational strategy. Computers and Chemical Engineering 91:380–391

Andrew (2012) Green Manufacturing: What Is It?. [online] CleanTechnica. Available at: https://cleantechnica.com/2012/04/15/green-manufacturing/ [Accessed 1 Jun. 2018]

Asif M, Searcy C, Zutshi A, Fisscher O (2013) An integrated management systems approach to corporate social responsibility. Journal of Cleaner Production 56:7–17

Bergmiller GG, McCright PR (2009a) Parallel models for lean and green operations. Proceedings of the 2009 Industrial Engineering Research Conference, Miami, FL, May

Bergmiller GG, McCright PR (2009b) Are lean and green programs synergistic? Proceedings of the 2009 Industrial Engineering Research Conference, Miami, FL, May

Bhattacharya A, Jain R, Choudhary A (2011) Green Manufacturing: Energy, Products and Processes. [online] Available at: https://www.cii.in/webcms/Upload/BCG-CII%20Green%20Mfg%20Report.pdf. Accessed 22 Dec 2018

Bicheno J (2004) The new lean toolbox: towards fast, flexible flow, 3rd edn. PICSIE Books, Buckingham

BMA I (2008) Lean Thinking: The Principles of Lean Manufacturing. [online] Maskell.com. Available at: www.maskell.com/lean_accounting/subpages/lean_manufacturing/lt_the_principles_of_lean_manufacturing.html [Accessed 13 Jun. 2018]

BP. (2018) BP statistical review of world energy. BP, London

Buesa RJ (2009) Adapting lean to histology laboratories. Annals of Diagnostic Pathology 13(5):322–333. https://doi.org/10.1016/j.anndiagpath.2009.06.005

Business, B. (2018). 5 Ways How Globalization Impacts Small Businesses | BusinessBlogs Hub. [online] BusinessBlogs hub. Available at: https://www.businessblogshub.com/2017/05/5-ways-how-globalization-impacts-small-businesses/ [Accessed 16 Jun. 2018]

Carter CR, Jennings MM (2002) Social responsibility and supply chain relationships. Transportation Research Part E: Logistics and Transportation Review 38(1):37–52. https://doi.org/10.1016/S1366-5545(01)00008-4

Carvalho H, Azevedo S, Machado V (2010) Supply chain performance management: lean and green paradigms. International Journal of Business Performance and Supply Chain Modelling 2(3/4):304

Castillo-Pérez V, Carrazco-Armendáriz L, Corral-Chacón M, Elizondo-Rios R (2018) Work team, lean manufacturing production and information systems transform an Enterprise. Advances in Intelligent Systems and Computing:359–369

Cherrafi A, Elfezazi S, Garza-Reyes J, Benhida K, Mokhlis A (2017) Barriers in green lean implementation: a combined systematic literature review and interpretive structural modelling approach. Production Planning and Control 28(10):829–842

Chiarini A (2014) Sustainable manufacturing-greening processes using specific lean production tools: an empirical observation from European motorcycle component manufacturers. Journal of Cleaner Production 85:226–233

Columbus L (2014) Ten Ways Big Data Is Revolutionizing Manufacturing. [online] Forbes.com. Available at: https://www.forbes.com/sites/louiscolumbus/2014/11/28/ten-ways-big-data-is-revolutionizing-manufacturing/#44e7e74cce16 [Accessed 27 Nov. 2017]

Crahmaliuc R (2018) Industry 4.0 – Smart Products and Smart Manufacturing. [online] SimScale. Available at: https://www.simscale.com/blog/2016/08/smart-products-industry-4-0/ [Accessed 14 Jun. 2018]

Crawford M (2016) 5 Lean Principles Every Engineer Should Know. [online] Asme.org. Available at: https://www.asme.org/engineering-topics/articles/manufacturing-design/5-lean-principles-every-should-know [Accessed 13 Jun. 2018]

Czabke J (2007) Lean thinking in the secondary wood products industry: challenges and benefits, Master Thesis, Oregon State University

Dekier L (2012) The Origins and Evolution of Lean Management System. Journal Of International Studies 5(1):46–51. https://doi.org/10.14254/2071-8330.2012/5-1/6

