Abstract

Inspired by plant roots, polypropylene fibers can be employed to improve the shear strength of soils. Since the previously applied studies focused on the drained and undrained strength of fiber-reinforced soils (FRS), the dual effects of the different strain paths and fiber contents on the strength properties have been neglected. Recently carried out investigations indicated that strain paths have significant effects on the behavior of soils, where a stable behavior in conventional tests can be changed to a completely unstable behavior. In this paper, the effects of the flexible fibers on the monotonic behavior of sands under different strain paths were investigated for the first time. There is not any previously applied study about the coupled volumetric–shear strain behavior of FRS and this research was aimed to explore such a behavior. Strain paths were conducted by applying controlled volumetric and shear strains, where the ratio between these strains was kept known for the undertaken tests. It is shown that the fiber inclusions can reduce the wrecking effects of strain paths until a threshold value of fiber content, while more fiber contents (more than the threshold value) can reduce their favorable influences. Effects of fiber content on the steady state and phase transformation stress ratios, maximum experienced shear stresses, and generated excess pore pressures were evaluated considering different strain paths, as well.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Mechanical properties of soils like strength and stability can be improved using soil reinforcement techniques. Application of geosynthetics such as geotextiles and geogrids is one of the conventional methods to enhance the strength of soils in a certain direction; however, in these approaches, weak planes can be generated on the interface of soils and geosynthetics. Inspired by the roots of plants, short fibers with a random distribution can be employed in soil improvement projects to increase the strength of soils against shear and tension stresses and to reinforce them against the generation of weak planes. The efficiency of the roots of plants on the stability of slopes and reinforcement of soils have been well discussed by previously applied studies. Consequently, same as the roots of plants, randomly distributed flexible fibers can be employed to improve the stability of slopes, as well as to remediate liquefiable sites.

Most of the applied studies on the mechanical behavior of fiber-reinforced soils (FRS) have reported a considerable enhancement in the peak strength, post-peak strength, and deformability of soils. Consoli et al. [1] investigated the strength of fiber-reinforced sands using the ring shear apparatus to evaluate the behavior of these soils under large strains. It has been revealed that application of the polypropylene fibers can significantly improve the shear strength parameters of sands for large deformations. Ibraim et al. [2] assessed the influences of randomly distributed polypropylene fibers on the strength of clean sands against static liquefaction. It has been shown that the application of the fibers can improve drainage conditions in the sand samples and can reduce the potential of liquefaction in these soils. Diambra et al. [3], using compression and extension triaxial tests, revealed that the fibers are most effective in increasing the strength of sands in the compression mode of shearing, while for extension mode, the effects are not considered. These results indicate the importance of the direction of fibers with respect to the applied loads. Hamidi and Dehghan [4], using triaxial compression tests, investigated the effects of the fibers on the strength properties, stiffness, and deformations of the cemented sands gravely. Using the drained and undrained tests, it was demonstrated that the application of fibers could increase the peak strengths and residual strengths of samples. In addition, it was shown that larger volumetric strains could be tolerated with samples reinforced by fibers; however, the tangent elastic modulus of samples at the onset of loading was decreased for the tested samples. Eldesouky et al. [5] evaluated the effects of fibers on the dilative behavior of sandy soils using direct shear tests. It was shown that an increment in the moisture content of soils could reduce the effects of fibers on the shear strength and dilation of samples. Eskisar et al. [6] investigated the influences of fibers on the strength of sands against liquefaction using undrained cyclic triaxial tests. Parameters such as fiber content, length of fibers, and density of soil were employed to assess effects of them on the liquefaction of samples. Li et al. [7] evaluated the effects of fiber reinforcement on the strength of the biologically treated sands. Mirzababaei et al. [8] investigated the effects of fiber inclusions on the physical and mechanical properties of clay samples. Yildiz et al. [9], by developing a large-scale direct shear apparatus, investigated the influences of plant roots (as natural fibers) on the strength of sands. Zhang and Russell [10] studied the effects of fibers on the static liquefaction of sands by conducting some consolidated undrained triaxial tests (under compression shearing mode). Ghadr and Bahadori [11] applied some hollow cylindrical torsional shear tests to investigate the anisotropic behavior of fiber-reinforced sands, and some other researchers assessed the influences of randomly distributed fibers on the shear failure of soil [12, 13]. Cardoza and Lalita [14] evaluated the effects of roots (as natural fibers) on the cohesion and friction angle of granular soils (with different grain sizes and distributions) using direct shear tests. It was shown that the existence of roots could increase the cohesion of soils significantly and can lead to an increment in friction angle as well. Lv et al. [15] utilized different types of fibers to provide additional reinforcement in bio-cemented sands. Besides the applied experimental studies on the effects of natural and synthetic fibers, the development of constitutive models to simulate the mechanical behavior of fiber-reinforced soils has been carried out by researchers [16,17,18]. Wang et al. [19] proposed a numerical approach based on the equivalent additional stress concept to predict the behavior of fiber-reinforced sands by considering the effects of fiber–soil interactions. Gao et al. [20] extended a constitutive model based on the model proposed by Li and Dafalias [21] to predict the behavior of fiber-reinforced sands. In this modified constitutive model, the effects of fibers on the effective void ratio and effective stresses are discussed. Previously, it was assumed that the conventional stress–strain paths (consolidated drained and consolidated undrained paths) are the most critical paths for soil behavior. Therefore, all of the mentioned studies have been applied by considering consolidated drained or undrained paths as the most critical paths for the strength of soils. However, recently conducted investigations revealed that the partially drained strain paths could lead to more crucial behavior in sandy soils. A partially drained path is a path in which both volumetric strains and excess pore pressures can be developed simultaneously in the soil media. Applied centrifuge tests by Adamidis and Madabhushi [22] demonstrated that the seismic responses of granular soils could not be considered a fully undrained procedure because of the unavoidable generation of pore water flow during the loading phase. Analytical models also have shown that liquefaction of sands would not occur only in fully undrained situations, and procedures such as rearrangement of particles, redistribution of voids, and flow of pore water can result in partial drainage in the liquefied soils [23]. Using element tests, Vaid and Eliadorani [24] have shown that a little water inlet during the shearing of soils can significantly alter the behavior of sands. By employing a digital pressure–volume controller apparatus and the triaxial tests, Gananathan [25] investigated the effects of different strain paths on the sands and revealed that the partially drained strain paths could result in a considerable softening in the samples. The same results have been reported by Sivathayalan and Logeswaran [26], Chu et al. [27], and Wanatowski et al. [28], which show the importance of the experienced strain paths on the response of soils. However, most of the studies about the partially drained behavior of soils have been conducted using triaxial tests; direct simple shear (DSS) apparatus can also be undertaken to study about effects of strain paths. To this aim, specified coupled volumetric–shear strain paths can be applied to the samples, where samples can experience both volumetric changes and excess pore water generation. Lashkari et al. [29] carried out such a study to evaluate the monotonic behavior of sands in partially drained conditions and to validate a state-dependent constitutive model for these paths. Tohidvand et al. [30] investigated the effects of partially drained paths on the monotonic, cyclic, and post-cyclic behavior of sandy soils using a direct simple shear (DSS) apparatus.

