Abstract

Clays are activated by a classic process and realized in relatively high temperatures. Increasing the clay surface acidity leads to the increase of the specific surfaces of clays with deeper destruction of their crystal lattice; with the training of amorphous silica. This later can cause many degradation reactions such as isomerization of polyunsaturated fatty acids, decomposition of unsaturated fatty acids and sterols, and to dehydration of sterols which leads to steradienes formation. With the aim to prepare bleaching earths with high efficiency, and having less negative effects, ultrasonic waves were introduced during activation process. The experimental conditions of this new activation process allowed the acid concentration and activation time to be considerably reduced. The influence of activated clays with ultrasound on physico-chemical properties of bleached oils, mainly on fatty acid composition, sterols, and steradienes was investigated. It was proved that these clays, activated with the new technique, led to the removal of unacceptable compounds with the least possible losses of oil and desirable fractions. The noticed losses in sterols were suggested to be strongly dependent on the influence of activation process, mainly on surface acidity of bleaching earths.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Refining process subjects vegetable oils to relatively high temperatures, alkali and acid mediums, resulting from bleaching earths and sodium hydroxide, and to metal processing equipment. These factors can be at the origin of various important modifications at the level of the physico-chemical properties of treated oils. Alterations noted in minor components of refined vegetable oils are of great interest to be considered in studies from nutritional viewpoints (Rabascall and Riera 1987).

The bleaching on activated clays allows mainly, eliminating the colored pigments and undesirable constituents (Henderson 1993). Clays, activated by the classic process, present very important acidities of surface which can be at the origin of numerous reactions of chemical degradation at the level of the glyceridic part and minor fractions of bleached oils (Bonvehi et al. 2001).

Indeed, the classic activation, realized generally in the presence of solutions highly concentrated by sulphuric acid and in temperatures relatively high, leads by the increase of the specific surfaces of clays, in a very deep destruction of their crystal lattice with the training of amorphous silica and increasing the clay surface acidity (Margulis 1985). This may later cause many degradation reactions such as isomerization of polyunsaturated fatty acids, decomposition of unsaturated fatty acids and sterols, and to the dehydration of sterols which leads to steradienes formation (Bonvehi et al. 2001).

To prepare bleaching earths with high efficiency, and having fewer negative effects, we have introduced ultrasonic waves during activation process. The action of ultrasound is mainly mechanical towards solid bodies, leading to fragmentation and surface activation, due to the implosion of bubbles by microjets of liquid. The cavitation phenomenon, which is composed of nucleation, growth and implosion of cavitation bubbles, favors the impregnation of reagents on the solid catalytic support (Margulis 1985). The experimental conditions of this new activation process allows the acid concentration and activation time to be reduced considerably.

In the present work, two approaches were evaluated. The first part concerns the optimization of the main parameters of activation such as; the concentration of the sulphuric acid, the duration of attack and the amplitude of ultrasound waves. Clays activated in the new conditions were characterized by the determination of their specific surfaces, their chemical compositions and by the IR and RX techniques. The second part is reserved for the study of the consequences of this mode of activation on the physico-chemical properties (acidic composition, composition of the minor part of bleached oil).

2 Materials and Methods

2.1 Materials

Olive oil and neutralized pomace–olive oil were provided by Agrozitex Refinery (Sfax, Tunisia). Commercial bleaching earth ‘actisyl’ (Südchemie, Germany) was considered as a reference. The raw material used for the preparation process of bleaching earths with ultrasound was selected from the south of Tunisia (El Hamma-Gabes). All used chemicals were of analytical grade.

2.2 Activation Process and Bleaching Conditions

2.2.1 Classic Activation Process

Optimal activation conditions of raw clay using classic process were released in our laboratory and presented in previous published work (Jahouach et al. 2006). Bleaching earths T1 (20 g/200 ml of H2SO4 15 N at 70 °C and during 3 h) and T2 (20 g/200 ml of H2SO4 15 N at 70 °C and during 6 h), having the highest adsorption capacity against pomace–olive oils, were considered as references to discuss the results shown in the present work.

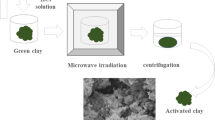

2.2.2 Activation Process with Application of Ultrasound

Activation process was achieved at low frequencies of ultrasonic waves (20 kHz), with the aim to prepare bleaching earths, using sulphuric acid. An ultrasonic generator type Bioblock Scientific 750 W was used. It is fitted with an immersible probe that is dipped in the liquid at the top of the tank and emits the sound vibration into the solution via a titanium alloy rod of 13 mm diameter.

