Abstract

The conventional soil stabilization methods using additives such as cement and lime are losing scope owing to their non-environment-friendly nature. This inspires the use of industrial by-products in soil modification for sustainable development. This paper presents the results of an extensive laboratory investigation on mechanical properties of fiber reinforced Karewa soil stabilized with cement kiln dust (CKD). A total of 11 groups of samples were prepared at four different percentages of glass fiber (i.e., 0.3%, 0.6%, 0.9% and 1.2%) and three percentages of CKD (i.e., 7%, 14% and 21%) each by dry unit weight of soil. For determination of optimum soil–CKD–fiber mixes, standard proctor compaction and pH tests were conducted. The strength improvement was evaluated by performing unconfined compression strength and split tensile strength tests after curing of 7, 14 and 28 days. The stress–strain patterns of fiber reinforced and CKD-treated samples displayed strain hardening and strain softening characteristics, respectively. The strength test results revealed an improvement of 9.6 times as that of untreated soil at CKD content of 14% and fiber content 0.9%. The technical benefits of combining two ground improvement techniques (chemical stabilization and fiber reinforcement) are evident in the present study. The formation of cementitious products due to CKD-addition was affirmed through XRD spectroscopy. Microstructural analysis was conducted using field emission scanning electron microscopy and an apparent change in pore volume distribution was observed, with both size and amount of micro and macropores considerably reduced signifying increased number of particle contacts per unit volume.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Fine grained soils are generally weak from engineering perspective with high compressibility and low shear strength and are found in many geographic regions of the world. The existence of such soil deposits beneath foundations is normally associated with bearing capacity problems, differential settlement issues and undesirable lateral movements on loading, consequently, demand proper treatment before subjecting them to different geotechnical applications [1]. Various ground improvement methods have evolved over the years for mitigation of problematic soil deposits. Ground treatment using cement, lime and other cementious materials has been in vogue for a long time [2,3,4,5,6]. For mitigation of unstable fine-grained soils, chemical stabilization techniques have been frequently used in construction projects to augment the bearing capacity, reduce settlements and permeability and control shrinking/swelling [7]. However, such procedures are now discouraged given the environmental concerns associated with them. The use of industrial by-products for ground improvement is an intrinsically eco-friendly affair as it represents a “beneficial reuse” application of materials which otherwise have to be disposed or landfilled [8]. As such, researchers are compelled to focus on utilization of materials which are cost-effective and harmless to the ecosystem. The potential of industrial by-products (IBPs’) in soil mitigation has, therefore, become a research hotspot in the modern times [9,10,11,12]. Cement kiln Dust (CKD), a by-product of cement industry, poses environmental and health problems and also land reclamation issues. Effective utilization of such a material would not only solve the disposal problem but would also serve as a profitable and eco-friendly soil stabilization solution. The pozzolanic property of CKD makes it a good binder to help in modifying the characteristics of marginal soils [13,14,15,16,17,18]. The characterization of fresh and stockpiled CKD has led Sreekrishnavilasam et al. [19] to the conclusion that CKD can potentially be used for soil modification, as grouting fillers and daily cover material for sanitary landfills. Notwithstanding, the strength improvement in soil due to chemical additives, they often result in abnormally high stiffness and brittle behavior.

Fiber reinforcement in soils is regarded as an effective technique of soil improvement given its adaptability, cost-effectiveness and reproducibility [20, 21]. Besides improving the shear strength of soils, it has been found equally effective in controlling swell and shrinkage [22]. Sometimes, the discrete fiber reinforcement outperforms the traditional geosynthetics like geogrids and geotextiles and exhibits a better ecological potential than chemical stabilization [23]. This method of random distribution of fibers in soil is advanced over systematic reinforcement procedures in many ways; it ensures isotropic strength and eradicates the potential planes of weakness along soil fiber interface, its addition with soil is convenient and similar to that of cement or lime addition, it exhibits greater toughness and ductility and also reduces the post-peak strength drop considerably, the technique is comparatively economical as the initial cost of fibers is low and at times is freely available at a construction site [24, 25]. Soil reinforcement by using tire chips is also considered as a potential liquefaction mitigation technique [26]. Owing to the technical benefits of fiber reinforcement, researchers and field practitioners have been thoroughly working in this field. Experimental works have been carried on natural (coarse as well as fine grained) and artificial soils by incorporation of synthetic and natural fibers. Notable laboratory studies through triaxial tests, CBR tests, unconfined compression tests, direct shear tests and consolidation tests reported in the literature have established the efficacy of using randomly discrete fibers as soil reinforcement [27,28,29,30,31,32].

The use of discrete fibers in combination with chemical additives overcomes the individual shortcomings of these two methods. Cementitious materials, no doubt, cause a remarkable improvement in strength when mixed with soil but at the same time transform the soil into an overly brittle mass. Fiber reinforcement, on the other hand, offers relatively less improvement in terms of strength but shows better performance in deformation behavior. Thus, the combination of these two methods is a doubly advantageous procedure and is thoroughly researched for finding better combinations and optimum dosages of materials. Kumar and Sharma [33] conducted a laboratory investigation to determine the effect of cement dust and polypropylene fibers on pond ash properties and asserted its feasibility in highway embankment construction, low land area reclamation and as a backfill material for retaining walls. Sharma [34] in his study on stabilization of clayey soil using cement kiln dust and polypropylene fiber recognized the applicability of cement kiln dust as soil stabilizer. Puppala et al. [35] investigated the utilization of fly ash in combination with polypropylene fiber for treatment of expansive soils. Gupta and Kumar [36] conducted an experimental investigation including compaction test, unconfined compression strength test, split tensile strength and California bearing ratio test on clay–pond ash mixes treated with cement and fibers and concluded that the proposed method was effective in stabilizing clayey soil.

