Abstract

Purpose

Based on the capabilities of polycaprolactone-based nanofibers (PCL) in the wound healing process, some of polycaprolactone’s weaknesses, such as hydrophobicity and cell non-adhesion to it, were improved by grafting collagen to the surface of the nanofibers.

Methods

First, polymeric solutions of PCL/chitosan/gelatin in acetic acid/formic acid solvent were prepared for electrospinning in this study. The effects of various factors on the electrospinability and morphology of the fabricated fiber were then investigated, including the volumetric ratio of solvents, chitosan concentration, gelatin concentration, and solution flow rate. In addition, the appropriate conditions for electrospinning of PCL/chitosan/gelatin solution were obtained without the addition of any other substance to increase the electrospinability of the solution, and the electrospinability range of the aforementioned solution was presented. Following electrospinning, the extracted collagen from the rat tail tendon with two different mass ratios was grafted onto the nanofiber surface. Following that, the morphology, chemical compositions, swelling, water vapor transmission rate, contact angle, tensile strength, cell viability, and human fibroblast cell adhesion of this nanofiber were investigated.

Results

The solution’s electrospinability range was introduced, and a beadless nanofiber was formed under the proposed appropriate electrospinning conditions. According to the results of scanning electron microscopy, the mean diameter of beadless nanofiber was 282 ± 37 nm. It was also demonstrated that the nanofiber has significant swelling, good mechanical properties, an acceptable water vapor transmission rate, and appropriate cell attachment, viability, and migration. Furthermore, it was demonstrated that grafting collagen on the scaffold surface can significantly improve cell attachment, viability, and migration.

Conclusions

This PCL-based nanofiber mat can be considered as a skin tissue scaffold.

Lay Summary

As a potential skin tissue scaffold, an electrospun PCL-based mat was prepared in this study. In addition, for the first time, an optimum condition was introduced for electrospinning of PCL/chitosan/gelatin solution without the addition of any other additives, and various tests such as water vapor transmission rate were performed to evaluate its properties. Furthermore, collagen was grafted onto the proposed nanofiber mat, and the results of the tests show that grafting collagen can improve cell attachment, viability, and migration on the scaffold, and the produced mat has great potential as a skin tissue scaffold.

Future Works

Based on the findings of this study, the authors strongly advise that the performance of the scaffold, which is grafted with 0.4% collagen solution, be investigated using immunostaining and in-vivo tests, as well as a quantitative examination of cell adhesion, for further evaluations.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Skin is the largest organ in the body, accounting for approximately 8% of the total body weight. This organ is critical in protecting other parts of the body. According to this fact, skin loss caused by burning, other accidents, or diseases is always a significant problem that can cause patients to experience a variety of mental and physical difficulties [1, 2]. As a result, it is critical to find a suitable solution to this problem. Many advances have been made in the field of wound healing over the last three decades. Tissue engineering is one of the leading sciences in this field, and scaffolds play an important role in this subject. Scaffolds, in general, have specific physical and chemical properties that can aid in cell growth and proliferation during wound healing. However, none of the previous scaffolds are completely satisfactory [3]. At the same time, they do not have the issues associated with traditional healing processes, and their roles in wound healing can potentially be improved.

Various scaffolds containing various substances have been studied for skin treatment in recent years. According to the previous research [4,5,6,7], polycaprolactone (PCL), chitosan, gelatin, and collagen are good choices for manufacturing scaffolds due to their favorable properties. PCL is a synthetic polymer with desirable characteristics such as hydrophobicity, biodegradability, high flexibility, low degradation rates, and biocompatibility [8]. The use of this polymer to improve wound healing has shown that the presence of this polymer does not cause skin inflammation and also aids in natural skin regeneration [5, 7, 9]. PCL has excellent mechanical properties, and many researchers have used it in their studies due to its simple manufacturing process and high flexibility [10]. This synthetic polymer has recently been used in tissue engineering, including the creation of scaffolds for the regeneration of various organs such as the bone [11], skin [12], ligaments [13], cartilage [14], nerve [11], and vascular tissues [15]. This polymer is also highly soluble in organic solvents and has excellent processing properties, allowing it to be used to create scaffolds via a variety of methods, including electrospinning [16, 17]. PCL, on the other hand, has limited biofunctional properties and a slow biodegradation rate [10]. As a result, blending PCL with naturally derived polymers like chitosan, gelatin, and collagen can help to eliminate these undesirable properties. Chitosan possesses distinct properties such as biocompatibility, biodegradability, non-toxicity, wound healing acceleration, antibacterial, and antifungal properties. As a result, this natural polymer has found widespread application in tissue engineering products [4,5,6,7, 9, 18,19,20]. Chitosan is made by deacetylating chitin, and its structure is very similar to glycosaminoglycans (GAGs) of the extracellular matrix [4,5,6,7, 9, 18, 19].

Gelatin, another natural substance that can be blended with PCL, is a protein derived from the partial hydrolysis of collagen, the main structural protein of the skin’s extracellular matrix. Gelatin is frequently added to hydrophobic polymers to compensate for their lack of cell identification sites and thus improve scaffold-cell interactions [9, 21].

Collagen is a natural polymer that has the potential to be used in tissue engineering. The benefits of this polymer include biocompatibility, biodegradability, good cell interaction, low immunogenicity, and non-toxicity. Collagen, on the other hand, has low mechanical strength, slow angiogenesis, limited antibiosis, rapid degradation, and a high price [4, 9, 22]. As a result, in some studies [23, 24], collagen was grafted onto the surfaces of scaffolds to benefit from its valuable properties.Collagen is a natural polymer that can be used in tissue engineering. The advantages of this polymer are biocompatibility, biodegradability, good interaction with cells, low immunogenicity, and non-toxicity. On the other hand, collagen has low mechanical strength, slow angiogenesis, limited antibiosis, quick degradation, and high cost [4, 9, 22]. In the following, some previously published works that used the aforementioned substances are presented.

Shalumon et al. used electrospinning to produce scaffolds from chitosan and PCL in 2010. Their findings demonstrated that this scaffold can absorb proteins and cells and is a viable candidate for skin treatment [25]. Schueren and colleagues created an electrospun scaffold out of chitosan and PCL. As a solvent, an acetic acid/formic acid solution was used. Different acetic acid to formic acid ratios were used in the electrospinning process, and the properties of the produced nanofibers were studied. According to their findings, a mixture of acetic acid and formic acid in various ratios can be used as a suitable solvent for the electrospinning process, resulting in beadless nanofibers of varying diameters [26]. Zarghami et al. prepared polyethylene oxide, chitosan, PCL, and olive oil nanofibers using an electrospinning process and evaluated their suitability for wound dressing. According to their findings, the aforementioned nanofiber has a high potential for use in wound dressing applications [27].

