Abstract

Concrete beams reinforced with rectangular spiral shear reinforcement instead of the ordinarily closed stirrups have been recently extended. However, this extension has never been addressed for light-weight concrete structural elements. An experimental program is conducted in this research to investigate the shear performance of light-weight concrete beams that are transversely reinforced with continuous rectangular spirals. Four groups, including 20 specimens, were constructed where the groups contain two different shear span to depth ratios of 2.0 and 1.5 and have two different spiral spacing of 200 mm and 150 mm. Five different inclination angles of the spiral reinforcement were considered for each group: 85°, 80°, 77.2°, 75o, and 72.5°. The beams were tested under static four-point loading. Test results have shown that using rectangular spiral reinforcement has enhanced the shear capacity and deflection of the test specimens. Shear strength enhancement has ranged from 3% up to 47% compared to the ordinarily closed stirrups. Test results have also shown that the angle of inclination, which would result in the best performance, is influenced by the shear span to depth ratio. The optimum angles were found 85° and 75°, for the shear span to depth ratio of 2.0 and 1.5, respectively.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Most reinforced concrete (RC) beams are constructed using ordinarily closed stirrups (OCS) that are arranged perpendicularly to the beam longitudinal axis. The overall performance of concrete members with rectangular cross-sections that are transversely reinforced with spiral reinforcement (SR) has been significantly improved. Furthermore, the use of spiral shear reinforcement (SSR) is more economical than using OCS and can prevent premature shear failure mechanisms [1].

Light-weight concrete (LWC) is a new light-weight compliant material for construction, which represents a range of technical, environmental, and economic advantages [2,3,4,5]. Concrete with a cylinder compressive strength of at least 17 MPa and a density between 1350 and 1900 kg/m3 can be defined as structural LWC [6]. The most crucial advantage of LWC lies in its reduced weight while maintaining adequate strength [7,8,9]. The higher cost of the LWC is stabilized by reducing the size of structural members, reduction of reinforcement steel, and reduction of the concrete volume, which results in overall cost reduction [3, 10,11,12].

Reinforced light-weight aggregate concrete is composed of cement, sand, water, light-weight aggregates, and steel reinforcement. It is quietly similar to regular reinforced concrete. However, light-weight concrete has been used for many years for structural purposes due to its observable advantages compared to the normal-weight concrete, such as; higher strength-weight ratio, lower thermal coefficient, and better heat and sound insulation density typically 20–40% lower than the normal-weight concrete. Kang et al. [13] investigated the shear behavior of reinforced light-weight concrete beams without web reinforcement. They found that the shear span to depth ratio adversely affects the shear strength of light-weight reinforced concrete beams. Ababneh et al. [14] studied the shear behavior of light-weight concrete beams made with synthetic fibers. They showed that the utilization of the fibers enhanced the shear strength, ductility, stiffness, and toughness of the tested light-weight concrete beams.

This study investigates the shear behavior of LWC beams that are reinforced with SR at different inclination angles compared to beams reinforced with OCS. Application of rectangular spiral reinforcement (RSR) in rectangular RC members can improve their overall performance [15]. Karayannis and Chalioris, and others [16,17,18,19] studied the experimental shear behavior of concrete beams that were reinforced with RSR. It was found that beams transversely reinforced with SSR had a higher shear strength of 15–17% than the beams reinforced with OCS. De Corte and Boel [20] studied the experimental shear behavior of concrete beams reinforced with continuous SR. They tested 24 RC beams with different shear span to depth ratios (a/d) under a static four-point load scheme. They showed that spirally shaped shear reinforcement improved the structural performance of the RC beams.

Shatarat et al. [21] experimentally investigated the shear behavior of concrete beams reinforced with continuous SSR under a static four-point loading configuration by testing 28 RC beams 206 mm wide, 300 mm height, and 2440 mm long. Two shear span to depth ratios were considered; 2.5 and 3.0 using three different spacing; 125, 150, and 200 mm. They showed that the use of rectangular spiral shear reinforcement (RSSR) had increased the shear capacity and ductility of RC beams, and they recommended the use of RSSR. They also found that the best inclination angle for spiral stirrups is 80°.

