Abstract

Nanogels combine the favourable properties of hydrogels with those of colloids. They can be soft and conformable, stimuli-responsive and highly permeable, and can expose a large surface with functional groups for conjugation to small and large molecules, and even macromolecules. They are among the very few systems that can be generated and used as aqueous dispersions. Nanogels are emerging materials for targeted drug delivery and bio-imaging, but they have also shown potential for water purification and in catalysis. The possibility of manufacturing nanogels with a simple process and at relatively low cost is a key criterion for their continued development and successful application. This paper highlights the most important structural features of nanogels related to their distinctive properties, and briefly presents the most common manufacturing strategies. It then focuses on synthetic approaches that are based on the irradiation of dilute aqueous polymer solutions using high-energy photons or electron beams. The reactions constituting the basis for nanogel formation and the approaches for controlling particle size and functionality are discussed in the context of a qualitative analysis of the kinetics of the various reactions.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Nanogels: Soft, Dynamic, Challenging Nanoparticles

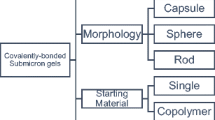

Hydrogels are macroscopic, three-dimensional networks of hydrophilic polymer chains that can absorb a significant amount of water. The presence of chemical (i.e. covalent or ionic) crosslinks, physical crosslinks (e.g. van der Waals interactions, hydrogen bonds, crystalline domains, intermolecular complexes), or a combination of both, prevents or delays polymer dissolution when these materials are exposed to aqueous solutions. Nanogels are nanoscalar polymeric networks. The IUPAC defines a nanogel as a gel particle of any shape with an equivalent diameter of 1–100 nm [1]. The definition has often been extended to sub-micron gel particles, thus overlapping with the size range of microgels, which spans 100 nm to 100 μm.

Many different polymeric architectures have been classified as nanogels, including hydrophilic or hydrophobic crosslinked polymer nanoparticles, core-crosslinked or shell-crosslinked micelles of amphiphilic polymers, liposomes modified with crosslinkable polymers, and various composite inorganic/crosslinked polymer nanostructures [2]. Here, we will be mainly concerned with hydrophilic polymer networks that can be swollen by water or aqueous solutions.

Nanogels are characterised by an “equilibrium” swelling condition that is the result of the same force balance that governs the swelling of their macroscopic analogues [3]. Hydration and osmotic “repulsive” forces drive the polymer segments apart, favouring the ingress of solvent, while elastic “attractive” forces are attributed to chain stretching and bond deformation that tend to restore the unstrained chain conformation. When nonpolar chain segments, hydrogen bonding groups or complexing moieties are present in the network (as part of the backbone or as lateral grafts), further components of the attractive forces shall be considered; they can be classified as hydrophobic [4], hydrogen-bonding [5] and coordination bonding forces [6], respectively. If ionisable groups are present, repulsion between fixed electric charges in the network should also be taken into account, alongside the extra contribution to the osmotic pressure owing to the presence of counterions [7]. The swelling degree of nanogels, and thus their hydrodynamic size, is the result of their chemical structure, crosslinking degree and density, and the quality of the solvent (its chemical composition and temperature) in which they are dispersed.

Aside from intraparticle forces, inter-particle forces also affect the behaviour of nanogels. In general, nanogels are characterised by high colloidal stability in aqueous media, mainly due to the steric stabilisation exerted by the dangling chains stretching out in the solvent and the very small density mismatch with the solvent. When ionisable groups are present, electrostatic stabilisation can also contribute to the overall stability, provided that the ionic strength of the dispersing medium is not too high. As expected, there is a very strong interplay between intra- and inter-particle interactions, and the conditions that favour the collapse of the network can also affect the colloidal stability of the nanoparticles, leading to their association [8].

This highly dynamic internal structure of nanogels makes them flexible and adaptive in shape. When nanogels are used as drug carriers, their flexibility and shape-changing ability can facilitate the bypass of biological barriers, ensure protection of the payload, and enable the interaction of any attached ligand with its receptors. For example, poly(N-vinylpyrrolidone)-based nanogels covalently conjugated to insulin can protect the hormone from enzymatic degradation by conforming around the protein. When they reach the cell membrane, the insulin becomes exposed to the receptors where the hormone activates its signalling cascade. The multiple weak interactions established between the polymeric segments of the nanogel and the protein when in the culture medium are reverted by the stronger interactions between the protein and its receptor when the nanocarriers approach the cell membrane [9].

Numerous techniques have been applied for measuring the particle size and size distribution of nanogels, most of which express the results in terms of equivalent spherical radius. In most cases, when the nanoparticles are non-spherical, different measurement techniques produce different size distributions. Therefore, a form factor should be preliminarily determined. All characterisations will be sensitive to heterogeneous impurities; therefore, particular care should be taken in sample preparation, storage and handling.

Some analytical techniques can strongly influence the size and shape of nanogels, especially when the preparation forces the nanogels to lose part or most of their hydration water and to interact with other materials and surfaces or, for example, with the substrates used for sample deposition such as in scanning electron microscopy (SEM), transmission electron microscopy (TEM) or atomic force microscopy (AFM). It must also be emphasised that these techniques require the analysis of numerous images to obtain statistically relevant morphological characterisations.

Laser light scattering is the most common methodology for characterising nanogel particle size as dispersions in a given medium. Particle size is determined as the radius of the impenetrable sphere that would scatter light at the same angle and intensities. In particular, dynamic light scattering (DLS) measurements are related to the Brownian motion of the dispersed particles in the medium [10]. This movement causes fluctuations in the total intensity of the scattered light, which in turn are related to the velocity of the particles moving with their hydration shell. Larger particles move less rapidly than smaller particles, and the intensity fluctuations yield information on particle size through the determination of an average diffusion coefficient and the use of the Stokes–Einstein equation, which relate the diffusion coefficient with the hydrodynamic radius, Rh, of the particle. The equation is valid for spherical, smooth, rigid non-interacting particles, and the method is rigorously applicable only to monodisperse systems. Light scattering should always characterise non-interacting objects (i.e. dilute systems). It is also advisable to perform the analysis at several scattering angles (multiangle DLS) in order to establish whether the unknown particle size and/or shape distribution is actually affecting the results, since at certain angles the scattering intensity of some particles may completely overwhelm the weak scattering signal of other particles, thus making them invisible.

Static light scattering (SLS), performed on dispersions of different concentrations, can be applied to determine the weight average molecular weight, Mw, from total intensity measurements; the root mean square radius of the nanoparticle or radius of gyration, Rg, and the second virial coefficient, B2, which represents the interaction potential between two particles (negative values indicate attractive forces, positive values denote repulsive forces), from the dependence of the total intensity on the angle [11]. Since solvent quality can affect the internal organisation of nanogels and their interaction with the dispersing/swelling medium, laser light scattering can depict the system only in a set of specific measurement conditions, which may or may not be close to the application conditions.

Nanogels, similar to their macroscopic analogues, can be designed to be stimuli-responsive, i.e. to change their swelling behaviour and permeability upon the application of a trigger [12].

For example, if the nanogel is made by a weak polyelectrolyte (a polyacid or a polybase), changes in the environmental pH (stimulus) can cause changes in the degree of ionisation of the polyelectrolyte. The related change in the osmotic pressure will result in nanogel swelling or shrinking, respectively. As a result, nanogels can modify their optical behaviour (refractive index) and take up or release molecules (response). Protonation/deprotonation processes can also change the surface charge density of the nanoparticles [13, 14].

If the nanogels are made by polymers with functional groups such as azobenzene, spirobenzopyran, triphenylmethane, or cinnamonyl, which undergo reversible structural changes under UV–vis light irradiation, hydrophilic to hydrophobic transitions can be induced by a specific wavelength [15].

Similarly, when the network is formed by homo- or copolymers that exhibit a lower critical solution temperature (LCST), hydrophilic to hydrophobic transitions can be induced by a temperature increase. Such is the case with nanogels based on poly(N-alkylacrylamides), poly(NIPAm) being the most investigated, as well as poly(N-vinylcaprolactam), poly(methyl vinyl ether), block copolymers of poly(ethylene oxide) and polypropylene oxide, and various derivatives of cellulose (e.g. hydroxypropyl methylcellulose, hydroxypropylcellulose and carboxymethylcellulose) often crosslinked with divinyl sulfone [16]. The quality of the solvent is worsened by the increase in temperature, and hydrophobic association of polymeric segments occurs (hydration water molecules are released, increasing the overall entropy of the system). The responsiveness manifests as volume collapse, and the specific transition temperature is referred to as the “volume phase transition temperature” (VPTT), generally similar to the LCST of the corresponding linear polymer.