Gautam et al. used a PCL/gelatin scaffold for skin tissue regeneration in 2014. In this study, collagen was grafted to the polycaprolactone/gelatin scaffold to create a new scaffold. This scaffold has adequate cell adhesion and has a high potential for use in skin tissue engineering [23]. Gomes and colleagues developed tissue engineering scaffolds in 2017 using PCL, gelatin, chitosan, and polyethylene oxide. Polyethylene oxide is actually added to the solution to increase its electrospinability. Based on their findings, the produced scaffold had good mechanical properties and high cell adhesion [9]. Despite the benefits of collagen mentioned earlier, and the importance of surface modification, the effect of grafting collagen on the produced scaffold was not studied in their work. Furthermore, despite the fact that the presence of chitosan in the solution can cause problems with electrospinning and that studying the electrospinning process characteristics appears to be critical, the effects of changing electrospinning parameters such as voltage and solution flow rate, as well as the effects of changing solution characteristics such as chitosan and gelatin concentrations, were not studied in their work.

Furthermore, the electrospinning of polycaprolactone, chitosan, and gelatin solutions without the addition of any other substances has never been studied in order to study the application of polycaprolactone, chitosan, and gelatin in the field of skin tissue engineering. There are numerous other important factors that must be considered in the application of the produced scaffold as a skin regenerator, such as the water vapor transmission rate and surface modification of the nanofibers, as well as additional analyses that have not previously been performed. Furthermore, proper methods for improving the performance of the scaffolds in skin regeneration would be critical.

As a result, in order to address the aforementioned unknown aspects of using PCL-based nanofibrous scaffold for skin tissue engineering, a nanofibrous scaffold composed of polycaprolactone, chitosan, and gelatin was prepared for the first time using the electrospinning method without the addition of any other substances to the polymer solution in the current study. In addition, the effects of different electrospinning parameters such as the volumetric ratio of acetic acid to formic acid, chitosan concentration, gelatin concentration, applied voltage, and solution flow rate on fiber morphology and solution electrospinability were investigated, and for the first time, an appropriate electrospinability range was introduced for this solution. Furthermore, different percentages of collagen were grafted onto the nanofiber to assess the effect of surface modification of the PCL/chitosan/gelatin nanofiber scaffold on its physical, mechanical, and biological properties, which had not previously been done for this scaffold. FTIR, SEM, water vapor transmission rate, swelling test, tensile strength test, contact angle measurement, cell growth and proliferation assay, cell adhesion test, and quantitative toxicity test were used to evaluate the physical, mechanical, chemical, and biological properties of the scaffolds produced.

Based on the results, the best electrospinning conditions for the preparation of the PCL/chitosan/gelatin nanofiber scaffold were discovered and reported, and the remarkable effects of surface modifications were achieved and presented based on the measured and reported properties such as its favorable water vapor transmission rate. It was also discovered that the prepared scaffold has the potential to be used for skin tissue engineering.

Materials and Methods

Materials

Low molecular weight chitosan and PCL with a molecular weight of 80,000–90,000 were purchased from Sigma-Aldrich Company. Collagen was extracted from the rat tail tendon as described later. For the extraction of collagen, 2-propanol solution (≥ 99.8% purity) was acquired from Merck Chemical Company. Acetic acid and formic acid as electrospinning solvents were afforded by Merck Chemical Company. Also, 1-ethyl-3-(3-dimethylaminopropyl) carbodiimide (EDAC( was obtained from Sigma-Aldrich for activating the carboxyl groups of gelatin and chitosan. In this research, the fibroblast cells were extracted from the human foreskin to study the biological properties of the prepared scaffolds. L929 mouse fibroblast cells (NCBI C161) from the cell bank of Pasteur Institute of Iran were used in an indirect MTT test.

Electrospinning Method

The solvent for the electrospinning solution was acetic acid/formic acid in volumetric ratios of 70:30, 50:50, and 30:70. PCL, chitosan, and gelatin were separately dissolved in the prepared solvent to make the electrospinning solution. The electrospinning solution was made as follows: 0.75 g of PCL was dissolved in 3 ml of solvent and stirred for 24 h. Chitosan solution was prepared by dissolving 0.0025 g of chitosan in 1 ml of the solvent and stirring for 18 h. In addition, 0.1 g of gelatin was dissolved in 1 ml of the solvent and stirred for 18 h. By thoroughly mixing the prepared chitosan and gelatin solutions, a homogeneous chitosan–gelatin solution was obtained. After 3 h of stirring, the PCL solution was added to the chitosan–gelatin solution, and it was stirred for 2.5 h to achieve a pale yellow solution. The prepared solution was loaded into a 5 ml syringe with a 12.5 mm inner diameter. The distance between the nozzle (21G) and the collector was set to 12.5 cm, and a voltage of 16.5 kV was applied. A syringe pump with a flow rate of 0.4 ml/h was used to inject the solution. Fibers were collected on a 10 × 25 cm2 sheet of aluminum that was wrapped around the rotating drum collector.

Furthermore, the range of the electrospinability of the produced solution was studied for the first time in this study without the addition of any other substances by changing the chitosan concentration, acetic acid to formic acid volumetric ratio, solution flow rate, applied voltage, and gelatin concentration. In the results section, all of the concentration ranges, volumetric ratios, applied voltages, and flow rates are detailed.

Collagen Extraction and Grafting

In this study, collagen was extracted from the rat’s tail. The rats’ tails were first immersed in a 70% ethanol solution. The tails were then washed in phosphate buffer solution (PBS, pH = 7.4) before the skin of the rat’s tail was removed with surgical scissors. The fascicles of the tail tendons were removed, and the tendons were placed in several flasks filled with PBS. The tendons were then washed in isopropanol for 5 min. The tendons were placed in a container with 2 l of acetic acid (0.02 N) and kept at 4 °C for at least 48 h. A viscous solution was obtained at the end of this step. At 4 °C, the solution was centrifuged at 15,000 rpm for 30 min. Finally, the supernatant solution was separated and dried using the freeze-drying method, yielding solid collagen.

Collagen grafting on the surface of nanofibers was performed according to the method presented by Gautam et al. [23]. In brief, the nanofibrous scaffold was soaked in EDAC solution (10 mg/ml in PBS) for 4 h at 4 °C. As a result, the carboxyl groups of gelatin and chitosan were activated and can now be bonded to collagen’s amine groups. The activated nanofibrous mat was then removed from the EDAC solution, and immersed in 0.2 wt.% or 0.4 wt.% collagen solutions for 24 h at 4 °C. Finally, the scaffold was removed and air-dried.

Isolation of Fibroblast Cells and Cell Culture

The samples of the infant’s foreskin were collected aseptically from hospitals of Shiraz University of Medical Sciences, and transferred to the stem cell laboratory of Burn and Wound Healing Research Center. To isolate human fibroblast cells, the infant’s foreskin was immersed in a PBS containing antibiotics (penicillin, 100 g/mL; and streptomycin, 100 g/mL) for 30 s under completely sterile conditions. Primary normal human skin fibroblast cells were isolated from human skin using type-II collagenase (Sigma-Aldrich, USA) and cultured in DMEM with 20% FBS (Gibco Life Technologies) to the third passage, as previously described [28].

