Abstract

The effect of shear box size, geotextile type and properties and sand grain shape and size on the sand–geotextile interaction was investigated experimentally by conducting interface tests with conventional (100 mm) and large-scale (300 mm) direct shear boxes. Triaxial compression tests were also conducted on reinforced sand samples in order to evaluate the effectiveness of a methodology developed for obtaining interface friction coefficient values. Four uniform sands, one with subangular grains and three with rounded grains of different sizes were tested in dry and dense condition. Seven nonwoven polypropylene geotextiles of various types and properties and seven woven geotextiles with or without apertures were used in the tests. The conventional shear box is satisfactory for testing materials like those used in the present investigation because it gave comparable interface friction coefficient values to those obtained by the large-scale shear box. The sand–geotextile interaction behavior depends on the surface characteristics of the geotextiles and the interlocking of sand grains in geotextile apertures. The rounded shape and decrease in size of sand grains more effectively mobilize the soil–geotextile interface friction. The results of triaxial compression tests are in quantitative and qualitative agreement with the results of direct shear tests, for geotextiles without apertures. The friction efficiency for geotextiles with apertures obtained from triaxial compression tests attains a maximum value for an aperture ratio (aperture size of geotextile / mean grain size of sand) value approximately equal to 1.9, in agreement with the results of other studies.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Design procedures for reinforced sand structures require quantification of the interaction behavior at the sand–reinforcement interface. This is accomplished by conducting large-scale laboratory direct shear and pullout tests and is expressed in terms of an apparent friction angle (δ) or an interface friction coefficient (tanδ). The above mentioned experimental procedures are rather costly because they require the use of specially designed and constructed large-size direct shear or pullout boxes and specialized personnel. More specifically, both ASTM D5321 [1] and EN ISO 12957-1 [2] direct shear tests call for a square shear box of 300 mm in size. While such a large shear box is appropriate for geonets, geogrids, many geocomposites, and large particle-sized soils, Koerner [3] considers it to be excessive for geotextiles (and certainly for geomembranes) against sands, silts and clays. Conventional geotechnical engineering laboratory shear boxes (e.g., 100 mm), are felt to be satisfactory for geotextile testing [3]. It is, therefore, of merit to verify the suitability of interface direct shear tests using a 100 mm shear box, by comparing their results obtained for geotextiles manufactured with different processes and having different properties with those of standardized tests using a 300 mm shear box.

The interaction behavior at sand–geotextile interfaces has been investigated extensively by conducting monotonic and cyclic direct shear tests [4,5,6,7,8,9,10,11,12,13,14,15] and it was found that it depends on the surface characteristics, the type, the strength and the stiffness of the geosynthetic [5,6,7]. On the other hand, the results of direct shear tests on interfaces between dense Ottawa 20–30 sand and a nonwoven needle-punched geotextile of four different densities indicated that the apparent friction angle is independent of the geotextile density [8]. With identical particle size distribution, particle shape affects the peak and residual friction angles in sand–woven geotextile interfaces [15] and the friction coefficient for rounded sand–woven geotextile interfaces is lower than the one obtained for angular sand–woven geotextile interfaces [11]. It has also been found that the opening size of mesh relative to the soil grain size influences the interaction between soil and geotextile [9, 10, 14] and that the apparent friction angle can decrease with increasing [4] or decreasing [13] sand grain size. The aforementioned observations show that the effect of geotextile type and properties and sand grain shape and size on the sand–geotextile interaction needs further documentation.

Free draining granular materials, e.g. sands, are specified as backfill material for reinforced soil structures. Consequently, the mechanical behavior of sand–geotextile composites has been investigated in the past by conducting triaxial compression tests on sand specimens reinforced with sheets of geotextiles [16,17,18,19,20,21,22,23,24,25,26,27]. The results of these investigations have provided valuable information about the effect of several important parameters on the mechanical behavior of geotextile–reinforced sands. In an attempt to extend the use of the triaxial compression test to the study of the interaction behavior at the sand–reinforcement interface, a methodology was developed for obtaining friction coefficient (tanδ) values from the results of laboratory tests using conventional triaxial compression testing equipment. Triaxial compression tests were conducted on reinforced sand samples [28, 29] and the experimental investigation was supplemented with results from a linear elastic analysis of similar reinforced sand samples under triaxial loading conditions [30]. It is, therefore, of merit to investigate the effectiveness of this methodology for a wide range of sands with different characteristics and geotextiles manufactured with different processes and having different properties and to compare the results obtained with those of interface direct shear tests.

Four sands differing in grain shape or grain size and 14 nonwoven and woven geotextiles with or without apertures were tested for the purposes of the present investigation. Ninety-three direct shear tests with conventional and large-scale equipment as well as 129 triaxial compression tests were performed on 22 and 16 sand–geotextile interfaces, respectively, and the results obtained are reported herein.