Dües CM, Tan KH, Lim M (2013) Green as the new lean: how to use lean practices as a catalyst to greening your supply chain. Journal of Cleaner Production 40:93–100

Eibel D, Joanneum F (2014) Green Manufacturing - an essential success factor in a globalization world

Enaghani, M., Arashpour, M., and Karimi, M., (2009). The relationship between lean and TPM, Master Thesis, University of Boras

EPA, U (2000). Pursuing Perfection: Case Studies Examining Lean Manufacturing Strategies, Pollution Prevention, and Environmental Regulatory Management Implications. [online] Epa.gov. Available at: https://www.epa.gov/sites/production/files/2013-11/documents/perfection.pdf [Accessed 13 Jun. 2018]

Erdil N, Aktas C, Arani O (2018) Embedding sustainability in lean six sigma efforts. Journal of Cleaner Production 198:520–529

European Commission (2015). Managing resources. [online] European Commission - Basics - Managing resources. Available at: http://ec.europa.eu/environment/basics/green-economy/resources/index_en.htm [Accessed 31 May 2018]

Ferguson M, Toktay L (2009) The effect of competition on recovery strategies. Production and Operations Management 15(3):351–368

Florida R (1996) Lean and green: the move to environmentally conscious manufacturing. California Management Review 39(1):80–105

Galeazzo A, Furlan A, Vinelli A (2014) Lean and green in action: interdependencies and performance of pollution prevention projects. Journal of Cleaner Production 85:191–200

Garrett F (2017) Henry Ford and the World Wars | Military History of the Upper Great Lakes. [online] Ss.sites.mtu.edu. Available at: http://ss.sites.mtu.edu/mhugl/2015/10/12/henry-ford/ [Accessed 9 Nov. 2017]

Garza-Reyes J (2015a) Lean and green – a systematic review of the state of the art literature. Journal of Cleaner Production 102:18–29

Garza-Reyes J (2015b) Green lean and the need for six sigma. International Journal of Lean Six Sigma 6(3):226–248. https://doi.org/10.1108/IJLSS-04-2014-0010

Gilbreth F (1921) Process Charts. The American Society Of Mechanical Engineers, New York, pp 3-7

Hajmohammad S, Vachon S, Klassen R, Gavronski I (2013) Lean management and supply management: their role in green practices and performance. Journal of Cleaner Production 39:312–320

Hall J (2001) Environmental supply-chain innovation. Greener Management International 2001(35):105–119

Hallam C, Contreras C (2016) The interrelation of Lean and green manufacturing Practices: A case of push or pull in implementation. 2016 Portland International Conference on Management of Engineering and Technology (PICMET). https://doi.org/10.1109/picmet.2016.7806669

Handfield R, Walton S, Seegers L, Melnyk S (1997) ‘Green’ value chain practices in the furniture industry. Journal of Operations Management 15(4):293–315

Helu M, Dornfeld D (2012) Principles of Green Manufacturing. Green Manufacturing, pp 107–115. https://doi.org/10.1007/978-1-4419-6016-0_5

Hines, P. (2009). Lean and green, source magazine the home of lean thinking, third ed. sapartners

History.com, S(2010a). Model T. Retrieved November 05, 2017, from http://www.history.com/topics/model-t

History.com, S(2010b). Interchangeable Parts. Retrieved November 02, 2017, from http://www.history.com/topics/inventions/interchangeable-parts

Hong B, How B, Lam H (2016) Overview of sustainable biomass supply chain: from concept to modelling. Clean Technologies and Environmental Policy 18(7):2173–2194

Hui I, He L, Dang C (2002) Environmental impact assessment in an uncertain environment. International Journal of Production Research 40(2):375–388

Industrial Timestudy Institute. (2017). Time Study & Methods Engineering. [online] Available at: http://industrialtimestudy.com/timestudy-methods/ [Accessed 5 Dec. 2017]

Ishak I, Jamaludin R, Abu N (2017) Green technology concept and Implementataion: a brief review of current development. Advanced Science Letters 23(9):8558–8561