Nanogels made of polypeptides and polysaccharides can undergo segmental helix–coil transition, generally at a temperature lower than their “upper critical solution temperature” (UCST). Gelatin nanogels containing triple helices have displayed significant volume transitions when heated above the helix–coil transition temperature [17].

A wide range of interactions have also been demonstrated between specific functional groups grafted onto nanogels with (bio)molecules present in their environments. Coupling of complementary portions of DNA or RNA semi-helices and interactions between an immobilised enzyme and its substrate, or an antibody or a fragment of the antibody with its antigen, are some examples. These interactions, characterised by high selectivity and often also by reversibility, can be exploited to provide specific functions. When nanogels are designed as drug delivery devices (DDD), ligand–receptor interactions can be exploited for preferential accumulation of the nanocarriers at a target site and/or for cellular internalisation [18].

The molecular imprinting approach has been used to synthesise nanogels capable of catalysing specific reactions or that exhibit protein-binding/release properties toward specific biomolecules, with potential application in areas such as bioseparation, biosensing and drug delivery [19–21].

Attempts to produce self-oscillating nanogels are also documented [22, 23]. For example, networks of N-isopropylacrylamide (NIPAM), a monomer carrying the ruthenium catalyst for the Belousov–Zhabotinsky (BZ) reaction, 2-acrylamido-2-methylpropane sulfonic acid (AMPS) and methacryloamido propyl trimethylammonium chloride (MATAC) as a capture site for an ionic oxidising agent (bromate ion) in the presence of malonic acid have been produced. Self-motility is the target function [23].

In conclusion, the combination of the typical properties of hydrogels, including soft and rubbery consistency, high solvent uptake, stimuli-responsiveness and biocompatibility, and those of nanocolloids, such as controlled size at the nanoscale, extremely large specific surface area, and enormous possibilities for surface functionalisation, render nanogels very fascinating nanoparticles. The main limitations are strictly connected to their manufacturing, as will be discussed below.

2 Nanogel Manufacturing

Nanogels have been designed and synthesised for application in a large number of technological areas, including medicine, mainly as drug nanocarriers [2, 4, 9, 12, 14, 15], in vivo imaging tracers and biological sensors [6, 24], for separation and water treatment [25, 26], in catalysis [27], and as nano-biomachines [22, 23]. They can also be used as building blocks for the self-assembly of well-organised 3D structures at a relatively high concentration by exploiting hydrophobic association or electrostatic interactions [28–31]. The supramolecular macrogels thus obtained have been proposed as smart gating membranes [32], for the fabrication of active photonic crystals and coatings with physical and chemical patterns [33, 34], and for generating bioactive scaffolds for regenerative medicine [35].

Although nanogel applications can be very diverse, some general manufacturing requirements can be identified. It is generally helpful to limit the size to between ten and a few hundred nanometres, with a narrow particle size distribution. In addition to controlling size and size distribution, control of the macromolecular architecture is often required. Core–shell structures, hollow nanoparticles, particles with a density gradient, or non-spherical or shape-changing nanoparticles may be desired. Further requirements can be related to industrialisation, such as ease of scale-up, limited use of toxic or expensive chemicals, and the achievement of high yields of the recovered (purified) product. The synthetic route should chosen so as to avoid degradation of the precursor or any other component eventually present in the system (e.g. through hydrolysis). One other very important requirement, especially for biomedical applications, is the absence of residual organic solvents, catalysts, monomers or other potentially toxic compounds.

Many comprehensive and highly specialised reviews of different synthetic strategies have already been published [36–40]. In this review, the main features and the commonly recognised advantages and disadvantages of conventional approaches will be briefly highlighted, with particular focus on processes that yield permanent nanogels, i.e. covalent networks. In the following sections we will focus on a specific synthetic approach that exploits the interaction of high-energy radiation with aqueous solutions of polymers.

The most common synthetic approaches for the preparation of nanogels are:

-

(i)

micro-/nanofabrication methodologies;

-

(ii)

synthesis from monomers with di- or multifunctional comonomers (crosslinkers) in homogeneous or heterogeneous phase;

-

(iii)

self-assembly processes that exploit ionic, hydrophobic or covalent interactions of pre-synthesised polymers.

2.1 Nanogel Micro-/Nanofabrication Methodologies

One of the most interesting approaches to micro-/nanofabrication of nanogels is based on the possibility of transferring a pattern generated onto a photomask into an elastomeric mould, which in turn is used to shape the particles [41]. The method of choice for fabricating masters with nanoscale features (≥10 nm) and arbitrary geometries is electron beam lithography. This technology is not widely accessible, since it requires costly equipment and expert operators. Conventional photolithography is much less expensive and more widespread, but cannot generate features smaller than about 1 μm, being limited by the wavelength of the UV–vis laser light used. It can be applied either to harden (negative photoresists) or to etch materials (positive photoresists) at the site of irradiation. More recently, multi-photon absorption (MPA) photolithography (also known as direct laser writing) offers the opportunity to produce sophisticated patterns in two or three dimensions, with features that are smaller than the wavelength of light (up to 100 nm), by combining shorter-wavelength laser light (near-infrared [NIR] femtosecond lasers) with focusing systems. MPA can induce photochemical reactions anywhere in the focal volume of a laser beam that is passed through the objective of a microscope. The photochemical reactions can take place only at the centre of the spot where the intensity is sufficiently high.

The lithographically produced masters are used to generate “soft” moulds, which replicate their nanoscale features into the nanoparticles, provided that they are wet and filled by the nanoparticle precursors. After polymerisation and crosslinking, the nanogels must be detached from their nano-moulds and harvested. These steps imply the use of suitable solvent baths and drying stages [42]. While this approach has the greatest flexibility in terms of shape and composition (which can be controlled independently), it still appears to be far from a possible application for large-scale nanogel production, since it requires several consecutive steps and integration of different technologies. It is worth mentioning that one-dimensional temperature-responsive nanogels with an aspect ratio as high as 130 have been produced by nano-moulding [43].

In the production of nanogels with microfluidic devices, the nanogel microstructure can be nicely controlled by adjusting the flow ratio and mixing time in the microchannels. In this case, productivity is low [44, 45]. In principle, the chemical reactions that transform monomers and/or polymers into covalently crosslinked networks can be any of those already applied to produce macrogels—e.g. polymerisation of methacrylate groups, reactions between complementary functional groups (isocyanates and alcohols), Michael-type addition, click chemistry—provided that the device materials are inert and compatible with the reactants and the reaction conditions.

2.2 Nanogels Prepared by Polymerisation in Dilute Solutions or Heterogeneous Systems

Polymerisation in dilute solutions or in heterogeneous systems is the oldest and most common route for the production of nanogels [46]. Since the early 1990s, colloidal gels, with dimensions ranging tens to hundreds of nanometres, have been prepared by free-radical polymerisation in dilute solutions or by heterophase polymerisation, such as (inverse) miniemulsion or (inverse) microemulsion, or by precipitation and dispersion polymerisation. As a result, permanent chemical linkages (covalent bonds) between polymeric segments are formed.

In the polymerisation of dilute monomer systems, crosslinking is achieved by the use of di/multi-functional monomers, and the formation of long-range networks is prevented by a relatively low concentration of monomers. Reducing the monomer concentration increases the distance between propagating chains and limits the probability of intermolecular crosslinking. The major limitation of this approach is the low reaction rate and low yield of recovered product, owing to the low concentration of reactants in the system. Another possibility is to start with a higher concentration of monomers and to stop the polymerisation at low conversions by adding a chain terminator or a monofunctional monomer. With this technique, product purification from the unreacted monomers is required.

A higher reaction rate can be achieved by a local increase in monomer concentration in self-assembled nanoreactors, such the nanodroplets of a mini- or microemulsion or the micro-/nanoparticles of a phase-separating polymer. In particular, several nanogel systems have been produced in the aqueous pods of inverse mini- or microemulsion, using from C6 to C10 linear or cyclic alkanes as a nonpolar continuous phase, water-soluble initiators and catalysts, and one or a mixture of surface-active agents (surfactants) [47–50].

