Abstract

A treatment system composed of a double-chamber anaerobic (DCA) reactor in conjunction with a constructed wetland (CW) of horizontal sub-surface flow, for the treatment of leachates generated in the municipal sanitary landfill of a typical mid-sized city was investigated. The aim of this work was to assess the capability of the system to remove pollutants such as organic load, nutrients and solids. The system was evaluated at hydraulic retention times (HRT) of 7.97, 5.31 and 2.88 days. The highest removal efficiencies for the system were obtained at HRT of 7.97 days and were 89% and 91% for TCOD and BOD, respectively. In the case of NO3−, NO2−, NH4+ and Total Kjeldahl Nitrogen (TKN), their removal rates were estimated at 88%, 93%, 93% and 85%, respectively; whilst for TS, TVS and TTSS they were 88%, 86% and 90%, respectively, again at HRT of 7.97 d. Efficiencies of 78%, 83% and 77% were obtained respectively for TCOD, BOD and TKN in DCA reactor at HRT of 1.5 d. Typha domingensis was identified as a species capable of adapting to the physicochemical conditions of the leachate, exhibiting an average growth of 196 cm. In leachate there were found low concentrations of heavy metals, being aluminum the metal with the highest concentrations (between 3.31–10.09 mg/L). Results show that it is feasible to implement the DCA reactor in series with a constructed wetland for the treatment of sanitary landfill leachates. Therefore, this system can be replicated for the treatment of leachates with similar conditions.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Landfills are the most commonly used method for the final disposal of solid waste in the world (Renou et al. 2008). Production and discharge to the environment of byproducts generated during operation activities in landfills represents one of the major health challenges (Zazouli et al. 2012). Byproducts commonly found in landfills are leachates, which are originated by the degradation of organic materials. These leachates permeate through the different solid waste layers, increasing the concentration of pollutants to levels that are highly aggressive to the environment (Peng 2017). Other toxic agents, such as heavy metals, organochlorine compounds and high organic loads have also been found in leachates (Zazouli et al. 2012). Unappropriated management of untreated leachates has become a common practice in many developing countries, requiring the need of implementing reliable and low-cost technologies for their effective treatment (Madera et al. 2014).

Current leachate treatment technologies have considerable disadvantages, such as a high investment costs and unstable sludge production, which in turn demands large disposal areas. In order to increase removal efficiencies of toxic pollutants present in leachates, and to meet current local regulations, it is necessary to improve existing processes or implement alternative and affordable technologies for their treatment (Heyer and Stegmann 2005; Sun et al. 2015). However, the complex composition of leachates hampers the stabilization and operation of existing treatment systems, causing extreme operating conditions that inhibit the decomposition and efficient removal of contaminating materials. Thus, the design and selection of an efficient system is a challenging task (Zazouli et al. 2012).

Anaerobic digestion has proved to be an effective method capable to stabilize biodegradable composites of organic solid waste and in return producing renewable energy in the form of biogas (Gaur and Suthar 2017). An anaerobic treatment system commonly used for the treatment of wastewater with high concentrations of organic loads is the upflow anaerobic sludge blanket (UASB) reactor (Khan et al. 2012; Perez et al. 2019). This system is capable to yield removal efficiencies up to 80% (El-Sheikh et al. 2011).

It has been reported that if influent is directly supplied from landfill leachates, UASB performance decreases significantly, reaching minimum organic material removal efficiencies of 15% (El-Gohary and Kamel 2016), an average of 49% (Bohdziewic and Kwarciak 2008) and a maximum of 70% (Katsoni et al. 2014). However, considering the high toxicity, complexity and composition of the leachates, a residual of 30% in the discharge can be still harmful to the environment (Wu et al. 2016). Therefore, there is a need of developing and implementing more efficient treatment technologies for these leaching systems (Wu et al. 2016; Peng et al. 2008).

In order to increase the efficiency of the conventional UASB reactor, Galindo et al. (2012) proposed a technological modification to this reactor, pointing to a double-chamber anaerobic (DCA) reactor. In chamber 1 (C1) the hydrolysis and acidogenesis phases are carried out, while in chamber 2 (C2), acetogenesis and methanogenesis are carried out (Diamantis et al. 2009). With these modifications, the DCA reactor presents operational conditions similar to those existing in the UASB reactor, therefore, conversion rates or removal of the organic matter is governed mainly by two factors: (1) the performance of the microbiological process, and (2) the reactor hydraulics. Galindo (2012) reported that DCA reactors present practical operational advantages with respect to UASB reactors. Some of these advantages are: i) greater specialization of the bacterial consortia specific to the anaerobic digestion phases; ii) lower surface area requirement; iii) better buffer capacity; iv) better dilution of toxic agents in C1, thus decreasing their effect on the methanogenic bacteria, that are present in greater proportion in C2; and iv) larger removal efficiencies. Other operational advantages of DCA reactors are: better distribution of the influent with stable upward velocities (avoiding the loss of biomass and particulate material), a more clarified effluent with low solids concentrations, as well as high chemical oxygen demand (COD) removal efficiencies. In general, it has been reported that UASB reactors operating with different substrates in two-stages exhibit better performances than those operating individually (Diamantis and Aivasidis 2007; Diamantis and Aivasidis 2010).

Despite the fact that high removal efficiencies can be obtained in anaerobic systems such as UASB reactors, their effluents still present high concentrations of nutrients, organic matter and pathogenic microorganisms, enforcing the need for post-treatment processes (Khan et al. 2011; Khan et al. 2013). To this end, constructed wetlands are the most commonly used alternative due to they are inexpensive and environmentally friendly (Akinbile et al. 2012; Yalcuk and Ugurlu 2009). These systems are widely used for the treatment of different effluents, and even as a post-treatment unit for complex organic substrates such as leachates (Rengers et al. 2016).

