Abstract

The study presents a novel approach to overcome the height limitations of traditional cantilever retaining walls by introducing relief shelves which are horizontal reinforced concrete platforms provided at regular intervals along the stem height. A parametric study is carried out by varying unit weight, soil friction angle, and number of shelves. It is observed that the provision of shelves improves the factor of safety against sliding and overturning as the earth pressure on the stem is reduced compared to the cantilever retaining wall without shelves. Design charts are presented for shelf lengths for different stem heights and soil properties. The pseudo-static analysis uses the Mononobe-Okabe approach by applying constant horizontal and vertical accelerations to represent earthquake forces for retaining walls with shelves. Mathematical expressions are developed for the factor of safety against sliding and overturning. It is observed that retaining walls with shelves are more stable under static and dynamic conditions compared to those walls without shelves.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

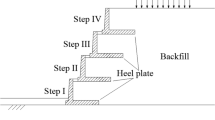

To sustain vertical or almost vertical backfills, retaining walls are built to withstand the lateral pressure of soil. There have been instances, where lateral earth pressure must be resisted with tall retaining walls. Such scenarios may be suitable for reinforced soil walls. Nevertheless, if undrained conditions prevail, it is better to use a well-graded granular material to build such walls because of its higher shear resistance and good soil-reinforcement interaction. Thus, the availability of suitable backfill material is a requirement for its appropriateness in the construction of reinforced soil walls. Reducing the lateral thrust on the wall is one way to address these problems; this will, of course, lower the project cost and the wall’s sectional dimensions. In the counterfort retaining wall, as opposed to the cantilevers in the cantilever retaining wall, the vertical stem, and the heel slab function as a single slab because the stem and the rear slab are connected by counterforts at appropriate intervals. Even though these walls are built all over the world, the observed behavior is not uniform at all locations. For retaining walls of any height, there are no design standards available for choosing the ideal quantity, sectional size, and placement of relief shelves.

The reinforced concrete cantilever retaining walls can be utilized successfully for higher altitude retaining walls if the stem has shelves. The effective lateral earth pressure on the wall is significantly reduced if the shelves are extended up to the rupture surface, which is advantageous in comparison to a cantilever retaining wall without shelves (Jumikis 1964). Up to a height of 10–12 m, counterforts are affordable.

A pressure relief shelf is a horizontal cantilever platform that is monolithically built with the retaining wall stem and extends into the backfill at right angles. The inclusion of shelves reduces the earth pressure on the stem and thus improves the factor of safety against sliding and overturning compared to the cantilever retaining walls without shelves. In the present study, the effectiveness of shelves by varying numbers of shelves ranging from none to four shelves and spaced equally along the stem height is investigated under static conditions.

The present study also highlights the significant impact of relief shelves in improving safety factors against sliding and overturning, under seismic conditions. The methodology includes a pseudo-static analysis, which applies a seismic force as a static force at a particular location and is also performed to evaluate seismic stability. The equations are developed for the pseudo-static factor of safety against sliding and overturning and are compared with the static case, revealing that retaining walls with shelves are more stable under both static and dynamic conditions than those without shelves.

This advancement offers a practical solution for constructing taller and slender retaining walls in challenging terrains, contributing to safer and more economical infrastructure development. The findings provide valuable insights into the design and application of retaining walls, promoting the adoption of this innovative technique in engineering practices. The results are compared with existing static studies; however, no meagre data is available on pseudo-static analysis of retaining walls with shelves.

2 Literature Review

Over time, numerous studies on single-shelf retaining walls have been carried out to determine the parameters that affect the pressure distribution along the wall height as the shelf positions and dimensions change in response to varying loads. These variables also affect the type of pressure variation on the wall and the shelf because the wall moves forward due to stress in the backfill soil (Yakolova 1974). A decrease in lateral earth pressure was ascertained in counterfort retaining walls by adding one or more shelves beyond the theoretical rupture surface (Jumikis 1964). Coulomb’s earth pressure could be applied to cantilever walls with relieving shelves. The introduction of relieving shelves reduced the overall active earth pressure and its distribution. The extent to which the width of the shelf is provided reduces the overall active earth pressure and its distribution (Chaudhuri and Garg 1973).

In retaining walls with shelves, the earth must be adequately compacted up to the relief shelf, the shelf must be built, the soil must be deposited and compacted, etc. It is challenging to predict how much consolidation will take place beneath the shelves, and it will be irrespective of the compaction condition. The wall needs to be sufficiently thick and well-reinforced on both faces to carry this moment of unexpected shear (Bowles 1996). Optimization was done using a single shelf in a counterfort retaining wall, using finite element analysis PLAXIS-2D AE, the influence of shelf stiffness, number, and position on the lateral earth pressure distribution, top wall movement, and maximum bending moment on the wall (Greco 2001). A manual method to examine the best location of the shelf the earth pressure, and the bending moment is a very difficult task and time-consuming (Dharshan and Keerthi Gowda 2016). The impact of relief shelf width on the distribution of lateral earth pressure was investigated through parametric simulations. Analysis revealed that, in comparison to retaining walls without relieving shelves, the lateral thrust on retaining walls with shelves can be lowered to 43 to 48% (Singla and Gupta 2015). A model study was conducted with 31 cantilever retaining wall models with shelves to examine the effects of height, width, thickness, and the number of shelves on the distribution of earth pressure and the deformation of the wall. Reduced earth pressure and reduced bending were noted in the retaining wall, which increased the stability (Farouk 2015). The stability of a retaining wall with a shelf is usually checked for factors of safety against sliding, overturning, and bearing pressure. According to numerical findings, there is less ground pressure when there is a relief shelf behind the wall (Chauhan et al. 2015). The stability of the retaining wall is studied for different failure criteria in FEM by the Mohr–Coulomb (MC) and hardening soil (HS) model, which presented more stress at the stem of the retaining wall in the HS model (Gokkus and Tuskan 2017). Retaining walls are proven to reduce the earth pressure on the stem by providing multiple shelves of equal or varying lengths. To ensure that junction moments are balanced without increasing stem moments, it is advisable to maintain shelves of different lengths (Choudhury and Nimbalkar 2008).

