Abstract

The aim of this work is to evaluate an effective filtration technique for residual organic pollutants and heavy metals removal using two types of sand rich in iron oxide as a massive filter (sieved and gross sand). X-ray diffraction, X-ray fluorescence (XRF), scanning electron microscopy, energy dispersive spectroscopy (EDS) and specific surface area BET were investigated to characterize the sand. Experimental results showed that the BOD5 removal was found to be 93% for gross sand (GS) and 96% for sieved sand (SS). The COD removal was equal to 98.9 and 99.7% for GS and SS, respectively. The hydrogen bonding, complexation/precipitation process, ions exchanges and electrostatic interactions are the main phenomena proposed to describe residual organic pollutants removal. For heavy metals adsorption, results show a great efficiency removal between 90 and 100% for both cases. The adsorption mechanism was proposed based on zero-point charge, FTIR analysis, fluorescence (XRF) and EDS. The fixation of heavy metals onto the sand could be referred to hydrogen bonding, electrostatic interaction, ion exchange and electron donor–acceptors.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Increased urbanization and population growth have resulted in an increase in water requirements, which has resulted in excessive use of water resources with a large volume of pollutants. Moreover, wastewater becomes an important source of pollution and a major human health problem (Chaves et al. 2016; Ellis and Butler 2015; Miao et al. 2015).

In recent years, several environmental problems were observed as a result of water contamination by organic and inorganic pollutants characterized by their persistence, toxicity and bioaccumulation capacity. Therefore, they must be removed before being discharged into a receiver medium (Albishri and Mahmoud 2013; Ji et al. 2012; Gebru and Das 2017; Karnib et al. 2014; Tunali et al. 2006; Liu et al. 2013; Shannon et al. 2008). Heavy metals are the most common environmental water pollutants and pose a potentially carcinogenic risk to humans, such as anemia, nervous system deterioration, failure of kidneys, and DNA-protein cross-linkage leading to cancer of the kidneys, liver and gastric tract (An et al. 2001; Chaudhry et al. 2016a, 2017a; Yan and Viraraghavan 2003; Inglezakis et al. 2002). Unlike organic pollutant waste, heavy metals are characterized by a long-term persistence and high non-biodegradability (O’Carroll et al. 2013; Jiang et al. 2010; Hongjie et al. 2009; Zhong et al. 2014). For these reasons, effective elimination of organic pollutants and inorganic pollutants has become an important issue today (Gaikwad 2004; Uzun and Güzel 2000).

Today, innovative and cost-effective solutions to wastewater treatment and wastewater reutilization with new materials and techniques become a priority (Ding et al. 2014). Iron oxide sand filtration can be an effective innovative technique to solve these problems. A number of papers have used different types of sand rich in iron oxide such as sand coated with iron oxide modified with sulfate (Vaishya and Gupta 2005), iron impregnated quartz sand (IIS) (Vaishya and Gupta 2003), Ce(IV) doped iron oxide (Zhang et al. 2003), silica-containing iron(III) oxide (Zeng 2003), iron-oxide-coated polymeric materials (Katsoyiannis and Zouboulis 2002) and iron oxide coated sand (Gupta et al. 2005), iron-zirconium oxide-coated sand (Chaudhry et al. 2017b; Chaudhry and Khan 2017), iron oxide activated red mud (Khan et al. 2015), and zirconium oxide-coated marine sand (Khan et al. 2013). Various techniques have been explored to remove heavy metals and organic pollutants from wastewater such as electrocoagulation (Adhoum et al. 2004; Hanay and Hasar 2011; Heidmann and Calmano 2008; Kabdasli et al. 2009), ion exchange (Sapari et al. 1996), precipitation, adsorption (Chen and Wang 2000; Siddiqui and Chaudhry 2017), and ion exchange-assisted membrane separation (Dzyazko and Belyakov 2004; Vasilyuk et al. 2004). Among these techniques, filtration using sand is an innovative method for treating water contaminated by toxic pollutants. The simplicity, low energy consumption and relatively low operational costs make sand filtration one of the most common pretreatments currently used in large installations (Bar-Zeev et al. 2012).

Sand filtration is an efficient process which can be used for wastewater treatment (Al-Jlil 2009; Liu et al. 2003). It displays two roles: (1) adsorption of heavy metals and the fixation of the biomass, which could be developed on the grains of sand and (2) the biodegradation of the organic matter (Hua et al. 2003; Weber-Shirk 2002).

In this study, sand filtration and the adsorption process were used to remove organic pollutants and heavy metals (Cr, Pb and Cu) using a new type of sand rich in iron oxide (also, called black sand). This type of sand is distributed in some places located close to estuaries by the Atlantic Ocean: Oum Er-Rbia, Tensift, Massa and Souss (Agadir). The sand comes from mechanical decomposition of the hercynian eruptive rocks of the Triassic basalts located upstream. Effects of key parameters and fixation mechanism were investigated to study both processes.

