Abstract

For enhancing the performance of polymer electrolyte membrane (PEM) fuel cells, copper plates are widely used as the current collectors. The degraded surfaces of the copper plates affect the performance of fuel cells adversely. This work investigates the effects of corrosion in the copper current collector plates on the performance of PEM fuel cells. The experiments were conducted on a single PEM fuel cell with a working area of 25 cm2. To bring out the effect of corrosion, a set of copper plates were allowed to get tarnished by keeping them open to the atmosphere for 2 months. Then, the plates were used as the current collectors in the PEM fuel cell and the performance of the PEM fuel cell was monitored. It was observed that the ohmic losses increased drastically with a maximum voltage drop of 0.4 V. The tarnished surface of copper plates was subsequently polished using emery sheets and the same set of experiments were repeated. It was observed that the performance of the PEM fuel cell decreased to 43.64% due to corrosion and the performance got recovered by 21.8% due to polishing. The surface degradation of the plates was characterized and a correlation for degraded performance was suggested.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The polymer electrolyte membrane (PEM) fuel cell is an electrochemical device that converts the chemical energy of hydrogen and an oxidant (air/oxygen) continuously delivered in the active area into electrical energy (Barbir 2005). The byproducts of this reaction are low temperature heat and water, which produce zero or very low harmful emissions (O'Hayre et al. 2006). Hence, PEM fuel cells have been widely used in comparison to other types of fuel cells for producing electricity (Mench 2008). The main components of PEM fuel cells are supporting endplates, current collecting plates, bipolar plates, electrodes, membrane/ electrolyte, catalyst layer, and gas diffusion layers (Das and Bansode 2010). The combination of membrane/electrolyte, catalyst layer, and gas diffusion layers is called membrane electrode assembly (MEA), which also acts as the main functional part of a PEM fuel cell (Jithesh 2014). The membranes are designed to conduct the protons and it is impermeable to gases. The gas diffusion layers are usually made of carbon cloth, and between the porous electrode and the polymer membrane is a layer of catalyst particles (platinum supported on carbon). Bipolar plates distribute the reactant gases through flow fields and also provide physical strength to the cell. Widely used bipolar plates are graphite plates, which are expensive (Barbir 2005). Hence, stainless steel plates are preferred over graphite plates because of its enhanced properties such as electrical and thermal conductivity and cost-effectiveness. In PEM fuel cells, three different types of flow distributors: parallel, serpentine, and mixed designs are used. Bansode et al. (2010) proved experimentally that the mixed-flow distributors have better performance than parallel and serpentine flow distributors. Though electricity is produced in bipolar plates, the current generated is transferred to the external circuit or electronic load via current collectors. It can be said that the current and voltage measurement in PEM fuel cells are dependent on the performance of the current collectors. As the electrical conductivity of the copper is high, copper current collector plates are preferred over other metal current collector plates in PEM fuel cells. However, the copper current collector plates have a greater tendency to get corroded due to surface oxidation.

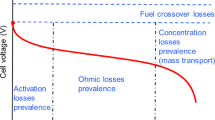

Activation losses, ohmic losses, and concentration losses are the three major losses associated with fuel cells (Barbir 2005). Each loss has a major impact on the fuel cell's performance, so it needs to be thoroughly investigated. Ohmic losses are relatively high, which occur due to the resistance offered by the electrically conductive components of PEM fuel cells (Mennola et al. 2002). Surface oxidation within the fuel cell is inevitable due to the continuous availability of water in the fuel cell which causes the tarnish (thin layer of corrosion) in the metal plates. However, the resistance offered by the corrosion in the metal plates is not accounted for ohmic losses. For example, when stainless steel plates are used in the fuel cells, which have good corrosion resistance, it is found to be highly susceptible to corrosion due to the presence of water essential for the electrochemical reaction (Wang et al. 2003; Lee et al. 2004). Moreover, it is a well known fact that the development of tarnished/ corroded surfaces on any metal components of fuel cell offers resistance, which results in reducing the current produced in the PEM fuel cell. In the case of copper current collector plates, the surface oxidation leads to the formation of tarnished surfaces which in turn leads to the changes in the conductivity of copper plates.