Cantilever retaining walls above 6 m height in hilly terrains work out to be more effective and show improved performance and are therefore recommended. Based on the parametric study, the stem displacement is reduced by 24.05 to 82.87% along with the reduction in the lateral earth pressure, when the shelves along the cantilever retaining wall are positioned at identical heights. The analysis with three shelves resulted in the least amount of stem top movement and the greatest reduction of wall pressure (Goel and Patra 2008). For retaining walls with varying heights, the behavior and optimal design were studied. The relieving platform reduces the cross-section of the retaining wall, thus reducing the consumption of the construction material and increasing stability. A failure case of a retaining wall with five shelves, in the city of Hyderabad was reported. The failure observed was compressive in nature under the shelf whereas tensile stresses were observed above the shelf. Providing longer widths of shelves drastically increases the bending moment and develops unanticipated stresses that might have been neglected and thus cause distress and failure (Chauhan et al. 2015). The concept of placing a pressure relief shelf on the rear fill side of a retaining wall reduces overall earth pressure on the wall, resulting in fewer sections of the wall and, ultimately, a more inexpensive wall (Singla and Gupta 2015).

The relieving platform’s feasibility and economy are checked for varying heights from 3 to 10 m and are proven to be economical with relieving platforms for heights above 5.5 m (Dhamdhere et al. 2018). An average of 15–25% execution economy is achieved when the pressure relief shelves are extended to failure planes for shelves up to three numbers (Bhoyar and Awachat 2019). Economical location for one, two, three, and four shelves was compared with no shelves and it was found that the economy improved with an increase in the number of shelves (Faldesai and Savoikar 2019). Shelves reduce the bending moments in the stem and also the outward deflection of the stem. The deflection of the stem decreases when the friction angle increases. If the shelf width is kept constant, the thrust on the stem is reduced, but the bending moment at the junction of the stem and shelf increases. Varying shelf length reduces the moment at stem shelf junctions (Aldonkar and Savoikar 2022). The displacements in the reliving shelf and at the bottom of the retaining wall are compared using Mohr–Coulomb (MC) and hardening soil (HS) models. It is observed that the displacement at the retaining wall base in the MC model is more critical than in the HS model (Aldonkar and Savoikar 2020). The top displacement of stem and lateral earth pressure decreases with an increase in the number of shelves and the friction angle (Aldonkar and Savoikar 2021). Providing relief shelves reduces the earth pressure, and as a result, the stem section and its cost are reduced (Padhye and Ullagaddi 2011).

For free-standing walls, the Mononobe-Okabe (M–O) method (Mononobe and Matsuo 1929) (Okabe 1926) gives conservative values of earthquake forces acting on it (Wood 2023). For stiff walls, where the M–O method is not applicable, seismic forces can be evaluated based on equations given by Wood (Wood 2019).

From the above literature survey, it can be seen that the retaining wall with shelves is not a new technique and was studied in 1964. Provision of shelves at regular intervals decreases the earth pressure on the stem and also increases the factor of safety. However, in most of the cases, the shelf length was uniform and shelves were located at regular intervals on the stem. Also, in most of the cases, the earth pressure acting on the stem was assumed to be triangular and shelves were designed as a cantilever. In the present study, the shelves at equal intervals along the stem height are considered, but of varying length, which is calculated such that the sum of moments at the shelf-stem junction is minimum.

3 Model Dimensions

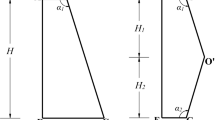

In the present study, a fixed base vertical cantilever rigid retaining wall having a height of 12 m and having progressively longer shelves from top to bottom was taken into consideration. The wall supporting a cohesionless backfill material with horizontal ground is considered in the analysis. The retaining wall was dimensioned as per the IS 456:2000 (IS 2000). A 40 cm shelf thickness was adopted in all the succeeding analyses. Furthermore, the shelves are located at equal heights along the stem in case of one, two, and three shelves. The minimum base slab length should be in the range of 0.5H to 0.7H. The adopted base slab length in the present study is 0.6H. The thickness of the base slab is H/10 to H/14 or should not be less than 300 mm. Similarly, the minimum stem thickness should be 300 mm. The toe length to be maintained is 0.2H. The shelf lengths are calculated based on Eqs. (1) to (5).

