Abstract

The construction industry generates tons of waste annually worldwide, causing a significant impact on the environment. The massive accumulation of construction and demolition waste exacerbates this problem, particularly in countries like Peru where the construction industry is rapidly growing. This research proposes addressing this challenge by substituting natural aggregates in concrete production with recycled concrete aggregates (RCA), treated beforehand. The main objective is to assess the feasibility of using RCA in concrete as a partial substitute for coarse aggregate and to analyze the physical and mechanical properties of concrete incorporating RCA to address its use in the Peruvian context. Within the methodology employed, five types of samples with recycled concrete at proportions of 10%, 20%, 30%, and 40% by weight of coarse aggregate were prepared, and physical and mechanical properties were evaluated at 7, 14, and 28 days. The results showed that the optimal RCA content was 20%, where slump, unit weight, and air content decreased but remained within permissible ranges. Additionally, it was observed that mechanical properties remained stable without significant variations. The compressive strength did not exhibit values lower than 21 MPa compared to the reference concrete. Likewise, the modulus of elasticity, tensile strength, and flexural strength decreased, showing a consistent trend. Consequently, it can be concluded that recycled aggregates are viable as effective substitutes for natural aggregates in the production of sidewalks, slabs, pavements, etc., offering a sustainable and environmentally friendly alternative.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

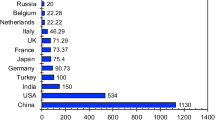

Developed and developing countries have significantly increased the proportion of construction and demolition waste, as is the case of the United States, which generates more than 500 million tons annually [1], and this is also supported by Cimentada et al. [2], stating that the annual generation of construction and demolition waste (CDW) is approximately 1 ton per inhabitant, where construction waste represents between 30 and 40% of the total urban waste, the annual amount of construction waste deposited has exceeded 400 million tons [3].

Materials resulting from the construction and demolition of buildings constitute an important solid waste stream with a considerable amount released annually [4]. As a fundamental part of this issue, the total volume of cement production worldwide amounted to 4.1 billion tons in 2022 [5]. Indeed, the most commonly used building materials are cement and concrete [6, 7], which account for approximately 5–8% of total global CO2 emissions [8, 9]. In addition, the European Union, the United States and China produce approximately 0.93, 0.57 and 1.8 billion tons of CDW, respectively [10]. Also, the World Bank has predicted that the generation of CDW will be about 2590 million tons in 2030 and will further increase to 3400 million tons in 2050 [11]. In South America, specifically in the country of Peru, construction and demolition waste can be converted into recycled aggregates, and can be used for the construction of civil works such as pavement, bicycle paths or sidewalks [12]. However, there is still not much variety of in-depth studies to know their behavior, so it is necessary to study them with materials from the area for scientific and environmental purposes.

Therefore, the use of recycled aggregates from CDW instead of conventional aggregates has a double environmental benefit: it decreases the land required for waste disposal and reduces the consumption of natural resources [13]. The construction industry [14], in terms of CDW, generates between 45 and 60% of the total waste going to informal landfills [15], which causes environmental imbalances [16].

The environmental pollution generated by CDW is alarming, so the use of recycled aggregates to produce concrete is the ideal solution to this problem, since less natural aggregates are consumed, and the construction aggregates would have a better destination due to the demand for infrastructure [17,18,19,20]. Continuing research has established that concrete is a versatile material in which different wastes can be consumed for environmentally sustainable development [21, 22].

Regarding the physical properties of concrete with the incorporation of recycled concrete aggregates (RCA), according to Hemant et al. [23], they evidenced a decrease in workability of 11.67%, when replacing natural coarse aggregate (NCA) with RCA by 25%. This is the effect of the absorption capacity of the stone material that directly influences a good workability [24]. Likewise, Harish et al. [25], used the same percentage of substitution achieving only 20% reduction in the workability of the reference concrete; in addition, they observed a minimal reduction in the unit weight of the concrete, being 2.9%. Generating internal porosity, due to the diversity of recycled concrete granular material forming internal cavities in its hardening stage [26]. On the other hand, Şimşek et al. [27], achieved their best results when they substituted 20% of NCA for RCA, obtaining a variation of 2% in the unit weight of the samples, they also pointed out an increase of the air content by 6%, and indicated that the temperature did not present significant changes for any percentage of substitution. Still, there are gaps on the behavior of the RCA material on the physical properties of concrete, so it is necessary to continue studying them in different conditions and design.