Besides the possible partially drained behavior of sands in conventional loading situations, fiber-reinforced sands have more potential to experience such behavior by improving the drainage condition like what can be observed by roots in nature. Therefore, soils adjacent to the fibers can behave like the soil media adjacent to a drainage path. The coupled volumetric–shear strain (partially drained) behavior of fiber-reinforced sands has not been studied yet, and this paper is organized to investigate the dual effects of these strain paths and fiber inclusions on the mechanical behavior of sands for the first time. In this research, coupled volumetric–shear strain behavior of FRS was compared with the conventional constant volume and constant pressure strain–stress paths. Effects of the induced anisotropy on the behavior of samples were discussed and the effects of different amounts of fiber content on the behavior of sands were evaluated. Details of the test procedure are presented in the next section, achieved results and discussions about them are given in “Results and discussion”, and the conclusions are provided in the last section.

Employed Materials, Apparatus, and Tests Procedures

Firoozkuh No. 161 Sand and Employed Polypropylene Fibers

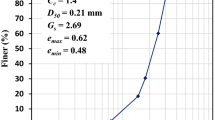

In this study, Firoozkuh No. 161 fine sand was used as granular soil material where different researches have been conducted on this soil, till now [29,30,31]. The selected sandy soil was industrially produced by crushing parent rocks and consists of particles with angular shapes. The particle size distribution of the employed sandy soil is presented in Fig. 1a, the SEM photo of the particles is given in Fig. 1b, and the main physical properties of the sand particles are detailed in Table 1.

The used polypropylene fibers are shown in Fig. 2, and the main physical and mechanical properties of the fibers are introduced in Table 2. As mentioned before, flexible fibers like polypropylene fibers can be employed to synthetically simulate the effects of the plant roots.

