Abstract

Nanotechnology’s advancements have revolutionized industries, but concerns about its health risks for workers have intensified. Occupational health specialists play a vital role in assessing and mitigating these risks. While nanotechnology offers benefits in manufacturing, medicine, and materials science, addressing health effects and regulating nanomaterials are critical for workplace safety and efficiency. This study reviews the pros and cons of Nanotechnology in Occupational Health, examining 75 articles from reputable databases with a focus on originality and relevance. By analyzing publications up to 2024, the research team highlights key insights on the impact of Nanotechnology in promoting workplace safety and health. Initially, 198 articles were considered, leading to the selection of 73 articles that met the inclusion criteria after applying exclusion criteria. The chosen articles focused on practical and occupational aspects, including the use of nanomaterials in products such as textiles, personal protective equipment (PPE), air purification, and sensors, in alignment with the study’s objectives. The integration of nanotechnology in occupational health has led to transformative advancements in workplace monitoring, protection, and worker well-being. Nanosensors improve air quality monitoring, while smart textiles enable real-time vital sign tracking and toxic substance detection for worker safety. Despite these benefits, challenges like nanoparticles’ reactivity and health concerns require risk assessment, collaborative efforts, and regulatory frameworks to ensure safe nanomaterial use and protect worker health and the environment.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The new century is witnessing a surge in technological breakthroughs, with nanotechnology playing a pivotal role [49, 50]. This revolutionary field has opened doors to scientific exploration and progress, significantly impacting occupational health [46]. Nanotechnology focuses on manipulating materials at the Nano scale (1–100 nanometers) to leverage their unique properties for novel applications [84]. However, as nanotechnology finds increasing use in industrial settings, concerns regarding potential health risks for workers have intensified [23]. The distinctive properties of nanomaterial’s, such as their high surface area-to-volume ratio, enhanced reactivity, and improved strength, have driven their widespread adoption across various industries in recent years. These advancements have facilitated the development of innovative products and solutions. However, the very features that make nanomaterial’s so beneficial also raise safety concerns, The primary worry lies in the potential negative effects on human health and the environment, particularly due to the high mobility of certain nanomaterials combined with their unique characteristics [40].

Occupational health is a multidisciplinary field concerned with the health, safety and well-being of people in all occupations. Due to the high number of incidents and exposure factors that occur in all types of work environments and their consequences, Occupational health and safety has become a very important issue for stakeholders to take care of human resources [81]. Nanotechnology provides many advantages for occupational health and safety through the creation of new materials for protective equipment, enhanced drug delivery for workplace-related ailments, and accurate sensors for identifying risks in work environments.

For example, Nano catalysts will greatly increase the efficiency of chemical reactions and will also significantly prevent the production of waste materials in reactions. The use of nanoparticles in the production of other materials can increase their strength or reduce their weight, increase their chemical and thermal resistance, and change their reaction to light and other radiations.

These advancements may enhance worker safety, minimize exposure to dangerous substances, and offer better treatment choices. Nevertheless, concerns exist about the potential health effects of nanomaterials in workplaces, including respiratory and skin toxicity, along with the importance of thorough risk assessment and regulation. Thorough investigation, risk assessment, and ethical deliberation are essential for the safe and responsible utilization of nanotechnology in occupational health, weighing its advantages and disadvantages [22].

-

1.

Here are some relevant case studies and examples of successful nanotechnology implementations in occupational health settings that can be considered for inclusion:

-

2.

1. Controlling Nanomaterial Exposure in a Research Laboratory: This case study, conducted by the National Institute for Occupational Safety and Health (NIOSH), illustrates the effective utilization of engineering controls, work practices, and personal protective equipment in a research laboratory to minimize worker exposure to carbon nanotubes [58].

-

3.

Nanoparticle Filtration in the Semiconductor Industry: This example showcases how semiconductor manufacturing companies have successfully employed nanofiber-based air filtration systems to capture ultrafine particles and safeguard workers from exposure during crucial production processes.

-

4.

Nanotechnology-Enhanced Protective Clothing: This case study explores the development and implementation of personal protective equipment (PPE), such as clothing and gloves, that incorporate nanomaterials to provide workers in high-risk occupations with enhanced durability, chemical resistance, and barrier properties.

-

5.

Real-time Exposure Monitoring with Nano-enabled Sensors: This practical example focuses on the use of wearable nano-sensors to monitor worker exposure to nanomaterials in real-time. This allows for immediate risk mitigation and improved collection of occupational health data.

-

6.

Nanotechnology in Workplace Decontamination: This case study demonstrates the use of nanomaterial-based decontamination solutions to safely and effectively remove nanomaterials from work surfaces, equipment, and the surrounding environment.

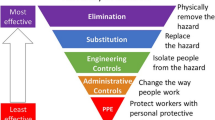

The use of nanomaterials in workplaces presents a significant challenge for occupational health professionals. These experts are particularly concerned about the potential health risks associated with worker exposure (through inhalation or skin contact) that could lead to work-related illnesses. To mitigate these risks, occupational health specialists play a vital role. They assess potential hazards, monitor exposure levels, and implement essential preventive measures. This includes staying updated on the latest research regarding nanomaterial toxicity, providing guidance on safe work practices, and advocating for effective engineering controls and personal protective equipment (PPE) to minimize exposure.

The beneficial aspect of nanotechnology in the workplace is significant; it offers several important positive aspects for the workplace, particularly in the fields of manufacturing, medicine and materials science. In manufacturing, nanomaterials can improve the performance and durability of products, leading to more efficient processes and better product quality. In medicine, nanotechnology enables the development of targeted drug delivery systems, diagnostic tools and personalized medicine, which can lead to more effective treatments with fewer side effects. In addition, nanotechnology in materials science has the potential to create advanced materials with unique properties, such as increased strength, conductivity and catalytic activity, leading to the development of innovative and high-performance products. In addition, nanotechnology can also contribute to environmental sustainability by enabling the development of more efficient energy storage, pollution abatement technologies and water treatment solutions. Overall, the beneficial aspects of nanotechnology in the workplace are significant due to its potential to improve the productivity, efficiency and quality of products, as well as its potential to address pressing societal and environmental challenges [21, 22, 72]. These improvements can contribute to a safer working environment and improve the quality of protective equipment. Due to their tiny size, nanomaterials can lead to the production of safety equipment such as respirators and gloves that are not only lighter and more robust, but also more flexible, without sacrificing comfort or freedom of movement [66], Khanlari et al. [38]. In addition, nano-enabled devices, including nanosensors, offer the potential to instantly detect hazardous environments and toxic materials, which could help prevent work-related health problems and exposure to harmful substances [59, 78].

The tiny size that gives nanoparticles unique advantages also raises concerns about their biokinetics and potential for harm if workers are exposed during production, handling or disposal [14, 37, 94]. The unknown long-term health effects and the challenges of monitoring and managing exposure to nanomaterials in the workplace require critical assessment [26, 75]. For people involved in nanotechnology-related activities, a variety of potentially hazardous exposure circumstances can be expected. Indeed, NMs pose significant but unknown hazards that may endanger a wide range of workers, including researchers, laboratory technicians, cleaners, production workers, transportation personnel, warehouse and retail workers, individuals working in disposal and waste management facilities, and possibly emergency responders dealing with spills and disasters related to NMs, who may be exposed to various forms of exposure to these potential, revolutionary xenobiotics [34].