The existing literature on fiber reinforced soils has unanimously validated the strength improvement caused by the incorporation of fibers in soil. However, the margin of improvement is lesser as compared to cementitious or supplementary cementitious materials. Moreover, there is an ambiguity regarding the parameters affecting the mechanical behavior of fiber reinforced soils and also on the interaction mechanisms between soil particles and fibers. Additionally, the growing consciousness regarding the need for sustainable development has caused an increasing interest in utilization of waste materials for soil remediation. As such, researchers have aimed at finding new combinations of fiber reinforcements and supplementary cementitious materials.

In view of the literature cited, this study is pursued to investigate the effect of a novel combination of glass fibers and CKD on mechanical behavior of composite soil. A series of compaction tests, pH tests, UCS tests and STS tests were conducted corresponding to different percentage of CKD and fiber content. The samples were tested under varying curing periods. XRD test results and FESEM images were used to analyze and explore the underlying mechanisms responsible for modification of the soil structure of the composites. The findings of this study are encouraging with regard to the feasibility and practical applications of the fiber reinforced cemented soil.

Experimental program

The present study was aimed at evaluating the mechanical behavior of fiber reinforced cemented as well as uncemented soils. The experimental program is subdivided into two sections. The first section gives a brief description of the materials used in the study, their physical and chemical properties and the sample preparation methods employed. In the next section, the details of the testing program adopted in the study are given.

Materials

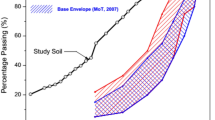

The soil was collected from a site located in Pampore (upper Karewas, 34°02′07.6″ N 74°54′27.4″ E), and basic tests on undisturbed and representative samples were carried out for its geotechnical characterization. Karewas are conspicuous lacustrine silty formations spread across the Kashmir valley, possessing undesirable properties in terms of strength, deformation, compressibility and liquefaction susceptibility, especially under saturated conditions [37]. The tests procedures adopted in the study conformed to the relevant ASTM standards. The physical, index and mechanical properties were determined and are listed in Table 1. From the gradation curve as shown in Fig. 1 and the index properties, the soil can be classified as silt of intermediate plasticity as per ISCS soil classification system.

Stockpiled CKD was collected from a cement manufacturing plant located in the vicinity of the soil sampling site, and its physical and chemical properties were determined in the laboratory. CKD is a typically fine-grained pozzolanic alkaline material in an off-white color which gets generated as a by-product during the cement manufacturing process. It derives its cementitious nature from the presence of oxides like silica, alumina, lime, etc., which are approximately one-third as that of ordinary Portland cement. The constituents of CKD may vary quantitatively with the type of manufacturing process and the raw feed, but generally it falls in a certain range [19]. Figure 2 shows the X-ray diffractogram of CKD. The chemical constituents of soil and kiln dust were obtained through X-ray fluorescence analysis and are shown in the form of a pie chart in Fig. 3. CKD used in the study contains significant amount of calcium oxide (CaO) which is responsible for imparting it pozzolanic properties.

Glass fibers of average length of 18 mm and an approximate diameter of 20 µm (as seen under scanning electron microscope) were used as randomly distributed reinforcing elements. This fiber length was chosen considering the authors earlier work on optimization of glass fiber content and length [38]. Among all synthetic fibers, glass fibers have been widely accepted as reinforcing elements primarily for their exceptionally high tensile strength, dimensional stability, low cost of fabrication and excellent chemical and alkali resistance.

Sample preparation and test methods

In the preparation of different specimen types, for untreated soil, a predetermined quantity of water based on its OMC was added to the dry soil. For soil–CKD mixes, dry soil and CKD were initially mixed in a known ratio and thereafter the required amount of water was added. Subsequently, the samples were statically compacted and subjected to closed room curing for specific curing regimes (7, 14 and 28 days). For soil–fiber–CKD specimens, fibers were added in increments to a dry mixture of soil–CKD. This was to ensure the homogenous dispersion of fibers in the dry state only. Thereafter the water was sprinkled and the mixture was thoroughly mixed manually to prevent fiber rolling. The same procedure as stated above was followed later onwards, until testing. For possible field applications of the mixes considered in this study, the mixing will either be done at the site itself (in place mixing) or at some centrally mixing plant which is later hauled to the jobsite. The bulk utilization in the field would follow more or less similar steps as in the laboratory (i.e., mixing, compaction and curing). Mixing in field is generally achieved by pug-mill type mixers, compaction by rollers and curing by applying some bitumen surface coating.

An overview of the systematic methodology adopted to envisage the objectives is as follows.

-

(i)

The pH tests on soil–CKD mixes were conducted following the procedure stated by Eades and Grim [39]. This method was essentially devised to determine the lime requirements for soil stabilization. However, researchers [13, 40] have adopted the same method for determining the pH of soil–CKD mixes. pH test results help in judging the optimum requirement of the stabilizer (CKD in our case) to be used for the soil improvement. The procedure involves mixing distilled water with air-dried solids in a ratio of 5:1. After periodic shaking, the pH of the slurry is measured after 1 h using glass electrode standardized with a buffer solution. Initially pH of natural soil and CKD was determined. Thereafter, the soil CKD mixes were tested for pH values with percentage ranging from 0 to 28% at 7% intervals.