4 Material Properties

The foundation and the backfill soil are considered as dry, non-cohesive soil. A parametric study is carried out by considering the backfill, foundation soil having a unit weight of 16 kN/m3, 18 kN/m3, and 20 kN/m3 and internal friction angle of 25°, 30°, and 35°. In the present parametric analysis, a standard range of values of friction angle is used, which is 25–35° and a corresponding unit weight of 16 to 20 kN/m3. These values are so chosen based on the specifications of governing agencies like the American Association of State Highway and Transportation Officials (AASHTO) (American Association of State Highway and Transportation Officials (2002)), the Ministry of Road Transport and Highways of India (MORTH) (Ministry of Road Transport and Highways (2013)), Indian Road Congress (IRC) (IRC:SP:1022014) specifications recommend standard friction angles in the range of 25–40° to represent loose, medium dense to well-graded soils with corresponding unit weights of 15, 16.5, and 20 kN/m3 (Dinesh et al. 2010; Choudhury and Nimbalkar 2007). Backfill soil carries no surcharge load and is analyzed for cantilever retaining walls for no and one to four shelves.

5 Methodology

The moment equilibrium approach was adopted and the spreadsheet was used to compute the shelf lengths as shown in Fig. 1. Expressions are generated for the shelf lengths, considering the moment equilibrium at each junction, and maintaining the height of each segment constant.

Shelf lengths for varying stem heights are presented in Table 1 for stem heights 10 m, 12 m, 15 m, 18 m, and 20 m. The shelf lengths are graphically represented for all unit weights of soil in the form of a chart. Figure 2 depicts a bar graph for a stem height of 10 m and Fig. 3 depicts a bar graph for a stem height of 12 m. As seen from Table 1 and Figs. 2 and 3, the shelf length is inversely proportional to the friction angle, and the shelf length provided increases from top to bottom. Similar results were obtained by Chauhan et al. (2016) (Chauhan and Dasaka 2018). These tables and figures can be used as a handy guide in finding out the required length of shelves for given values of friction angle and number of shelves.

6 Static Analysis

Expanded polystyrene, glass fiber inclusion, geo-inclusion materials, cardboard, and recycled tire chips combined with sand as a lightweight backfill material are just a few pressure-relieving methods to lower the horizontal earth pressure acting on the stem. The most practical way is to use retaining walls with relief shelves, which lower the overall earth pressure across the wall height. The retaining wall proportions are impacted by the horizontal earth pressure that the backfill exerts on it. Relief shelves help in lowering the earth pressure which results in a cost-effective design. The relieving shelves are R.C.C. horizontal platforms that are inserted in the stem of the cantilever retaining wall. By adding such shelves, the retaining wall height can be extended even higher as the pressure on the stem of the wall is narrowed.

6.1 Parametric Studies

In the present study, a 12-m high retaining wall with progressively longer shelves from top to bottom was taken into consideration. Using Eqs. (1) to (5), the shelf lengths are computed based on the minimal moment at the stem and shelf junction. The retaining wall dimensions are determined using IS:456–2000 and the fundamental design thumb rule; a 40 cm thick shelf is used in all analyses. Shelves are located at equal spacing along the stem heights. A parametric study is performed to compute the factor of safety against sliding and overturning with unit weight (γ) varying from 16 kN/m3, 18 kN/m3, 20 kN/m3, and soil friction angle varies from 25°, 30°, 35° and for no shelf and one to four shelves.

6.1.1 Effect of the Number of Shelves on the Factor of Safety

The static study of cantilever retaining wall with relieving shelves is done for no shelf and one, two, and three shelves located equidistance on the stem is studied and the factor of safety against sliding and overturning is found out. The coefficient of friction μ = 0.5 between the concrete base and cohesionless soil is considered. A minimum factor of safety of 1.5 is desirable to resist sliding. Table 2 shows the variation of factors of safety against sliding and overturning for no shelf, single shelf, two shelves, three shelves, and four shelves. As the number of shelves increases, the stabilizing forces increase and the destabilizing forces and moments decrease. It can be seen that as the number of shelves increases, the factor of safety against sliding and overturning also increases, indicating that shelves help in reducing the earth pressure on the stem and hence are advisable. Figure 4 shows the variation of the factor of safety with several shelves. It is observed that the highest factor of safety against sliding and overturning is observed for the shelves case, which indicates that the higher the number of shelves, the higher the level of safety since disturbing forces and moments get reduced drastically.

6.1.2 Effect of Unit Weight of Factor of Safety

To understand the effect of the unit weight of soil, variation in unit weight is considered for no shelf and one shelf case. With the increase in unit weight, the factor of safety against sliding and overturning is observed to decrease marginally. This may be because, with the increase in unit weight, the earth pressure also increases resulting in higher destabilizing forces. A plot of a factor of safety against sliding and overturning with variation in unit weight of soil is represented in Fig. 5 for a typical case of one shelf and ϕ = 35°. The slightly higher factor of safety is observed for a unit weight of 16 kN/m3 compared to 18 kN/m3 and 20 kN/m3. Also, a large difference in the factor of safety in the case of a single shelf compared to no shelf is observed. Similar results are observed for more number of shelves. Table 3 shows the variation of the factor of safety for varying stem heights.

6.1.3 Effect of Friction Angle on the Factor of Safety

The effect of friction angle on the factor of safety against sliding and overturning is studied by varying friction angle in degrees from 25, 30, and 35 and for a unit weight of 16 kN/m3. With the increase in friction angle, the factor of safety increases, with unit weight being constant. This is because since the coefficient of earth pressure decreases with the increase in friction angle, the lateral earth pressure intensity also decreases on the stem leading to higher stability and enhancement in the safety factor against sliding and overturning. A plot comparing the effect for no shelf and one shelf cases is represented in Fig. 6 for the wall height of 12 m. Table 4 shows the variation of the factor of safety against sliding and overturning for various values of friction angle and different stem heights from 10 to 20 m.