Extensive studies have been carried out to understand the oxidation of copper by oxygen and air (Tylecote 1950; Wagner and Grunewald 1938). At high temperatures, the thickness of the oxide film increases drastically and follows parabolic rate law, whereas, at low temperatures, the oxidation rate reduces after the oxide film formed attains several nanometers in thickness (Mrowec and Stoklosa 1971; Roy et al. 1991). Feng et al. (2003) studied the kinetics of copper powder oxidation in dry and humid air conditions and found that the oxidation process was controlled by electron transport across it as long as the oxide film remains thin. The electron migration across the metal/ oxide interface is controlled as the film thickens, and these mechanisms control the oxidation kinetics at low temperatures. On the other hand, at higher temperatures, the oxidation process is controlled by the diffusion process.

Thus, from the literature, it can be seen that most of the studies related to copper oxidation are focused on different substrate materials and surfaces (Young et al. 1956; Liu et al. 2006; Nam and Ju 2013; Rahman and McCarthy 2017; Jayaramu et al. 2019). However, it is necessary to have a good understanding of the oxidation of copper on the application such as the electrochemical performance of PEM fuel cell assembly. Therefore, this paper brings out the effects of corrosion in copper plates due to aging on the performance of a complete PEM fuel cell system.

Design and Fabrication of a Single PEM Fuel Cell

The experiments were carried out on a PEM fuel cell with an active area of 25 cm2. Nafion® 212-NR membrane was used as the electrolyte, catalyst layers (CL), and Ballard carbon paper (MGL 370) was used as the gas diffusion layer (GDL) in the membrane electrode assembly (MEA). 0.5 mg/cm2 of platinum loading was coated on the cathode side and 0.25 mg/cm2 of platinum loading was coated on the anode side of the membrane and used as the catalyst layers. The mixed-flow field of 3 sets, grooved on 4 mm thick graphite plates, as shown in Fig. 1. Aluminum plates with a thickness of 18 mm were used as the endplates. Copper plates with a thickness of 2 mm were used as the current collectors on both sides of the PEM fuel cell.

Experimental Setup

The schematic representation of the fuel cell setup with the test station for a single PEM fuel cell is shown in Fig. 2. The test station consists of external humidification facilities. Separate flowmeters were used to regulate the reactant flow rate of hydrogen and oxygen. The cell voltage, current, and temperatures are recorded simultaneously using a data acquisition unit. To apply the electrical load to the fuel cell, an electronic load box with an accuracy of ± 0.01 A was used.

Experimental Methodology

The PEM fuel cell used in the present experimental research work was fed with humidified (100% RH) hydrogen gas on the anode side and humidified (100% RH) oxygen gas on the cathode side. On the anode and cathode sides, the fabricated copper plates of 2 mm thickness were used as current collectors. The membrane electrode assembly (MEA) was activated and the experiments were conducted at ambient temperature without cell heating. The polarization curve was plotted by varying the current with a time increment of 5 s. The PEM fuel cell using conventional non-corroded (pristine) copper plates as the current collectors is also mentioned as the PEM fuel cell with pristine copper plates hereafter.

To bring out the effect of corrosion in the current collectors (copper plates) on the performance of PEM fuel cells, a similar set of experiments were conducted on PEM fuel cell with tarnished copper plates as current collectors. The tarnished copper plates were obtained by exposing the conventional non-corroded copper plates to the atmosphere at a room temperature ranging between 28 °C and 35 °C for 2 months. The second set of experiments in the PEM fuel cell was conducted by replacing the conventional non-corroded copper plates with tarnished copper plates. The PEM fuel cell using tarnished/corroded copper plates as the current collectors is also mentioned as the PEM fuel cell with tarnished copper plates hereafter.