-

(ii)

Moisture Density relationships were evaluated through standard Proctor test conforming to the ASTM D698-12 [41]. Air-dried soil samples were blended with desired percentage of CKD and were hand mixed to a uniform composition. This was followed by incremental mixing of water and the mixtures were compacted in a standard mold producing a compactive effort of 600 kN-m/m3. A total of 8 proctor compaction tests were performed with different combinations of soil–CKD and fiber. Initially cemented soils without fiber were tested for compaction. Thereafter, for a constant soil–CKD mix, fibers were added in different proportions to obtain compaction curves of fiber reinforced cemented soils.

-

(iii)

UCS tests were conducted to examine the performance of various soil–CKD–fiber mixes under uniaxial compression in accordance with ASTM D 2166-00 [42]. The unconfined compression strength is a widely adopted index to estimate the soil improvement. There were 28 different samples tested for UCS. Sample preparation was done by hand mixing dry soil with CKD. After obtaining a uniform soil–CKD dry mix, fibers were incrementally added by dry weight of mix, and the desired water content was mixed to form a homogenous mixture. Much care was taken to avoid floc formation due to fibers. The mixture was then transferred to a cylindrical mold in which samples were statically compacted to respective MDD and OMC of composites by giving equal rotations on both sides. The target density was achieved by regulating height and weight of soil samples. The samples of 50 mm diameter and 100 mm height were extruded and cured in desiccators for a period of 7, 14 and 28 days to evaluate the effect of curing time on strength of samples. The tests were repeated and representative values of strengths were reported.

-

(iv)

Split tensile strength (STS) tests were performed on samples of 50 mm diameter and 100 mm height, with similar mix proportions as considered for UCS testing. The split tensile test is a very convenient indirect yet reliable procedure for determination of tensile strength of fine-grained soils. Despite being an important parameter in design of earthen structures and slopes where tension cracks develop, tensile strength of soils has not been taken up extensively due to lack of proper equipment for its direct measurement [43, 44]. The cylindrical samples were placed horizontally length-wise between the two platens attached to the ram and base of universal testing machine. The maximum load corresponding to each specimen was recorded which in turn was used to calculate the STS of samples.

$$T = \frac{{2P}_{\mathrm{max}}}{\Pi DH}$$(1)where T = split tensile strength; Pmax = maximum load taken by the sample; D and H = diameter and height of the specimen, respectively.

-

(v)

Microstructural and chemical analysis of samples was conducted through FESEM and XRD spectroscopy to identify the underlying interaction mechanisms and the new products (if any) formed due to cementation. Field emission scanning electron microscopy (FESEM) is a conventional procedure employed for analyzing the microstructural details of soil fabric, giving information regarding shape, size and orientation of particles. The FESEM analysis becomes even more significant in soil stabilization studies, in order to observe the topographical features and, moreover, for confirmation of cementitious formations which are otherwise non-detectable [8]. From the tested samples of UCS before and after treatment, sample pellets were taken from along the failure planes and gold coated for FESEM examination. For XRD tests, samples were prepared by hand grinding the soil pellets using mortar and pestle into an ultra-fine homogenous powder, spread uniformly with the help of a microscope slide and placed in the sample holder inside the machine. XRD patterns were generated using Cu-kbeta radiation at 40 kV and 30 mÅ. The scanning range of 2θ was from 5° to 80° with a step width of 0.02°.

Results and discussion

Effect of CKD addition on pH and consistency indices

A suite of pH tests was conducted, initially for natural soil and pure CKD and then the soil–CKD mixes with CKD content of 7, 14, 21 and 28%. The pH tests were conducted following the procedure stated by Eades and Grim. To initiate and sustain a pozzolanic reaction and to ensure the solubility of silicon and aluminum ions, it is important to maintain the medium at elevated pH [13]. Thus, the pH tests were performed to determine the CKD content required to satisfy the chemical reactions taking place and to investigate whether pH would reflect the performance of CKD treated soil. The pH of CKD–water mixture was around 12.25 while that of soil was 7.3. Generally, at a pH of 12 and above it is supposed that sufficient CKD is available to satisfy ion exchange reactions. Figure 4a shows the variation of pH corresponding to different CKD concentrations and from the results it is concluded that CKD in the range of 7–14% is an optimum range for soil stabilization because beyond this value, pH varies asymptotically and attains a stable value. The optimized range of CKD is further verified through compaction and strength tests.

For the evaluation of effect of CKD on consistency indices, Casagrande’s liquid and plastic limit tests were conducted. From the test results, it was concluded that the CKD addition results in a substantial reduction in the plasticity index of the soil, thus improving the soil workability. For untreated soil, the LL was found to be 36% which increased to 40.55% at CKD 14%. Likewise, there was a consistent increase in plastic limit from 25% for untreated soil to 32% at CKD 14%. Thus, the plasticity index was reduced from 11% for the control soil to 8.55% to the treated soil. Figure 4b illustrates the effect of CKD addition on consistency indices. The possible reasons for these trends are the physical (fineness) and chemical (high alkali content) composition of the CKD which results in an increased affinity for water. Although there is inconsistency in the literature with regard to the effects on consistency indices, the results of the current study are also supported by the findings of Miller and Azad [13] and Sreekrishnavilasam et al. [14].