In the case of miniemulsion polymerisation, the monomers are dispersed in the continuous phase with the aid of a surfactant, by providing significant amounts of (mechanical) energy for the generation of a large interfacial area, e.g. by ultrasonication or high-pressure homogenisation. The locus of polymerisation and simultaneous crosslinking is confined to the interior of the droplets, and the surfactants responsible for droplet stabilisation also prevent inter-particle crosslinking. Submicron-sized polymer nanogels (50–500 nm) have been obtained at high yields and with very good control of particle size distribution. An important consequence for the industry is that water-soluble compounds can be directly incorporated/encapsulated into the polymer particles by dissolving/dispersing them in the monomer prior to polymerisation. Since these systems are only kinetically stable, they are strongly dependent on process parameters, i.e. on the shear rate. The produced nanoparticles generally have dimensions that are larger than a few hundred nanometres. Unlike miniemulsions, microemulsions are thermodynamically stable systems due to the presence of a large amount of surfactant. The final products are nanogel particles that can be much smaller (5–50 nm), coexisting with empty micelles. The chemical structure of the nanogels is controlled by the nature, concentration and relative ratio of the monomers and crosslinking agent, by their solubility and hence the partition coefficient between the dispersed and continuous phase, and by the concentration and distribution of the initiator in the system. The major drawback is the high amount of surfactant required. Removal of surfactants and residual monomers often necessitates repeated treatments with water and organic solvents and a final drying step. Re-dispersion from the dry form often causes irreversible aggregation.

In dispersion or precipitation polymerisation, the polymerisation starts in the continuous phase (the solvent), up to the point where the propagating polymer chain is no longer soluble, and phase separation from the solvent occurs, forming particles (nucleation). These nuclei may aggregate and precipitate, or they can be stabilised by the presence of low molecular weight or polymeric surfactants or by electrostatic stabilisation, e.g. when either the initiator or the monomers carry electric charges. Core–shell crosslinked structures can be produced by seeded polymerisation, where the core (nucleated seeds) and the shell are composed of two different crosslinked polymers that are not covalently connected. This approach has also been applied for the production of hollow nanogels using a sacrificial degradable core, or hairy nanogels by the sequential addition of a macromolecular comonomer [51].

Another strategy for producing nanogels relies on reversible-deactivation radical polymerisation (RDRP) techniques, such as atom-transfer radical polymerisation (ATRP), nitroxide-mediated polymerisation (NMP) or reversible addition-fragmentation chain transfer (RAFT) [52]. All these techniques are based on reversible deactivation of growing chains, most of which are in a dormant form. Given that interconversion of active and dormant forms is rapid compared to propagation, all chains are able to grow at the same rate. RDRP makes possible the synthesis of nanogel architecture by the sequential addition of different monomers. Moreover, if the initiating species are fully consumed prior to any appreciable chain growth, all chains grow at the same rate, and the molecular weight distribution of the polymer and particle size is much narrower than in conventional free-radical polymerisation. Synthesis can be carried out at much higher monomer and crosslinker concentrations (up to 20 % in weight) than in conventional methods. Electrically charged molecular or macromolecular initiators can be used as stabilisers. With this technique, hairy nanogels with covalently linked polymer chains have been produced. Reaction kinetics and mechanisms are affected by the specific nature of the monomers, crosslinkers and initiators used. Despite the enormous progress made, however, not all RDRP techniques known today are equally well suited for upscaling from small laboratory experiments to large-scale industrial processes. For example, the controlling agent must be cost effective and ecologically sound. Furthermore, residual metals in ATRP or the chemical nature of the end groups (RAFT) may be an issue for some applications [53].

2.3 Nanogels Produced by Self-Assembly and Crosslinking of Preformed Polymers

This approach has led to a variety of nanoconstructs. Liquid–liquid phase separation of a polymer solution into a polymer-rich (coacervate phase) and a polymer-depleted phase is induced by a change in the quality of solvent (addition of a non-solvent, change in temperature, pH, etc.). The microscopic droplets of the coacervate phase are kept in suspension by stirring. The droplet size can be “transferred” into the nanogel particle size by securing the polymeric colloid through chemical crosslinking [54].

Electrostatic self-assembly of polyelectrolytes by complex coacervation is another example. This process is strongly driven by the release of counterions to increase the overall entropy of the system, and requires the presence of two oppositely charged polyelectrolytes in non-stoichiometric ratios to impart a non-balanced charge (electrostatic stabilisation of the nanoparticles). Colloids based on electrostatic chitosan–DNA [55, 56], chitosan–protein [57] and chitosan–polysaccharide [58] complexes are among the most studied. Because of the electrostatic nature of these complexes, they are intrinsically pH- and ionic strength-responsive.

Chelating ligands, iminodiacetic acid or malonic acid, have been conjugated to hyaluronic acid (HA) and used as a precursor polymer [59]. By mixing the ligand-conjugated HA with cisplatin (CDDP), crosslinking occurred via coordination of the ligands with the platinum in CDDP, resulting in the spontaneous formation of CDDP-loaded HA nanogels. The nanogels showed pH-responsive release of CDDP, because the stability of the ligand–platinum complex decreases in an acidic environment.

Suspension polymerisation of temperature-sensitive photo-crosslinkable polymers can be followed by UV-induced crosslinking at a temperature higher than polymer LCST [60]. Surfactant concentration for the polymerisation is kept below the critical micelle concentration (CMC) to prevent suppression of the temperature-driven coil-to-globule transition by the repulsive electrostatic forces between the ionic heads of the adsorbed surfactant molecules. Particle size decreases with increased sodium dodecyl sulfate (SDS) concentration (nucleation of a larger number of particles) and decreases with increased chromophores, and the nanogels also display significant temperature responsiveness.

3 Radiation-Engineered Nanogels

Radiation chemistry, i.e. the use of ionising radiation from radioisotopes and accelerators to induce chemical changes in materials, is a versatile tool for polymer synthesis and modification. The use of water as the primary medium for the absorption of ionising radiation and the effects of aqueous radiolysis products on dissolved monomers and polymers have formed the basis of a variety of applications in polymer synthesis and modification, particularly in the formation of polymer nanoparticles, which are unique with respect to conventional free-radical polymerisation and crosslinking [61]. The advantages of using radiation chemistry for this purpose are many, and include low energy consumption, minimal use of potentially harmful chemicals, easier control of the exothermal heat of the reaction and simple production schemes. An additional advantage for medical applications is that the material can be sterile as manufactured.

Many macroscopic hydrogels have been prepared by irradiation of aqueous polymer solutions to absorbed radiation doses higher than a critical value, called gelation dose (Dg), when the polymer concentration is above a critical polymer concentration (Cpc) [62]. These parameters have generally been determined by sol–gel analysis based on the gravimetric determination of the sol and gel fractions after irradiation. The filter cut-off affects the separation of the gel fraction from its sol, and traditional paper filters may be unable to separate the gel nanoparticles from the soluble fraction. Therefore, the reported Dg and Cpc can define only the low dose and concentration thresholds for wall-to-wall hydrogels to form. For concentrations below Cpc, macroscopic gelation is not observed, and only micro-/nanogels are expected to form.

A more detailed explanation of how ionising radiation leads to the formation of micro-/nanogels from polymer aqueous solutions will now be provided.

Briefly, high-energy radiation induces the formation of radical sites on the polymer backbone and/or on side chains, which should then evolve mainly through combination to form the desired product. The prevalence of combination over other possible reactions depends primarily on the polymer chemical structure and on the radical concentration [63]. Typical polymers that mainly undergo crosslinking upon irradiation are poly(ethylene oxide) (PEO), poly(vinyl alcohol) (PVA), poly(N-vinyl pyrrolidone) (PVP), poly(vinyl methyl ether) (PVME), poly(N-isopropyl acrylamide) (PNIPAM) and poly(acrylic acid) (PAA). Temperature and the presence of co-solutes and dissolved gases also affect the chemistry of polymers irradiated in aqueous solution [64, 65]. A distinct advantage of using ionising irradiation of polymer aqueous solutions for the synthesis of micro-/nanogels is that the process requires no surfactants to control the locus of reaction, and chemically stable polymers can be used as a starting material. As a result, purification is simpler and products are non-toxic.

The first syntheses of micro-/nanogels via irradiation of dilute aqueous solution of polymers date back to the 1960s, although the formation of such micro-/nanostructures was reported a few years earlier by Charlesby and Alexander [64]. Sakurada and Ikada [66] described the synthesis of PVA micro-/nanogels. Schnabel and Borwardt [67] reported the formation of PEO nanogels. In both cases gamma rays were used. For PVA, micro-/nanogel formation was generally associated with a reduction in intrinsic viscosity (after an initial increase) and simultaneous increase in the turbidity of the solutions. In particular, nanoparticles in the 10–60-nm range were detected by SEM, whereas particles with diameters of 80–240 nm resulted from turbidity experiments. This apparent discrepancy between the values derived by the two measurements was attributed to the fact that turbidity measures the overall microparticle, which results from both inter- and intramolecular crosslinking, whereas SEM detects the primary nanoparticle, meaning the intramolecularly crosslinked, single chain. From both measurements, the smaller particles were obtained for the higher doses.