The considered activation parameters in this process are:

-

acid concentration: 0.5–2.5 mol/l;

-

activation time: 30–60 min;

-

amplitude of ultrasonic waves: 25–75 %;

-

temperature: 30 °C.

Activated clay samples were then washed with bi-distilled water, filtered, dried and then screened from humidity. The variation of activation conditions (Table 1 ) has enabled a dozen of bleaching earths to be prepared. Specific surfaces of raw and activated clays have been determined according to BET analytical method (Brunauer-Emmett and Teller) with nitrogen adsorption, using an ASAP 2010 system (Jouenne 1990).

2.2.3 Bleaching Conditions of Adsorption Capacity (Bleaching Index)

The adsorption performance of clays activated with ultrasound was assessed by bleaching tests neutralized pomace–olive oils, using an atmospheric batch system. This process consisted of mixing neutralized oils with 2 % (g/g) acid activated clays at a temperature of 85 °C, stirring for 45 min followed by centrifugation (4000 trs/min) and filtration, to provide clean and clear oils.

The efficiency of bleaching was released by measuring the absorbance of neutralized and treated oils at 500 nm, using a NOVASPEC II spectrophotometer. The adsorption capacity of bleached oils is given by the Eq. (1).

I B is the bleaching index (%), A 500 is the oil absorbance at 500 nm.

Conditions giving the highest adsorption efficiency were considered as optimum for the new developed activation process.

2.3 Analytical Methods of Bleached Oils

A detailed analytical study of fatty acid composition and principal minor components of bleached oils has been released with the aim of investigating the influence of bleaching on physico-chemical properties of treated oils.

2.4 Fatty Acid Composition

Fatty acid composition was determined following the official AOCS method (1997). A Hewlett Packard 5890 series II gas chromatograph (GC) equipped with flame ionization detector was used. Methyl esters of fatty acids were analyzed on a CPSIL capillary column (25 m, 0.25 mm i.d., 0.2 μm film thickness). The oven temperature was programmed from 100 to 150 °C at 4.8 °C/min, then from 150 to 170 °C at 1 °C/min and held at 170 °C for 10 min.

2.5 Sterol Composition

Total sterol analysis was carried out according to DGF official method with a modification adapted to olive oils (Verleyen et al. 2002a, b, c). Gas chromatographic separations were performed on a HP 6890 series gas chromatographic system, equipped with capillary column EC5 (30 M, 0.25 mm, 0.25 μm), using helium as a carrier gas with a velocity of 20 cm s−1 and a split ratio of 1:10. A temperature program with injection at 285 °C, holding for 30 min and rising at 10 °C/min to 300 °C that are held for 10 min, was considered to separate the different components. Detection was done by flame ionization with the detector temperature set at 360 °C. Identification of sterols was performed according to the relative retention time reported in the COI analysis method (International Olive Oil Council 1992) and confirmed by GC/MS. The mass spectrometry technique allowed different components to be identified by comparing their mass spectra with those presented by the data base (Wiley 6th and the NIST Mass Spectral Library-1998) and by literature (Van Hoed et al. 2006; Lognay et al. 1993). Concentration of the different sterols present in oils was expressed as mg sterol/100 g of oil. Cholesterol was used as an internal standard for determining response factors.

2.6 Steradienes

Stigmastadienes, present in bleached oils were analyzed according to the DGF Official method (Fiebig 1999). This method involves separation of lipid classes on a silica gel chromatographic column, followed by HPLC analysis. Liquid chromatographic separations were performed on a HPLC chromatograph (KONTRON 422), equipped with a reversed-phase on a column Lichrospher RP18 (particle size 5 μm, 250 mm × 4.6 mm id). Steradienes were eluted with 1 ml/min isocratic flow rate of acetonitrile/tert-butyl methyl ether (7/3 v/v). UV detection was released at 235 nm.

2.6.1 Metal and Chlorophyll Contents

Phosphorous (P), iron (Fe), calcium (Ca) and magnesium (Mg) were quantified by inductive coupled plasma (ICP), according to the analytical official method AOCS (2000). The analysis was performed on a Thermo Jarell-Atom Scan 25 system (1350 W, flow rate: 1.5 l/min).

The chlorophyll (pheophytin) contents in bleached oils, residual from the neutralization, were determined according to the official method (Wolf 1992a, b). Which is based on quantification by a spectrophotometric analysis. The amount of chlorophylls in treated oils, calculated relatively to neutralized oil, were given according to the Eq. (2):

where A 630, A 670, A 710 are, respectively, absorbance of oil at 630, 670 and 710 nm, L is the cell width (1 cm).

