Abstract

A prompt gamma-neutron activation analysis (PGNAA) system was developed to detect the iron content of iron ore concentrate. Because of the self-absorption effect of gamma-rays and neutrons, and the interference of chlorine in the neutron field, the linear relationship between the iron analytical coefficient and total iron content was poor, increasing the error in the quantitative analysis. To solve this problem, gamma-ray self-absorption compensation and a neutron field correction algorithm were proposed, and the experimental results have been corrected using this algorithm. The results show that the linear relationship between the iron analytical coefficient and total iron content was considerably improved after the correction. The linear correlation coefficients reached 0.99 or more.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Prompt gamma-neutron activation analysis (PGNAA) is a form of rapid and non-contact multi-elemental analysis technique, which has been widely used for element detection and analysis in various fields, such as cement, coal, and mineral resource industries [1,2,3,4,5,6,7,8,9,10,11,12,13,14,15]. With real-time, online detection results from PGNAA, a factory can adjust the control parameters simultaneously and hence improve the product quality. The PGNAA technique is based on the detection of prompt gamma-rays emitted through thermal neutron capture (nth, γ) or neutron inelastic scattering (n, n′ γ) [1, 2]. It can distinguish the elemental categories in the material from the characteristic γ-ray energy spectrum and estimate the element content from the intensities of characteristic energy peaks in the spectrum [3, 4]. PGNAA technology involves neutron moderation technology, characteristic gamma-ray energy spectrum technology, and the spectrum deconvolution technique [5,6,7,8,9,10]. At present, PGNAA technology is widely used to detect high contents of light elements or low contents of heavy elements in a sample, such as calcium, silicon, iron, and aluminum in cement [1, 4, 12]. Owing to the self-shielding effect of gamma-rays and neutrons in some heavy elements [16,17,18,19,20], which increases the error of PGNAA technology in the detection of heavy element concentrates, the applications of PGNAA technology using heavy elements are limited.

In the steel industry, the sintering process is quite sensitive to the iron ore concentrate grade; thus, real-time and accurate detection of the grade is very important to improve the sintering process and sinter quality. Here, a new correction algorithm, with gamma-ray self-absorption and neutron self-absorption considered, for the detection of iron ore concentrate grade by PGNAA is developed. By means of the new correction algorithm, the linear correlation between the iron analytical coefficient and the total iron content has been improved from 0.79747 to 0.99886, and the influence of chlorine in the sample on the detection error has been reduced as well. As a result, an effective and accurate real-time detection of the iron ore concentrate grade during the sintering process has been demonstrated based on PGNAA technique and the new correction algorithm.

2 Experiment

2.1 Equipment setup

A PGNAA was used to detect the iron content in iron ore concentrate in the experiment. Figure 1 schematically shows the equipment setup [15]. Two 20 μg 252Cf neutron sources were placed in the source chamber. Two 5 inch × 5 inch (diameter × height) NaI detectors were used as the prompt gamma-ray detector. The experimental equipment was produced by DFMC, which was suitable for a one-meter-wide belt. The spectrum acquisition time of each sample was set to 3600 s. Because of the strong shielding ability of iron on gamma-rays, the characteristic gamma-ray of a sample containing iron should have strong gamma-ray self-absorption [21]. To measure the self-attenuation degree of gamma-rays, one gamma-ray attenuation degree detection system was installed after the PGNAA, which included a 137Cs gamma-radiation source installed below the belt and a γ-ray detector installed above the belt, as shown in Fig. 2.

2.2 Sample preparation and experimental load

Six calibration samples and nine validation samples, with differing iron contents, were prepared for the experiment. Silicon, magnesium, calcium, and chlorine interference elements were added in sample 2-1# ~ 2-9# to simulate a real test. The compositions of the calibration samples are shown in Table 1, and the compositions of the verification samples are listed in Table 2.

An inflection curve is observed for the analytical coefficient between the deconvolution coefficient of iron and the sample load owing to the gamma-ray self-attenuation effect, as shown in Fig. 3. In Fig. 3, the linear region is between 60 and 130 kg. To obtain more rational results, 110 kg was selected as the experimental load in this study.

2.3 Gamma-ray self-absorption correction

The following compensation formula [22] for gamma-ray self-absorption is used to correct for self-attenuation:

where \(I_{{0_{{E_{i} }} }}\) is the energy spectrum without attenuation, \(I_{{E_{i} }}\) is energy spectrum obtained by the PGNAA detector, \(\mu_{{mE_{i} }}\) is the characteristic gamma-ray mass attenuation coefficient with energy Ei, \(\mu_{{mE_{i} }}\) is related to the atomic number of the material and the energy of the gamma-ray, N is the detector count rate of the gamma-ray attenuation degree detection system when there is material on the belt, N0 is the detector count rate of the gamma-ray attenuation degree detection system with no material on the belt, and \(\mu_{0}\) is the mass attenuation coefficient of the 137Cs radioactive source with energy equal to 0.662 MeV.

