Abstract

Adsorption of lead is an environmentally sustainable approach to remediate lead pollution in water to protect human and environmental health. Therefore, the current study seeks to develop a new adsorbent material using alginate carbon nanoparticle (ACNP) composite beads and explore its efficacy in removing lead ions through a series of batch experiments. SEM and EDX analysis have been used to characterize ACNP composite. ACNP showed strong Pb2+ adsorption at pH 5.5. The pseudo-first-order model cannot adequately fit the experimental data. The high R2 (0.99) and strong agreement between the observed qe (13.81 mg/g) and computed qe (14.62 mg/g) values demonstrate the pseudo-second-order model's applicability to explain and interpret the experimental data. The intraparticle diffusion model had a low R2 value, indicating that intraparticle diffusion was not the only rate-controlling step for the removal of Pb2+ ions by the ACNP composite beads and chemisorption was involved in the adsorption process. The Langmuir model's strong correlation coefficient (R2 = 0.997) confirms monolayer coverage and chemisorption of Pb2+ onto the adsorbent surface. The experimental findings demonstrated good compatibility for the Freundlich model, indicating chemical adsorption. The linear graph of the Temkin isotherm matches well, with R2 of 0.97 confirming chemical adsorption. The DKR mean free energy, E = 13.3 kJ/mol, indicate chemisorption with ion-exchange mode. The values of ΔG° indicate favorable adsorption at lower temperatures, whereas the value of ΔH° (− 65.0 kJ mol−1) implies exothermic adsorption, as evidenced by decreased Pb2+ adsorption as temperature rises. HCl solution can be used to regenerate ACNP composite beads. Therefore, the current work suggests that ACNP composite beads might be a suitable material for sequestering lead ions from aqueous solutions.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Heavy metals are extremely poisonous and carcinogenic, and they accumulate throughout the food chain, causing severe harm to humans and other living species. Heavy metals, such as lead, mercury, chromium, copper, zinc, and arsenic, are discharged into the environment by industries. Heavy metals are harmful even at trace levels, and strict regulations on their release into the environment are currently in place [1,2,3,4]. Lead (Pb2+) ions are one of the most dangerous, poisonous, and carcinogenic heavy metal ions, with a variety of antagonistic effects on tissues and living organisms [5,6,7]. Lead (Pb) is a metal that is widely found in drinking water and food as a result of industrial activity expansions. In this context, the EPA and WHO guidelines regulate the maximum residual limit level for lead ions in drinking water to 10 μg/L [8, 9]. Poisoning from lead is most commonly caused by ingesting contaminated food or water. In humans, the toxicological consequences of Pb2+ ions include anemia, sterility, hypertension, learning difficulties, abortion, renal damage, and mental retardation [10]. As a result, removing Pb2+ from water is critical for human and environmental health protection. Although numerous strategies for dealing with water pollution have been proposed, such as adsorption [11, 12], photo-degradation [13], ion-exchange [14], chemical precipitation, and electrochemical treatment [15], widespread application of these technologies is difficult due to their high costs and complicated processes. As a result of these constraints, there is a need to investigate low-cost and efficient adsorbents that are ecologically friendly and remove metal ions to acceptable ranges. Adsorption is well recognized as a competitive technology due to its ease of use, cheap cost, and great performance through the use of a wide range of adsorbents [16, 17]. Sodium alginate (SA) is a natural polymer derived from marine brown algae that is a non-toxic, biodegradable, and biocompatible natural anionic polysaccharide. Alginate is mostly comprised of –l-guluronate (G) and –d-mannuronate (M). It has carboxyl (–COOH) and hydroxyl (–OH) functional groups along the polymer. Due to its chemical structure, alginate has various advantages in a variety of applications. One of these applications is the possibility of employing functional groups as sites for coordination and interaction with polyvalent metal ions for removal from aqueous solutions [18,19,20,21,22,23]. To improve the performance and stability of alginate for environmental applications, various materials have been introduced into alginate hydrogel (microspheres) including biochar, activated carbon (AC), graphene oxide (GO), carbon nanoparticles (CNs), magnetic materials and microorganisms [24,25,26]. Carbon nanoparticles (CNs) have a wide range of uses related to pollutants removal due to their unique properties, which give them great ability to adsorb pollutants, as well as their high surface area. However, the powder form of CNs has some limitation in its application, where CNs is so small and forms aggregates making it difficult to separate them from aqueous solution [27,28,29]. As well, the incorporation of these carbonaceous elements into alginate hydrogels or beads facilitates their separation and regeneration from aqueous solutions [30, 31]. Therefore, this work aims to develop a new adsorbent material by incorporating the CNs into natural polymeric structures such as alginates to form ACNP composite porous bead to enhance alginate and CNs performance and stability in environmental applications, as well as investigate its lead ions removal effectiveness using a series of batch tests.

Materials and methods

Chemicals and reagents

All chemicals such as a stock solution of Pb2+ ions were prepared in deionized water from lead chloride (PbCl2, with 99.8% purity, Fisher Chemical). Sodium Chloride, sodium hydroxide and hydrochloric acid (37%) were supplied by Fluka (Germany). A stock solution (1000 mg/L) of Pb2+ ions was prepared followed by the preparation of different working solutions of desired concentrations by proper dilution. Sodium alginate was purchased from Fisher Scientific Limited (UK) (40mesh/60). Calcium chloride and carbon nano-powder < 100 nm particle size (TEM) were purchased from Sigma Aldrich (Germany).

Preparation of alginate carbon nanoparticle (ACNP) composite beads

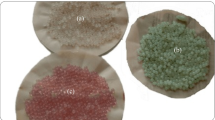

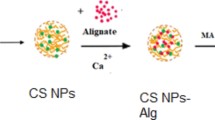

Preparation of alginate carbon nanoparticle (ACNP) composite beads, sodium alginate solution (2%) (w/v) was prepared by dissolving 2 g of sodium alginate in 100 mL distilled water with stirring for 3 h. The resulting solution was degassed by sonication for 30 min to get rid of gas bubbles. Carbon nano-powder (0.1 g) was added to the alginate solution with stirring for 3 h at room temperature. The resulting solution was degassed by sonication for ½ hour. The ACNP composite beads were prepared by dropping the alginate carbon nano-powder mixture solution into magnetically stirred 3% (w/v) CaCl2 solution by NRC-5Pro microencapsulation apparatus (invented and manufactured by our group) (Korany A. Ali, Variable electric charge microencapsulation device, Egyptian Patent: application no. 533/2019) to give gel beads (diameter 5 mm). A micrometer was used to check the size of the prepared beads.