There is current scientific evidence that RCA influences the mechanical properties of concrete, mentioning some relevant research. Based on the research of Vu et al. [28], in which they compared the compressive strength of a standard concrete and one with 10% substitution of natural coarse aggregate for RCA, where its strength varied by only 6.1%. Olofinnade et al. [29], mentions that with a 20% substitution of NCA by RCA, they obtained a variation of 11.5%, corroborating this improvement in compressive strength according to [30,31,32]. According to the results of the research conducted by Khaleel et al. [33], where the values of modulus of elasticity (MOE) were compared between a reference concrete and another one incorporating 35% RCA, a variation of 14% in MOE was observed. Other investigations when comparing their information, had better results where they achieved a significant variation [34, 35]. The MOE of concrete presents a reduction for all percentages of substitution with RCA [36].

According to the results of Lesovik et al. [37], they performed a comparison between the tensile strength of a reference concrete and another one incorporating 33.3% RCA, a minimum variation of only 0.15% was obtained. The use of recycled concrete material is shown to be useful and significant compared to the excessive use of natural aggregates [26, 35]. Regarding flexural strength, the study of Monisha et al. [38], substituted NCA for RCA by 20% obtaining a minimum variation of 0.45%, similarly, the study of Hemant et al. [23], who substituted NCA for 25% RCA, produced flexural strengths only 8. 8% lower than that of the reference concrete, with great difference with respect to the percentage of substitution when using 100% RCA, where better results were obtained in flexural strength with a difference of 3.9% with respect to the reference concrete [39], The decrease in mechanical properties depends on the interaction between the old bonded mortar and the new cement mortar [40].

From the review carried out, it can be seen that numerous studies have been carried out on the incorporation of recycled aggregates into concrete, and that their characteristics are similar, regardless of their origin. Several studies have shown that it is feasible to use them in proportions lower than 50%, which contributes to reduce the uncontrolled extraction of natural resources and the massive CO2 emissions generated by this process. Unlike other research, this proposal stands out for extracting the best of previous studies, since it carries out an exhaustive analysis of the existing literature, synthesizing the most relevant findings and selecting the most accurate and reliable information, in addition to proposing a more precise range of substitution percentages, since it works with 4 substitution percentages with a minimum variation of 10%, which allows more reliable results to be obtained.

Emphasizing that there are no studies in the country of Peru on these issues being an important point to encourage research in Latin American countries. Technological advances are also essential to find permanent solutions to economic and environmental challenges, as well as offering new jobs and promoting energy efficiency. Other important ways to facilitate sustainable development are the promotion of sustainable industries and investment in scientific research and innovation in line with the Sustainable Development Goals (SDGs).

The main objective of this study is to evaluate the feasibility of using RCA in concrete as a partial substitute for coarse aggregate at the following percentages 10%, 20%, 30% and 30%. The physical and mechanical properties of a reference concrete were analyzed, which served as a guide for comparison with the different samples that had the incorporation of RCA. The physical and chemical properties of the recycled aggregates were also studied, for a mix design with a minimum strength of 21 MPa, in order to obtain the appropriate proportion for the concrete.

Materials and methods

Materials

Portland cement

In the present study, Portland cement of common use (Type I), commercialized in Peru, was used, which was adequate to join other ingredients to solidify the concrete and to contemplate the considerations described in ASTM C150 [41].

Aggregates, recycled concrete aggregates and water

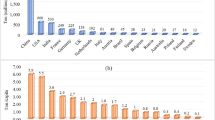

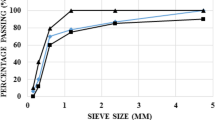

The coarse aggregate was extracted from the Pacherrez quarry and the fine aggregate from the Pátapo—La Victoria quarry, both located in the Lambayeque Region—Peru. Figure 1 shows the granulometric curve of the fine aggregate and coarse aggregate, the fine aggregate was yellow sand with dimensions in the range of 4.8 mm–75 µm with a fineness modulus of 2.97, while the maximum nominal size of the coarse aggregate was 25.4 mm according to ASTM C136 [42].

Likewise, the physical and mechanical characteristics of the aggregates were also identified, such as fineness modulus, unit weight or specific gravity, according to the standards detailed in Table 1. The recycled aggregate with a nominal maximum size of 19 mm was extracted from the crushing of laboratory-tested specimens; the chemical properties of the RCA are shown in Table 2. Potable water extracted from the laboratory was used for the preparation of the concrete and later for curing the hardened samples according to ASTM C1602M [43].