It has to be mentioned that all analyses were performed in triplicate and the mean values were reported.

3 Results and Discussion

A dozen bleaching earths (T1, T2, …, T10) have been prepared by varying principal activation parameters: acid concentration, activation time and the amplitude of ultrasonic waves. The temperature is maintained constant at 30 °C. These activated clays, used in bleaching pomace–olive oils containing more than 20 ppm of chlorophyll have contributed to results presented in Table 1.

According to these results, the application of ultrasound during the activation process enabled bleaching earths to be prepared with high performance in quite moderate conditions, compared to classic activation process (acid concentration = 10 M, activation time = 6 h and T = 120 °C (Jahouach et al. 2006; Taylor and Jenkins 1988; Gannouni et al. 1999), which are relatively too severe. In fact, optimal bleaching earths, prepared with the new process, were obtained for very low concentration 0.5 M, at 30 °C and during 30 min. The performance of these results was attributed, essentially, to the action of ultrasonic waves by increasing the dispersion of clay particles. In consequence, they contributed to the increase of contact surface of clay particles with acid solution by cavitation phenomenon (Mason 1998).

In fact, because of the immense temperatures and pressures, high heating and cooling rates generated by cavitation bubble collapse, and ultrasound provides an unusual mechanism for generating high-energy chemistry (Mason 1991). The transfer of acoustic energy to the product considered by activation is instantaneous and throughout the whole product volume. This contributes to a reduction of the total processing time (Mason 1998; Povey and Mason 1998; Suslick 1988). The microjets of the liquid (sulphuric acid solution), resulting from the implosion of cavitation bubbles, considerably increase the diffusion rate of acid solution in clay pores, which favors the cation exchange reaction on its internal surface (exchange of protons against clay metallic cations).

Selected activated bleaching earths (T3, T6, T8), having the highest performance, were considered to evaluate the consequences of the new activation method on stability of bleached oils. Activated clays Tc1 and Tc2, prepared by applying the classic process on the same raw material, using sulphuric acid, were considered in this study with the commercial earth (Actisyl) while the objective is to investigate the influence of activation processes on physico-chemical properties of treated oils.

Neutralized pomace–olive oil, containing 20 ppm of chlorophylls, was treated with activated earths, prepared in optimal experimental conditions mentioned in Table 2.

Illustrated results showed that bleaching permitted, in all considered cases, the removal of almost all pigments. These results are in agreement with international standards, relative to pomace–olive oil IOC (1995).

3.1 Influence of Activation Process on Fatty Acid Composition

According to results of gas chromatographic analysis illustrated in Table 3, no significant modifications were detected in fatty acid composition of bleached oils. It appears that activation process did not have any influence on fatty acids, and especially on unsaturated ones, contrary to the established results in many recent studies (Brimberg 1982; Wolf 1992a, b). In fact, these studies recorded the appearance of isomerization reactions in unsaturated fatty acids, attributed generally to a substantial increase of surface acidity of bleaching earths, activated in very hard experimental conditions (Wolf 1992a, b).

3.2 Influence of Activation Process on Sterols

Industrial processes of edible oils and fats lead to the formation of several undesirable products such as steradienes, which results from sterol dehydration (Ferrari et al. 1996). Sterol losses during refining process are extremely dependant on operating conditions of different steps of this chemical treatment. Many parameters can contribute to the loss of sterols during bleaching step such as adsorption, condensation, decomposition (Weber et al. 1992), isomerization and dehydration (Verleyen et al. 2002a, b, c; Pizzoferrato et al. 1993).

Sterolic compounds (phytosterols) were identified by the relative retention times revealed in their GC–MS chromatograms, by analyzing their major ion fragmentation (Van Hoed et al. 2006; Lognay et al. 1993). It appears, according to results presented by Table 4, that the principal sterolic compounds detected in neutralized and bleached pomace–olive oils are: β-sitosterol, Δ5-avenasterol, campesterol and campestanol. The identified terpenic alcohols are: cycloartenol, 24-methylenecycloartanol and citrostadienol.