The Direct Simple Shear Apparatus

In this research, a fully automatic stack ring-type direct simple shear (DSS) apparatus was employed to investigate the behavior of sand samples under different strain paths. The used apparatus is shown in Fig. 3a, and the schematic view of the apparatus is shown in Fig. 3c. In this apparatus, the solid rings would not allow isotropic consolidation, which is a usual consolidation manner in the triaxial tests. However, the K0 consolidation was applied based on the limitations of the used apparatus; it should be considered that the K0 consolidation has more correspondence to what happened in nature. Isotropic consolidation is a rare phenomenon and can be considered a simplification of the stress state at the commencement of the shear loading phase. Direct simple shear devices have been mostly developed to assess soil behavior in plain strain conditions with K0 consolidation.

Strain paths are applied to the sample using controlled coupled volumetric to shear strain rates (dξv/dγ). In this paper, bilinear strain paths were employed to let the samples reach their steady state at the ultimate stresses (for the paths with a linear relationship between volumetric and shear strains, a steady state cannot be reached because of the non-constant volumetric deformations at large strains). The bilinear partially drained tests were applied in three phases; the first phase was for the consolidation of samples up to the targeted effective stress, the second phase was applied to conduct the first line of the bilinear strain paths, and the third one was applied for the second line of the bilinear strain paths. The third phase was equivalent to the constant volume condition, as the changes in the volumetric strains were equal to zero. The linear partially drained tests were applied in two phases; first, consolidation was applied, then the shearing phase was initiated. A sample of the conducted strain paths is given in Fig. 4, where it is compared with a sample linear strain path. It was shown by Monkul et al. [32] that both dry and saturated clean sands exhibited equivalent behavior under a constant volume or constant pressure direct simple shear tests. Therefore, it could be assumed that variations of total vertical stresses during shearing could be considered the same as the pore pressure variations, as is usual in most of the applied DSS tests (for example Lashkari et al. [29], Tohidvand et al. [30], Monkul et al. [32], Hubler et al. [33]). In addition, as the volume change in stake ring-type direct shear apparatus is one dimensional, volume changes were measured using the recorded changes in the height of the samples (changes of heights were measured by LVDT). The position of the used LVDTs is shown in Fig. 3c.

All of the samples (clean sands and fiber-reinforced sands) were prepared using the wet tamping procedure with moisture of 5%. Figure 3b shows one of the prepared samples inside the DSS cell. All of the used samples had a diameter of 7 cm and a thickness of 2 cm. In addition, it should be mentioned that, however, in some of the applied tests, the steady state was not achieved in the samples, the ultimate states in all of the tests were approaching such a steady condition. Therefore, the asymptotic state can approximately be considered as the steady state in the tests. In this paper, phase transformation was considered as the state of the transformation from a contractive (or dilative) behavior to a dilative (or contractive) one.

Experimental Procedure and Tests Program

In this paper, the consolidated constant volume and constant pressure strain–stress paths (equivalent to consolidated undrained and consolidated drained paths in the triaxial tests) were undertaken to evaluate the behavior of both clean sand (unreinforced) and reinforced sand on the conventional paths. In addition, bilinear strain paths with known values of volumetric and shear strains (an example can be seen in Fig. 4) were applied to the samples to assess the dual effects of different strain paths and fiber contents on the strength of sands. The coupled volumetric and shear strains can simulate a partially drained situation, as described by Lashkari et al. [29] and Tohidvand et al. [30]. The tests program is given in Table 3, where CPD means consolidated partially drained, CV and CP are used to recognize consolidated constant volume and consolidated constant pressure tests. As shown in Table 2, different fiber contents (FC), initial relative densities (Dr0), and different strain paths were employed to better illustrate the influences of effective parameters on the behavior of sands. In Table 2, Drac is the relative densities that were achieved after consolidation. As can be observed in Table 2, differences between after consolidation relative densities are negligible. In addition, as the initial relative densities were achieved by precise calculations and preparations, there is not any diversion from the aimed values in Dr0. The negligible differences in Drac values occurred because of the small errors between the targeted vertical stresses and the applied ones by the device. It should be noted that there are two different approaches in the preparation of FRS samples. In the first approach, some of the volumes of soil particles are replaced by fibers so that the specific volume of the FRS sample matches the specific volume of the plain sand [33]. In the second approach, the volume of sand is kept constant and the addition of fibers replaces some of the voids. In this approach, the specific volume will be kept constant [16]. In this research, the second approach was used; therefore, specific volumes of samples with constant fiber content were equal.