Removal of contaminants in CWs occurs by the action of aerobic bacteria, which are attached to the filter medium (gravel) and plant roots. These provide adequate conditions for the filtration, absorption and consumption of nutrients, favoring the development of symbiotic processes in the rhizosphere (bacteria/roots) (Shehzadi et al. 2014; Mojiri et al. 2016; El-Khateeb et al. 2009). In addition, sedimentation removes solids and contaminants entrained in leachates.

In CW systems, the Typha genus is one of the most widely used plant due to its wide geographic distribution and tolerance to drastic changes in temperature conditions, as well as its resistance to high pollution levels (Li et al. 2010a). Particularly, the species Typha domingensis, used in the present investigation, is characterized by having a deep radicular system and a spongy plant structure that favors the processes of fixation and accumulation of nutrients and heavy metals (Mojiri et al. 2016).

The species Typha domingensis has been identified as a viable phytoremediator for the treatment of leachates (Mojiri et al. 2013; Mojiri et al. 2016). This plant develops dense and extensive rhizomes that propagate and grow even in difficult conditions, which promotes a greater oxygen transfer and increases contaminant removal efficiencies (Li et al. 2010a). In addition, this plant has certain suitable morphological characteristics such as its size, robustness of its stem as well as surface area of its leaves (Uotila et al. 2019) that allows greater adsorption and elimination of complex organic waste. Its roots provide a pathway or hydraulic route through which the substrate to be treated flows (Li et al. 2010a), allowing the development of a large variety of microorganisms within the system (rhizosphere), which contribute to the degradation of pollutants (Shehzadi et al. 2014).

Considering the difficulty of getting high removal rates for some existing contaminants in leachates by using systems operating individually (El-Gohary and Kamel 2016), a commonly used strategy to rise up efficiency levels is the combination of two or more treatment methods (Sun et al. 2010; Wu et al. 2016; Katsoni et al. 2014). In addition to efficiency rising, this alternative strategy reduces treatment costs (Li et al. 2010b).

In the present study, it is proposed to evaluate the performance of a treatment system composed out of two combined biological systems for the treatment of landfill leachates generated in a sanitary landfill, i.e., a DCA reactor operating in series with a constructed wetland. The DCA performance with synthetic and municipal wastewater was assessed in terms of its capability to remove organic load, nutrients and solids. In addition, the performance of a constructed wetland as a post-treatment unit was evaluated. To this end, an abundant native plant in the study area (i.e., Typha domingensis species) was used.

2 Materials and Methods

2.1 Characterization of Leachates

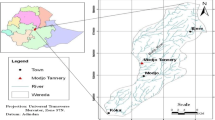

Considering landfill age, three types of leachates were retrieved from the sanitary landfill evaluated (city of Riohacha, La Guajira-Colombia), namely, young, old and mixed. The young leachate was taken from the currently used cell with 6 months of operation; the old leachate was taken from a cell which was closed just before starting the current cell operation. The mixed leachate was prepared in the laboratory using equal proportions of the young and old leachates. In order to evaluate the degree of treatability of each type of leachate, they were first characterized. Their content of organic matter, metal concentrations, nutrients and solids, among others, were first determined. In the analyses of the samples, the techniques established in the standard methods were applied (APHA et al. 2012).

2.2 Experimental System Design

During the experiments, a DCA was coupled in series with a CW (feed from C2), as can be seen in the experimental scheme shown in Fig. 1. The DCA, with a nominal volume capacity of 12 L, was built out of transparent acrylic, and consisted of two chambers, C1 and C2, with respective volumes of 7.5 and 4.5 L. Each chamber was equipped with individual biogas measurement system. Due to its dimensions, this DCA can be considered as laboratory-scale.

In order to obtain retention times similar to operational CW of horizontal sub-surface flow conditions, the wetland was built in rectangular shape at pilot-scale. It was built out of acrylic sheets with dimensions of 25 cm high, 40 cm wide, 110 cm long (leading to a total volume of 110 L). The wetland had a slope of 0.36%, ratio L:W 2.7:1.0, which is slightly inferior to the ratio recommended (3.0:1.0) by the United States Environmental Protection Agency (EPA 2000). However, in the literature, there have been studies reporting ratios much smaller: 1.1:1.0 (Abdel-shafy et al. 2009), 1.3: 1.0 (Saeed et al. 2012), and 2.5:1.0 (Mburu et al. 2013). To promote an ascending and descending coil flow, baffles were employed. Baffles deflect the flow inducing a zig-zag fluid flow trajectory into the four chambers, which way increasing the distance covered by the flow on its way up to the effluent and also improves micromixing in the system. As a support material, 44 L of gravel with porous size of 65% (29 L). Due to the high rate of evaporation in the study area, the gravel remained submerged 5 cm below thee liquid surface, therefore, the CW working volume (liquid) was 51 L and 44 L free volume. The gravel with 1/2″, 3/8″, 1/4″ and 1/8″ mean diameter, distributed from top to bottom were used. 25 specimens of Typha domingensis, equivalent to a coverage area of 0.03 m2 per plant unit were sown. The system was fed employing a 600 rpm peristaltic pump, which allowed maintaining a constant flow at each HRT evaluated. The system operated at environmental conditions at sea level in the coast (city of Riohacha, La Guajira-Colombia).

2.3 Experimental System Operation

Inoculation of the DCA

Inoculation was previously characterized determining the following parameters: granulometry (500 samples), sedimentation rate, specific gravity, total solids and moisture content (Luo et al. 2014). The inoculated sludge was supplied by a brewing industry; 1.5 L and 0.9 L were added in C1 and C2, respectively, corresponding to 20% of the DCA volume used, which is common in this type of reactors (Bohdziewic and Kwarciak 2008; Galindo et al. 2012).