Characterization of the Scaffolds

Scanning Electron Microscopy (SEM)

The microstructure, morphology of the as-prepared nanofibers, and cell attachment and cell growth on the nanofibrous scaffolds were all observed using scanning electron microscopy (VEGA TESCAN, Czech Republic). The samples were mounted on metal stubs, and a 200 Angstrom gold film was coated under vacuum using a sputter coater (Bal-Tec Company, Swiss). SEM photographs were analyzed with ImageJ 2 software to determine the diameter of the prepared nanofibers. The image analyzer was used to measure the average diameters of 50 fibers that were chosen at random.

FTIR and ATR-FTIR Analysis

FTIR (RX1 Spectrum model, Perkin Elmer) and ATR-FTIR (RX1 Spectrum model, Perkin Elmer) spectroscopy were used in this study to examine the chemical structure of the samples and identify collagen grafting on the electrospun nanofibrous mats, respectively. To perform FTIR, the sample was first ground with KBr powder and formed into a pellet. The resolution of the instrument was 4 cm−1, and the wavelength range was 4000–400 cm−1. ATR-FTIR analysis was also used to investigate collagen grafting on the surface of nanofibers.

Water Vapor Transmission Rate (WVTR)

The water vapor transmission rate was measured according to the ASTM E96 standard. In this method, at first, the as-prepared nanofiber mat was placed at the mouth of the cup. Two thirds of the cup height was filled with water. The initial weight of cups (\({W}_{0}\)) was measured, and the cups were then placed in the desiccator containing beads of silica gel to control the humidity of the desiccator environment. To maintain a constant temperature, the desiccator was placed in an oven at 37 °C. After 24 h, the cups were re-weighed (\({W}_{24}\)). Then, the water vapor transmission rate was calculated by Eq. 1.

where \(A\) is the surface area of the nanofiber mat that was placed at the mouth of the cups.

Swelling Test

The fluid absorption capacity of a skin substitute is an essential property for keeping a moist environment over the wound bed. In order to study the swelling behavior of the nanofibrous mat, the initial weight of the dry samples \(\left({M}_{i}\right)\) was measured. Then, the specimens (1 cm × 1 cm) were immersed in PBS in a tightly sealed container and placed in an oven at 37 °C. The samples were removed from PBS after 1 h and 24 h of soaking, and surface water of the samples was blotted out with filter paper and weighed \(\left(M\right)\). The swelling percentages of the nanofibers were calculated by Eq. 2.

Tensile Strength Test

A rectangular sample of 5 × 1 cm2 in size was prepared, and a tensile test was carried out in accordance with the ASTM D882 standard. The samples were placed in a vacuum at ambient temperature and humidity, and pressure of 25 inHg before the test. The Brookfield CT3 texture analyzer and a load cell of 4.5 kg were used for this test. To calculate the elongation at break (EB), Eq. 3 was used, where L0 is the initial length of the sample and \({L}_{max}\) is the maximum length at the break.

Also, Eq. 4 was used to calculate the ultimate tensile strength (UTS). In this equation, \({F}_{\mathrm{max}}\) is the maximum input load at the tear point, and \(A\) is the cross-section area of the sample.

Contact Angle Measurement

This test is used to determine the hydrophilicity of the nanofibers produced. The Kruss contact-angle measurement setup (model DSA100) was used to determine the water contact angle of the nanofiber. The contact angles were measured after placing a droplet of distilled water (≈2 µl) on the surface of the nanofiber mat using image analysis of droplet photographs captured with a digital camera. For each nanofiber sample, the average contact angle was calculated using measurements taken at three different locations.

Cell Adhesion Test

The amount of cell adhesion on the scaffold was investigated in this test using images obtained from the SEM. The scaffold was first sterilized by being placed in a 96-well culture plate and then exposed to UV light for 45 min. The buffered saline (PBS, pH = 7.2) containing penicillin (100 g/ml) and streptomycin (100 g/ml) was then poured into the wells and sterilized for 2 h. After removing the buffer solution, the culture medium (DMEM supplemented with 10% FBS, penicillin (100 g/ml), and streptomycin (100 g/ml)) was added and incubated for 24 h at 37 °C. After removing the culture medium, the human fibroblast cells were seeded on the nanofibrous scaffold and incubated for another 24 h at 37 °C. The culture medium was removed at 24, 48, and 72 h after incubation, and a glutaraldehyde solution (2.5 V%) was poured on the scaffold for 4 h at 4 °C to stabilize the cells. Following the removal of the glutaraldehyde, the scaffold was washed sequentially with 25, 50, 75, and 100 V% ethanol to dry completely. SEM was used to examine the interactions between fibroblast cells and nanofibrous scaffolds [29].

Indirect and Direct MTT Test

Cell growth and proliferation on the as-prepared nanofibrous scaffold were evaluated using indirect and direct MTT tests at 1, 3, and 7 days (for indirect MTT test) and 1 day (for direct MTT test) after cell seeding.

To perform an indirect MTT test, L929 mouse fibroblast cells (NCBI C161) from the cell bank of Pasteur Institute of Iran were used. After defrosting, the cells were transferred to a flask which was contained RPMI culture medium with 10% FBS, and then the flask was placed in an incubator at 37 °C, 90% humidity, and 5% CO2 concentration. The culture medium was replaced every 3 or 4 days. To study the toxicity of the nanofibrous samples and their impact on the growth and proliferation of the cells, the specimens of the nanofiber scaffolds were first irradiated by ultraviolet light for sterilization. The extraction process was then performed according to the ISO 10993–5 standard. According to this standard, for each 6 cm2 surface area, 1 ml of the culture medium was added to each sterile specimen. Then, after 7 days, the culture medium was removed and added to the proliferated L929 fibroblast cells. A specific amount of culture medium (RPMI) containing 10% FBS was also considered as control.

In the direct MTT test, the specimens of the scaffold were placed in a 96-well culture plate and sterilized by UV radiation for 45 min. Then, the buffered saline (PBS, pH = 7.2) which contained antibiotics (penicillin, 100 μg/ml; streptomycin, 100 μg/ml) was poured into it and left for sterilization for 2 h. The buffer solution was then removed.

In both the indirect and direct MTT assays, 1 × 104 cells with 100 μl of culture medium were poured into each well of a 96-well cell culture plate. Then, the plate was placed in an incubator at 37 °C for 24 h to keep the cells sticking to the bottom of the plate (for indirect MTT test) or on the scaffold (for direct MTT test). After ensuring cell adhesion, the culture medium was removed to the greatest extent possible, and 90 μl of the extracted specimens plus 10 μl of FBS (for indirect MTT test) or 100 μl of the culture medium contained 10% FBS (for direct MTT test) was added to each well and incubated for 24 h at 37 °C. After that, the culture medium is removed, and 100 μl MTT at a concentration of 0.5 mg/ml is poured into the wells and incubated for 4 h. Afterward, the solution was removed, and isopropanol was added to dissolve the purple crystals. For better dissolution of MTT sedimentation, the plate was placed in the incubator shaker for 15 min. After that, the concentration of dissolved material in isopropanol was measured using an ELISA reader (STAT FAX 2100, USA) at 570 nm. Wells with a higher number of live cells have a higher optical density (OD) than wells with fewer cells. Equations 5 and 6 can be used to calculate the toxicity and the viability percentage of the nanofibers, respectively.