All of the tests were applied based on the published ASTM codes (ASTM D4253 to calculate emax, ASTM D4254 to calculate emin, ASTM D854 to calculate Gs (specific gravity of soil), ASTM D6913 to calculate particle size distribution, and ASTM D6528 for direct simple shear tests).

Results and Discussion

In this section, the achieved results of the conventional and partially drained tests (with known values of volumetric to shear strain increment) are presented and discussed. Effects of the strain paths on the different characteristic parameters of the clean sands and fiber-reinforced sands (FRS) are evaluated.

Effects on \(\left( {\tau /\sigma^{\prime}_{{\text{v}}} } \right)_{{{\text{ss}}}}\) and \(\left( {\tau /\sigma^{\prime}_{{\text{v}}} } \right)_{{{\text{PT}}}}\)

Stress ratios at the steady state (\(\left( {\tau /\sigma^{\prime}_{{\text{v}}} } \right)_{{{\text{ss}}}}\)) and phase transformation state (\(\left( {\tau /\sigma^{\prime}_{{\text{v}}} } \right)_{{{\text{PT}}}}\)) can be considered as the two main characteristic properties of soils that can identify stress–strain behavior of them. Previously applied studies indicated that different strain paths could affect these stress ratios due to the shearing of soil particles. However, the effects of the fiber content (FC) on the evolution of these stress ratios remained non-investigated yet. Results of the denser sand samples with Dr0 = 60% are presented in Fig. 5. Figure 5a shows that the stress paths of clean sands are affected by different strain paths significantly. It can be seen in Fig. 5a that the contractive behavior of samples is magnified by increasing the ratio of the volumetric strain increments to the shear strain increments (dξv/dγ) from zero (which corresponds to the constant volume tests) to + 0.5%. In contrast to the expansive paths (positive values of dξv/dγ), the contractive paths lead to more increment in the strength of samples. Figure 6a shows changes in the mobilized stress ratios of clean sands. As can be seen in this figure, achieved stress ratios are affected by strain paths considerably, where the steady-state stress ratio is increased from 0.51 (for dξv/dγ = − 2%) to 0.61 (dξv/dγ = + 0.5%). Stress paths of the fiber-reinforced sands under different strain paths are given in Fig. 5b, c. Differences between the behaviors of samples with different strain paths are ignorable for tests with 0.1% and 0.25% of fiber contents. However, these differences are increased again for tests with 0.5% of fiber content. Such behavior indicates that the inclusion of fibers can reduce the effects of induced strain paths on the experienced stress paths of samples until a certain (threshold) amount. The larger amount of fibers can reduce the resistance of FRS against different strain paths. Figure 6d shows that the samples with 0.5% of fibers have almost the same stress ratio evolution during tests, whereas based on the results depicted in Fig. 6a–c, other samples have experienced considerably different evolution paths.

Changes in the steady-state stress ratios with respect to different values of dξv/dγ are presented in Fig. 7a. As demonstrated in this figure, for clean sand, increment of dξv/dγ resulted in increment of steady-state stress ratio (\(\left( {\tau /\sigma^{\prime}_{{\text{v}}} } \right)_{{{\text{ss}}}}\)). Clean sand samples exhibited an incremental behavior for steady-state stress ratios by increasing values of dξv/dγ, while FRS samples showed different behavior. For example, samples with 0.1% of fiber show first a decrement in the values of \(\left( {\tau /\sigma^{\prime}_{{\text{v}}} } \right)_{{{\text{ss}}}}\), then these values increased by increasing values of dξv/dγ. Besides the samples with 0.5% of fibers, other samples exhibited almost the same steady-state stress ratio for tests with dξv/dγ = 0.5%. Such results indicate the importance of strain paths on the steady-state behavior of fiber-reinforced sands. As is shown in Fig. 7b, small changes in the induced strain path can significantly change the steady-state behavior of FRS samples. The same trend can be found for phase transformation stress ratios (\(\left( {\tau /\sigma^{\prime}_{{\text{v}}} } \right)_{{{\text{PT}}}}\)) as shown in Fig. 7c and d. For contractive strain paths \(\left( {\tau /\sigma^{\prime}_{{\text{v}}} } \right)_{{{\text{PT}}}}\) of the FRS samples are larger than the \(\left( {\tau /\sigma^{\prime}_{{\text{v}}} } \right)_{{{\text{PT}}}}\) values of the clean sand samples. However, for expansive strain paths, the occurred changes in the phase transformation stress ratios depend on the fiber content. A threshold fiber content can be observed again for the phase transformation stress ratios. These results demonstrate that a sample with a constant percentage of fibers can behave differently under different strain paths. In addition, for a certain strain path, crucial stress ratios of the FRS samples can be affected by changing the amount of fiber. Where, sometimes the occurred changes can result in the selection of uneconomical parameters, and ignoring the effects of expansive strain paths can result in the non-conservative selection of parameters.