Characterization of adsorbent

The surface morphology of the ACNP composite beads was determined using a Model Quanta 250 FEG (Field Emission Gun). Using the sputtering process, the gel surface was first covered with a thin coating of gold. Element content information of materials in this work was obtained by Energy-dispersive X-ray spectroscopy (EDX). The surface structure of the prepared beads was characterized by Scanning Electron Microscopy (SEM). SEM images were taken at various magnifications and revealed a high porosity and an enormous number of cavities in the morphology.

Determination of point of zero charge (pHPZC)

The pHPZC of the alginate carbon nanoparticle (ACNP) composite beads was determined by using degassed 0.01 M NaCl solutions, at 298 K. In different flasks, 50 mL of 0.01 M NaCl solution were taken and the pH values were adjusted at 2, 4, 6, 8, 10, 12 and 14 using HCl or NaOH solutions and then mixed with 50 mg of ACNP composite beads. Each flask was covered with Parafilm and shaken for 24 h. The final pH values of the solutions were recorded and the difference between the initial and final pH (the so-called Δ pH) was plotted against the initial pH values. The PZC values were calculated from Δ pH vs. pH plots, at the pH where Δ pH = 0 [32].

Batch experiments for lead adsorption

Adsorption measurement was determined by batch experiments of known amounts of the adsorbent with 50 mL of aqueous lead solutions of known concentration in a series of 250 mL Erlenmeyer conical flasks. The mixture was shaken at a constant temperature of 25 °C using an orbital shaker incubator at 120 rpm for a period of 240 min. The residual lead concentration in the reaction mixture was analyzed by inductive coupled plasma optical emission spectrometry (Agilent ICP-OES 5100, Australia) according to examination standard methods. Adsorption experiments were conducted by varying initial solution pH (2–5.5), contact time (30–300 min.), adsorbent dose (0.1–0.5 g) and initial lead concentration (20–250 mg/L) under the aspect of adsorption kinetics and adsorption isotherm study. Before adding alginate carbon nanoparticle (ACNP) composite beads, the pH of the solutions was adjusted by adding a negligible volume of 0.01 or 0.1 mol/L HCl and/or NaOH solutions.

The percentage of Pb2+ ions removal efficiency (R%) was calculated by using Eq. (1) as follows:

where

Co = initial lead concentration (mg/L),

Ce = equilibrium or final lead concentration in the solution (mg/L).

The equilibrium adsorption capacity qe (mg Pb/g ACNP) i.e., the quantity of lead adsorbed by unit mass of ACNP composite beads was determined by the following Eq. (2):

where

qe = lead adsorbed at equilibrium (mg/g),

m = adsorbent mass (g),

v = solution volume in (L).

The distribution coefficient (Kd) of lead between the aqueous phase and the solid phase was calculated from the following Eq. (3):

Kinetic modelling

The kinetic parameters, which are useful for the prediction of adsorption rate, give important information for designing and modelling the adsorption processes. Thus, the kinetics of lead onto alginate carbon nanoparticle (ACNP) composite beads were investigated using pseudo-first and second-order kinetic models.

The pseudo-first-order model

The Lagergren pseudo-first-order model described the adsorption kinetic data which is the earliest known equation describing the adsorption rate based on the adsorption capacity. The integral form of the pseudo-first-order model is generally expressed as:

where qt and qe are the adsorption capacity at time t and at equilibrium, respectively (mg/g), k1 is the rate constant of pseudo-first-order adsorption (liters per minute), and t is the contact time (minute). To obtain the rate constants, plot log (qe − qt) versus t to give a linear relationship from which k1 and predicted qe can be determined from the slope and intercept of the plot, respectively.

The pseudo-second-order model

The adsorption kinetic may be described by the pseudo-second-order model. The simplified linear equation of pseudo first–second-model is described as:

where k2 is the pseudo-second-order rate constant in mg/g min. The plot of t/qt versus t shows a linear relationship. Where the values of k2 and equilibrium adsorption capacity qe could be calculated from the intercept and slope.

Adsorption isotherm

Four extensively used adsorption isotherm models, namely, Langmuir, Freundlich, Dubinin-Kaganer-Radushkevich (DKR) and Temkin were selected to correlate the experimental data and to describe the adsorption isotherms exactly. The deviation between experimentally observed and theoretically calculated data can be described by the square of the correlation coefficient (R2).

Langmuir adsorption isotherm

This model assumed that adsorption takes place at specific homogeneous sites within the adsorbent and it has been used successfully for many adsorption processes of monolayer adsorption [33]. The linear Langmuir equation can be written as follows:

where Ce (mg/L) represents the equilibrium concentration of the solute, qe (mg/g) is the amount of lead adsorbed per unit mass of the adsorbent, qmax (mg/g) represents the maximum adsorption capacity, b (L/mg) is the Langmuir constant. qmax and b are calculated by the linear plots of Ce/qe against Ce.

Freundlich adsorption isotherm

This model considers a heterogeneous adsorption surface that has unequal available sites with different energies of adsorption [34]. The linear Freundlich equation can be expressed as follows:

where qe is the equilibrium adsorption capacity (mg/g), Ce is the equilibrium concentration of lead in solution (mg/L), kf represents a Freundlich constant related to the adsorption capacity and n is also a Freundlich constant related to the adsorption intensity. Kf and n can be determined from the intercept and slope of the linear plot of ln qe against log Ce.