Start-Up of the System

To select the sludge with the best sedimentation characteristics, the system was operated initially for 10 h at upflow velocities of 3 m/h and 5 m/h for C1 and C2, respectively. To help the bacteria to acclimate to the new substrate, this was diluted with tap water by applying dilutions of 30% and 60%, and the reactor was operated for 20 days for each dilution with an inflow of 0.33 L/h. To stimulate growth in the bacteria population, 10 g of glucose per liter of leachate was added during the first 20 days. To account for high pH values of the leachate, it was necessary to add 25% H2SO4 (1.32 mL per liter of leachate) solution in the DCA influent, until obtaining a neutral pH, which favors the growth and development of the microbial population. Sulfuric acid can affect the anaerobic digestion due to the conversion of SO42− to S2− (He et al. 2018). In this study, SO42− concentration values in the DCA inflow was found to be in the range 102–315 mg/L, which is lower than the inhibition range (>1000 mg/L). On the other hand, it has been reported that sulfate concentration of about 200 mg/L stimulate the microorganism activity (Toncel et al. 2001).

To populate the wetland, samples of Typha domingensis were obtained from a natural lagoon (Laguna Salá) located in the urban area of the city of Riohacha. The selection was made considering the criteria and/or characteristics of young and healthy specimens (Liu et al. 2015; Mojiri et al. 2016; Song et al. 2018). In order to acclimate the seedlings to the new substrate, the samples remained for 30 days in plastic containers filled with leachate diluted at 50% (10 days) and 70% (20 days). During this time, their development was monitored until the specimens reached 5 cm of stem length, 30 cm in the leaf blade, and 15 cm in the root (Li et al. 2010a; Song et al. 2018), then subsequently moved to the experimental system. The growth of the plants was monitored in detail, except on the roots in order to avoid damages.

2.4 Analytical Methods

In order to evaluate the degree of contaminant removal, 10 samples were taken at each HRT in the following sampling points: influent, effluent of C1, C2, and wetland. In the DCA, the production of biogas and methane percentage was additionally measured. Temperature, pH and alkalinity were monitored daily. To account for the efficiency of removal in the system, the following parameters were measured: TCOD, BOD, total solids (TS), total volatile solids (TVS), total fixed solids (TFS), total suspended solids (TSS), nitrate, nitrite, ammonium, and total Kjeldahl nitrogen (TKN). For this, standard methods were followed (APHA et al. 2012).

The removal parameters were measured under steady-state conditions of the system, which was reached when the operational parameters and methane production remained constant. The system was evaluated at the following HRTs: 7.97 d, 5.31 d and 2.88 d. The HRTs in each unit (C1, C2, DCA and wetland) are presented in Table 1.

3 Results and Discussion

The results of the characterization of the three leachates indicate that the old leachate presents adequate conditions for its degradation by biological treatment. The pH of the three leachate samples presented alkaline values (8.31 to 8.88), their temperature was maintained in the range of 27 to 29 °C (Table 2), which favors the growth and development of bacteria population present in the inoculum of the reactor (El-Gohary and Kamel 2016; El-Khateeb et al. 2009).

The total alkalinity values for the three leachate samples (new, old and mixed) exhibited an average value of 9382 mg/L (Table 2), which indicates the high resistance to acidification. The BOD remained in the range between 2000 mg/L and 2500 mg/L, whilst for the TCOD values between 12,000 mg/L and 13,500 mg/L were registered, indicating the presence of high concentrations of organic load. These values are similar to those reported in other studies (El-Gohary and Kamel 2016; Sun et al. 2010), and can be attributed to the prolonged absence of rainfall before and during sampling. The physicochemical composition between young and old leachate was found to be very similar due to the short time passed between operation (young) and closure (old) of the cells. Due to this similitude, the old leachate was selected as a substrate for the fact that it exhibited a lower concentration of heavy metals and ammonium, and in addition, there are more facilities for accessing and obtaining samples.

According to Directive 2006/11/CE, El BOCM N°269 (European Parliament 2006), the concentration of heavy metals detected in the three leachates was found to be below the limits required. Aluminum concentrations were registered in the interval 3.31 to 10.09 mg/L, resulting in concentrations lower than the inhibitory values for growth and development of bacteria population. Sondhi et al. (2010) and Mudhoo and Kumar (2013) reported that concentrations between 200 and 300 mg/L are not inhibitory of biological processes nor affect the removal efficiency in UASB reactors. Hegazy (2011) determined that aluminum toxicity levels for Typha domingensis are above 100 mg/kg. These low concentrations of heavy metals might be attributed to the absence of industries in the city under study and the surrounding areas. In light of these results, metals were not monitored during the operation of the system.

3.1 Characteristics of the Sludge and Typha domingensis

The results of the sludge characterization reflect a great variability in the size of the granules in the range between 0.02 mm and 4 mm, which avoids the instability in the sludge bed (Luo et al. 2014). The sedimentation velocity of the sludge was 37.4 m/h, which is within the recommended range (29 to 42 m/h) for the formation of a good granular sludge (Luo et al. 2014). This condition is indicative of good retention of active biomass, and is one of the main operational advantages of DCAs (Borzacconi et al. 2018). The specific gravity of the sludge was slightly higher than that of water (1.02). These results are within the range reported in the literature for this type of sludge, between 1 and 1.07 (Ghangrekar et al. 2005; Huang et al. 2005), ensuring adequate retention of biomass within the DCA (Bhunia and Ghangrekar 2007).

Mean growth for Typha domingensis was established in the interval 196 ± 10.0 cm. Song et al. (2018) employed the species Typha latifolia, Scirpus tabernaemontani and Phacelurus latifolius for leachate treatment, reporting plant growth in the intervals 199 ± 18 cm, 156 ± 17 cm and 187 ± 21 cm, respectively. As can be seen, Typha latifolia presented the highest growth compared to the other two species, confirming its capacity to adapt to this substrate.

3.2 Operational Parameters

Average and standard deviation values of the operational parameters measured in C1 and C2 influents are shown in Table 3.