Understanding the direct and indirect implications of nanotechnology in the field of occupational health plays a pivotal role in maximizing its advantages while minimizing associated risks. The primary aim of this review is to examine the current situation, identify areas in need of further investigation, and clarify the complex relationship between nanotechnology and occupational health.

The study’s results are expected to not only point out current uncertainties but also provide suggestions to effectively resolve them, ultimately aiding in informed decision-making and influencing the course of research and practice in this critical area.

Regarding the unresolved issues of Nanotechnology and Occupational Health and also direct and indirect applications of the present review, we can say the following:

Unresolved issues

-Long-term effects of nanoparticles on human health: Insufficient information is available regarding the long-term effects of nanoparticle exposure on human health.

-Environmental hazards of nanoparticles: The full extent of environmental hazards posed by nanoparticles remains unknown.

-Regulations for nanoparticles: Ongoing development of regulations for nanoparticles is yet to be completed.

Direct Applications

-This study can aid employers and workers in comprehending the advantages and risks associated with nanotechnology in the workplace.

-This study can contribute to the formulation of regulations for nanoparticles.

-This study can assist in the development of new approaches for controlling and preventing occupational hazards linked to nanotechnology.

Indirect Applications:

-This study can facilitate the creation of new nanotechnology-related products and services.

-This study can educate employers and workers on the subject of nanotechnology.

-This study can help raise public awareness about nanotechnology.

Method

The present study is a review of the advantages and drawbacks of Nanotechnology in the field of Occupational Health. The data collection was carried out using articles published in this field from databases. The selection of articles was conducted without any biased intention or time limit, up to 2024. Search articles in the databases of Google Scholar, PubMed, Scopus, IEE Xplore and Web of Science using keywords such as nanotechnology and occupational health, benefit of nanotechnology, disadvantage of nanotechnology, impact of nanotechnology on occupational safety, health risk of nanotechnology in the workplace, nanotechnology application in occupational health, toxicology of nanomaterial, challenges of implementing nanotechnology in health sector, environmental impact of nanotechnology, nanomedicines, and nanoparticles (Fig. 1).

The inclusion criteria considered the originality of the articles, Articles related to health and medical fields، related review articles, their availability, and all the articles that accurately stated the advantages and disadvantages of nanotechnology in occupational health. It should be noted that the words "AND" and "OR" were used during the search in all the above-mentioned databases. The exclusion criteria also encompass the unavailability of the full text of the article, articles in languages other than English, Unpublished manuscripts, books, letters to the editor, and articles in other fields and any articles that did not meet the inclusion criteria. Finally, by utilizing the above-mentioned keywords and excluding irrelevant studies, a total of 73 articles were included in the study, which were meticulously analyzed by the research team. It should be noted that review articles that were relevant to the research title were used in the study’s introduction and discussion sections, but were excluded from the study’s results section because the research was a review. The information extracted at this stage was examined based on the authors’ names, the year of publication, the studied method, and other factors influencing Nanotechnology in Occupational Health (Fig. 2).

Results

At the outset, 198 articles were initially selected from various databases. Out of these articles, 127 met the inclusion criteria, and after applying both the inclusion and exclusion criteria, 73 articles were ultimately selected. It should be noted that while there were numerous articles in the field of occupational health and nanotechnology, an effort was made to choose articles that focused on practical and occupational aspects, aligning with the study’s objectives. Table 1 lists several research papers. Based on the provided list of research articles, nanomaterials are used in various products, like textiles, personal protective equipment (PPE), air purification, sensors.

Discussion

Advantages of application of nanomaterials in occupational Health

Air monitoring

The enhanced air quality monitoring facilitated by nanomaterials is directly associated with the occupational health aspect of exposure assessment and hazard prevention. One of the most desirable environmental applications of nanotechnology is in cleaning air pollution, in which various nanomaterials are used as nanoabsorbers, nanocatalysts, nanofilters, and nanosensors. These nanomaterials have the ability to absorb several pollutants in the air [73]. Traditional sensors have limitations in detecting toxic substances at extremely low concentrations, often failing to provide accurate and timely measurements. In contrast, nanosensors exhibit unparalleled sensitivity, enabling the detection of minute quantities of harmful agents with remarkable precision [85]. One example of the use of nanomaterials in air quality monitoring is the development of nanowire-based gas sensors. Nanowires made of materials such as zinc oxide, tin dioxide, or graphene are used to detect various gases and volatile organic compounds. In addition, commercial products such as nanotechnology-enabled portable air quality monitors offered by companies like Aeroqual use nanomaterial-based sensors for accurate and real-time measurement of air pollutants [33]. The unique characteristics of nanomaterials, such as their high surface-to-volume ratio, customized surface properties, and enhanced reactivity, play a crucial role in enhancing air quality monitoring for occupational health benefits. Thanks to these properties, nanosensors can detect trace pollutants with high sensitivity and selectivity, providing real-time data to assess air quality in the workplace and identify potential occupational exposure risks. In addition, the miniaturization made possible by nanotechnology enables the development of portable and wearable air quality monitoring devices, enhancing the capability to monitor air quality in various work environments.

Smart textiles

The field of nanotechnology has opened up new possibilities for the creation of intelligent textiles that possess the extraordinary ability to monitor vital bodily functions and promptly detect contact with harmful substances. These breakthrough textiles represent a significant advancement in safeguarding the well-being of workers, as they can be seamlessly integrated with workwear and protective clothing. Using nanotechnology, these smart textiles can continuously monitor vital signs such as pulse rate, body temperature, and respiratory rate to detect irregularities or health problems at an early stage [42, 77]. The integration of nanosensors into textiles allows for the detection and measurement of exposure to dangerous substances, offering crucial data to reduce risks and safeguard workers. The immediate availability of data obtained from these smart textiles facilitates rapid intervention and guarantees timely remediation of health hazards. The fusion of nanotechnology and textiles exemplifies the potential for groundbreaking solutions to enhance workplace safety. It highlights the revolutionary impact of nanotechnology in transforming workplace health monitoring and risk reduction [12]. The utilization of nanotechnology in smart textiles allows for the incorporation of miniature physiological sensors, transmission modules, and processing functions. These systems enable immediate monitoring of health status and offer potential benefits for occupational health by enabling early detection of health problems or continuous monitoring of prevailing conditions [5]. Examples of applications of nanomaterials in smart textiles include the integration of nanomaterials such as carbon nanotubes, graphene, and nanoparticles into textiles to create smart fabrics with properties such as increased mechanical strength, flame resistance, and antimicrobial activity. Commercial products include nanotechnology-enhanced protective clothing for industrial workers and medical professionals, utilizing coatings of nanomaterials to enhance water and oil repellency and improve breathability [39]. The special characteristics of nanomaterials, such as their unique mechanical, electrical, and optical properties, have led to the benefits of smart textiles in occupational health applications. For example, incorporating nanomaterials into textiles can enhance mechanical strength and abrasion resistance, thereby increasing the durability and lifespan of personal protective equipment (PPE). In addition, coatings based on nanomaterials can provide textiles with water and oil repellent properties, antimicrobial properties, and enhanced breathability. This helps protect workers more effectively from workplace hazards. Furthermore, the integration of nanomaterials enables the development of smart sensor textiles that can detect environmental factors such as temperature, humidity, and chemical exposure, providing real-time feedback to ensure worker safety [9, 10].