DKR adsorption isotherm

Another adsorption isotherm (DKR model) was used to evaluate the porosity apparent free energy and adsorption characteristics [35]:

where qe is adsorption capacity at equilibrium (mol/g), Xm is the theoretical DKR monolayer adsorption capacity (mol/g), β (mol2/J2) is a constant allied to adsorption energy, and ε (J/mol) is the Polanyi potential related to the equilibrium concentration and can be defined as follows:

The mean adsorption energy, E (kJ/mol) provides information regarding chemical and physical adsorption, and can be derived by using the following equation [36]:

Temkin adsorption isotherm

The adsorption data were analyzed using the linear form Eq. (11) of the Temkin isothermal model to estimate the heat of adsorption of adsorbate molecules with the extent of coverage over the surface of adsorbent particles [37]:

where qe is the amount of analyte (mg/g) adsorbed at equilibrium, Ce is the final concentration (mol/L) at equilibrium, bt is the Temkin isotherm energy constant (J/mol) related to the heat of adsorption and At is the Temkin isotherm constant.

Thermodynamic studies

Adsorption thermodynamic parameters were calculated from the temperature variations using the van’t Hoff equation [38] and the values of other variables (ACNP dose, contact time, initial concentration of lead ions and pH) were fixed. The changes of Gibbs free energy change (ΔG°), enthalpy (ΔH°), and entropy (ΔS°) of adsorption of Pb2+ ions on (ACNP) composite beads were calculated using the next equations.

where the gas constant R = 8.314 J mol−1 K; T in K; Kc = qe/Ce (L/mg) the constant of standard thermodynamic equilibrium.

Analytical method

The concentration of lead ions in the aqueous solution (Ceq, mg/L) was analyzed according to APHA (2017) [39], using Agilent ICP-OES 5100, Australia. Synchronous Vertical Dual View (SVDV) after calibration with a series of Pb calibration solutions.

Batch adsorption/desorption studies

The ability of alginate carbon nanoparticle (ACNP) composite beads to regenerate as an adsorbent material for re-use under appropriate and cost-effective conditions is assessed using the desorption process. In this experiment, ACNP composite beads loaded with Pb2+ ions were placed into a flask containing 50 mL of HCL with different concentrations (0.1, 0.2, 0.3, and 0.4 M) as a desorbing agent. The mixture was agitated for 120 min at 120 rpm using a rotary shaker at ambient temperature. The mixture was then filtered, and the Pb2+ ions concentration in the filtrate was determined. Before being used again, the eluted ACNP composite beads were rinsed several times with deionized water to eliminate any remaining desorbing solution. The adsorption–desorption cycle was done five times, each time using the same ACNP composite beads and a 150 mg/L initial concentration. The regeneration efficiency (RE %) of ACNP composite beads as an adsorbent agent is calculated using the equation below.

where, qr and q0 denote the adsorption capacity (mg/g) of the ACNP composite beads after regeneration and before regeneration (original capacity) (mg/g), respectively [40].

Results and discussion

Characterization of adsorbent

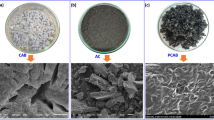

The surface morphology of the ACNP composite beads was determined using a Model Quanta 250 FEG (Field Emission Gun). Using the sputtering process, the gel surface was first covered with a thin coating of gold. Element content information of materials in this work was obtained by Energy-dispersive X-ray spectroscopy (EDX). The surface structure of the prepared beads was characterized by Scanning Electron Microscopy (SEM). SEM images were taken at various magnifications and revealed a high porosity and a enormous number of cavities in the morphology. Figure 1 is obvious that the surface of the beads was very porous, which provides more active sites for metal ion adsorption. Since the porous structure of the alginate active carbon ensures sufficient space for metal ion adsorption that increased its ability to adsorb Pb2+ metal ions.

EDX analysis was employed to further investigate the structure of ACNP composite beads, Fig. 2a, b represents a comparison of the EDX of raw and Pb-loaded ACNP composite beads, respectively. The adsorption of Pb2+ ions onto the adsorbent-based energy dispersion peaks observed for the corresponding metal ions is confirmed by EDX analysis. The EDX analysis of polymer ACNP composite beads shows the peaks corresponding to the C, O and N atoms (Fig. 2a). A strong peak appears in the EDX spectrum of the Pb-loaded ACNP adsorbents corresponding to the Pb2+ ions (Fig. 2b). As a result, the EDX indicates that Pb2+ ions are trapped on the surface of the ACNP composite beads. In addition to Pb2+ ions peak, the peaks that correspond to C, O and N atoms are additionally present. This demonstrates that Pb2+ ions are connected with the chelating groups such as COOH, OH linkage in the formation of coordinate bonds. The corresponding peak for Ca2+ ions was due to the CaCl2 that was used as cross-linker for coagulation of alginate beads.

Optimization of lead adsorption conditions

Point of zero charge (pHPZC)

The point of zero charge, abbreviated as pHPZC, refers to the adsorbent's electrical neutrality in solution at a specific pH value [41]. In the current work, the pHPZC of ACNP composite beads was calculated using the pH drift technique [42]. Figure 3 depicts a graph of ΔpH vs initial pH, and the pHZPC of alginate carbon nanoparticle (ACNP) composite beads was determined to be 7.4.

Effect of pH

pH value is an essential factor that affects the adsorption process because speciation and surface charge fluctuate as a function of pH. To minimize metal precipitation at higher pH levels, adsorption was carried out at pH values ranging from 2 to 5.5, where solid Pb(OH)2 was the dominant species from pH 6 to 14 [43, 44]. Figure 4 illustrates the effect of pH on the adsorption of Pb2+ ions onto ACNP composite beads at the equilibrium contact times (120 min). It is obvious that the adsorption of Pb2+ ions by ACNP composite beads increased progressively as the pH rose from 2 to 5.5, reaching a maximum value at a pH 5.5 (Fig. 4). As a result, the optimal pH (pH = 5.5) was adopted for the following lead adsorption experiments on ACNP composite beads. When the pH of the solution increased, the concentration of H+ ions in the solution dropped, resulting in greater deprotonation of the surface of the alginate carbon nanoparticle (ACNP) composite beads, as a result, the competition for binding sites on the ACNP composite beads between H+ and Pb2+ ions reduced leading to high adsorption. ACNP composite beads have a pHPZC of 7.4, so it was expected that the adsorption will be very low at lower pH values due to great protonation which enhances the positive charge on the ACNP composite beads surface. Hence, repulsion between Pb2+ and the adsorbent was predicted, but an excellent adsorption has occurred, this implies that the adsorption process of Pb2+ ions and H+ in ACNP composite beads is dependent on ion exchange rather than electrostatic force [45].