Results and Discussion

Electrospinning Results

A variety of factors can influence the morphology of the produced electrospun nanofiber, including polymer/solvent type, polymer concentration in the final solution, and other operational parameters such as solution flow rate, applied voltage, and nozzle-collector distance [30,31,32]. In this study, a solution of PCL, chitosan, and gelatin was used to make the nanofiber scaffold without the addition of any other substance. Because the electrospinning of this solution had not previously been studied, the effects of the electrospinning parameters on the morphology of the produced nanofiber scaffold were investigated by conducting various experiments to determine the best electrospinning conditions.

Studied Parameters

The chitosan concentration, volumetric ratio of acetic acid to formic acid, applied voltage, gelatin concentration, and solution flow rate were all changed to investigate the effects of electrospinning parameters on the electrospinability and morphology of the produced nanofiber scaffold.

Base Case Conditions

To obtain the operational electrospinning parameters, different sets of experiments were carried out which resulted in the production of a beadless nanofiber mat with an acceptable diameter. The favorable solution concentrations and operating conditions are listed in Table 1. The presented operational conditions and solution concentrations in Table 1 were chosen as the base case condition.

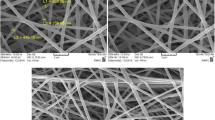

Figure 1 depicts SEM images of the nanofiber scaffold produced in accordance with the conditions listed in Table 1. According to Fig. 1, the produced nanofiber scaffold contains only a few number of beads. The mean diameter of the nanofiber scaffold was also determined using ImageJ software, and it was found to be 282 ± 37 nm. The size distribution of the base case scaffold is shown in Fig. 1c, indicating that 95% of fibers have a diameter of less than 300 nm.

SEM images of the produced nanofibers by electrospinning of the solutions at the base case conditions with different magnifications. a 2000x, b 20000x, and c the size distribution of Table 1 sample

The Effects of Electrospinning Parameters

The Effect of Changing the Acetic Acid to Formic Acid Volumetric Ratio

Five different acetic acid to formic acid volumetric ratios were investigated to determine the effect of changing this parameter on the morphology of the produced scaffold, while all other parameters and polymer concentrations remained constant. Table 2 summarizes the findings.

According to the results of Table 2, pure acetic acid and pure formic acid cannot be used as solvents for electrospinning of the PCL/chitosan/gelatin solution. Nanofibrous mats were also formed in all three volumetric ratios of acetic acid to formic acid (30:70, 50:50, and 70:30). While the same volume of solution was used for electrospinning in all three ratios, a thicker layer of the nanofibrous mat was formed when the solvent was 70:30 acetic acid to formic acid. As a result, the volumetric ratio of acetic acid to formic acid of 70:30 was chosen as the appropriate solvent ratio.

The Effect of Changing the Chitosan Concentration

The presence of chitosan in the solution can decrease the electrospinability of the solution due to its cationic properties [9]. Accordingly, the effect of chitosan concentration on electrospinability and the nanofiber diameter was studied. Table 3 shows the results of electrospinning different PCL/chitosan/gelatin solutions with varying chitosan concentrations to determine the required corresponding applied voltages that resulted in the creation of beadless nanofiber.

To obtain the results shown in Table 3, all electrospinning parameters were set to the same values as the base condition, with the exception of chitosan concentration and applied voltage. Following that, the required applied voltage for forming a nanofiber was determined for each studied concentration of chitosan. As can be seen, increasing the chitosan concentration raises the applied voltage required for electrospinning the solution. In fact, increasing the chitosan concentration in the electrospinning solution increases its viscosity [26]. Previous research has shown that the viscosity of a solution plays an important role in its electrospinability [26, 33]. The solution cohesiveness increases as the viscosity increases, and the solution flow becomes more unstable [33]. As a result, increasing the chitosan concentration requires a higher voltage to be applied in order to achieve a stable flow and, as a result, form a stable Taylor cone. The findings are consistent with those of other previously published studies [26, 33].

Equation 7 was obtained using linear regression based on the obtained experimental data of the required applied voltage versus chitosan concentration for achieving a stable electrospinning process, as shown in Table 3. Actually, Eq. 7 represents the required voltage for stable electrospinning as a function of chitosan concentration.

where \(V\) and CS% denote the required voltage in kV and the chitosan concentration in \(w/v\%\), respectively. R-square of this equation is equal to 0.9934 (R2 = 0.9934), indicating the precision of the obtained equation.

As previously stated, increasing the chitosan concentration is preferable due to the unique properties of chitosan in wound healing and its antibacterial properties. Furthermore, based on the findings of this study, it is clear that the chitosan concentration should be less than 1.5 w/v% in order to achieve stable electrospinning. In addition to the role of chitosan in the wound healing process, the morphology of the produced nanofiber is important for selecting the optimal chitosan concentration [34]. As a result, the SEM was used to depict the morphologies of the produced nanofibers, which are shown in Figs. 2 and 3 at various magnifications.

By comparing the morphologies of the produced nanofibers, it is clear that increasing the chitosan concentration increases the number of beads in the nanofibrous mat. Also, for all three studied chitosan concentrations, the mean diameters of the produced nanofiber scaffolds were determined using the ImageJ software, and it was discovered that for 0.5, 1, and 1.5% w/v of chitosan, the diameters of the produced nanofibers were equal to 282 ± 37, 120 ± 31, and 108 ± 22 nm, respectively, indicating that increasing the chitosan concentration decreases the mean diameter of the nanofiber.

Equation 8 was obtained through regression of the obtained results. This equation depicts the diameter of nanofibers as a function of chitosan concentration.

where \(D\) is the average nanofiber diameter in nanometers. According to the calculated R-square (\({R}^{2}=0.964\)), it is clear that Eq. 8 is a reliable model for estimating the diameter of the produced nanofiber as a function of chitosan concentration.

Finally, because the nanofibers produced should be beadles [35], 0.5 w/v% chitosan in the electrospinning solution was chosen as the preferred chitosan concentration for future experiments.

The Effect of Changing the Solution Flow Rate

In this work, three different solution flow rates were investigated, while all other parameters were kept the same as in the base case condition. The morphologies of the produced scaffolds were determined by varying the solution flow rate and are shown in Table 4. According to the results, increasing the solution flow rate from 0.2 ml/h to 0.4 ml/h reduced the number of beads in the nanofiber mat, while increasing the flow rate from 0.4 to 0.6 ml/h resulted in no nanofiber formation.