Materials

The direct shear and triaxial compression tests were conducted using four clean, uniform sands in dry and dense condition. The properties of these sands are presented in Table 1. It should be noted that three sands (designated as R 20–30, R 30–40 and R 40–100) are standard Ottawa quartz sands with rounded grains and grain sizes limited between ASTM E11 [31] sieve size Nos. 20 and 30, 30 and 40, and 40 and 100, respectively. As shown in Fig. 1, the fourth sand (designated as S 20–30) has subangular grains of the same sizes with R 20–30 sand and was tested in order to investigate the effect of grain shape on sand–geotextile interaction. The values of the angle of internal friction (φ) of the sands in dry and dense condition were determined by conducting triaxial compression tests and are also shown in Table 1. These φ values are used for normalizing the obtained values of the interface friction angle (δ).

Seven nonwoven polypropylene geotextiles and seven woven geotextiles with or without apertures, provided by eight different manufacturers, were tested during this investigation. The geotextiles were selected in order to cover a wide range of types of the commercially available products. Pertinent properties of the geotextiles, according to the manufacturers, are presented in Table 2. More specifically, two needle-punched with comparable properties (TS 50 and B 200), one needle-punched with thermally treated surfaces (F 400) and four thermally bonded products with different properties (SF 40, SF 56, SF 77 and SF 111), constitute the group of the selected nonwoven geotextiles. The set of woven geotextiles consists of three polypropylene with different properties (TP 240, TP 310 and TP 400), one standard grade polypropylene (SG 80/80), one high strength polyester/polyamide (HS 400/50), as well as two products with apertures of different size, one polyester with PVC coating and aperture size (A) equal to 1.20 mm (H 50.145) and one polyethylene with aperture size (A) equal to 0.77 mm (N 66447). Enlarged images of all geotextile types used in the present study are shown in Fig. 2.

Experimental Procedures

Conventional and large-scale direct shear equipment was utilized to conduct the tests on sand–geotextile interfaces in order to investigate the effect of shear box size, geotextile type and properties and sand grain shape and size on the sand–geotextile interaction. Triaxial compression tests were also conducted on geotextile reinforced sands and their results were used for the determination of the friction coefficient (tanδ) at sand–geotextile interfaces by applying a special methodology.

Direct Shear Testing

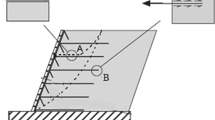

The direct shear tests with the large shear box were performed on interfaces between dry, dense R 20–30 sand and selected nonwoven and woven geotextiles of various types, in order to investigate the effect of shear box size on the sand–geotextile interaction by comparing with results obtained from tests conducted using a conventional direct shear box (100 mm). The large-scale tests were conducted using a direct shear apparatus of controlled displacement with a 300 mm square shear box. A cross section of the square shear box is shown in Fig. 3a. The normal load, with maximum value of 100 kN, is applied hydraulically to the top plate whereas the horizontal displacement of adjustable rate is applied through electric motors to the lower part of the shear box. The upper part of the shear box is held in place by the reaction of the load ring. A system described in detail by Athanasopoulos et al. [8], which was designed and fabricated in order to make the shear box capable of accommodating interface shear testing, was used in the tests. For sand–geotextile interface testing, the proper parts of the system were placed and assembled in the lower part of the shear box in the order indicated in Fig. 3b. The geotextile sheet was placed and clamped on the rough interface plate and dry sand was placed and compacted in layers in the upper part of the shear box. The sand was compacted using a hand operated tamper and care was taken in order to produce sand layers with constant density. The relative density (Dr) of the sands ranged from 83 to 93%. As reported in available literature, the difference between the angles of internal friction (φ) of medium dense (Dr = 46%) and dense (Dr = 80%) sand is 6.5° [32]. For the same type of sand, the increase of sand relative density from an average value of 51% (medium dense condition) to an average value of 93% (dense condition) results in an increase of the friction angle δ by 6°–7° in sand–nonwoven geotextile interfaces [32, 33] and by 5°–10° in sand–woven geotextile interfaces [34]. Finally, negligible differences in the friction angles φ and δ were obtained by Lee and Manjunath [35] for an increase of sand relative density from 50 to 80%. Based on this information, it can be concluded that the range of sand relative density in the present study does not have a substantial effect on the results obtained since it is not expected to cause variations in the friction angles φ and δ larger than 1°. The large-scale tests were conducted according to ASTM Standard D5321 [1], with normal stresses (σn) equal to 100, 200 and 400 kPa, at a constant rate of shearing equal to 1 mm/min and were completed at a horizontal displacement of 30 mm.