Effect of contact time

One of the key factors influencing adsorption equilibrium is contact time. The effect of contact time was monitored in batch experimental mode with Pb2+ ions initial concentration of 150 mg/L and contact time range of 30–240 min, while the other parameters were fixed at pH 5.5 and 0.4 g ACNP composite beads at room temperature. The experimental findings shown in Fig. 5 demonstrated that at equilibrium, 14.3 mg/g (74.7%) of the lead ions in the solution were adsorbed. It may thus be concluded that the metal-binding rate with adsorbent is higher throughout the early phases and up to the optimal contact period, which was determined to be 120 min. This might be owing to the fact that all sites on the surface of the ACNP composite beads are available, as well as the strong lead concentration gradient. From 120 to 240 min, the rate became constant, indicating that the system had reached equilibrium. Odubiyi et al. [46] noticed a similar pattern in their study of the removal of metal ions from aqueous solution using activated charcoal produced derived from cocoa pod husk, as did Gupta et al. [47], who found that the adsorption effectiveness of lead and nickel ions using waste rubber tyre increased for the first 2 h of contact time before levelling off. As a result, for future experiments, 120 min was established as the equilibrium duration for lead adsorption by ACNP composite beads.

Effect of adsorbent dosage

The effect of adsorbent dosage was studied for 50 mL of Pb2+ solution for 120 min at the range of 0.1–0.7 g ACNP composite beads. The pH was set at 5.5, and the initial concentration of Pb2+ ions was 150 mg/L. The results illustrated in Fig. 6 indicate that when the adsorbent dose increased from 0.1 and 0.4 g, the proportion of lead ions eliminated increased. These findings are explained by the fact that increasing the adsorbent dose gradually increases the adsorption sites available for metal ions. Further increasing the adsorbent dosage up to 0.7 g resulted in no significant increase in adsorption and consistent adsorption. This might be attributable to oversaturation of the adsorbent's attachment sites, which is caused by metal ion overcrowding on the sites [48,49,50]. As a result, throughout the rest of the batch studies, 0.4 g of the adsorbent dose was employed as the operational dosage. The adsorbent's adsorption capacity equilibrium (qe) dropped from 16 to 3.4 mg/g as the dose of ACNP composite beads increased from 0.1 to 0.7 g. This might be owing to the fact that the maximum adsorption was reached after a certain dosage of ACNP composite beads, while the Pb2+ ions concentration remains constant even with further addition of adsorbent, therefore the amount of Pb2+ ions adsorbed per unit mass decreased due to lower availability of Pb2+ ions per unit mass of the adsorbent [51,52,53].

Effect of lead initial concentration

The effect of initial Pb2+ ions concentration on its adsorption was investigated by mixing 0.4 g of ACNP composite beads with 50 mL of lead solutions ranging from 50 to 300 mg/L for 120 min at a pH of 5.5, As a function of the initial concentrations of Pb2+ ions in the solution, the adsorption capacity and removal efficiency of the ACNP composite beads are displayed in Fig. 7. The adsorption capacity of ACNP composite beads increased linearly with increasing initial Pb2+ ion concentrations until reaching a saturation value of 200 mg/L (qe = 17.13 mg/g). This might be due to the fact that the available adsorption surface and active sites were fully utilized, which is not possible at low concentrations [54, 55]. As the metal ion concentration increased from 50 to 300 mg/L, the removal percentage of Pb2+ ions declined from 92.4 to 47.7%. At higher metal ion concentrations the available adsorption sites of the adsorbent material get saturated and become fewer, consequently, the percentage of metal ions removed decreases as the initial metal ion concentration increases [56, 57].

Adsorption kinetics and mechanism

The kinetics of adsorption in terms of the order of rate constant can be used to study the dynamics of adsorption. The adsorption rate is an important parameter when selecting an adsorbent; the adsorbent should have a significant adsorption capacity as well as a rapid adsorption rate.

For the pseudo-first-order model, the rate of adsorption was predictable to be proportional to the first power of concentration, where the adsorption was characterized by diffusion through a boundary. In this model (Lagergren model), by plotting the values of log (qe–qt) vs t, the value of k1 and qe can be calculated from the slope and intercept of the obtained line, respectively (Fig. 8). The correlation coefficient (R2) is used to assess the model's validity. The low value of R2 (0.81) denotes that the pseudo-first-order model is unable to adequately match the experimental data. Furthermore, the deviation of the calculated qe (2.99 mg/g) from the experimental qe value (13.81 mg/g) indicates that this model does not adequately explain experimental data and the rate of adsorption do not follow this equation. Therefore, the kinetic data of adsorption were described using the pseudo-second-order-kinetic equation. The plot of t/qt versus t for the pseudo-second-order kinetic model (Fig. 9) showed a straight line with a strong correlation coefficient. From the intercept and slope, the k2 and equilibrium adsorption capacity (qe) are determined, respectively. The high values of R2 (0.99 for adsorption of Pb2+ ion) and strong agreement between the experimental qe (13.81 mg/g) and calculated qe (14.62 mg/g) values demonstrate the pseudo-second-order model's applicability in explaining and interpreting the experimental data (Table 1). This model is used to explain chemical adsorption, particularly metal ion adsorption on various adsorbents [58]. According to pseudo-second-order model, the results demonstrated that the adsorption is reversible and the rate of the whole removal process was dominated by chemical adsorption. The later process possibility is explored using the intra-particle diffusion model based on diffusive mass transfer where the adsorption rate is expressed in terms of the square root of time (t). The intraparticle diffusion (Fig. 10) shows multi-linearity in the adsorption process implying that two steps are operational. The first stage, at 5–11 min1/2, its attributed to the diffusion of Pb2+ ions through the solution to the boundary layer of the (ACNP) composite beads followed by a gradual adsorption over the (ACNP) surface, where intraparticle diffusion is rate-limiting. The second stage at 11–15.5 min1/2 is the final equilibrium stage where the intraparticle diffusion starts to slow down due to extremely low available active sites (ACNP) composite beads left in solution. The two stages in the plot suggest that the adsorption process occurs via diffusion (meso- and macropores) [49]. The values of kd (mg g−1 min−1/2) and C (mg/g) were calculated from the slope and intercept of the plot of qt versus t1/2 for each linear stage separately (Table 1).