Effect on compaction behavior

Standard proctor tests were conducted out on soil and cement kiln dust mixes from 0 to 21% at an increment of 7% mixed with 0.3, 0.6, 0.9 and 1.2% glass fiber. Figure 5a demonstrates the compaction curves of various mixes considered in the study. Table 2 summarizes the compaction results of various mixes considered in the study. For natural soil the OMC and MDU values were 19.15% and 16.68 kN/m3, respectively. The addition of CKD markedly improved the compaction behavior as an increase in MDU was seen up to 14% of CKD. Beyond, 14% CKD, there was a drop in MDU value indicating an optimum content for compaction behavior. The OMC, on the other hand, increased continuously with increase in CKD content from 0 to 21%. Moreover, the effect of fiber addition on compaction parameters was comparatively insignificant and inconsistent at the same time. Thus, no conclusive remarks could be made on the effect of fiber addition on compaction behavior except for that, it marginally influences the behavior. From the compaction results, the mix designated as S86CKD14 was deemed to be an ‘effective mix’ having OMC and MDU of 21.2% and 17.3 kN/m3 and was, therefore, considered for fiber incorporations. Figure 5b shows the variations in OMC and MDU corresponding to different percentage of CKD.

Although there are inconsistencies reported in the literature, with regard to the effect of chemical additives on compaction characteristics but our results are corroborated by the findings of many studies including [33, 34, 45]. Baghdadi et al. [46] reported a similar trend with MDU increasing up to 50% of CKD and decreasing there onward. Al-Refeai and Karni [47] have also reported an increase in OMC and MDU with addition of CKD for treatment of dune sand. On the other hand, Ghavami et al. [15] have reported an increase in OMC and reduction in MDU on addition of cement and CKD. Likewise, other researchers have also reported MDU reduction and OMC increment [13, 48]. The dust particles being slightly denser with a higher specific gravity than those of soil particles, reflects in elevation of the MDU of soil–CKD mixes. The depreciation in MDU values beyond 14% CKD is an indication of excess CKD which results in disintegration of the soil structure [33]. The water affinity of calcium oxide present in CKD and the water held in the flocculated structure formed as a result of cementation reaction account for indefinite increase in OMC for all CKD percentage.

Effect of CKD and fiber addition on UCS and STS

To examine the effect of various parameters on undrained strength of the soil, three series of UCS tests were performed. Fiber reinforced samples followed by CKD stabilized and fiber reinforced cemented samples, were systematically tested and the stress strain plots were obtained. Tables 3 and 4 summarize the UCS test results of all the mixes considered in the study. The effect of CKD addition on UCS strength is remarkably significant. From stress strain plots, it is also observed that the curing time plays an instrumental role in the development of strength. The 28 days strength of untreated soil is 121 kN/m2 while as soil + 14% CKD composite yields a peak strength 843 kN/m2. At low CKD content (7%), there is a noticeable effect on UCS yet not substantial. As the CKD content is increased to 14%, there is a dramatic increase in peak strength of the composites. However, beyond 14%, the strength values are marginally affected. This is a clear indication of existence of an optimum content of CKD for application in stabilization processes for soils containing predominantly silt particles. Interestingly, the performance of soil–CKD composites as seen under compression is also reflected in pH values. The stress strain response resembled a typical strain softening behavior. The failure strain varied between 3 and 3.75% which is significantly lesser than fiber reinforced cemented as well as uncemented soils. The curing period showed a positive correlation with UCS values for all mixes, which is indicative of pozzolanic reactions taking place resulting in the formation of cementitious products over time.

As for the fiber reinforced uncemented soils, the stress strain curves as shown in Fig. 6e are representative of strain–hardening behavior. The UCS values gradually increase with increase in fiber concentration and attain a maximum value at GF = 0.9%. Beyond this fiber percentage, there is a drop in UCS value. This is due to the fact that at higher fiber percentage the structural integrity of samples is compromised as a result of floc formations and improper mixing. However, the improvement is comparatively lesser than that of CKD stabilized soil samples. The deformation pattern of fiber reinforced soil samples is substantially improved and samples fail in an axial strain range of 5–12%. Moreover, the ductility of the samples is considerably larger than those of unreinforced soil.

The combined effect of fiber and CKD on stress strain behavior of soil samples is shown in Fig. 6d. The summary of UCS test results of various soil–CKD–fiber mixes are summarized in Table 4. The fiber inclusion further leads to the progressive development of strength. In fact, the effect of fiber on UCS is accentuated in cemented soils than those of uncemented soils. The peak strength for the mix (S86CKD14GF0.9) reaches to a maximum value of 1090 kN/m2. Moreover, the samples fail at relatively larger axial strain than the cemented soil (around 6%). The residual strength is higher due to fiber incorporation unlike the cemented soils where post peak gets drastically reduced to minimum or even zero (catastrophic failure). Thus, the brittleness of the stress–strain response of cemented soils is reduced due to incorporation of fibers.