Due to the failure of the electric field to stretch the solution, increasing the solution flow rate causes the solution to be electrosprayed rather than electrospun [36, 37]. As a result, a solution flow rate of 0.4 ml/h was chosen as the appropriate flow rate.

The Effect of Changing the Gelatin Concentration

Table 5 shows the results of an investigation into the effect of changing the gelatin concentration on the morphologies of the produced nanofibers. The results showed that increasing the gelatin concentration increases the number of beads in the produced scaffold while decreasing the electrospinability of the solution due to increasing the solution viscosity.

Based on the benefits of gelatin in wound healing and the results shown in Table 5, a solution containing 2 w/v% gelatin was chosen for further research.

In the following sections, the scaffold was produced based on the achieved results and the best electrospinning conditions presented. Furthermore, collagen with varying weight percentages was grafted on the produced scaffolds, as described in the “Collagen Extraction and Grafting” As a result, the properties of the produced scaffolds with and without collagen grafting were presented in the following sections.

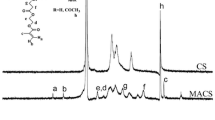

FTIR and ATR-FTIR Results

The FTIR results for neat PCL, chitosan, gelatin, and extracted collagen are shown in Fig. 4F1. In addition, the results of the ATR-FTIR test for collagen-grafted nanofibers and nanofibers without collagen are shown in Fig. 4F2. Because each substance has distinct absorption bands, the achieved peak frequencies of the studied substances are compared to previously published data in order to ensure that all of the mentioned substances are present in the final nanofibers.

According to the FTIR results for the extracted collagen sample Fig. 4F1A, the 3226 and 1658 cm−1 peak frequencies represent the amide group I, the 1551 cm−1 peak frequency represents the amide II group, and the 1238 cm−1 peak frequency represents the amide III group. Previous research [38, 39] indicates that the peak frequencies mentioned are typical absorption bands in type I collagen. Peaks at 3590, 1688, 1540, and 1240 cm−1 in the FTIR spectrum of gelatin (Fig. 4F1B) indicate N–H groups in the amide I, C = O in the amide I, N–H in the amide II, and N–H in the amide III [40], respectively. The symmetric and asymmetric stretching of the CH2 group is expressed in the FTIR spectrum of the PCL (Fig. 4F1C), while the symmetric and asymmetric stretching of the C–O–C group is expressed in the peak frequencies 1240 and 1174 cm−1. The carbonyl group has a peak frequency of 1730 cm−1 [41, 42]. Furthermore, peaks at 3435, 2893, 1271, and 1150 cm−1 in the FTIR spectrum of chitosan (Fig. 4F1D) represent O–H and N–H, C-H, C-O groups in carboxylic acid, and C-O in the ether, respectively [43].

Based on the ATR-FTIR analysis of Fig. 4F2A which is related to the fibers without grafting of collagen, the spectra of 2942, 2863, 1240, 1722, 1293, and 1186 cm−1 indicate the presence of PCL in the fiber. Also, the spectrum 1396 cm−1 represents the amide III, 1082 and 1045 cm−1 represent the stretching of the COO, the spectrum 3439 cm−1 also represents the stretching of the N–H amide group, 2940 cm−1 represents the N–H group in the chitosan spectrum, and 1650 cm−1 corresponds to the C = O in the amide I, which prove the presence of chitosan and gelatin in the fiber.

On the other hand, for the grafted nanofibers, 3306, 1641, 1546, and 1238 cm−1 spectra in Fig. 4F2B and F2C represent the existence of collagen in the fibers which collagen was grafted on their surfaces. The presence of these peaks proves that collagen grafting on the surface of the nanofiber was done successfully. The difference between the intensity of the peaks of fibers grafted by 0.2% collagen (Fig. 4F2C) and 0.4% collagen solutions (Fig. 4F2B) is due to the difference in the degree of collagen grafting on the nanofiber mats.

Swelling Degree of the As-Prepared Nanofibers

The ability of biomedical polymers to absorb water is an important property. One of the most important characteristics of modern wound dressings is their ability to absorb wound secretion while also providing and maintaining a moist environment over the wound bed. Figure 5 depicts the swelling of the produced nanofibrous mats with and without collagen grafting at 1 and 24 h after soaking in PBS.

Based on the results of this test, it is clear that the swelling amounts at 24 h increase in comparison to the water uptake at 1 h for all samples, which is predictable due to the greater immersion time of nanofibers in the buffer. A previous study [9] has shown that PCL did not show any significant swelling properties due to its hydrophobicity. As can be seen in Fig. 5, adding chitosan and gelatin to PCL (without collagen grafting) led to an increase in the swelling of the nanofiber mat to 94.37 ± 5.52% at 24 h, which suggests nanofibrous mat’s hydrophilicity improvement due to the presence of chitosan and gelatin. The obtained results also indicate that collagen grafting on the nanofibers increases the degree of swelling of the produced nanofibers. In addition, two-way ANOVA statistical analysis was used, and the p-values revealed that grafting collagen significantly increased swelling. Figure 5 depicts the p-values as well. These findings are supported by the hydrophilicity of collagen, chitosan, and gelatin.

Mechanical Properties of the Prepared Nanofibers

The mechanical strength of the suitable skin substitute should be comparable to that of human skin. As a result, investigating the mechanical properties of developed skin scaffolds is an important topic in the field of skin tissue engineering. Table 6 shows the results of the tensile test of the as-prepared nanofibrous mats and the mechanical properties of human skin [44].

PCL is a synthetic polymer with good mechanical properties [45]. When the results in Table 6 are compared to the previously published data for the mechanical properties of PCL [45], it can be seen that adding chitosan, gelatin, and collagen to PCL, reduces the ultimate tensile strength, Young’s modulus, and elongation at the breakpoint of the produced nanofibers. In fact, chitosan, gelatin, and collagen are natural polymers with lower mechanical strength compared to PCL. Accordingly, adding these natural polymers to PCL reduces the mechanical properties of the as-prepared nanofibrous scaffolds. In addition, the data in Table 6 show that collagen grafting reduced the tensile strength of the nanofiber. However, by comparing the mechanical properties of the skin and the nanofibers produced, it is possible to conclude that the scaffolds have acceptable mechanical properties.

Water Vapor Transmission Rate of the Nanofibers

The water vapor transmission rates of the produced nanofiber mats are presented in Table 7.

Because of the hydrophilic nature of collagen, the WVTR of the sample that is grafted with 0.2% collagen solution has a higher WVTR than a non-grafted nanofiber. In fact, grafting collagen onto the nanofiber mats increases their hydrophilicity. As a result, water vapor transmission through a sample grafted with a 0.2% collagen solution will be facilitated. However, in samples grafted with a 0.4% collagen solution, the collagen layer on the nanofiber surfaces thickens in addition to increasing the hydrophilicity of the samples, and thus the WVTRs of the samples decrease due to the thickening of the collagen layer.

