Abstract

In this paper, a novel material for Co(II) adsorption, titanate sodium nanotubes (Na2Ti2O5-NTs) were synthesized and characterized, and then they were used to remove Co(II) from aqueous solution and compared with titanic acid nanotubes (H2Ti2O5-NTs) and potassium hexatitanate whiskers (K2Ti6O13). The results showed that the adsorption of Co(II) on the materials was dependent on pH values and was a spontaneous, endothermic process. Specifically, Na2Ti2O5-NTs exhibited much more efficient ability to adsorb Co(II) from aqueous solution, with the maximum adsorption capacity of 85.25 mg/g. Furthermore, Na2Ti2O5-NTs could selectively adsorb Co(II) from aqueous solution containing coexisting ions (Na+, K+, Mg2+, and Ca2+). The results suggested that Na2Ti2O5-NTs were potential effective adsorbents for removal of Co(II) or cobalt-60 from wastewater.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

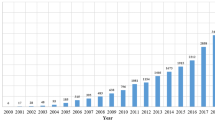

Due to its moderate half-life (T 1/2 = 5.27 year) and high emission energy (1.33 and 1.17 MeV γ-rays), cobalt-60 (60Co) is widely used in industry, agriculture, scientific research, and medical application [1], etc. Unfortunately, a large amount of radioactive 60Co wastewater will inevitably be generated during the process of 60Co manufacture and application. The existence of 60Co wastewater will be harmful for human health and living environment due to the intense radiation of 60Co even at low concentrations. Hence, it is necessary to employ efficient methods to remove 60Co from wastewater.

As it is well known, there are many approaches for the removal of cobalt from aqueous solution, including extraction, precipitation, ion-exchange method, and liquid membrane enrichment [2–5]. Among all of these methods, inorganic ion-exchange method has attracted more attention over the last decade because of the merits of inorganic adsorbent, such as good mechanical properties, pronounced resistance to radiation, high selectivity, and excellent adsorption capacity. In recent years, different inorganic adsorbents have been developed for the removal of cobalt from aqueous solution, such as natural and modified clays [6, 7], carbon materials [8], metal oxides [9], titanate materials [10], and other specific materials [11, 12]. Titanium-containing material, a kind of available inorganic material, was also used in cobalt wastewater treatment due to its satisfactory sorption properties. For instance, Kim et al. [13] pointed the adsorption of Co(II) onto the Fe–Ti–O material with the adsorption capacity of 22.4 mg/g. Xu et al. [14] investigated the adsorption behavior of Co(II) on potassium hexatitanate whiskers (K2Ti6O13) and showed the potential ability for Co(II) adsorption on such material.

In recent years, titanate nanotubes (TNTs), synthesized by hydrothermally treating commercial TiO2, have attracted increasing attentions in the environmental remediation field due to the unique adsorption properties [15–17]. Meanwhile, the adsorption behavior of TNTs to various environmental contaminants including organic dyes [18], heavy metal ions [19, 20], and radionuclides [21] have been widely investigated. For example, the TNTs had also been applied to remove Pb(II) [22], Cd(II) [23], and Th(IV) [24] from wastewater with the adsorption capacities of 299.5, 65.97 and 232.6 mg/g, respectively. All of these investigations have indicated that TNTs are promising adsorbents for the application in the environmental contaminants removal from wastewater.

Generally, the specific surface area, pore volume, and ion-exchange capacity of TNTs are related to their preparation method and final component. Recently, the titanate sodium nanotubes (Na2Ti2O5-NTs) were obtained on a titanium plate after being treated in NaOH aqueous solution [25–27]. The titanium metal acts as a template for the organization as well as a titanium source. And the prepared Na2Ti2O5-NTs had been demonstrated to have more uniform one-dimensional nanostructures and a much smoother surface than those synthesized from initial titanium dioxide powder in alkaline solution [16]. However, such Na2Ti2O5-NTs were usually more desirable for applications involving catalysis, filtration, sensing, and photovoltaic cells because of its excellent cation exchangeability [28]. There were scarcely reports focusing on employing this Na2Ti2O5-NTs to remove Co(II) from aqueous solution.

Considering the large specific surface area and good cation-exchange capability belonging to this kind of Na2Ti2O5-NTs, we speculated that the Na2Ti2O5-NTs might be used as a novel adsorption material for the removal of Co(II) from aqueous solution. Therefore, in our present work, the Na2Ti2O5-NTs were prepared, characterized, and then used to remove Co(II), which was compared with titanic acid nanotubes (H2Ti2O5-NTs) and K2Ti6O13. Based on this study, we try to find a particular and more efficient sorbent to separate or enrich Co(II), especially trace 60Co from wastewater.