Occupational medicine

The progress of occupational medicine through the use of nanomaterials is closely connected to advancements in medical observation, diagnosis, and treatment of occupational diseases and injuries. The domain of nanotechnology has facilitated the advancement of innovative medical technologies and therapies that can enhance the assessment and treatment of health issues in the workplace. These include the timely detection of diseases caused by exposure, targeted drug delivery systems, and minimally invasive diagnostic procedures [49, 50]. More precise and sensitive imaging methods, nano-devices and nano-robotics for early biochemical change detection, targeted and less toxic drug treatments, and improved regenerative medicine supports are just a few of the ways that nanotechnology is predicted to revolutionize the biomedical industries. Because of the still-unpredictable toxicological behavior of nano-sized materials, some worries have surfaced regarding the potential negative effects that nano-enabled applications may have on human health, particularly on workers exposed throughout the product life cycle [44]. Nanomaterials exhibit distinctive physical and chemical characteristics, including their nanoscale dimensions, expansive surface area, and customizable surface properties, which have driven advancements in the field of occupational medicine. These attributes facilitate the creation of precise drug delivery platforms that enhance the effectiveness of medications used to manage occupational ailments and reduce their adverse effects. Nanomaterial-based wound dressings offer advanced solutions for promoting rapid and effective wound healing. These dressings incorporate nanoparticles, nanofibers, and nanocomposites with unique properties, including antimicrobial effects, enhanced cell growth, and improved moisture control. Nanomaterials enable targeted drug release, inhibit bacterial growth, reduce inflammation, and accelerate tissue regeneration, leading to quicker wound closure and reduced infection risk. Overall, nanomaterial-based wound dressings offer innovative approaches to optimize wound care outcomes and enhance the healing process for various types of wounds. Nanomaterials can be customized to encapsulate drugs or imaging agents, protecting them from degradation and transporting them to the intended site in a controlled manner. This targeted delivery strategy enhances the accuracy and efficiency of therapies for occupational diseases, while reducing overall toxicity and improving patient outcomes [74].

Personal protective equipment (PPE)

The incorporation of nanomaterials into personal protective equipment (PPE) represents a significant advancement in the field of occupational health. Nanotechnology can be applied to conventional personal protective equipment (PPE) to enhance its structural integrity, durability, and versatility, thereby increasing its effectiveness in mitigating the risks associated with occupational exposure. Nanomaterials enhance the protective capabilities of personal protective equipment (PPE) and provide increased protection against a variety of workplace-related risks, ranging from chemical hazards to physical injuries. Nanomaterials play a key role in enhancing the protective capabilities of personal protective equipment (PPE), minimizing worker exposure to harmful agents, and ensuring a safer workplace (Alberto, Matos et al. [3]). The utilization of nanomaterials such as polymeric nanofibers, metal or metal oxide NPs or nanocomposites, and carbon nanomaterials in personal protective equipment (PPE) improves the durability of protective clothing and revolutionizes workplace safety by offering tailored protection solutions. Nanotechnology allows for personal protective equipment (PPE) tailored to specific workplace hazards and different industrial environments. By leveraging the unique properties of nanomaterials, such as their large surface-to-volume ratio and customizable features, personal protective equipment (PPE) manufacturers can develop innovative protective solutions that offer superior performance and comfort while meeting safety standards. Through the strategic use of nanomaterials, personal protective equipment (PPE) becomes more than just a physical barrier; it transforms into a dynamic tool that offers enhanced protection and safety for workers in hazardous work environments [17, 66]. Both the commercial and academic sectors have examples of nanomaterials in Personal Protective Equipment (PPE). Nanoparticles, nanofibers, and nanocomposites are being integrated into personal protective equipment (PPE) to enhance toughness, chemical resistance, and thermal stability. Studies show that nanotechnology can be used to enhance the protective functions of personal protective equipment (PPE) (Maher et al. [48], De Luca et al. [18]). Nanomaterials, with their high surface-to-volume ratio and ability to be utilized with minimal material, can offer robust and long-lasting protection in occupational safety and health devices. Nanomaterials could be modified to enhance features such as antimicrobial properties, flame resistance, and protection against exposure to toxic substances. By incorporating nanotechnology into PPE, lighter and more effective equipment can be developed for workers in various industrial sectors [17, 62].

Ergonomics

Incorporating nanotechnology (Nanotechnology,” “Nanomaterial,” and “Nanoparticle) into ergonomics has real-world benefits that enhance health and safety in numerous job environments. In the realm of physical ergonomics, the capacity to tailor materials and equipment using nanotechnology has resulted in the development of products across all categories aimed at optimizing human efficiency and reducing the occurrence of musculoskeletal problems. Ergonomic furniture and tools can be crafted from advanced nanocomposite materials to provide strength at a fraction of the normal weight, reducing physical strain and improving the health of the individuals using them. In environmental ergonomics, nanotechnology is enabling the development of innovative solutions, such as self-cleaning surfaces that utilize a nanocoating to repel contaminants and pathogens. This technology helps shared workspaces to maintain hygiene and reduces the risk of infection. Overhead lights for workers and guests shift in color and intensity to simulate bright midday light. Glass used in construction invites light into interior spaces while blocking excessive heat in hotter months, reducing energy costs and keeping workers comfortable. These drops in temperature also reduce energy expenses. Nanotechnology has created exciting new opportunities for cognitive ergonomics applications in the workplace that can transform cognition-related performance from a declining function to a stable or improving skill. Nanosensors embedded in smart devices and other wearables can monitor workers’ stress levels and cognitive performance, providing data to optimize work environments and promote good mental health. The advancement of nanotechnology in ergonomics is crucial for progressing workplaces towards comprehensive worker health, safety, and well-being. It holds promise as an innovative approach in ergonomics and occupational health [28, 56].

UV protection

The incorporation of nanoparticles such as zinc oxide (ZnO) and titanium dioxide (TiO2) into protective coatings or clothing represents a significant advancement in strengthening defenses against harmful ultraviolet radiation, particularly for individuals engaged in outdoor occupations. This innovative application utilizes the unique properties of nanoparticles to enhance the protective capabilities of coatings and clothing, thereby improving their effectiveness in shielding against the harmful effects of ultraviolet radiation. By utilizing the inherent characteristics of nanoparticles, such as their high surface area-to-volume ratio and exceptional light-absorbing properties, this integration serves as a proactive approach to reduce the risk of UV-induced skin damage and associated health concerns for outdoor workers. As a result, this technological integration demonstrates the ongoing development of protective measures, highlighting a collective effort to prioritize the well-being and safety of individuals exposed to the challenges of outdoor environments [87], Aguilera et al. [2], [67].

Safety equipment

Nano-enhanced safety equipment, such as harnesses and lanyards, can be stronger and more durable, providing better protection against falls and other accidents. Recent advancements in nanotechnology have revolutionized the design and manufacturing of safety gear, leading to the development of innovative materials with enhanced structural integrity and resistance to wear and tear. Nanomaterials, such as carbon nanotubes and graphene, are being incorporated into safety equipment to enhance their mechanical properties, increasing their durability and reliability in protecting workers in high-risk environments. This cutting-edge approach not only enhances the protective capabilities of the gear but also contributes to the overall improvement of workplace safety standards, ensuring a safer working environment for employees across various industries [76].