7 Pseudo-Static Analysis

The pseudo-static analysis represents the shaking caused by an earthquake through seismic acceleration that generates inertial forces acting through the failure mass centroid. The seismic coefficient values have a major impact on the outcomes of pseudo-static analysis. The seismic effect is modeled using the pseudo-static technique. The evaluation of seismic slope stability and ensuring serviceability of the slope after the earthquake is significant. The seismic slope stability can be ascertained by evaluating the safety factor using pseudo-static or pseudo-dynamic approaches and the force-based equilibrium method. Pseudo-static method of analysis does not consider the time effect of the applied earthquake load and the effect of shear and primary waves passing through the soil media. Pseudo-static analysis is one of the simplest approaches used in earthquake engineering to analyze the seismic response of soil embankments and slopes. In the pseudo-static analysis, the peak ground acceleration is converted into a pseudo-static inertia force and applied as a horizontal incremental gravity load. Figure 7 shows the forces acting on the cantilever retaining wall under static and pseudo-static cases.

Pseudo-static analyses represent the effects of an earthquake by applying static horizontal and/or vertical accelerations to a potentially unstable mass of soil. The inertial forces induced by these pseudo-static accelerations increase the driving forces and may decrease the resisting forces acting on the soil. Stability is expressed in terms of the pseudo-static factor of safety calculated by limit equilibrium procedures. Selection of an appropriate pseudo-static acceleration requires great care and attention, values considerably smaller than the peak acceleration of the sliding mass are usually used. As a pseudo-static extension of the Coulomb analysis, however, the M–O analysis (Mononobe and Matsuo 1929; Okabe 1926) is subject to all the limitations of pseudo-static analyses as well as the limitations of Coulomb theory. As in the case of pseudo-static slope stability analyses, determination of the appropriate pseudo-static coefficient is difficult and the analysis is not appropriate for soils that experience significant loss of strength during earthquakes (e.g., liquefiable soils).

The pseudo-static acceleration required to bring a slope to the point of incipient failure is known as the yield acceleration. The coefficient of minimum active earth pressure is given by Eq. (6):

KA is the coefficient of minimum active earth pressure given by Eq. (7) for the case of a cohesionless backfill inclined at an angle β with the horizontal which is considered zero in this study,

where \(\theta ={\text{tan}}^{-1}\frac{{k}_{h}}{(1-{k}_{v })}\)

g = 9.81 m/sec.2

For dry cohesionless backfill, Rankine’s theory predicts a triangular active pressure distribution oriented parallel to the backfill surface. The active pressure PA acts at a point located at H/3 above the base of a wall of height H, with magnitude given by Eq. (8):

Under earthquake excitation, the horizontal earthquake force can be calculated as follows by using Eq. (9):

where

The force \({P}_{AE}\) will act as a height (H′) from the top of the base slab as given by Eq. (12) below:

The overturning moment created by the horizontal pseudo-earthquake force is calculated by using Eq. (13) as below:

Following are the equations (Eq. 14 to 37) to calculate the stabilizing and driving forces of retaining walls with relief shelves for investigating factors of safety (Eq. 38) under static and seismic conditions. The relief shelves are of concrete and add to the stabilizing force as shown in Fig. 7.

C1 is the weight of concrete in the stem acting vertically downward

C2 is the base slab concrete weight acting vertically downward

C3 is the concrete shelf force acting vertically downward

C4, C5 is the concrete shelf force acting vertically downward in case of two, or three shelves.

Weight of soil (W1) on shelf, single shelf case

The weight of soil (W2) below shelf 1 is given by:

Weight of soil (W3) on base slab beyond the shelf and till end of base slab, single shelf case is given by:

Similarly, the weight of soil on the shelves and beyond shelf length is calculated as W4, W5, W6, and W7 for two, or three shelves.

8 Driving Forces

Earth pressure of the soil above the shelf is given by:

Earth pressure of the soil below the shelf is given by:

The horizontal force in the case of two shelves and three shelves is calculated as PA1, PA2, PA3, and PA1, PA2, PA3, PA4.

Earthquake pressures developed above and below the shelves are calculated as follows:

The horizontal earthquake force in the case of two shelves and three shelves is calculated as \({P}_{{AE}_{1, }}{P}_{{A}_{E2}, }{P}_{{A}_{E3}}\) and \({P}_{{A}_{E1, }}{P}_{{A}_{E2}, }{P}_{{AE}_{3} }{P}_{{A}_{E4}}\)

The point of application of the pressure above and below the shelves is given by:

The lever arm for two shelves and three shelves cases are calculated as \({h}_{1}\),\({h}_{2}, {h}_{3}\) for two shelves and \({h}_{1}\),\({h}_{2}, {h}_{3 }{h}_{4}\) for three shelves.

The lever arm is calculated for the moment developed due to the forces on the retaining wall as below:

The points of application of the earthquake pressure \({P}_{{AE}_{1}}\) and \({P}_{{AE}_{2}}\) acting above and below the shelf are calculated below.