After the completion of the second set of experiments in the PEM fuel cell, the tarnished surfaces of copper plates were removed and polished using emery paper. Figure 3 presents the photographs of copper plates in both anode and cathode sides, which clearly shows the difference between tarnished and polished surfaces in the copper plates. In addition, the third set of experiments in the PEM fuel cell was carried out using the polished copper current collector plates. The PEM fuel cell using polished copper plates as the current collectors is also mentioned as the PEM fuel cell with polished copper plates hereafter.

Scanning electron microscope (SEM) microstructural studies of copper plates were captured using High-Resolution Scanning Electron Microscope (Inspect F). SEM microstructural analysis was performed on a small copper samples of size 3 × 3 cm, cut from the tarnished plate (both anode and cathode side). The electrical conductivity tests were conducted on the same copper samples of size 3 × 3 cm2 using Keithley 4 probe measuring unit. There was no significant difference between the anode and cathode side copper plates. The samples were then polished using the emery paper and SEM analysis was performed. For comparison, the electrical conductivity tests were also conducted on the polished copper samples.

To theoretical value of hydrogen flow rate \({\dot{(m}}_{{H}_{2}})\) is calculated using the following equation (Barbir, 2012):

where \({M}_{{H}_{2}}\) is the molecular weight of the hydrogen (2.016 g/mol), \({S}_{{H}_{2}}\) is the hydrogen stoichiometry, n is the number of electrons transferred, \(I\) is the cell current (A), and F is the Faraday’s constant (26.801 A.h/mol or 96,485 C/mol).

The theoretical value of oxygen flow rate \({(\dot{m}}_{{O}_{2}})\) is calculated using the following equation:

where \({M}_{{O}_{2}}\) is the molecular weight of the oxygen (31.999 g/mol), and \({S}_{{O}_{2}}\) is the oxygen stoichiometry. The experiments were conducted with the hydrogen stoichiometry of 1.2 and the oxygen stoichiometry of 2.5. In the current study, the hydrogen flow rate ranges from 0 to 0.5 lpm and the oxygen flow rate ranges from 0 to 0.75 lpm.

Results and Discussion

The results of experiments conducted on the PEM fuel cells are presented in this section. The experiments were repeated four times and the data points are the average of four independent experiments. However, the precision of the experiments based on these four repeated runs falls within 2%. The effect of corrosion in copper current collector plates on the performance of PEM fuel cells was brought out in terms of voltage and power density.

Effect of Copper Corrosion in Cell Voltage

Figure 4 compares the variation of voltage with current density, i.e., V–I (voltage–current density) polarization curve of a single PEM fuel cell using conventional non-corroded (pristine), tarnished and polished copper plates as current collectors. Usage of tarnished copper plates as current collectors resulted in altering the shape of the polarization curve. At lower current densities, i.e., for current densities less than 0.1 A/cm2, the V–I curves of both PEM fuel cell with pristine and tarnished copper plates are similar. For current densities of more than a value of 0.1 A/cm2, the slope of the polarization curve of the PEM fuel cell with tarnished copper plates increased in comparison to the polarization curve of the PEM fuel cell with pristine copper plates. The voltage difference between the PEM fuel cell with pristine and tarnished copper plates at current densities of 0.6 A/cm2, 0.8 A/cm2, 1.0 A/cm2 and 1.2 A/cm2 were 0.11 V, 0.16 V, 0.2 V and 0.25 V, respectively. For current densities more than a value of 1.2 A/cm2, the concentration losses dominate and result in further voltage drop. It can be seen from Fig. 4 that at a current density of 1.4 A/cm2, the voltage of PEM fuel cell with tarnished copper plates attains a minimum voltage value of 0.1 V, whereas at the same current density, the voltage of the PEM fuel cell with pristine copper plates was 0.5 V. This indicates that the voltage losses due to corrosion of copper current collector plates is significant and can be considered as another important factor in addition to the above-mentioned losses.