Total sterol contents (Table 5) of neutralized and bleached pomace–olive oils, ranged between 608.5 and 687.7 mg/100 g of oil. These oils were very rich in β-sitosterol and 24-methylènecycloartanol. They contained less amounts of cycloartenol, Δ5-avénasterol, citrostadienol and traces of campesterol and campestanol. In all considered samples, no stigmasterol was detected in total sterol fraction, generally promoted by high temperatures during processing (Verleyen et al. 2002a, b, c). It seems that activation methods are strongly implicated in the influence of bleaching earths on sterolic composition of treated oils (Table 5). The highest total sterol losses (11 %) were noted in oils bleached by activated clays Tc1 and Tc2, prepared by classic process which used concentrated sulphuric acid solutions. On the other hand, bleaching earths T3, T6 and T8, activated using ultrasound, led to total sterol losses that were relatively less important (0.8–4.2 %). It was noted that activated clay T3 (prepared with 0.5 M acid solution) led to a loss of 0.9 % in total sterols, less than those noted in the case of bleaching with activated clays T6 (2.9 %) and T8 (4.2 %) (prepared with sulphuric acid concentrations, respectively, of 1.5 and 2.5 M). In fact, the dehydration and isomerisation of sterols (Verleyen et al. 2002a, b, c) as well as their oxidation to hydroperoxides (Pizzoferrato et al. 1993) or sterol condensation leading to disteryl ethers formation (Weber et al. 1992) during bleaching process upon contacting the surface of the acid activated clays in combination with a sterol adsorption in the pores of bleaching earths might explain their reduction (Verleyen et al. 2002a, b, c).

Total sterol losses were accompanied with steradienes formation. Besides, the analysis of dehydrated components has gained importance as a method to detect bleached oils and fats. These steradienes are useful as proof that oils have undergone a bleaching process in relatively hard conditions. These compounds, noted generally during bleaching, are due to acid-catalyzed dehydration on the surface of the acid activated bleaching earths and/or to dehydration promoted by heating (Ferrari et al. 1996), leading generally to 3,5-stigmastadiene formation (Verleyen et al. 2002a, b, c), through the reactional mechanism, outlined in Fig. 1.

According to these results, it is clear that activation method and preparation conditions of bleaching earths, mainly the acid concentration solution, have an important influence on the chemical composition of sterolic fraction in bleached oils. In fact, activation process using high concentrated acid solutions, has contributed to an increase of clay surface acidity which could be the origin of many undesirable reactions such as sterols dehydration. Applying ultrasonic technique during activation process contributed to bleaching earths with high efficiency, characterized with important adsorption capacity and a low surface acidity. In consequence, a significant interaction term was deduced between optimum conditions of the new activation process and losses in total sterols.

The variation of the sterolic composition can significantly influence the oxidative stability of bleached oils.

3.3 Determination of Metal Traces

Generally, oxidation of vegetable oils is influenced by the presence of pro-oxidants (traces of metals), which are characterized by their undesirable effects on oil stability and their flavor composition (Velasco and Dobarganes 2002; Smouse 1994). These traces of metals, persisting generally from industrial extraction and refining process, have to be removed during bleaching stage. Results presented in Table 6 show a decrease in phosphorous, iron and calcium amounts in oils bleached by activated clays T3, T6 and T8. The persistent metal traces in bleached oils are acceptable and remain in accordance with limits fixed by international standards IOC (1995).

4 Conclusion

Applying ultrasonic waves during activation process contributed to very efficient bleaching earths, having properties similar to the commercial one. These activated clays, obtained using very low concentrated acid solutions (0.5 M), are characterized with very high adsorption capacity and a low surface acidity, and lead to many alterations such as isomerization and degradation of unsaturated fatty acids being avoided.

Principal minor components seem to undergo considerable changes that are strongly dependent on activation process and principal implicated parameters. Highest sterol losses were noted in oils bleached on clays activated with classic process (Tc1 and Tc2), which are prepared with the use of high concentrated acid solutions. The lowest losses were noted in oils bleached on clays activated with the new developed process, applying ultrasound. Decreases in total sterols were accompanied by formation of proportional quantities of 3,5-stigmastadienes, resulting from β-sitosterol dehydration.

To conclude, applying ultrasonic waves during activation process contributed to bleaching earths with high performance. The use of these activated clays prepared with low acid concentration and during short time, led to many alterations generally met in fatty acid composition or minor compounds during processing being avoided or reduced. Because of the efficiency and economic advantages of the new activation process using ultrasonic technique, it can be extrapolated to pilot scale with the aim of investigating its valorization in industry.