The linear absorption coefficient, \(\mu\), of the material is defined as follows:

where Ni is the atomic density of each element and \(\sigma_{i}^{\gamma }\) stands for the total microscopic photon atomic cross section.The calculation formula of parameter Nelement is defined as follows:

where mρ is the mass density of the material being measured, Mi is the atomic weight of each element, fi is the proportion of each element, \(f_{\text{element}}\) is the proportion of current element, and NA is Avogadro’s constant.

The characteristic gamma-rays are not all produced at the bottom of the detection area. They are generated at every location in the detection area; thus, the final correction formula, with a correction factor k, can be rewritten as follows:

The main materials in the iron ore concentrate are calcium oxide, silicon dioxide, ferrous oxide, ferric oxide, magnesium oxide, and chlorine. The corresponding composition of each material is listed in Table 3. Iron ore contains six elements: oxygen, magnesium, silicon, calcium, iron, and chlorine; the atomic proportions (fi) of each element are listed in Table 4. The linear absorption coefficient, μ, of iron ore concentrate can be calculated from Eqs. 2 and 4, and the atomic proportions are listed in Table 4. The \(\frac{{ - \mu_{mE} }}{{\mu_{0} }}\) data for each element are listed in Table 5.

Using the characteristic energy spectrum, \(I_{{E_{i} }}\) (1 MeV ≤ Ei ≤ 10 MeV), constant \(\frac{{ - \mu_{{mE_{i} }} }}{{\mu_{0} }}\) (1 MeV ≤ Ei ≤ 10 MeV), and count rate N and N0 in Eq. 4, the energy spectrum after compensation, \(I_{{0_{{E_{i} }} }}\) (1 MeV ≤ Ei ≤ 10 MeV), is obtained.

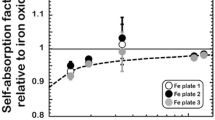

The gamma-ray self-absorption compensation parameters and data of the six calibration samples are listed in Table 6. The energy spectra before and after gamma-ray self-absorption compensation are shown in Fig. 4a, b, respectively. The relationship between the analytical coefficient and iron content, before and after gamma-ray self-absorption compensation, is shown in Fig. 5a, b, respectively.

2.4 Neutron self-absorption correction

Self-absorption in the PGNAA technique is comprised of two parts: gamma-ray self-absorption and neutron self-absorption [16,17,18]. A bigger neutron-absorption cross section will result in more neutron self-absorption. The neutron capture reaction cross section and characteristic gamma-ray energy of different materials are listed in Table 7 [19].

Previous work regarding neutron self-absorption correction [20] by Professor Wen-bao Jia is compared with the current iron ore concentrate detection experiment listed in Table 8. It is clear that the total neutron capture cross section of iron is quite strong in the iron ore concentrate detection experiment, contrasting with the experiment by Professor Jia, which means the influence of sample thickness on detection results is higher than that of previous evaluation.

The experimental samples contain silicon, calcium, magnesium, chlorine, and other interfering elements. The test results of iron can be disturbed by these elements. The iron element test result, found by a PGNAA, can be expressed by the following formula:

where \(m^{\prime}_{\text{Fe}}\) is the iron grade, as detected by the PGNAA, and K is a constant representing all other contributing factors. \(\sigma_{i}^{n}\) is the neutron-absorption cross section of each element listed in Table 7.

The formula for the contribution of each element (excluding iron) to the measurement error of iron is as follows:

The contribution of iron to the measurement error of the iron grade is:

The formula for the total error in iron grade detection is:

Formula 9 shows that the changes in the content of chlorine will cause the greatest error in the result. Because chlorine has a large neutron-absorption cross section, the neutron field of the entire system will change considerably when the content of chlorine changes, and, furthermore, it induces more error in the detection of other elements.

The concentration of iron, mFe, and chlorine, mCl, can be expressed as follows [20]:

where \(\varPhi_{0}\) and \(\varPhi_{1}\) are the neutron flux upon it entering (0) and leaving (1) the sample, \(A_{\text{Fe}}^{0}\) is the analytical coefficient of the energy spectrum of iron when the iron content is mFe, \(A_{\text{Cl}}^{0}\) is the analytical coefficient of the energy spectrum of chlorine when the content is mCl, kFe and kCl are scaling factors between the concentration and analytic coefficient, f is the geometric factor for the NaI scintillation detector, and \(\eta\) is the detection efficiency.