Such a great influence of strain path on the steady-state behavior of sands can be reduced in loose sands, as shown in Fig. 8. In other words, denser FRS samples show more sensitivity against applied strain paths compared to loose sands. In the loose sands with fiber inclusions (synthetic or natural fibers), the steady-state stress ratio is always larger than the steady-state stress ratio of the clean sands, as shown in Fig. 8b. Therefore, for loose sands, constant volume tests can be applied to reach a conservative design; however, for dense or medium-dense sands, constant volume tests are not sufficient to safely determine the characteristic parameters of fiber-reinforced soils.

Effects on τ max

It has been revealed by previously applied studies that fiber-reinforced soils can resist larger shear stresses compared to clean sands (unreinforced sands). Results of the denser sand samples with Dr0 = 60% are presented in Fig. 9. This figure shows that the experienced maximum shear stress of clean and reinforced sands can be affected by strain paths. For clean sands, experienced τmax will be decreased in the expansive strain paths in comparison with the constant volume strain path, while these values will be increased by increasing induced strain ratios (dξv/dγ). The same results can be observed for FRS samples as shown in Fig. 9b–d. However, in contrast to the clean sands, τmax of FRS samples are larger than the τmax values of constant pressure tests for 0.1% and 0.25% of fiber content. Samples with 0.5% of fiber content exhibited almost the same behavior as the clean sands by considering changes of τmax for different strain paths. In other words, the reached values of τmax are reduced to smaller values in comparison with the achieved values of τmax for constant pressure tests in FRS samples with 0.5% of fiber.

Figure 10 shows that for loose sands, fibers not only increased the reached maximum shear stresses but also minimized the effects of different strain paths on the achieved values of τmax. Therefore, it can be inferred that experienced strain paths can affect the behavior of denser FRS samples more than looser ones.

Effects on u f and EPP

Generated excess pore pressures (EPPs) during the shearing of sands can be affected by the induced strain paths significantly. Results of the denser sand samples with Dr0 = 60% are presented in Fig. 11. For clean sands (FC = 0%), as shown in Fig. 11a, expansive strain paths lead to positive EPPs. However, contractive strain paths resulted in negative values of EPPs, which corresponds to an increment in the shear strength of samples. For samples with 0.1% and 0.25% of fibers, all strain paths resulted in negative EPPs. In other words, the addition of fibers reduced the possibility of positive excess pore water generation and increased the strength of samples. For samples with FC = 0.5%, samples generated positive EPPs in expansive strain paths again (same as the behavior of clean sand samples). Such a trend can exhibit the importance of fiber content on the behavior of fiber-reinforced soils. Based on the achieved results, the correct selection of fiber content can improve the mechanical properties of sands, while exceeding the threshold values of fiber contents will lead to the return of unfavorable features to the soil mass. Such a behavior can be seen in Fig. 12, where a reduction in the ultimate values of EPPs (EPPf) before the threshold value of fiber contents and an increment of EPPs after those values can be seen. In addition, Fig. 12b shows that sufficient contents of fibers can reduce the generation of pore water pressures for all of the applied strain paths; however, for expansive strain paths (positive values of dξv/dγ), amount of this improvement is reduced.

Same to the other features of the fiber-reinforced sands discussed before, the effects of strain paths on the generation of pore water pressures are reduced for loose samples, as shown in Fig. 13. This figure shows that for both contractive and expansive strain paths, almost same trend in generation of EPPs will be achieved. In addition, Fig. 13 demonstrates that fiber reinforcement will reduce generated EPPs compared to clean sands significantly.

Interpretation of the Results

Gao et al. [20] proposed that the mean effective stress of the sand skeleton in the FRS samples would be larger than the mean effective stress of clean sands for their ultimate states. Therefore, the shear strength of FRS samples will be larger than the unreinforced sands. The same results were achieved in the applied tests for all of the conducted fiber contents and strain paths in this paper (unless the sample with 0.5% of fiber under an expansive strain path). However, Gao et al. [20] proposed this trend of behavior for compression triaxial tests; the achieved results demonstrated that this increment in the felt mean effective stress at large strains could be extended for simple shear tests and different strain paths. Figure 14b shows the amount of the increment in shear strength depending on the fiber content and strain path. Contractive strain paths lead to more increment in the shear strength, while expansive strain paths result in less increment. In other words, in the expansive strain paths, the sand skeleton feels less effective stress compared to contractive paths. Such behavior can be related to the deformation of fibers in different strain paths. In the expansive strain paths, pore water pressure increases because of the water inlet; therefore, not only particle-to-particle contacts will be decreased, but also particle-to-fiber contacts will be reduced. By decreasing contacts between particles and fibers, fibers will experience less deformation and will have less role in the shear strength of sands. Gao et al. [20] proposed Eq. (1) to calculate the modified mean effective stress of FRS samples in the compression triaxial tests.