The split tensile strength tests were conducted on similar mixes as considered for UCS testing. Figure 7 illustrates the split tension test stages of a specimen. The test results of fiber reinforced samples are tabulated in Table 5. The STS value for untreated soil was 22 kN/m2 which was increased to a maximum value of 326 kN/m2 for mix S86CKD14GF0.9. Variations in STS values as a function of fiber content are presented in Fig. 8a. The post-tension strength of cemented samples without fiber reduced almost instantly to zero. However, this was not the case with fiber reinforced cemented samples as the ‘bridge effect’ of fibers maintained some residual post-tensile strength. The STS values constantly increased with curing periods from 7 to 28 days, much similar to the trend followed by UCS values. In fact, STS values apparently increased proportionally with the UCS values. Consoli et al. [49] also reported the positive impact of fibers on tensile strength of cemented soils. Thus, a graph as shown in Fig. 8b between STS and UCS values was plotted to explore the functional relationship between the two quantities. The mean of STS/UCS ratio for the experimental data set available in this study is 0.24. For cement fiber reinforced Botucatu residual soil, Festugato et al. [50] reported a value of STS/UCS = 0.156. Since, while calculating this ratio, we have considered all the three kinds of mixes (cemented without fiber, fiber reinforced, fiber reinforced cemented) together, the ratio appears to be slightly overestimated. Table 6 summarizes the results of various mixes after 7, 14 and 28 days curing.

The improvements in soil strength are a direct consequence of the structural changes caused due to physical and chemical reaction of CKD with soil particles. The physical change is reflected in terms of gradation, because the fineness of CKD improves the particle size distribution of the composite and also fills the voids present in the soil structure [51]. The primary mechanisms responsible for changes in chemical makeup of the soil–CKD composite include cation exchange, flocculation/agglomeration and pozzolanic reactions. The cation exchange process involves the exchange between Ca2+ ions (released due to CKD) and the metal ions (Na+ and Al3+) ions present in the soil. Flocculation is induced by the van der Waals forces which help in overcoming the repulsion due to negatively charged surfaces of soil particles. It helps in reorientation of particles from parallel to edge-to-face orientation. The aforementioned processes result in numerous textural and structural changes of the soil [52]. Likewise, the pozzolanic reactions involve the reaction of calcium hydroxide ions with aluminum and silicates in presence of water. They result in formation of cementitious products like calcium silicates and aluminum hydrates. Ca2+ + 2(OH)− + SiO2 → C–S–H; Ca2+ + 2(OH)− + Al2O3 → C–A–H.

The solubility of the silicates and aluminates and their potential to react with binder is largely governed by the pH. At 14% CKD content, the pH value is as high 12.339; therefore, the maximum strength is found at this concentration. This study, therefore, proposes an optimum dosage of cement kiln dust at 14% of dry weight of soil. Many other researchers have also recommended the optimum CKD content in the same range. However, based on CBR performance of poor subgrade soil treated with cement kiln dust, Mosa et al. [51] have proposed 20% of CKD as optimum dosage. The variations in establishing the optimum concentration of CKD for a particular soil type may be attributed to different soil (granulometry) and chemical composition (pH) of both soil and CKD.

XRD test results

The x-ray diffractograms of untreated soil and the treated soil with varying percentage of CKD after 28 days are shown in Fig. 9. For untreated soil, there was predominance of quartz (SiO2) at peak positions of (2θ = 20.84° and 26.62°) in addition to illite, muscovite and few traces of albite. For treated specimens, the x-ray diffractograms reveal that there is a reduction in the peak intensities of quartz and other soil minerals. This can be ascribed to the pozzolanic reactions taking place between soil and additives [53]. The degree of reduction in the peak intensities for various treated samples is different depending upon the concentration of CKD used for stabilization. The percentage reduction in peak intensities increases with increase in CKD content. Simultaneously, some additional peaks are observed in case of treated soils which are indicative of cementitious products formed in the course of the chemical reactions. The new peaks of calcite (CaCO3) and Portlandite are seen at peak positions of (2θ = 27.88° and 27.66°).

Interface morphologies

For the purpose of investigating the underlying mechanisms responsible for changing the mechanical behavior of reinforced/treated soil, some FESEM images with discussions are shown below. Figure 10a shows the SEM image of unreinforced untreated soil. It is seen that the soil particles are loosely compacted and the pore spaces are significantly large. The porous phase fraction in percent of total image size is measured using image analysis tool ImageJ and is equal to 45.79% as shown in Fig. 10b. Likewise, the microstructure of fiber reinforced soil without CKD is somewhat similar to unreinforced soil with comparable porous phase fraction. This is expected of fiber reinforced soils because they do not alter the chemical makeup of soils [54]. They rather interact physically by bonding with the soil particles which could also be seen in Fig. 10c. The soil particles wrap themselves around fibers and the overall strength of the composite is determined by this bond strength itself. The level of strength improvement in combined use of fiber and cementitious materials is more due to higher interaction between fiber and soil matrix [55]. Moreover, the uniform, random distribution of discrete fibers in the soil mass results in a three-dimensional spatial network which offers a confining effect at microscopic level thus contributing to the soil strength. The cementious formations in the form of needle like crystals could be seen. The microstructure appears to be transformed into a dense matrix, reducing the void spaces in the structure. Moreover, cementitious formations are also visible on the fiber surfaces which are basically responsible for accentuating the effect of fibers in cemented soils. The fiber reinforced cemented soil possesses the characteristics of both cemented and fiber reinforced soils with changes in physical structure and chemical makeup at the same time. The SEM images are reflective of the stress strain responses of the mixes considered in the study. The SEM images of CKD stabilized soils with and without fiber are shown in Fig. 10d–f.

Cost-effectiveness and sustainability

Besides the strict environment regulations associated with the management of CKD waste, the quantity of CKD produced and the cost incurred in its disposal is very high. CKD deposited in landfills becomes an environmental threat and upsets the vision of sustainability. The utilization of cement kiln dust for ground improvement, therefore, brings twofold advantages, i.e., it helps in getting rid of the disposal problem and produces ground improvement at the same time. Thus, utilizing additives like CKD for ground improvement serves as an efficient sustainable waste management practice. Moreover, it does not require any further processing or treatment prior to its use in ground improvement. Thus, being a by-product, its cost-effectiveness is indisputable.