In the late 1990s, Rosiak and Ulanski proposed a closed-loop system, where aqueous solutions were continuously pumped to a quartz irradiation cell and subjected to intense (about 1 kGy) pulses of 6 MeV electrons. This laboratory, and many others in the world, began successfully applying pulsed e-beams to produce micro-/nanogels. [68] Most of the crosslinking type polymers, including PVP [68, 69], PVA [70], PAA [71, 72], PVME [73–75], PAAm [76] and polyNIPAM copolymers [77], have been used.

With pulsed e-beam irradiation, the reaction kinetics that lead to nanogel formation can be affected by several irradiation parameters in addition to the total absorbed dose. In particular, the “average” dose rate is governed by the combination of the three adjustable parameters: pulse length, pulse frequency and dose rate during the pulse (proportional to the current). The electron energy is generally a fixed parameter that depends on the design of accelerator, and mainly affects the depth of radiation penetration. It is also worth mentioning that changes in temperature may occur due to the high dose rate [78].

Nanogels have also been successfully synthesised using industrial accelerators and the typical set-ups and doses applied for sterilisation (20–40 kGy). One advantage is the ability to produce already sterile nanogels for biomedical applications [79–82].

4 Mechanism of Radiation Synthesis of Nanogels

When nanogels are produced upon irradiation of dilute aqueous polymer solutions, the ionising radiation is primarily absorbed by water, the most abundant component. Direct energy absorption by the polymer molecules is negligible. Hence, the starting point of nanogel formation is the radiolysis of water, which leads to the production of oxidising and reducing species. The primary oxidising species are ·OH and H2O2, while the primary reducing species are e −aq , H· and H2. The radiation chemical yields (G values) in gamma- and electron-irradiated aqueous solutions are 0.28, 0.073, 0.28, 0.062 and 0.047 μmol J−1 for ·OH, H2O2, e −aq , H· and H2, respectively [83].

For most polymers, only the hydroxyl radical and the hydrogen atom are capable of producing a macroradical, mainly by hydrogen abstraction. As can be seen from the radiation chemical yields, the contribution from the hydrogen atom is less than 20 %. By saturating the aqueous solution with N2O prior to irradiation, the yield (G value) of the hydroxyl radical can be doubled, since the solvated electron is scavenged by N2O to produce hydroxyl radicals.

The desired reaction for gel formation is the combination of two carbon (C)-centred macroradicals—in other words, crosslinking. For nanogel formation, a prevalence of intramolecular crosslinking is a prerequisite. However, C-centered macroradicals can also undergo intermolecular crosslinking, and other reactions such as radical–radical disproportionation, reaction with molecular oxygen and, depending on the structure of the radical, unimolecular fragmentation. These reactions do not contribute to the formation of the network but can still be important for the functionalisation of the nanogel. The relative importance of the disproportionation reaction in relation to the radical–radical combination reaction depends on the nature of the radicals and solvent properties, and can thus be seen as an inherent property of a given polymer in a given solvent. Hence, nothing can be done to favour the combination reaction relative to the disproportionation reaction for a given polymeric solution [84].

The reaction between the C-centred radical and molecular oxygen can result either in the formation of a peroxyl radical or, if the radical is reducing, in oxidation of the radical and formation of a superoxide. The latter reaction is possible for C-centred radicals with –OR and –NR2 substituents in the α-position. Reducing C-centred radicals can also be oxidised by H2O2. The reaction with molecular oxygen can be efficiently suppressed, at least initially, by purging the solution with N2O or an inert gas prior to irradiation.

Intermolecular crosslinking can also compete with intramolecular crosslinking and lead to the formation of larger particles.

The possible reactions of the polymer macroradical are depicted in Scheme 1.

When nanogels are produced by pulsed electron beams, irradiation is not continuous, and every short pulse of electrons is followed by a relatively long interval without irradiation. Radical reactions are induced during the electron pulse, but they may not be entirely completed before the next electron pulse is absorbed by the sample. Follow-up chemical reactions will also occur between and during pulses. These factors make the kinetic analysis of the reaction system more complex than that for a system exposed to continuous irradiation.

Ideally, we can divide the overall process into two steps:

-

(i)

Polymer radical formation by interaction of water–radiolysis product with the polymer or nanogel embryos.

-

(ii)

Polymer radical follow-up reactions.

4.1 Polymer Radical Formation

With regard to the first step, a simplification that can be made when analysing data from pulsed e-beam irradiation of aqueous polymer solutions is that all hydroxyl radicals produced upon radiolysis of water are scavenged by the polymeric solute to form carbon-centered macroradicals. The average number of macroradical centers formed in a pulse would then be determined simply from the radiation chemical yield of hydroxyl radicals and the dose per pulse. This may be true at higher polymer concentrations but not necessarily at lower concentrations, where other reactions involving the hydroxyl radical, such as hydroxyl radical recombination, could efficiently compete with the reaction of hydroxyl radicals with the polymer. Even though the concentration can be fairly high in terms of repeating units, the actual polymer molar concentration is low, and therefore the average distance between polymer chains is large. This distance increases with polymer molecular weight at a given weight fraction of polymer in solution (i.e. with decreasing polymer molar concentration).

At a high dose rate (as in most cases of pulsed e-beam irradiation), radical–radical combination reactions are favoured, and a higher molar concentration of the polymer is required to scavenge all the hydroxyl radicals formed. If the polymer concentration is not high enough, the hydroxyl radical combination will yield hydrogen peroxide, and conversion of initially formed hydroxyl radicals to polymer radicals will not be quantitative. This was recently demonstrated for PVP nanogel formation, where it was experimentally shown that the formation of hydrogen peroxide as a function of dose increases with decreasing polymer concentration [85]. These experimental findings were further supported by numerical simulations of the kinetics of the reaction system (aqueous polymer solution exposed to e-beam pulses at a given frequency) [85]. The fact that H2O2 build-up is possible under certain conditions also means that the chemical environment in the irradiated polymer solution will be different at low and high polymer concentrations, as the production of H2O2 will be higher in the more dilute polymer solutions. At low polymer concentration, only a fraction of the produced hydroxyl radicals are scavenged by the polymer chains. This will have an impact on the overall process. H2O2 is an oxidant but also a precursor for O2, which will strongly influence the chemistry of C-centred polymer radicals.

To achieve full hydroxyl radical scavenging capacity, the distance between hydroxyl radicals and scavengers must be short enough to prevent the occurrence of all other possible reactions for the hydroxyl radical. For polymer solutions, since the repeating units are clustered in chains, the scavenging capacity is unevenly distributed in the solution. Hence, for a fraction of the radiolytically formed and homogeneously distributed hydroxyl radicals, the polymer is out of reach. The competing reactions involved in the overall process can be accounted for by normal competition kinetics on the basis of the Smoluchowski model, and have been illustrated here by introducing the concept of an “active scavenging volume”, within which there is a significant probability for reaction between hydroxyl radicals and the polymer chain. This distance is the average diffusion distance given by the hydroxyl radical lifetime in a specific system. At a low dose rate, the lifetime—taking only hydroxyl radical recombination into account—is long and the average diffusion distance is also long. At a high dose rate, the hydroxyl radical lifetime—and thus also the average diffusion distance—is short. Hydroxyl radicals produced farther away than the average diffusion distance, i.e. outside the active scavenging volume, will not be able to react with the polymer, since this reaction is outcompeted by the radical–radical combination of hydroxyl radicals, and the hydroxyl radical will therefore not exist long enough to reach the polymer. This situation is illustrated in Fig. 1a. The number of radicals per polymer chain will depend on the number of hydroxyl radicals that are within reach of the polymer chain (i.e. within the active scavenging volume) (see Fig. 1a’). For a given dose rate, this number will be independent of the polymer concentration up to the polymer concentration at which the hydroxyl radical could theoretically reach more than one polymer chain. At this point, the active scavenging volumes can be regarded as overlapping. From this polymer concentration upwards, the number of radicals per polymer chain will begin to decrease with increasing polymer concentration (i.e. with increasing overlap of the active scavenging volumes). The concentration effect is illustrated in Fig. 1a, a’, b, b’. The dose rate affects the concentration at which the active scavenging volume overlap occurs, as well as the number of radicals per macromolecule formed at lower concentrations. At a higher dose rate, the hydroxyl radical concentration during the electron pulse is higher, which means that the number of hydroxyl radicals available for each polymer chain is higher. However, the distance between hydroxyl radicals and polymer chains within which there is a significant probability for reaction is shorter than at the lower dose rate, due to the increased probability of radical–radical reactions at the higher hydroxyl radical concentration. This implies that the active scavenging volume of the polymer chain is smaller at a higher dose rate. Nevertheless, the radical concentration per macromolecule will increase with increasing dose rate, although the increase is not proportional to the dose rate. A direct consequence of the decreased active scavenging volume at higher dose rates is that a higher polymer concentration is required to achieve active scavenging volume overlap, i.e. full scavenging capacity. The dose rate effect is illustrated in Fig. 1a, a’, c, c’.