Effect of Copper Corrosion in Power Density

Figure 5 compares the variation of power density with respect to the current density, i.e., P–I polarization curves of a single PEM fuel cell with pristine, tarnished and polished copper plates as current collectors. Similar to the variation of the V–I polarization curve in Fig. 4, the power density of PEM fuel cell with pristine and tarnished copper plates do not vary initially. When the current density reached a value of 0.25 A/cm2, the performance of PEM fuel cell with pristine and tarnished copper plates differed and the P–I polarization curve started to diverge. Further increase in the current density resulted in increasing the difference in power densities between the PEM fuel cell with pristine and tarnished copper plates. When the current density was increased to a value of 0.97 A/cm2, PEM fuel cell with tarnished copper plates attained the maximum power density of 0.39 W/cm2. Further increase in current density resulted in a decrease in the power density of the PEM fuel cell with tarnished copper plates, whereas at the same current density value of 0.97 A/cm2, the power density of the PEM fuel cell with pristine copper plates was 0.56 W/cm2 which is relatively higher than the PEM fuel cell with tarnished copper plates and showed an increasing trend. The maximum power density of the PEM fuel cell with pristine copper plates was 0.7 W/cm2 at the current density of 1.42 A/cm2. It is evident from Fig. 5 that the performance of the PEM fuel cell with tarnished copper plates is much lower than the performance of the PEM fuel cell with pristine copper plates due to the effect of corrosion in copper current collector plates in the PEM fuel cell with tarnished copper plates. From the observed maximum power densities of the PEM fuel cell with pristine and tarnished copper plates, the percentage of power density loss due to corrosion in copper current collector plates was calculated to be 44.3%. Hence, it could be said that the corrosion in the current collectors affected the overall performance of the PEM fuel cell significantly.

Performance of PEM Fuel Cell after Polishing the Tarnished Copper Plates

From Figs. 4 and 5, it can be observed that marked improvement in voltage and current density of PEM fuel cell occurs due to the removal of the oxidation layer in copper current collector plates. After polishing the tarnished copper plates, the ohmic losses in PEM fuel cell were reduced with an increase in a voltage drop of 0.13 V at a current density of 1.13 A/cm2 (Fig. 4). However, the performance of the PEM fuel cell with polished copper plates in terms of voltage and the current density was still lower than the performance of the PEM fuel cell with pristine copper plates (Figs. 4 and 5).

After polishing the tarnished copper current collector plates, the performance of the PEM fuel cell (PEM fuel cell with polished copper plates) increased for current densities more than a value of 0.4 A/cm2 in comparison to the PEM fuel cell with tarnished copper plates as shown in Fig. 5. The maximum power density of the PEM fuel cell increased from 0.39 W/cm2 (tarnished copper plates) to 0.51 W/cm2 (polished copper plates) owing to the removal of the oxidation layer from the tarnished copper plates (Fig. 5). Thus, the polishing of the corroded surface of copper current collector plates enhanced the performance of the PEM fuel cell. Though polishing of tarnished copper current collector plates resulted in improving the performance of PEM fuel cell with tarnished copper plates, the performance was lesser than the PEM fuel cell with pristine copper plates utilizing the conventional non-corroded copper current collector plates. This behavior is attributed to the changes in roughness and reduction in the surface thickness of copper current collector plates used in PEM fuel cell due to polishing. Thus, it can be said that the removal of the oxidation layer on copper current collector plate surfaces also has a significant effect on the performance of the PEM fuel cell.

Correlation for Corroded Cell

The voltage of the PEM fuel cell is given by (Barbir 2005)

where ET is the theoretical cell potential (V), R is the gas constant (8.134 J/mol K), \({i}\) is the cell current density (A/cm2), \({i}_{0}\) is the exchange current density (A/cm2), α is the transfer co-efficient, F is Faraday’s constant (96,485 s A/mol), n is the number of electrons transferred, A is the active area of the cell (cm2), Rcell is the overall resistance of the cell (Ω), and \({i}_{L}\) is the limiting current density (A/cm2).

This equation can be written shortly as

Due to the corrosion in the current collectors, the resistance of the copper plates increases. Therefore, the measured current value through the current collectors is not the actual value of current produced by the PEM fuel cell. In order to correlate the deviation of current measured, the following equation is proposed with a non-dimensional correction factor in terms of the resistance. The equation can be written as

where Rpr is the resistance of the pristine copper plate (Ω), Rtr is the resistance of the tarnished copper plate (Ω) and n is a constant value.