All the other direct shear tests were conducted using a conventional apparatus of controlled displacement with a 100 mm square shear box. The specimen configuration used in these tests, is shown schematically in Fig. 4a and is depicted in Fig. 4b. The dry sand was placed and compacted in the lower part of the shear box. The sands were compacted using a hand operated tamper and care was taken in order to produce sand layers with constant density. The geotextile sheet was placed and fixed on the rough surface of a wooden block and, then, the block with the geotextile sheet was placed in the upper part of the shear box in contact with the sand. Taking into consideration that evidence of negative influence on the test results was not found in the literature for this test setup and that it is also suggested by Koerner [3], it is intuitively believed that placing the sand and the geotextile in the lower and the upper parts of the shear box, respectively, will yield practically the same results as the customary test setup used in the large-scale tests. Since geotextiles of different thickness and compressibility were tested in this study, it was very complicated to adjust the height effectively with the wooden block in the lower part of the shear box so as the sand–geotextile interface to coincide with the shearing plane. This adjustment was accurately made in the large-scale tests with the “adjustable height spacer” included in the system of Fig. 3b. Thus, the specimen configuration of Fig. 4 was preferred in the conventional tests for simplicity reasons. All conventional tests were conducted at a relative density (Dr) of the sands between 87 and 97%, with normal stresses (σn) equal to 100, 200 and 400 kPa, at a constant rate of shearing equal to 0.25 mm/min and were completed after failure at the sand–geotextile interface (peak value of shear force). The chosen rate of shearing is equal to 0.25%/min with reference to the dimension of the shear box in the shearing direction and is comparable to the equivalent shearing rate of 0.33%/min used in the large-scale tests. A number of conventional tests were repeated for the verification of data resulting in differences between shear stress values at failure ranging from 1.1 to 10.6%. Consequently, the repeatability of the tests is considered satisfactory.

Triaxial Compression Testing

Triaxial compression tests were conducted using specimens with a diameter of 70 mm and an overall height of 144 mm. The specimens were reinforced with a number of horizontal geotextile layers (N) equal to 3, 5 or 7. The geotextile discs had a diameter equal to the diameter of the specimens and were placed in the positions shown in Fig. 5a–c, respectively. The sands were compacted using a special hand operated tamper and extreme care was taken in order to produce sand layers with constant density. Tests were conducted at an average relative density of the sands equal to 88%, with confining pressures (σ3) equal to 10, 25, 50, 100, 200 and 400 kPa and at a constant rate of axial displacement equal to 0.6 mm/min. Duplicate tests were conducted on specimens prepared with 2, 4 and 6 (N-1) geotextile layers, arranged as shown in Fig. 5d–f, respectively, in order to determine the effect of the reinforcement disc placed at the mid-height of the specimen. This was dictated by consistent observations indicating that slippage between sand and geotextile occurred definitely at least on this reinforcement disc. Reinforced sample configurations same as those shown in Fig. 5b, e have been used previously [28,29,30] in an attempt to separate the effect of the central reinforcement layer and to estimate values for the interface friction coefficient (tanδ) using the computation method described in “Computation Method of Interface Friction Coefficient”.

Direct Shear Test Results

Typical “shear stress—horizontal displacement” curves obtained from large-scale and conventional direct shear tests, conducted on various sand–geotextile interfaces, are shown in Fig. 6. All curves obtained present a peak indicating failure at the sand–geotextile interface. The typical “vertical displacement—horizontal displacement” curves presented in Fig. 7, show an initial decrease and a subsequent increase of the specimen height as shearing progresses. Although the measured values are low, these observations signify compression and expansion at the sand–geotextile interface, respectively. The shear and normal stress values at failure were used to plot the “shear stress–normal stress” diagrams, in order to evaluate the interface shearing resistance between the geotextiles and the sands. As it is typically shown in Fig. 8, the interaction behavior can be described by a linear Mohr–Coulomb failure envelope with adhesion values equal to zero. Values of interface friction coefficient (tanδ) were obtained from the slope of the failure envelopes and are independent of the interfacial normal stress. The interface friction coefficient values were also normalized in terms of the internal friction coefficients (tanφ) of the corresponding sands. The resulting values of friction efficiency (E φ = tanδ/tanφ) range from 71 to 104% and are in good agreement with the typical range for geotextiles which is equal to 60–100% of soil friction [3].

Finally, two series of large-scale tests were conducted on the R 20–30 sand—HS 400/50 geotextile interface, by shearing in the machine and cross machine directions, respectively. This was dictated by the significant difference in tensile strength of this geotextile in the two directions, as shown in Table 2. However, nearly equal tanδ values (difference = 2.8%) were obtained for the two directions of HS 400/50 geotextile.