Shatarat et al. [22] studied the shear behavior of self-compacting concrete (SCC) beams made with a rectangular spiral reinforcement. They adopted two different spirals spacing of 200 and 150 mm and five different angles of inclination for the spiral reinforcements (85°, 80°, 77.2°, 75°, and 72.5°). They showed that the utilization of continuous spiral reinforcement increased the shear strength of the beams up to 16.67% compared to the traditional closed stirrups. They found that the optimum angle of inclination is 85°, and they recommended the use the continuous spiral reinforcements in SCC.

Karayannis [23] investigated the cyclic behavior of exterior RC joints made with a rectangular spiral reinforcement. He found that using RSSR enhanced the strength, hysteretic energy absorption, and failure mechanisms compared to the specimens made with traditional stirrups. Maranan et al. [24] studied the shear behavior of geo-polymer concrete beams made with continuous rectangular spiral glass-fiber-reinforced polymer (GFRP) composites. They found that the shear strength and deflection of beams made with GFRP spirals were 20% and 120% greater than that measured in conventionally reinforced beams.

Continuous RSSR has been recently used in the design of the normal strength RC beams instead of the OCS. However, this extension has never been addressed for LWC structural elements. The experimental shear behavior of light-weight concrete beams that are transversely reinforced with continuous rectangular spiral stirrups (RSSR) has never been addressed in the existing literature. Furthermore, the preferable inclination angle of the spiral rectangular stirrups in light-weight concrete beams still lacks in the current literature. Moreover, researchers have never checked the suitability of the current shear equations suggested by the ACI-318M-14 [6], which is used for predicting the shear capacity of RC beams transversely reinforced with ordinary rectangular stirrups, in predicting the shear capacity of RC beams reinforced with rectangular spiral stirrups.

Therefore, the current study investigates the shear performance of LWC beams that are reinforced with RSSR. This research experimentally and analytically investigates the shear behavior of rectangular RC beams that are transversely reinforced with RSR. Two different pitch spacing (150 and 200 mm), five inclination angles (72.5°, 75°, 77.2°, 80° and 85°), and two shear span to depth ratios of (1.5 and 2.0) were used. This research aims to investigate the shear strength of light-weight concrete beams, which are reinforced with continuous rectangular spiral reinforcement using two different shear span to depth ratios a/d because the shear span to depth ratio is one of the factors governing the shear behavior of RC beams; therefore, the shear span to depth ratio can have a significant effect on the shear behavior of the beams. The research also aims to find the preferable inclination angle for the rectangular spiral stirrups to be used in the light-weight concrete beams. The experimental shear capacities of the beams were then compared to the analytical values predicted using the ACI Building Code (ACI 318M-14) [6]. This comparison is made to check the suitability of the current shear equations suggested by the ACI-318M-14 [6], which is used for predicting the shear capacity of RC beams transversely reinforced with ordinary rectangular stirrups, in predicting the shear capacity of RC beams reinforced with rectangular spiral stirrups.

2 Experimental Program

2.1 Material Properties

Natural light-weight aggregates called “Tuff stone” were used in this study; the bulk density of these light-weight aggregates is 636 kg/m3, water absorption is 11.1%, and abrasion value is 38%. Three different samples of maximum 25-mm diameter light-weight aggregate (LWA) were graded to determine whether they lie within the limits of the envelope for the grading of course aggregates. The grading of the aggregates has a considerable effect on the workability and stability of the concrete mix. Ordinary Portland—Pozzolana Cement (CEM II/A-P 42.5 N) conforming to Jordanian and European standards JS30-1:2007 and EN197-1:2000, respectively, with an initial setting time of 150 min and a specific gravity of 3100 kg/m3 was used in this research. Sand is a naturally accruing angular material composed of finely divided rock and mineral particles. The diameter of these particles ranges between 0.06 and 2.0 mm in size. The sand was provided from a local resource. Several trials were made to obtain the concrete mix design where mix proportion is demonstrated in Table 1. Twelve standard concrete cylinders that are 15 cm in diameter and 30 cm in height were cast and cured in water for 28 days before being tested. The average concrete compressive strength of all test specimens at 28 days is 33.7 MPa and that at 7 days is 26 MPa. The density of the concrete mix is 1835 kg/m3 with a 55 mm slump. The average yield and ultimate strengths of the longitudinal steel reinforcement for (Φ = 20) are 530 MPa and 710 MPa, respectively, and that for (Φ = 10) are 600 MPa and 750 MPa, respectively. In comparison, the average yield stress and ultimate strength of the transverse steel reinforcement are 240 MPa and 315 MPa, respectively.