The WVTR values are important because a low WVTR of the scaffold causes secretions to accumulate in the wound, allowing bacteria to penetrate and grow during the healing process. High WVTR, on the other hand, promotes wound drying [46]. As a result, a reasonable value for the WVTR is required for the produced nanofiber.

Previous research has determined that the WVTRs of ordinary skin, skin with a first-degree burn, and granulating wound are 204 ± 12, 279 ± 26, and 5138 ± 202 g m−2 day−1, respectively [46]. When the WVTR in Table 7 is compared to these values, it is possible to conclude that the produced scaffold has an acceptable WVTR.

Contact Angle of the Nanofiber

At room temperature, the hydrophilicity of the nanofibers was determined using the static sessile drop mode. Table 8 shows the contact angles of three samples measured at 1 to 5 s using ImageJ software. The hydrophilicity of the sample increases due to the hydrophilicity of collagen when the surface of the produced scaffold is modified by grafting collagen on its surface [39].

MTT Test Results

Direct Cytotoxicity Test

The results of the direct MTT tests are presented in Fig. 6.

Based on the results, it is clear that the ODs for the samples are higher than the control due to the presence of fibers. Cells grow in three spatial dimensions in the presence of fibers, and as a result, the ODs are higher than in the control sample. When the results were compared, it was discovered that the sample grafted with a 0.4% collagen solution had the highest OD due to the properties of the collagen. Indeed, collagen, as a protein, contains receptors that are critical for cellular interaction, and as a result, it can improve cell adhesion, growth, and proliferation [47]. As a result, the scaffold with more collagen has a greater OD. Furthermore, the one-way ANOVA analysis revealed that the sample containing 0.4% grafted collagen had a significantly higher OD than the sample containing no grafting (p-value < 0.05). Thus, it is clear that surface modification of the prepared nanofibers by grafting collagen is critical, and only the performance of surface-modified nanofibers was studied for the indirect cytotoxicity test and fibroblast cell proliferation.

Indirect Cytotoxicity Test and Proliferation of Fibroblast Cells

The cytotoxicity test, which demonstrates the biocompatibility of nanofibers as skin tissue engineering scaffolds, is one of the most important tests to evaluate their application as skin tissue engineering scaffolds. Figure 7 depicts the toxicity of nanofibers. Based on the findings, it was determined that the produced nanofibers were compatible with cells and that the scaffold was nontoxic. These findings were also supported by one-way ANOVA analysis. The ANOVA analysis revealed that there were no significant differences between the control and grafted scaffold viabilities (p-values for the scaffolds that are grafted by use of 0.2% and 0.4% collagen solutions are greater than 0.05).

The results of the 7-day fibroblast cell proliferation assay are also shown in Fig. 8. According to the results, the ODs of the scaffolds with grafted collagen increased significantly, as determined by two-way ANOVA analysis. The p-values are shown in the Table 9. These findings also show that the 0.4% collagen solution-grafted sample has a higher OD at all times studied, indicating that grafting collagen can improve cell proliferation. In general, the results demonstrated that the produced scaffolds are biocompatible, and that grafting collagen onto the scaffold can significantly improve the nanofiber’s capability as a skin scaffold.

Cell Adhesion, Growth, and Proliferation Assay

The cell adhesion on the scaffold was determined using SEM photographs. Figure 9 shows SEM images of nanofiber mats with and without collagen grafting that were seeded with human fibroblast cells. According to Fig. 9, it was discovered that grafting collagen can significantly increase cell adhesion due to collagen receptors. As a result, the findings indicated that grafting collagen can improve the scaffold’s ability to adhere to cells. As a result of the proper cell adhesion in collagen-grafted samples, scaffolds grafted with 0.2% and 0.4% collagen solutions were used for growth and cell proliferation assays.

Cell growth and proliferation were also studied using SEM imaging after 24, 48, and 72 h. Two scaffolds (grafted with 0.2% and 0.4% collagen solutions) were investigated in this test. Human fibroblast cells were also used. According to Fig. 10, cultured cells could grow and proliferate in both scaffolds, but the scaffold grafted with 0.4% collagen had better cell growth and proliferation. According to the observations, the scaffold has an acceptable ability to grow and propagate cells.

Collagen, as previously stated, serves as a suitable substrate for cell adhesion, growth, and proliferation. As a result, by grafting more collagen on the surface of the scaffold, the cell growth rate increases. Furthermore, these findings suggest that collagen surface modification of scaffolds is critical.

Conclusion

The electrospinning method was used to successfully prepare a nanofibrous scaffold of PCL, chitosan, and gelatin, which was then grafted with collagen. The effects of changing the values of various factors such as acetic acid volumetric ratio to formic acid, chitosan concentration, gelatin concentration, applied voltage, and solution flow rate on the morphologies of the produced nanofibers and electrospinabilities of the solutions were investigated. According to the results, a beadless scaffold was successfully constructed without the addition of any other substance to the PCL, chitosan, and gelatin solution. In addition, the feasibility of the produced scaffold as a skin scaffold was investigated by grafting the collagen on the fabricated scaffold.

As a result, various tests were performed to investigate the chemical, physical, and mechanical properties of the scaffolds produced. The non-toxicity behavior and the adhesion and growth of cells on the scaffolds were also investigated. The results showed that the as-prepared beadless nanofibrous scaffold has adequate mechanical strength. Furthermore, based on the FTIR test results, it is possible to conclude that all of the ingredients, namely PCL, chitosan, and gelatin, are presented in a nanofiber mat without changing their chemical natures. Furthermore, the ATR-FTIR test of the collagen grafted nanofibers showed that collagen was successfully grafted on the nanofibers’ surface. Other tests revealed that the nanofibers produced have acceptable degrees of swelling and good water vapor permeabilities, with values in the range of skin vapor permeabilities. According to the results of the cellular toxicity and cell culture tests, the fibers were not toxic and provide good environments for cell growth and proliferation, and surface modification of the scaffold by grafting collagen could significantly improve cell growth and proliferation. As a result, the produced scaffold is a good candidate for skin tissue engineering, and surface modification is required to improve its properties. Based on the findings of this study, the authors strongly advise that the performance of the scaffold, which is grafted with 0.4% collagen solution, be investigated using immunostaining and in-vivo tests, as well as a quantitative examination of cell adhesion, for further evaluations.

Data Availability

The data presented in this article were gathered as a result of the aforementioned experiments. The sources of the materials used are also mentioned in the article.

Code Availability

Not applicable.

References

Groeber F, Holeiter M, Hampel M, Hinderer S, Schenke-Layland K. Skin tissue engineering — In vivo and in vitro applications. Adv Drug Deliv Rev. 2011;63(4):352–66. https://doi.org/10.1016/j.addr.2011.01.005.

Pereira RF, Barrias CC, Granja PL, Bartolo PJ. Advanced biofabrication strategies for skin regeneration and repair. Nanomed Nanotechnol Biol Med. 2013;8(4):603–21. https://doi.org/10.2217/nnm.13.50.