2 Materials and methods

2.1 Chemical reagents and instruments

Chemicals of analytical grade purity, including ethanol, acetone, K2CO3, NaOH, and HCl, were purchased from Chengdu Kelong Chemical Reagent Co., Ltd. (China). Metatitanic acid (H2TiO3) was provided by Wuxi Titanium Dioxide Co., Ltd. (China). Titanium foil (99.8 %) was obtained from Shenzhen Metal Materials Co., Ltd. (China). CoCl2·6H2O was offered by Chengdu Chemical Reagent Co., Ltd. (China). All metal nitrates were purchased from Chengdu Kelong Chemical Reagent Co., Ltd. (China).

XRD pattern of the products was conducted by a DX-2700 X-ray diffractometer (China). The morphology of the materials was analyzed by SEM (S-4800, Hitachi, Japan). The TEM image was obtained using a Tecnai G2F20 (FEI, USA). The specific surface area was determined by instrument (QUADRASORB SI). The potentiometric titration was performed using a G20 Compact Titrator (Mettler Toledo, Switzerland).

2.2 Preparation of Na2Ti2O5-NTs

Na2Ti2O5-NTs were synthesized via a hydrothermal process. In brief, titanium foil (99.8 % pure, 25 × 20 × 2 mm) was first immersed in 20 mL of 10 mol/L NaOH aqueous solution in a Teflon-lined stainless steel autoclave. After 24 h of reaction at 150 °C, the Ti foil was dipped in 2 mol/L NaOH solution at 85 °C for 1 h. Then it was immersed in distilled water at 85 °C for 30 min. Finally the titanium piece with thin film was alternately washed by deionized water until neutral. Then the Na2Ti2O5-NTs were dried in an oven at 80 °C for 6 h.

For a better evaluation of its adsorption ability toward Co(II), the sorption properties of two other typical titanate materials for cobalt removal reported in previous work [14, 29] were also investigated in this study. Thus, H2Ti2O5-NTs and K2Ti6O13 were prepared using the method described by S. Thennarasu et al. [15] and Liu et al. [30], respectively.

2.3 Batch sorption experiments

In this work, Co(II) adsorption on the Na2Ti2O5-NTs, H2Ti2O5-NTs, and K2Ti6O13 materials were investigated as functions of pH, contact time, initial concentration, temperature, and coexisting cations. For each experiment, 10 mg of adsorbent was added into a conical flask containing 50 mL Co(II) solution with designed concentration. The pH of the solution was adjusted by 0.1 mol/L HCl and NaOH solution. The supernatant of the solution was separated by membrane filters of 0.45 µm. The concentration of Co(II) in supernatant was determined by UV–Vis spectrophotometer (Shimadzu, UV2450) at λ = 487 nm using Nitroso-R salt method [31]. When studying the selective sorption of Co(II) on Na2Ti2O5-NTs, H2Ti2O5-NTs, and K2Ti6O13, the concentrations of Co(II) and other metal ions in supernatants were determined by inductively coupled plasma atomic emission spectroscopy (ICP-AES).

The adsorption capacity, q e (mg/g), and distribution coefficient, K d (mL/g), are calculated by the following Eqs. (1) and (2).

where C 0 (mg/L) and C e (mg/L) are the initial concentration and equilibrium concentration of metal ion, respectively, V (L) is the volume of the solution, and m (g) is the quality of the sorbent.

2.3.1 Effect of pH

To investigate the effect of pH on Co(II) sorption on three titanium-containing materials, the pH of the solution was adjusted by 0.1 mol/L HCl and NaOH solution in the range of pH 2 ~ 8. The initial concentration of Co(II) was 10 mg/L and the contact time was 24 h.

2.3.2 Effect of contact time and sorption kinetics

To investigate the effect of contact time and adsorption kinetics during the sorption process, experiments were performed with a different contact time ranging from 10 min to as long as 24 h, when an equilibrium was surely attained. The pH of the solution was 7 and the initial Co(II) concentration was 10 mg/L.

2.3.3 Effect of initial Co(II) concentration and adsorption isotherm

To investigate the effect of initial Co(II) concentration and adsorption isotherm, the batch experiments were performed in a wide range of initial Co(II) concentration from 10 mg/L to as large as 105 mg/L. The pH of the solution was 7, and the contact time was 24 h.

2.3.4 Effect of temperature and thermodynamic parameters

To investigate the effect of temperature, the experiments were conducted at 5, 15, 25, 35, and 45 °C, at the contact time of 24 h, and the pH of the solution was 7 and initial Co(II) concentration was 10 mg/L.