Effect of Shear Box Size

As explained earlier, the direct shear tests with the large-scale and the conventional shear box were conducted using the same normal stresses and equivalent shearing rates with the purpose of comparing their results. This comparison is made in Table 3 for interfaces between dry, dense sand with rounded grains and a variety of woven and nonwoven geotextiles. The value of friction coefficient (tanδ) from the large-scale tests on HS 400/50 geotextile is the average of the values obtained, as stated above, for the two directions of this geotextile. As shown in Table 3, the friction coefficient values obtained from the tests with the 300 mm shear box are generally either smaller or larger than the ones obtained from testing with the 100 mm shear box. The differences between the tanδ values obtained from the two shear boxes can be considered as low, since they are lower than ± 6% for the nonwoven geotextiles and range from − 10.4 to + 13.2% for the woven geotextiles. The larger differences observed for the woven geotextiles can possibly be attributed to their structure and geometry. In conclusion, the aforementioned observations indicate that the results of the two tests are comparable and, therefore, that the 100 mm shear box is suitable for interface testing of materials like those used in the present study. For that reason, the conventional 100 mm shear box was used for the parametric investigation presented in the subsequent sections.

Effect of Geotextile Type and Properties

As also shown in Table 3, the type of geotextile affects substantially the values of interface friction coefficient leading to differences between them as high as 31%. However, nonwoven geotextiles generally present tanδ values in the same range as woven geotextiles. Considering the properties of nonwoven or woven geotextiles of the same types and manufacturers (Table 4), the tanδ value does not present a consistent variation with increasing mass per unit area and tensile strength of the geotextile. The abovementioned observations indicate that the sand–geotextile interaction behavior depends mainly on the surface characteristics of the geotextiles which are strongly influenced by the geotextile type.

Effect of Sand Grain Shape and Size

The results of direct shear tests conducted with four different geotextiles and two sands having the same grain size and differing in grain shape are shown in Table 5. It is easily observed that the values of the friction coefficient are higher for sand with subangular grains than for sand with rounded grains. On the contrary, the friction efficiencies (E φ ) are higher for the sand with rounded grains indicating a more effective mobilization of soil friction in comparison with the sand with subangular grains. The same trend is also noticed on the basis of the results reported by Anubhav and Basudhar [11] for two woven geotextiles in contact with one sand with rounded grains and one sand with angular grains, having φ values equal to those of the sands tested in the present study. This behavior is attributed to the larger difference between the tanφ values compared to the difference between the tanδ values of the sands differing in grain shape. Presented in Table 6 are the results of direct shear tests conducted with one nonwoven and one woven geotextile without apertures in contact with three sands having the same (rounded) grain shape and differing in grain size. Although an increase of friction coefficient with decreasing sand grain size is obvious only for the nonwoven geotextile, the friction efficiency (tanδ/tanφ) increases with decreasing sand grain size in both geotextiles with the exception of R 40–100 sand—SG 80/80 geotextile interface. This increase may be possibly attributed to the more efficient mobilization of soil friction by the larger number of grains in contact with the geotextile, as the sand grain size decreases.

Triaxial Compression Test Results

The triaxial compression tests on geotextile reinforced sands were also conducted for the investigation of the mechanical behavior of the composite material and the results of that study can be found in another publication [36]. More specifically, it was observed that (a) the reinforced sands present higher shear strength than unreinforced sands for all geotextiles tested, (b) the shear strength of reinforced sand increases with increasing number of geotextile layers, (c) reinforced sands with subangular grains present higher shear strength than reinforced sands with rounded grains, and (d) the increase of the shear strength of reinforced sand caused by the decrease of sand grain size is generally not as pronounced as that effected by the sand grain shape [36]. As typically shown in Fig. 9, the triaxial compression tests yielded bilinear failure envelopes for the composite material irrespective of the number of geotextile layers (Fig. 9a), the sand grain shape (Fig. 9b) and the sand grain size (Fig. 9c), which is in good agreement with the observations of other investigators [16, 17]. In the part of the bilinear failure envelopes before the break point, failure of the composite material is due to slippage of the geotextile with regard to the surrounding soil (type I failure). After the break point, failure occurs by excessive deformation during which the geotextile is stretched in unison with the surrounding soil (type II failure). Therefore, values of friction coefficient tanδ were computed using the method of the subsequent section, for all triaxial compression tests conducted with the confining pressures (σ3) that resulted in points on the first part of the bilinear failure envelopes (type I failure).