Conclusions

The test results of this comprehensive laboratory investigation which included compaction tests, UCS tests, split tension tests, pH tests, X-ray and FESEM analysis on soil–CKD–fiber composites led us to following conclusions:

-

The CKD addition resulted in improvement in compaction characteristics with MDU increasing from 16.68 to 17.23 kN/m3 at CKD content of 14%.

-

Due to the presence of high calcium oxide content in the CKD, the pH of soil–CKD mixes increased and attained a stable value at 14% CKD. Increased pH favored pozzolanic reactions and added to the stability of reaction products leading to increased long-term strength.

-

The increase in strength for soil treated with CKD displayed time dependent behavior. At 28 days of curing the increase in strength was observed to be 7.5 times with treated soil specimens failing in relatively brittle mode.

-

The residual strength in soil–CKD–fiber specimens was observed to be higher as compared to soil–CKD samples owing to the presence of fibers in the former. Increased residual strength implies lower and controlled post-failure deformations under real life load-controlled situations.

-

The x-ray diffractograms of soil–CKD composites showed new characteristic peaks confirming the formation of cementitious products. The changes in the microstructure were confirmed with the help of FESEM images. It is observed that there are no significant changes in the microstructure of fiber reinforced samples and that soil–fiber interactions are largely physical in nature. In contrast to this, the microstructure of CKD stabilized samples exhibited denser configuration because of the formation of cementitious, subsequently filling the pore space.

This study is part of first author’s ongoing Ph.D. program which explores the potential of fibers in conjunction with CKD for ground improvement. Currently, the authors are working on CU triaxial testing of the fiber reinforced soil which aims to study the pore pressure response of fiber reinforced soils. The CBR performance of treated soil under soaked and unsoaked conditions, is also being investigated at the same time. This will be followed by the durability assessment of the proposed ground improvement technique. The durability criteria in the current study shall include, the effect of freeze–thaw and wet–dry cycles on the structural integrity of the treated samples. Moreover, the nondestructive testing (ultrasonic pulse wave velocity) of treated soil and its possible correlations with conventional strength/stiffness parameters will be examined.

The scope of current research program is, however, limited to laboratory study under static loading conditions. For researchers in future, it is recommended to work on cyclic/dynamic response of CKD treated soil with focus on mitigation of liquefaction susceptibility of fine sands/silts. The large-scale field testing for specific field applications like subgrade treatment, slope stabilization, in embankment construction, and as fill or foundation material also demands further attention of researchers.

Data availability

The study contains the experimentally generated data which is presented in the form of graphs and tables within the paper.

References

Horpibulsuk S, Kumpala A, Katkan W (2008) A case history on underpinning for a distressed building on hard residual soil underneath non-uniform loose sand. Soils Found 48(2):267–285. https://doi.org/10.3208/sandf.48.267

Ismail MA, Joer HA, Sim WH, Randolph MF (2002) Effect of cement type on shear behavior of cemented calcareous soil. J Geotech Geoenviron Eng 128(6):520–529. https://doi.org/10.1061/(ASCE)1090-0241(2002)128:6(520)

Al-Rawas AA (2002) Microfabric and mineralogical studies on the stabilization of an expansive soil using cement by-pass dust and some types of slags. Can Geotech J 39(5):1150–1167. https://doi.org/10.1139/t02-046

Haralambos SI (2009) Compressive strength of soil improved with cement. In: Contemporary topics in ground modification, problem soils, and geo-support, pp 289–296. https://doi.org/10.1061/41023(337)37

Consoli NC, Winter D, Rilho AS, Festugato L, dos Santos Teixeira B (2015) A testing procedure for predicting strength in artificially cemented soft soils. Eng Geol 195:327–334. https://doi.org/10.1016/j.enggeo.2015.06.005

Mir BA, Sridharan A (2019) Mechanical behaviour of fly-ash-treated expansive soil. Proc Inst Civ Eng Ground Improv 172(1):12–24. https://doi.org/10.1680/jgrim.16.00024

Arulrajah A, Abdullah A, Bo MW, Bouazza A (2009) Ground improvement techniques for railway embankments. Proc Inst Civ Eng Ground Improv 162(1):3–14. https://doi.org/10.1680/grim.2009.162.1.3

Latifi N, Horpibulsuk S, Meehan CL, Abd Majid MZ, Tahir MM, Mohamad ET (2017) Improvement of problematic soils with biopolymer—an environmentally friendly soil stabilizer. J Mater Civ Eng 29(2):04016204. https://doi.org/10.1061/(ASCE)MT.1943-5533.0001706

Mistry MK, Shukla SJ, Solanki CH (2021) Reuse of waste tyre products as a soil reinforcing material: a critical review. Environ Sci Pollut Res. https://doi.org/10.1007/s11356-021-13522-4

Dermatas D, Meng X (2003) Utilization of fly ash for stabilization/solidification of heavy metal contaminated soils. Eng Geol 70(3–4):377–394. https://doi.org/10.1016/S0013-7952(03)00105-4

Venkatachalam MN, Balu S (2022) A review on the application of industrial waste as reinforced earth fills in mechanically stabilized earth retaining walls. Environ Sci Pollut Res. https://doi.org/10.1007/s11356-021-17953-x