2.3.5 Effect of coexisting cations

Generally, the removal of Co(II) from wastewater may be influenced due to the presence of other metals ions. To investigate the effect of coexisting ions on Co(II) adsorption onto Na2Ti2O5-NTs, H2Ti2O5-NTs, and K2Ti6O13, we choose Na+, K+, Mg2+, and Ca2+ as competitive ions. The pH of the solution was 7 and all initial concentration of metal ions were 10 mg/L.

Throughout all the batch experiments, the phase ratio was 10 mg of adsorbents to 50 mL of solution, and the samples were shaken at a frequency of 150 r/min.

3 Results and discussion

3.1 Characterization of prepared materials

In our work, we used XRD, SEM, TEM, and BET as well as potentiometric titration methods to analyze the phase (crystal) composition, surface morphology, specific surface area, and zero point of charge of Na2Ti2O5-NTs, H2Ti2O5-NTs, and K2Ti6O13 materials. The results were shown as following.

3.1.1 XRD

The XRD patterns of Na2Ti2O5-NTs, H2Ti2O5-NTs, and K2Ti6O13 are shown in Fig. 1. XRD patterns of Na2Ti2O5-NTs (a) presented remarkable diffraction peaks at 2θ = 10.2°, 24.3°, 28.6°, and 48.1°, which were all of the main characteristic peaks of sodium titanate (Na2Ti2O5·H2O, JCPDS NO.57-0123), as suggested by some authors [32, 33]. As shown in (b) and (c), the samples mainly consisted of titanic acid (H2Ti2O5·H2O, JCPDS NO.47-0124) and potassium hexatitanate whiskers (K2Ti6O13, JCPDS NO.74-2075), respectively. For (a) and (b), the peaks at 28.6° and 25.4° correspond to the (600) and (310) crystal plane of Na2Ti2O5-NTs and H2Ti2O5-NTs, respectively.

3.1.2 SEM and TEM

The SEM and TEM images of the prepared materials are shown in Fig. 2. The SEM image of Na2Ti2O5-NTs (Fig. 2a) indicated that the material had a well dispersed smooth surface form and more uniform size than H2Ti2O5-NTs and K2Ti6O13 (Fig. 2b, c). Figure 2d, e shows the TEM images of the Na2Ti2O5-NTs and H2Ti2O5-NTs, respectively. They revealed that large quantity of hollow nanotubes with an outer diameter of approximately 10 nm were obtained.

3.1.3 BET

Previous work indicated that the specific surface area and pore inside of the material were important impact factors on adsorption capacity [34]. In this work, the specific surface area and pore size distribution of Na2Ti2O5-NTs, H2Ti2O5-NTs, and K2Ti6O13 were determined by the BET and BJH methods. The results are presented in Table 1. It could be seen that all of the titanium-containing materials had a mesoporous pore radius. Particularly, the Na2Ti2O5-NTs had an obviously smaller pore radius and a larger specific surface area.

3.1.4 Potentiometric titration

Potentiometric titration could be employed to determine the nature of the surface charge and to calculate the density of surface sites of the materials [35]. Hence, it was an available method to determine the surface properties of the as-prepared Na2Ti2O5-NTs, H2Ti2O5-NTs, and K2Ti6O13.

V eb1 and V eb2 (mL), which were obtained from the linear regression analysis of the Gran plot’s terminals, could be considered as the zero point and the end point of the titration, observed in Fig. 3a. The surface site density of the as-prepared materials is calculated by Eq. (3),

where H s (mmol/g) represents the density of the surface site, C b (mg/L) represents the concentration of NaOH, m s (g) represents the mass of the material, and M s represents the molar mass of the material. The H s values of Na2Ti2O5-NTs, H2Ti2O5-NTs, and K2Ti6O13 were found to be 0.912, 0.203, and 0.109 mmol/g, respectively, suggesting that the surface of the Na2Ti2O5-NTs had more activity sites than the other two materials.

The term TOTH (mol/L) referred to the concentration of protons consumed during the titration process, of which the value is calculated by Eq. (4),

where V 0 (mL) denotes the initial solution volume and V b (mL) corresponds to the volume of NaOH added at different titration points. The values of TOTH as a function of pH are presented in Fig. 3b. The pHzpc (zero point of charge) was measured to be 3.65, 5.41 and 6.97 for Na2Ti2O5-NTs, H2Ti2O5-NTs, and K2Ti6O13, respectively. The values indicated that the surface of Na2Ti2O5-NTs was likely neutral or positively charged at pH <3.65 and negatively charged at pH >3.65.

3.2 Sorption of Co(II) on titanium-containing materials

3.2.1 Effect of pH

For the sorption of Co(II), the pH value of the solution was one of the most crucial parameters because it could affect the surface charge as well as the speciation of Co(II) in aqueous solution [36].

