Abstract

Levees are critical structures for protecting low-lying areas from floods and understanding their erosion dynamics is essential for enhancing their resilience. This study investigates the erosion dynamics of earthen levees by examining different combinations of foundation and levee materials in seepage and overtopping conditions. Six experimental cases were conducted: three seepage erosion cases (Case I SE-S74, Case III SE-S85, Case V SE-S87) under seepage erosion failure conditions, using Mikawa silica sand No. 7 and 8 in the levee body and No. 4, 5, and 7 in the foundation and three overtopping erosion cases (Case II OE-S74, Case IV OE-S85, Case VI OE-S87) under overtopping erosion failure conditions, using same materials. The focus was on the impact of hydraulic conductivity differences between the levee and foundation materials on erosion resistance. SE-S74 and SE-S85, with high hydraulic conductivity ratios, demonstrated rapid phreatic line movement and significant erosion, including complete downstream slope failure and 30 to 35 percent crest erosion. In contrast, SE-S87, with a lower hydraulic conductivity ratio, showed no erosion, highlighting the importance of material compatibility. The overtopping erosion cases revealed that the time to erosion initiation and complete erosion increased with decreasing hydraulic conductivity differences, with all cases exhibiting a similar external progressive erosion pattern due to finer levee materials. Higher hydraulic gradients and conductivities result in faster seepage and greater erosion potential, which can lead to structural failures like downstream slope collapse or crest breaches. This study underscores the critical role of optimizing hydraulic conductivity ratios to enhance levee resilience, providing practical insights for improving levee design against seepage and overtopping erosion.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Levees are essential for protecting communities from floods, at the same time their failure can lead to severe consequences. As global flooding risks rise due to climate change and urbanization, levees face increasing pressure to withstand extreme conditions (Starosolszky 1994; O’Dell et al. 2021; National Academy of Sciences 2013; Sayers et al. 2015; Igarashi and Tanaka 2020a, b). It is crucial to understand that while levees are designed to protect against floods, their failure has the potential to intensify flooding issues, highlighting the importance of their resilience in safeguarding communities and minimizing the impacts of natural disasters. (Yen 1995; Tanaka 2009; Kundzewicz et al. 2013; Heine and Pinter 2012; Tanaka et al. 2012; Olson et al. 2015).

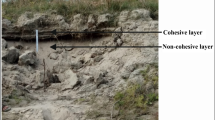

Levees can fail due to overtopping and seepage, causing erosion that may breach the levee and cause considerable damage to nearby flood plains. Levee breaches are a global issue that can cause severe flooding and damage to communities. For instance, in 2005, Hurricane Katrina caused catastrophic levee failures in Greater New Orleans, leading to widespread flooding and loss of life (Sills et al. 2008; Newberry 2010). In 2011, the Mississippi River experienced a record-breaking flood that caused several levee breaches, resulting in considerable damage to homes, businesses, and infrastructure (Van Heerden 2007). In Pakistan, during the 2010 flood, the most devastating breach occurred at Tori Levee on the right bank of the Indus River, downstream of the Guddu Barrage, which caused residual floods in northern Sindh and the adjoining regions of the Balochistan province (Naeem et al. 2021). In Japan, major cities often extend into areas situated below the designated high-water levels. When a levee breaches, it leads to severe flooding. Therefore, effective levee management becomes a serious aspect of flood control activities in the country (Nagasaka et al. 2012; Fujita and Hamaguchi 2012). Levee breaches pose a significant challenge in protecting communities from flooding and examples from Japan highlight the gravity of this issue, often intensified by seepage or infiltration from the foundation. Japan, with its complex network of rivers and susceptibility to typhoons, has faced several instances of levee breaches that underscore the vulnerabilities associated with flood defenses (Lin et al. 2020; Kawata 2008). One example is the 2018 flooding in Hiroshima, where intense rainfall led to seepage-related breaches in the levees along the Oda River. The penetration of water through the levee foundations highlighted the limitations in addressing seepage, emphasizing the need for improved foundation designs (Igarashi and Tanaka 2020a, b; Yoshida et al. 2019). The Yabe River levee failed during the 2012 North Kyushu rains due to piping from the foundation (Yoshikawa and Kodaka 2017). This underlined the importance of addressing seepage at the foundation level to prevent disastrous breaches.

These examples not only highlight the immediate challenges posed by levee breaches but also emphasize the ongoing issues related to seepage and infiltration from foundations. Understanding and mitigating these challenges is important in strengthening levee systems against the complexities of extreme weather events, ensuring the resilience of flood defenses in vulnerable regions (Patel et al. 2024). Erosion dynamics refers to the complex interaction among water flow, sediment transport, and the materials comprising a levee (Gross et al. 2010; Chen et al. 2011). Understanding these processes is crucial for strengthening levee resilience. When a levee is breached, water erodes the soil, leading to structural weakening and compromising the overall integrity of the levee (Ogura and Tanaka 2019; Özer et al. 2019; Ali and Tanaka 2023). Therefore, a comprehensive study of erosion processes is essential for developing effective strategies to strengthen levee performance.