Table 2 shows the chemical composition of the original concrete, which subsequently formed part of the aggregates. These tests were performed according to the ICP—OES test and the general proportion of salts, chlorides and sulfates. The elements with the highest concentration are Ca, Sio2, Si and Fe, this behavior could be due to the fact that these elements are the main constituents of Portland cement. The chemical analysis reflects the composition of the recycled aggregate itself after processing.

Methods

To obtain the recycled concrete aggregate, it was decided to use laboratory concrete specimens previously subjected to compressive strength tests, with design strengths of 21 MPa and 28 MPa. These specimens were crushed in a specific way to obtain particles with dimensions between ¼ and ¾ inches. In the course of this process, the elimination of impurities was carried out in order to obtain a pure RCA.

In addition, a granulometric analysis was carried out to evaluate the granulometric distribution of the resulting material, as shown in Fig. 2. In order to carry out the evaluations by inductively coupled plasma (ICP) and to perform the analysis of chlorides and sulfates in the recycled concrete aggregate sample. The material was crushed and sieved through mesh No. 50. It is important to note that the parameters of the recycled aggregates remained within the limits allowed by ASTM C136 [42].

A number of 18 cylindrical specimens with dimensions of 150 × 300 mm were prepared, distributed in 5 groups, which constituted a set of 90 specimens for the evaluation of compressive strength, tensile strength and modulus of elasticity. Likewise, the flexural strength of the concrete was analyzed, 9 prismatic specimens of 530 × 150 × 150 mm were prepared, organized in 5 groups, totaling 45 specimens. The aggregates, carefully selected for their size and granulometry, were combined with the cement in the optimum proportions according to the designed mix, the precision in the dosage, carried out by electronic weighing, guaranteed the uniformity and quality of the concrete. No superplasticizer was used in any experimental mix.

The mix was kneaded in a high-speed mechanical mixer, controlling the time for 6 min and the speed to obtain a homogeneous, lump-free paste. For the preparation of the samples, the inside of the molds was lubricated, then filled in three layers and compacted with a needle vibrator, ensuring a dense and resistant concrete. After 24 h of setting, the specimens were demolded and cured in a controlled environment for 1 day. Finally, they were immersed in potable water for 7, 14 and 28 days, completing the curing process and maximizing their compressive strength.

The determination of the proportions of the materials was performed under the international standard ACI 211.1 [48], the mix designs (MD) can be seen in Table 3, where the amount of cement, water and fine aggregate was kept fixed for all mixes and additions were made for each percentage of RCA with respect to the weight of coarse aggregate. The proportion of the materials was determined based on the characteristics obtained from the coarse and fine aggregate, as well as the design properties of the concrete in the fresh state. The methodology of the study is shown in Fig. 3, with specific details on the process of obtaining, performing tests and interpreting results.

Workability, temperature, unit weight and air content

The workability of fresh concrete was determined according to ASTM C143M [49]. According to ASTM C1064M [50], the temperature of freshly mixed concrete was measured, as well as the loose and compacted unit weight according to ASTM C29 [44]. According to ASTM C231 [51], the air content of the freshly mixed concrete was defined, excluding any air that may exist inside the voids within the aggregate particles, Fig. 4 shows the tests performed on the fresh concrete.

Compressive strength, elastic modulus, flexural strength, and tensile strength

Figure 5 shows the mechanical tests performed on the concrete with the different RCA substitution percentages, where the compressive strength was performed according to ASTM C39 [52], the elastic modulus calculation was performed according to ASTM C469 [53], the flexural strength was performed according to ASTM C78 [54], and the tensile strength was performed according to ASTM C496 [55].

Results and discussion

Effect of RCA on the workability and temperature of concrete in the fresh state

As shown in Fig. 6, the reference concrete presented an average workability of 3.5 inches, which is within the acceptable range for the specific mix; however, the slump of the other mixes remained below the range of 3–4 inches for good workability. Three samples were taken for each test and for each addition percentage to analyze their variability, obtaining a variance of 0.01. When using 20% RCA, a slump decrease of 27.8% was observed with respect to the reference concrete sample.