Before the experiment, the species distribution of 0.17 × 10−3 mol/L of cobalt was simulated by MEDUSA (Make Equilibrium Diagrams Using Sophisticated Algorithms) [9]. As shown in Fig. 4, Co2+ was the main species when the solution pH value was lower than 8, but when the solution pH value was in the range of 8 ~ 9, the cobalt was presented in the forms of Co2+, Co(OH)+, or Co(OH)2. Furthermore, the cobalt thoroughly converted to Co(OH)2 precipitate when the solution pH value was higher than 9.

Based on the front simulation, the adsorption behavior influenced by pH was investigated in the range of pH 2 ~ 8. The results shown in Fig. 5 exhibited that the adsorption capacity of the Na2Ti2O5-NTs and H2Ti2O5-NTs showed an increase trend with the increase in the solution pH value, while there was little change on Co(II) adsorption on K2Ti6O13.

Meanwhile, the variation of pH values caused the surface charge of the materials changes, which could affect the electrostatic adsorption of metal ions from aqueous solution. The surface negative charge of the materials increased with the pH value rising when pH > pHzpc. Hence, the Na2Ti2O5-NTs tended to adsorb more Co(II) compared with the other two materials when the solution pH > 4, as the pHzpc of the Na2Ti2O5-NTs (3.65) was the lowest.

In general, the surface of the titanate nanotubes was rich in hydroxyl groups [24, 37]. Hence, the interaction of the Co(II) and the hydroxyl surface groups on the Na2Ti2O5-NTs and H2Ti2O5-NTs might be described by a surface ion-exchange mechanism of Co(II) with H+ on the material surface [38]. It is represented by the following Eq. (5),

where S represent the Na2Ti2O5-NTs and H2Ti2O5-NTs materials. From this equation, we could see that a competition may exist between H+ and Co(II) for occupancy of the binding sites at low pH conditions. As the pH increased, the degree of materials protonation would be reduced, and the Co(II) adsorption would increase, correspondingly.

3.2.2 Effect of contact time and sorption kinetics

The results of Co(II) adsorption on Na2Ti2O5-NTs, H2Ti2O5-NTs, and K2Ti6O13 as a function of contact time at room temperature are presented in Fig. 6. Specifically, the curves showed that the amount of Co(II) sorption onto Na2Ti2O5-NTs and H2Ti2O5-NTs increased rapidly in the first 2 h, then the adsorption capacity increased slowly until it basically remain unchanged, and the adsorption process achieved a dynamic equilibrium after 12 h. Hence, in order to ensure that every system could achieve equilibrium, 24 h was fixed as the optimum contact time for the following sorption experiments.

In this study, two classical models, pseudo-first-order and pseudo-second-order models were applied to evaluate the experimental data in order to investigate the kinetics of the sorption process. The integrated and linearized equation forms are given as Eqs. (6) and (7),

where q t (mg/g) is the amount of Co(II) adsorbed per gram of the adsorbent at any time, and k 1 (min−1) and k 2 [g/(mg·min)] are the sorption rate constants of pseudo-first-order and pseudo-second-order sorption, respectively.

The relevant kinetics parameters are shown in Table 2. The conformity between the experimental data and each predicted model was expressed by the correlation coefficient (R2). A higher value of correlation coefficient indicated that the pseudo-second-order model could well describe the adsorption process. The pseudo-second-order equation model assumed that the rate-limiting step is a chemical adsorption that involves exchanging electrons between the adsorbent and adsorbate [39, 40]. Therefore, the fitted results implied that the behavior of Co(II) adsorption on Na2Ti2O5-NTs was controlled by a chemical process. At the same time, the process of Co(II) adsorption on H2Ti2O5-NTs and K2Ti6O13 also occurred though a chemical process.

3.2.3 Effect of initial Co(II) concentration and adsorption isotherm

The adsorption capacity of Co(II) on the adsorbents as a function of different initial cobalt concentrations are shown in Fig. 7. It could be found that the sorption amounts of Co(II) on these materials all increased with the increasing of initial concentration of Co(II). Under the present experimental conditions, the maximum sorption capacity of Co(II) was up to 78.9 mg/g on Na2Ti2O5-NTs, 36.7 mg/g on H2Ti2O5-NTs, and 7.23 mg/g on K2Ti6O13. The result indicated that Na2Ti2O5-NTs had the highest adsorption capacity out of the other two adsorbents. This phenomena might be consistent with the larger surface area would result in higher sorption ability toward ions.

In the meanwhile, compared with the other more inorganic materials listed in Table 3, the as-prepared Na2Ti2O5-NTs showed higher sorption capacity for Co(II).