Numerous studies have significantly contributed valuable insights into the resilience and erosion dynamics of levees (Tanaka 2009; Tanaka et al. 2012; Ali and Tanaka 2023). Wan and Fell (2004a, c) examined the factors influencing soil erosion rates in embankment dams, providing insights into the erosion processes and implications for dam safety and design. Briaud et al. (2008) used an Erosion Function Apparatus (EFA) to study the erosion of various soil types, categorizing them based on factors such as compaction level, erosion rate, water velocity, and hydraulic shear stress. Xu and Zhang (2009) demonstrated that besides soil type, compaction level significantly influences erosion resistance, with higher compaction enhancing resistance, especially for fine soils. Ferrari et al. (2020) proposed a methodology focusing on numerically simulated flooding scenarios resulting from levee failures. The study investigated model selection, grid resolution, hydrological conditions, and breach parameters, shedding light on the vulnerability of different levee materials through various scenarios. Another study by Igigabel et al. (2021) underscored the importance of methodological developments in enhancing the resilience of levee systems. These works collectively contribute to the broader understanding of levee dynamics, offering insights into improving their resilience and effectiveness against the challenges posed by floods.

Overtopping and seepage are complicated processes influencing levee stability and are subjects of ongoing investigation which are highlighted by important studies like those by Ali and Tanaka (2023). While these studies have improved our understanding of hydraulic conductivity differences between levee foundation and levee materials, a limitation arises from changing both components at the same time. Recognizing this challenge drives current research and deepens our insights. Therefore, the current study seeks to overcome this challenge by intentionally varying the levee body and foundation materials independently. This deliberate approach allows for a detailed exploration of how each component influences levee erosion dynamics. Among the difficulties of infiltration and seepage interactions, this research aims to contribute to the field of levee engineering by improving the understanding of material compatibility which promotes enhanced stability and resilience. Specific goals of the current study include investigating the erosion behavior of diverse levee materials under varying hydraulic conditions. It also assessed how material properties, including permeability, cohesion, and shear strength, influenced the susceptibility to erosion. Additionally, it proposes informed strategies for enhancing levee resilience, emphasizing the importance of thoughtful material selection and design modifications. This comprehensive approach aims to provide valuable insights that contribute to the broader understanding of levee behavior and inform practices for constructing more resilient flood protection systems.

2 Materials and Experimental Setup

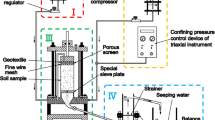

The experiments were conducted at Saitama University in Japan using a 6.5 m long, 0.5 m wide, and 1.2 m deep open channel flume equipped with one transparent glass side as shown in Fig. 1a. The embankment model within the flume was constructed to a scale that simulates real-world conditions, and the levee had a geometric scale ratio of 1:20, where the dimensions of the model levee corresponded to an average height of 5 m for a real levee in Japan.

Illustration of experimental configuration: a Side view of the flume with the levee model; b Cross-section of the levee model during seepage erosion tests; c Cross-section of the levee model during overtopping erosion tests (adapted from Ali and Tanaka 2023)

2.1 Flume and Levee Geometry

The flume was 6.5 m long, 0.5 m wide, and 1.2 m deep. The levee models constructed within the flume were 0.4 m high with a crest width of 0.25 m and side slopes of 1 V:1H schematic in Fig. 1b, c.

2.2 Hydraulic Conditions and Experimental Instruments

Flume experiments were conducted to aim at simulating medium flood or low tsunami conditions. The overtopping depth on the levees was maintained at 0.02 m, corresponding to 0.4 m in the scaled test specimen (1/20 scale). Overtopping depths were recorded around 0.3–0.6 m at the Kinugawa River in Joso City Japan in 2015 (Morrill-Winter et al. 2017; Nagumo et al. 2016) and at the Tokigawa River (Saitama Prefecture) during Typhoon Hagibis in 2019 (Igarashi and Tanaka 2022). This scaling ensured similarity in the Froude number, crucial for accurately representing real-world hydraulic conditions. To ensure controlled and consistent conditions during the seepage experiments, a stable water depth of 0.225 (m) on the upstream side of the levee was carefully maintained. This precise level was achieved by firmly closing the discharge control valve and the experiments were facilitated with the water pump operating continuously for approximately two hours. A steady discharge rate of 2.27 × 10−3 (m3/s) was maintained throughout the experiments. This rate provided about 0.02 m of overtopping depth on the crest during the three overtopping experimental conditions, contributing to the controlled flow conditions essential for the study.

2.3 Experimental Cases

During this study, six distinct experimental cases were conducted as shown in Fig. 1b, c, and detailed in Table 1. The experiments were designed to systematically investigate the impact of varying levee and foundation materials on levee erosion resistance. Specifically, the levee material varied between finer Mikawa silica sand No. 7 (MSS7) and No. 8 (MSS8), while the foundation material was varied among coarser Mikawa silica sand No. 4 (MSS4), No. 5 (MSS5), and No. 7 (MSS7). The experimental cases were organized as follows: Case I and Case II: The levee material was MSS7, and the foundation material was MSS4. Case III and Case IV: The levee material was MSS8, and the foundation material was MSS5. Case V and Case VI: The levee material was MSS8, and the foundation material was MSS7. The specific characteristics of these materials are detailed in Table 2. This systematic variation allowed for a comprehensive analysis of how different material combinations influence erosion dynamics under both seepage and overtopping conditions.

2.4 Soil Sample Analysis

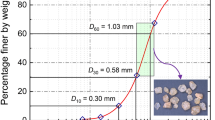

The embankment and foundation were created by compacting Mikawa silica sands (Mikawa Silica Co., Ltd.) with median grain sizes as shown in Fig. 2a. The optimum moisture content for the different sands is listed in Table 2 as determined by Ali and Tanaka (2023). The embankment and foundation were compacted to 82% to 85% of the maximum dry density using a hammer, with each 5 cm layer receiving 6 blows, achieving the desired compaction. To ensure the structural integrity of the levee models, soil samples were collected from specific locations on both the downstream and upstream slopes as depicted in Fig. 2b. These samples underwent comprehensive analyses for key parameters like compaction degree, dry density, water content, hydraulic conductivity, mean grain size, and optimum water content as listed in Table 2. By following this methodology, the complex relationship between material properties and levee erosion resistance was aimed to be understood, contributing to this critical field of research.