Schematic representation of radiolytic radical formation. Solid black line polymer chain; dotted line contours of the “active scavenging volume”; red dots hydroxyl radicals formed in water (left panels) and transferred to the polymer (right panels), completely or only partially; pairs of blue dots hydrogen peroxide formed from combination of hydroxyl radicals. Three possible situations are depicted: a–a’ low polymer concentration, relatively low dose rate; b–b’ higher polymer concentration, relatively low dose rate; c–c’ low polymer concentration, higher dose rate

4.2 Polymer Radical Follow-up Reactions

The radical follow-up reactions are also affected by polymer concentration and dose rate. The polymer radicals formed are not identical, as there are numerous possible radical sites. Furthermore, under conditions where it is possible to induce more than one radical site per macromolecule, neither the number of radical sites nor the distance between radical sites will be uniform. For these reasons, the reactive species in these systems will display varying reactivity depending on the type of reaction and the nature of the reactive species. In studying the disappearance of radical functionality in such a system, the kinetics cannot be described by simple first- or second-order rate expressions, as the reaction order changes during the course of the reaction. This has led to the development of so-called dispersive kinetics for analysing experimental results [86].

Under conditions where the average number of radicals per chain is constant, i.e. below a certain polymer molar concentration, the kinetics of follow-up reactions can be treated in a slightly simplified manner. It is important to note that we are discussing rates of intra- and intermolecular crosslink formation here rather than disappearance of radical functionality. Furthermore, we focus on initial events of the polymer radical follow-up reactions (i.e. formation of the first intra- or intermolecular crosslink). The rate constant (or distribution of rate constants, to be more exact, since there will be a distribution of radical species and positions of sites) for intramolecular combination (i.e. formation of intramolecular bonds) will depend on the average number of radicals per chain, and will therefore be constant in the polymer concentration range up to full scavenging capacity (at a given dose rate). Also, the rate constant (or distribution of rate constants) for intermolecular combination will depend on the average number of radicals per chain, and will thus be independent of polymer concentration below the polymer concentration corresponding to full hydroxyl radical scavenging capacity. Hence, the competition between intra- and intermolecular combination in this concentration region is given by the following expression:

where [P] is the molar concentration of radical-bearing polymer chains (equal to the total concentration of polymer chains under the present conditions), k 1 is the rate constant for intramolecular combination, and k 11 is the rate constant for intermolecular combination. Here, k 1 and k 11 can be represented by the average rate constants based on the distribution of reactive radical species. From this expression it is also obvious that intramolecular combination is favoured by low polymer concentration, and that the ratio between intra- and intermolecular combination can simply be controlled by the polymer concentration under the present conditions. The rate constants for both intra- and intermolecular combination will depend on the dose rate. A higher dose rate gives a higher number of radicals per polymer chain, thereby increasing the likelihood of both types of crosslinking reactions.

The influence of various parameters on intramolecular combination was investigated by Jeszka et al. [87] using Monte Carlo simulations. The dynamics of intramolecular radical–radical combination in oxygen-free aqueous solutions of PEO was studied, taking into account the number of radicals per chain, distance between radical sites, polymer chain length, formation of loops and radical transfer. This study clearly shows that the radical half-life due to intramolecular radical–radical combination reactions is strongly dependent on the number of radicals per polymer chain. The predicted first half-life of the radical is typically in the range of 10−5to 10−3 s. For multiple radical-bearing polymer chains, the half-life following the first intramolecular combination can be considerably longer. Consequently, the dose rate and the dose per pulse will have a strong impact on the reaction kinetics of the system.

It is interesting to note that the products from pulsed e-beam radiation-induced synthesis of PVP aqueous solutions at four different concentrations, exposed to the same total dose (40 kGy) at two different average dose rates, display very different particle size and molecular weight [79, 80]. The data are shown in Fig. 2. The average dose rate in this context is calculated as the dose delivered in the unit time that corresponds to the dose per pulse (ca. 0.74 and 13 Gy, for the low and high average dose rates, respectively), multiplied by the pulse frequency (37.5 and 300 Hz, respectively). The higher dose rate yields smaller particles with lower average molecular weight compared to the lower dose rate. This demonstrates that the number of radicals per polymer chain has a major influence not only on the kinetics of intramolecular crosslinking, but also on the competition between inter- and intramolecular crosslinking.

Hydrodynamic radius (Rh) from DLS and weight average molecular weight (Mw) from Zimm plot analysis of SLS measurements as a function of the polymer concentration for two different dose rates. Error bars for Rh represent the width of the size distributions. Batch-to-batch variability is lower than 5 %. Hydrodynamic radius and molecular weight of the non-irradiated polymer is 20 ± 10 nm and 0.41 MDa, respectively

The concentration dependence is well in line with the discussion above. It is clear that particle size increases with polymer concentration at both dose rates; however, the concentration dependence is more pronounced at the lower dose rate. This implies that the two effects are not entirely independent of each other.

A similar trend was observed for PVP by An et al. [88]. These authors also studied the kinetics of PVP radical consumption using pulse radiolysis. The approximate half-life of the radical in this study is 5 × 10−6 s, which is in fairly good agreement with the shortest half-life (for the highest radical concentration) presented by Jeszka et al. [87].

At polymer concentrations above the limit for full hydroxyl radical scavenging capacity, the number of radicals per polymer chain will decrease with increasing polymer concentration. Eventually, the average radical density per chain will reach one and below. At the point where the average radical density per chain is one, the concentration of radical-bearing chains has reached its maximum. Once the average radical density drops below one, the concentration of radical-bearing chains is dictated by the dose rate, and becomes independent of polymer molecule concentration (when increasing the concentration). The only process that can occur after a single pulse under these conditions is intermolecular combination. However, it should be kept in mind that the rate constant for intermolecular combination is also dependent on the number of radicals per chain, and reaches its minimum at one radical per chain. At high pulse repetition frequency, multiple radical sites per chain may still be formed, and the intramolecular crosslinking can also occur.

The polymer concentration dependence of the number of radical-bearing chains and average number of radicals per chain described above is illustrated in Fig. 3.

The trends discussed here are further confirmed by numerous other studies carried out with various polymers, irradiation set-ups and dose ranges. Schmitz and co-workers investigated the influence of the irradiation dose (0–7.5 kGy) by gamma irradiation on PVA aqueous solutions by measuring Rh and Rg of the polymer using DLS and SLS, respectively [89]. They also applied a Monte Carlo simulation to the dynamics of polymer chains, assuming that all the “contacts” between polymer segments resulted in a strong bond. The model was developed to support the interpretation of light scattering data. The starting system is formed by relatively short polymer chains in chain-extended conformation. As the chains are joined together in the intermolecular crosslinking process, the resulting structures increasingly resemble hairy cylinders with branches and looped regions. The predominant intermolecular crosslinking is well in line with the description above, given the relatively high molar polymer concentration and the low dose rate. It also explains the initial rapid increase of Mw, Rg and Rh with dose experimentally observed. Since intermolecular crosslinking progressively reduces the molar concentration of polymer and its diffusion coefficient, intramolecular crosslinking at some point becomes a competitive process. With time (dose), the hairy cylinders transform into soft spheres with a clearly identifiable surface. This explains why Mw continues to increase but much less steeply, Rh levels off, and Rg decreases. This model is actually similar to the one proposed by Brash and Burchard for the chemical crosslinking of PVA microgels [90].

A similar shift from inter- to intramolecular crosslinking with increasing dose was recently observed for e-beam-irradiated aqueous PVP solutions [91]. For semi-dilute polymer solutions, the particle size increases to a point where the molar concentration becomes low enough to favour intramolecular crosslinking. At higher doses, no further particle growth is observed.