In our work, the Langmuir and Freundlich isotherm adsorption models, two of the most commonly used models, were also employed to describe the sorption behaviors. The Langmuir isotherm model assumed that the sorption occurs on homogeneous surface by monolayer sorption [50]. The Langmuir adsorption isotherm model is represented as Eq. (8),

where q max (mg/g) is the maximum amount of adsorption Co(II) per unit mass of adsorbent, and K L (L/mg) is the Langmuir affinity constant that represents the affinity between the adsorbent and the adsorbate.With regard to the Freundlich isotherm, the linear equation is expressed by Eq. (9),

where K F [(mg/g)·(L/mg)1/n] is the constant related to the adsorption capacity of the adsorbent, 1/n is the constant related to the adsorption intensity of the adsorbent. The Freundlich isotherms were applicable to adsorption on heterogeneous solid surfaces.

All of the parameters calculated from the linear curves and the determination coefficient are shown in Table 4. The experimental data showed that the Langmuir isotherm (R 2 >0.99) could describe the adsorption of Co(II) better than Freundlich isotherm under our experimental conditions for these adsorbents. The results meant that the sorption of Co(II) on the Na2Ti2O5-NTs, H2Ti2O5-NTs, and K2Ti6O13 were probably a monolayer process. In addition, the maximum adsorption capacity of Co(II) deduced from Langmuir isotherm model onto Na2Ti2O5-NTs was up to 85.25 mg/g, while H2Ti2O5-NTs and K2Ti6O13 were 37.52 mg/g and 11.91 mg/g, respectively.

3.2.4 Effect of temperature and thermodynamic parameters

The effect of temperature on Co(II) sorption onto Na2Ti2O5-NTs, H2Ti2O5-NTs, and K2Ti6O13 are given in Fig. 8. It could be seen that the amounts of Co(II) adsorbed increased gradually with the rising of temperature, and higher temperature was beneficial to the Co(II) sorption process.

The thermodynamic parameters for Co(II) sorption on these adsorbents could be calculated from the temperature dependent sorption process. The change of thermodynamic parameters is obtained using Eq. (10),

where K d (mL/g) is the distribution coefficient, and T (K) and R [8.314 J/(mol K)] are the absolute temperature and the gas constant, respectively. ΔS [J/(mol K)] is the change of entropy, and ΔH (kJ/mol) is the change of enthalpy. The change of Gibbs free energy ΔG (kJ/mol) values is acquired by Eq. (11),

The values of ΔH and ΔS listed in Table 5 were derived from the slope and intercept of the plots of ln K d versus T −1 (Fig. 9). The positive value of ΔH implied that the sorption of Co(II) on Na2Ti2O5-NTs was an endothermic process. The negative value of ΔG revealed that the sorption process was spontaneous under all the experimental conditions. Meanwhile, the result showed that the adsorption of Co(II) onto H2Ti2O5-NTs and K2Ti6O13 was also an endothermic and spontaneous process.

3.2.5 Effect of coexisting cations

Generally, the removal of the targeted metal ions from wastewater may be influenced by other metals ions. To further investigate the selective adsorption capacity of Na2Ti2O5-NTs, H2Ti2O5-NTs, and K2Ti6O13 for Co(II), some alkali metal and alkaline earth metal ions (Na+, K+, Mg2+ and Ca2+) were selected as competitive ions.

In the condition of pH = 7, T = 298 K, C 0[Co(II)] = 10 mg/L, and without the presence of other metal ions, the adsorption capacities of Co(II) were 48.5 mg/g on Na2Ti2O5-NTs, 24.73 mg/g on H2Ti2O5-NTs and 0.8 mg/g on K2Ti6O13. The adsorption capacity of all three absorbents all decreased when the multiple cations (the concentration of added ions: Na+, K+, Mg2+, and Ca2+ were 10 mg/L, respectively) were coexisting in aqueous solution. This is because the adsorption sites of the material will be occupied by Na+, K+, Mg2+, and Ca2+, subject to certain restrictions of Co(II) adsorption, resulting in Co(II) removal decreased. Despite this, the adsorption capacity of Na2Ti2O5-NTs toward Co(II) was still 27.12 mg/g which was much higher than that of H2Ti2O5-NTs and K2Ti6O13.

On the other hand, the adsorption selectivity was described in this multiple cations coexisting system. As shown in Fig. 10, Co(II) could be absorbed more on Na2Ti2O5-NTs and H2Ti2O5-NTs than other cations. Under the condition of multiple ions coexisting in the same concentration, the adsorption capacity of Co(II) by Na2Ti2O5-NTs and H2Ti2O5-NTs were 27.12 mg/g and 15.34 mg/g, and accounted for 53.24 % and 41.18 % of their total adsorption quantity, respectively. The experimental results suggested that Na2Ti2O5-NTs has a higher adsorption selectivity for Co(II) than H2Ti2O5-NTs and K2Ti6O13 materials.