2.2 Specimens Details

A total of 20 RC beams with a rectangular cross-section of 200 mm × 400 mm and a total length of 2.44 m were tested. Specimens were divided into two groups based on their shear span to depth ratios. Each group contains different shear reinforcement arrangements: one specimen without shear reinforcement, two specimens with OCS at two different spacing 150 mm and 200 mm, and seven specimens with continuous RSSR with top inclination angles as shown in Fig. 1. Beams of the group (A) have 2000 mm span length with a/d of 2.0, while group (B) have 1650 mm span length with a/d of 1.5, as shown in Figs. 2 and 3 and Table 2.

Details of the spiral and traditional reinforcement [21]

The flexural reinforcement is the same for all test specimens; three tensile bottom bars of diameter 20 mm and two top bars of 10 mm as compression reinforcement. The diameter of the traditional and spiral stirrups is 5.5 mm. The transverse reinforcement ratio of the test specimens reinforced with continuous SR and OCS is the same.

2.3 Ultimate Shear and Flexure Beam Capacity Calculations

The shear and flexural capacities of the beams were calculated based on the ACI-318-19 guidelines to ensure that shear failure will occur. The nominal shear strength was calculated based on Eqs. (1)–(3) suggested by the ACI-318-19 guidelines, and it equals 80.7 kN. The flexural strength was calculated based on equation [4] proposed based on ACI-318-19, and it equals 158 kN m. The beams’ flexural strength capacities, with the shear span to depth ratios of 1.5 and 2, are greater than the twice shear strength capacity of the beam. The theoretical flexural load resulted for beams, with shear span to depth ratios of 2, is 219.5 kN, and that for beams, with shear span to depth ratios of 1.5, is 292.6 kN. To account for the effect of light-weight concrete, a modification factor \(\lambda\) is used as a multiplier of \(\sqrt{{f}_{\mathrm{c}}}\) in the following equations, where \(\lambda\) = 0.85 for sand-light-weight concrete and 0.75 for all-light-weight concrete.

where vn is the nominal shear strength, νc is the concrete shear strength, νs is the shear strength of shear reinforcement, \({f}_{\mathrm{c}}\) is the concrete compressive strength, ρl is the beam longitudinal reinforcement ratio, \({f}_{\mathrm{yt}}\) is the yield strength of the transverse steel reinforcement and \(\mathrm{\varnothing }\) is the angle between inclined stirrups and the longitudinal axis of the member, fy: yield strength of reinforcement steel.

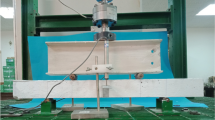

2.4 Test Setup

The test setup consists of a vertical loading system. Incremental loads, mid-span deflection, and crack propagation were recorded during the test. Beams are simply supported and were statically loaded. Linear variable displacement transducer was fixed at the mid-span of the beam to measure the mid-span vertical displacement. The geometry of the beams and the distance between the support and the concentrated loads are illustrated in Figs. 2 and 3 for groups A and B, respectively.

3 Test Results and Discussion

Incremental loads, mid-span deflection, failure mechanism, and crack propagation were recorded during the test. The experimental shear capacities of the beams were then compared to the analytical values predicted using the ACI318-14 guidelines. Table 2 shows the failure load, the corresponding shear force at failure, the angle of failure, and the maximum deflection of each test specimen. For group A specimens, with 200 mm spacing, the maximum load capacity was measured in specimen A200-85°, while the minimum load capacity was obtained in specimen A200-72.5°. Specimen A150-85° has the highest peak load, while specimen A150-77.2° has the lowest peak load for group A specimens with 150 mm spacing.