One limitation of irradiating dilute systems with highly energetic pulses lies in the difficulty of controlling particle size and molecular weight of nanogels in an independent way. Intramolecularly crosslinked, single polymer chains may result in nanoparticles that are too small, especially if the molecular weight of the starting polymer is relatively low (below a few hundred kiloDaltons). This problem has been circumvented by performing a first irradiation step at a higher polymer concentration, low dose rate, e.g. with gamma photons, and with a total dose lower than the gelation dose for the polymer. As shown above, these conditions favour intermolecular crosslinking, and thereby an increase in polymer molecular weight by chain extension and branching. The irradiation was then continued at a high “average” dose rate, with e-beams, after dilution of the system [83]. These conditions favour intramolecular crosslinking and the close up of polymer chains to yield particles. While this combination of irradiations yield the desired product, the need for two types of irradiation facilities makes the industrial scale-up of the process more complicated.

Polyelectrolytes in general, and PAA homopolymer and copolymers in particular, require a proper control of pH of the irradiated solutions to yield nanogels. It is fairly intuitive, but also confirmed by kinetic studies, that the bimolecular rate constant for radical combination and competition between inter and intra molecular crosslinking, should depend on the content of ionised base units, x i , in the polymer [92]. When x i is very small, the polyelectrolyte behaves like a nonionic polymer (pH <2 for PAA). In addition, hydrogen bonding can favour intramolecular association. With increased pH, intermolecular radical–radical combination becomes favoured, since ionisation induces expansion of the coils by intramolecular Coulomb repulsion. At high degrees of ionisation, the polymer conformation is chain-extended (rod-like and stiff), and intermolecular electrostatic repulsion slows recombination by several orders of magnitude. Chain scission then becomes a competitive process (pH >9 for PAA).

Changes in the chemical composition of nanogels are documented only for PVP-based systems irradiated at substantial doses. Sabatino et al. [79] showed that succinimide, carboxyl groups, ether-links and non-carboxylic hydroxyl groups were formed upon irradiation, and it was clear that the chemical change was most significant in systems of low polymer concentration. However, this is not surprising given the fact that the functionalisation process is radiation-driven and depends mainly on the absorbed dose, while the methods used to detect the chemical change are sensitive to the relative chemical change of the system rather than to the absolute change (that is why the chemical modification effects are most evident at low polymer concentration). The systems studied by Sabatino et al. [79] were saturated with N2O prior to irradiation, and therefore the only expected oxidising species would be the hydroxyl radical. As shown above, in systems containing low polymer concentrations, hydrogen peroxide can also be formed. At the very high doses applied (40 kGy), N2O will be completely consumed, and the chemical conditions during irradiation will become different from the starting conditions. Hence, several species may form that have the potential to influence the chemical functionality of the product. As shown for PVP, functionalisation appears to be a consequence of oxidative conditions.

Another experimental study on PVP functionalisation was conducted more recently [85]. In this work, Fourier transform infrared spectroscopy (FTIR) analysis also provides useful insights. The formation of succinimide rings and COOH groups is confirmed and shown to increase with dose. Primary amino groups were also detected and their concentration also increases with dose. The corresponding radiation chemical yields for their formation are in the range of nmol J−1. It is obvious that NH2-groups can only be formed as a consequence of double N–C bond scission of the pyrrolidone ring and that COOH groups can only be formed upon oxidative scission of the polymer backbone or the pyrrolidone rings. It has been speculated that the C–N bond scission required for NH2formation is facilitated by the presence of H2O2 or the subsequently formed O2. The most probable macroradical reactant for this reaction is an α-amino alkyl radical capable of reducing both H2O2 and O2.

Moreover, nanogels with specific functional groups, such as reactive moieties useful for bioconjugation of drugs or ligands or for providing stimuli-responsiveness, have been obtained by irradiating the polymer in the presence of unsaturated monomers [93] or through co-crosslinking of mutually complexing polymers [94, 95]. In the first case, a small amount of acrylic acid (AA) added to PVP competes with intermolecular crosslinking, and smaller nanogel particles than those of corresponding PVP systems irradiated without AA are obtained [93]. The AA grafted on PVP provides accessible carboxyl groups for the covalent attachment of peptides [96], proteins [9] and oligonucleotides [97]. In the second approach, where much lower dose rates and higher amounts of AA were used, the monomer polymerises first, then interacts with PVP by multiple hydrogen bonds. PVP act as a soft template for the forming PAA and binds it by the radiation-induced radical–radical combination process. The nanogels thus obtained showed pH responsiveness and were used to encapsulate and release an ophthalmic drug [98]. Similarly, aminopropyl methacrylamide (APMAM), a primary amino group carrying an acrylic monomer, has been simultaneously irradiated with aqueous PVP nanogels and grafted onto the nanogels. The nanoparticles were then decorated with fluorescent molecules and antibodies through a peptide linkage, showing active targeting functions [81, 82].

It is also worth mentioning that temperature- and pH-responsive nanogels have been produced starting from amphiphilic block copolymers organised in micellar aggregates, and inducing crosslinking by means of electron beam irradiation. Temperature responsiveness was provided by the polyNIPAAm block, while pH responsiveness was obtained by 5-methacryloyloxy pentatonic acid (5MPA) or 4-methacryloyloxy benzoic acid (4MBA) units [99]. Other researchers have produced nanogels by irradiating micellar systems or microemulsions [100, 101].

5 Concluding Remarks

Nanogels are fascinating polymer nanoparticles that, because of their tuneable chemical structure and highly permeable interiors to solvent molecules, can change shape and/or volume, electric charge and hydrophilic–lipophilic balance. As a result, nanogels can be stable colloids in aqueous media but can also assemble into supramolecular structures under a proper trigger.

These soft and dynamic nanoparticles are under intense development in cancer imaging, molecular diagnosis and targeted therapy. The basic rationale is that they can offer large and conformable cavities to incorporate bulky active ingredients such as therapeutic proteins, as well as hydrophobic pockets (in the proximity of crosslinking points) within which to host barely polar molecules, which is the case of many medical drugs. They can display several reactive groups, either directly linked to the network or at the terminus of dangling chains that stretch out in the solvent. When conjugated with targeting ligands such as monoclonal antibodies, peptides, oligonucleotides or small molecules, these nanoparticles can be used to target malignant tumor cells and the tumor microenvironment with high specificity and affinity.

The possibility of producing nanogels as aqueous dispersions, without necessarily going through a drying step for purification, is the best guarantee for controlled size, and hence functionality, at the nanoscale. Solvent removal that is required when organic solvents and toxic chemicals are used in manufacturing can cause irreversible aggregation and loss of performance.

The radiation chemistry of aqueous polymer solutions provides very interesting opportunities for the synthesis of nanomaterials in aqueous media. No initiators or catalysts are required to generate polymer radicals, and no soft (surfactants) or hard templates (moulds) are necessary to control the size of the nanoparticles. This possibility has been demonstrated with a variety of polymers, irradiation sources and processing conditions. The nanogels produced have generally shown average hydrodynamic diameter in a range of 20 to 200 nm and relatively narrow particle size distribution (polydispersity index [PDI] < 0.3). This is actually the target size range for intravenously administered soft drug nanocarriers so that they are able to evade the reticuloendothelial system (RES) (provided that the surface is hydrophilic and not strongly charged) and to display extravasation capability from the newly formed blood vessels at the tumor site.

Irradiation conditions that favour intramolecular crosslinking at some point in the process shall be chosen in order to transform the starting polymer into a crosslinked nanoparticle. The most important parameter to control appears to be the polymer molar concentration. Low molar concentrations favour intramolecular crosslinking over intermolecular crosslinking. There are some implications for excessive reduction of polymer concentration: the throughput in terms of valuable material becomes too low for the process to be attractive; nanogels size and crosslinking density become somewhat fixed; the radicals produced in water may not be completely scavenged by the polymer, yielding to other reactive molecules, which may provide reaction routes for the macroradicals different from their mutual combination. This last condition may or may be not desired. Dose and dose rate, in conjunction with polymer concentration, are two other important tuneable parameters for the process. Irradiation at lower dose rates with relatively high polymer concentrations can be pursued when chain extension or branching is desired in the early phase of the process, in order to increase the molecular weight, and thus the size, of the nanogel ultimately formed. Despite what has already been demonstrated and rationalised with kinetic studies, molecular simulations and product analysis, looking into the future, we feel that there are a number of research directions that are particularly promising but require a concerted effort for success. These include:

-

1.

Strengthening the foundations of radiation chemistry of aqueous polymer systems. A better understanding of the role of the various irradiation parameters and their inter-relationships is of paramount importance in controlling nanogel size and functionality and in establishing process design guidelines.

-

2.

Enlarging the library of polymers used as starting materials. The use of water-soluble or water-dispersible natural polymers and their derivatives can open up further application opportunities, especially when bioresorption or biodegradability is required.

-

3.