When the measured sample changes, the iron and chlorine contents become multiples of the original content p and k, respectively. The corresponding formulas are

where \(\varPhi_{1}^{{\prime }}\) represents the corresponding neutron flux exiting from the surface of the sample, and when the iron content of the sample becomes pmFe, the chlorine content of the sample becomes kmCl. \(A_{\text{Fe}}^{1}\) is the analytical coefficient of the energy spectrum of iron when the iron content is pmFe, \(A_{\text{Cl}}^{1}\) is the analytical coefficient of the energy spectrum of chlorine when the chlorine content is kmCl, and \(k^{\prime}_{\text{Fe}}\) and \(k^{\prime}_{\text{Cl}}\) are scaling factors.

From Eqs. (10)–(13), the expressions of p and k can be rewritten as:

The linear correction factor g(p, k) is defined as:

To determine \(\phi_{0}\), \(\phi_{1}\), and \(\phi_{1}^{{\prime }}\), a 3He neutron detector was added over the material to detect the neutron flux as shown in Fig. 2. Because the measured material itself slows fast neutrons, \(\phi_{0}\) is not the thermal neutron flux when the belt is empty. In this experiment, \(\phi_{0}\), the thermal neutron flux, was defined when 20-kg carbon powder was placed on the belt.

The final analytical coefficient is \(A_{\text{Fe}}^{\text{Final}} = A_{\text{Fe}}^{1} \times g\left( {p,k} \right)\). The data used in the calculation of the calibration samples are listed in Table 9. The calibration data are listed in Table 10. The final total iron calibration curve is shown in Fig. 6.

2.5 Calculation of check samples

To verify the reliability of the method, nine validation samples were prepared. The experimental data of each sample are listed in Table 11. The total iron content comparison curve of the validation samples is shown in Fig. 7.

3 Results and discussion

The experiment adopts the spectrum library least-squares approach to analyze the spectrum, effectively eliminating the influence of interference elements. The spectrum library was established before the experiment and contains the characteristic energy spectra of calcium, silicon, iron, aluminum, magnesium, chlorine, sulfur, sodium, and the background. Through the least-squares operation, the contribution of each element in the total spectrum can be found, which corresponds to the content of the element.

Because of the strong gamma-ray self-absorption and neutron-absorption effect of iron, the PGNAA detection result is quite poor, and thus, both gamma-ray self-absorption correction and neutron self-absorption correction should be incorporated into PGNAA detection.

Figure 4b shows the compensation effect of energy spectra at different iron concentrations. Figure 5a, b gives the relationship between the analytical coefficient and the iron content before and after gamma-ray self-absorption correction, respectively. Before compensation, the linear correlation coefficient between the analytical coefficient and the iron content is 0.79747 and is improved to 0.96627 after energy spectrum compensation.

Owing to the large neutron capture cross section of iron and chlorine, which considerably disturbs the iron grade detection result, the experimental results should be corrected to eliminate the interference of chlorine. As shown in Fig. 6, after neutron self-absorption correction and chlorine interference correction, the linear correlation coefficient between iron content and the analytical coefficient reaches 0.99886.

Figure 7 shows the total iron content comparison curve of the validation samples, in which the trend of calculated value is consistent with the actual value. The RMS error of the validation samples is 0.45, which is the ideal result.

4 Conclusion

Based on the PGNAA technique and a new correction algorithm, the linear correlation coefficient between the total iron content and analytical coefficient of six calibration samples was improved to 0.99886, and the RMS error of nine validation samples was decreased to 0.45, which is the ideal result. The PGNAA technique can be applied to real-time heavy element concentrate detection.

References

F.Y. Shi, J.Y. Ma, J.W. Zhao et al., Detection sensitivities of C and O in coal due to a channel in the moderator. Radiat. Meas. 46, 88–91 (2011). https://doi.org/10.1016/j.radmeas.2010.08.025

A.A. Naqvi, A Monte Carlo comparison of PGNAA system performance using 252Cf neutrons, 2.8-MeV neutrons and 14-MeV neutrons. Nucl. Instrum. Methods A 511, 400–407 (2003). https://doi.org/10.1016/s0168-9002(03)01949-1

A. Favalli, H.C. Mehner, V. Ciriello et al., Investigation of PGNAA using the LaBr 3 scintillation detector. Appl. Radiat. Isot. 68, 901–904 (2010). https://doi.org/10.1016/j.apradiso.2009.09.058

C. Oliveira, J. Salgado, F. Leitao, Density and water content corrections in the gamma count rate of a PGNAA system for cement raw material analysis using the MCNP Code. Appl. Radiat. Isot. 49, 923–930 (1998). https://doi.org/10.1016/s0969-8043(97)10111-7

A.X. da Silva, V.R. Crispim, Moderator-collimator-shielding design for neutron radiography systems using 252Cf. Appl. Radiat. Isot. 54, 217–225 (2001). https://doi.org/10.1016/s0969-8043(00)00291-8