Lever arm for forces exerted at stem (Lc1), shelf (Lc3), and base slab (Lc2) are calculated as below:

L1 = single shelf length

Point of application of the resultant earthquake force

To determine the factor of safety, the above equations aid in analyzing the stability against sliding and overturning. The friction force (R) is developed at the base slab and foundation soil and acts in the opposite direction of the sliding action. µ is the coefficient of friction adopted as 0.5, where N is the normal reaction to the downward stabilizing force.

The factor of safety against sliding for retaining walls with relief shelves is therefore given as

9 Results and Discussions

The pseudo-static analysis is performed to assess the effect of seismic acceleration coefficient, number of shelves, friction angle, etc., on the factor of safety against sliding and overturning. A spreadsheet program is developed to calculate the seismic earth pressures, the point of application of seismic force, and the factor of safety against sliding and overturning. The results are presented in the following discussions.

9.1 Effect of the Horizontal Seismic Coefficient on the Pseudo-Static Factor of Safety

The seismic acceleration coefficient used in the analysis is assumed to vary between 0 to 0.30 and is assumed to act as the horizontal pseudo-static coefficient kh and the vertical component kv (usually taken as 0.5 kh). Selecting an appropriate seismic coefficient is the most essential and challenging step in performing a pseudo-static stability analysis. The values of the seismic coefficient should, in theory, be determined by the strength of the inertial forces that the dynamic forces produced by an earthquake impose on the retaining wall system. The effect of the horizontal seismic acceleration coefficient on the factor of safety against sliding and overturning is presented in Fig. 8. With the increase in the seismic coefficient, the pseudo-static factor of safety drops considerably compared to the static case (kh = 0). With a three-shelf case, the reduction in the factor of safety is rapid up to kh = 0.15 and then proceeds more slowly after that. For a given kh value, it is observed that the factor of safety increases with the number of shelves, unit weight, and friction angle remaining constant. The effect of the horizontal seismic acceleration coefficient on the factor of safety is presented in Table 5. It can be seen that the factor of safety against sliding drastically reduces as the horizontal seismic acceleration coefficient increases. This is because seismic forces increase the disturbing forces, resulting in a lower factor of safety. However, it is further observed that this drastic fall in the factor of safety can be controlled by the introduction of more shelves. For instance, in Table 5, the highlighted values indicate safer limits for 12 m height retaining wall with γ = 16 kΝ/m3 and ϕ = 35°, for the factor of safety against sliding and overturning. A similar reduction in the factor of safety was reported by Karkanaki et al. (2019) for cantilever retaining walls without shelves for given values of friction angle and for kh ranging from 0 to 0.2 g. Also, it was reported that with an increase in friction angle from 20 to 40°, there was an improvement in the factor of safety against sliding.

9.2 Effect of Friction Angle on the Pseudo-Static Factor of Safety

The factor of safety is computed to determine the impact of varying friction angles for a given horizontal seismic coefficient (kh) of 0.2, unit weight of soil of 16kN/m3, and friction angle of 25°, 30°, and 35°. Figure 9 shows the variation of the factor of safety with friction angle for a particular value of kh. It is observed that the pseudo-static factor of safety increases with an increase in friction angle and number of shelves. The increase is more rapid for the factor of safety against overturning than the sliding factor of safety. Table 6 shows the variation of the factor of safety against sliding and overturning for various values of ϕ and no, one, two, three, and four shelves. The increase in the pseudo-static factor of safety against sliding increases gradually with the number of shelves but the pseudo-static factor of safety increases very rapidly. Also, the increase in the pseudo-static factor of safety against sliding with friction angle is gradual, while the pseudo-static factor of safety against overturning increases considerably with friction angle. The factor of safety against sliding increases by 140 to 178%. It can thus be seen that for a given value of kh = 0.2 g, a retaining wall with three or more shelves is safe against sliding (factor of safety > 1.5), indicating the usefulness of multiple shelves in giving stability to retaining walls under seismic forces.

9.3 Effect of Friction Angle on Seismic Earth Pressure Coefficient(Kae)

Figure 10 and Table 7 show the effect of friction angle on seismic earth pressure coefficient for a single shelf case. The seismic earth pressure coefficient increases considerably with horizontal seismic acceleration but reduces with an increase in friction angle. As a result of this seismic earth pressure also increases in the same proportion and hence there is a reduction in the pseudo-static factor of safety. Comparing these values with the static case (kh = 0), it is observed that the earth pressure coefficient is lowest in the static case. As the seismic earth pressure coefficient increases from 0 to 0.3 g, it is observed that the seismic lateral earth pressure coefficient also increases rapidly by 108 to 125%. Karkanaki et al. (2019) reported a similar reduction in seismic earth pressure coefficient, with an increase in friction angle.

9.4 Point of Application of Seismic Active Thrust (PAE)

It is necessary to determine the point of application of the resultant seismic force from the base of the wall. In the case of several shelves, since seismic earth pressure acts at different levels, the location of the resultant earth pressure shifts upwards. Table 8 shows the point of application of this resultant seismic force for various kh and friction angle values for no shelf, single shelf, two shelves, three shelves, and four shelves. On comparing with the static case, it is observed that, for no shelf, the point of application is 0.333H, but as the number of shelves increases, the point of application shifts to 0.473H. However, in the pseudo-static case, the point of application of resultant seismic force varies from 0.355H to 0.477H (for no shelf to four shelves case) for kh = 0.05. For kh = 0.3, the corresponding values are 0.456H to 0.495H. However, the point of application of this resultant force almost remains constant with an increase in friction angle values. Based on these results, the recommended values of the point of application are presented in Table 9 for different kh values and several shelves, friction angle, and unit weight remaining constant.