This result is like those obtained by Martínez et al. [30], who showed a slump reduction of 28.57% when using the same percentage of substitution. Within this range of slump reduction with 22.08% was Hemant et al. [23], who reported it with a 50% replacement of RCA. With this same percentage of replacement Harish et al. [25], obtained less favorable results, evidencing a reduction of 80% with reference to the standard concrete. This drop in settlement for any replacement rate proves some of the hypotheses put forward, since it is mainly due to the absorption capacity of the RCA, which is 8.4% higher than that of NCA. For the case of temperature varies from 27.5 to 30.7 °C, indicating according to ASTM C1064M [50], which is within the allowable ranges, this result agrees with the research of Şimşek et al. [27]. The results of temperature and slump are shown in Fig. 6.

Unit weight and air content

Figure 7 shows that when replacing the recycled concrete aggregate with natural aggregate in proportions of 10%, 20%, 30% and 40%, there is a decrease in its unit weight of 0.41%, 1.06%, 1.54% and 1.63%, respectively, compared to the reference concrete; likewise, 3 tests were carried out for each addition percentage to analyze its variability, obtaining a variance of 14.78. This effect that produces a reduction is due to the porosity originated by the RCA, since the density of this material is lower than that of the fine aggregate and coarse aggregate, directly influencing this property and the resistance.

Similar results were obtained by Şimşek et al. [27], who reported a 2% decrease in unit weight when replacing 20% with RCA, likewise, B. A. Harish et al. [25], indicated a 2.9% reduction in unit weight when replacing 50%, compared to conventional concrete, similarly, Elhadi et al. [26], when replacing 50% of NCA by RCA, evidenced a 3.9% decrease in unit weight compared to standard concrete, this explanation is given because RCA has a density 20.3% lower than natural aggregates.

In the case of air content, it varies from 1.52 to 0.41% with respect to the reference concrete when the percentage of replacement of NCA by RCA increases from 10 to 40%. This increase in air content is directly seen in the physical properties of RCA compared to NCA, which has a higher density and lower absorption capacity. Generating internal cavities where air is trapped, thus generating the increase in the results of this test. This result agrees with the investigations of Şimşek et al. [27], that according to ASTM C231 [51], this is within the permissible ranges. This decrease is due to the fact that the absorption capacity of RCA decreases the fluidity of the mixture in which air bubbles could easily integrate and generate voids in the concrete. The results of unit weights and air content can be seen in Fig. 7.

Compressive strength

As shown in Fig. 8, regarding the compressive strength after 28 days, of the different sample designs constituted by the substitution of 10, 20, 30 and 40% RCA, a decrease of 0.92, 2.13, 9.28 and 14.33% respectively is reflected, showing the optimum RCA content of 20%, according to the Anova Unificatory test and Tukey's multiple comparison tests, where it is obtained (p value = 0.38772748 > 0.05) determined that this variation of the strength is not significant, ensuring the viability of its use. The reduction in compressive strength is not significant because it is not lower than the strength of the design mix (21 MPa), in fact, the incorporated materials have an importance on this property even though the strength is below the reference concrete strength.

Similar results were presented by Martínez et al. [30], who with 20% RCA showed a decrease of 2.3% with respect to the standard concrete, similarly, Vu et al. [28], showed a drop of 6.1% with the same percentage of RCA substitution, these findings contrast with those investigated by Olofinnade et al. [29], who, when using RCA in percentages of 20 and 40%, evidenced a decrease in strength of 11.5 and 26.8%, respectively. Similarly, with a percentage of 50% RCA substitution, Harish et al. [25], noted a decrease of 8.6%, compared to the standard concrete. The average values of compressive strength are shown in Table 4.

Modulus of elasticity

As shown in Fig. 9, in relation to the modulus of elasticity, comparable results to standard concrete were observed, showing a minimum decrease of 0.8%, 2.55%, 5.52%, and 7.23% when RCA was substituted by 10%, 20%, 30%, and 40%, respectively. It is highlighted that the optimum RCA content is 20%, according to the results of the Anova Unifactor test and Tukey's multiple comparison tests, where it was obtained (p value of 0.06052731 > 0.05), indicating that this variation in the resistance is not significant, likewise it is observed that when the setting time increases, the modulus of elasticity also increases, these results were expected since this is also presented in the different investigations reviewed. The bond efficiency between the recycled aggregate and the cement paste may not be as optimal as in the case of natural aggregate, affecting the load transfer and, consequently, decreasing the overall strength of the concrete.