Materials and methods

The study was carried out using industrial effluent coming from the Tassila industrial zone in Agadir-Morocco as a wastewater model. All samples were collected in polyethylene bottles with a volume of 20 L. Physicochemical analyses [pH, conductivity, turbidity, biological oxygen demand for 5 days (BOD5), chemical oxygen demand (COD) and heavy metals] are normalized following the Moroccan norms, similar to the French AFNOR standards.

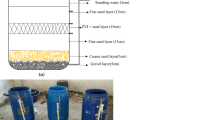

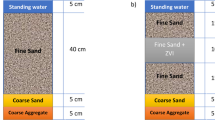

The pilot-scale filter

Figure 1 shows the pilot scale filter with a 2 m-high column and 20 cm in diameter. The two columns used in our study are filled with two types of RSIO (GS and SS). A layer of 15 cm of the same gravel was placed under the layer of sand in order to avoid the transport of the sand particles. The lower end of the column consists of a perforated plate allowing the flow of treated wastewater. The active layer (2 m) is composed of black sand.

Characterization techniques

The morphology and elemental composition of the samples were observed using a scanning electron microscope (SEM) equipped with a dispersive X-ray spectrometer (EDX). The crystal structure of the samples was characterized by an X-ray powder diffractometer. The molecular structure was analyzed by a Fourier transform infrared (FTIR) spectrometer. The Brunauer–Emmett–Teller surface measurements (BET) were carried out on a Micromeritics ASAP 2020M surface analyzer. X-ray fluorescence analysis (XRF) was performed on a wavelength dispersion spectrometer—Type Axios. COD and BOD5 measurements were detected, respectively, by a COD photometer (MD 200) and BOD meter (oxy-direct). Heavy metal ion concentrations were detected by AA-7000 graphite furnace atomic absorption spectrometry.

Experimental studies

The temperature and pH measurements were carried out by multimeter ASWA AD 1030 pH/mV. The conductivity measurement is determined using a CONS800 C864 multiparameter. Measurement of turbidity is determined by the standard THERMO Scientific ORION AQ4500 digital turbidimeter.

To measure the chemical oxygen demand, disposable tubes with integrated reagents were used; the principle consists in oxidizing the organic matter with a standard solution of potassium dichromate in the presence of sulfuric acid, to accelerate the oxidation of certain organic compounds. Silver sulphate was used as a catalyst. It should be noted that low concentrations were determined using tubes designed for the range of 3–150 mgO2/L, for high concentrations, the tubes between 20 and 1500 mgO2/L were used. The BOD measurement is carried out in a sample flask with a BOD sensor in a closed system. The BOD value is in mgO2/L.

In this study, we tested the removal efficiency of heavy metals Cr, Pb and Cu through the filtration process by sand rich in iron oxide. Whatman filter paper was used to filter the raw and treated samples for heavy metals analysis.

To avoid metal precipitation and biological growth, a few drops of concentrated nitric acid were added to the samples to obtain pH 2 (Assubaie 2015), then the samples were stored at 4 °C for analysis using AA-7000 graphite furnace atomic absorption spectrometry. Table 1 shows the concentrations of heavy metals [Cr(II), Pb(II), Cu(II)], at the input pilot system filled with RSIO.

Results and discussion

Characterization

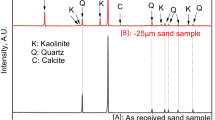

SEM/EDS/XDR and XRF analysis

Figure 2 shows the XRD pattern of both types of sand rich in iron oxide. The following compounds (Fe2O3, TiO2, SiO2 and ZrO2) were observed. The identification of the phase obtained is made by comparing experimental and reference data (JCPDS file). According to XRD analysis, the most intense peak of Fe2O3 was located at 2θ = 33.4, which is more intense in the SS compared with GS, and confirmed the results obtained by X-ray fluorescence (Table 2) (73.1% in GS and 80.4 in SS). For the other oxides (TiO2: 2θ = 49.8, SiO2: 2θ = 50.2, ZrO2: 2θ = 35.8) the same data was observed. The diminishment of XRD pattern intensity might be due to the oxide particles over the surface of the sand (Guo et al. 2012).

The sand images of scanning electron microscopy confirmed the texture of the sand particles (Fig. 3). The sand grains have a smooth surface with minor roughness. The irregular structured oxide particles on the surface of the sand created the morphology and made the material porous. These properties of surface make the sand a good amorphous material which can be used for the elimination of heavy metals in wastewater.