4 Conclusion

In the present study, we chose the titanium foil as a template to synthesize Na2Ti2O5-NTs by hydrothermal method and investigated the adsorption behavior of Co(II) on this material. The Na2Ti2O5-NTs with uniform microstructures and large surface area showed high sorption capacity toward cobalt. The maximum adsorption capacity of Co(II) on Na2Ti2O5-NTs was 85.25 mg/g, indicating that Na2Ti2O5-NTs were obviously more competitive than H2Ti2O5-NTs and K2Ti6O13. Additionally, the adsorption behavior of Co(II) on Na2Ti2O5-NTs could be described well by pseudo-second-order kinetic model (R2 >0.99) and the Langmuir isotherm model (R2 >0.99), indicating that the adsorption process may be a chemical and monolayer adsorption. The adsorption of Co(II) on Na2Ti2O5-NTs was an endothermic and spontaneous process which becomes more favorable at higher temperature. Meanwhile, the selectivity and capacity of the Na2Ti2O5-NTs for Co(II) uptake were higher than H2Ti2O5-NTs and K2Ti6O13. In summary, the results demonstrated that Na2Ti2O5-NTs is a promising material for Co(II)/60Co removal from aqueous solution.

References

E. Hernández-Barrales, F. Granados-Correa, Sorption of radioactive cobalt in natural Mexican clinoptilolite. J. Radioanal. Nucl. Chem. (1999). doi:10.1007/BF02345901

J.S. Kim, M.A. Keane, The removal of iron and cobalt from aqueous solutions by ion exchange with Na-Y zeolite: batch, semi-batch and continuous operation. J. Chem. Technol. Biotechnol. (2002). doi:10.1002/jctb.618

S. Rengaraj, S.H. Moon, Kinetics of adsorption of Co (II) removal from water and wastewater by ion exchange resins. Water Res. (2002). doi:10.1016/S0043-1354(01)00380-3

B. Ma, S. Oh, W.S. Shin et al., Removal of Co2 + , Sr2 + and Cs + from aqueous solution by phosphate-modified montmorillonite (PMM). Desalination (2011). doi:10.1016/j.desal.2011.03.072

P.H. Tewari, A.B. Campbell, W. Lee, Adsorption of Co2 + by oxides from aqueous solution. Can. J. Chem. (1972). doi:10.1139/v72-263

A. Malekpour, M. Edrisi, S. Hajialigol et al., Solid phase extraction–inductively coupled plasma spectrometry for adsorption of Co (II) and Ni (II) from radioactive wastewaters by natural and modified zeolites. J. Radioanal. Nucl. Chem. (2011). doi:10.1007/s10967-011-1013-2

M.Y. He, Y. Zhu, Y. Yang et al., Adsorption of cobalt (II) ions from aqueous solutions by palygorskite. Appl. Clay Sci. (2011). doi:10.1016/j.clay.2011.09.013

Y.V. Hete, S.B. Gholase, R.U. Khope, Adsorption study of cobalt on treated granular activated carbon. J. Chem. (2012). doi:10.1155/2012/472517

F. Granados-Correa, S. Bulbulian, Co (II) adsorption in aqueous media by a synthetic Fe–Mn binary oxide adsorbent. Water Air Soil Pollut. (2012). doi:10.1007/s11270-012-1175-8

S. Wang, L.Q. Tan, J.L. Jiang et al., Preparation and characterization of nanosized TiO2 powder as an inorganic adsorbent for aqueous radionuclide Co (II) ions. J. Radioanal. Nucl. Chem. (2013). doi:10.1007/s10967-012-2296-7

D. Gogoi, A.G. Shanmugamani, S.V.S. Rao et al., Studies on adsorptive removal of radioactive cobalt from alkaline waste generated in sodium cooled fast breeder reactors. J. Radioanal. Nucl. Chem. (2013). doi:10.1007/s10967-012-2291-z

Z.J. Liu, L. Chen, Z.C. Zhang et al., Synthesis of multi-walled carbon nanotube–hydroxyapatite composites and its application in the sorption of Co (II) from aqueous solutions. J. Mol. Liq. (2013). doi:10.1016/j.molliq.2012.12.011

K.R. Kim, K.J. Lee, J.H. Bae, Characteristics of Cobalt Adsorption on Prepared TiO2 and Fe-Ti-O Adsorbents in High Temperature Water. Sep. Sci. Technol. (1995). doi:10.1080/01496399508015410

W.Z. Xu, S.T. Chen, C.X. Li et al., Study on the adsorption behavior of potassium hexatitanate whisker to cobalt. Metall. Anal. (2009). doi:10.13228/j.issn.1000-7571.2009.06.007