C. Oliveira, J. Salgado, I.F. Goncalves et al., A Monte Carlo study of the influence of the geometry arrangements and structural materials on a PGNAA system performance for cement raw material analysis. Appl. Radiat. Isot. 48, 1349–1354 (1997). https://doi.org/10.1016/s0969-8043(97)00130-9

J.B. Yang, X.G. Tuo, Z. Li et al., Mc simulation of a PGNAA system for on-line cement analysis. Nucl. Sci. Tech. 21, 221–226 (2010). https://doi.org/10.13538/j.1001-8042/nst.21.221-226

A.A. Naqvi, M.M. Nagadi, Performance comparison of an 241Am-Be neutron source-based PGNAA setup with the KFUPM PGNAA setup. J. Radioanal. Nucl. Chem. 260, 641–646 (2004). https://doi.org/10.1023/b:jrnc.0000028225.07280.74

F. Zhang, J.T. Liu, Monte Carlo simulation of PGNAAsystem for determining element content in the rock sample. J. Radioanal. Nucl. Chem. 299, 1219–1224 (2014). https://doi.org/10.1007/s10967-013-2858-3

L.Z. Zhang, B.F. Ni, W.Z. Tian et al., Status and development of prompt γ-ray neutron activation analysis. Atom. Energy Sci. Technol. 39, 282–288 (2005). https://doi.org/10.3969/j.issn.1000-6931.2005.03.022. (in Chinese)

W. Zhang, L. Zhao, Y.F. Li, Neutron activation analyzer radiological monitoring system. Mod. Min. 8, 188–189 (2017). https://doi.org/10.3969/j.issn.1674-6082.2017.08.059

C.S. Lim, J.R. Tickner, B.D. Sowerby et al., An on-belt elemental analyser for the cement industry. Appl. Radiat. Isot. 54, 11–19 (2001). https://doi.org/10.1016/S0969-8043(00)00180-9

Q.F. Song, Y.L. Gong, W. Zhang et al., Feasibility study for on-line analysis of bauxite using a PGNAA system. China Min. Mag. 10, 171–174 (2015). https://doi.org/10.3969/j.issn.1004-4051.2015.10.037. (in Chinese)

B.R. Wang, G.H. Yin, Z.P. Yang, Identification system for chemical warfare agents with PGNAA method. Nucl. Electron. Detect. Technol. 27, 621–623 (2007). https://doi.org/10.3969/j.issn.0258-0934.2007.04.002. (in Chinese)

Y.L. Gong, W. Zhang, J.T. Tao, et al. CN 201348615Y, Adjustable multi element analyzer, 2008

C. Cheng, W.B. Jia, D.Q. Hei et al., Study of influence of neutron field and γ-ray self-absorption on PGNAA measurement. Atom. Energy Sci. Technol. 48, 802–806 (2014). https://doi.org/10.7538/yzk.2014.48.s0.0802. (in Chinese)

M.E. Medhat, Gamma-ray attenuation coefficients of some building materials available in Egypt. Ann. Nucl. Energy 36, 849–852 (2009). https://doi.org/10.1016/j.anucene.2009.02.006

L.T. Yang, C.F. Chen, X.X. Jin et al., Research on accurate calculation method of γ-ray self-absorption correction factor. Atom. Energy Sci. Technol. 51, 323–329 (2017). https://doi.org/10.7538/yzk.2017.51.02.0323. (in Chinese)

Reedy and Frankle, At. Data Nucl. Data Tables 80, 1, 2002. https://www-nds.iaea.org/pgaa. Accessed 9 Mar 2019

W.B. Jia, C. Cheng, Q. Shan et al., Study on the elements detection and its correction in aqueous solution. Nucl. Instrum. Methods B 342, 240–243 (2015). https://doi.org/10.1016/j.nimb.2014.10.010

K. Sudarshan, R. Tripathi et al., A simple method for correcting the neutron self-shielding effect of matrix and improving the analytical response in prompt gamma-ray neutron activation analysis. Anal. Chim. Acta 549, 205–211 (2005). https://doi.org/10.1016/j.aca.2005.06.021

Z.H. Wu, H.Q. Qi, N.X. Shen et al., Experimental Method of Nuclear Physics (Atomic Energy Press, Beijing, 1997), pp. 65–66. (in Chinese)

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was supported by the National Key Scientific Instrument and Equipment Development Projects (No. 2012YQ240121), Liaoning science and technology project (No. 2017220010), and Changchun Science and Technology Bureau Local Company and College (University, Institution) Cooperation Projects (No. 17DY023).

Rights and permissions

About this article

Cite this article

Zhao, L., Xu, X., Lu, JB. et al. Study on element detection and its correction in iron ore concentrate based on a prompt gamma-neutron activation analysis system. NUCL SCI TECH 30, 58 (2019). https://doi.org/10.1007/s41365-019-0579-1

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41365-019-0579-1