EDS analysis made it possible to observe the increase in the weight percentage of iron oxides and zirconium oxide from 73.1% (GS) to 80.4% (SS) and 2.83% (GS) to 5.1% (SS), respectively. Moreover, a decrease was found in the weight percentage of titanium and silicon 11.4–4.99% and 8.1–2.79% for GS and SS, respectively. These results have been confirmed by the fluorescence characterization technique (XRF).

FTIR

Figure 4 shows the FTIR spectrum of the main peaks which characterize the GS and SS. From Fig. 4, a wideband was observed at 3434 cm−1, related to hydroxyl elongation (–OH) (Abbasizadeh et al. 2013; Ba-Abbad et al. 2012). The bands observed at 2924 and 2854 cm−1 correspond to the asymmetric CH2 stretching vibration. The band at 1634 cm−1 was assigned to the vibration in the plane of the backbone of the aromatic cycle. The peaks located at 1464 and 1384 cm−1 were, respectively, associated with asymmetric and symmetric deviation CH3 vibrations (Maira et al. 2001). The peak characteristic of Si–O elongation, the flexion, and the rotation modes are observed at 1034, 545 and 464 cm−1, respectively (Bange et al. 2008; Hofman et al. 1996; Ma et al. 2003). The peaks between 800 and 450 cm−1 were attributed to the elongation of the Ti–O bands (Ba-Abbad et al. 2012; Bagheri et al. 2012). The peaks between 821 and 569 cm−1 are due to the stretching vibration of the (Al–O) connection (Fe–O) (Imtiaz et al. 2013). Finally, the peaks between 800 and 520 cm−1 are attributed to the elongation modes of (Zr–O) (Altass and Abd El Rahman 2016).

BET and zero-point charge of the two types of sand

Table 3 shows the specific surface area of both types of sand. The value of BET surface area is 0.884 m2 g−1 for the gross sand (GS) and 0.4229 m2 g−1 for the sieved sand (SS). As shown in Fig. 5 the point charge zero of the sand was determined by measuring the initial pH, and the final pH [potassium nitrate solution (0.1 M) was used with 0.1 g of sand]. The ratio of the initial pH and the final pH solution intersected at a point called a zero-point charge found at pH 6.83 for the gross sand (GS) and 7.9 for the sieved sand (SS) (Chaudhry et al. 2016b).

Heavy metals removal

Table 1S shows the results recorded in the output of the pilot system filled with gross sand. We observe that the average percentage of Cr(II), Pb(II) and Cu(II) elimination was reached, respectively, namely 99.7, 98.5 and 85.1%. For the pilot system filled with sieved sand as shown in Table 2S, the average percentage of elimination of Cr(II), Pb(II) and Cu(II) reached 95.9, 95.7 and 85.3%, respectively.

Monitoring heavy metals (Cr, Pb and Cu) show that the retention of heavy metals by RSIO is almost total. However, the presence of iron oxides in the sand affects significantly the mobility of heavy metals. Also, the presence of the element is involved in the maintenance of many metals (Benjamin et al. 1996), including the role of organic matter in the fixation of a major portion of trace metals. These elements are identified by X-ray fluorescence technique.

The fixing of heavy metals can have a toxic effect on sand microbial processes. However, many microorganisms are capable of developing a resistance strategy to heavy metals. The microorganisms can play a role in the mobilization of metals, and they can affect their bioavailability by fixing elements and release them, breaking down organic matter (Herman et al. 1995). Generally, there are two mechanisms for heavy metals adsorption, including specific adsorption and non-specific adsorption. Specific adsorption is a less reversible reaction, and happens slowly. Non-specific adsorption (or ion exchange) is reversible and occurs quite quickly (Xing et al. 2011).

Many studies have found that heavy metals can be removed by soils (Awan et al. 2003; Jiang et al. 2010). Accordingly, soils are natural materials that play a role in treating wastewater, before the heavy metals seep into groundwater, or flow into other areas or rivers. The most important process affecting the behaviors of heavy metals in soil is the adsorption of metals from liquid phase into their solid phase (Echeverria et al. 1998; Srivastava et al. 2005).

Results showed that the GS was performed for Cr(II), Pb(II) and Cu(II) removal compared with SS, which is explained by the higher elements percentages in the GS than in the SS.

The results found in this study show a high efficiency of elimination of heavy metals, which is in accord with other reported studies, for which the types of the same sand were used (Aba-aaki et al. 2013, 2014).

Possible mechanisms of heavy metals removal onto sand rich in iron oxide

Figure 6 shows possible mechanisms of heavy metals removal onto sand rich in iron oxide. The RSIO contains different functional groups (–OH, Fe–O, Al–O, Si–O, Ti–O), and different oxides (Fe2O3, TiO2, SiO2…), which are detected by the FTIR analysis, fluorescence (XRF) and EDS. Therefore, we propose a mechanism based on:

-

The interactions between the functional groups on the surface of the RSIO and heavy metals, especially the interaction mechanism between –OH and Cu(II), Cr(II), Pb(II) (Ait Ahsainea et al. 2017).