Standardisation and manufacturability. Especially for future use in biomedical applications, radiation-engineered nanogels—as well as other nanoparticles—must be standardised in terms of structural, physicochemical, morphological and biological properties; characterisations and manufacturing protocols should be defined to ensure the quality and safety of the products in collaboration with the relevant regulatory agencies.

Change history

28 September 2016

An erratum to this article has been published.

References

IUPAC (1997) Compendium of Chemical Terminology, 2nd ed. (the “Gold Book”). Compiled by A. D. McNaught and A. Wilkinson. Blackwell Scientific Publications, Oxford. XML on-line corrected version: http://goldbook.iupac.org (2006) created by M. Nic, J. Jirat, B. Kosata; updates compiled by A. Jenkins

Motornov M, Roiter Y, Tokarev I, Minko S (2010) Stimuli-responsive nanoparticles, nanogels and capsules for integrated multifunctional intelligent systems. Prog Polym Sci 35:174–211

Ricka J, Tanaka T (1984) Swelling of ionic gels: quantitative performance of the Donnan theory. Macromolecules 17:2916–2921

Akiyoshi K, Kobayashi S, Shichibe S, Mix D, Baudys M, Kim SW, Sunamoto J (1998) Self-assembled hydrogel nanoparticle of cholesterol-bearing pullulan as a carrier of protein drugs: complexation and stabilization of insulin. J Control Release 54(3):313–320

Chen Y, Ballard N, Bon SAF (2013) Waterborne polymer nanogels non-covalently crosslinked by multiple hydrogen bond arrays. Polym Chem 4:387–392

Lim C-K, Singh A, Heo J, Kim D, Lee KE, Jeon H, Koh J, Kwon I-C, Kim S (2013) Gadolinium-coordinated elastic nanogels for in vivo tumor targeting and imaging. Biomaterials 34:6846–6852

López-León T, Carvalho ELS, Seijo B, Ortega-Vinuesa JL, Bastos-González D (2005) Physicochemical characterization of chitosan nanoparticles: electrokinetic and stability behaviour. J Colloid Interf Sci 283:344–351

Israelachvili JN (2011) Intermolecular and surface forces, 3rd edn. Academic Press, San Diego

Picone P, Ditta LA, Sabatino MA, Militello V, San Biagio PL, Di Giacinto ML, Cristaldi L, Nuzzo D, Dispenza C, Giacomazza D, Di Carlo M (2016) Ionizing radiation-engineered nanogels as insulin nanocarriers for the development of a new strategy for the treatment of Alzheimer’s disease. Biomaterials 80:179–194

Brown W, Nicolai T (1993) Dynamic light scattering: the method and some applications. Ed. Clarendon Press, Oxford

Wyatt PJ (1993) Light scattering and the absolute characterization of macromolecules. Anal Chim Acta 272:1–40

Maya S, Sarmento B, Nair A, Rejinold NS, Nair SV, Jayakumar R (2013) Smart stimuli sensitive nanogels in cancer drug delivery and imaging: a review. Curr Pharm Des 19(41):7203–7218

Shen X, Zhang L, Jiang X, Hu Y, Guo J (2007) Reversible surface switching of nanogel triggered by external stimuli. Angew Chem Int Ed 46:7104–7107

Du J-Z, Sun T-M, Song W-J, Wu J, Wang JA (2010) Tumor-acidity-activated charge-conversional nanogel as an intelligent vehicle for promoted tumoral-cell uptake and drug delivery. Angew Chem Int Ed 49:3621–3626

Zha L, Banik B, Alexis F (2011) Stimulus responsive nanogels for drug delivery. Soft Matter 7:5908–5916

Bromberg LE, Ron ES (1998) Temperature-responsive gels and thermogelling polymer matrices for protein and peptide delivery. Adv Drug Deliv Rev 31:197–221

Gandhi SS, Yan H, Kim C (2014) Thermoresponsive gelatin nanogels. ACS Macro Lett 3:1210–1214

Xu S, Olenyuk BZ, Okamoto CT, Hamm-Alvarez SF (2013) Targeting receptor-mediated endocytotic pathways with nanoparticles: rationale and advances. Adv Drug Deliv Rev 65(1):121–138

Lei Ye (ed) (2013) Molecular imprinting: principles and applications of micro- and nanostructured polymers. CRC Press

Carboni D, Flavin K, Servant A, Gouverneur V, Resmini M (2008) The first example of molecularly imprinted nanogels with aldolase type I activity. Chemistry 14(23):7059–7065

Pan G, Guo Q, Cao C, Yang H, Li B (2013) Thermo-responsive molecularly imprinted nanogels for specific recognition and controlled release of proteins. Soft Matter 9:3840–3850

Varga I, Szalai I, Mészaros R, Gilányi T (2006) Pulsating pH-responsive nanogels. J Phys Chem B 110(41):20297–20301

Sakai T, Yoshida R (2004) Self-oscillating nanogel particles. Langmuir 20(4):1036–1038

Wu W, Zhou S (2010) Hybrid micro-/nanogels for optical sensing and intracellular imaging. Nano Rev 1:5730

Kondo K, Kaji N, Toita S, Okamoto Y, Tokeshi M, Akiyoshi K, Baba Y (2010) DNA separation by cholesterol-bearing pullulan nanogels. Biomicrofluidics 4(3):32210–32218

Akl MA, Sarhan AA, Shoueir KR, Atta AM (2013) Application of crosslinked ionic poly(vinyl alcohol)nanogel as adsorbents for water treatment. J Dispers Sci Technol 34(10):1399–1408

Resmini M, Flavin K, Carboni D (2012) Microgels and nanogels with catalytic activity. Top Curr Chem 325:307–342

Kuroda K, Fujimoto K, Sunamoto J, Akiyoshi K (2002) Hierarchical self-assembly of hydrophobically modified pullulan in water: gelation by networks of nanoparticles. Langmuir 18(10):3780–3786

Nakai T, Hirakura T, Sakurai Y, Shimoboji T, Ishigai M, Akiyoshi K (2012) Injectable hydrogel for sustained protein release by salt-induced association of hyaluronic acid nanogel. Macromol Biosci 12(4):475–483

Li Y, Ye Z, Shen L, Xu Y, Zhu A, Wu P, An Z (2016) Formation of multidomain hydrogels via thermally induced assembly of pisa-generated triblock terpolymer nanogels. Macromolecules 49(8):3038–3048

Xia L-W, Xie R, Ju X-J, Wang W, Chen Q, Chu L-Y (2013) Nano-structured smart hydrogels with rapid response and high elasticity. Nat Commun 4:2226–2236

Luo F, Xie R, Liu Z, Ju X-J, Wang W, Lin S, Chu L-Y (2015) Smart gating membranes with in situ self-assembled responsive nanogels as functional gates. Sci Rep 5:14708–14721

Reese CE, Mikhonin AV, Kamenjicki M, Tikhonov A, Asher SA (2004) Nanogel nanosecond photonic crystal optical switching. J Am Chem Soc 126(5):1493–1496

Tian L, Liu K-K, Fei M, Tadepalli S, Cao S, Geldmeier JA, Tsukruk VV, Singamaneni S (2016) Plasmonic nanogels for unclonable optical tagging. ACS Appl Mater Interfaces 8(6):4031–4041

Saez-Martinez V, Olalde B, Juan MJ, Jurado MJ, Garagorri N, Obieta I (2010) Novel bioactive scaffolds incorporating nanogels as potential drug eluting devices. J Nanosci Nanotechnol 10(4):2826–2832

Oh JK, Drumright R, Siegwart DJ, Matyjaszewski K (2008) The development of microgel/nanogels for drug delivery applications. Prog Polym Sci 33(4):448–477

Kabanov AV, Vinogradov SV (2009) Nanogels as pharmaceutical carriers: finite networks of infinite capabilities. Angew Chem Int Ed Engl 48(30):5418–5429

Sanson N, Rieger J (2010) Synthesis of nanogels/microgels by conventional and controlled radical crosslinking copolymerization. Polym Chem 1:965–977

Zhang X, Malhotra S, Molina M, Haag R (2015) Micro- and nanogels with labile crosslinks—from synthesis to biomedical applications. Chem Soc Rev 44:1948–1973

Ulański P, Rosiak JM (2004) Polymeric Nano/Microgels. In: Nalwa HS (ed) Encyclopedia of nanoscience and Nanotechnology, vol VIII, pp 845–871, ISBN 1-58883-001-2. American Scientific Publishers, Stevenson Ranch

Lipomi DJ, Martinez RV, Cademartiri L, Whitesides GM (2012) Soft lithographic approaches to nanofabrication, chapter 7.11. In: Matyjaszewski K and Möller M (eds) Polymer science: a comprehensive reference, 1st edn. Elsevier, Amsterdam, pp 211–231