Smart lighting

Nanotechnology has the potential to revolutionize lighting systems by enabling the creation of adaptive lighting solutions that can dynamically adjust to natural light conditions. This innovation can significantly reduce eye strain and enhance visibility in work environments. Through the integration of nanomaterials, such as quantum dots and nanophosphors, into lighting technologies, it becomes possible to achieve precise control over the color temperature and intensity of illumination. This capability allows for the emulation of natural daylight, which not only promotes a more comfortable and productive working environment but also contributes to energy efficiency by optimizing the use of artificial lighting. So the next generation of lighting systems and devices with less light pollution will be made possible in large part by nanotechnology [57], Mishra et al. [52].

Noise

Nanomaterials (Nanocomposite” polymeric foams) provide numerous benefits in reducing noise, making them highly desirable for effective and economical sound-absorbing materials. One of the key advantages of nanomaterials in reducing noise lies in their exceptional surface area-to-volume ratio. Nanomaterials, due to their nanoscale dimensions, possess a remarkably high surface area, which enables increased interaction with sound waves. This improved interaction allows nanomaterials to efficiently dissipate and absorb acoustic energy, leading to superior noise reduction capabilities. Furthermore, the utilization of nanomaterials enables the development of lightweight and compact sound-absorbing solutions. The intrinsic lightweight nature of nanomaterials, combined with their high performance, allows for the development of thin, space-efficient acoustic panels and coatings. This not only saves space but also facilitates easy installation in various settings, making nanomaterial-based acoustic solutions highly practical and versatile. In conclusion, nanomaterials offer a multitude of advantages in reducing noise, including their high surface area-to-volume ratio, tunable properties, and lightweight nature. These characteristics make nanomaterials an indispensable resource in the pursuit of efficient and cost-effective sound absorption for reducing noise in vehicles, buildings, and large spaces [20, 91].

Air quality

The advancement of filters through the use of nanomaterials is directly related to the identification, measurement, and control of chemical contaminants. Enhancements in filter technology using nanomaterials play a crucial role in maintaining clean and safe working environments by effectively capturing and removing contaminants, pollutants, and particles that could pose health risks to workers (Roy et al. [71]). Commercial products such as nanofiber-based respirator filters, air purifiers with nanocomposite filters, and Heating, Ventilation, and Air Conditioning (HVAC) systems incorporating nanomaterial-enhanced filters are prevalent in the market [16, 93]. Nanomaterials developed for advanced filters offer unique features that contribute to their advantages and applications in occupational health. Features such as high surface area-to-volume ratio, fine particle size, and enhanced adsorption capabilities enable nanomaterial-based filters to efficiently trap and remove contaminants from the air. Nanomaterials such as carbon nanotubes, graphene, and metal oxide nanoparticles offer superior filtration efficiency, antimicrobial properties, and chemical resistance. These properties make them ideal for capturing a wide range of air pollutants and maintaining clean indoor air quality in workplaces. The unique characteristics of nanomaterials enable the development of high-performance filters that can effectively protect the health and well-being of workers by reducing exposure to harmful airborne particles and pollutants, thereby enhancing occupational health and safety standards [6, 55]. Advanced photocatalysts utilizing nanomaterials offer a powerful solution for improving indoor air quality in workplaces. Titanium dioxide (TiO2) and zinc oxide (ZnO) are popular nanomaterials used in photocatalytic applications because of their capacity to produce reactive oxygen species when exposed to light, resulting in the degradation of contaminants. When these nanomaterial-based photocatalysts are incorporated into air purification systems or coated on surfaces within a workspace, they act as catalysts for chemical reactions that effectively degrade volatile organic compounds (VOCs) emitted from cleaning products, furniture, and building materials. Additionally, the photocatalytic action of nanomaterials can help combat indoor pollutants such as formaldehyde, tobacco smoke, and microbial agents, providing a safer and more comfortable environment for workers. When illuminated with light, nanomaterial-based photocatalysts trigger oxidation and decomposition reactions that break down harmful substances into harmless byproducts such as water vapor and carbon dioxide. This photocatalytic process not only purifies the air but also helps eliminate odors and neutralize allergens and pathogens, contributing to a cleaner and safer indoor environment for workers. By reducing exposure to indoor air pollutants and creating a more comfortable and healthier workplace, advanced photocatalysts utilizing nanomaterials play a significant role in enhancing occupational health and well-being, ultimately improving productivity and employee satisfaction in the workplace [45], Hadi et al. [32], Ratti et al. [68].

Thermal insulation

The thermal insulation properties of nanomaterials are closely related to thermal comfort and energy efficiency in occupational health. Maintaining optimal thermal conditions in work environments is essential for the well-being and productivity of employees. Effective thermal insulation provided by nanomaterials can help regulate indoor temperatures, reduce energy consumption for heating and cooling, and create a more comfortable and sustainable workspace. Examples of applications of nanomaterials for thermal insulation in occupational settings include insulated clothing, building materials, and energy-efficient windows. Nanomaterials such as aerogels, carbon nanotubes, and graphene have been developed and integrated into these applications to improve thermal insulation properties. For instance, nanoparticle-infused fabrics can provide lightweight and breathable insulation for workers in extreme temperatures, while nanocomposite materials in walls and roofs can improve the energy efficiency of buildings by minimizing heat transfer. The special features of nanomaterials that contribute to their advantage in thermal insulation and their application in occupational health include their low thermal conductivity, high surface area, and lightweight nature. Nanomaterials possess unique structural characteristics at the nanoscale that enable them to effectively trap and slow down the transfer of heat, providing superior insulation properties compared to conventional materials. Additionally, the high surface area-to-volume ratio of nanomaterials allows for increased interaction with heat, while their lightweight nature ensures that thermal insulation can be achieved without adding bulk or weight to insulated products. These qualities make nanomaterial-based thermal insulation solutions ideal for improving thermal comfort, reducing energy costs, and enhancing occupational health by creating environments that are conducive to employee well-being and productivity [1, 79].

Biosensors

The utilization of biosensors incorporating nanomaterials (such as carbon nanomaterials, metal nanoparticles, nanofibers, nanowires, and nanotubes, etc.) is closely related to occupational safety and health monitoring in the workplace. Biosensors offer a valuable tool for real-time detection and analysis of various biomarkers, toxins, and contaminants that could pose risks to the health and safety of workers. By utilizing nanomaterials in biosensor technology, occupational health professionals can monitor and assess exposure levels, detect early signs of health hazards, and implement timely interventions to safeguard the well-being of employees [61]. Applications of nanomaterial-based biosensors in occupational health include monitoring air quality for harmful gases and particulate matter, detecting biological agents like pathogens and allergens, and assessing occupational exposure to toxic chemicals. Nanomaterials such as carbon nanotubes, quantum dots, and metallic nanoparticles have been developed and integrated into biosensors for various applications. This integration enables sensitive and selective detection of target analytes with high precision and efficiency. The unique characteristics of nanomaterials that contribute to their advantages and applications in biosensors for occupational health include their high surface-to-volume ratio, adjustable properties, and increased sensitivity. Nanomaterials offer a large surface area for biomolecule immobilization, which enhances interactions with target analytes and boosts detection sensitivity. Additionally, the unique optical, electrical, and catalytic properties of nanomaterials enable the development of highly specific and responsive biosensors capable of detecting a wide range of occupational hazards. By harnessing these special features, nanomaterial-based biosensors play a critical role in enhancing occupational health and safety measures by providing rapid, accurate, and on-site monitoring capabilities for identifying potential risks and ensuring a healthy work environment for employees [11, 92].