10 Summary and Discussions

The concept of using relieving shelves is not new. (Jumikis 1964) had presented the same in 1964. However, for a considerable time, it had not gained popularity. Of late, research has been taking place on the same concept and this concept has found certain applications in the field. Shelves are treated as cantilevers in the present case and the lengths of shelves are calculated to reduce the joint moment to a minimum, which results in increasing the length of shelves from the top to the bottom of the stem. The present case compares the static and the seismic factors of safety against sliding and overturning for different parameters such as several shelves, friction angle, seismic acceleration coefficient, etc. The results provide a very good comparison between the static and seismic cases (Chauhan and Dasaka 2018; Karkanaki et al. 2019). Pseudo-static case provides first-hand information for designers about the seismic stability aspects, i.e., reduction in factor of safety due to earthquakes and the benefits of providing the shelves. The purpose of this analysis is to find a stable and safe configuration for cantilever retaining walls with shelves which will reduce the cost of construction of retaining walls when heights exceed 10 m. Data about shelf lengths for various cases, factors of safety, seismic earth pressure coefficients, and point of application of resultant seismic forces under various cases will be very helpful for designers to plan and design the retaining walls when the height of soil retained exceeds 10 m, under varying shelf length case.

The seismic analysis performed in the present study is limited to pseudo-static analysis of cantilever retaining walls with shelves for cohesionless backfill. The active earth pressure distribution behind the stem and above the shelves is assumed to be triangular in nature as per Rankine’s theory. However, in the shorter relief shelves (not extended to the rupture line), the pressure distribution may not be triangular Klein Solution (Klein 1964). The future scope lies in the seismic analysis of cantilever retaining walls with longer and shorter relief shelves under pseudo-dynamic or time history analysis. Also, the cost comparison of retaining walls with relief shelves with other similar retaining structures like counterfort retaining walls can be made.

The practical issues may arise in construction of shelves. Shelves are to be cast monolithically with stem. While constructing the retaining wall with shelves, the soil within shelves must be well compacted up to the shelves; then, shelves are cast and subsequently soil is placed and properly compacted above the shelves. Over period of the time, improper compaction may result in settlement of the soil below the shelves leaving a gap between shelf and the soil. It is difficult to assess the actual level of consolidation expected below the shelves. The shelf may bend like a cantilever and may break, which can result into inward movement of wall toward the backfill, resulting in passive pressure. The stem and the shelves need to be adequately reinforced to take care of these additional bending stresses developing due to passive pressures (Bowles 1996). However, since the shelves are designed as cantilevers, there may not be any design issues as regards to the behavior of the shelves as cantilever, but it may affect the stability of the system as a whole, which needs to be investigated.

11 Conclusions

In the present case, the parametric analysis for the cantilever retaining wall with no, one, two, three, and four shelves is presented under static and pseudo-static cases by varying the number of shelves, unit weight, friction angle, and horizontal seismic acceleration coefficient. Based on this parametric study undertaken in the present case the following important conclusions are drawn:

-

i)

When the shelf is provided, the lateral earth pressure acting on the stem of the retaining wall decreases. As the number of shelves increases, the Rankine earth pressure distribution decreases on the stem.

-

ii)

Moment equilibrium at the junction of stem and shelf has been used to design the shelf length since the number and length of cantilever shelves can increase the moment at the stem shelf junction. With the increase in friction angle of the soil, the shelf length reduces due to less earth pressure. The design chart of shelf length can be used as a handy guide in finding out the required length of shelves for given values of friction angle and number of shelves.

-

iii)

As the number of shelves and angle of internal friction increases, the earth pressure on the stem decreases, and the safety factor against overturning and sliding is observed to increase considerably, thus indicating the usefulness of the relief shelves. Similar results have been reported by other researchers.

-

iv)

The seismic analysis indicates that the factor of safety against sliding and overturning decreases considerably with an increase in retained height and no shelf case. Also, as the horizontal seismic acceleration coefficient increases, there is a drastic decrease in the factor of safety. However, as the number of shelves increases, there is considerable improvement in the factor of safety, tending toward the safer side. The factor of safety against sliding is found to increase by 140 to 178% when relief shelves are provided.

-

v)

For the higher seismic acceleration coefficients such as kh = 0.2 g and above, the retaining wall with three or more shelves is safe against sliding (factor of safety > 1.5), indicating the usefulness of multiple shelves in giving stability to retaining walls under seismic forces.

-

vi)

With the increase in the horizontal seismic acceleration coefficient, the seismic earth pressure coefficient also increases leading to an increase in seismic earth pressure for a given value of friction angle. The point of application of resultant force increases from 0.333H to 0.473H for the static case from no shelf to four shelves case and from 0.453H to 0.496H for the seismic case with kh = 0.3.

-

vii)

The tables and graph provided for shelf length, the seismic earth pressure coefficient, the point of application of resultant force, and the factors of safety for sliding and overturning will be very helpful for the designers to choose the number of shelves and arrive at the stable and economical design of retaining walls with height of retained soil more than 10 m.