-

Another possibility is that Cu(II), Cr(II) and Pb(II) could be retained through ions exchanges on the sand surface (Xing et al. 2011).

-

According to the zero-point charge of the sand, the adsorption mechanism referred to electrostatic interaction. (Anfar et al. 2017; Zbair et al. 2018).

-

According to the results of FTIR analysis and fluorescence (XRF), Metal-O functional and Fe2O3, TiO2, SiO2 oxides may participate in the complexing and precipitation process of heavy metals onto sand (Benjamin et al. 1996).

-

Other biological interactions (Herman et al. 1995).

pH turbidity and conductivity parameters

-

As shown in Fig. 7a, the pH of the sewage fixed at the inlet of the column varies between 5.69 and 7.19 with an average value of 6.45. The pH of the treated water with gross sand varied between 7.62 and 8.10 with an average value of 7.87, and between 7.51 and 7.95, for water treated with sieved sand.

-

As shown in Table 3S, the turbidity values vary between 100 and 300 NTU in the sewers installed at the inlet of the column and between 0.86 and 4.37 NTU for water treated with gross sieved sand. Concerning the water treated by sieved sand, it takes values between 2.07 and 5.92 NTU.

-

As shown in Fig. 7b, the conductivity of the sewage varies between 2142 and 4978 μS/cm, and that of gross sand treated water between 1967 and 4647 μS/cm, whereas for water treated with sieved sand it changes between 1327 and 4337 μS/cm.

Our filtration system based on the use of RSIO shows more effective and stable wastewater treatment results than other soil-based systems such as wetland systems or compact filtration systems. According to the recorded results of pH, it is observed that the pH increases after filtration by the two types of sand rich in iron oxide, and this can be explained by the alkalinity of our sand (Achak et al. 2011; Mekki et al. 2007). Most suspended solids are removed after the raw sewage has drained onto the gravel pack by sand. This is mainly due to physical processes (filtration and sedimentation) and sieving in the gravel packet (Abissy and Mandi 1999). The average conductivity of the water treated by the two types of RSIO decreases after infiltration. These average values are in agreement with the Moroccan surface water standards (< 2700 μs/cm). This is due to the high content of ionic constituents present in our studied sand.

COD and BOD5 parameters

Chemical oxygen demand results indicate that the concentration of this parameter for wastewater entering the pilot system fluctuates between 6130 and 33,000 mgO2/L with an average value of 16,731 mgO2/L (Table 3S). As shown in Table 3S, the COD concentrations measured at the outlet was ranged from 31 to 178 mgO2/L with an average of 105 mgO2/L, and from 9 to 70 mgO2/L with an average of 41 mgO2/L for gross sand and sieved sand, respectively. Figure 8 shows the percentage reduction of COD in gross sand varies between 97.4 and 99.9% with an average reduction of 98.9% and the percentage of COD reduction in sieved sand changes between 98.7 and 99.9% with an average reduction of 99.7%.

Concerning biological oxygen demand BOD5, the concentration of wastewater used at the entry of the pilot system changes between 229 and 368 mgO2/L with an average value of 285 mgO2/L (Table 3S). The BOD5 concentrations measured at the outlet when using gross sand vary from 17 to 23 mgO2/L with an average value of 19 mgO2/L (Table 3S), and the reduction percentage of BOD5 which fluctuates between 90 and 95.4% with an average reduction 93.1% of BOD5 (Fig. 1S). The concentrations of BOD5 measured at the outlet from the sieved sand go from 6 to 16 mgO2/L with an average value of 11 mgO2/L (Table 3S), and the reduction percentage of BOD5 which varies between 94.4 and 98% with an average reduction of 96.1% of BOD5 (Fig. 1S).

The concentrations of COD and BOD5 measured during treatment with gross sand were lower than those measured with sieved sand rich in iron oxide. The pilot system operates fully under aerobic/anaerobic conditions. The reduction of oxygen between the inlet and the outlet made it possible to check the presence of active microorganisms (Casas and Bester 2015). Reduction of organic pollutants is achieved by biodegradation (Chen et al. 2009; Latrach et al. 2016; Luanmanee et al. 2002). The rate of removal of organic pollutants by the system has shown significant retention. This is linked to better oxygenation at the surface of the pilot system, enabling aerobic bacteria to ensure better mineralization and oxidation of organic pollution (Polprasert et al. 1996), and thus the physical retention of organic pollutants in sand iron oxide (Abissy and Mandi 1999).