Vibration

The application of nanomaterials in anti-vibration equipment is related to ergonomic factors, noise control, and injury prevention in the field of occupational health. Vibrations generated by machinery, tools, and equipment in industrial settings can result in musculoskeletal disorders, discomfort, and fatigue among workers. By incorporating nanomaterials into anti-vibration technologies, occupational health professionals can mitigate the harmful effects of vibrations, reduce the risk of injuries, and enhance the overall well-being and productivity of employees. Examples of applications of nanomaterials in anti-vibration equipment include vibration-damping coatings for tools and machinery, shock-absorbing materials for protective gear, and vibration isolators for workstations and seating. Nanomaterials such as graphene-based composites, carbon nanotubes, and polymer nanocomposites have been developed and employed in these applications to enhance vibration resistance and attenuation. These nano-enhanced materials can effectively dissipate mechanical energy, reduce vibrations transmitted to the human body, and provide enhanced protection against repetitive stress injuries caused by prolonged exposure to vibrations [19, 53]. The special features of nanomaterials that contribute to their advantage in anti-vibration applications and their relevance to occupational health include their high strength-to-weight ratio, flexibility, and damping properties. Nanomaterials possess unique mechanical characteristics at the nanoscale that make them ideal for absorbing and dispersing vibrational energy, thereby reducing the impact on human operators and equipment. The exceptional resilience and versatility of nanomaterials allow for the development of innovative anti-vibration solutions that address specific ergonomic challenges in the workplace, ultimately promoting a safer and more comfortable environment for employees. By harnessing the inherent properties of nanomaterials, anti-vibration equipment incorporating these advanced materials plays a vital role in preventing occupational injuries, enhancing worker comfort, and improving overall occupational health and well-being [24, 82].

Drawbacks of application of nanomaterials in Occupational Health

Nanoparticles exhibit higher reactivity because of their small size and large surface area. While this characteristic has various benefits and applications, it may pose risks to the safety of employees and the environment. These risks include staying suspended in the air for a long time, the possibility of accumulation in the environment, easy absorption, and potential damage to various organs of the body. Engineered nanomaterials have gained significant attention due to their unique properties and wide-ranging applications. However, concerns have been raised regarding the potential toxicological effects of exposure to these materials through various routes. This article aims to explore the toxicological effects of exposure (respiratory, dermal, and gastrointestinal) to engineered nanomaterials, encompassing studies on cell culture, animals, and human/epidemiology.

Routes of exposure

Respiratory exposure

Exposure to engineered nanomaterials can occur through inhalation, especially in occupational settings where aerosolized particles are generated during manufacturing or handling processes. This route of exposure raises concerns about the potential for nanomaterials to reach the deep lung and exert adverse effects [29]. In vitro studies have shown that specific engineered nanomaterials can trigger oxidative stress, inflammation, and cellular damage in respiratory cell lines. These findings raise concerns about the potential for respiratory toxicity upon inhalation exposure [27]. Animal studies have provided insights into the pulmonary effects of engineered nanomaterials, including lung inflammation, fibrosis, and potential systemic translocation. These studies contribute to our understanding of the potential health hazards associated with respiratory exposure [4, 7]. Epidemiological studies have explored the potential health effects of occupational and environmental exposure to engineered nanomaterials. These studies provide valuable data on respiratory outcomes in exposed populations, contributing to risk assessment and management strategies [96]. Specific engineered nanomaterials that have been studied for their potential respiratory toxicity include carbon nanotubes, metal nanoparticles (such as silver and titanium dioxide), quantum dots, and silica nanoparticles. These nanomaterials have been shown to induce oxidative stress, inflammation, and cellular damage in respiratory cell lines. They also cause lung inflammation, fibrosis, and potential systemic translocation in animal studies. The effective dose of engineered nanomaterials can vary depending on factors such as the specific type of nanomaterial, exposure duration, route of exposure, and individual susceptibility. In studies assessing respiratory toxicity, effective doses are typically determined through dose-response experiments where various concentrations of nanomaterials are administered to cells in vitro or animals in vivo. The effective dose required to elicit toxic effects may vary for different nanomaterials and specific endpoints being measured. It is important to conduct thorough dose-response studies to determine the dose levels at which adverse effects occur and establish safe exposure limits for nanomaterials in occupational and environmental settings (Pietroiusti et al [64], [60]).

Dermal exposure

Dermal exposure to engineered nanomaterials can occur during manufacturing processes, product use, or environmental release. The skin serves as a potential route for nanomaterial entry into the body, raising questions about the potential toxicological effects on skin cells and systemic absorption [47]. In vitro studies focusing on dermal exposure have highlighted the potential for nanomaterials to induce skin cell toxicity, inflammation, and oxidative stress. Understanding these effects is crucial for assessing the safety of products containing nanomaterials [95]. Animal studies have provided insights into the dermal effects of engineered nanomaterials, including skin irritation, sensitization, and potential systemic effects following dermal exposure. These findings contribute to the overall understanding of dermal toxicity [13]. Human studies have investigated the potential health effects of dermal exposure to engineered nanomaterials in occupational and consumer settings. These studies provide valuable insights into skin health and systemic effects, contributing to risk assessment and management [83]. Various engineered nanomaterials have been investigated for their potential dermal toxicity, including silver nanoparticles, titanium dioxide nanoparticles, zinc oxide nanoparticles, and carbon-based nanomaterials like fullerenes and carbon nanotubes. These nanomaterials have been shown to exhibit skin cell toxicity, inflammation, and oxidative stress in in vitro studies. Additionally, they have been linked to skin irritation, sensitization, and potential systemic effects in animal studies after dermal exposure. The effective dose of engineered nanomaterials for dermal toxicity can vary depending on factors such as the specific nanomaterial, exposure duration, concentration, and experimental design. Dose-response studies are typically conducted to determine the dose levels at which adverse effects occur in skin cells or animals [89].

Gastrointestinal exposure

Engineered nanomaterials can enter the body through ingestion, either via contaminated food and water sources or by directly consuming products containing nanomaterials. Understanding the potential toxicological effects of gastrointestinal exposure is crucial for assessing overall risk. In vitro studies focusing on gastrointestinal exposure have revealed potential effects on intestinal cells, including disruption of barrier function, inflammation, and oxidative stress. Understanding these effects is crucial for assessing the safety of nanomaterial-containing food and products [63]. Animal studies have provided insights into the gastrointestinal effects of engineered nanomaterials, including gut barrier integrity, microbiome alterations, and potential systemic effects following ingestion. These findings contribute to the overall understanding of gastrointestinal toxicity [41]. One of the main concerns regarding gastrointestinal exposure to engineered nanomaterials (ENMs) is their potential to disrupt the normal functioning of intestinal cells. In vitro studies, which utilize cell cultures to simulate the effects of engineered nanomaterials (ENMs) on the gastrointestinal tract, have shown that exposure to specific types of ENMs can cause disruption of barrier function, inflammation, and oxidative stress in intestinal cells. These effects have been observed in various types of engineered nanomaterials (ENMs), such as silver, titanium dioxide, and carbon nanotubes, emphasizing the necessity for additional research into their potential toxicity [15, 54]. The effects of titanium dioxide nanoparticles (TiO2 NPs) on intestinal cells were investigated using a cell culture model. The results showed that exposure to TiO2 nanoparticles at a concentration of 100 μg/mL caused a significant increase in oxidative stress and inflammation in the cells [70]. This suggests that even at low doses, engineered nanomaterials (ENMs) can have detrimental effects on the gastrointestinal system. Animal studies have also provided valuable insights into the potential gastrointestinal effects of engineered nanomaterials (ENMs). In a study, rats were orally administered titanium dioxide nanoparticles (TiO2 NPs) at doses of 1, 10, or 100 mg/kg for 14 days. The results showed that even at the lowest dose, TiO2 nanoparticles caused alterations in the gut microbiome, leading to a decrease in beneficial bacteria and an increase in potentially harmful bacteria. This disruption to the gut microbiome can have far-reaching effects on overall health, including digestion, immune function, and metabolism [69, 80]. Effective risk assessment and management strategies are essential for mitigating the potential toxicological effects of exposure to engineered nanomaterials. This involves integrating toxicological data, conducting exposure assessments, and considering regulatory requirements to ensure the safe use of nanomaterials in various applications. In conclusion, the toxicological effects of exposure to engineered nanomaterials through respiratory, dermal, and gastrointestinal routes are a subject of significant research and regulatory interest. Understanding the potential health hazards associated with these exposure routes is crucial for ensuring the safe development and use of nanomaterials in various applications. Continued research efforts and comprehensive risk assessment are essential for advancing our understanding of nanomaterial toxicology and ensuring the protection of human health and the environment.