The temperature, which was higher than 25 °C, remained within the expected range of anaerobic digestion in tropical climate regions (Sun et al. 2010). The pH of the leachate varied in the range between 8.54 and 8.82, for which it was necessary to neutralize it (to pH = 7). However, the pH increased during the process, reaching values of 7.35 and 7.82 in C1 and C2, respectively. This tendency towards alkalinity is characteristic of an old leachate (Renou et al. 2008). The concentration of volatile fatty acids (VFA) was reduced due to the development of the methanogenic phase that transforms them into methane and carbon dioxide (Kheradmand et al. 2010; Kurniawan et al. 2006; Renou et al. 2008). Temperature and pH values increased when shifting from C1 to C2 chamber. The total alkalinity increased during the process, with maximum values of 2500 mg/L and 3100 mg/L for C1 and C2, respectively. This behavior shows that the processes and development of microbial activity (i.e., hydrolysis, fermentation, methanogenesis) occur in a different way in each chamber (Galindo 2012).

Highest biogas and methane generation was recorded at HRT of 7.97 d, with an average of 2783 mL/d and 58% of CH4, yielding amounts of 550 mL/d for C1, and 2233 mL/d for C2, which is concomitant with the highest removal rates and efficiency of the system. The largest amounts of biogas produced in C2 can be attributed to bacteria separation between acidogenic and methanogenic, and to predominant hydrolysis processes in C1 which facilitates the degradation in C2 incrementing methane (CH4) production. This occurs when anaerobic treatment is performed in two stages (González et al. 2007).

Figure 2 presents biogas and methane production profiles at the considered HRT. The production of biogas is closely linked to the amount of organic matter removed (Bohdziewic and Kwarciak 2008). According to the work reported by Abudi et al. (2016), a low biogas production can be the result of either a low presence of organic matter, or a poor performance of the digester, which causes a partial conversion of the organic waste that enter into the system. Despite the fact that HRTs in C1 and C2 were smaller than 2 days, in a study conducted at a similar HRT, biogas production has been reported (Peng et al. 2008). These authors did not report HRT, but from the COD, the working volume present in the reactor, as well as the organic volumetric load, it was possible to infer it.

Given the complexity and high organic loads of the leachates, a prolonged contact time between the bacterial consortiums and the substrate is needed. Therefore, the highest efficiency in the removal of TCOD for the system (DCA + wetland) was achieved at HRT equal to 7.97 d, with an average efficiency of 89%, which corresponds to 18,040 mg/L. Studies based on similar systems, reported lower efficiencies for the removal of TCOD, namely around of 37% (El-Gohary and Kamel 2016), 50% (Bohdziewicz and Kwarciak 2008), and 60% (Luo et al. 2014).

The behavior of TCOD and BOD and the percentages of removal in each component of the system can be seen in Figs. 3, 4, 5 and 6. The highest percentages of removal reached in the DCA were 78% and 83% for TCOD and BOD, respectively. Landfill leachates are characterized by having TCOD values above 10,000 mg/L (Zayen et al. 2016); in our case, the TCOD was found in a range of 10,047 mg/L to 20,240 mg/L (Fig. 3), which coincides with other studies (Sun et al. 2010; Zayen et al. 2016; El-Gohary and Kamel 2016), where it was obtained a TCOD for the influent between 7856 and 22,500 mg/L.

Highest efficiencies of TCOD removal were achieved in C2 (58%) and in the wetland (49%) at 7.97 d. It is important to note that the highest proportion of pollutants removed was in the DCA, reaching a removal of 15,787 mg/L, which is equivalent to 78% of the organic matter present in the leachate (Fig. 4). Similar to TCOD, the BOD of the leachate was higher than 2500 mg/L (Fig. 5). This value is much higher than the range of 100 to 500 mg/L reported in the literature (Bohdziewic and Kwarciak 2008, Madera et al. 2014, Liu et al. 2015), which could be attributed to variations in the age of the leachate.

The average removal for BOD was 91% and 85%, for HRTs of 7.97 d and 5.31 d, respectively (Fig. 6). These results are similar to those obtained in an anaerobic bioreactor with a fixed bed of ascending flow at a pilot scale, where 80% removal was reported for BOD at HRT of 4.5 d (Zayen et al. 2016). It is important to note that the highest amount of BOD removal occurred in the DCA, with rates of 62% and 54% for C1 and C2, respectively. On the other hand, for the wetland, the removal efficiency did not exceed 48%; however, because the wetland is a post-treatment unit, this is a reasonable value.

Old leachates are characterized by having high amounts of total solids (El-Gohary and Kamel 2016; Ye et al. 2011). Furthermore, climatic conditions of the region where the study was carried out, such as high evaporation rates and low rainfall, promote the appearance of high concentrations of total solids (36 to 39 g/L). The average concentrations in the influent and effluent of the system for HRT of 7.97 d were 38.8 ± 0.11 g/L and 4.6 ± 0.96 g/L. Average removal efficiencies of 88%, 73% and 70% were obtained for HRTs of 7.97 d, 5.31 d and 2.88 d, respectively. It was found that the combination employed in this study (DCA + wetland) favored the elimination of the solids present in the leachate, not only by biological action, but also by the physical process (sedimentation) that occurs in the system (El-Khateeb et al. 2009). Average values obtained at HRT of 7.97 d for fixed and volatile solids of the influent were established at 18.8 ± 0.10 g/L, and 20.0 ± 0.10 g/L, for TFS and TVS, respectively, which yield removal percentages of 94%, 66% and 64% for TFS at HRT of 7.97, 5.31 and 2.88 days, respectively. For TVS, removal efficiencies were established at 86%, 78% and 71% for HRTs of 7.97 d, 5.31 d and 2.88 d, respectively. In the case of TSS, the influent mean value recorded at HRT of 7.97 d was in the range 2.89 ± 0.10 g/L, yielding removal percentages of 90%, 82% and 68% for HRT of 7.97, 5.31 and 2.88 days, respectively.