Computation Method of Interface Friction Coefficient

A method developed for computing values of the interface friction coefficient (tanδ) from the results of triaxial compression tests [28,29,30], was used in this investigation. More specifically, the “equivalent” confining stress increase (Δσ3) concept [37] attributes the observed shear strength increase, due to reinforcement, to the development of an additional confining pressure Δσ3 which is considered uniformly distributed over the entire cylindrical surface of the reinforced soil specimen and can be expressed, for failure conditions, as [17]:

where σ3 is the same minor principal stress for tests on reinforced and unreinforced soil in kPa, σ1 is the major principal stress at failure of the unreinforced soil in kPa and Δσ1 is the major principal stress difference at failure between reinforced and unreinforced soil in kPa. Therefore, the contribution of the geotextile disc at the mid-height of the specimens to the shear strength increase was quantified by determining the corresponding confining stress increase (Δσ3). This was achieved by (a) conducting triaxial compression tests with the same confining pressure (σ3) for unreinforced sand and sand reinforced as shown in Fig. 5, (b) determining Δσ3,N and Δσ3,N−1 for N (3, 5, 7) and N−1 (2, 4, 6) layers of reinforcement, respectively, by applying Eq. 1 and (c) setting Δσ3 = Δσ3,N – Δσ3,N−1. The value of the interface friction coefficient (tanδ) was then computed by applying Eq. (2) [28,29,30]:

where R0 is the radius of the reinforcement disc in cm, H is the overall height of the specimen in cm and σ1r is the major principal stress at failure in kPa, which is set equal to the axial stress at failure of the sand specimen reinforced with N layers of geotextile.

Parameters of Friction at Sand–Geotextile Interfaces

The values of the interface friction coefficient (tanδ), computed using Eq. 2 for specimens tested in triaxial compression, generally indicate a dependence of tanδ on the applied confining pressure to the sand–geotextile interface. However, the actual interfacial normal stress cannot be evaluated reliably and the applied confining pressure (σ3) can be considered as a good qualitative indicator of the interface normal stresses developing during the triaxial compression test. Accordingly, presented in Fig. 10 are the results obtained for the interfaces between SG 80/80 woven geotextile and all sands tested during the present investigation using the specimen configurations shown in Fig. 5b, e (5 and 4 geotextile layers). It can be observed that the value of the friction coefficient tanδ decreases with increasing normal stress (increasing σ3) in agreement with the results of pullout tests [37]. In view of that, the average values of friction coefficient tanδ obtained from all specimens with 5 and 4 geotextile layers tested in triaxial compression, are presented in Table 7 for simplicity reasons. These values of tanδ were also normalized with regard to the internal friction coefficients (tanφ) of the corresponding sands and the resulting values of friction efficiency (E φ ) are also presented in Table 7. For the geotextiles without apertures (SF 56 and SG 80/80), the values of E φ range generally between 65 and 104% and are in good agreement with the typical range of friction property of geotextiles, which is equal to 60–100% of soil friction [3]. The values of E φ obtained for the interfaces between sands with rounded grains and geotextiles with apertures (H 50.145 and N 66447), are higher than 100% and range from 116 to 131%. These high E φ values can be attributed to the interlocking of sand grains in geotextile apertures. Values of E φ considerably higher than 100% were also reported by Athanasopoulos [38] for sands in contact with a geotextile with apertures. The relatively low E φ values obtained for S 20–30 sand can be considered as mobilized values indicating that maximum E φ values were not reached in these tests. For that reason, triaxial compression tests were conducted on S 20–30 sand specimens reinforced with 3 and 2 as well as with 7 and 6 layers of H 50.145 geotextile, arranged as shown in Fig. 5a, d, c, f, respectively. The methodology of the preceding section was applied to the results of these tests and the obtained values of friction coefficient tanδ for the combinations of 3–2 and 7–6 geotextile layers are equal to 0.54 and 0.34, respectively. These values are lower than the value of 0.63 obtained for the S 20–30 sand—H 50.145 geotextile interface and the combination of 5–4 geotextile layers (Table 7). Consequently, the tanδ values were not improved by conducting the triaxial compression tests with a combination of geotextile layers different from that of 5–4 layers which gives the best results.

The average values of friction coefficient tanδ obtained from triaxial compression tests, are also compared in Table 7 to the values obtained from the direct shear tests conducted with 100 mm shear box. For sand with subangular grains (S 20–30), the tanδ values obtained from triaxial compression tests are lower than those obtained from interface direct shear tests; for sands with rounded grains, the tanδ values obtained from triaxial compression tests are equal or higher than those obtained from interface direct shear tests. For geotextiles without apertures, the tanδ values obtained from the two tests are comparable, since the differences between them range from − 13.3 to + 9.2% and can be considered as low. The only exception is R 30–40 sand—SF 56 geotextile interface, where the large difference between the two tests (− 30.3%) is attributed to the very high value of tanδ obtained from the triaxial compression test. On the contrary, the results of the two tests are not comparable for geotextiles with apertures, since the observed differences in tanδ are as high as ± 36% (Table 7). These large differences are attributed (a) to the low tanδ values obtained from triaxial compression tests with S 20–30 sand, which are considered as mobilized and not as maximum, and (b) to the high tanδ values obtained from triaxial compression tests with R 20–30 sand, possibly due to a more effective interlocking of sand grains in geotextile apertures in comparison with that developed during direct shear testing.