Abbreviations

- B :

-

Length of relief shelf (m)

- B 1 :

-

Single and top-shelf length (m)

- B 2 :

-

Second and middle shelf length (m)

- B 3 :

-

Third and bottom shelf length (m)

- C 1 :

-

Stem concrete weight (kN)

- C 2 :

-

Base slab concrete weight (kN)

- C 3 :

-

Top shelf concrete weight (kN)

- C 4 :

-

Middle shelf concrete weight (kN)

- C 5 :

-

Bottom shelf concrete weight (kN)

- g :

-

Acceleration due to gravity (m/s2)

- H :

-

Total height of wall (m)

- h :

-

Center-to-center distance between shelves (m)

- h 1, h 2, h 3, h 4 :

-

Point of application of static active force above each shelf and heel (m)

- h 1 ′, h 2 ′ :

-

Point of application for seismic force (m)

- H′:

-

Point of application of resultant earthquake force (m)

- K A :

-

Active earth pressure coefficient

- k h :

-

Horizontal pseudo-static seismic coefficients

- k v :

-

Vertical pseudo-static seismic coefficients

- L c1, L c2, L c3 :

-

Respective lever arm of concrete force in the stem, base slab, and for the single shelf (m)

- LA1, LA2 :

-

Lever arm of static earth pressure from the base of retaining wall (m)

- LA1 ′, LA2 ′ :

-

Lever arm of dynamic earth pressure from the base of the retaining wall (m)

- n1h:

-

Heel length (m)

- n2h:

-

Toe length (m)

- N :

-

Normal reaction to the downward stabilizing force (kN)

- P A :

-

Static component of active thrust (kN)

- P AE :

-

Horizontal earthquake force (kN)

- P AE1 :

-

Earthquake pressure developed above top shelf (kN)

- P AE2 :

-

Earthquake pressure developed above middle shelf (kN)

- P AE3 :

-

Earthquake pressure developed above bottom shelf (kN)

- P AE4 :

-

Earthquake pressure developed above the heel (kN)

- ΔP AE :

-

Dynamic component of active thrust (kN)

- P A1 :

-

Static component of active thrust above top shelf (kN)

- P A2 :

-

Static component of active thrust above top shelf (kN)

- P A3 :

-

Static component of active thrust above top shelf (kN)

- P A4 :

-

Static component of active thrust above top shelf (kN)

- R :

-

Friction force at the base slab and foundation soil (kN)

- t 1 :

-

Thickness of the base slab (m)

- t 2 :

-

Thickness of the stem (m)

- t 3 :

-

Thickness of the shelves (m)

- W 1 :

-

Soil weight of top shelf (kN)

- W 2 :

-

Soil weight below top shelf length (kN)

- W 3 :

-

Soil weight with the difference between the tip of the bottom shelf length and base slab (kN)

- W 4 :

-

Soil weight with the difference between tip of middle and bottom shelf lengths (kN)

- W 5 :

-

Soil weight with the difference between tip of top and middle shelf lengths (kN)

- W 6 :

-

Soil weight below middle shelf length (kN)

- W 7 :

-

Soil weight below bottom shelf (kN)

- β :

-

Slope angle for superimposed load

- δ :

-

Friction of the soil–wall interface (°)

- ɸ :

-

Internal friction of backfilled soil (°) and foundation soil (°)

- γ :

-

Unit weight of backfilled soil (kN/m3)

- γ conc :

-

Unit weight of concrete (kN/m3)

- μ :

-

Coefficient of friction

- θ :

-

Inclination of the retaining wall

References

Bhoyar, P., Awachat, G.: Static analysis and design of retaining wall with and without shelve using software. Int Res J Eng Technol 06(05), 348–354 (2019)

Chaudhuri, R., Garg, A.K.: Design of retaining walls with relieving shelves. IRC J. 35, 289–325 (1973)

Chauhan, V.B., Dasaka, S.M., Khan, R.: Numerical study on the behavior of rigid retaining wall with relief shelves. Proc Indian Geotech Conf IGC2015 2015, 1–8 (2015)

Dhamdhere, D., Rathi, V., Kolase, P.: Design and analysis of retaining wall. Int. J. Manag. Technol. Eng. 8(9), 1246–1263 (2018)

Dharshan, K., Keerthi Gowda, B.S.: Stability enhancement of cantilever earth retaining wall with pressure relief shelf by soft computing technique. Adv. Eng. Appl. Sci. Int. J. 6(2), 65–68 (2016)

Dinesh, B.V., Nair, G.J., Prasad, A.G.V., Nakkeran, P.V., Radhakrishna, M.C.: Estimation of sedimentary layer shear wave velocity using micro-tremor H/V ratio measurements for Bangalore city. Soil Dyn. Earthq. Eng. 30, 1377–1382 (2010)

Djireb, S., Mabrouki, A., Benmeddour, D., Mellas, M.: Investigation of active earth pressures and failure mechanism of retaining walls with a relief shelf. Innov. Infrastruct. Solutions 5(50), 1–15 (2020)

Ertugrul, O.L., Trandafir, A.C.: Reduction of lateral earth forces acting on rigid non-yielding retaining walls by EPS geofoam inclusions. J. Mater. Civ. Eng. ASCE 23(12), 1711–1718 (2011)

Goel, S., Patra, N.R.: Effect of arching on active earth pressure for rigid retaining walls considering translation mode. Int. J. Geomech. 8(2), 123–133 (2008)

Jumikis, A.R.: Mechanics of Soils. D Van Nostrad Co., Inc, New Jersey (1964)