Adsorption isotherms

The equilibrium adsorption data may be used to better understand the interaction between adsorbate and adsorbent, as well as to design and run the adsorption process. For the data analysis, many isothermal models were employed. In this work, four models are used to explore the single-solute adsorption process: Freundlich, Langmuir, Dubinin–Kaganer–Radushkevich (DKR), and Temkin isotherms [59, 60].

Langmuir isotherm

Figure 11 shows the Langmuir isotherm for the adsorption of Pb2+ ions by ACNP, and Table 2 lists the calculated parameters. The high correlation coefficient (R2 = 0.997) and the closeness between the calculated Langmuir adsorption capacity (qe cal = 19.19 mg/g) and the measured experimental value (qe exp = 13.81 mg/g) indicated a good agreement between the parameters and confirms the monolayer coverage and chemisorption of Pb2+ onto the adsorbent surface [61].

Freundlich isotherm

The findings in Fig. 12 and Table 2 reveal that the experimental results were well suited to the Freundlich model, with R2 = 0.96. A value of n greater than one was also found, indicating that there is a high affinity between the adsorbent and the adsorbate, denoting chemical adsorption [62]. The kf value was 4.2, which reflects the adsorption capacity of the adsorbent, i.e., the higher the value, the better the ability to adsorb the Pb2+ ions present in the solution.

Temkin isotherm

The Temkin isotherm takes into account the interaction of adsorbent and adsorbate and is based on the concept that the free energy of adsorption varies with surface coverage. The Temkin model predicts a linear reduction in heat of adsorption with increasing surface coverage.

Linear plots for Temkin adsorption isotherm (Fig. 13) fit quite well with correlation coefficients ≥ 0.97 (Table 2) indicating chemical adsorption [63].

Dubinin– Kaganer–Radushkevich (DKR) isotherm

In general, if the magnitude of E is in the 8–16 kJ/mol range, the adsorption is chemisorption with ion-exchange mode, but, in the case of E values of 1–8 kJ/mol, it is physical adsorption [64, 65]. In this study, the linear plot of the DRK model as shown in Fig. 14 revealed that Xm was 48.1 mg/g, the mean free energy was 13.3 kJ/mol, and the R2 was 0.97, confirming chemisorption with ion-exchange mode.”

Thermodynamic studies

To investigate the nature of Pb2+ adsorption on ACNP, the relevant parameters of standard free energy (ΔG°), enthalpy change (ΔH°), and entropy change (ΔS°) were computed using the linear Van't Hoff formula.

The ln Kc against 1/T (Fig. 15) were used to determine the ΔH° and ΔS°, and the results are presented in Table 3.

The values of ΔG° indicate favorable adsorption at lower temperature while the value of ΔH° (− 65.0 kJ mol−1) indicates the exothermic adsorption, which is corroborated by decreasing Pb2+ adsorption as temperature increases. Negative entropy value (− 206.94 J K−1 mol−1) indicates the strong affinity of ACNP toward Pb2+ and the adsorbed ions are more ordered on the surface of the adsorbent [41, 66].

Elution of lead

Stability is a critical issue when the same sorbent material is employed in repeated adsorptions cycles. Using 0.4 M of HCl as a desorbing agent successfully desorbed 88.3% of loaded lead ions against 50% for 0.1 M HCl. The adsorption capacity (qe mg Pb2+ ions/g ACNP) and regeneration efficiency (RE%) of ACNP composite beads as an adsorbent agent are shown in Fig. 16.

After cycle 5, the adsorption capacity of alginate carbon nanoparticle (ACNP) composite beads towards Pb (II) ions dropped by less than 3%, from 13.9 mg Pb (II)/ g ACNP to 13.5 mg Pb/ g ACNP. As a result, regeneration of ACNP composite beads after adsorption equilibrium was possible. The regeneration efficiency of ACNP composite beads for Pb (II) can be classified as stable because the RE % for all 5 cycles was greater than 97%. It is well known that acidic conditions are favorable for the desorption of trace metals from aqueous solutions. The following mechanisms are proposed to explain why: (1) lower pH favors metal cation desorption or dissolution; (2) at lower pH, there is a considerable competition between protons (H+) and metal ions for adsorption sites, resulting in metal ions being replaced by protons [44, 67]. These results indicate that the adsorbent had a high potential for adsorption of Pb2+ ions and that the adsorption–desorption process employing composite was reversible. The heavy metal-loaded alginate carbon nanoparticle (ACNP) composite beads can be regenerated by HCl solution. The regenerability and recyclability of ACNP composite beads demonstrated it is a promising material for sequestering heavy metals aqueous solution.