The results recorded for the treatment of organic pollution by sand rich in iron oxide used in this study present a better elimination capacity compared with the type of sand already used by the percolation infiltration process (Et-taleb et al. 2014).

Conclusion

The use of two types of rich sand in iron oxide (RSIO) as a massive filter for wastewater treatment has demonstrated its effectiveness on a pilot scale to remove heavy metals and organic pollutants from industrial wastewater. The results obtained in terms of physicochemical analyses of treated wastewater show a good reduction of the organic load (COD: 98.9% and BOD5: 93.1%) by the GS and (COD: 99.7% and BOD5: 96.1%) by SS. The results obtained for heavy metals removal show an improved performance: 99.7% [Cr(II)), 98.5% (Pb(II)), 85.1% (Cu(II)) for GS and 95.9% (Cr(II)), 95.7% (Pb(II)], 85.3% (Cu(II)) for SS. These values are in line with the Moroccan water standards used for irrigation. According to FTIR, XRD and EDS, a possible mechanism of heavy metals removal onto sand rich in iron oxide was proposed, referring to:

-

Interactions between hydrogen bonding functions (OH–) and Cu(II), Cr(II), Pb(II).

-

Ion exchange process.

-

Electrostatic interaction.

-

Complexation and precipitation process.

-

Other biological interactions.

Sand filtration showed a major efficiency for industrial wastewater depollution, in particular, the removal of micro-pollutants (heavy metals). This study confirms the ability and efficiency of RSIO for the removal of heavy metals and organic pollutants from industrial wastewater samples.

References

Aba-aaki R, Ez-zahery M, Et-taleb S, El Haouti R, Hamma MS, El Alem N (2013) Retention of heavy metals (Pb, Cd, Cr and Zn) by a sand area of Agadir: equilibrium and kinetic. MATEC Web of Conferences 5, 04020. https://doi.org/10.1051/matecconf/20130504020

Aba-aaki R, Ez-zahery M, Et-Taleb S, El haouti R, Bousskri A, Abbaz M, Lhanafi S, El Alem N (2014) Monitoring of heavy metals (Cd, Pb, Cr and Zn) of industrial wastewater by the process of infiltration percolation (Case of Sand of M’Zar and Sand of Oued Souss). Moroc J Chem 2(5):494–501

Abbasizadeh S, Keshtkar AR, Mousavian MA (2013) Preparation of a novel electrospun polyvinyl alcohol/titanium oxide nanofiber adsorbent modified with mercapto groups for uranium(VI) and thorium(IV) removal from aqueous solution. Chem Eng J 220:161–171

Abissy M, Mandi L (1999) The use of rooted aquatic plants for urban wastewater treatment: case of Arundo donax. J Water Sci 12(2):285–315

Achak M, Ouazzani N, Mandi L (2011) Elimination des polluants organiques des effluents de l’industrie oléicole par combinaison d’un filtre à sable et un lit planté. J Water Sci 24(1):35–51

Adhoum N, Monser L, Bellakhal N, Belgaied JE (2004) Treatment of electroplating wastewater containing Cu2+, Zn2+ and Cr(VI) by electrocoagulation. J Hazard Mater 112(3):207–213

Ahsainea HA, Zbairb M, El Haouti R (2017) Mesoporous treated sewage sludge as outstanding low-cost adsorbent for cadmium removal. Desalination Water Treat 85:330–338

Albishri HM, Mahmoud ME (2013) Solid-phase removal of dissolved organic species from water and identification by GC–MS. CLEAN Soil Air Water 41(8):773–779

Al-Jlil SA (2009) COD and BOD reduction of domestic wastewater using activated sludge, sand filters and activated carbon in Saudi Arabia. Biotechnology 8(4):473–477

Altass HM, Abd El Rahman SK (2016) Surface and catalytic properties of triflic acid supported zirconia: effect of zirconia tetragonal phase. J Mol Catal A Chem 411:138–145

An HK, Park BY, Kim DS (2001) Crab shell for the removal of heavy metals from aqueous solution. Water Res 35(15):3551–3556

Anfar Z, El Haouti R, Lhanafi S, Benafqir M, Azougarh Y, El Alem N (2017) Treated digested residue during anaerobic co-digestion of Agri-food organic waste: methylene blue adsorption, mechanism and CCD-RSM design. J Environ Chem Eng 5:5857–5867

Assubaie FN (2015) Assessment of the levels of some heavy metals in water in Alahsa Oasis farms, Saudi Arabia, with analysis by atomic absorption spectrophotometry. Arab J Chem 8(2):240–245

Awan MA, Qazi IA, Khalid I (2003) Removal of heavy metals through adsorption using sand. J Environ Sci 15(3):413–416