Toxicological data

Nanotechnology has revolutionized various industries, offering innovative solutions and advancements. However, the potential health risks associated with long-term exposure to nanomaterials have raised concerns, especially in the field of occupational health. This section aims to explore the drawbacks of nanotechnology, focusing on the lack of toxicological data related to long-term exposure. It emphasizes the necessity for thorough research and regulatory considerations. One of the primary drawbacks of nanotechnology in the context of occupational health is the limited understanding of the chronic effects of long-term exposure to nanomaterials. While short-term toxicological studies provide valuable insights into immediate hazards, the long-term implications of continuous exposure remain inadequately explored [69]. The absence of data presents challenges in accurately assessing the potential health risks encountered by workers in nanotechnology-related industries. The dynamic nature of nanomaterial interactions within biological systems presents challenges in predicting cumulative effects over extended periods of exposure. The accumulation, distribution, and potential bio-persistence of nanomaterials in the body raise concerns about the development of chronic health conditions, necessitating comprehensive long-term toxicological assessments [43, 98]. The biological processes (absorption, distribution, metabolism, and excretion; ADME) that control the bioavailability and actual accumulation in living organisms, particularly metabolism and transport, are major determinants of the harmful effects of nanomaterials. It is essential to describe the biological processes and actual dose in the target organ or tissues using quantitative or qualitative methods in order to assess their biosafety [8]. The integration of epidemiological research focusing on occupational cohorts exposed to nanomaterials is crucial for capturing long-term health outcomes and identifying potential associations with chronic exposure. Longitudinal studies can contribute to the accumulation of real-world evidence, enhancing the understanding of cumulative health effects and informing occupational health policies and practices. Addressing the lack of toxicological data related to long-term exposure to nanomaterials requires multidisciplinary collaboration between researchers, industry stakeholders, and regulatory agencies. By fostering partnerships, the scientific community can collectively design and execute long-term studies that encompass diverse nanomaterial types, exposure scenarios, and relevant endpoints, thereby advancing the understanding of chronic health risks. The integration of predictive toxicology approaches and alternative testing methods holds promise in addressing the challenges associated with long-term toxicological assessments. By using computational modeling, high-throughput screening, and organ-on-a-chip technologies, researchers can gain insights into the long-term effects of nanomaterials, complementing traditional in vivo studies and expediting the generation of comprehensive toxicological data [86].

Occupational exposure limits

The rapid advancement of nanotechnology has led to the widespread use of nanomaterials across various industries, raising concerns about the potential health risks faced by workers exposed to these engineered particles. Although some nanomaterial’s have occupational exposure limits but One of the significant drawbacks of nanotechnology in the field of occupational health is the absence of established occupational exposure limits (OELs) and specific protection laws tailored to address the unique properties and potential hazards of nanomaterials.

The absence of established OELs for some nanomaterials poses a substantial challenge in ensuring the protection of workers from potential exposure-related health hazards. Conventional OELs designed for larger particles may not adequately account for the distinct physicochemical properties and toxicological effects of nanomaterials, highlighting the need for tailored exposure limits that consider nanoparticle-specific characteristics [25].

Recent research papers have underscored the intricate toxicological profiles of nanomaterials, emphasizing their potential to induce adverse health effects upon occupational exposure. From respiratory toxicity to dermal and systemic effects, the unique properties of nanomaterials necessitate specialized protection laws and exposure limits that account for their distinct modes of interaction with biological systems [88, 97].

Environmental pollution

Recent research has brought attention to the potential for contamination of water, soil, and air resulting from activities related to nanomaterial production, consumption, and research. The release of nanomaterials into the environment during manufacturing processes, product usage, and laboratory experimentation raises significant concerns about their impact on natural ecosystems and human health. Studies have emphasized the importance of comprehensive risk assessments and mitigation strategies to address the potential contamination of environmental matrices by nanomaterials, highlighting the need for proactive measures to protect environmental quality [30], Wigger et al. [90]).

The quality of nanoparticles and the sources from which they are released into the environment vary greatly. These days, there are no set rules or regulations governing the rapid development and growth of nanotechnologies, which has a negative impact on the environment and on workers in both indoor and outdoor environments. The massive and ongoing use of NPs for commercial and industrial applications has made it imperative to consider whether the risks to human health and the environment posed by these NPs can be outweighed by their growing use [36].

Moreover, recent academic discussions have emphasized the involvement of multiple stakeholders, including regulatory agencies, industry participants, and research institutions, as essential in addressing the potential contamination of environmental media by nanomaterials. Collaborative efforts aimed at developing guidelines, best practices, and monitoring protocols have been highlighted as crucial components in mitigating the environmental impact of activities related to nanomaterial production, consumption, and research. The incorporation of interdisciplinary research findings and proactive measures into policy development has been identified as a key strategy to minimize the potential contamination of water, soil, and air surrounding entities engaged in nanomaterial-related activities.

Potential psychological impacts of working with nanomaterials

Working with nanomaterials can have potential psychological impacts on employees, primarily stemming from stress and anxiety related to perceived health risks and safety concerns. Studies have shown that the uncertainty surrounding the long-term effects of exposure to nanomaterials can lead to heightened levels of anxiety among workers, as they grapple with the implications of working with substances whose health effects remain poorly understood. The perception of risk enhanced by media reports and varying regulatory guidance can contribute to a sense of vulnerability, impacting mental well-being and job satisfaction. Additionally, the complexity and novelty of nanotechnology may create feelings of inadequacy or fear of inadequacy among workers, particularly if they believe they lack the necessary training or understanding to handle these materials safely. Research indicates that such psychological strains can lead to reduced productivity, increased absenteeism, and even long-term mental health issues if not adequately addressed through effective communication, support systems, and comprehensive training programs. Thus, it is essential for organizations to recognize and mitigate these psychological impacts to foster a healthier work environment and enhance overall employee well-being [31].

Economic implications

The integration of nanotechnology in occupational health can have significant economic consequences such as:

Reducing treatment costs and developing treatment methods, improving work quality and reducing occupational accidents and increasing productivity, developing new products and services in the field of occupational health and creating innovation and new markets and reducing safety costs, as well as reducing accidents and Diseases Long-term health care costs are reduced.