This finding coincides with the research of Martinez et al. [30], who reported a decrease of 0.95% when using 20% RCA, without this variation being statistically significant, on the other hand, Zhang et al. [34], employed 50% RCA and observed a drop of 6.26% compared to standard concrete. With this same percentage of substitution, Zhang et al. [35], obtained comparable results, registering a decrease in the modulus of elasticity of 9.76%. A comparison shows that, although Younis et al. [33] used 35% RCA, they obtained less favorable results, with a decrease of 14% compared to standard concrete. The average values of modulus of elasticity are shown in Table 5.

Tensile strength

As shown in Fig. 10, regarding the tensile strength after 28 days, it is reflected that the samples with RCA additions of 10, 20 and 30% present a decrease of 0.64, 1.94 and 8.84%, respectively. According to the results of the Unifactorial Anova test and Tukey's multiple comparisons tests, where it was obtained (p value of 0.06657203 > 0.05), showing that the variation in tensile strength is not significant for any of the three percentages evaluated. In summary, the reduction in concrete strength when using recycled aggregate in proportions lower than 40% can result from quality variability, the presence of impurities, reduced stiffness, bonding problems, and the partial contribution of recycled aggregate to the mechanical properties of concrete.

These results are similar to those obtained by Lesovik et al. [37], who reported a decrease in tensile strength of 0.15%, replacing 33.3% of RCA, however, there are significant differences in the variation of this property, this could be due to different variables such as the origin of the aggregates, the mix design and the parameters used to control the samples from their preparation to the moment of testing. Thus, when compared with the researches of Harish et al. [25], and Zhang et al. [35], who noted a decrease of 12.32 and 14.36%, respectively, when replacing RCA by 50%, another similar study was performed by Elhadi et al. [26], who using the same percentage of RCA, showed a decrease in tensile strength of 19.76% compared to standard concrete. The average values of tensile strength are shown in Table 6 below.

Flexural strength

As shown in Fig. 11, the flexural strength remained stable, the samples with 10 and 20% addition showed a minimum drop in strength of 0.71 and 2.08%, respectively, according to the Anova Unificatory test and Tukey's multiple comparisons tests, where it is obtained (p value = 0.54314294 > 0.05) determined that this variation in strength is not significant. The stiffness of recycled aggregate can be lower than that of natural aggregate, which directly impacts the mechanical response of concrete, reflected in a decrease in modulus of elasticity and tensile and flexural strength.

These results are comparable with those obtained by Monisha et al. [38], who replaced the NCA by 20% RCA obtaining a minimum variation of 0.45%, similarly, the study conducted by Hemant et al. [23], who replaced the NCA by 25% RCA, producing flexural strengths only 8. 8% lower than that of the standard concrete, with great difference with respect to the percentage of substitution Sastri and Jagannadha [39], who using 100% RCA, obtained better results in flexural strength with a difference of 3.9% with respect to the standard concrete. The average values of tensile strength are shown in Table 7.

Conclusions

It is concluded that the substitution of natural coarse aggregates by recycled aggregates has a significant influence on the physical properties of concrete. The following conclusions are presented with respect to the findings:

The physical and chemical properties of recycled materials can show variations due to the diversity of their sources of origin. This diversity can affect the consistency and quality of the recycled aggregate, having a direct effect on the properties of the concrete.

The workability and the percentage of air decrease, due to the absorption produced by the RCA being higher than when using the NCA, affecting the fluidity of the mixture and generating internal porosity in the fresh concrete.

It is concluded that using 20% RCA, the mechanical properties remained stable, compressive strength showed an insignificant decrease of 2.13%, modulus of elasticity by 2.55%, tensile strength by 1.94%, and flexural strength by 2.08%. These results were achieved using exclusively recycled concrete aggregate, but do not ensure the same optimal percentage for any other type of recycled aggregates, thus suggesting that recycled concrete aggregates are viable as effective substitutes for natural aggregates in concrete production. It is a sustainable and environmentally friendly alternative, as well as suggesting the use of durability indicators to examine long-term properties.

The sample incorporating 20% RCA presented results that statistically showed no significant divergence in the mechanical properties of the concrete and remained within the admissible limits for the physical properties. Therefore, it is concluded that this level of substitution represents the optimal choice, and visual examinations to characterize differences in concrete texture or aggregate distribution at RCA substitution levels are suggested for future work.

The 20% RCA concrete proposal complies with local codes for application to works such as sidewalks, low traffic rigid pavements and non-structural concrete.