Zhong SP, Zhang YZ, Lim CT. Tissue scaffolds for skin wound healing and dermal reconstruction. Wiley Interdisc Rev: Nanomed Nanobiotechnol. 2010;2(5):510–25. https://doi.org/10.1002/wnan.100.

Wang F, Wang M, She Z, Fan K, Xu C, Chu B, Chen C, Shi S, Tan R. Collagen/chitosan based two-compartment and bi-functional dermal scaffolds for skin regeneration. Mater Sci Eng, C. 2015;52:155–62. https://doi.org/10.1016/j.msec.2015.03.013.

Prasad T, Shabeena EA, Vinod D, Kumary TV, Anil Kumar PR. Characterization and in vitro evaluation of electrospun chitosan/polycaprolactone blend fibrous mat for skin tissue engineering. J Mater Sci - Mater Med. 2015;26(1):28. https://doi.org/10.1007/s10856-014-5352-8.

Gholipour KA, Bahrami SH, Nouri M. Chitosan-poly(vinyl alcohol) blend nanofibers: morphology, biological and antimicrobial properties. e-Polymers. 2009;9:1580. https://doi.org/10.1515/epoly.2009.9.1.1580.

Jung S-M, Yoon GH, Lee HC, Shin HS. Chitosan nanoparticle/PCL nanofiber composite for wound dressing and drug delivery. J Biomater Sci Polym Ed. 2015;26(4):252–63. https://doi.org/10.1080/09205063.2014.996699.

Sowmya B, Hemavathi AB, Panda PK. Poly (ε-caprolactone)-based electrospun nano-featured substrate for tissue engineering applications: a review. Prog Biomater. 2021. https://doi.org/10.1007/s40204-021-00157-4.

Gomes S, Rodrigues G, Martins G, Henriques C, Silva JC. Evaluation of nanofibrous scaffolds obtained from blends of chitosan, gelatin and polycaprolactone for skin tissue engineering. Int J Biol Macromol. 2017;102:1174–85. https://doi.org/10.1016/j.ijbiomac.2017.05.004.

Sarasam AR, Samli AI, Hess L, Ihnat MA, Madihally SV. Blending chitosan with polycaprolactone: porous scaffolds and toxicity. Macromol Biosci. 2007;7(9–10):1160–7. https://doi.org/10.1002/mabi.200700001.

Pei W. Application of polycaprolactone-based biopolymer scaffolds in tissue engineering. Chin J Tissue Eng Res. 2021;25(34):5506–10. https://doi.org/10.12307/2021.247.

Lin Z, Zhao C, Lei Z, Zhang Y, Huang R, Lin B, Dong Y, Zhang H, Li J, Li X. Epidermal stem cells maintain stemness via a biomimetic micro/nanofiber scaffold that promotes wound healing by activating the Notch signaling pathway. Stem Cell Res Ther. 2021;12(1):341. https://doi.org/10.1186/s13287-021-02418-2.

Safi IN, Al-Shammari AM, Ul-Jabbar MA, Hussein BMA. Preparing polycaprolactone scaffolds using electrospinning technique for construction of artificial periodontal ligament tissue. J Taibah Univ Med Sci. 2020;15(5):363–73. https://doi.org/10.1016/j.jtumed.2020.07.007.

Mirzaei Z, Kordestani S, Kuth S, Schubert DW, Detsch R, Roether JA, Blunk T, Boccaccini AR. Preparation and characterization of electrospun blend fibrous polyethylene oxide: polycaprolactone scaffolds to promote cartilage regeneration. Adv Eng Mater. 2020;22(9):2000131. https://doi.org/10.1002/adem.202000131.

Liu X, Chen B, Li Y, Kong Y, Gao M, Zhang LZ, Gu N. Development of an electrospun polycaprolactone/silk scaffold for potential vascular tissue engineering applications. J Bioact Compat Polym. 2021;36(1):59–76. https://doi.org/10.1177/0883911520973244.

Mondal D, Griffith M, Venkatraman SS. Polycaprolactone-based biomaterials for tissue engineering and drug delivery: current scenario and challenges. Int J Polym Mater Polym Biomater. 2016;65(5):255–65. https://doi.org/10.1080/00914037.2015.1103241.

Ekram B, Abd El-Hady BM, El-Kady AM, Amr SM, Gabr H, Waly AI, Guirguis OW. Enhancing the stability, hydrophilicity, mechanical and biological properties of electrospun polycaprolactone in formic acid/acetic acid solvent system. Fibers Polymers. 2019;20(4):715–24. https://doi.org/10.1007/s12221-019-8795-1.

Ge Y, Tang J, Fu H, Fu Y, Wu Y. Characteristics, controlled-release and antimicrobial properties of tea tree oil liposomes-incorporated chitosan-based electrospun nanofiber mats. Fibers Polymers. 2019;20(4):698–708. https://doi.org/10.1007/s12221-019-1092-1.

Kalantari K, Afifi AM, Jahangirian H, Webster TJ. Biomedical applications of chitosan electrospun nanofibers as a green polymer – review. Carbohyd Polym. 2019;207:588–600. https://doi.org/10.1016/j.carbpol.2018.12.011.

Piasecka-Zelga J, Zelga P, Gronkowska K, Madalski J, Szulc J, Wietecha J, Ciechańska D, Dziuba R. Toxicological and sensitization studies of novel vascular prostheses made of bacterial nanocellulose modified with chitosan (MBC) for application as the tissue-engineered blood vessels. Regen Eng Translat Med. 2021;7(2):218–33. https://doi.org/10.1007/s40883-021-00209-y.

Kt Nijenhuis. Gelatin. In: Thermoreversible networks: viscoelastic properties and structure of gels. Berlin: Springer Berlin Heidelberg; 1997. p. 160–93. https://doi.org/10.1007/BFb0008709.

Yamauchi M. Collagen biochemistry: an overview. In: Phillips GO, editor. bone morphogenetic protein and collagen. Allografts in bone healing: biology and clinical applications, vol. 2. Singapore: World Scientific; 2004. p. 93–148. https://doi.org/10.1142/9789812795298_0006.

Gautam S, Chou C-F, Dinda AK, Potdar PD, Mishra NC. Surface modification of nanofibrous polycaprolactone/gelatin composite scaffold by collagen type I grafting for skin tissue engineering. Mater Sci Eng, C. 2014;34:402–9. https://doi.org/10.1016/j.msec.2013.09.043.

Zhu Y, Wu Z, Tang Z, Lu Z. HeLa cell adhesion on various collagen-grafted surfaces. J Proteome Res. 2002;1(6):559–62. https://doi.org/10.1021/pr020007a.

Shalumon KT, Anulekha KH, Chennazhi KP, Tamura H, Nair SV, Jayakumar R. Fabrication of chitosan/poly(caprolactone) nanofibrous scaffold for bone and skin tissue engineering. Int J Biol Macromol. 2011;48(4):571–6. https://doi.org/10.1016/j.ijbiomac.2011.01.020.