Conclusion

The current work aims to develop a new adsorbent material using alginate carbon nanoparticle (ACNP) composite beads, as well as investigate its lead removal effectiveness using a series of batch tests. The results indicate that the pseudo-first-order model cannot adequately match the experimental data, but the pseudo-second-order model can explain and interpret the experimental data. With a correlation coefficient value of 0.997, the Langmuir model confirms the monolayer coverage and chemisorption of Pb2+ onto the adsorbent surface. The experimental findings demonstrated good compatibility for the Freundlich model, with R2 = 0.96 and n greater than 1, indicating chemical adsorption. Linear graphs of the Temkin adsorption isotherm of Pb2+ onto ACNP match well, with correlation values of 0.97 confirming chemical adsorption. The DKR model's mean free energy, E = 13.3 kJ/mol, and R2 = 0.97 indicate chemisorption adsorption. The adsorption of Pb2+ onto ACNP was most likely mediated by ion-exchange processes. The results were better fitted to the Langmuir isotherm rather than Temkin, DKR, and Freundlich isotherms. The thermodynamic study revealed an exothermic adsorption of Pb2+ ions on ACNP with a negative entropy value (− 206.94 J K−1 mol−1), indicating ACNP's significant affinity for Pb2+. HCl solution can be used to regenerate ACNP composite beads. As a result, the current work suggests that ACNP composite beads may be a suitable material for sequestering Pb2+ ions from aqueous solutions.

Availability of data and materials

All data generated or analyzed during this study are included in this published article.

References

Selvi A, Rajasekar A, Theerthagiri J, Ananthaselvam A, Sathishkumar K, Madhavan J, Rahman PK (2019) Integrated remediation processes toward heavy metal removal/recovery from various environments—a review. Front Environ Sci 7:66

Theerthagiri J, Lee S, Karuppasamy K, Arulmani S, Veeralakshmi S, Ashokkumar M, Choi MY (2021) Application of advanced materials in sonophotocatalytic processes for the remediation of environmental pollutants. J Hazard Mater 412:125245

Theerthagiri J, Lee SJ, Karuppasamy K, Park J, Yu Y, Kumari MA, Chandrasekaran S, Kim HS, Choi MY (2021) Fabrication strategies and surface tuning of hierarchical gold nanostructures for electrochemical detection and removal of toxic pollutants. J Hazard Mater 420:126648

Vijayaraghavan P, Lourthuraj AA, Arasu MV, Abdullah Al-Dhabi N, Ravindran B, Woong Chang S (2021) Effective removal of pharmaceutical impurities and nutrients using biocatalyst from the municipal wastewater with moving bed packed reactor. Environ Res 200:111777

Anyakora C (2010) Heavy metal contamination of ground Water: the surulere case study. Res J Environ Earth Sci 2:39–43

Nodeh HR, Shakiba M, Gabris MA, Bidhendi ME, Shahabuddin S, Khanam R (2020) Spherical iron oxide methyltrimethoxysilane nanocomposite for the efficient removal of lead (II) ions from wastewater: kinetic and equilibrium studies. Desalin Water Treat 192:297–305

Yu Y, Naik SS, Oh Y, Theerthagiri J, Lee SJ, Choi MY (2021) Lignin-mediated green synthesis of functionalized gold nanoparticles via pulsed laser technique for selective colorimetric detection of lead ions in aqueous media. J Hazard Mater 420:126585

Dongre RS (2020) Lead: toxicological profile, pollution aspects and remedial solutions. In: Chooto P (ed) Lead chemistry. Intech Open, Rijeka

Arbabi M, Hemati S, Amiri M (2015) Removal of lead ions from industrial wastewater: a review of removal methods. Shahrekord Univ Med Sci 2:105–109

El-Kady AA, Abdel-Wahhab MA (2018) Occurrence of trace metals in foodstuffs and their health impact. Trends Food Sci Technol 75:36–45

Ibrahim HS, El-Kady AA, Ammar NS, Meesuk L, Wathanakul P, Abdel-Wahhab MA (2013) Application of isotherm and kinetic models for the removal of lead ions from aqueous solutions. J Environ Eng 139(3):349–357

Wang J, Zhang L, Zhang T, Du T, Li T, Yue T, Li Z, Wang J (2019) Selective removal of heavy metal ions in aqueous solutions by sulfide-selector intercalated layered double hydroxide adsorbent. J Mater Sci Technol 35:1809–1816

Ali MEM, Jamil TS, Abdel-Karium A, El-Kady AA (2019) Utilization of activated carbon for maximizing the efficiency of zirconium oxide for photodegradation of 4-octylphenol. J Environ Sci Health Part A 55(11):1055–1065

Senguttuvan S, Senthilkumar P, Janaki V, Kamala-Kannan S (2020) Significance of conducting polyaniline based composites for the removal of dyes and heavy metals from aqueous solution and wastewaters—a review. Chemosphere 267:129201

Ntagia E, Fiset E, Hong LTC, Vaiopoulou E, Rabaey K (2020) Electrochemical treatment of industrial sulfidic spent caustic streams for sulfide removal and caustic recovery. J Hazard Mater 388:121770

El-Kady AA, Sharaf HA, Abou-Donia MA, Salah-Abbès SAJB, Naguib MN, Oueslati R, Abdel-Wahhab MA (2009) Adsorption of Cd2+ ions on an Egyptian montmorillonite and toxicological effects in rats. J Appl Clay Sci 44:59–66

Sellaoui L, Franco D, Ghalla H, Georgin J, Netto MS, Dotto GL, Bonilla-Petriciolet A, Belmabrouk H, Bajahzar A (2020) Insights of the adsorption mechanism of methylene blue on Brazilian berries seeds: experiments, phenomenological modelling and DFT calculations. Chem Eng J 394:125011

Ali KA, Hassan ME, Elnashar M (2017) Development of functionalized carrageenan, chitosan and alginate as polymeric chelating ligands for water softening. Int J Environ Sci Technol 14(9):2009–2014. https://doi.org/10.1007/s13762-017-1298-y

Zhan W, Xu C, Qian G, Huang G, Tang X, Lin B (2018) Adsorption of Cu(II), Zn(II), and Pb(II) from aqueous single and binary metal solutions by regenerated cellulose and sodium alginate chemically modified with polyethyleneimine. RSC Adv 8:18723–18733

Li S-S, Song Y-L, Yang H-R, An Q-D, Xiao Z-Y, Zhai S-R (2020) Modifying alginate beads using polycarboxyl component for enhanced metal ions removal. Int J Biol Macromol 158:493–501