For example: the costs of research and development, equipment and infrastructure, and training and acceptance can lead to a reduction of long-term costs, an increase in the quality of work life, and greater competitiveness among companies.

For example: the costs of research and development, equipment and infrastructure, and training and acceptance can lead to a reduction of long-term costs, an increase in the quality of work life, and greater competitiveness among companies.

Ethical considerations

The ethical questions about nanotechnology in the workplace arise from the state of knowledge about the hazards of nanomaterials and the risks they may pose to workers. The lack of clarity on these issues requires an interim assessment of the hazards and risks that might exist in various situations. Workers will be able to exercise their autonomy only if the processes leading to hazard identification and risk assessment are transparent and understandable. Employers will conform to the principles of autonomy, beneficence, nonmaleficence, justice, privacy and respect for persons to the extent that they a) accurately portray hazards and risks, b) are precautionary in their approach to hazards, c) engage in communication and dialogue with workers, and d) take the necessary steps to control risks so that they appear reasonable and acceptable to workers (Schulte and Salamanca).

Comparison of nanotechnology with other emerging technologies in occupational health

Nanotechnology is increasingly seen as a transformative field in various sectors, including occupational health. To fully understand its unique contributions and challenges, it is important to compare it with other emerging technologies such as biotechnology, artificial intelligence (AI), and wearable health technologies. Nanotechnology offers unique capabilities such as enhanced materials, improved drug delivery, and advanced sensing technologies that can significantly impact occupational health. However, it shares common challenges with biotechnology, AI, and wearable technologies, particularly concerning regulatory frameworks, understanding long-term effects, and managing ethical considerations. While each emerging technology provides solutions to improve occupational health, they must be carefully evaluated within the context of workplace safety, regulatory standards, and long-term health impacts. The complexity and pace of these advancements underscore the need for a collaborative approach that seeks to harness their benefits while mitigating potential risks.

Social Implications of Nanotechnology in Occupational Health

As nanotechnology continues to evolve and find its way into various industrial applications, it brings with it a range of social implications that can significantly impact workforce dynamics and job roles. Here are some potential changes to consider:

Shift in Skill Requirements: The introduction of nanotechnology in the workplace often necessitates new skill sets. Workers may need training to understand nanomaterials and their properties, which could lead to opportunities for reskilling and upskilling. This may widen the skills gap, as not all existing workers will have easy access to training programs.

Job Creation in Emerging Fields: As industries adopt nanotechnology, new roles will likely emerge in research, development, quality control, and compliance. This could stimulate job growth, particularly for those with expertise in nanotechnology, materials science, and engineering.

Changes in Task Structures: The implementation of nanotechnology may lead to a reorganization of tasks within the workplace. Automation and enhanced monitoring through nanotech can change the way certain jobs are performed, potentially reducing manual labor while increasing demand for oversight and technical roles.

Inequality and Access Issues: As nanotechnology advances, there’s a risk of exacerbating existing inequalities in the workforce. Access to training and development opportunities may be limited for certain demographics, which could lead to disparities in job quality and security between those who are able to adapt to new technologies and those who are not.

Potential for Job Displacement: While nanotechnology can create new job opportunities, it may also result in the displacement of some traditional jobs, particularly in manufacturing and labor-intensive sectors. Addressing this potential displacement will be critical to ensure a balanced transition.

Scalability of nanotechnology solutions in occupational health for small and medium-sized enterprises (SMEs)

The scalability of nanotechnology solutions in occupational health presents unique opportunities and challenges, especially for small and medium-sized enterprises (SMEs). While the potential benefits are significant, including enhanced safety, efficiency, and product quality, there are several factors to consider regarding the adoption and implementation of these technologies in SMEs [51].

Cost Considerations

-

Initial Investment: SMEs often operate with limited budgets, making the initial investment in nanotechnology solutions challenging. Advanced nanotechnology applications may require substantial upfront costs for equipment, materials, and training.

-

Economic Viability: The long-term economic benefits, such as reduced workplace hazards and improved productivity, can be difficult for SMEs to quantify in advance, potentially hindering adoption.

Access to Research and Development

-

Collaboration with Research Institutions: SMEs may lack the resources to conduct independent research and development. Collaborating with universities and research institutions can facilitate access to the latest nanotechnology innovations and pilot projects tailored to their specific needs.

-

Innovation Networks: Joining innovation networks or industry groups can enable SMEs to share knowledge, best practices, and resources, helping them to implement scalable nanotechnology solutions effectively.

Customization of Solutions

-

Tailored Applications: Nanotechnology applications often need to be customized for specific occupational health challenges. SMEs may benefit from developing partnerships with technology providers that offer scalable, customizable solutions that address their unique operational requirements.

-

Flexible Implementations: Solutions that can be scaled incrementally (e.g., starting with small-scale pilot applications) allow SMEs to assess effectiveness and costs before committing to large-scale implementation.

Regulatory Compliance and Safety Standards

-

Navigating Regulations: SMEs may struggle with the regulatory requirements associated with incorporating nanotechnologies. Simplified guidance and support from regulatory bodies can facilitate compliance and encourage adoption.

-

Adopting Best Practices: Developing clear, industry-specific guidelines can assist SMEs in implementing nanotechnology solutions while adhering to safety and health regulations, thereby ensuring employee well-being.

Training and education

-

Workforce Development: Ensuring that employees understand and can effectively utilize new nanotechnology solutions is crucial. SME leaders can implement training programs to upskill their workforce, which is essential for maximizing the benefits of nanotechnology.

-

Resources for Training: Collaborating with industry associations to access training resources, workshops, and seminars can help SMEs build a knowledgeable workforce proficient in nanotechnology applications.

The role of policy and advocacy in promoting safe and effective use of nanotechnology in occupational health

Policy and advocacy play a crucial role in promoting the safe and effective use of nanotechnology in occupational health by establishing regulatory frameworks that ensure the safety of workers exposed to nanomaterials. Effective policies can drive the development of standardized guidelines for the manufacture, handling, and disposal of nanomaterials, while also addressing gaps in toxicological data and occupational exposure limits. Advocacy efforts can raise awareness among stakeholders—such as employers, employees, and the general public—about the potential risks and benefits of nanotechnology, fostering informed dialogue and promoting best practices in workplace safety. By mobilizing resources and encouraging collaboration between the scientific community, industry leaders, and regulatory bodies, policymakers can support research initiatives that identify safe usage protocols and develop effective training programs for workers. Additionally, advocacy organizations can influence legislation and funding priorities to ensure that nanotechnology’s integration into occupational health prioritizes both innovation and worker safety, creating an environment conducive to sustainable development and broad societal trust.

The regulatory framework surrounding nanotechnology in the field of occupational health varies from country to country, encompassing a combination of specific regulations, guidelines, and general workplace safety frameworks. Let us examine in greater detail some significant regulations and guidelines in various regions:

United States: The Occupational Safety and Health Administration (OSHA) has issued a guidance document entitled “Protecting Workers from Exposure to Nanomaterials.” This publication provides recommendations for employers to evaluate and manage potential risks. Additionally, the National Institute for Occupational Safety and Health (NIOSH) has developed specific Recommended Exposure Limits (RELs) for certain nanomaterials, such as carbon nanotubes and nanofibers.

European Union: The REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation necessitates the registration and safety assessment of nanomaterials. Moreover, the European Commission has published the “Recommendation on the definition of nanomaterial,” which aims to establish a common understanding of what constitutes a nanomaterial for regulatory purposes.