Van der Schueren L, Steyaert I, De Schoenmaker B, De Clerck K. Polycaprolactone/chitosan blend nanofibres electrospun from an acetic acid/formic acid solvent system. Carbohyd Polym. 2012;88(4):1221–6. https://doi.org/10.1016/j.carbpol.2012.01.085.

Zarghami A, Irani M, Mostafazadeh A, Golpour M, Heidarinasab A, Haririan I. Fabrication of PEO/chitosan/PCL/olive oil nanofibrous scaffolds for wound dressing applications. Fibers Polym. 2015;16(6):1201–12. https://doi.org/10.1007/s12221-015-1201-8.

Hashemi SS, Rafati AR. Comparison between human cord blood serum and platelet-rich plasma supplementation for Human Wharton’s Jelly Stem Cells and dermal fibroblasts culture. Int J Med Res Health Sci. 2016;5(8):191–6.

Vashisth P, Nikhil K, Roy P, Pruthi PA, Singh RP, Pruthi V. A novel gellan–PVA nanofibrous scaffold for skin tissue regeneration: fabrication and characterization. Carbohyd Polym. 2016;136:851–9. https://doi.org/10.1016/j.carbpol.2015.09.113.

Thompson CJ, Chase GG, Yarin AL, Reneker DH. Effects of parameters on nanofiber diameter determined from electrospinning model. Polymer. 2007;48(23):6913–22. https://doi.org/10.1016/j.polymer.2007.09.017.

Anindyajati A, Boughton P, Ruys AJ. Modelling and optimization of polycaprolactone ultrafine-fibres electrospinning process using response surface methodology. Materials (Basel). 2018;11(3):441. https://doi.org/10.3390/ma11030441.

Gu SY, Ren J, Vancso GJ. Process optimization and empirical modeling for electrospun polyacrylonitrile (PAN) nanofiber precursor of carbon nanofibers. Eur Polymer J. 2005;41(11):2559–68. https://doi.org/10.1016/j.eurpolymj.2005.05.008.

Huang Z-M, Zhang YZ, Kotaki M, Ramakrishna S. A review on polymer nanofibers by electrospinning and their applications in nanocomposites. Compos Sci Technol. 2003;63(15):2223–53. https://doi.org/10.1016/S0266-3538(03)00178-7.

Shalihah H, Kusumaatmaja A, Triyana K, Nugraheni A. Optimization of chitosan/PVA concentration in fabricating nanofibers membrane and its prospect as air filtration. Mater Sci Forum. 2016;901:20–5 (Paper presented at the International Conference on Science and Technology, Yogyakarta).

Elsabee MZ, Naguib HF, Morsi RE. Chitosan based nanofibers, review. Mater Sci Eng, C. 2012;32(7):1711–26. https://doi.org/10.1016/j.msec.2012.05.009.

Andrady AL. Science and technology of polymer nanofibers. Hoboken: John Wiley & Sons Inc; 2008.

Ramakrishna S, Fujihara K, Teo W-E, Lim T-C, Ma Z. An introduction to electrospinning and nanofibers. Singapore: World Scientific; 2005. https://doi.org/10.1142/5894.

Chen Z, Mo X, He C, Wang H. Intermolecular interactions in electrospun collagen–chitosan complex nanofibers. Carbohyd Polym. 2008;72(3):410–8. https://doi.org/10.1016/j.carbpol.2007.09.018.

Sadeghi AR, Nokhasteh S, Molavi AM, Khorsand-Ghayeni M, Naderi-Meshkin H, Mahdizadeh A. Surface modification of electrospun PLGA scaffold with collagen for bioengineered skin substitutes. Mater Sci Eng, C. 2016;66:130–7. https://doi.org/10.1016/j.msec.2016.04.073.

Mostafa AA, Ibrahim DM, Korowash SI, Fahim F, Oudadesse H. Nano-hybrid-composite scaffolds from substituted apatite/gelatin. Key Eng Mater. 2014;587:233–8. https://doi.org/10.4028/www.scientific.net/KEM.587.233.

Chiono V, Vozzi G, D’Acunto M, Brinzi S, Domenici C, Vozzi F, Ahluwalia A, Barbani N, Giusti P, Ciardelli G. Characterisation of blends between poly(ε-caprolactone) and polysaccharides for tissue engineering applications. Mater Sci Eng, C. 2009;29(7):2174–87. https://doi.org/10.1016/j.msec.2009.04.020.

Gautam S, Dinda AK, Mishra NC. Fabrication and characterization of PCL/gelatin composite nanofibrous scaffold for tissue engineering applications by electrospinning method. Mater Sci Eng, C. 2013;33(3):1228–35. https://doi.org/10.1016/j.msec.2012.12.015.

Hadipour-Goudarzi E, Montazer M, Latifi M, Aghaji AAG. Electrospinning of chitosan/sericin/PVA nanofibers incorporated with in situ synthesis of nano silver. Carbohyd Polym. 2014;113:231–9. https://doi.org/10.1016/j.carbpol.2014.06.082.

Gallagher AJ, Ní Anniadh A, Bruyere K, Otténio M, Xie H, Gilchrist MD (2012) Dynamic tensile properties of human skin. Paper presented at the Proceedings of the 2012 International IRCOBI Conference on the Biomechanics of Injury, Dublin, Ireland. Corpus ID: 111341757

Rosa DS, Guedes CGF, Bardi MAG. Evaluation of thermal, mechanical and morphological properties of PCL/CA and PCL/CA/PE-g-GMA blends. Polym Testing. 2007;26(2):209–15. https://doi.org/10.1016/j.polymertesting.2006.10.003.

HashemiDoulabi A, Mirzadeh H, Imani M, Samadi N. Chitosan/polyethylene glycol fumarate blend film: physical and antibacterial properties. Carbohyd Polym. 2013;92(1):48–56. https://doi.org/10.1016/j.carbpol.2012.09.002.

Davidenko N, Schuster CF, Bax DV, Farndale RW, Hamaia S, Best SM, Cameron RE. Evaluation of cell binding to collagen and gelatin: a study of the ffect of 2D and 3D architecture and surface chemistry. J Mater Sci - Mater Med. 2016;27(10):148. https://doi.org/10.1007/s10856-016-5763-9.

Acknowledgements

The authors would like to express their gratitude to Shiraz University and Shiraz University of Medical Sciences for providing the necessary facilities.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

Table 9 shows the p-values of two-way ANOVA analysis for the indirect cytotoxicity test and fibroblast cell proliferation.

Rights and permissions

About this article

Cite this article

Sheikhi, F., Khorram, M., Hashemi, SS. et al. Preparation, Characterization, and Surface Modification of Polycaprolactone-Based Nanofibrous Scaffold by Grafting with Collagen for Skin Tissue Engineering. Regen. Eng. Transl. Med. 8, 545–562 (2022). https://doi.org/10.1007/s40883-022-00254-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40883-022-00254-1