Mir BA, Sridharan A (2013) Physical and compaction behaviour of clay soil–fly ash mixtures. Geotech Geol Eng 31(4):1059–1072. https://doi.org/10.1007/s10706-013-9632-8

Miller GA, Azad S (2000) Influence of soil type on stabilization with cement kiln dust. Constr Build Mater 14(2):89–97. https://doi.org/10.1016/S0950-0618(00)00007-6

Sreekrishnavilasam A, Rahardja S, Kmetz R, Santagata M (2007) Soil treatment using fresh and landfilled cement kiln dust. Constr Build Mater 21(2):318–327. https://doi.org/10.1016/j.conbuildmat.2005.08.015

Ghavami S, Naseri H, Jahanbakhsh H, Nejad FM (2021) The impacts of nano-SiO2 and silica fume on cement kiln dust treated soil as a sustainable cement-free stabilizer. Constr Build Mater 285:122918. https://doi.org/10.1016/j.conbuildmat.2021.122918

Ebrahimi A, Edil TB, Son YH (2012) Effectiveness of cement kiln dust in stabilizing recycled base materials. J Mater Civ Eng 24(8):1059–1066. https://doi.org/10.1061/(ASCE)MT.1943-5533.0000472

Kumar JS, Janewoo U (2016) Stabilization of expansive soil with cement kiln dust and RBI grade 81 at subgrade level. Geotech Geol Eng 34(4):1037–1046. https://doi.org/10.1007/s10706-016-0024-8

Al-Homidy AA, Dahim MH, Abd El Aal AK (2017) Improvement of geotechnical properties of sabkha soil utilizing cement kiln dust. J Rock Mech Geotech Eng 9(4):749–760. https://doi.org/10.1016/j.jrmge.2016.11.012

Sreekrishnavilasam A, King S, Santagata M (2006) Characterization of fresh and landfilled cement kiln dust for reuse in construction applications. Eng Geol 85(1–2):165–173. https://doi.org/10.1680/geimogacl.32774.0036

Prabakar J, Sridhar RS (2002) Effect of random inclusion of sisal fibre on strength behaviour of soil. Constr Build Mater 16(2):123–131. https://doi.org/10.1016/S0950-0618(02)00008-9

Tang CS, Cheng Q, Wang P, Wang HS, Wang Y, Inyang HI (2020) Hydro-mechanical behavior of fiber reinforced dredged sludge. Eng Geol 276:105779. https://doi.org/10.1016/j.enggeo.2020.105779

Viswanadham BVS, Phanikumar BR, Mukherjee RV (2009) Swelling behaviour of a geofiber-reinforced expansive soil. Geotext Geomembr 27(1):73–76. https://doi.org/10.1016/j.geotexmem.2008.06.002

Tang CS, Shi B, Zhao LZ (2010) Interfacial shear strength of fiber reinforced soil. Geotext Geomembr 28(1):54–62. https://doi.org/10.1016/j.geotexmem.2009.10.001

Zornberg JG (2002) Discrete framework for limit equilibrium analysis of fibre-reinforced soil. Géotechnique 52(8):593–604. https://doi.org/10.1680/geot.2002.52.8.593

Shukla SK (2017) Fundamentals of fibre-reinforced soil engineering. Springer, Singapore. https://doi.org/10.1007/978-981-10-3063-5

Huang Y, Wen Z (2015) Recent developments of soil improvement methods for seismic liquefaction mitigation. Nat Hazards 76:1927–1938. https://doi.org/10.1007/s11069-014-1558-9

Amadi AA, Eberemu AO, Momoh OH (2013) Use of coir fiber reinforcement technique to improve strength of cement kiln dust treated black cotton soil subgrade. In: Geosynthetics. Long Beach, pp 223–229

Kaniraj SR, Havanagi VG (2001) Behavior of cement-stabilized fiber-reinforced fly ash–soil mixtures. J Geotech Geoenviron Eng 127(7):574–584. https://doi.org/10.1061/(ASCE)1090-0241(2001)127:7(574)

Park SS (2009) Effect of fiber reinforcement and distribution on unconfined compressive strength of fiber-reinforced cemented sand. Geotext Geomembr 27(2):162–166. https://doi.org/10.1016/j.geotexmem.2008.09.001

Murray JJ, Frost JD, Wang Y (2000) Behaviour of a sandy silt reinforced with discontinuous recycled fiber inclusions. Transp Res Rec 1714(1):9–17. https://doi.org/10.3141/1714-02

Zaimoglu AS, Yetimoglu T (2012) Strength behaviour of fine grained soil reinforced with randomly distributed polypropylene fibers. Geotech Geol Eng 30(1):197–203. https://doi.org/10.1007/s10706-011-9462-5

Yetimoglu T, Salbas O (2003) A study on shear strength of sands reinforced with randomly distributed discrete fibers. Geotext Geomembr 21(2):103–110. https://doi.org/10.1016/S0266-1144(03)00003-7

Kumar JS, Sharma P (2018) Geotechnical properties of pond ash mixed with cement kiln dust and polypropylene fiber. J Mater Civ Eng 30(8):04018154. https://doi.org/10.1061/(ASCE)MT.1943-5533.0002334

Sharma RK (2017) Laboratory study on stabilization of clayey soil with cement kiln dust and fiber. Geotech Geol Eng 35(5):2291–2302. https://doi.org/10.1007/s10706-017-0245-5