The equation can be replaced with a constant ‘c’:

The new correlation in terms of non-dimensional numbers has been developed based on the present experimental data obtained. The cell voltage is a function of cell resistance and the non-dimensional correction factor of change in resistance due to copper corrosion. The constant and exponents in the equations are estimated by multi-parameter non-linear square fitting and it is shown in the following equation:

Similarly, the equation for the polished copper plate surface can be written as

where Rpol is the resistance of the polished copper plate (Ω).

The present experimental data were compared with the developed correlation and the parity plot is shown in Fig. 6. The new correlation predicts more than 80% of data within \(\pm 20\mathrm{\%}\) error band.

Effects on Cell Voltage and Temperature of PEM Fuel Cell at Static Current Test

The variation in cell voltage of a single PEM fuel cell with pristine, tarnished and polished copper plates as current collectors at a constant current density of 0.8 A/cm2 is shown in Fig. 7a. Initially, the cell voltage of PEM fuel cell with pristine copper plates was above 0.61 V. When the PEM fuel cell with pristine copper plates was operated continuously for 240 min, the voltage dropped to 0.56 V which is attributed to the increase in ohmic loss caused due to the increase in cell temperature. The cell voltage of the PEM fuel cell with tarnished copper plates was 0.48 V at low temperature and the voltage difference due to corrosion was 0.13 V. In addition, when the PEM fuel cell with tarnished copper plates was operated for another 240 min, the cell voltage dropped to 0.41 V. This indicates that the formation of the oxidation layer due to corrosion in the copper plate increased the ohmic loss in PEM fuel cell. After the removal of the oxidation layer in the tarnished copper plate, i.e., after polishing of tarnished copper plates, the PEM fuel cell with polished copper plates was also operated for 240 min and it was observed that the cell voltage dropped from the initial value of 0.54 V–0.50 V at the end of the experiment (Fig. 7a).

Similarly, the variation in cell voltage of a single PEM fuel cell with pristine, tarnished and polished copper plates as current collectors at a constant current density of 1.0 A/cm2 is shown in Fig. 7b. The ohmic resistance is directly proportional to the square of the current and at higher current densities, the temperature of the PEM fuel cell increases which resulted in a significant voltage drop in the PEM fuel cell with tarnished copper plates. The voltage of the PEM fuel cell with tarnished copper plates dropped at higher current density as well as with higher temperature. After 240 min of the experiment, the voltage drop observed in the PEM fuel cell with tarnished copper plate was 0.07 V. The voltage drop results confirm the increase in ohmic resistance in PEM fuel cells due to the formation of oxidation layer in tarnished copper plates.

The variation of cell temperature of the PEM fuel cell pristine, tarnished and polished copper plates with time at the current density of 0.8 A/cm2 is shown in Fig. 8a. The PEM fuel cell was operated at ambient temperature and then the load is applied to maintain the static current density of 0.8 A/cm2. Since heat is produced due to the electrochemical reaction, the temperature of the PEM fuel cell was increased. At low current density, the rise in temperature of the cell was lower when compared with the operation of the PEM fuel cell at higher current densities. From Fig. 8a, it is found that the cell temperature of the PEM fuel cell with the tarnished copper plates is very high compared to the PEM fuel cells with pristine copper plates. The additional resistance due to the oxidation layer in the tarnished plates caused the rise in temperature of the PEM fuel cell with tarnished copper plates. The variation of temperature of the PEM fuel cell with pristine, tarnished and polished copper plates with time at the current density of 1 A/cm2 is shown in Fig. 8b. When the PEM fuel cell was operated at the higher current density, the temperature of the PEM fuel cell was increased more. The rise in temperature of the PEM fuel cell increased the rate of evaporation of liquid water and thus more amount of water was removed by the reactant stream. The maximum temperature difference of 5–6 °C was observed when the PEM fuel cell was continuously operated for 240 min.