2.5 Monitoring and Data Collection

During the seepage erosion experiments, which lasted for over two hours, and the overtopping erosion experiments, which lasted only for two minutes, visual inspection, video recording, and high-speed camera techniques were used to monitor both the levee and water surface configurations.

2.6 Data Analysis

The data collected from the visual inspections, video recordings, and high-speed camera footage were analyzed to identify erosion patterns, rates, and progression stages. The analysis focused on comparing the erosion dynamics across different material combinations and experimental conditions, providing insights into the factors influencing levee erosion resistance.

3 Results

3.1 Findings of seepage erosion cases

3.1.1 Erosion Dynamics in Seepage Erosion Case I SE-S74

The erosion dynamics were characterized by the following various stages in seepage erosion Case I SE-S74, which used MSS7 for the levee body and MSS4 for the foundation.

-

I. Initiation (0–2 min)

Water appeared at the downstream toe two minutes earlier than the upstream water level reached 0.225 m as shown in Fig. 3a, indicating the onset of the erosion process.

-

II. Early Erosion (2–10 min)

The beginning of slip failures and the formation of cracks were observed within the first five minutes. Approximately 60% of the downstream slope experienced failure within the first 10 min as shown in Fig. 3b–d. The erosion process exhibited rapid progression during this initial phase.

-

III. Intermediate Erosion (10–20 min)

The erosion process continued at a significant pace, with 100% of the downstream slope failing by the 20 min mark as shown in Fig. 3e. Failures extended progressively towards the crest during this phase.

-

IV. Continued Erosion (20–90 min)

After the initial 20 min, the erosion slowed down and progressed at a slower rate. About 30% of the crest had eroded by the 90 min mark as shown in Fig. 3f–h.

-

V. Stabilization (Beyond 90 min)

Beyond the 90 min mark, the progression of erosion began to slow down significantly. Further propagation of failure or erosion became limited. The system reached a state of relative stability, with no major changes observed after this point.

3.1.2 Erosion Dynamics in Seepage Erosion Case III SE-S85

In this section, a detailed analysis of the erosion dynamics observed in Seepage erosion Case III SE-S85 has been listed, where the levee body was MSS8, and the foundation was MSS5. The erosion process exhibits distinctive patterns as shown below.

-

I. Initiation (5 min)

In this experimental case, water began to appear at the downstream toe, indicating the onset of the erosion process, approximately 5 min after the upstream water level reached 0.225 (m) as shown in Fig. 4a.

-

II. Early Erosion (0–20 min)

During the first 20 min, the erosion process demonstrated slow progression. Approximately 15% of the downstream slope experienced failure during this initial phase. The initial signs of erosion included the development of cracks and localized slip failures indicated in Fig. 4b, c.

-

III. Intermediate Erosion (20–60 min)

Between the 20 – 60 min mark, the erosion process intensified significantly. By the 60 min mark, approximately 100% of the downstream slope had eroded. Failures extended further towards the crest during this phase, indicating the substantial extent of the failure can be seen in Fig. 4d, e.

-

IV. Continued Erosion (60–150 min)

The erosion process continued beyond the initial 60 min but at a notably slower rate. By the 150 min mark, a maximum of 35% of the downstream slope had experienced failure as indicated in Fig. 4f–h. The progression of erosion slowed down significantly during this phase.

-

V. Stabilization (Beyond 150 min)

Beyond the 150 min mark, no further significant failures or changes in erosion dynamics were observed. The levee system reached a state of relative stability, with no major alterations in the erosion process.

3.1.3 Erosion Dynamics in Seepage Erosion Case V SE-S87

In seepage erosion Case V SE-S87, which used MSS8 for the levee body and MSS7 for the foundation, the results were markedly different as shown in Fig. 5a, b.

-

Initiation to Stabilization:

No erosion or appearance of water at the downstream toe was observed even after 2 h. This case demonstrated exceptional resistance to seepage erosion, indicating excellent material compatibility and significantly lower hydraulic conductivity differences between the levee and foundation material.

3.2 Phreatic Line Dynamics in Seepage Erosion Cases

Understanding the behavior of the phreatic (saturation) line is crucial for analyzing the stability and erosion resistance of levees under seepage conditions. This section discusses the movement of the phreatic line at two critical times: initially, when the upstream water level reaches 0.225 m, and subsequently, after approximately one hour. The dynamics are compared across three experimental cases as shown in Fig. 6a–f. The red line showing the phreatic line above this line is saturated soil and below is unsaturated.

-

Case I SE-S74

In Case I SE-S74, where the hydraulic conductivity ratio (kE/kF) between the levee and foundation materials is approximately 60, the movement of the phreatic line is rapid due to the high hydraulic conductivity of the foundation material and the significant difference in material properties as shown in Fig. 6a, d. When the upstream water level reaches 0.225 m, the phreatic line quickly rises above the downstream toe, even before the water fully reaches the set level. This rapid ascent is indicative of quick saturation and a substantial risk of failure. Indeed, early erosion is observed with 60% downstream slope failure within the first 10 min, progressing to 100% downstream slope failure and 15% crest erosion within 20 min. This demonstrates the immediate impact of a high hydraulic conductivity foundation on erosion dynamics.