S. Thennarasu, K. Rajasekar, K.B. Ameen, Hydrothermal temperature as a morphological control factor: preparation, characterization and photocatalytic activity of titanate nanotubes and nanoribbons. J. Mol. Struct. (2013). doi:10.1016/j.molstruc.2013.06.064

Z.H. Li, Z.Q. Liu, Q.Z. Yan et al., Preparation and performance of titanate nanotube by hydrothermal treatment. Rare Metals (2008). doi:10.1016/S1001-0521(08)60112-6

S. Sreekantan, L.C. Wei, Study on the formation and photocatalytic activity of titanate nanotubes synthesized via hydrothermal method. J. Alloy. Compd. (2010). doi:10.1016/S1001-0521(08)60112-6

C.K. Lee, K.S. Lin, C.F. Wu et al., Effects of synthesis temperature on the microstructures and basic dyes adsorption of titanate nanotubes. J. Hazard. Mater. (2008). doi:10.1016/j.jhazmat.2007.04.129

H.Y. Niu, J.M. Wang, Y.L. Shi et al., Adsorption behavior of arsenic onto protonated titanate nanotubes prepared via hydrothermal method. Microporous Mesoporous Mater. (2009). doi:10.1016/j.micromeso.2009.02.005

S.S. Liu, C.K. Lee, H.C. Chen et al., Application of titanate nanotubes for Cu (II) ions adsorptive removal from aqueous solution. J. Chem. Eng. (2009). doi:10.1016/j.cej.2008.06.034

G.D. Sheng, S.T. Yang, D.L. Zhao et al., Adsorption of Eu(III) on titanate nanotubes studied by a combination of batch and EXAFS technique. Sci. China Chem. (2012). doi:10.1007/s11426-011-4370-3

Y.C. Chen, S.L. Lo, J. Kuo, Pb(II) adsorption capacity and behavior of titanate nanotubes made by microwave hydrothermal method. Coll. Surf. A (2010). doi:10.1016/j.colsurfa.2010.03.017

T. Wang, W. Liu, L. Xiong et al., Influence of pH, ionic strength and humic acid on competitive adsorption of Pb(II), Cd (II) and Cr(III) onto titanate nanotubes. J. Chem. Eng. (2013). doi:10.1016/j.cej.2012.11.029

J.L. Liu, M.B. Luo, Z.Z. Yuan et al., Synthesis, characterization, and application of titanate nanotubes for Th(IV) adsorption. J. Radioanal. Nucl. Chem. (2013). doi:10.1007/s10967-013-2607-7

M. Yada, Y. Inoue, M. Uota et al., Plate, wire, mesh, microsphere, and microtube composed of sodium titanate nanotubes on a titanium metal template. Langmuir (2007). doi:10.1021/la062654c

Y.P. Guo, N.H. Lee, H.J. Oh et al., Structure-tunable synthesis of titanate nanotube thin films via a simple hydrothermal process. Nanotechnology (2007). doi:10.1088/0957-4484/18/29/295608

N. Xiao, Z.H. Li, J.W. Liu et al., Effects of calcination temperature on the morphology, structure and photocatalytic activity of titanate nanotube thin films. Thin Sol. Film. (2010). doi:10.1016/j.tsf.2010.07.120

Z.R. Tian, J.A. Voigt, J. Liu et al., Large oriented arrays and continuous films of TiO2-based nanotubes. J. Am. Chem. Soc. (2003). doi:10.1021/ja0369461

L.Y. Zheng, H.Y. Shi, Study on the Adsorption of Cobalt Titanate Nanotubes. Guangzhou Chem. Ind. (2013). doi:10.3969/j.issn.1001-9677.2013.08.037

C.Y. Liu, H.B. Yin, Y.M. Liu et al., Synthesis of potassium hexatitanate whiskers starting from metatitanic acid and potassium carbonate and sulfate by calcination method. Mater. Res. Bull. (2009). doi:10.1016/j.materresbull.2008.09.038

H.S. Klooster, NITROSO R-SALT, A NEW REAGENT FOR THE DETECTION OF COBALT. J. Am. Chem. Soc. (1921). doi:10.1021/ja01437a007

M. Qamar, C.R. Yoon, H.J. Oh et al., Effect of post treatments on the structure and thermal stability of titanate nanotubes. Nanotechnology (2006). doi:10.1088/0957-4484/17/24/004

C.K. Lee, C.C. Wang, M.D. Lyu et al., Effects of sodium content and calcination temperature on the morphology, structure and photocatalytic activity of nanotubular titanates. J. Coll. Interface Sci. (2007). doi:10.1016/j.jcis.2007.08.008