References

Bonvehi J, Serra S, Torrento MS, Ventura Coll FV (2001) A laboratory study of the bleaching process in stigmasta-3,5-diene concentration in olive oils. J Am Oil Chem Soc 78(3):305–310

Brimberg UI (1982) Kinetics of bleaching of vegetable oils. J Am Oil Chem Soc 59(2):74–78

Ferrari RA, Schulte E, Esteves W, Brühl L, Mukherjee KD (1996) Minor constituents of vegetable oils during industrial processing. J Am Oil Chem Soc 73(5):587–592

Fiebig HJ (1999) Determination of Δ3,5-steradienes in fats and oils. Lipid/Fett 101(11):442–445

Gannouni A, Bellagi A, Bagane M (1999) Préparation d’une argile activée pour la décoloration de l’huile d’olive. Ann Chim Sci Mat Fr 24:407–416

Henderson JH (1993) A laboratory study of the press effect in adsorptive bleaching. J Am Oil Chem Soc 70(9):831–835

International Olive Oil Council (1992) Determination of the composition and content of sterols by capillary-column gas chromatography. COI/T-20, Doc. No.10

International Olive Oil Council (1995) Commercial standard applied to olive and pomace-olive oil. Eur. Community. No. 2

Jahouach W, Essid K, Trabelsi M, Frikha MH (2006) Alteration of chemical composition and the oxidative stability of bleached pomace-olive oil on activated clays. J Agric Food Chem 54(19):7137–7143

Jouenne GA (1990) Traité de céramique et matériaux minéraux. Septima, Paris, pp 294–295

Lognay G, Lacoste F, Marlier M, Mordret F, Auge C, Raoux R, Wagstaffe PJ, Boenke A, Severin M (1993) The certification materials by GC-MS. Fat Sci Technol 3(1):98–104

Margulis MA (1985) Theory kinetic and mechanism of acousto chemical reaction. Ultrasonics 23(4):157–166

Mason TJ (1991) Practical sonochemistry. Ellis Horwood, New York

Mason TJ (1998) Power ultrasound in food processing—the way forward. Blackie Academic & Professional, London

Official Method (1997) Determination of fatty acids in edible oils and fats by capillary GLC. Ce 1e-91, Am Oil Chem Soc, USA

Official Methods and Recommended Practices (2000) Determination of metal traces. Am Oil Chem Soc, Ca 20–99, USA

Pizzoferrato L, Nicoli S, Lintas C (1993) GC-MS characterization and quantification of sterols and cholesterol oxidation products. Chromatographia 35(5):269–274

Povey MJW, Mason TJ (1998) Ultrasound in food processing. Academic Press, London

Rabascall NH, Riera JB (1987) Variaciones del contenido en tocoferoles y tocotrienoles durante los procesos de obtencione hidrogenacion de aceites comestibles. Grasas Aceites 38(3):145–148

Smouse TH (1994) Factors affecting oil quality and stability. In: Warner K, NA, Eskin M (eds) Methods to assess oil quality and stability. The American Oil Chemist Society, Champaign

Suslick KS (1988) Ultrasound, chemical–physical and biological effects. VCH, London

Taylor DR, Jenkins DB (1988) Acid activated clays. Transactions 282:1901–1910

Van Hoed V, Depaemelaere G, Vila Ayala J, Santiwattana P, Verhé R, De Greyt W (2006) Influence of chemical refining on the major and minor components of rice bran oil. J Am Oil Chem Soc 83(4):315–321

Velasco J, Dobarganes C (2002) Oxidative stability of virgin olive oil. Eur J Lipid Sci Technol 104(104):661–676

Verleyen T, Forcades M, Verhé R, Dewettinck K, Huygebaert A, De Greyt W (2002a) Analysis of free and esterified sterols in vegetable oils. J Am Oil Chem Soc 79(2):117–122

Verleyen T, Cortes E, Verhé R, Dewettinck K, Huyghebaert A, De Greyt W (2002b) Factors determining the steradiene formation in bleaching and deodorization. Eur J Lipid Sci Technol 104(6):331–339

Verleyen T, Sosinska U, Ioannidou S, Verhé R, Dewettinck K, Huyghebaert A, De Greyt W (2002c) Influence of vegetable oil refining process on free and esterified sterols. J Am Oil Chem Soc 79(10):947–953

Weber N, Bergenthal D, Bruhl L, Schulte E (1992) Disterylether-artefacte derfettbleichung. Fat Sci Technol 94(5):182–192

Wolf JP (1992a) Investigation of the complex thermal behavior of fats. In: Karleskind A (ed) Manuel des corps gras. Lavoisier, Paris

Wolf RL (1992b) Trans-polyunsaturated fatty acids in French edible rapeseed and soybean oils. J Am Oil Chem Soc 69(2):106–110

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Essid, K., Jahwach-Rabai, W., Trabelsi, M. et al. Sterolic Composition of Neutralized Oils Bleached with Clays Activated with Ultrasound. Iran J Sci Technol Trans Sci 40, 183–189 (2016). https://doi.org/10.1007/s40995-016-0086-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40995-016-0086-8