The optimum level of 20% RCA could potentially be applied to other recycled aggregates from the Lambayeque region, because it has similar characteristics to quarries near the coastal zone. However, other areas with different characteristics, such as the Peruvian highlands and jungle, should be further investigated.

Visual examinations to characterize differences in concrete texture or aggregate distribution at different RCA substitution levels are suggested for future work.

Data availability

The manuscript has been paraphrased quoting each paragraph by the corresponding author, also, the ideas that are written in the request are taken into account by the authors of the manuscript.

References

de Andrade GP, de Castro Polisseni G, Pepe M, Toledo Filho RD (2020) Design of structural concrete mixtures containing fine recycled concrete aggregate using packing model. Constr Build Mater 252:119091

Cimentada A, Sainz-Aja J, De Brito J, Thomas C (2020) Macro- and micro-properties of multi-recycled aggregate concrete. J Clean Prod 245:118843

Wu Y, Qi Z, Niu M, Yao Y, Luo Z, Zhang K (2022) Effect of moisture condition of brick-concrete recycled coarse aggregate on the properties of concrete. Materials 15(20):7204

Nguyen TN, Vo VH, Vo TG, Le TA (2023) Application of recycled fine aggregate from construction and demolition materials for mortar. Lecture notes in civil engineering, vol 268. Springer, Singapore, p 1065

Garside M (2023) Global cement production 1995–2022. Estadista. Available: https://www.statista.com/statistics/1087115/global-cement-production-volume/#statisticContainer. Accessed 10 Oct 2023

Muñoz Perez S, Garcia Chumacero J, Charca Mamani S, Villena Zapata L (2023) Influence of the secondary aluminum chip on the physical and mechanical properties of concrete. Innov Infrastruct Solut 8:45

García J, Arriola G, Villena L, Muñoz S (2023) Strength of concrete using partial addition of residual wood ash with respect to cement | resistencia del concreto utilizando adición parcial de ceniza de madera residual respecto al cemento. Rev Polit 52(1):45–54

Lu B, Caijun S, Cao Z, Guo M, Zheng J (2019) Effect of carbonated coarse recycled concrete aggregate on the properties and microstructure of recycled concrete. J Clean Prod 233:421–428

Dilshad Kakasor IJ, Abdulrahman PI, Mohammed AS, Kurda R, Qaidi SM, Asteris PG (2023) Machine learning techniques and multi-scale models to evaluate the impact of silicon dioxide (SiO2) and calcium oxide (CaO) in fly ash on the compressive strength of green concrete. Constr Build Mater 400:132604

Zhao H, Liu F, Yang H, Wang S (2023) A unified calculation method for temperatures of recycled aggregate concrete members exposed to fire: tests and numerical study. Structures 57:105212

Kaza S, Yao L, Bhada-Tata P, Van Woerden F (2018) What a waste 2.0: a global snapshot of solid waste management to 2050. World Bank, Washington

RPP (2022) Renacer de los escombros: residuos de construcción y demolición pueden ser reusados para crear infraestructura urbana. [Online]. Available: https://rpp.pe/campanas/valor-compartido/renacer-de-los-escombros-residuos-de-construccion-y-demolicion-pueden-ser-reusados-para-crear-infraestructura-urbana-noticia-1400754. Accessed 1 March 2023

De Andrade Salgado F, De Andrade Silva F (2022) Recycled aggregates from construction and demolition waste towards an application on structural concrete: a review. J Build Eng 52:104452

Emad W, Mohammed AS, Kurda R, Ghafor K, Cavaleri L, Qaidi SM, Hassan A, Asteris PG (2022) Prediction of concrete materials compressive strength using surrogate models. Structures 46:1243–1267

Khoury E, Cazacliu B, Remond S (2019) Control of effective water in recycled aggregate concrete using power curves of the mixer. Mater Today Commun 21:100721

Kirthika S, Singh S (2020) Durability studies on recycled fine aggregate concrete. Constr Build Mater 250:118850

Hoai-Bao L, Quoc-Bao B (2020) Recycled aggregate concretes—a state-of-the-art from the microstructure to the structural performance. Constr Build Mater 257:119522

Bidabadi MS, Akbari M, Panahi O (2020) Optimum mix design of recycled concrete based on the fresh and hardened properties of concrete. J Build Eng 32:101483

Sua-iam G, Makul N (2023) Self-compacting concrete produced with recycled concrete aggregate coated by a polymer-based agent: a case study. Case Stud Constr Mater 19:e02351