where \({P}^{s}\) is the mean effective stress that feels by the sand skeleton, P is the mean effective stress of the clean sand, and \({P}^{f}\) is a strain-level-dependent variable. It was indicated that \({P}^{f}\) could be increased from zero (for zero deviatoric strains) to its maximum value at enough large strains. In this paper, it is shown that the value of \({P}^{f}\) not only depends on the strain level but also depends on the strain path. In addition, for loose sands, as the void ratios are large enough to reduce particle-to-particle and particle-to-fiber contacts, expansive and contractive strain paths have fewer effects on the behavior of FRS samples compared to denser sands. In loose sands, the applied contractive strain paths should first lead to sufficient contact between particles and fibers to be able to exhibit their influences. For expansive strain paths, the strain rate cannot significantly affect particle-to-fiber contacts as these contacts are small at the initial state of the loose FRS samples. Therefore, the effects of the experienced strain paths are notable for dense or medium-dense samples; however, they are ignorable for loose sands. As described, the effects of strain paths are not considered for loose FRS samples because of enough void ratio to deal with the water inlet or outlet, fibers can increase the shear strength of these samples yet because of the additional stresses that are tolerated by fibers.

Interpretation of the threshold fiber content can be made by hiring the concept of effective void ratio that has been proposed for silty sands. Based on this concept, the increment of shear strength will be increased by increasing their content up to a certain value. Until this threshold value, fibers cannot provide a weak plane in the soil, as they cannot affect the number of particle-to-particle and particle-to-fiber contacts. By exceeding the fiber content from the threshold value, additional fibers will not participate in the aimed functionality of them, (they will not increase the shear strength more). Instead of the targeted role of the fibers, the additional fibers will reduce the connection of sand particles compared to the FRS samples with efficient fiber content. In this paper, maximum fiber content is selected equal to 0.5%; therefore, additional fibers only reduced the strength of samples compared to other FRS samples and increased the strength compared to clean sands. However, it is obvious that if an ideal sample with 100% of fibers could be prepared, the shear strength would be less than the clean sand (FC = 0%). The same behavior can be found in silty sands, where exceeding the silt content from the threshold content will have resulted in the separation of sand particles and a reduction in the shear strength.

Conclusion

In this paper, the effects of the flexible fibers on the behavior of sands under different strain paths are evaluated for the first time. Geosynthetic and natural fibers (roots) can increase the stability and strength properties of soils; however, non-conventional strain paths can affect such an improving effect. The main achievements of this research can be summarized as follows:

-

It is shown that an experienced strain path can influence both steady state and phase transformation stress ratios of clean sands significantly. For example, the steady-state friction angle varies from 28° to 34° for paths with dξv/dγ = − 2% to dξv/dγ = + 0.5%.

-

By employing polypropylene fibers to prepare FRS samples, it is demonstrated that the fiber content can reduce the effects of different strain paths on the characteristic stress ratios of sands. For example, differences between maximum and minimum steady-state friction angles reduce from 6° to 2° for paths with dξv/dγ = − 2% to dξv/dγ = + 0.5%, respectively, in clean sand and FRS sand with 0.5% fiber.

-

In addition, the stress paths of sands under various strain paths will be almost the same as the conventional constant volume strain path for FRS samples with fiber content less than a threshold value. By exceeding fiber content from the threshold value, the experienced stress paths will approach the clean sand's stress paths under different strain paths.

-

The favorable effects of fibers will be decreased by exceeding the threshold fiber content. Based on the applied tests and achieved results, it is exhibited that the flexible fibers can reduce the generation of excess pore pressure and consequently increase the shear strength of soils. Such an improvement will be reduced if the fiber content exceeds the threshold value again.

-

The results indicate that denser FRS samples are more sensitive to the applied strain path compared to loose FRS samples. For loose FRS samples, it is shown that the sandy soil exhibited almost the same behavior against contractive and expansive strain paths.

Data Availability

The authors confirm that the data supporting the findings of this study are available within the article. Raw data that support the findings of this study are available from the corresponding author, upon reasonable request.