With respect to nutrients, low concentrations of total Kjeldahl nitrogen (TKN) were recorded. Mean concentrations around 4500 mg/L ± 165 mg/L for the influent were obtained. In the case of effluents, the values were 700, 520 and 1120 mg/L for HRT of 7.97 d, 5.31 and 2.88 d, respectively (see Fig. 7), obtaining higher efficiencies (77%) in the DCA, at 7.97 d. The ratio COD:N:P for nutritional requirements was stablished at 100:23:3, which turns out to be superior to 100:5:1 reported by El-Gohary and Kamel (2016). The previous result suggests that no limitation of macronutrients existed in the process. Other reported values for nutrients concentrations for leachate treatment allowed to stablish the ratio 100:8:1 (Guven et al. 2018), which is smaller than that determined in the present study.

Nitrate values (820 μg/L ± 40.4) were recorded, which were below the typical range (5 to 10 mg/L) for old leachates (Sun et al. 2010). This could be attributed to the presence of low concentrations of total nitrogen in the influent. Additionally, nitrification depends on dissolved oxygen which is nil or very scarce in this type of substrate. Figure 8 shows the behavior of nitrate in the different components of the treatment system. The overall average efficiencies were 88%, 72% and 71% for 7.97, 5.31 and 2.88 d, respectively. Other studies report higher values for nitrates (50 mg/L to 1200 mg/L) (Wu et al. 2015; Miao et al. 2014). Nitrite levels showed similar conditions as nitrates, remaining in the range between 800 and 835 μg/L (Fig. 9), with removal rates of 93%, 85% and 74% for each of the HRTs evaluated.

Ammonium (660 μg/L ± 75), as well as nitrate and nitrite concentrations, were found to be below values reported in the literature (40–99 mg/L; Madera et al. 2014). This may be attributed to pH and alkalinity values, which promotes the formation of ammonia, as well as its elimination by nitrification and denitrification (Wu et al. 2015). Ammonium removal rates of 93%, 85% and 77% were determined for HRT of 7.97 d, 5.31 d and 2.88 d, respectively. In the case of DCA (effluent in C2), ammonium removal rates of 65%, 56% and 48% were determined for HRT of 1.5 d, 1.0 d and 0.5 d, respectively. In Fig. 10, the decrease of ammonium with respect to the days of operation can be seen, which decreases to form nitrite (Fig. 9) to nitrate (Fig. 8).

The results obtained show that combined DCA + wetland systems have a favorable effect on the treatment of leachates. Yuan et al. (2016) evaluated the efficiency of three discontinuous reactors (anaerobic, aerobic and decantation). They found removals in terms of TCOD between 63% and 80%, which are lower than those obtained in the present study, ranging between 85% and 90%.

There are studies reporting a substantial decrease in the efficiency of anaerobic processes when the concentration of limiting elements, such as Ni, Co and Mo, are found in the range 12 and 28 μg/L (Eftaxias et al. 2018). It should be pointed out that these elements were not monitored in the present study, however, there were obtained high removal efficiencies, as it was previously reported, which suggests that no limitation of these micronutrients existed.

In Table 4, it can be seen that the efficiency of the in series system (DCA + wetland and UASB-A/O) is bigger than that for individual treatment systems, with exception to COD and NH4+ removal in membrane bioreactor. Thus, better efficiencies are obtained with these combined systems. Several advantages of the DCA + wetland system can be pointed out: specialization of the bacterial consortium towards anaerobic digestion phases, better removal efficiencies, alternative options for the metabolization of pollutants (anaerobic/aerobic), formation of complex organic waste as the basis for further degradation processes by biological systems, low energy and surface requirements, minimum sludge generation and a source of energy due to methane generation. These advantages surpass by far some disadvantages presented such as regular maintenance procedures, among others.

4 Conclusions

An in-series system was studied, composed of a double-chamber anaerobic reactor and a wetland for treatment of leachates from a municipal sanitary landfill of a medium-sized city located in the Caribbean coast of Colombia. According to the results obtained, this system can be used as a viable option for the treatment of leachates generated in similar municipal sanitary landfills. By employing this technology, there were obtained maximum removal efficiencies for TCOD, BOD and TKN of 89%, 91% and 84%, respectively. The double-chamber anaerobic reactor contribution in the removal rate was of 78%, 83% and 77% for TCOD, BOD, and TKN, respectively, at HRT of 1.5 d. The combined system proposed in this study was found to exhibit positive rates of leachate treatment not only by biological action, but also by sedimentation occurring in the constructed wetland. Therefore, the wetland may be considered as a viable post-treatment unit, where the Typha domingensis species as a phytoremediating agent showed an adequate growth indicating its positive ability for adapting to the leachate characteristics.

References

Abdel-Shafy HI, El-Khateeb MA, Regelsberger M, El-Sheikh R, Shehata M, (2009) Integrated system for the treatment of blackwater and greywater via UASB and constructed wetland in Egypt. Desalin Water Treat 8(1e3), 272e278

Abudi Z, Hu Z, Sun N, Xiao B, Rajaa N, Liu C, Guo D (2016) Batch anaerobic co-digestion of OFMSW (organic fraction of municipal solid waste), TWAS (thickened waste activated sludge) and RS (rice straw): influence of TWAS and RS pretreatment and mixing ratio. Energy. 107:131–140. https://doi.org/10.1016/j.energy.2016.03.141

Akinbile C, Yusoff M, Ahmad Z (2012) Landfill leachate treatment using subsurface flow constructed wetland by Cyperus haspan. Waste Manag 32(7):1387–1393. https://doi.org/10.1016/j.wasman.2012.03.002

APHA, AWWA, WEF. (2012). Standard methods for the examination of water and wastewater. Standard Methods. https://doi.org/10.2105/AJPH.51.6.940-a

Bhunia P, Ghangrekar M (2007) Required minimum granule size in UASB reactor and characteristics variation with size. Bioresour Technol 98(5):994–999. https://doi.org/10.1016/j.biortech.2006.04.019