Ba-Abbad MM, Kadhum AAH, Mohamad AB, Takriff MS, Sopian K (2012) Synthesis and catalytic activity of TiO2 nanoparticles for photochemical oxidation of concentrated chlorophenols under direct solar radiation. Int J Electrochem Sci 7:4871–4888

Bagheri S, Shameli K, Abd Hamid SB (2012) Synthesis and characterization of anatase titanium dioxide nanoparticles using egg white solution via Sol–Gel method. J Chem 2013:1–5

Bange JP, Patil LS, Gautam DK (2008) Growth and characterization of SiO2 films deposited by flame hydrolysis deposition system for photonic device application. Prog Electromagn Res 3:165–175

Bar-Zeev E, Belkin N, Liberman B, Berman T, Berman-Frank I (2012) Rapid sand filtration pretreatment for SWRO: microbial maturation dynamics and filtration efficiency of organic matter. Desalination 286:120–130

Benjamin MM, Sletten RS, Bailey RP, Bennett T (1996) Sorption and filtration of metals using iron-oxide-coated sand. Water Res 30(11):2609–2620

Casas ME, Bester K (2015) Can those organic micro-pollutants that are recalcitrant in activated sludge treatment be removed from wastewater by biofilm reactors (slow sand filters)? Sci Total Environ 506:315–322

Chaudhry SA, Khan TA (2017) Zirconium oxide-coated sand based batch and column adsorptive removal of arsenic from water: isotherm, kinetic and thermodynamic studies. Egypt J Petrol 26:553–563

Chaudhry SA, Khan TA, Ali I (2016a) Adsorptive removal of Pb(II) and Zn(II) from water onto manganese oxide-coated sand: isotherm, thermodynamic and kinetic studies. Egypt J Basic Appl Sci 3(3):287–300

Chaudhry SA, Ahmed M, Siddiqui SI, Ahmed S (2016b) Fe(III)–Sn(IV) mixed binary oxide-coated sand preparation and its use for the removal of As(III) and As(V) from water: application of isotherm, kinetic and thermodynamics. J Mol Liq 224:431–441

Chaudhry SA, Khan TA, Ali I (2017a) Equilibrium, kinetic and thermodynamic studies of Cr(VI) adsorption from aqueous solution onto manganese oxide coated sand grain (MOCSG). J Mol Liq 236:320–330

Chaudhry SA, Zaidi Z, Siddiqui SI (2017b) Isotherm, kinetic and thermodynamics of arsenic adsorption onto iron-zirconium binary oxide-coated sand (IZBOCS): modelling and process optimization. J Mol Liq 229:230–240

Chaves LC, Navoni JA, de Morais Ferreira D, Batistuzzo de Medeiros S, Ferreira da Costa T, Petta RA, Souza do Amaral V (2016) Water mutagenic potential assessment on a semiarid aquatic ecosystem under influence of heavy metals and natural radioactivity using micronuclei test. Environ Sci Pollut Res 23:7572–7581

Chen JP, Wang X (2000) Removing copper, zinc, and lead ion by granular activated carbon in pretreated fixed-bed columns. Sep Purif Technol 19(3):157–167

Chen X, Luo AC, Sato K, Wakatsuki T, Masunaga T (2009) An introduction of a multi-soil-layering system: a novel green technology for wastewater treatment in rural areas. Water Environ J 23(4):255–262

Ding Z, Hu X, Morales VL, Gao B (2014) Filtration and transport of heavy metals in graphene oxide enabled sand columns. Chem Eng J 257:248–252

Dzyazko YS, Belyakov VN (2004) Purification of a diluted nickel solution containing nickel by a process combining ion exchange and electrodialysis. Desalination 162:179–189

Echeverria JC, Morera MT, Mazkiaran C, Garrido JJ (1998) Competitive sorption of heavy metal by soils. Isotherms and fractional factorial experiments. Environ Pollut 101(2):275–284

Ellis JB, Butler D (2015) Surface water sewer misconnections in England and Wales: pollution sources and impacts. Sci Total Environ 526:98–109

Et-taleb S, El haouti R, Abbaz M, Lhanafi S, Ez-zahery M, Aba-aaki R, El Alem N (2014) Comparison of the clogging phenomenon wastewater through two types of sand: one virgin and one used during treatment with infiltration. J Mater Environ Sci 5(6):1906–1912

Gaikwad RW (2004) Removal of Cd(II) from aqueous solution by activated charcoal derived from coconut shell. Electron J Environ Agric Food Chem 3(4):702–709

Gebru KA, Das C (2017) Removal of Pb(II) and Cu(II) ions from wastewater using composite electrospun cellulose acetate/titanium oxide (TiO2) adsorbent. J Water Process Eng 16:1–13