Abou-Zeid RE, Ali KA, Gawad RMA, Kamal KH, Kamel S, Khiari R (2021) Removal of Cu (II), Pb (II), Mg (II), and Fe (II) by adsorption onto alginate/nanocellulose beads as bio-sorbent. J Renew Mater 9(4):601. https://doi.org/10.32604/jrm.2021.014005

Gao C, Wang X-L, An Q-D, Xiao Z-Y, Zhai S-R (2021) Synergistic preparation of modified alginate aerogel with melamine/ chitosan for efficiently selective adsorption of lead ions. Carbohydr Polym 256:117564

Sutirman ZA, Sanagi MM, Aini WIW (2021) Alginate-based adsorbents for removal of metal ions and radionuclides from aqueous solutions: a review. Int J Biol Macromol 174:216–228

Zhuang Y, Yu F, Chen H, Zheng J, Ma J, Chen J (2016) Alginate/graphene double-network nanocomposite hydrogel beads with low-swelling, enhanced mechanical properties, and enhanced adsorption capacity. J Mater Chem A 4(28):10885–10892

Rezaei H, Haghshenasfard M, Moheb A (2017) Optimization of dye adsorption using Fe3O4 nanoparticles encapsulated with alginate beads by Taguchi method. Adsorp Sci Technol 35:55–71. https://doi.org/10.1177/0263617416667508

Wang B, Gao B, Zimmerman A, Lee X (2018) Impregnation of multiwall carbon nanotubes in alginate beads dramatically enhances their adsorptive ability to aqueous methylene blue. Chem Eng Res Design 133:235–242. https://doi.org/10.1016/j.cherd.2018.03.026

Tian Y, Gao B, Morales VL, Wu L, Wang Y, Munoz-Carpena R, Yang L (2012) Methods of using carbon nanotubes as filter media to remove aqueous heavy metals. Chem Eng J 210:557–563. https://doi.org/10.1016/j.cej.2012.09.015

Ding ZH, Hu X, Morales VL, Gao B (2014) Filtration and transport of heavy metals in graphene oxide enabled sand columns. Chem Eng J 257:248–252. https://doi.org/10.1016/j.cej.2014.07.034

Inyang M, Gao B, Zimmerman A, Zhang M, Chen H (2014) Synthesis, characterization, and dye sorption ability of carbon nanotube–biochar nanocomposites. Chem Eng J 236:39–46. https://doi.org/10.1016/j.cej.2013.09.074

Wang B, Gao B, Wan Y (2018) Comparative study of calcium alginate, ball-milled biochar, and their composites on methylene blue adsorption from aqueous solution. Environ Sci Pollut Res. https://doi.org/10.1007/s11356-018-1497-1

Wang B, Gao B, Wan YS (2018) Entrapment of ball-milled biochar in ca-alginate beads for the removal of aqueous Cd(II). J Ind Eng Chem 61:161–168. https://doi.org/10.1016/j.jiec.2017.12.013

Nasiruddin M, Sarwar A (2007) Determination of points of zero charge of natural and treated adsorbents. Surf Rev Lett 14:461–469

Langmuir I (1918) The adsorption of gases on plane surfaces of glass, mica and platinum. J Am Chem Soc 40:1361–1403

Freundlich H (1907) Ueber Kolloidfällung und adsorption. Zeitschrift für Chemie and Industrie der Kolloide 1:321–331

Dubinin M, Serpinsky V (1981) Isotherm equation for water vapor adsorption bymicroporous carbonaceous adsorbents. Carbon 19:402–403

Wang F, Tan L, Liu Q, Li R, Li Z, Zhang H, Hu S, Liu L, Wang J (2015) Biosorption characteristics of Uranium (VI) from aqueous solution by pollen pini. J Environ Radioact 150:93–98. https://doi.org/10.1016/j.jenvrad.2015.07.002

Temkin M, Pyzhev V (1940) Recent modifications to Langmuir isotherms. Acta Phys 12:217–222

Lima EC, Gomes AA, Tran HN (2020) Comparison of the nonlinear and linear forms of the Van’t Hoff equation for calculation of adsorption thermodynamic parameters (ΔS0 and ΔH0). J Mol Liq 311:113315

APHA (2017) Standard method for water and wastewater, 23rd edn. American Public Health Association, Washington, DC

Sun K, Jiang JC, Jun-ming X (2009) Chemical regeneration of exhausted granular activated carbon used in citric acid fermentation solution decoloration. Iran J Chem Chem Eng (IJCCE) 28(4):79–83

Saleh TA (2015) Isotherm, kinetic, and thermodynamic studies on Hg(II) adsorption from aqueous solution by silica- multiwall carbon nanotubes. Environ Sci Pollut Res Int 22:16721–16731

Chutia P, Kato S, Kojima T, Satokawa S (2009) Arsenic adsorption from aqueous solution on synthetic zeolites. J Hazard Mater 162:440–447

Liu Q, Liu Y (2003) Distribution of Pb(II) species in aqueous solutions. J Colloid Interface Sci 268(1):266–269. https://doi.org/10.1016/S0021-9797(03)00638-6

El-Kady AA, Carleer R, Yperman J, D’Haen J, Abdel-Ghafar HH (2016) Kinetic and adsorption study of Pb(II) towards different treated activated carbons derived from olive cake wastes. Desalin Water Treat 57(18):8561–8574

Zhu C, Dong X, Chen Z, Naidu R (2016) Adsorption of aqueous Pb(II), Cu(II), Zn(II) ions by amorphous tin(VI) hydrogen phosphate: an excellent inorganic adsorbent. Int J Environ Sci Technol 13:1257–1268. https://doi.org/10.1007/s13762-016-0964-9

Odubiyi OA, Awoyale AA, Eloka-Eboka AC (2012) Wastewater treatment with activated charcoal produced from cocoa pod husk. Int J Environ Bioenergy 4(3):162–175

Gupta V, Nayak A, Agarwal S, Tyagi I (2014) Potential of activated carbon from waste rubber tire for the adsorption of phenolics: effect of pre-treatment conditions. J Colloid Interface Sci 417:420–430. https://doi.org/10.1016/j.jcis.2013.11.067