References

Consoli NC, Casagrande MDT, Coop MR (2007) Performance of a fibre-reinforced sand at large shear strains. Géotechnique 57(9):751–756. https://doi.org/10.1680/geot.2007.57.9.751

Ibraim E, Diambra A, Wood DM, Russell AR (2010) Static liquefaction of fibre reinforced sand under monotonic loading. Geotext Geomembr 28(4):374–385. https://doi.org/10.1016/j.geotexmem.2009.12.001

Diambra A, Ibraim E, Wood DM, Russell AR (2010) Fibre reinforced sands: experiments and modelling. Geotext Geomembr 28(3):238–250. https://doi.org/10.1016/j.geotexmem.2009.09.010

Dehghan A, Hamidi A (2015) Impact of fiber reinforcement on deformation characteristics of cemented sand-gravel mixtures. J Eng Geol 9(2):2730. https://doi.org/10.18869/acadpub.jeg.9.2.2729

Eldesouky HM, Morsy MM, Mansour MF (2016) Fiber-reinforced sand strength and dilation characteristics. Ain Shams Eng J 7(2):517–526. https://doi.org/10.1016/j.asej.2015.06.003

Eskisar T, Karakan E, Altun S (2016) Effects of fiber reinforcement on liquefaction behavior and pore pressure development of sand. In: Proceedings of the 12th international congress on advances in civil engineering (ACE 2016)

Li M, Li L, Ogbonnaya U, Wen K, Tian A, Amini F (2016) Influence of fiber addition on mechanical properties of MICP-treated sand. J Mater Civ Eng 28(4):04015166. https://doi.org/10.1061/(ASCE)MT.1943-5533.0001442

Mirzababaei M, Arulrajah A, Haque A, Nimbalkar S, Mohajerani A (2018) Effect of fiber reinforcement on shear strength and void ratio of soft clay. Geosynth Int 25(4):471–480. https://doi.org/10.1680/jgein.18.00023

Yildiz A, Graf F, Rickli C, Springman SM (2018) Determination of the shearing behaviour of root-permeated soils with a large-scale direct shear apparatus. CATENA 166:98–113. https://doi.org/10.1016/j.catena.2018.03.022

Zhang X, Russell AR (2020) Assessing liquefaction resistance of fiber-reinforced sand using a new pore pressure ratio. J Geotech Geoenviron Eng 146(1):04019125. https://doi.org/10.1061/(asce)gt.1943-5606.0002197

Ghadr S, Bahadori H (2019) Anisotropic behavior of fiber-reinforced sands. J Mater Civ Eng 31(11):04019270. https://doi.org/10.1061/(ASCE)MT.1943-5533.0002917

Çelik S, Ghalehjough BK, Majedi P, Akbulut S (2017) Effect of randomly fiber reinforcement on shear failure surface of soil, behind flexible retaining walls at different conditions. http://nopr.niscpr.res.in/handle/123456789/42750

Dogan Kucukcongar Ş, Çelik S, Karimi Ghalehjough B (2022) Experimental and numerical investigation for estimating optimal depth-bearing capacity of randomly fiber-reinforced sandy soils. J Sci Ind Res 81(10):1037–1049. https://doi.org/10.56042/jsir.v81i10.62442

Kavazanjian E, Hambleton JP, Makhnenko R, Budge AS (2020) Geo-congress 2020: biogeotechnics. American Society of Civil Engineers, Reston, pp 214–223. https://doi.org/10.1061/9780784482834.024

Lv C, Zhu C, Tang CS, Cheng Q, Yin LY, Shi B (2021) Effect of fiber reinforcement on the mechanical behavior of bio-cemented sand. Geosynth Int 28(2):195–205. https://doi.org/10.1680/jgein.20.00037

Wood DM, Diambra A, Ibraim E (2016) Fibres and soils: a route towards modelling of root-soil systems. Soils Found 56(5):765–778. https://doi.org/10.1016/j.sandf.2016.08.003

Ghadr S, Samadzadeh A, Bahadori H, Assadi-Langroudi A (2020) Liquefaction resistance of fibre-reinforced silty sands under cyclic loading. Geotext Geomembr 48(6):812–827. https://doi.org/10.1016/j.geotexmem.2020.07.002

Ghadr S, Bahadori H, Assadi-Langroudi A (2019) Anisotropy in sand–fibre composites and undrained stress–strain implications. Int J Geosynth Ground Eng 5:1–13. https://doi.org/10.1007/s40891-019-0174-x