Puppala A, Hoyos L, Viyanant C, Musenda C (2001) Fiber and fly ash stabilization methods to treat soft expansive soils. In: Soft ground technology, pp 136–145. https://doi.org/10.1061/40552(301)11

Kumar A, Gupta D (2016) Behavior of cement-stabilized fiber-reinforced pond ash, rice husk ash–soil mixtures. Geotext Geomembr 44(3):466–474. https://doi.org/10.1016/j.geotexmem.2015.07.010

Khan RA, Shah MY (2016) Earthquake induced liquefaction features in the Karewas of Kashmir Valley North-West Himalayas, India: implication to paleoseismicity. Soil Dyn Earthq Eng 90:101–111. https://doi.org/10.1016/j.soildyn.2016.08.007

Gul N, Mir BA (2022) Parametric study of glass fiber reinforced fine-grained soil with emphasis on microstructural analysis. Int J Geotech Eng 16(6):716–728. https://doi.org/10.1080/19386362.2022.2049524

Eades JL, Grim, RE (1966) A quick test to determine lime requirements for lime stabilization. In: Highway research record, No. 139

Nasr AM (2014) Utilisation of oil-contaminated sand stabilised with cement kiln dust in the construction of rural roads. Int J Pavement Eng 15(10):889–905. https://doi.org/10.1080/10298436.2014.893321

ASTM D698-12 (2012) Standard Test methods for laboratory compaction characteristics of soil using standard effort (12,400 ft-lbf/ft3 (600 kN-m/m3)). ASTM International

ASTM D2166 (2013) Standard test method for unconfined compressive strength of cohesive soil. ASTM International

Ramanathan B, Raman V (1974) Split tensile strength of cohesive soils. Soils Found 14(1):71–76. https://doi.org/10.3208/sandf1972.14.71

Tang CS, Wang DY, Cui YJ, Shi B, Li J (2016) Tensile strength of fiber-reinforced soil. J Mater Civ Eng 28(7):04016031. https://doi.org/10.1061/(ASCE)MT.1943-5533.0001546

Ismail AIM, Belal ZL (2016) Use of cement kiln dust on the engineering modification of soil materials, Nile Delta, Egypt. Geotech Geol Eng 34(2):463–469. https://doi.org/10.1007/s10706-015-9957-6

Baghdadi ZA, Fatani MN, Sabban NA (1995) Soil modification by cement kiln dust. J Mater Civ Eng 7(4):218–222. https://doi.org/10.1061/(ASCE)0899-1561(1995)7:4(218)

Al-Refeai TO, Al-Karni AA (1999) Experimental study on the utilization of cement kiln dust for ground modification. J King Saud Univ Eng Sci 11(2):217–231. https://doi.org/10.1016/S1018-3639(18)30999-1

Solanki P, Khoury N, Zaman M (2007) Engineering behavior and microstructure of soil stabilized with cement kiln dust. In: Soil improvement, pp 1–10. https://doi.org/10.1061/40916(235)6

Consoli NC, De Moraes RR, Festugato L (2011) Split tensile strength of monofilament polypropylene fiber-reinforced cemented sandy soils. Geosynth Int 18(2):57–62. https://doi.org/10.1680/gein.2011.18.2.57

Festugato L, da Silva AP, Diambra A, Consoli NC, Ibraim E (2018) Modelling tensile/compressive strength ratio of fibre reinforced cemented soils. Geotext Geomembr 46(2):155–165. https://doi.org/10.1016/j.geotexmem.2017.11.003

Mosa AM, Taher AH, Al-Jaberi LA (2017) Improvement of poor subgrade soils using cement kiln dust. Case Stud Constr Mater 7:138–143. https://doi.org/10.1016/j.cscm.2017.06.005

Sargent P (2015) The development of alkali-activated mixtures for soil stabilisation. Handbook of alkali-activated cements, mortars and concretes. Woodhead Publishing, pp 555–604. https://doi.org/10.1533/9781782422884.4.555

Gupta D, Kumar A (2016) Strength characterization of cement stabilized and fiber reinforced clay–pond ash mixes. Int J Geosynth Ground Eng 2(4):1–11. https://doi.org/10.1007/s40891-016-0069-z

Tang C, Shi B, Gao W, Chen F, Cai Y (2007) Strength and mechanical behavior of short polypropylene fiber reinforced and cement stabilized clayey soil. Geotext Geomembr 25(3):194–202. https://doi.org/10.1016/j.geotexmem.2006.11.002

Tabakouei AR, Narani SS, Abbaspour M, Aflaki E, Siddiqua S (2022) Coupled specimen and fiber dimensions influence measurement on the properties of fiber-reinforced soil. Measurement 188:110556. https://doi.org/10.1016/j.measurement.2021.110556

Acknowledgements

The study was conducted as part of author’s PhD work at National Institute of Technology Srinagar. The authors duly acknowledge the Civil Engineering Department of the institute for providing the laboratory facilities during the course of this study. Thanks are due to the Central Research Facility Centre (CRFC), NIT Srinagar, for providing research facilities in conducting FESEM and XRD tests. The first author acknowledges the financial support of Ministry of Education, Government of India (MoE), in the form of research fellowship.

Funding

The authors declare that no funds or grants were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no competing interests to declare.

Ethical approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gul, N., Mir, B.A. Influence of glass fiber and cement kiln dust on physicochemical and geomechanical properties of fine-grained soil. Innov. Infrastruct. Solut. 7, 344 (2022). https://doi.org/10.1007/s41062-022-00943-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-022-00943-4