By comparing the triaxial compression test results obtained for the two sands (S 20–30 and R 20–30) having the same grain size and differing in grain shape (Table 7), it is observed that tanδ values are higher and friction efficiencies E φ are lower for sand with subangular grains (S 20–30) than for sand with rounded grains (R 20–30). This observation does not apply to the triaxial compression tests conducted with the two geotextiles with apertures for the reasons given in the previous paragraph. From the results of triaxial compression tests conducted with geotextiles without apertures in contact with three sands (R 20–30, R 30–40 and R 40–100) having the same grain shape and differing in grain size (Table 7), it can be seen that both friction coefficient and efficiency increase with decreasing sand grain size with the exception of the R 30–40 sand—SF 56 geotextile interface. Therefore, the results of triaxial compression tests for geotextiles without apertures are also in qualitative agreement with the direct shear test results regarding the effect of sand grain shape and size on the sand–geotextile interaction. For geotextiles with apertures, the effect of sand grain size on friction efficiency is quantified using the aperture ratio (A/D 50 ), defined as the ratio of the aperture size of the geotextile to the mean grain size of the sand. The aperture sizes (A) of H 50.145 and N 66447 geotextiles are equal to 1.20 and 0.77 mm, respectively, and the mean grain sizes (D 50 ) of sands are presented in Table 1. Due to the different aperture sizes of the two geotextiles used, the results obtained from triaxial compression tests on the three sands with rounded grains and the two geotextiles with apertures are presented together in Fig. 11. It is evident that there is a relationship between friction efficiency and aperture ratio and that the most favorable interlocking of sand grains in geotextile apertures, resulting in the maximum value of friction efficiency, is developed for an optimum value of aperture ratio approximately equal to 1.9. This optimum value of aperture ratio is in agreement with the value of 1.6 reported by Athanasopoulos [38] and lies between the value of 1.0 reported by Juran et al. [39] and Vangla and Latha Gali [14] and the value of 3.1 reported by Bauer and Mowafy [40].

Conclusions

Based on the results of this investigation and within the limitations posed by the number of tests conducted and the materials used, the following conclusions may be advanced:

-

The interaction at the sand–geotextile interface determined by conducting direct shear tests can be described by linear failure envelopes presenting negligible adhesion values and friction coefficient values ranging from 71 to 104% of the internal friction coefficients of the sands.

-

The direct shear tests conducted with 300 and 100 mm square shear boxes gave comparable values for the interface friction coefficient. Therefore, the 100 mm shear box is appropriate for interface testing of materials similar to those used in the present investigation.

-

The sand–geotextile interaction behavior depends on the surface characteristics of the geotextiles which are strongly influenced by the geotextile type as well as on the interlocking of sand grains in geotextile apertures.

-

Rounded shape and decreasing size of the sand grains were found to mobilize more effectively the soil friction at the sand–geotextile interface.

-

The values of the interface friction coefficient decrease with increasing confining pressure applied during the triaxial compression tests and, as a result, with increasing interface normal stress developing during these tests.

-

For geotextiles without apertures, the values of the interface friction coefficient obtained by triaxial compression tests are in good agreement with the typical range for similar geotextiles (60–100% of soil friction). For geotextiles with apertures, triaxial compression tests generally yield interface friction coefficients significantly higher than the internal friction coefficients of sands, in agreement with the results of other investigators.

-

The results of sand–geotextile interface friction obtained from triaxial compression tests are in quantitative and qualitative agreement with the results obtained by interface direct shear tests, for geotextiles without apertures.

-

For geotextiles with apertures, the aperture ratio (aperture size of geotextile / mean grain size of sand) affects substantially the friction efficiency. According to the experimental results reported herein, the maximum value of friction efficiency is developed for an optimum value of aperture ratio approximately equal to 1.9, in agreement with the results of other investigations.

-

Based on the comparisons made with the interface direct shear test results of this study and the experimental results of other studies, there are adequate indications that the triaxial compression testing techniques used in this investigation for estimating values of the friction coefficient at sand–geotextile interfaces offer a feasible alternative to pullout and direct shear tests.

The aforesaid conclusions are limited to uniform sands with grain sizes similar to those used in this investigation. Also, the effect of well graded backfill materials on the soil–geotextile interaction is not discussed in the present study.