Bohdziewic J, Kwarciak A (2008) The application of hybrid system UASB reactor-RO in landfill leachate treatment. Desalination. 222(1–3):128–134. https://doi.org/10.1016/j.desal.2007.01.137

Borzacconi L, López I, Passeggi M (2018) I-178 - seguimiento de las características de la manta de lodos en un reactor UASB piloto. XXVII Congresso Interamericano de Engenharia Sanitária e Ambiental. Researchgate. https://www.researchgate.net/publication/238755947_I178__SEGUIMIENTO_DE_LAS_CARACTERISTICAS_DE_LA_MANTA_DE_LODOS_EN_UN_REACTOR_UASB_PILOTO. Accedido 17 de diciembre de 2018

Delgardo S, Villarroel R, González E, Morales, M (2011) In: Biomass - Detection, Production and Usage, D. Matovic (ed.), In-Tech, Rijeka, Croatia 20, 265–288

European Parliament (2006) Directiva 2006/11/CE Del Parlamento Europeo Y Del Consejo, relativa a la contaminación causada por determinadas sustancias peligrosas vertidas en el medio acuático de la Comunidad. 15 de febrero de 2006. Disponible en: http://www.madrid.org/rlma_web/html/web/FichaNormativa.icm?ID=845. Accedido 17 de diciembre de 2018

Diamantis V, Aivasidis A (2007) Comparison of single- and two-stage UASB reactors used for anaerobic treatment of synthetic fruit wastewater. Enzym Microb Technol 42(1):6–10, ISSN 0141-0229. https://doi.org/10.1016/j.enzmictec.2007.07.014

Diamantis V, Aivasidis A (2010) Two-stage UASB design enables activated-sludge free treatment of easily biodegradable wastewater. Bioprocess Biosyst Eng 33(2):287–292. https://doi.org/10.1007/s00449-009-0323-z

Diamantis V, Verstraete W, Aivasidis A (2009) Upflow anaerobic clarification tank (UACT) to upgrade existing anaerobic effluents. Water Sci Technol 59:2411–2419. https://doi.org/10.2166/wst.2009.306

Eftaxias A, Diamantis V, Aivasidis A (2018) Anaerobic digestion of thermal pre-treated emulsified slaughterhouse wastes (TESW): effect of trace element limitation on process efficiency and sludge metabolic properties. Waste Manag 76:357–363. https://doi.org/10.1016/j.wasman.2018.02.032

El-Gohary F, Kamel G (2016) Characterization and biological treatment of pre-treated landfill leachate. Ecol Eng 33:45–63. https://doi.org/10.1016/j.ecoleng.2016.05.074

El-Khateeb A, Al-Herrawy A, Kamel M, El-Gohary F (2009) Use of wetlands as post-treatment of anaerobically treated effluent. Desalination. 245(1–3):50–59. https://doi.org/10.1016/j.desal.2008.01.071

El-Sheikh M, Saleh H, Flora J, AbdEl-Ghany M (2011) Biological tannery wastewater treatment using two stage UASB reactors. Desalination. 276(1–3):253–259. https://doi.org/10.1016/j.desal.2011.03.060

EPA (2000) Design manual constructed wetlands for municipal wastewater treatment. US EPA CERI, National Service Center for Environmental Publications (NSCEP), Cincinnati, Ohio, p 166

Galindo A (2012) Evaluación de un sistema biológico en serie para el tratamiento de las aguas Residuales de la Ciudad de Maracaibo, Venezuela, Tesis para obtener el título de doctor en ingeniería ambiental, Universidad del Zulia

Galindo A, Rincón N, Pérez J, Marín J, Causado E, (2012) Evaluación de un Reactor de Doble Cámara Constituido por dos Reactores UASB en Serie para el Tratamiento de Aguas Residuales Municipales. XXXIII Congreso Interamericano de Ingeniería Sanitaria y Ambiental, realizado en Salvador, Bahía, Brasil. 1–11. https://www.researchgate.net/publication/306092338_EVALUACION_DE_UN_REACTOR_DE_DOBLE_CAMARA_CONSTITUIDO_POR_DOS_REACTORES_UASB_EN_SERIE_PARA_EL_TRATAMIENTO_DE_AGUAS_RESIDUALES_MUNICIPALES. Accedido 17 de diciembre de 2018

Gaur R, Suthar S (2017) Anaerobic digestion of activated sludge, anaerobic granular sludge and cow dung with food waste for enhanced methane production. J Clean Prod 164:557–566. https://doi.org/10.1016/j.jclepro.2017.06.201

Ghangrekar M, Asolekar S, Joshi S (2005) Characteristics of sludge developed under different loading conditions during UASB reactor start-up and granulation. Water Res 39(6):1123–1133. https://doi.org/10.1016/j.watres.2004.12.018

Ghawi A, Kriš J (2009) A CFD methodology for the design of rectangular sedimentation tanks in potable water treatment plants. J Water Supply Res Technol AQUA 58(3):212–220. https://doi.org/10.2166/aqua.2009.027

González P, Chamy R, Poirrier P (2007) Tratamiento Anaerobio de Aguas Residuales Urbanas en Reactores de Una y Dos Fases a Baja Temperatura. Chile, Revista AIDIS, Vol. 2, Disponible en: http://www.revistas.unam.mx/index.php/aidis/article/view/14384. Accedido 17 de diciembre de 2018

Guven H, Sadik-Akca M, Iren H, Keles F, Ozturk I, Altinbas M (2018) Co-digestion performance of organic fraction of municipal solid waste with leachate: preliminary studies. Waste Manag 71:775–784. https://doi.org/10.1016/j.wasman.2017.04.039

He R, Yao X, Chen M, Ma R, Li H, Wang C, Ding S (2018) Conversion of sulfur compounds and microbial community in anaerobic treatment of fish and pork waste. Waste Manag 76:383–393. https://doi.org/10.1016/j.wasman.2018.04.006