Characterization of Pristine, Tarnished and Polished Copper Plates

The SEM images and EDAX graphs of the pristine, tarnished, and polished copper plates used as current collectors in the PEM fuel cell are shown in Figs. 9 and 10, respectively. The SEM images evidence the presence of oxide on the tarnished copper plate surfaces in comparison to the un-corroded/pristine copper plate (Fig. 9). The elemental composition of tarnished copper samples determined using EDAX also indicated the presence of oxide/ oxygen elements on the surface of tarnished copper plates (Fig. 10).

When the tarnished plate was polished using the emery sheet, a change in the surface texture was occurred. The oxidation layer was removed by the rubbing process which increased the roughness of the copper plate surfaces. The change in the surface texture of copper plates due to corrosion can be seen clearly in Fig. 9. The oxidation surface has increased the wettability, which influences the performance more than the roughness.

The electrical conductivity and resistivity values of the tarnished, polished and pristine copper current collector plates are tabulated in Table 1. Due to the presence of an oxide layer in the copper plate, the electrical conductivity of the tarnished copper plate decreased to 67.2%. Even though polishing of the oxidation layer increased the conductivity of the copper plate, the electrical conductivity of the polished copper plate was lesser than that of the pristine copper plate (Table 1).

The relative differences in the electrical conductivities of copper plate samples presented in Table 1 are similar to the differences in the performance of the fuel cell evaluated in terms of V–I and P–I polarization curves shown in Figs. 4 and 5. The maximum current and power densities of the PEM fuel cell with pristine, tarnished and polished copper plates are shown in Fig. 11. The data from Table 1 and Figs. 4 and 5 are collated and the difference in maximum current and power densities of the pristine, tarnished and polished cells are also compared in Fig. 11. The electrical conductivity of tarnished copper plate used in PEM fuel cell with tarnished copper plates was less than the electrical conductivity of pristine copper plate used in PEM fuel cell with pristine copper plates. Similarly, the maximum current and power densities of the PEM fuel cell with tarnished copper plates were significantly less than that of the PEM fuel cell with pristine copper plates. Polishing of tarnished copper plate resulted in increasing the electrical conductivity of copper plate, and also the maximum current and power densities of the PEM fuel cell with polished copper plates. However, the values of electrical conductivity of polished copper plate and, maximum current and power densities of PEM fuel cell with polished copper plates were less than the pristine copper plate and PEM fuel cell with pristine copper plates, respectively.

Conclusions

The performance of a single PEM fuel cell was monitored by varying the surface conditions of the copper plates, which are used as current collectors. The effect of corrosion of copper current collector plates in the PEM fuel cell was brought out by comparing the polarization curves of PEM fuel cell with pristine and tarnished copper plates. Comparison of V–I polarization curves showed that a 0.4 V difference was observed when the PEM fuel cell with tarnished copper plates attained the minimum voltage and at the current density of 1.2 A/cm2, it was observed that the performance of the PEM fuel cell decreased to 43.64%. Similarly, it was observed from P–I polarization curves that 44.3% of power density was lost due to the corrosion of copper current collector plates in the PEM fuel cell. This indicates that the resistance offered due to corrosion in copper current collector plates is significantly high, even though the resistance of other main components did not change significantly. After removing the oxidation layer by polishing the tarnished copper plates, it was observed that the performance of the PEM fuel cell increased. After polishing, the performance of the PEM fuel cell recovered back to 21.8% at the current density of 1.2 A/cm2. However, it was lower than the performance of the PEM fuel cell with pristine copper plates due to the change in roughness and reduction of the surface thickness of copper plates due to polishing. From static current tests, it is found that the drop in cell voltage and the rise in cell temperature occurred due to the oxidation layer formed over the copper plates. Hence, it can be concluded that the corrosion in current collectors, especially in copper plates, decrease the performance of the PEM fuel cell significantly which needs to be considered to assess the long-term performance and maintenance of the PEM fuel cells. Removal of the oxidized layer from the tarnished copper plates can be a strategy to mitigate this effect.