Guo J, Wang R, Tjiu WW, Pan J, Liu T (2012) Synthesis of Fe nanoparticles@ graphene composites for environmental applications. J Hazard Mater 225:63–73

Gupta VK, Saini VK, Jain N (2005) Adsorption of As(III) from aqueous solutions by iron oxide-coated sand. J Colloid Interface Sci 288(1):55–60

Hanay Ö, Hasar H (2011) Effect of anions on removing Cu2+, Mn2+ and Zn2+ in electrocoagulation process using aluminum electrodes. J Hazard Mater 189(1):572–576

Heidmann I, Calmano W (2008) Removal of Zn(II), Cu(II), Ni(II), Ag(I) and Cr(VI) present in aqueous solutions by aluminium electrocoagulation. J Hazard Mater 152(3):934–941

Herman DC, Artiola JF, Miller RM (1995) Removal of cadmium, lead, and zinc from soil by a rhamnolipid biosurfactant. Environ Sci Technol 29(9):2280–2285

Hofman R, Westheim JGF, Pouwel J, Fransen T, Gellings PJ (1996) FTIR and XPS studies on corrosion resistant SiO2 coatings as a function of the humidity during deposition. Surf Interface Anal 24(1):1–6

Hongjie W, Jin K, Huijuan LIU, Jiuhui QU (2009) Preparation of organically functionalized silica gel as adsorbent for copper ion adsorption. J Environ Sci 21(11):1473–1479

Hua J, An P, Winter J, Gallert C (2003) Elimination of COD, microorganisms and pharmaceuticals from sewage by trickling through sandy soil below leaking sewers. Water Res 37(18):4395–4404

Imtiaz A, Farrukh MA, Khaleeq-ur-Rahman M, Adnan R (2013) Micelle-assisted synthesis of Al2O3·CaO nanocatalyst: optical properties and their applications in photodegradation of 2,4,6-trinitrophenol. Sci World J 2013:1–11

Inglezakis VJ, Loizidou MD, Grigoropoulou HP (2002) Equilibrium and kinetic ion exchange studies of Pb2+, Cr3+, Fe3+ and Cu2+ on natural clinoptilolite. Water Res 36(11):2784–2792

Ji F, Li C, Tang B, Xu J, Lu G, Liu P (2012) Preparation of cellulose acetate/zeolite composite fiber and its adsorption behavior for heavy metal ions in aqueous solution. Chem Eng J 209:325–333

Jiang MQ, Jin XY, Lu XQ, Chen ZL (2010) Adsorption of Pb(II), Cd(II), Ni(II) and Cu(II) onto natural kaolinite clay. Desalination 252(1):33–39

Kabdaşlı I, Arslan T, Ölmez-Hancı T, Arslan-Alaton I, Tünay O (2009) Complexing agent and heavy metal removals from metal plating effluent by electrocoagulation with stainless steel electrodes. J Hazard Mater 165(1):838–845

Karnib M, Kabbani A, Holail H, Olama Z (2014) Heavy metals removal using activated carbon, silica and silica activated carbon composite. Energy Proced 50:113–120

Katsoyiannis IA, Zouboulis AI (2002) Removal of arsenic from contaminated water sources by sorption onto iron-oxide-coated polymeric materials. Water Res 36(20):5141–5155

Khan TA, Chaudhry SA, Ali I (2013) Thermodynamic and kinetic studies of As(V) removal from water by zirconium oxide-coated marine sand. Environ Sci Pollut Res 20(8):5425–5440

Khan TA, Chaudhry SA, Ali I (2015) Equilibrium uptake, isotherm and kinetic studies of Cd(II) adsorption onto iron oxide activated red mud from aqueous solution. J Mol Liq 202:165–175

Latrach L, Ouazzani N, Masunaga T, Hejjaj A, Bouhoum K, Mahi M, Mandi L (2016) Domestic wastewater disinfection by combined treatment using multi-soil-layering system and sand filters (MSL–SF): a laboratory pilot study. Ecol Eng 91:294–301

Liu Q, Mancl K, Tuovinen OH (2003) Biomass accumulation and carbon utilization in layered sand filter biofilm systems receiving milk fat and detergent mixtures. Bioresour Technol 89(3):275–279

Liu C, Xie X, Zhao W, Liu N, Maraccini PA, Sassoubre LM, Boehm AB, Cui Y (2013) Conducting nanosponge electroporation for affordable and high-efficiency disinfection of bacteria and viruses in water. Nano Lett 13(9):4288–4293

Luanmanee S, Boonsook P, Attanandana T, Saitthiti B, Panichajakul C, Wakatsuki T (2002) Effect of intermittent aeration regulation of a multi-soil-layering system on domestic wastewater treatment in Thailand. Ecol Eng 18(4):415–428