Wang D, Lu C, Zhu Z, Zhang Z, Liu S, Ji Y, Xing Z (2023) Mechanical performance of recycled aggregate concrete in green civil engineering: review. Case Stud Constr Mater 19:e02384

Jadon S, Kumar S (2023) Stone dust and recycled concrete aggregates in concrete construction: an efficient way of sustainable development. Mater Today Proc. https://doi.org/10.1016/j.matpr.2023.04.221

Amin M, Agwa I, Mashaan N, Mahmood S, Abd-Elrahman M (2023) Investigation of the physical mechanical properties and durability of sustainable ultra-high performance concrete with recycled waste glass. Sustainability 15(4):3085

Sharma HR, Thakur A, Aditya TK (2021) Mechanical characteristics of concrete containing basalt fiber and recycled aggregate. In: 2021 2nd Indo-European conference on sustainable materials, environment and construction 23–24 September 2021, Mohali, India

Chachar KH, Oad M, Memon BA, Siyal ZA, Siyal KF (2023) Workability and flexural strength of recycled aggregate concrete with steel fibers. Eng Technol Appl Sci Res 13(3):11051–11057

Harish B, Venkata Ramana N, Gnaneswar K (2020) A study on properties of recycled coarse aggregate and it’s concrete. IOP Conf Ser Mater Sci Eng 998:012025

Elhadi KM, Ali T, Qureshi MZ, Anwar N, Zaid O, Majdi A, Qaisar M, Khan A (2023) Improving the engineering properties of sustainable recycled aggregate concrete modified with metakaolin. Case Stud Constr Mater 19:e02430

Simsek O, Pourghadri Sefidehkhan H, Gökçe HS (2022) Performance of fly ash-blended Portland cement concrete developed by using fine or coarse recycled concrete aggregate. Constr Build Mater 357:129431

Vu XH, Vo TC, Phan VT (2021) Study of the compressive strength of concrete with partial replacement of recycled coarse aggregates. Eng Technol Appl Sci Res 11(3):7191–7194

Olofinnade OM, Oyawoye IT, Ogara JI, Ede AN, Ndambuki JM, Akinwumi II, Ajao AM (2019) The use of recycled concrete aggregate for concrete production incorporating calcined clay as pozzolanic admixture. IOP Conf Ser Mater Sci Eng 640:012047

Martínez Lage I, Vázquez Burgo P, Velay Lizancos M (2020) Sustainability evaluation of concretes with mixed recycled aggregate based on holistic approach: technical, economic and environmental analysis. Waste Manag 104:9–19

Li A, Zhou G, Zhang X, Meng E (2021) Compressive mechanical properties of a novel recycled aggregate concrete with recycled lightweight aggregate. Adv Mater Sci Eng 2021:13

Amorim Júnior NS, Silva GA, Dias CM, Ribeiro DV (2019) Concrete containing recycled aggregates: estimated lifetime using chloride migration test. Constr Build Mater 222:108–118

Younis KH, Amin AA, Ahmed HG, Maruf SM (2020) Recycled aggregate concrete including various contents of metakaolin: mechanical behavior. Adv Mater Sci Eng 1687–8434:2020

Zhang X, Zhou G, Xu P, Fu L, Deng D, Kuang X, Yuhui F (2023) Mechanical properties under compression and microscopy analysis of basalt fiber reinforced recycled aggregate concrete. Materials 16(6):2520

Zhang H, Wang Y, Lehman DE, Geng Y, Kuder K (2020) Time-dependent drying shrinkage model for concrete with coarse and fine recycled aggregate. Cem Concr Compos 105:103426

Makul N, Fediuk R, Amran M, Zeyad A, Murali G, Vatin N, Klyuev S, Ozbakkaloglu T, Vasilev Y (2021) Use of recycled concrete aggregates in production of green cement-based concrete composites: a review. Crystals 11(3):232

Lesovik V, Lesovik R, Albo Ali W (2021) Effect of recycled course aggregate from concrete debris on the strength of concrete. In: Innovations and technologies in construction (BUILDINTECH BIT 2021) 9th–10th March 2021, Belgorod, Russia

Ramasam M, Jaganathan D, Soundararajan K, Shanmugam D (2020) Study on partial replacement of natural aggregate concrete (NAC) with recycled aggregate concrete (RAC). IOP Conf Ser Mater Sci Eng 955:012056