Australia: The national work health and safety authority, Safe Work Australia, has formulated the “Code of Practice for the Safe Use of Nanomaterials in the Workplace.” This code offers guidance on the identification, assessment, and control of risks arising from nanomaterials.

Japan: The Ministry of Health, Labour and Welfare has issued the “Guidelines for Handling of Nanomaterials in the Workplace” to assist employers in the management of potential health and safety risks associated with nanomaterials.

Canada: The Canadian Centre for Occupational Health and Safety (CCOHS) has developed a resource titled “Nanotechnology: What Are the Occupational Health and Safety Concerns?” This resource aims to educate employers and workers on the potential hazards and best practices related to nanomaterials.

Overall, the regulatory landscape for nanotechnology in the context of occupational health is continuously evolving. Emphasis is placed on providing guidance and recommendations to employers and workers regarding the identification, assessment, and control of potential risks associated with nanomaterials in the workplace [35].

Training and education

Worker training and education are essential components for the safe handling of nanomaterials in occupational health, as they equip employees with the knowledge and skills necessary to recognize, assess, and mitigate potential risks associated with nanomaterials. Comprehensive training programs should encompass the unique properties and potential hazards of nanomaterials, proper use of personal protective equipment (PPE), and effective procedures for handling, storage, and disposal. Additionally, ongoing education is crucial to keep workers informed about new developments, emerging risks, and evolving regulatory guidelines related to nanotechnology. Engaging workers through interactive training methods, such as simulations and hands-on workshops, can enhance understanding and retention of safety practices while fostering a culture of safety within the workplace. By prioritizing education and training, organizations can empower workers to act as proactive participants in safeguarding their health and well-being and ensure compliance with safety standards, ultimately contributing to a safer work environment in the context of nanotechnology utilization.

Integration of nanotechnology with other occupational health technologies

The integration of nanotechnology with other occupational health technologies, such as IoT and artificial intelligence (AI), presents significant opportunities to enhance workplace safety and health monitoring. By leveraging IoT devices, nanomaterials can be embedded in sensors that continuously monitor environmental conditions and worker exposure to hazardous substances in real-time, providing actionable data that enables timely interventions. AI can analyze vast amounts of data collected from these sensors to identify patterns and predict potential health risks associated with nanomaterial exposure, facilitating proactive measures and informed decision-making. Furthermore, AI-driven predictive analytics can enhance the design of training programs, allowing customization based on specific workplace conditions and individual worker needs. This synergy not only fosters a more resilient and responsive occupational health framework but also aids in the development of advanced nanotechnology applications, ultimately promoting a safer work environment and improving overall employee health outcomes while driving innovation in safety practices [65].

Global disparities in access to nanotechnology solutions in occupational health

Global disparities in access to nanotechnology solutions in occupational health are evident, particularly between developed and developing countries, where differences in resources, infrastructure, and regulatory environments can limit the adoption and application of nanotechnological advancements. In many low- and middle-income nations, limited financial resources restrict investment in research, training, and the procurement of advanced safety equipment or materials, often leaving workers vulnerable to health risks associated with nanomaterials. To mitigate these disparities, several strategies can be implemented, such as fostering international collaborations to promote knowledge sharing and technology transfer, enabling developing countries to access and adapt existing nanotechnology solutions suited to their specific occupational health challenges. Additionally, establishing funding mechanisms and grants targeted at enhancing occupational health infrastructure in underserved regions can facilitate investments in training, education, and safety practices. Advocacy for the development of standardized guidelines that account for diverse economic contexts can also ensure that nanotechnology applications are both safe and practical across different settings. Lastly, incorporating local stakeholders in decision-making processes and implementation practices will ensure that solutions are culturally relevant and consider the unique socio-economic landscapes of affected regions, ultimately advancing equitable access to safe and effective nanotechnology solutions in occupational health worldwide.

Limitations and challenges

The practical implementation of nanotechnology in occupational health faces several significant limitations and challenges, including the lack of standardized regulatory frameworks specific to nanomaterials, resulting in insufficient safety practices and exposure limits. There are critical gaps in toxicological data and risk assessment methodologies, as traditional methods may not adequately address the unique properties and behaviors of nanomaterials. Furthermore, the complexity of these materials makes understanding long-term health effects challenging, while the necessity for specialized training and effective personal protective equipment (PPE) adds to workplace implementation issues. Economic considerations, such as high initial costs and limited market readiness, can deter investment and innovation, while interdisciplinary collaboration is often hindered by varying professional languages and goals. Additionally, public awareness and ethical concerns surrounding monitoring and consent complicate acceptance and integration in occupational health practices. Addressing these multifaceted challenges will require concerted efforts from industry stakeholders, researchers, and regulatory agencies to ensure worker safety while harnessing the potential benefits of nanotechnology.

Some suggestions

The vision of nanotechnology in occupational health is one that promotes improved safety and health for workers. The use of nanotechnology has led to the development of innovative products and solutions, contributing to a safer and healthier workplace. However, it is essential to address the challenges and concerns associated with nanotechnology, such as potential health risks and the lack of regulation, to ensure the responsible and ethical application of this technology in the workplace. By doing so, we can fully harness the potential of nanotechnology to enhance occupational health and safety for all workers.

There are several suggestions to mitigate the drawbacks of nanotechnology in occupational health:

-

1.

Enforce stringent safety regulations: The foremost step to reduce the risks of nanotechnology in the workplace is to enforce strict safety regulations. Governments and regulatory bodies should formulate and implement guidelines for the handling and use of nanomaterials. This encompasses proper labeling, storage, and disposal of nanoparticles, as well as providing workers with protective equipment and training.

-

2.

Conduct risk assessments: Before introducing any new nanotechnology into the workplace, conducting a comprehensive risk assessment is crucial. This involves identifying potential hazards, evaluating the level of exposure, and implementing appropriate control measures. It will aid in identifying areas that require special attention and developing effective risk management strategies.

-

3.

Foster responsible manufacturing: Industries engaged in nanotechnology production should embrace responsible manufacturing practices. This includes adhering to green chemistry principles, minimizing the release of nanoparticles into the environment, and designing products with end-of-life considerations. This approach not only reduces potential risks to workers but also benefits the environment and society as a whole.

-

4.

Develop safer nanomaterials: Another avenue to mitigate the health hazards of nanotechnology is to develop safer nanomaterials. Scientists and researchers should focus on developing nanoparticles that are less toxic and biodegradable. This not only enhances the safety of workers but also minimizes the environmental impact of nanotechnology.

-

5.

Educate and train workers: Proper education and training are imperative for workers exposed to nanoparticles. They should receive education about the potential risks and how to handle them safely. Regular training programs should be conducted to update workers on new safety protocols and procedures.

-

6.

Encourage research on health effects: While nanotechnology has shown promising benefits, there remains a dearth of research on its potential health effects. Governments and organizations should promote and fund research on the health effects of nanoparticles. This will aid in developing improved safety guidelines and control measures.

-

7.

Promote transparency and communication: Employers should foster transparency and open communication with their workers. This entails informing them about the potential risks of working with nanoparticles, providing access to safety data sheets, and encouraging them to report any health concerns. This will cultivate a culture of safety and aid in promptly identifying and addressing any safety issues.

-

8.

Develop monitoring and surveillance systems: Monitoring and surveillance systems should be established to track the level of exposure to nanoparticles and any associated health effects. This will facilitate the identification of potential risks and the implementation of control measures before they become a major problem.

Conclusion