-

Case III SE-S85

Case III SE-S85 also has a high hydraulic conductivity ratio of 60. The phreatic line here also shows rapid movement due to the high permeability of the foundation material as shown in Fig. 6b, e. At the initial stage, as the water reaches 0.225 m, the saturation line ascends quickly, causing early signs of instability. By the 5 min mark, water appears at the downstream toe, and significant erosion is observed with complete downstream slope failure and 35% crest erosion occurring within the first 60 min. The rapid rise and high phreatic line underscore the vulnerability of the levee to erosion when there is a large disparity in hydraulic conductivity between the levee and foundation materials.

-

Case V SE-S87

In stark contrast, Case V SE-S87 demonstrates a slower movement of the phreatic line as shown in Fig. 6c, f. With a hydraulic conductivity ratio of 8, which is significantly lower than in SE-S74 and SE-S85, the difference in material properties is minimized. When the water level reaches 0.225 m, the phreatic line rises much more gradually. Even after one hour, the phreatic line remains well below the downstream toe, reflecting a much slower saturation process. This controlled ascent contributes to the stability observed in SE-S87, where no erosion occurs, highlighting the importance of optimizing material compatibility to enhance levee resilience.

3.3 Overtopping Erosion Cases

Overtopping erosion experiments conducted in Cases II OE-S74, IV OE-S85, and VI OE-S87 shed light on the crucial role of levee materials in levee stability. The overtopping erosion cases consistently showed that a smaller difference in hydraulic conductivity between materials delays erosion initiation, emphasizing the role of material properties in controlling erosion rates as shown in Fig. 7a, b. When a levee is made with MSS8 there is a delay in levee erosion in the case of OE-S87. This underscores the significant threat that overtopping poses to levee integrity. In cases where the levee crest is fixed, such as with a pavement, the erosion dynamics would differ, with the substrate material playing a critical role in determining the depth of the scour hole and the collapse process of the levee body. However, in this study, the crest was not fixed, so the embankment material significantly influenced the erosion patterns observed. All cases displayed a consistent erosion pattern, with external progressive surface erosion starting on the downstream slope, and extending to the levee crest, and upstream slope. Ebrahimi et al. (2024) conducted a numerical investigation into the hydraulic mechanisms during embankment dam overtopping, finding that the process typically involves initial overtopping, surface erosion, headcut formation and progression, and eventual breach development. Experimental results during the current study observed initial overtopping at the downstream face followed by crest headcut migration, were consistent with these findings. These findings suggest that during overtopping events, the levee material properties, rather than the foundation material, hold a greater influence on determining the rate and pattern of erosion.

To mitigate the risks associated with overtopping, levee design should prioritize selecting levee materials with superior erosion resistance. This could involve utilizing finer materials along with clay content or exploring options specifically engineered for enhanced erosion resistance. By understanding the interplay between overtopping erosion and levee materials, we can design more resilient levee systems capable of withstanding the destructive forces of overtopping events.

4 Discussion

4.1 Interpretation of Findings

This study investigates the erosion dynamics of earthen levees through three seepage erosion cases and three overtopping erosion cases, comparing SE-S74 and SE-S85 with a previous study by Ali and Tanaka (2023). The experimental design varied foundation materials while keeping the levee material constant, and vice versa, allowing a systematic analysis of each material’s impact on levee erosion. This approach provides a comprehensive understanding of the factors influencing erosion resistance.

4.1.1 Keeping Levee material constant varying foundation material (SE-S74 vs. IO-E7-F5 and IO-E8-F4 vs. SE-S85)

The discussion is initiated by comparing Seepage erosion Case I SE-S74 and IO-E7-F5, maintaining a constant levee material while varying the foundation material. In Seepage erosion Case I SE-S74 (Table 1), the observed erosion dynamics were quite pronounced. The outcome revealed that 100% of the downstream slope experienced failure, and there was notable erosion on the crest, accounting for approximately 30% of its total extent as shown in Figs. 8a and 9a. The erosion process in SE-S74 exhibited a series of distinct stages and eventually stabilized after 90 min.

Surface profiles of Levee at different time intervals a For Seepage erosion Case I SE-S74, b For Seepage erosion Case IO-E7-F5 (Ali and Tanaka 2023)

On the other hand, IO-E7-F5 featuring the same MSS7 levee material but MSS5 foundation material, demonstrated a remarkably different erosion response. Notably, only 65% of the downstream slope failed, there were no instances of crest failure observed in this case extent as shown in Figs. 8b and 9b.

On the other hand, a rapid and extensive erosion process was observed in Seepage erosion case IO-E8-F4. Remarkably, within the initial 60 min, 100% of the downstream slope failed, and there was substantial crest erosion, accounting for 70% of the total crest extent as indicated in Figs. 10a and 11a. In contrast, SE-S85 displayed a distinct erosion pattern. It reached a stabilization point after 150 min, with 100% downstream slope failure and approximately 35% crest erosion as shown in Figs. 10b and 11b. However, despite sharing the foundation material with IO-E7-F5, SE-S85 did not match the erosion resistance exhibited by IO-E7-F5.