Abbreviations

- V :

-

Voltage of the cell, V

- I :

-

Current of the cell, A

- i :

-

Current density of the cell, A/cm2

- P :

-

Power of the cell, W

- p :

-

Power density of the cell, W/cm2

- R:

-

Gas constant (8.134 J/mol K)

- \({i}_{0}\) :

-

Exchange current density (A/cm2)

- \({i}_{L}\) :

-

Limiting current density (A/cm2)

- F:

-

Faraday’s constant (96,485 s A/mol)

- PEM:

-

Polymer electrolyte membrane

- SEM:

-

Scanning electron microscope

References

Bansode AS, Sundararajan T, Das SK (2010) Computational and experimental studies on the effect of flow distributors on the performance of PEMFC. J Fuel Cell Sci Technol 7:051014-1–51111

Barbir F (2005) PEM fuel cells - Theory and Practice. Elsevier

Das SK, Bansode AS (2010) Heat and mass transport in proton exchange membrane fuel cells—a review. Heat Transfer Eng 30(9):691–719

Feng Z, Marks CR, Barkatt A (2003) Oxidation-rate excursions during the oxidation of copper in gaseous environments at moderate temperatures. Oxid Met 60(5–6):393–394

Jayaramu P, Gedupudi S, Das SK (2019) An experimental investigation on the influence of copper ageing on flow boiling in a copper microchannel. Heat Transf Eng 41(4):333–350

Jithesh PK (2014) Studies on water management and self-humidification in PEM fuel cells (Ph. D. thesis), India, Indian Institute of Technology Madras.

Lee SJ, Huang CH, Lai JJ, Chen YP (2004) Corrosion-resistant component for PEM fuel cells. J Power Sources 131(1–2):162–168

Liu J., Huang X, Li Y, Sulieman KM, He X. Sun F (2006) Hierarchical nanostructures of cupric oxide on a copper substrate: Controllable morphology and wettability, J. Mater. Chem, 16(45), 4427–4434

Mench MM (2008) Fuel cell engines. John Wiley & Sons

Mennola T, Mikkola M, Noponen M, Hottinen T, Lund P (2002) Measurement of ohmic voltage losses in individual cells of a PEMFC stack. J Power Sources 112(1):261–272

Mrowec S, Stoklosa A (1971) Oxidation of copper at high temperature. Oxid Met 3:291–311

Nam Y, Ju YS (2013) A comparative study of the morphology and wetting characteristics of micro/nanostructured Cu surfaces for phase change heat transfer applications. J Adhes Sci Technol 27(20):2163–2176

O’Hayre R, Cha SW, Prinz FB, Colella W (2006) Fuel cell fundamentals. Wiley

Rahman MM, McCarthy M (2017) Boiling enhancement on nanostructured surfaces with engineered variations in wettability and thermal conductivity. Heat Transf Eng 38(14–15):1285–1295

Roy SK, Bose SK (1991) Sircar SC (1991) Pressure dependencies of copper oxidation for low- and high-temperature parabolic laws. Oxid Met 35:1–18

Tylecote RF (1950) The oxidation of copper at 350–900 C. In air. J Inst Met 78:327–350

Wagner C, Grunewald K (1938) Theory of the tarnishing process. III z Physik Chem 40:455–475

Wang H, Sweikart MA, Turner JA (2003) Stainless steel as bipolar plate material for polymer electrolyte membrane fuel cells. J Power Sources 115(2):243–251

Young FW, Cathcart JV, Gwathmey AT (1956) The rates of oxidation of several faces of a single crystal of copper as determined with elliptically polarized light. Acta Metall 4(2):145–152

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Johnson, N.A.B., Sen, A.K. & Das, S.K. Experimental Investigation on the Adverse Effect of Corrosion in the Current Collectors on the Performance of PEM Fuel Cells. Trans Indian Natl. Acad. Eng. 7, 1167–1177 (2022). https://doi.org/10.1007/s41403-022-00352-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41403-022-00352-0