Ma M, Zhang Y, Yu W, Shen HY, Zhang HQ, Gu N (2003) Preparation and characterization of magnetite nanoparticles coated by amino silane. Colloids Surf A Physicochem Eng Aspects 212(2):219–226

Maira AJ, Coronado JM, Augugliaro V, Yeung KL, Conesa JC, Soria J (2001) Fourier transform infrared study of the performance of nanostructured TiO2 particles for the photocatalytic oxidation of gaseous toluene. J Catal 202(2):413–420

Mekki A, Dhouib A, Sayadi S (2007) Polyphenols dynamics and phytotoxicity in a soil amended by olive mill wastewaters. J Environ Manag 84(2):134–140

Miao X, Tang Y, Wong CW, Zang H (2015) The latent causal chain of industrial water pollution in China. Environ Pollut 196:473–477

O’Carroll D, Sleep B, Krol M, Boparai H, Kocur C (2013) Nanoscale zero valent iron and bimetallic particles for contaminated site remediation. Adv Water Resour 51:104–122

Polprasert C, Dan NP, Thayalakumaran N (1996) Application of constructed wetlands to treat some toxic wastewaters under tropical conditions. Water Sci Technol 34(11):165–171

Sapari N, Idris A, Hamid NHA (1996) Total removal of heavy metal from mixed plating rinse wastewater. Desalination 106(1):419–422

Shannon MA, Bohn PW, Elimelech M, Georgiadis JG, Marinas BJ, Mayes AM (2008) Science and technology for water purification in the coming decades. Nature 452(7185):301–310

Siddiqui SI, Chaudhry SA (2017) Removal of arsenic from water through adsorption onto metal oxide-coated material. Mater Res Found 15:227–276

Srivastava P, Singh B, Angove M (2005) Competitive adsorption behavior of heavy metals on kaolinite. J Colloid Interface Sci 290(1):28–38

Tunali S, Cabuk A, Akar T (2006) Removal of lead and copper ions from aqueous solutions by bacterial strain isolated from soil. Chem Eng J 115(3):203–211

Uzun I, Güzel F (2000) Adsorption of some heavy metal ions from aqueous solution by activated carbon and comparison of percent adsorption results of activated carbon with those of some other adsorbents. Turk J Chem 24(3):291–298

Vaishya RC, Gupta SK (2003) Arsenic removal from groundwater by iron impregnated sand. J Environ Eng 129(1):89–92

Vaishya RC, Gupta SK (2005) Modeling Arsenic(V) removal from water by sulfate modified iron-oxide coated sand (SMIOCS). Sep Sci Technol 39(3):645–666

Vasilyuk SL, Maltseva TV, Belyakov VN (2004) Influence of water hardness on removal of copper ions by ion-exchange-assisted electrodialysis. Desalination 162:249–254

Weber-Shirk ML (2002) Enhancing slow sand filter performance with an acid-soluble seston extract. Water Res 36(19):4753–4756

Xing S, Zhao M, Ma Z (2011) Removal of heavy metal ions from aqueous solution using red loess as an adsorbent. J Environ Sci 23(9):1497–1502

Yan G, Viraraghavan T (2003) Heavy-metal removal from aqueous solution by fungus Mucor rouxii. Water Res 37(18):4486–4496

Zbair M, Anfar Z, Ait Ahsaine H, El Alem N, Ezahri M (2018) Acridine orange adsorption by zinc oxide/almond shell activated carbon composite: operational factors, mechanism and performance optimization using central composite design and surface modeling. J Environ Manag 206:383–397

Zeng L (2003) A method for preparing silica-containing iron(III) oxide adsorbents for arsenic removal. Water Res 37(18):4351–4358

Zhang Y, Yang M, Huang X (2003) Arsenic(V) removal with a Ce(IV)-doped iron oxide adsorbent. Chemosphere 51(9):945–952

Zhong QQ, Yue QY, Li Q, Gao BY, Xu X (2014) Removal of Cu(II) and Cr(VI) from wastewater by an amphoteric sorbent based on cellulose-rich biomass. Carbohydr Polym 111:788–796

Acknowledgements

This work was supported by the University of Ibn Zohr faculty of sciences. We would like to thank the Moroccan foundation for Advanced Science, Innovation and Research (Mascir) for their support and cooperation.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors confirm that this article has no conflict of interest.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Haouti, R.E., Anfar, Z., Et-Taleb, S. et al. Removal of heavy metals and organic pollutants by a sand rich in iron oxide. Euro-Mediterr J Environ Integr 3, 17 (2018). https://doi.org/10.1007/s41207-018-0058-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41207-018-0058-9