Karkanaki, A.R., Ganjian, N., Askari, F.: Pseudo-static analysis of cantilever retaining walls using upper bound limit analysis approach. J. Cent. South Univ. 26, 241–255 (2019)

Klein, G.K.: Calculation of retaining walls. Vysshaya Shkola, Moscow (1964). (in Russian)

Mononobe, N., Matsuo, H.: On the determination of earth pressures during earthquakes. Proc. World Eng. Congr. Tokyo Jpn. 9, 177–185 (1929)

Okabe, S.: General theory of earth pressures and seismic stability of retaining wall and dam. J. Jpn. Soc. Civil Eng. 10(6), 1277–1323 (1926)

Singla, S., Gupta, S.: Optimization of reinforced concrete retaining walls of varying heights using relieving platforms. Int. J. Eng. Res. Technol. 4.06, 1071–1077 (2015)

Wood, J.H.: Earthquake design of flexible soil-retaining structures. Proc. Inst. Civil Eng. Geotech. Eng. 172.1, 1–9 (2019)

Wood, J.H.: Earthquake design loads for retaining walls. Bull. N. Z. Soc. Earthq. Eng. 56.4, 36–45 (2023)

Yakolova, P.I.: Experimental investigations of earth pressure on walls with two relieving platforms in the case of breaking loads on the backfill. Soil. Mech. Fndn. Eng. 11(3), 151–155 (1974)

Aldonkar, S., Savoikar. P.: Comparative behavior of mechanical response of earth retaining structures with two different material models. Proceedings of International Conference on Advances in Computer Methods and Geomechanics, Lecture Notes in Civil Engineering, 55 Springer Nature, Singapore 67–76 (2020)

Aldonkar, S., Savoikar, P.: Parametric study using FE analysis of cantilever retaining wall with pressure relieving shelves. Proceedings of International Conference on Civil Engineering Trends and Challenges for Sustainability, N.M.A.M. Institute of Technology, NITTE, Karkala, 19–20 November 2021, Lecture Notes in Civil Engineering, Springer Nature, Singapore 797–808 (2021)

Aldonkar, S., Savoikar, P.: Effect of variation of unit weight and friction angle on deflection and bending moment of retaining walls with shelves. Proceedings of International Conference on Recent Development in Sustainable Infrastructure (Research & Practices) ICRDSI-2020, Lecture Notes in Civil Engineering, 207. Springer Nature, Singapore 309–319 (2022).

American Association of State Highway and Transportation Officials (AASHTO): Standard Specification for Highway Bridges, Section 5 - Retaining Walls, 17th Edition, (2002)

Bowles, J. E.: Foundation analysis and design. 5th Edition. McGraw Hill Books Company (1996).

Chauhan, V. B., Dasaka, S. M.: Performance of rigid retaining wall with relief shelves. J. Perform. Constr. Facil. ASCE, 32.3 04018021 (2018)

Choudhury, D., Nimbalkar, S.: Determination of point of application of seismic active thrust on retaining wall. Proceedings of the 4th International Conference on Earthquake Geotechnical Engineering, June 25–28, 2007 Greece, Paper No. 1249 (2007)

Choudhury D., Nimbalkar S.: Computation of point of application of seismic passive resistance by Pseudo-dynamic method. 12th Int. Conf. Int. Assoc. Comput. Methods Adv. Geomech. (IACMAG), 2636–2643 (2008)

Faldesai, M., Savoikar, P.: Comparative analysis and behavior of cantilever retaining wall with and without relief shelves. Proceedings of the IACMAG Symposium 2019, IIT Gandhinagar 2019, 5–7, March 2019, 537–551 (2020)

Farouk, H. S.: Effectiveness of using shelves with cantilever retaining walls. AEI 2015 Am. Soc. Civil. Eng. (ASCE), 627–637 (2015)

Gokkus, U., Tuskan, Y.: Cantilever beam-like design of RC retaining wall with multiple pressure relief shelves and elastic foundation. Int. J. Adv. Res. (IJAR), 2070–2077 (2017)

Greco, V.: Pseudo-static thrust on cantilever walls. Soils & Foundations. 41.3, 87–92, Japanese Geotechnical Society (2001).

IRC:SP:102: Guidelines for Design and Construction of Reinforced Soil Walls, Indian Road Congress, 4–7 (2014)

IS 456: Plain reinforced concrete - Code of Practice (2000).

Ministry of Road Transport and Highways (MORTH): Specifications for Road and Bridge Works. Section 2500: Retaining Walls, Clause 2501: General Requirements. Fifth Edition. Government of India, New Delhi (2013)

Padhye, R. D., Ullagaddi, P. B.: Analysis of retaining wall with pressure relief shelf by Coulomb’s method. Proceedings of Indian Geotechnical Conference, Kochi 15–17 December 2011 671–673 (2011)

Que, Y., Gui, X., Chen, F.: Active earth pressure against cantilever retaining walls with the long relief shelf rotating about the bottom. Int. J. Geomech. ASCE, 22.10 06022026 (2022)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Aldonkar, S.S., Savoikar, P.P. Stability Analysis of Retaining Walls with Shelves by Static and Pseudo-Static Method. Transp. Infrastruct. Geotech. (2024). https://doi.org/10.1007/s40515-024-00447-x

Accepted:

Published:

DOI: https://doi.org/10.1007/s40515-024-00447-x