A. Arifi, H.A. Hanafi, Adsorption of cesium, thallium, strontium and cobalt radionuclides using activated carbon. J. At. Mol. Sci. (2010). doi:10.4208/jams.100809.112309a

X.M. Ren, J.X. Li, X.L. Tan et al., Comparative study of graphene oxide, activated carbon and carbon nanotubes as adsorbents for copper decontamination. Dalton Trans. (2013). doi:10.1039/C3DT32969K

F. Granados, V. Bertin, S. Bulbulian et al., 60 Co aqueous speciation and pH effect on the adsorption behavior on inorganic materials. Appl. Radiat. Isot. (2006). doi:10.1016/j.apradiso.2005.06.016

Q. Chen, L.M. Peng, Structure and applications of titanate and related nanostructures. Int. J. Nanotech. (2007). doi:10.1504/IJNT.2007.012314

Q. Su, B.C. Pan, B.J. Pan et al., Fabrication of polymer-supported nanosized hydrous manganese dioxide (HMO) for enhanced lead removal from waters. Sci. Total Environ. (2009). doi:10.1016/j.scitotenv.2009.06.045

Y.S. Ho, Review of second-order models for adsorption systems. J. Hazard. Mater. (2006). doi:10.1016/j.jhazmat.2005.12.043

Y.S. Ho, G. McKay, Sorption of dyes and copper ions onto biosorbents. Process Biochem. (2003). doi:10.1016/S0032-9592(02)00239-X

L. Tan, Y. Jin, J. Chen et al., Sorption of radiocobalt (II) from aqueous solutions to Na-attapulgite. J. Radioanal. Nucl. Chem. (2011). doi:10.1007/s10967-011-1121-z

K.G. Bhattacharyya, S.S. Gupta, Adsorption of Fe(III), Co (II) and Ni (II) on ZrO–kaolinite and ZrO–montmorillonite surfaces in aqueous medium. Coll. surf. A. (2008). doi:10.1016/j.colsurfa.2007.09.037

L. Chen, Y. Huang, L. Huang et al., Characterization of Co (II) removal from aqueous solution using bentonite/iron oxide magnetic composites. J. Radioanal. Nucl. Chem. (2011). doi:10.1007/s10967-011-1337-y

K. Li, Z. Liu, T. Wen et al., Sorption of radiocobalt (II) onto Ca-montmorillonite: effect of contact time, solid content, pH, ionic strength and temperature. J. Radioanal. Nucl. Chem. (2012). doi:10.1007/s10967-011-1400-8

N.N. Nassar, Kinetics, equilibrium and thermodynamic studies on the adsorptive removal of nickel, cadmium and cobalt from wastewater by superparamagnetic iron oxide nanoadsorbents. Can. J. Chem. Eng. (2012). doi:10.1002/cjce.20613

M. Liu, C. Chen, J. Hu et al., Synthesis of magnetite/graphene oxide composite and application for cobalt (II) removal. J. Phys. Chem. C (2011). doi:10.1021/jp208575m

D. Gogoi, A.G. Shanmugamani, S.V.S. Rao et al., Studies on removal of cobalt from an alkaline waste using synthetic calcium hydroxyapatite. J. Radioanal. Nucl. Chem. (2013). doi:10.1007/s10967-012-2378-6

Z.Q. Guo, Y. Li, S.W. Zhang et al., Enhanced sorption of radiocobalt from water by Bi(III) modified montmorillonite: a novel adsorbent. J. Hazard. Mater. (2011). doi:10.1016/j.jhazmat.2011.05.004

D.M. Manohar, B.F. Noeline, T.S. Anirudhan, Adsorption performance of Al-pillared bentonite clay for the removal of cobalt (II) from aqueous phase. Appl. Clay Sci. (2006). doi:10.1016/j.clay.2005.08.008

I. Langmuir, The adsorption of gases on plane surfaces of glass, mica and platinum. J. Am. Chem. Soc. (1918). doi:10.1021/ja02242a004

Acknowledgments

Some samples were measured by ICP-OES which was provided by the Institute of Chemistry, Sichuan University.

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was supported by the Applied Basic Research Programs Funded Project of Sichuan Province (No 2012JY0100), National Natural Science Foundation and China Academy of Engineering Physics joint fund (No U1330125) and the National Fund of China for Fostering Talents in Basic Science (J1210004).

Rights and permissions

About this article

Cite this article

Li, DM., Li, FZ., Liao, JL. et al. Efficient removal of Co(II) from aqueous solution by titanate sodium nanotubes. NUCL SCI TECH 27, 143 (2016). https://doi.org/10.1007/s41365-016-0135-1

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41365-016-0135-1