Rolland JP, Maynor BW, Euliss LE, Exner AE, Denison GM, DeSimone JM (2005) Direct fabrication and harvesting of monodisperse, shape-specific nanobiomaterials. J Am Chem Soc 127(28):10096–10100

Omichi M, Marui H, Takano K, Tsukuda S, Sugimoto M, Kuwabata S, Seki S (2012) Temperature-responsive one-dimensional nanogels formed by the cross-linker-aided single particle nanofabrication technique. ACS Appl Mater Interfaces 4(10):5492–5497

Zhang H, Tumarkin E, Sullan RMA, Walker GC, Kumacheva E (2007) Exploring microfluidic routes to microgels of biological polymers. Macromol Rapid Commun 28(5):527–538

Bazban-Shotorbani S, Dashtimoghadam E, Karkhaneh A, Hasani-Sadrabadi MM, Jacob KI (2016) Microfluidic directed synthesis of alginate nanogels with tunable pore size for efficient protein delivery. Langmuir 32(19):4996–5003

Nesvadba P (2012) Radical polymerization in industry. In: Chatgilialoglu C, Studer A (eds) Encyclopedia of radicals in chemistry, biology and materials. John Wiley & Sons, Inc, New York

Oh JK, Bencherif SA, Matyjaszewski K (2009) Polymer atom transfer radical polymerization in inverse miniemulsion: a versatile route toward preparation and functionalization of microgels/nanogels for targeted drug delivery applications. Polymer 50(19):4407–4423

Medeiros SF, Santos AM, Fessi H, Elaissari A (2010) Synthesis of biocompatible and thermally sensitive poly(N-vinylcaprolactam) nanogels via inverse miniemulsion polymerization: effect of the surfactant concentration. J Polym Sci A Polym Chem 48:3932–3941

Klinger D, Aschenbrenner EM, Weiss KC, Landfester K (2012) Enzymatically degradable nanogels by inverse miniemulsion copolymerization of acrylamide with dextran methacrylates as crosslinkers. Polym Chem 3:204–216

Sarika PR, James NR (2015) Preparation and characterisation of gelatin–gum arabic aldehyde nanogels via inverse miniemulsion technique. Int J Biol Macromol 76:181–187

Blackburn WH, Lyon LA (2008) Size controlled synthesis of monodispersed, core/shell nanogels. Colloid Polym Sci 286(5):563–569

Muller AHE, Matyjaszewski K (eds) (2010) Controlled and living polymerizations from mechanisms to applications. Wiley-VCH Verlag GmbH, Weinheim

Destarac M (2010) Controlled Radical Polymerization: industrial stakes, obstacles and achievements. Macromol React Eng 4(3–4):165–179

Lupitskyya R, Minko S (2010) Robust synthesis of nanogel particles by an aggregation-crosslinking method. Soft Matter 6:4396–4402

Li Y, Maciel D, Rodrigues J, Shi X, Tomás H (2015) Biodegradable polymer nanogels for drug/nucleic acid delivery. Chem Rev 115(16):8564–8608

Lee JI, Kim HS, Yoo HS (2009) DNA nanogels composed of chitosan and Pluronic with thermo-sensitive and photo-crosslinking properties. Int J Pharma 373(1–2):93–99

Zubareva A, Ilyina A, Prokhorov A, Kurek D, Efremov M, Varlamov V, Senel S, Ignatyev P, Svirshchevskaya E (2013) Characterization of protein and peptide binding to nanogels formed by differently charged chitosan derivatives. Molecules 18(7):7848–7864

Siqueira Franco Picone C, Lopes Cunha R (2013) Chitosan–gellan electrostatic complexes: influence of preparation conditions and surfactant presence. Carbohydr Polym 94(1):695–703

Hiramoto S, Amano Y, Sato M, Suzuki Y, Shinohara M, Emoto S, Yamaguchi H, Ishigami H, Sakai Y, Kitayama J, Ito T (2016) Production of cisplatin-incorporating hyaluronan nanogels via chelating ligand-metal coordination. Bioconjug Chem 27(3):504–508

Vo CD, Kuckling D, Adler H-JP, Schonhoff M (2002) Preparation of thermosensitive nanogels by photo-cross-linking. Colloid Polym Sci 280:400–409

Dispenza C, Grimaldi N, Sabatino MA, Soroka IL, Jonsson M (2015) Radiation-engineered functional nanoparticles in aqueous system. J Nanosci Nanotech 15(5):3445–3467

Rosiak JM (1994) Radiation formation of hydrogels for drug delivery. J Control Release 31(1):9–19

Charlesby A (1960) Atomic radiation and polymers. Pregamon Press, Oxford

Charlesby A, Alexander P (1955) Reticulation of polymers in aqueous solution by γ-rays. J Chim Phys PCB 52:699–709

Charlesby A, Alexander P (1957) Effect of X-rays and γ-rays on synthetic polymers in aqueous solution. J Polym Sci 23:355–375

Sakurada I, Ikada Y (1996) Effects of Gamma Radiation on Polymer in Solution (IX): a turbidimetric study on solution of poly(vinyl alcohol) irradiated below critical concentration for gel-formation (Special Issue on Physical, Chemical and Biological Effects of Gamma Radiation, VII). Bull Inst Chem Res Kyoto Univ 44(1):66–73

Schnabel W, Borgwardt U (1969) Über die vernetzung von polyäthylenoxid in lösung unter der einwirkung von 60CO-γ-strahlen. Makromol Chem 123:73–79

Ulanski P, Rosiak JM (1999) The use of radiation technique in the synthesis of polymeric nanogels. Nucl Instrum Methods Phys Res B 151(1–4):356–360

Kadlubowski S (2014) Radiation-induced synthesis of nanogels based on poly(N-vinyl-2-pyrrolidone)—a review. Radiat Phys Chem 102:29–39 and references herein

Ulanski P, Janik I, Rosiak JM (1998) Radiation formation of polymeric nanogels. Radiat Phys Chem 52:289–294

Ulanski P, Kadlubowski S, Rosiak JM (2002) Synthesis of poly (acrylic acid) nanogels by preparative pulse radiolysis. Radiat Phys Chem 63(3–6):533–537

Kadlubowski S, Grobelny J, Olejniczak W, Cichomski M, Ulanski P (2003) Pulses of fast electrons as a tool to synthesize poly (acrylic acid) nanogels. Intramolecular cross-linking of linear polymer chains in additive-free aqueous solution. Macromolecules 36(7):2484–2492

Arndt K-F, Schmidt T, Reichelt R (2001) Thermo-sensitive poly(methyl vinyl ether) micro-gel formed by high energy radiation. Polymer 42:6785–6791

Querner C, Schmidt T, Arndt K-F (2004) Characterization of structural changes of poly(vinyl methyl ether) gamma-irradiated in diluted aqueous solutions. Langmuir 20(7):2883–2889

Schmidt T, Janik I, Kadlubowski S, Ulanski P, Rosiak JM, Reichelt R, Arndt K-F (2005) Pulsed electron beam irradiation of dilute aqueous poly (vinyl methyl ether) solutions. Polymer 46(23):9908–9918

El-Rehim HAA (2005) Swelling of radiation crosslinked acrylamide-based microgels and their potential applications. Radiat Phys Chem 74(2):111–117

Picos-Corrales LA, Licea-Claveríe A, Arndt K-F (2012) Stimuli-responsive nanogels by e-beam irradiation of dilute aqueous micellar solutions: Nanogels with pH controlled LCST. Chapter 7: Polymer Nanotechnology. In: Nanotechnology 2012: advanced materials, CNTs, particles, films and composites, vol 1. NSTI publication

Chmielewski AG, Haji-Saeid M, Shamshad Ahmed S (2005) Progress in radiation processing of polymers. Nucl Instrum Methods Phys Res Sect B 236(1):44–54

Sabatino MA, Bulone D, Veres M, Spinella A, Spadaro G, Dispenza C (2013) Structure of e-beam sculptured poly(N-vinylpyrrolidone) networks across different length-scales, from macro to nano. Polymer 54(1):54–64

Dispenza C, Sabatino MA, Grimaldi N, Spadaro G, Bulone D, Bondì ML, Adamo G, Rigogliuso S (2012) Large-scale radiation manufacturing of hierarchically assembled nanogels. Chem Eng Trans 27:229C–234C

Dispenza C, Sabatino MA, Grimaldi N, Bulone D, Bondi ML, Casaletto MP, Rigogliuso S, Adamo G, Ghersi G (2012) Minimalism in radiation synthesis of biomedical functional nanogels. Biomacromolecules 13:1805–1817