Hegazy A (2011). Phytoremediation of industrial wastewater potentiality by Typha domingensis. Int J Environ Sci Tech, 8(3):639–648, ISSN 1735-1472. doi: https://doi.org/10.1007/BF03326249

Heyer KU, Stegmann R, (2005) Landfill Systems, Sanitary Landfilling of solid wastes, and long-term problems with leachate, In: Environmental Biotechnology: Concepts and Applications, H.-J. Jördening and J. Winter (eds.), Wiley-VCH Verlag GmbH & Co. KGaA. 8–14

Huang JS, Wu CS, Chen CM (2005) Microbial activity in a combined UASB–activated sludge reactor system. Chemosphere. 61(7):1032–1041. https://doi.org/10.1016/j.chemosphere.2005.03.027

Katsoni A, Mantzavinos D, Diamadopoulos E (2014) Sequential treatment of diluted olive pomace leachate by digestion in a pilot scale UASB reactor and BDD electrochemical oxidation. Water Res 15(57):76–86. https://doi.org/10.1016/j.watres.2014.03.010

Khan A, Gaur R, Kazmi A, Lew B (2013) Sustainable post treatment options of anaerobic effluent. Biodegradation - Engineering and Technology, Rolando Chamy and Francisca Rosenkranz, IntechOpen, doi: 105772/56097

Khan A, Gaur R, Lew B, Diamantis V, Mehrotra I, Kazmi A (2012) UASB/flash aeration enable complete treatment of municipal wastewater for reuse. Bioprocess Biosyst Eng 35(6):907–913. https://doi.org/10.1007/s00449-011-0675-z

Khan A, Gaur R, Tyagi V, Khursheed A, Lew B, Mehrotra I, Kazmi A (2011) Sustainable options of post treatment of UASB effluent treating sewage: a review. Resour Conserv Recycl 55(12):1232–1251, ISSN 0921-3449. https://doi.org/10.1016/j.resconrec.2011.05.017

Kheradmand S, Karimi-Jashni A, Sartaj V (2010) Treatment of municipal landfill leachate using a combined anaerobic digester and activated sludge system. Waste Manag 30(6):1025–1031. https://doi.org/10.1016/j.wasman.2010.01.021

Kurniawan T, Lo W, Chan G (2006) Physico-chemical treatments for removal of recalcitrant contaminants from landfill leachate. J Hazard Mater 129(1–3):80–100. https://doi.org/10.1016/j.jhazmat.2005.08.010

Li S, Lissner J, Mendelssohn LA, Brix H, Lorenzen B, McKee KL, Miao S (2010a) Nutrient and growth responses of cattail (Typha domingensis) to redox intensity and phosphate availability. Ann Bot 105:175e184

Li G, Wang W, Du Q (2010b) Applicability of nanofiltration for the advanced treatment of landfill leachate. J Appl Polym Sci 116(4):2343–2347. https://doi.org/10.1002/app.31769

Liu R, Zhao Y, Doherty L, Hu Y, Hao X (2015) A review of incorporation of constructed wetland with other treatment processes. Chem Eng J 219:220–230. https://doi.org/10.1016/j.cej.2015.05.023

Luo J, Zhou J, Qian G, Liu J (2014) Effective anaerobic biodegradation of municipal solid waste fresh leachate using a novel pilot-scale reactor: comparison under different seeding granular sludge. Bioresour Technol 165:152–157. https://doi.org/10.1016/j.biortech.2014.03.141

Madera C, Peña M, Peña-Salamanca E, Lens PN (2014) Cr(VI) and COD removal from landfill leachate by polyculture constructed wetland at a pilot scale. Environ Sci Pollut Res 22(17):12804–12815. https://doi.org/10.1007/s11356-014-3623-z

Mburu N, Tebitendwa S, Rousseau D, van Bruggen J, Lens P (2013) Performance evaluation of horizontal subsurface flow-constructed wetlands for the treatment of domestic wastewater in the tropics. J Environ Eng 139(3):358–367. https://doi.org/10.1061/(ASCE)EE.1943-7870.0000636

Miao L, Wang K, Wang S, Zhu R, Li B, Peng Y, Weng D (2014) Advanced nitrogen removal from landfill leachate using real-time controlled three-stage sequence batch reactor (SBR) system. Bioresour Technol 159:258–265. https://doi.org/10.1016/j.biortech.2014.02.058

Mojiri A, Aziz H, Zahed M, Aziz S, Razip M (2013) Phytoremediation of heavy metals from urban waste leachate by southern cattail (Typha domingensis). International Journal of Scientific Research in Environmental Sciences (IJSRES) 1(4):63–70. https://doi.org/10.12983/ijsres-2013-p063-070

Mojiri A, Ziyang L, Mohd-Tajuddin R, Farraji H, Alifar N (2016) Co-treatment of landfill leachate and municipal wastewater using the ZELIAC/zeolite constructed wetland system. Journal of Environmental Stability 166:124–130. https://doi.org/10.1016/j.jenvman.2015.10.020

Mudhoo A, Kumar S (2013) Effects of heavy metals as stress factors on anaerobic digestion processes and biogas production from biomass. S. Int J Environ Sci Technol 10(6):1383–1398. https://doi.org/10.1007/s13762-012-0167-y

Peng Y (2017) Perspectives on technology for landfill leachate treatment. Arab J Chem 10(2):S2567–S2574. https://doi.org/10.1016/j.arabjc.2013.09.031

Peng Y, Zhang S, Zeng W, Zheng S, Mino T, Satoh H (2008) Organic removal by denitritation and methanogenesis and nitrogen removal by nitritation from landfill leachate. Water Res 42(4–5):883–892. https://doi.org/10.1016/j.watres.2007.08.041