ISO (2015) Practical tools for addressing climate change. Retrieved October 20, 2017, Available at:https://www.iso.org/publication/PUB100067.html

Issa T, Chang V, and Issa T (2010) Sustainable business strategies and PESTEL framework. GSTF International Journal on Computing 1(1):73–80

Jabbour C, Jabbour A, Govindan K, Teixeira A, Freitas W (2013) Environmental management and operational performance in automotive companies in Brazil: the role of human resource management and lean manufacturing. Journal of Cleaner Production 47:129–140

Japan G (2017) Recent Development of the Joint Crediting Mechanism (JCM). Available at: https://www.carbon-markets.go.jp/document/20170522_JCM_goj_eng.pdf. Accessed 2 Feb 2018

Jason S., 2016, The efficiency, cost savings and sustainability equation <www.sdcexec.com/home/article/ 12193183/the-efficiency-cost-savings-and-sustainability-equation> accessed 22.03.2018

JCM. (2017). Retrieved November 02, 2017, from https://www.jcm.go.jp/projects/15#!/issuance

Kim S, Kara S (2012) Impact of technology on product life cycle design: functional and environmental perspective. Leveraging technology for a sustainable world. pp 191–196. https://doi.org/10.1007/978-3-642-29069-5_33

Kemp R and Pearson P (2008) MEI project about measuring eco-innovation, Final report, Maastricht. Available at: http://www.merit.unu.edu/MEI/papers/Final%20report%20MEI%20project%20DRAFT%20version%20March%2026%202008.pdf. Accessed 2 Feb 2018

Kochnev I (2007) What, if any, are the diffrences between the Toyota production system and lean?. innovationlighthouse.com. Accessed 21 Feb 2018

Krishnan N, Raoux S, Dornfeld D (2004) Quantifying the environmental footprint of semiconductor equipment using the environmental value systems analysis (EnV-S). IEEE Transactions on Semiconductor Manufacturing 17(4):554–561

Kumar S, Kumar N, Haleem A (2015) Conceptualisation of sustainable green lean six sigma: an empirical analysis. International Journal of Business Excellence 8(2):210

Kurdve M, Zackrisson M, Wiktorsson M, Harlin U (2014) Lean and green integration into production system models – experiences from Swedish industry. Journal of Cleaner Production 85:180–190

Lele S (2009) Getting serious about green manufacturing. Frost & Sullivan Market Insight. Available at: http://www.frost.com/prod/servlet/market-insight-print.pag?docid=188029142. Accessed 24 Jan 2018

Leong WD, Lam HL, Tan CP, Ponnambalam SG (2018) Development of multivariate framework for lean and green process. Chemical Engineering Transactions 70:2191–2196. https://doi.org/10.3303/CET1870366

Liker J (2004) The Toyota way. McGraw-Hill, New York

Loiseau E, Saikku L, Antikainen R, Droste N, Hansjürgens B, Pitkänen K, Leskinen P, Kuikman P, Thomsen M (2016) Green economy and related concepts: an overview. Journal of Cleaner Production 139:361–371

Lopetegui M, Yen P, Lai A, Jeffries J, Embi P, andPayne, P. (2014) Time motion studies in healthcare: What are we talking about? Journal of Biomedical Informatics 49:292–299. https://doi.org/10.1016/j.jbi.2014.02.017

Ma J, Yin F, Liu Z, Zhou X (2012) The eco-design and green manufacturing of a refrigerator. Procedia Environmental Sciences 16:522–529

Maloni M, Brown M (2006) Corporate social responsibility in the supply chain: an application in the food industry. Journal of Business Ethics 68(1):35–52

Maruthi G, Rashmi R (2015) Green Manufacturing: It's tools and techniques that can be implemented in manufacturing sectors. Materials Today: Proceedings 2(4–5):3350–3355. https://doi.org/10.1016/j.matpr.2015.07.308

Maynard, M. (2013). How Eiji Toyoda Created The Modern Version Of Toyota. Retrieved November 09, 2017, from https://www.forbes.com/sites/michelinemaynard/2013/09/17/how-eiji-toyoda-created-the-modern-version-of-toyota/#a204fdc2d70e