Sastri M, Jagannadha Rao K (2022) Studies on the effect of recycled concrete aggregates on concrete with mixed fibre and pozzolans. In: Advancements in sustainable materials and infrastructure 24/08/2022–25/08/2022, Hyderabad, India

Chinchillas-Chinchillas MJ, Rosas-Casarez CA, Arredondo-Rea SP, Gómez-Soberón JM, Corral-Higuera R (2019) SEM image analysis in permeable recycled concretes with silica fume. A quantitative comparison of porosity and the ITZ. Materials 12(13):2201

ASTM C150 (2022) Standard specification for portland cement. ASTM International, West Conshohocken

ASTM C136 (2020) Standard test method for sieve analysis of fine and coarse aggregates. ASTM International, West Conshohocken

ASTM C1602 (2022) Standard specification for mixing water used in the production of hydraulic cement concrete. ASTM International, West Conshohocken

ASTM C29 (2023) Standard test method for bulk density (“unit weight”) and voids in aggregate. ASTM International, West Conshohocken

ASTM C128 (2023) Standard test method for relative density (specific gravity) and absorption of fine aggregate. ASTM International, West Conshohocken

ASTM C127 (2016) Standard test method for relative density (specific gravity) and absorption of coarse aggregate. ASTM International, West Conshohocken

ASTM C566 (2019) Standard test method for total evaporable moisture content of aggregate by drying. ASTM International, West Conshohocken

ACI-211.1 (2007) Standard practice for selecting proportions for normal, heavyweight, and mass concrete. American Concrete Institute, Farmington

ASTM C143M (2020) Standard test method for slump of hydraulic-cement concrete. ASTM International, West Conshohocken

ASTM C1064M (2017) Standard test method for temperature of freshly mixed hydraulic-cement concrete. ASTM International, West Conshohocken

ASTM C231 (2022) Standard test method for air content of freshly mixed concrete by the pressure method. ASTM International, West Conshohocken

ASTM C39 (2021) Standard test method for compressive strength of cylindrical concrete specimens. ASTM International, West Conshohocken

ASTM C469 (2022) Standard test method for static modulus of elasticity and poisson’s ratio of concrete in compression. ASTM International, West Conshohocken

ASTM C78 (2022) Standard test method for flexural strength of concrete (using simple beam with third-point loading). ASTM International, West Conshohocken

ASTM C496 (2017) Standard test method for splitting tensile strength of cylindrical concrete specimens. ASTM International, West Conshohocken

Acknowledgements

We are grateful to the Professional School of Civil Engineering of Civil Engineering of the Universidad Señor de Sipan for providing us with the facilities to carry out the research.

Funding

The present research work has no source of financing; it is financed by the authors' own resources.

Author information

Authors and Affiliations

Contributions

Conceptualization: [Juan Martin Garcia Chumacero]; [Jarlin Miguel Pardo Becerra], [Sócrates Pedro Muñoz Pérez], [Edwin Adolfo Diaz Ortiz], Methodology: [Juan Martin Garcia Chumacero]; [Socrates Pedro Muñoz Pérez], [Jarlin Miguel Pardo Becerra], [Jose Luis Quispe Osorio], [Yander Mavila Briceño Mendoza]; Formal analysis and research: [Jarlin Miguel Pardo Becerra]; Writing—preparation of the original draft: [Sócorates Pedro Muñoz Pérez], [Jarlin Miguel Pardo Becerra]; Writing—revision and editing: [Juan Martin Garcia Chumacero]; Supervision: [Sócrates Pedro Muñoz Pérez], [Edwin Adolfo Diaz Ortiz], [Jose Luis Quispe Osorio], [Yander Mavila Briceño Mendoza]. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

No, the authors declare that they have no conflict of interest as defined by Springer, nor any other interest that could influence the outcome and/or discussion of this paper.

Ethical approval

The manuscript has not been submitted to more than one journal, is considered an original work with new findings presented in the manuscript, has not been submitted elsewhere in any form or language.

Informed consent

Informed consent is not necessary for this type of research.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Muñoz Pérez, S.P., Pardo Becerra, J.M., García Chumacero, J.M. et al. Evaluation of the physical and mechanical properties of concrete with the incorporation of recycled concrete aggregate. Innov. Infrastruct. Solut. 9, 204 (2024). https://doi.org/10.1007/s41062-024-01517-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-024-01517-2