Perez J, Galindo M, Ramírez-Muñoz J (2019) Comparison of different methods for evaluating the hydraulics of a pilot-scale upflow anaerobic sludge blanket reactor. Environmental Processes 6(1):25–41. https://doi.org/10.1007/s40710-019-00354-1

Rengers E, Barbosa J, Loureiro P, Janzen J (2016) Hydraulic performance of a modified constructed wetland system through a CFD-based approach. J Hydro Environ Res 12:91–104. https://doi.org/10.1016/j.jher.2016.04.002

Renou S, Givaudan JG, Poulain S, Dirassouyan F, Moulin P (2008) Landfill leachate treatment: review and opportunity. J Hazard Mater 150(3):468–493. https://doi.org/10.1016/j.jhazmat.2007.09.077

Saeed T, Afrin R, Muyeed AA, Sun G (2012) Treatment of tannery wastewater in a pilot-scale hybrid constructed wetland system in Bangladesh. Chemosphere 88(9):1065–1073. https://doi.org/10.1016/j.chemosphere.2012.04.055

Shehzadi M, Afzal M, Khan MU, Islam E, Mobin A, Anwar S, Khan QM (2014) Enhanced degradation of textile effluent in constructed wetland system using Typha domingensis and textile effluent-degrading endophytic bacteria. Water Res 58:152–159. https://doi.org/10.1016/j.watres.2014.03.064

Sondhi A, Guha S, Harendranath C, Singh A (2010) Effect of aluminum (Al3+) on granulation in upflow anaerobic sludge blanket reactor treating low-strength synthetic wastewater. Water Environment Research 82:715–724(10). https://doi.org/10.2175/106143010X12609736966603

Song U, Waldman B, Soo-Park J, Lee K, Park S, Lee E (2018) Improving the remediation capacity of a landfill leachate channel by selecting suitable macrophytes. J Hydro Environ Res 20:31–37. https://doi.org/10.1016/j.jher.2018.04.005

Sun H, Zhao H, Bai B, Chen Y, Yang Q, Peng Y (2015) Advanced removal of organic and nitrogen from ammonium-rich landfill leachate using an anaerobic-aerobic system. Chin J Chem Eng 23(6):1047–1051. https://doi.org/10.1016/j.cjche.2014.03.007

Sun H, Yang Q, Peng Y, Shi X, Wang S, Zhang S (2010) Advanced landfill leachate treatment using a two-stage UASB-SBR system at low temperature. J Environ Sci 22(4):481–485. https://doi.org/10.1016/S1001-0742(09)60133-9

Toncel E, Gutierrez E, Galindo A, Perez J, Rojano R, Daza S (2001) Remoción de sulfato en un reactor UASB utilizando glucosa como sustrato a temperaturas mesofílicas. Revista Técnica de la Facultad de Ingeniería Universidad del Zulia 24:46–56

Uotila P, Raus T, Tomović G, Niketic M (2019) Typha domingensis (Typhaceae) new to Serbia. 34(2):111–114. UDK 582.542.7:581.95(497.11)

Wojciechowska E, Gajewska M, Obarska-Pempkowiak H (2010) Potential and limits of landfill leachate treatment in a multi-stage subsurface flow constructed wetland – Evaluation of organics and nitrogen removal. Pol J Environ Stud 19(3):643–650. https://doi.org/10.1016/j.biortech.2017.03.185

Wu L, Zhang L, Xu Y, Liang C, Kong H, Shi X, Peng Y (2016) Advanced nitrogen removal using bio-refractory organics as carbon source for biological treatment of landfill leachate. Sep Purif Technol 160:306–313. https://doi.org/10.1016/j.seppur.2016.06.033

Wu L, Peng Y, Shi X, Peng C, Zhang J (2015) Advanced nitrogen removal via nitrite from municipal landfill leachate using a two-stage UASB-A/O system. Chin J Chem Eng 23(7):1225–1230. https://doi.org/10.1016/j.cjche.2015.05.014

Yalcuk A, Ugurlu A (2009) Comparison of horizontal and vertical constructed wetland systems for landfill leachate treatment. Bioresour Technol 100(9):2521–2526. https://doi.org/10.1016/j.biortech.2008.11.029

Ye J, Mu Y, Cheng X, Sun D (2011) Treatment of fresh leachate with high-strength organics and calcium from municipal solid waste incineration plant using UASB reactor. Bioresour Technol 102(9):5498–5503. https://doi.org/10.1016/j.biortech.2011.01.001

Yuan Q, Jia H, Poveda M (2016) Study on the effect of landfill leachate on nutrient removal from municipal wastewater. J Environ Sci Manitoba 43:153–158. https://doi.org/10.1016/j.jes.2015.10.023

Zayen A, Schories G, Sayadi S (2016) Incorporation of an anaerobic digestion step in a multistage treatment system for sanitary landfill leachate. Waste Manag 53:32–39. https://doi.org/10.1016/j.wasman.2016.04.030

Zazouli MA, Yousefi Z, Eslami A, Ardebilian MB (2012) Municipal solid waste landfill leachate treatment by Fenton, photo-Fenton and Fenton-like processes: effect of some variables. Iranian Journal of Environmental Health Science & Engineering 9(1):3. https://doi.org/10.1186/1735-2746-9-3

Acknowledgments

Authors of this work would like to express their gratitude to the University of La Guajira-Colombia and Colciencias, for the funding granted to conduct this project. Additionally, we would like to thank company Interaseo S.A.S E.S.P., for the support given by accessing the sanitary landfill. Finally, special gratitude is conveyed to Dr. Jorge Ramirez-Muñoz from Universidad Autónoma Metropolitana-Azcapotzalco in Mexico City, for his technical contributions.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Galindo Montero, A.A., Pimienta Serrano, E.V. & Montiel, J.I.P. Sanitary Landfill Leachate Treatment with Double Chamber Anaerobic Reactor in Series with Constructed Wetland. Environ. Process. 6, 695–712 (2019). https://doi.org/10.1007/s40710-019-00380-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40710-019-00380-z