Wang Y, Guo P, Lin H, Li X, Zhao Y, Yuan B, Cao P (2019) Numerical analysis of fiber-reinforced soils based on the equivalent additional stress concept. Int J Geomech 19(11):04019122. https://doi.org/10.1061/(asce)gm.1943-5622.0001504

Gao Z, Lu D, Huang M (2020) Effective skeleton stress and void ratio for constitutive modeling of fiber-reinforced sand. Acta Geotech 15:2797–2811. https://doi.org/10.1007/s11440-020-00986-w

Li XS, Dafalias YF (2000) Dilatancy for cohesionless soils. Géotechnique 50(4):449–460. https://doi.org/10.1680/geot.2000.50.4.449

Adamidis O, Madabhushi SPG (2018) Experimental investigation of drainage during earthquake-induced liquefaction. Géotechnique 68(8):655–665. https://doi.org/10.1680/jgeot.16.P.090

Lakeland DL, Rechenmacher A, Ghanem R (2014) Towards a complete model of soil liquefaction: the importance of fluid flow and grain motion. Proc R Soc A Math Phys Eng Sci 470(2165):20130453. https://doi.org/10.1098/rspa.2013.0453

Vaid YP, Eliadorani A (1998) Instability and liquefaction of granular soils under undrained and partially drained states. Can Geotech J 35(6):1053–1062. https://doi.org/10.1139/t98-061

Gananathan N (2002) Partially drained response of sands (Doctoral dissertation, University of British Columbia)

Sivathayalan S, Logeswaran P (2008) Experimental assessment of the response of sands under shear–volume coupled deformation. Can Geotech J 45(9):1310–1323. https://doi.org/10.1139/T08-068

Chu J, Lo SC, Lee IK (1993) Instability of granular soils under strain path testing. J Geotech Eng 119(5):874–892. https://doi.org/10.1061/(ASCE)0733-9410(1993)119:5(874)

Wanatowski D, Chu J (2011) Pre-failure instability behavior of sand in strain path testing under plane-strain conditions. Soils Found 51(3):423–435. https://doi.org/10.3208/sandf.51.423

Lashkari A, Falsafizadeh SR, Rahman MM (2021) Influence of linear coupling between volumetric and shear strains on instability and post-peak softening of sand in direct simple shear tests. Acta Geotech 16(11):3467–3488. https://doi.org/10.1007/s11440-021-01288-5

Tohidvand HR, Hajialilue-Bonab M, Katebi H, Nikvand V, Ebrahimi-Asl M (2022) Monotonic and post cyclic behavior of sands under different strain paths in direct simple shear tests. Eng Geol 302:106639. https://doi.org/10.1016/j.enggeo.2022.106639

Maleki Tabrizi E, Tohidvand HR, Hajialilue-Bonab M, Mousavi E, Ghassemi S (2023) An investigation on the strain accumulation of the lightly EICP-cemented sands under cyclic traffic loads. J Road Eng. https://doi.org/10.1016/j.jreng.2023.03.002

Monkul MM, Gültekin C, Gülver M, Akın Ö, Eseller-Bayat E (2015) Estimation of liquefaction potential from dry and saturated sandy soils under drained constant volume cyclic simple shear loading. Soil Dyn Earthq Eng 75:27–36. https://doi.org/10.1016/j.soildyn.2015.03.019

Hubler JF, Athanasopoulos-Zekkos A, Zekkos D (2017) Monotonic, cyclic, and postcyclic simple shear response of three uniform gravels in constant volume conditions. J Geotech Geoenviron Eng 143(9):04017043. https://doi.org/10.1061/(ASCE)GT.1943-5606.0001723

Acknowledgements

The authors wish to thank the Department of Civil Engineering, University of Tabriz for providing permission to conduct the geotechnical investigations. Also, the authors would like to thank the anonymous reviewers for providing invaluable review comments and recommendations for improving the scientific level of the article.

Funding

This research received no external funding.

Author information

Authors and Affiliations

Contributions

HT: writing—original draft preparation, methodology, conceptualization, investigation, resources; EMT: conceptualization, methodology, validation, visualization, investigation; AEI: validation, visualization, supervision, writing—review, and editing; MHB: supervision, writing—review, and editing; MF: supervision, writing—review, and editing. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tohidvand, H.R., Maleki Tabrizi, E., Esmatkhah Irani, A. et al. Effects of the Fiber Reinforcement on the Monotonic Behavior of Sands Considering Coupled Volumetric–Shear Strain Paths. Int. J. of Geosynth. and Ground Eng. 9, 39 (2023). https://doi.org/10.1007/s40891-023-00462-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40891-023-00462-x