Surface profiles of Levee at different time intervals a For Seepage erosion case IO-E8-F4 (Ali and Tanaka 2023), b For Seepage erosion Case III SE-S85

4.1.2 Keeping Foundation material constant varying Levee material (IO-E7-F5 vs. SE-S85)

Drawing further comparisons, the Seepage erosion case IO-E7-F5 was compared with SE-S85 of which foundation material MSS5 was the same while varying the levee material. Exceptional erosion resistance was consistently observed in Seepage erosion case IO-E7-F5. It displayed only 65% downstream slope failure, with no crest failures observed, despite a subtle difference in fineness between its levee material and that of SE-S85. On the other hand, SE-S85 reached a stabilization point after 150 min, experiencing 100% downstream slope failure and approximately 35% crest erosion. The impressive performance of IO-E7-F5 can be attributed to a delicate balance between material properties and the hydraulic conductivity ratios. Although both cases used the same foundation material, the levee material in IO-E7-F5 was a better fit. It effectively countered erosion, surpassing the erosion resistance of SE-S85, despite having a finer material in the levee body.

4.2 Seepage Erosion Insights

The seepage erosion cases in our study demonstrate the critical influence of foundation material on levee stability. Case I SE-S74, using MSS4 for the foundation, resulted in complete downstream slope failure (100%) and 30% crest erosion. Conversely, Case IO-E7-F5, with MSS5 for the foundation (hydraulic conductivity difference about 50 times lower), exhibited significantly less erosion (65% downstream slope failure and no crest erosion). These observations align with Wan and Fell (2004a, 2004c), who noted that higher hydraulic conductivity in foundation materials accelerates seepage and erosion processes.Similarly, Case III SE-S85 showed severe erosion with complete downstream slope failure (100%) and 35% crest erosion, paralleling Case IO-E8-F4. Both cases highlight the need to minimize hydraulic conductivity disparities between levee and foundation materials for improved erosion resistance. Case V SE-S87, which exhibited no erosion even after 120 min, underscores the importance of optimizing hydraulic conductivity ratios. The minimal difference in hydraulic conductivity between the levee and foundation materials in SE-S87 (approximately four times lower than in SE-S75) significantly enhanced erosion resistance, supporting the conclusions of Jia et al. (2022) and Van Beek et al. (2010).

4.3 Theoretical Analysis of Seepage Erosion Dynamics

The phenomenon of seepage erosion in levees is a critical aspect of hydraulic engineering, involving complex interactions between water flow and soil properties. When water infiltrates a levee structure due to hydraulic gradients, it permeates through the soil, exerting forces that can lead to internal erosion and structural instability.

In theoretical analysis, the hydraulic gradient (i) plays a pivotal role as it dictates the rate of water flow through the soil. This gradient, coupled with the hydraulic conductivity (k) of the soil, determines the seepage velocity (v), which describes how quickly water moves within the levee structure. As water seeps through, it applies shear stress (τ) on the soil particles. This shear stress, when surpassing a critical threshold (τc) causes soil particles to detach and erode.

The erodibility of the soil, often quantified by the erodibility coefficient (kd), influences the erosion rate. Finer soils have lower critical shear stresses and higher erosion rates compared to coarser soils with higher shear stress thresholds. This understanding is crucial for predicting where erosion might initiate and how quickly it could progress within the levee structure.

4.3.1 Key Theoretical Insights

4.3.1.1 Hydraulic Gradient and Seepage Velocity

The hydraulic gradient (i) equation (Eq. 1) and hydraulic conductivity (k) of the soil determine the seepage velocity (v) equation (Eq. 2), which influences the rate at which water moves through the levee. Higher gradients and conductivities lead to faster seepage and greater erosion potential (Bear 2013) as listed in Table 3.

Δh = Difference in hydraulic head.

L = Length of the seepage path

k = Hydraulic conductivity (m/s).

4.3.1.2 Shear Stress and Erosion

Shear stress (τ) equation (Eq. 3) exerted by seeping water on soil particles causes erosion when it surpasses the critical shear stress (τc) (Knighton 2014). The erodibility coefficient (kd) quantifies this process, with finer soils being more prone to erosion (Hanson and Simon 2001).

ρ = Density of water.

g = Acceleration due to gravity.

R = Hydraulic radius.

Ie = Slope of the energy grade line.

4.3.1.3 Erosion Rate

The erosion rate (E) equation (Eq. 4) depends on the difference between shear stress and critical shear stress. Higher differences result in increased erosion rates, particularly in soils with high hydraulic conductivity. (Auerswald et al.2014; Briaud et al.1999; Wan and Fell 2004a, 2004b).

E = Erosion rate (mass per unit area per unit time).

kd = Erodibility coefficient.

τ = Applied shear stress.

τc = Critical shear stress.

Experimental observations validate these theoretical insights as summarized in Table 3. Cases where there are significant differences in hydraulic conductivity between the levee body and the foundation soil tend to experience more severe erosion. For instance, combinations, where the foundation soil has higher hydraulic conductivity, lead to faster seepage and increased erosion rates, resulting in structural failures such as downstream slope collapse or levee crest breaches. Seepage erosion in levees is a dynamic process influenced by hydraulic gradients, soil properties, and erosion mechanics.

4.4 Phreatic Line Dynamics and Erosion Resistance

The study of phreatic line dynamics during seepage erosion experiments highlights the significant impact of hydraulic conductivity ratios between levee and foundation materials on levee stability. High hydraulic conductivity ratios, as seen in SE-S74 and SE-S85, resulted in rapid phreatic line movement, severe erosion, early water appearance at the downstream toe, and substantial slope and crest failures. Conversely, SE-S87, characterized by a lower hydraulic conductivity ratio, exhibited slower phreatic line movement, maintaining stability with no erosion observed. These findings underscore the importance of minimizing differences in hydraulic conductivity to enhance erosion resistance and overall levee resilience, providing valuable insights for optimizing material compatibility in levee design.