References

ASTM D5321 (2006) Standard test method for determining the coefficient of soil and geosynthetic or geosynthetic and geosynthetic friction by the direct shear method, vol. 04–13. Geosynthetics, ASTM International, West Conshohocken

EN ISO 12957–1 (2005) Geosynthetics—Determination of friction characteristics: part 1—Direct shear test. European Committee for Standardization, Brussels

Koerner RM (2005) Designing with geosynthetics, 5th edn. Pearson–Prentice Hall, Upper Saddle River

Formazin J, Batereau C (1985) The shear strength behavior of certain materials on the surface of geotextiles. In: Proceedings of the 11th international conference on soil mechanics and foundation engineering, San Francisco, USA, vol 3, pp 1773–1775

Williams ND, Houlihan MF (1987) Evaluation of interface friction properties between geosynthetics and soils. In: Proceedings of geosynthetics’87, New Orleans, USA, vol 2, pp 616–627

Eigenbrod KD, Locker JG (1987) Determination of friction values for the design of side slopes lined or protected with geosynthetics. Can Geotech J 24:509–519

Koutsourais M, Sandri D, Swan R (1998) Soil interaction characteristics of geotextiles and geogrids. In: Proceedings of the 6th international conference on geosynthetics, Atlanta, USA, vol 2, pp 739–744

Athanasopoulos GA, Katsas CE, Ioannidis AA, Pelekis PC (2002) Evaluation of sand–geotextile interface friction angle by a modified 300 × 300 mm direct shear box. In: Proceedings of the 7th international conference on geosynthetics, Nice, France, vol 4, pp 1301–1304

Subaida EA, Chandrakaran S, Sankar N (2008) Experimental investigations on tensile and pullout behaviour of woven coir geotextiles. Geotext Geomembr 26:384–392. https://doi.org/10.1016/j.geotexmem.2008.02.005

Hsieh CW, Chen GH, Wu J-H (2011) The shear behavior obtained from the direct shear and pullout tests for different poor graded soil-geosynthetic systems. J GeoEng 6:15–26

Anubhav, Basudhar PK (2013) Interface behavior of woven geotextile with rounded and angular particle sand. J Mater Civ Eng 25:1970–1974. https://doi.org/10.1061/(ASCE)MT.1943-5533.0000774

Vieira CS, Lopes ML, Caldeira LM (2013) Sand–geotextile interface characterisation through monotonic and cyclic direct shear tests. Geosynth Int 20:26–38. https://doi.org/10.1680/gein.12.00037

Choudhary AK, Krishna AM (2016) Experimental investigation of interface behaviour of different types of granular soil/geosynthetics. Int J of Geosynth Ground Eng 2:4. https://doi.org/10.1007/s40891-016-0044-8

Vangla P, Latha Gali M (2016) Effect of particle size of sand and surface asperities of reinforcement on their interface shear behaviour. Geotext Geomembr 44:254–268. https://doi.org/10.1016/j.geotexmem.2015.11.002

Afzali-Nejad A, Lashkari A, Shourijeh PT (2017) Influence of particle shape on the shear strength and dilation of sand-woven geotextile interfaces. Geotext Geomembr 45:54–66. https://doi.org/10.1016/j.geotexmem.2016.07.005

Gray DH, Athanasopoulos GA, Ohashi H (1982) Internal/external fabric reinforcement of sand. In: Proceedings of the 2nd International Conference on Geotextiles, Las Vegas, USA, vol 3, pp 611–616

Gray DH, Al-Refeai T (1986) Behavior of fabric- vs. fiber-reinforced sand. J Geotech Eng 112:804–820

Chandrasekaran B, Broms BB, Wong KS (1989) Strength of fabric reinforced sand under axisymmetric loading. Geotext Geomembr 8:293–310

Baykal G, Guler E, Akkol O (1992) Comparison of woven and nonwoven geotextile reinforcement using stress path tests. In: Proceedings of the international symposium on earth reinforcement practice, Fukuoka, Japan, vol 1, pp 23–28

Ashmawy AK, Bourdeau PL (1998) Effect of geotextile reinforcement on the stress–strain and volumetric behavior of sand. In: Proceedings of the 6th international conference on geosynthetics, Atlanta, USA, vol 2, pp 1079–1082

Haeri SM, Noorzad R, Oskoorouchi AM (2000) Effect of geotextile reinforcement on the mechanical behavior of sand. Geotext Geomembr 18:385–402

Wu JH, Wang DQ, Wang LJ (2002) Experimental study on geosynthetic reinforcement. In: Proceedings of the 7th international conference on geosynthetics, Nice, France, vol 4, pp 1285–1288

Madhavi Latha G, Murthy VS (2007) Effects of reinforcement form on the behavior of geosynthetic reinforced sand. Geotext Geomembr 25:23–32. https://doi.org/10.1016/j.geotexmem.2006.09.002