McGrath, W. (2007). Impact analysis of large scale lean manufacturing initiatives upon manufacturing process innovation in Irish companies, Master thesis, Waterford Institute of Technology

MDV (2013) Green Technology Financing Scheme | MDV. Retrieved from http://www.mdv.com.my/en/product-services/programmes/green-technology-financing-scheme/. Accessed 5 Dec 2017

Melnyk S, Sroufe R, Montabon F, Hinds T (2001) Green MRP: identifying the material and environmental impacts of production schedules. International Journal of Production Research 39(8):1559–1573

Melnyk S, Sroufe R, Calantone R (2002) Assessing the effectiveness of US voluntary environmental programmes: an empirical study. International Journal of Production Research 40(8):1853–1878

MIDA. (2017). MIDA | Malaysian Investment Development Authority. Retrieved from http://www.mida.gov.my/home/frequently-asked-questions/posts/. Accessed 5 Dec 2017

Mittal V, Sangwan K (2014) Prioritizing drivers for green manufacturing: environmental, social and economic perspectives. Procedia CIRP 15:135–140

Mohnty RP, Deshmukh SD (1998) Managing green productivity, some strategic directions. Production Planning and Control 9(7):624–633

Mourtzis D, Papathanasiou P, Fotia S (2016) Lean rules identification and classification for manufacturing industry. Procedia CIRP 50:198–203. https://doi.org/10.1016/j.procir.2016.04.097

Nawanir G, Fernando Y, Teong L (2018) A second-order model of lean manufacturing implementation to leverage production line productivity with the importance-performance map analysis. Global Business Review 19(3_suppl):S114–S129

Nukman Y, Farooqi A, Al-Sultan O, Alnasser A, Bhuiyan M (2017) A strategic development of green manufacturing index (GMI) topology concerning the environmental impacts. Procedia Engineering 184:370–380

Pampanelli A, Found P, Bernardes A (2014) A lean & green model for a production cell. Journal of Cleaner Production 85:19–30

Parker S (2003) Longitudinal effects of lean production on employee outcomes and the mediating role of work characteristics. J Appl Psychol 88(4):620–634. https://doi.org/10.1037/0021-9010.88.4.620

Paul I, Bhole G, Chaudhari J (2014) A review on green manufacturing: It's important, methodology and its application. Procedia Materials Science 6:1644–1649

Pavnaskar SJ, Gershenson JK, Jambekar AB (2003) Classification scheme for lean manufacturing tools. International Journal of Production Research 41(13):3075–3090. https://doi.org/10.1080/0020754021000049817

Pettersen J (2009) Defining lean production: some conceptual and practical issues. The TQM Journal 21(2):127–142

Qin S (2014) Process data analytics in the era of big data. AICHE Journal 60(9):3092–3100

Rehman M, Shrivastava R (2013) Green manufacturing (GM): past, present and future (a state of art review). World Review of Science, Technology and Sustainable Development 10(1/2/3):17

Reich-Weiser C, Vijayaraghavan A, Dornfeld D (2010) Appropriate use of green manufacturing frameworks. 17th CIRP LCE Conference, Hefei, pp 196-201.

Rodríguez D, Van Landeghem H, Lasio V, BuyensD (2017) Determinants of job satisfaction in a lean environment. International Journal of Lean Six Sigma 8(2). https://doi.org/10.1108/ijlss-01-2016-0002

Rojko A (2017) Industry 4.0 concept: background and overview. International Journal of Interactive Mobile Technologies (iJIM) 11(5):77

Rouse, M. (2015). What is just-in-time manufacturing (JIT manufacturing)?. [online] WhatIs.com. Available at: https://whatis.techtarget.com/definition/just-in-time-manufacturing-JIT-manufacturing [Accessed 13 Jun. 2018]

Sawhney R, Teparakul P, Bagchi A, Li X (2007) En-lean: a framework to align lean and green manufacturing in the metal cutting supply chain. International Journal of Enterprise Network Management 1(3):238

Sezen B, Çankaya S (2013) Effects of green manufacturing and eco-innovation on sustainability performance. Procedia - Social and Behavioral Sciences 99:154–163