Kosa SA, Al-Zhrani G, Abdel Salam M (2012) Removal of heavy metals from aqueous solutions by multi-walled carbon nanotubes modified with 8-hydroxyquinoline. Chem Eng J 181–182:159–168

Cherono F, Mburu N, Kakoi B (2021) Adsorption of lead, copper and zinc in a multi-metal aqueous solution by waste rubber tires for the design of single batch adsorber. Heliyon 7:e08254

Embaby MA, Abdel Moniem SM, Fathy NA, El-kady AA (2021) Nanocarbon hybrid for simultaneous removal of arsenic, iron and manganese ions from aqueous solutions. Heliyon 7(10):e08218

Babu BV, Gupta S (2008) Adsorption of Cr(VI) using activated neem leaves: kinetic studies. Adsorption 14:85–92. https://doi.org/10.1007/s10450-007-9057-x

Hayeeye F, Yu QJ, Sattar M, Chinpa W, Sirichote O (2018) Adsorption of Pb2+ ions from aqueous solutions by gelatin/activated carbon composite bead form. Adsorp Sci Technol 36(1–2):355–371. https://doi.org/10.1177/0263617417693006

Bayramoglu G, Akbulut A, Acıkgoz-Erkaya I, Yakup AM (2018) Uranium sorption by native and nitrilotriacetate-modified Bangia atropurpurea biomass: kinetics and thermodynamics. J Appl Phycol 30:649–661. https://doi.org/10.1007/s10811-017-1238-8

Nodeh MMK, Bidhendi GN, Gabris MA, Akbari-adergani B, Nodeh HR, Masoudi A, Shahabuddin S (2020) Strontium oxide decorated iron oxide activated carbon nanocomposite: a new adsorbent for removal of nitrate from well water. J Braz Chem Soc 31:116–125. https://doi.org/10.21577/0103-5053.20190138

Rezania S, Mojiri A, Park J, Nawrot N, Wojciechowska E, Marraiki N, Zaghloul NSS (2022) Removal of lead ions from wastewater using lanthanum sulfide nanoparticle decorated over magnetic graphene oxide. Environ Res 204:111959. https://doi.org/10.1016/j.envres.2021.111959

Sayed M, Abbas M, Abdel Moniem SM, Ali MEM, Naga SM (2019) Facile and room temperature synthesis of superparamagnetic Fe3O4/C core/shell nanoparticles for efficient removal of Pb(II) from aqueous solution. Chem Sel 4(6):1857–1865

Parmar P, Shukla A, Goswami D, Patel B, Saraf M (2020) Optimization of cadmium and lead biosorption onto marine Vibrio alginolyticus PBR1 employing a Box-Behnken design. Chem Eng J Adv 4:100043. https://doi.org/10.1016/j.ceja.2020.100043

Ho YS, McKay G (1999) Pseudo-second order model for sorption processes. Process Biochem 34:451–465

Lasheen MR, Ammar NS, Ibrahim HS (2012) Adsorption/desorption of Cd(II), Cu(II) and Pb(II) using chemically modified orange peel: equilibrium and kinetic studies. Solid State Sci 14:202–210

Wu Q, Xian Y, He Z, Zhang Q, Wu J, Yang G, Zhang X, Qi H, Ma J, Xiao Y, Long L (2019) Adsorption characteristics of Pb(II) using biochar derived from spent mushroom substrate. Sci Rep 9:1–11. https://doi.org/10.1038/s41598-019-52554-2

Gupta VK, Ganjali MR, Nayak A, Bhushan B, Agarwa S (2012) Enhanced heavy metals removal and recovery by mesoporous adsorbent prepared from waste rubber tire. Chem Eng J 197:330–342

Menezes JMC, da Silva Bento AM, da Silva JH, de Paula Filho FJ, da Costa JGM, Coutinho HDM, Teixeira RNP (2020) Equilibrium, kinetics and thermodynamics of lead (II) adsorption in bioadsorvent composed by Caryocar coriaceum Wittm barks. Chemosphere 26:128144. https://doi.org/10.1016/j.chemosphere.2020.128144

Boparai HK, Joseph M, O’Carroll DM (2011) Kinetics and thermodynamics of cadmium ion removal by adsorption onto nano zerovalent iron particles. J Hazard Mater 186:458–465. https://doi.org/10.1016/j.jhazmat.2010.11.029

Shen S, Pan T, Liu X, Yuan L, Zhang Y, Wang J, Guo Z (2010) Adsorption of Pd(II) complexes from chloride solutions obtained by leaching chlorinated spent automotive catalysts on ion exchange resin Diaion WA21J. J Colloid Interface Sci 345:12–18

Shi J, Fang Z, Zhao Z, Sun T, Liang Z (2015) Comparative study on Pb(II), Cu(II), and Co(II) ions adsorption from aqueous solutions by arborvitae leaves. Desalin Water Treat 57:1–8

Hikmat NA, Qassim BB, Khethi MT (2014) Thermodynamic and kinetic studies of lead adsorption from aqueous solution onto petiole and fiber of palm tree. Am J Chem 4:116–124

Zhou Y, Hynes RJ (2011) A comparison of inorganic solid wastes as adsorbents of heavy metal cations in aqueous solution and their capacity for desorption and regeneration. Water Air Soil Pollut 218:457–470

Author information

Authors and Affiliations

Contributions

SMAM: performed the experiments, analyzed and interpreted the data, and wrote the paper. MAE: conceived and designed the experiments; performed the experiments; analyzed and interpreted the data; wrote the paper. AAE-K: designed the experiments; performed the experiments; analyzed and interpreted the data; wrote the paper. KAA: preparation of ACNP; characterizations of the produced ACNP with interpretations of results; wrote the paper.

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Abdel Moniem, S.M., Embaby, M.A., El-Kady, A.A. et al. Novel alginate carbon nanoparticle composite beads for efficient removal of Pb2+ ions from aqueous solutions. Nanotechnol. Environ. Eng. 8, 399–411 (2023). https://doi.org/10.1007/s41204-022-00295-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41204-022-00295-5