4.5 Overtopping Erosion Insights

The overtopping erosion experiments demonstrated consistent erosion patterns despite varying foundation materials (MSS4, MSS5, and MSS7). This finding aligns with the work of Fell and Fry (2007), who discussed the critical influence of material compatibility on erosion processes. Each case exhibited rapid erosion initiation on the downstream slope leading to crest and upstream slope failures within 1 to 1.5 min, indicating that levee material properties influence overtopping erosion behavior like the observations made by Islam and Tsujimoto (2015) and Coleman et al. (2002) on overtopping levee breach failures in earth dams and levees.

The findings suggest that under overtopping conditions, the levee materials (MSS7 and MSS8) make them more susceptible to rapid surface erosion. This consistent erosion pattern across different foundation materials implies that, while foundation material properties are important, the primary focus should be on selecting erosion-resistant levee materials to withstand overtopping forces.

4.6 Implications for Levee Design

The findings of this study hold significant implications for designing resilient levee systems, emphasizing the critical role of material compatibility between levee and foundation materials. The summary of experimental results has been listed in Table 4, exemplified by cases like IO-E7-F5 and SE-S87 with minimal downstream slope failure and no failure, underscoring the benefits of matching grain size and fineness. This aspect is further underscored by real-world examples. For instance, the catastrophic levee failures during Hurricane Katrina in New Orleans (Sills et al. 2008; Newberry 2010) and the Tori Levee breach during the 2010 Pakistan floods (Naeem et al. 2021) illustrate how mismatches in material properties can lead to severe consequences. Similarly, in Japan, the 2018 flooding in Hiroshima and the Yabe River levee failure during the 2012 North Kyushu rains due to piping from the foundation (Yoshikawa and Kodaka 2017) highlighted the vulnerabilities of levees due to seepage and infiltration issues. Other notable failures include the levee of the Ombrone Pistoiese River in Italy induced by seepage during the 2009 flood event (Michelazzo et al.2018), the Attabad Lake landslide dam in Pakistan 2010 due to piping and subsequent erosion (Gardezi et al.2021) and the Riotoro landslide dam in Costa Rica (Schuster and Highland (2001) further demonstrating the impact of erosion and slope instability. These incidents highlight how differences in material properties can lead to catastrophic failures. Scaling considerations in our flume experiments aimed to simulate real-world conditions, ensuring applicability by maintaining similarity in hydraulic conditions. Numerical simulations are recommended for generalizing optimal levee and substrate material conditions. This integrated approach enhances understanding and guides future research toward more resilient levee designs.

5 Conclusion

This study comprehensively investigated the erosion dynamics of earthen levees under both seepage and overtopping failure conditions using various combinations of foundation and levee materials. Key findings from the six experimental cases reveal the critical influence of material compatibility on levee stability and erosion resistance.

-

Case I SE-S74 and Case III SE-S85 demonstrated significant erosion, with 100% downstream slope failure and 30% and 35% crest erosion, respectively. The high hydraulic conductivity ratio between the foundation and levee materials (kE/kF ≈ 60) influenced to rapid phreatic line movement and accelerated erosion.

-

In contrast, Case V SE-S87, which featured a lower hydraulic conductivity ratio (kE/kF ≈ 8), showed no signs of erosion, highlighting the importance of minimizing hydraulic conductivity differences to enhance erosion resistance.

-

Overtopping erosion cases experienced rapid external progressive erosion on the downstream slope within 1 to 1.5 min, despite differences in foundation materials. The results indicate that a smaller difference in hydraulic conductivity between the levee and foundation materials delays erosion, highlighting the considerable influence of material properties on erosion rates. The consistent behavior observed across these cases emphasizes the dominant role of levee material in controlling overtopping erosion.

-

The experimental and theoretical analysis of seepage erosion in levee structures demonstrates that the erosion rate (E) is significantly influenced by the hydraulic conductivity of the foundation soil. Cases with coarser foundation materials (MSS4) exhibited higher erosion rates, leading to more severe structural failures, including complete downstream slope failures and notable crest failures. Conversely, cases with finer foundation materials (MSS7) showed lower erosion rates, resulting in less severe or no structural failures. This correlation underscores the importance of selecting foundation materials with lower hydraulic conductivity to enhance the stability and resilience of levee structures against seepage erosion.

The findings underscore the necessity of carefully selecting and optimizing foundation and levee materials to mitigate erosion risks. Ensuring material compatibility, particularly by reducing differences in hydraulic conductivity, can significantly enhance levee resilience against both seepage and overtopping erosion. Future research should further explore these relationships to develop even more effective strategies for erosion resistance in levee systems.

Data Availability

No datasets were generated or analysed during the current study.

References

Ali L, Tanaka N (2023) Experimental investigation of levee erosion during overflow and infiltration with varied hydraulic conductivities of levee and foundation properties in saturated conditions. GeoHazards. 4(3):286-301.https://doi.org/10.3390/geohazards4030016.

Auerswald K, Fiener P, Martin W, Elhaus D (2014) Use and misuse of the K factor equation in soil erosion modeling: an alternative equation for determining USLE nomograph soil erodibility values. CATENA 118:220–225

Bear J (2013). Dynamics of fluids in porous media. Book by Courier Corporation.