Simona U, Cristina D (2015) Review on Lean Tools used in Manufacturing Process Improvement (I), Ovidius University Annals. Economic Sciences Series 15(1):642–647

Simons DW, Mason RJ (2003) Lean and green thinking - doing more with less. ECR Journal 3(1):84–91

Stock T, Seliger G (2016) Opportunities of sustainable manufacturing in industry 4.0. Procedia CIRP 40:536–541

Strategosinc. (2017). A Brief History of Lean Manufacturing. [online] Available at: http://www.strategosinc.com/just_in_time.htm [Accessed 3 Nov. 2017]

Taylor S (1992) Green management: the next competitive weapon. Futures 24(7):669–680

Tortorella GL, Fettermann DC, Fries CE (2016) Relationship between lean manufacturing implementation and leadership styles. In: Proceedings of the 2016 International Conference on Industrial Engineering and Operations Management, pp 85–96

TOYOTA. C. (2018). Toyota Global Site | Jidoka. [online] Toyota Motor Corporation Global Website. Available at: www.toyota-global.com/company/vision_philosophy/toyota_production_system/jidoka.html [Accessed 13 Jun. 2018]

UNEP (2011) Towards a green economy: pathways to sustainable development and poverty eradication - a synthesis for policy makers, www.unep.org/greeneconomy. Accessed 5 Dec 2017

UNIDO (2010) Motor systems Effi ciency supply curves. United Nations Industrial Development Organisation (UNIDO), Vienna

Vachon S, Klassen R (2006) Extending green practices across the supply chain. International Journal of Operations & Production Management 26(7):795–821

Van Berkel R (2010) Quantifying sustainability benefits of industrial symbioses. Journal of Industrial Ecology 14(3):371 f Ind

Verrier B, Rose B, Caillaud E (2016) Lean and green strategy: the lean and green house and maturity deployment model. Journal of Cleaner Production 116:150–156

Vila C, Abellán-Nebot J, Albiñana J, Hernández G (2015) An approach to sustainable product lifecycle management (green PLM). Procedia Engineering 132:585–592

Villa A, Taurino T (2013) From JIT to Seru, for a production as lean as possible. Procedia Engineering 63:956–965. https://doi.org/10.1016/j.proeng.2013.08.172

Womack J, Jones DT (1994) From lean production to the lean enterprise. Harvard Business Review 72:93–104

World Bank (2012) Inclusive green growth: the pathway to sustainable development. © World Bank, Washington, DC https://openknowledge.worldbank.org/handle/10986/6058 license: CC BY 3.0 IGO. Accessed 5 Dec 2017

Yatim P, Ngan L, Lam HL (2017) Financing green growth in Malaysia: enabling conditions and challenges. Chemical Engineering Transactions 61:1579–1584. https://doi.org/10.3303/CET1761261

Yong L (2014). Emerging green technologies for the manufacturing sector. [online] Unido.org. Available at: https://www.unido.org/sites/default/files/2015-01/Institute_Emerging_green_trends_Future_of_Manufacturing_0.pdf. Accessed 22 Feb 2018

Zhong R, Xu X, Klotz E, Newman S (2017) Intelligent manufacturing in the context of industry 4.0: a review. Engineering 3(5):616–630. https://doi.org/10.1016/j.eng.2017.05.015

Zhu Q, Sarkis J, Geng Y (2005) Green supply chain management in China: pressures, practices and performance. International Journal of Operations & Production Management 25(5):449–468

Zimmer L (2000) Get lean to boost profits. Forming and Fabricating 7:12–23

Funding

This study was financially supported by the Ministry of Higher Education (FRGS/1/2016/TK03/MUSM/01/1). Research funding and support were received from Newton Fund and the EPSRC/RCUK (Grant Number: EP/PO18165/1).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Leong, W.D., Lam, H.L., Ng, W.P.Q. et al. Lean and Green Manufacturing—a Review on its Applications and Impacts. Process Integr Optim Sustain 3, 5–23 (2019). https://doi.org/10.1007/s41660-019-00082-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41660-019-00082-x