Figure 4a and b illustrates the load–deflection curves for group A specimens spaced at 200 mm and 150 mm, respectively. For group A specimens, spaced at 200 mm, the use of SR did not influence the deflection, but it increased the ultimate load values up to 17% compared to the OCS. The use of SR also increased the stiffness of group A specimens, spaced at 200 mm, compared to the OCS. For group A specimens spaced at 150 mm, the maximum ultimate load was measured in specimen A150-85° followed by specimen A150-80° with RSR, which is higher than that measured in specimen A150-90° with OCS. Figure 5a and b illustrates the load–deflection curves for group B specimens, spaced at 200 mm and 150 mm, respectively. The use of RSR increased the ultimate load of the test specimens in this group up to 47% compared to the OCS. For group B specimens, spaced at 200 mm, the maximum ultimate load was measured in specimen B200-75° followed by specimen 200°–85° with RSR, which is higher than that measured in specimen B200-90° with OCS. The maximum displacement in this group was measured in specimen B200-75° followed by specimen B200-72.5°, which is greater than that obtained in specimen B200-90° with OCS. For group B specimens spaced at 150 mm, the maximum ultimate load and displacement were measured in specimen B150-77.2°. All specimens in this group, which were reinforced with RSR, have higher loads than the control specimen with OCS. The minimum ultimate load was measured in specimen B200-72° and specimen B150-80° for group 200 mm and 150 mm, respectively. Test results have shown that the specimens with 150 mm spacing have higher ultimate loads and deflection than the specimens with 200 mm spacing regardless of the a/d ratio. Based on the test results, it is recommended to transversely reinforce the RC beams with rectangular spiral reinforcement to increase their shear capacities. The recommended inclination angle of the rectangular spiral reinforcement is 85° for beams with a shear a/d ratio of 2.0 and 75° for beams with a shear a/d ratio of 1.5.

4 Contribution of the Rectangular Spiral Reinforcement

Test results have shown that the use of the RSR has improved the shear strength of the test specimens. Figures 6 and 7 show the increasing percentage in the shear capacity of spirally reinforced beam specimens compared to the specimens with OCS in group A and group B, respectively.

Spirally reinforced specimens in group A, spaced at 200 mm, exhibited 2–17% increase in the shear capacity compared to the control beam with OCS. Group A specimens, spaced at 150 mm, exhibited a 4–15% increase in the shear capacity compared to the control beam with OCS A150-90°. Group B specimens, spaced at 200 mm, exhibited a 7–47% increase in the shear capacity of the test specimen compared to the control beam. This percentage has reduced to 6–15% in group B specimens spaced at 150 mm.

5 Crack Pattern

The cracking pattern of the beams at failure and the experimentally measured cracking angles (θ) of all test specimens are shown in Figs. 8 and 9 for group A and group B, respectively. The spirally reinforced beams of group A specimens exhibited a slightly higher cracking angle than the beam reinforced with OCS. The spirally reinforced beams of group B specimens, exhibited a slightly lower cracking angle than the beam reinforced with OCS. All test specimens in groups A and B failed under pure shear failure with diagonal shear cracking. Control specimens without shear reinforcement failed in a brittle manner. The failure mechanism of group A and group B are quite similar.

6 Comparison Between the Experimental and Theoretical Shear Capacities Calculated Using ACI 318-14 Code Shear Design Provision

The shear capacity of the test specimens was then predicted according to ACI-318M-14 [6] to check the suitability of the equations suggested by ACI-318M-14 [6] in predicting the shear capacity of RC beams reinforced with RSR. The theoretical shear strength was predicted based on ACI-318M-14, using Eqs. (1)–(3) listed in Sect. 2.3 to provide a material of comparison and further discussion of the test data.