Briaud JL, Ting FC, Chen HC, Gudavalli R, Perugu S, Wei G (1999) SRICOS: prediction of scour rate in cohesive soils at bridge piers. J Geotech Geoenviron Eng 125(4):237–246

Briaud JL, Chen HC, Govindasamy AV, Storesund R (2008) Levee erosion by overtopping in New Orleans during the Katrina Hurricane. J Geotech Geoenviron Eng 134(5):618–632

Chen Z, Stuetzle CS, Cutler BM, Gross JA, Franklin WR, Zimmie TF (2011). Analyses, simulations, and physical modeling validation of levee and embankment erosion in geo-frontiers 2011: Advances in Geotechnical Engineering Conference paper in Geotechnical Special Publication (pp. 1503–1513).

Coleman SE, Andrews DP, Webby MG (2002) Overtopping breaching of homogeneous embankments. J Hydraul Eng 128(9):829–883

Ebrahimi M, Mohammadi M, Meshkati SMH et al (2024) (2024) Embankment dams overtopping breach: A numerical investigation of hydraulic results. Iran J Sci Technol Trans Civ Eng. https://doi.org/10.1007/s40996-024-01387-9

Fell R, Fry JJ (2007) The state of the art of assessing the likelihood of internal erosion of embankment dams, water retaining structures, and their foundations. In Book Internal Erosion of Dams and Their Foundations, CRC Press, Year 2007:9–32

Ferrari A, Dazzi S, Vacondio R, Mignosa P (2020) Enhancing the resilience to flooding induced by levee breaches in lowland areas: a methodology based on numerical modeling. Nat Hazard 20(1):59–72

Fujita M, Hamaguchi N (2012) Japan and economic integration in east asia: post-disaster scenario. Ann Reg Sci 48:485–500. https://doi.org/10.1007/s00168-011-0484-y

Gardezi H, Bilal M, Cheng Q, Xing A, Zhuang Y, Masood T (2021) A comparative analysis of attabad landslide on january 4, 2010, using two numerical models. Nat Hazards 107:519–538

Gross JA, Stuetzle CS, Chen Z, Cutler B, Franklin WR, Zimmie TF (2010). Simulating levee erosion with physical modeling validation in International Conference on Scour and Erosion (ICSE-5) 2010 Conference paper in Geotechnical Special Publication (pp. 326–337). https://doi.org/10.1061/41147(392)31.

Hanson GJ, Simon A (2001) Erodibility of cohesive streambeds in the loess area of the midwestern USA. Hydrol Process 15(1):23–38

Heine RA, Pinter N (2012) Levee effects upon flood levels: an empirical assessment. Hydrol Process 26(21):3225–3240. https://doi.org/10.1002/hyp.8261

Igarashi Y, Tanaka N (2020). The effects of levee-breach timing at the upstream of the Tokigawa River and the junction section of the Tokigawa and Oppegawa Rivers on the flood volume from the rivers. J Jpn Soc Civil Eng Ser B1 (Hydraulic Engineering). 76(1) 284–94

Igarashi Y, Tanaka, N (2020). The effects of levee breaching at the Irumagawa River Basin in Typhoon Hagibis 2019 on the flood volume from the rivers and discharge-hydrograph. J Jpn Soc Civil Eng, Ser. 76(2) I 637-I 642

Igarashi Y, Tanaka N (2022) The effects of levee-breach timing at the upstream of the Tokigawa river and the junction section of the Tokigawa and Oppegawa Rivers on the flood volume from the rivers. Journal of JSCE 10(1):213–227

Igigabel M, Diab Y, Yates ML (2021). Enhancing the resilience of levee systems through methodological developments. In FLOODrisk 2020–4th European Conference on Flood Risk Management (pp. null-null). Budapest University of Technology and Economics.https://doi.org/10.3311/FloodRisk2020.19.2.

Islam MS, Tsujimoto T (2015) Experimental and numerical approaches to overtopping levee breach effects in a river and floodplain. Am J Civil Eng 3(2):31–42. https://doi.org/10.11648/j.ajce.20150302.12

Jia Y, Ding Y, Wang X, Zhang J, Chen X (2022) A numerical analysis of the leakage characteristics of an embankment dam slope with internal erosion. Front Earth Sci 10:866238

Kawata Y (2008) Urban flood control policy for sustainability under global warming in Japan. WIT Trans Ecol Environ 118:273–282

Knighton D (2014) Fluvial forms and processes: a new perspective. Routledge

Kundzewicz ZW, Pińskwar I, Brakenridge GR (2013) Large floods in europe, 1985–2009. Hydrol Sci J 58(1):1–7. https://doi.org/10.1080/02626667.2012.745082

Lin SS, Zhang N, Xu YS, Hino T (2020) Lesson learned from catastrophic floods in western Japan in 2018: sustainable perspective analysis. Water 12(9):2489

Michelazzo G, Paris E, Solari L (2018) On the vulnerability of river levees induced by seepage. J Flood Risk Manag 11:S677–S686

Morrill-Winter J, Fields W, Needham JT (2017) Levee breach consequence model validated by case study in Joso. Association of State Dam Safety Officials Inc, Japan

Naeem B, Azmat M, Tao H, Ahmad S, Khattak MU, Haider S, Ahmad S, Khero Z, Goodell CR (2021) Flood hazard assessment for the tori levee breach of the Indus River Basin. Pak Wat 13(5):604

Nagasaka T, Nakamura Y, Yoshikawa K (2012) Maintenance and management of a continuous river levee system discussed from a damage-based viewpoint. J Jpn Soc Hydrol Wat Resources 25(4):226–242

Nagumo N, Ohara M, Kuribayashi D, Sawano H (2016) The 2015 flood impact due to the overflow and dike breach of Kinu River in Joso City. Jpn J Disaster Res 11(6):1112–1127

National Academy of Sciences (2013) Levees and the national flood insurance program: improving policies and practices. National Academies Press.