Kim Y-S, Oh S-W, Cho D-S (2010) Effect of non-woven geotextile reinforcement on mechanical behavior of sand. J Korean Geosynth Soc 9:39–45

Nguyen MD, Yang KH, Lee SH, Wu CS, Tsai MH (2013) Behavior of nonwoven-geotextile-reinforced sand and mobilization of reinforcement strain under triaxial compression. Geosynth Int 20:207–225. https://doi.org/10.1680/gein.13.00012

Benessalah I, Arab A, Villard P, Merabet K, Bouferra R (2016) Shear strength response of a geotextile-reinforced Chlef sand: a laboratory study. Geotech Geol Eng 34:1775–1790. https://doi.org/10.1007/s10706-016-9988-7

Denine S, Della N, Muhammed RD, Feia S, Canou J, Dupla J-C (2016) Effect of geotextile reinforcement on shear strength of sandy soil: laboratory study. Stud Geotech Mech 38:3–13. https://doi.org/10.1515/sgem-2016-0026

Atmatzidis DK, Athanasopoulos GA, Markou IN (1992) Soil–reinforcement friction angle by triaxial compression tests. In: Proceedings of the 2nd Greek National Conference on Geotechnical Engineering, Thessaloniki, Greece, vol 1, pp 19–26 (in Greek)

Atmatzidis DK, Athanasopoulos GA (1994) Sand–geotextile friction angle by conventional shear testing. In: Proceedings of the 13th International conference on soil mechanics and foundation engineering, New Delhi, India, vol 3, pp 1273–1278

Atmatzidis DK, Athanasopoulos GA, Papantonopoulos CI (1994) Sand–geotextile interaction by triaxial compression testing. In: Proceedings of the 5th international conference on geotextiles, geomembranes and related products, Singapore, vol 1, pp 377–380

ASTM E11 (2009) Standard specification for wire cloth and sieves for testing purposes. ASTM International, West Conshohocken

Gourc JP, Lalarakotoson S, Muller-Rochholz H, Bronstein Z (1996) Friction measurement by direct shearing or tilting process: development of a European standard. In: Proceedings of the 1st European Geosynthetics Conference, Maastricht, Netherlands, pp 1039–1046

Miyamori T, Iwai S, Makiuchi K (1986) Frictional characteristics of non-woven fabrics. In: Proceedings of the 3rd International Conference on Geotextiles, Vienna, Austria, vol 3, pp 701–705

Makiuchi K, Miyamori T (1988) Mobilization of soil–geofabric interface friction. In: Proceedings of the international geotechnical symposium on theory and practice of earth reinforcement, Fukuoka, Japan, pp 129–134

Lee KM, Manjunath VR (2000) Soil–geotextile interface friction by direct shear tests. Can Geotech J 37:238–252

Markou I (2016) Effect of grain shape and size on the mechanical behavior of reinforced sand. In: Proceedings of the 3rd international conference on transportation geotechnics, procedia engineering, vol 143, pp 146–152. https://doi.org/10.1016/j.proeng.2016.06.019

Ingold TS (1982) Reinforced earth. Thomas Telford, London

Athanasopoulos GA (1993) Effect of particle size on the mechanical behaviour of sand–geotextile composites. Geotext Geomembr 12:255–273

Juran I, Knockenmus G, Acar YB, Arman A (1988) Pull-out response of geotextiles and geogrids (synthesis of available experimental data). In: Proceedings of geosynthetics for soil improvement, Nashville, ASCE, pp 92–111

Bauer GE, Mowafy YM (1990) The effect of grid geometry and aggregate size on the stress transfer mechanism. In: Proceedings of the 4th International conference on geotextiles, geomembranes and related products, The Hague, vol 2, p 801

Acknowledgements

The interface direct shear tests with the 300 mm shear box were conducted by the author at the University of Patras, Greece (Department of Civil Engineering, Geotechnical Engineering Laboratory). Thanks are expressed to Professor D.K. Atmatzidis for the permission to use this equipment for conducting the tests. The interface direct shear tests with the 100 mm shear box and the triaxial compression tests were conducted in the Soil Mechanics and Foundation Engineering Laboratory of Democritus University of Thrace by the students P. Aggonas, E. Anastasiadis, S. Antoniadis, P. Bogiatzopoulos, D. Ioannou and M. Voulgaris, whose careful work is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Markou, I.N. A Study on Geotextile—Sand Interface Behavior Based on Direct Shear and Triaxial Compression Tests. Int. J. of Geosynth. and Ground Eng. 4, 8 (2018). https://doi.org/10.1007/s40891-017-0121-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40891-017-0121-7