A comparison was then made between the shear capacity of the tested specimens obtained experimentally and theoretically by the ACI318-14 shear provisions. The ratios of the shear capacities obtained from the test to the theoretical shear capacity were calculated and included in Table 3. The experimental and theoretical contributions of spiral reinforcement and concrete to the shear capacity of the beams are also demonstrated in Table 3. It is clear from Table 3 that the ratio of (Vexp/Vtheo) is greater than 1.0 for all test specimens. The maximum ratio is 4.31 for beam B200-75°, while the lowest value is 2.25 for beam B150-77.2°. This implies that the design provision for the ACI-318M-14 code is more conservative in the estimation of the ultimate shear strength for beams with continuous rectangular spirals. Similarly, Table 4, which shows the ratio of experimental shear stresses and theoretical shear stresses, implies that all the ratios are higher than 1.0 with the higher percentage for B200-75° and the lowest value for beam B150-77.2°. Therefore, a new shear capacity equation in the ACI314-14 could be suggested to cover all spiral reinforcement cases. This indicates that the current ACI design provisions for shear underestimate the shear capacity of RC beams that are transversely reinforced with RSR. Therefore, the ACI318-14 design shear equation, which is used to predict the shear strength of RC beams transversely reinforced with ordinary rectangular stirrups, is applicable but conservative in estimating the shear capacity of RC beams that are transversely reinforced with rectangular spiral stirrups.

7 Conclusions

An experimental program is conducted in this research to investigate the shear performance of light-weight concrete beams that are reinforced with continuous rectangular spirals. Twenty specimens that include four groups were tested where the groups contain two different a/d of 2.0 and 1.5 and have two different spiral spacing of 200 mm and 150 mm. Five different inclination angles of the SR were considered for each group: 85°, 80°, 77.2°, 75o, and 72.5°. The beams were tested under static four-point loading. The following points summarize the research outcomes:

-

Beams reinforced with RSR have higher shear and deflection capacity over beams reinforced with OCS.

-

For concrete beams that were reinforced with RSR and have shear a/d of 2.0, the shear capacity is 17% higher than that obtained with OCS at a spacing of 200 mm and 150 mm.

-

For concrete beams that were reinforced with RSR and have shear a/d of 1.5, the shear capacity is 47% higher than that obtained with OCS at a spacing of 200 mm and 150 mm.

-

The inclination angle of the RSR is significantly influenced by the shear a/d ratio.

-

The optimum inclination angle of the SR is 85° for beams with a shear a/d ratio of 2.0.

-

The optimum inclination angle of the SR is 75° for beams with a shear a/d ratio of 1.5.

-

Beam specimens with 150 mm spacing have higher ultimate loads and deflection than beam specimens with 200 mm spacing regardless of the shear a/d ratio.

-

The ACI318-14 code underestimates the shear strength of beams that were reinforced with continuous RSR. Therefore, the ACI318-14 design shear equation is applicable but conservative in estimating the shear capacity of RC beams that are transversely reinforced with RSR.

References

Sheikh SA, Toklucu MT (1993) Reinforced concrete columns confined by circular spirals and hoops. ACI Struct J 90:542–553. https://doi.org/10.14359/3949

Haque M, Al-Khaiat H, Kayali O (2004) Strength and durability of light-weight concrete. Cem Concr Compos 26:307–314. https://doi.org/10.1016/S0958-9465(02)00141-5

Oktay H, Yumrutaş R, Akpolat A (2015) Mechanical and thermophysical properties of light-weight aggregate concretes. Constr Build Mater 96:217–225. https://doi.org/10.1016/J.CONBUILDMAT.2015.08.015

Chi J, Huang R, Yang C, Chang J (2003) Effect of aggregate properties on the strength and stiffness of light-weight concrete. Cem Concr Compos 25:197–205. https://doi.org/10.1016/S0958-9465(02)00020-3

Kockal NU, Ozturan T (2011) Strength and elastic properties of structural light-weight concretes. Mater Des 32:2396–2403. https://doi.org/10.1016/j.matdes.2010.12.053

ACI Committee 318 (2019) Building code requirements for structural concrete (ACI 318–19) and commentary. ACI Committee, American Concrete Institute