Newberry B (2010) Katrina: macro-ethical issues for engineers. Sci Eng Ethics 16:535–571. https://doi.org/10.1007/s11948-009-9167-9

O’Dell J, Nienhuis JH, Cox JR, Edmonds DA, Cussolini P (2021) A global open-source database of flood-protection levees on river deltas (openDELvE). Nat Hazards Earth Syst Sci Discus 2021:1–16. https://doi.org/10.5194/nhess-2021-291

of Geotechnical and Geoenvironmental Engineering, ASCE, 135(12): 1957–1970.

Ogura M, Tanaka N (2019). Erosion analysis by overflowing water on local river embankment and consideration of the effects of soil conditions on erosion. Journal of Japan Society of Civil Engineers, Ser. B1 (Hydraulic Engineering), 75(2), I_943-I_948.

Olson K, Matthews J, Morton LW, Sloan J (2015) Impact of levee breaches, flooding, and land scouring on soil productivity. J Soil Water Conserv 70(1):5A-11A. https://doi.org/10.2489/jswc.70.1.5A

Özer IE, van Damme M, Jonkman SN (2019) Towards an International Levee Performance Database (ILPD) and its use for macro-scale analysis of levee breaches and failures. Water 12(1):119. https://doi.org/10.3390/w12010119

Patel S, Gohil M, Pathan F, Mehta D, Waikhom S (2024) Assessment of flood risk and its mapping in Navsari district, Gujarat. Iran J Sci Technol, Trans Civil Eng 48(2):1021–1028

Sayers P, Galloway G, Penning-Rowsell E, Yuanyuan L, Fuxin S, Yiwei C, Kang W, Le Quesne T, Wang L, Guan Y (2015) Strategic flood management: ten ‘golden rules’ to guide a sound approach. Int J River Basin Manag 13(2):137–151. https://doi.org/10.1080/15715124.2014.902378

Schuster RL, Highland LM (2001). Socioeconomic and environmental impacts of landslides in the western hemisphere (No. 2001–276).

Sills GL, Vroman ND, Wahl RE, Schwanz NT (2008) Overview of new orleans levee failures: lessons learned and their impact on national levee design and assessment. J Geotech Geoenviron Eng 134(5):556–565

Starosolszky, Ö. (1994). Flood control by levees. In: Rossi, G., Harmancioğlu, N., Yevjevich, V. (eds) Coping with floods. NATO ASI Series, vol 257. Springer, Dordrecht. https://doi.org/10.1007/978-94-011-1098-3_37.

Tanaka N (2009) Vegetation bioshields for tsunami mitigation: review of effectiveness, limitations, construction, and sustainable management. Lands Ecol Eng 5:71–79. https://doi.org/10.1007/s11355-008-0058-z

Tanaka N, Yagisawa J, Yasuda S (2012) Characteristics of damage due to tsunami propagation in river channels and overflow of their levees in great east japan earthquake. Int J River Basin Manag 10(3):269–279

Van Heerden IL (2007) The failure of the New Orleans levee system following Hurricane Katrina and the pathway forward. Public Adm Rev 67:24–35

Van Beek VM, De Bruijn H T J, Knoeff J G, Bezuijen A, Förster U (2010). Levee failure due to piping: A full-scale experiment in proceedings 5th International conference on scour and erosion (ICSE-5), November 2010, San Francisco, USA. Reston, American Society of Civil Engineers. S. pp 283–292. https://hdl.handle.net/20.500.11970/100310.

Wan CF, Fell R (2004a) Investigation of rate of erosion of soils in embankment dams. J Geotech Geoenviron Eng 130(4):373–380

Wan CF, Fell R (2004c) Laboratory tests on the rate of piping erosion of soils in embankment dams. Geotech Test J 27(3):295–303

Xu, Y, Zhang, LM (2009). "Breaching Parameters for Earth and Rockfill Dams." Journal

Yen BC (1995). Hydraulics and effectiveness of levees for flood control. US- Italy Research Workshop on the Hydrometeorology, Impacts, and Management of Extreme Floods Perugia (Italy), November 1995.

Yoshida M, Kamiya D, Abe M (2019) Characteristics of disaster-related information in case of the heavy rain event of July 2018 A case study of Okayama, Hiroshima, and Ehime Prefectures. J Jpn Soc Civil Eng Ser B1 (Hydraul Eng) 75(1):350–361

Yoshikawa T, Kodaka T (2017) A consideration of the failure mechanism of river levees due to water seepage based on model tests and soil-water-air coupled finite deformation analysis. In: proceedings of the 19th international conference on soil mechanics and geotechnical engineering, pp 1319–1322

Author information

Authors and Affiliations

Contributions

All authors contributed to the concept and the development of the idea. Ali Liaqat contributed to the experimental setup and generation of results. Norio Tanaka contributed to the revision of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no competing interests to declare that are relevant to the content of this article.

The authors declare no competing interests.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ali, L., Tanaka, N. Enhancing Levee Resilience Through Material Compatibility: A Comprehensive Study on Erosion Dynamics. Iran J Sci Technol Trans Civ Eng (2024). https://doi.org/10.1007/s40996-024-01575-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40996-024-01575-7