Cembureau (1974) Lightweight aggregate concrete: technology and world applications. Associazione Italiana Technico Economica del Cemeto, Paris

Spratt BH (1975) An introduction to light-weight concrete. Cement and Concrete Association

Slate FO, Nilson AH, Martinez S (1986) Mechanical properties of high-strength lightweight concrete. ACI J Proc 83:606–613. https://doi.org/10.14359/10454

Kong FK, Evans RH (1983) Handbook of structural concrete. McGraw-Hill

Juan KY (2011) Cracking mode and shear strength of lightweight concrete beams. National University of Singapore

Xiaopeng L (2005) Structural lightweight concrete with pumice aggregate. National University of Singapore

Kang THK, Kim W, Kwak YK, Hong SG (2011) Shear testing of steel fiber-reinforced light-weight concrete beams without web reinforcement. ACI Struct J 108:553–561. https://doi.org/10.14359/51683212

Ababneh A, Al-Rousan R, Alhassan M, Alqadami M (2017) Influence of synthetic fibers on the shear behavior of light-weight concrete beams. Adv Struct Eng 20:1671–1683. https://doi.org/10.1177/1369433217691773

Lo TY, Tang WC, Cui HZ (2007) The effects of aggregate properties on light-weight concrete. Build Environ 42:3025–3029. https://doi.org/10.1016/J.BUILDENV.2005.06.031

Shahrooz BM, Forry ML, Anderson NS et al (2016) Continuous transverse reinforcement—behavior and design implications. ACI Struct J 113:1085–1094. https://doi.org/10.14359/51689154

Karayannis CG, Chalioris CE (2013) Shear tests of reinforced concrete beams with continuous rectangular spiral reinforcement. Constr Build Mater 46:86–97. https://doi.org/10.1016/J.CONBUILDMAT.2013.04.023

Karayannis CG, Chalioris CE, Mavroeidis PD (2005) Shear capacity of RC rectangular beams with continuous spiral transversal reinforcement. Comput Methods Exp Meas 41:379

Chalioris CE, Karayannis CG (2013) Experimental investigation of RC beams with rectangular spiral reinforcement in torsion. Eng Struct 56:286–297. https://doi.org/10.1016/J.ENGSTRUCT.2013.05.003

De Corte W, Boel V (2013) Effectiveness of spirally shaped stirrups in reinforced concrete beams. Eng Struct 52:667–675. https://doi.org/10.1016/J.ENGSTRUCT.2013.03.032

Shatarat N, Katkhuda H, Abdel-Jaber M, Alqam M (2016) Experimental investigation of reinforced concrete beams with spiral reinforcement in shear. Constr Build Mater 125:585–594. https://doi.org/10.1016/J.CONBUILDMAT.2016.08.070

Shatarat N, Mahmoud HM, Katkhuda H (2018) Shear capacity investigation of self compacting concrete beams with rectangular spiral reinforcement. Constr Build Mater 189:640–648. https://doi.org/10.1016/J.CONBUILDMAT.2018.09.046

Karayannis CG (2015) Mechanics of external RC beam-column joints with rectangular spiral shear reinforcement: experimental verification. Meccanica 50:311–322. https://doi.org/10.1007/s11012-014-9953-6

Maranan GB, Manalo AC, Benmokrane B et al (2018) Shear behaviour of geopolymer-concrete beams transversely reinforced with continuous rectangular GFRP composite spirals. Compos Struct 187:454–465. https://doi.org/10.1016/j.compstruct.2017.12.080

Acknowledgements

The authors would like to thank the deanship of academic research at the University of Jordan for their financial support to perform this research.

Funding

This study was funded by the deanship of academic research at the University of Jordan.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Al-Zaidaneen, H., Murad, Y., Jaber, M.A. et al. Shear Strength of Light-Weight Reinforced Concrete Beams with Continuous Rectangular Spiral Reinforcement. Int J Civ Eng 20, 291–303 (2022). https://doi.org/10.1007/s40999-021-00667-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40999-021-00667-z