Abstract

This paper presents a laboratory study carried out to investigate the mechanical behavior of Chlef sand emphasizing the effect of non-plastic fines content (silt) and plastic fines content (clay) on the sand-silt-clay mixture behavior. For this purpose, a series of direct shear tests were performed. The samples under study were taking account two initial relative densities for their preparation (RD = 55 and 85%). The test results showed that the shear strength of Chlef sand decreases with the increase of silt content from 0 to 40%, and for sand-clay and sand-silt-clay mixtures, the variation of shear strength has a threshold value; a decrease until 20% fines content followed by an increase considering the percentage of fines is higher. Cohesion increases with the increase of silt content, while for the sand-clay and sand-silt-clay mixtures, the cohesion increases until a threshold of 20% fines content with a same tendency as the variation of the direct shear strength. Contrariwise, a slight variation of the friction angle at the peak has been observed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The city of Chlef is located in the north of Algeria 210 km from the capital Algiers, and these areas have experienced a great seismic activity and an unstable region which show a big vulnerability of the shear strength against the exposed loading (Brahim et al. 2018). When planning a site for construction, we often encounter soils made up of a mixture of sand-clay or sand-silt. A good knowledge of these sites requires laboratory and in situ studies in order to know their behavior. Previous studies have focused on clean sand, and it is only since the 1990s that studies have focused primarily on the role of plastic and non-plastic fines. Numerous studies have been carried out in several laboratories, and the results are contradictory when it comes to the role of fines; Amini and Qi (Amini and Qi 2000) and Ling et al. (Ling et al. 2009) concluded that the addition of fines content in granular soils increases the resistance of soils, while other works showed that the resistance of granular soils decreases with the addition of the fines content ((Monkul et al. 2016); (Monkul et al. 2017); (Arab 2009); (Belkhatir et al. 2010; Aouali et al. 2018)). Even some studies such as those of Benghalia et al. (Benghalia et al. 2015) and Bouferra and Shahrour (Bouferra and Shahrour 2004) indicate that the resistance decreases to a certain value of fines content and then tends to increase again. Another point of view has been reported by Thevanayagam and Martin (Thevanayagam and Martin 2002), which indicates that the physical nature of silty sand is different than that of clean sand.

Bouri et al. (Bouri et al. 2019) indicate that the shear strength of a soil is the principal parameter for evaluating the stability of building sites, so it is important to study the shear behavior of a vulnerable sand such as the sand of Chlef. They have performed a series of direct shear test on Chlef sand based on the sand-silt mixtures; their results indicate that the shear strength and friction angle decrease with the increase in silt content and the cohesion increases also. Many other researches on the literature review were interested to study the effect of non-plastic fines content on the mechanical behavior of Chlef granular soil ((Belkhatir et al. 2010); (Belkhatir et al. 2011); (Aouali et al. 2018; Bouri et al. 2019)). A study performed by Ling et al. (2012) reports on the seismic performance of three geosynthetic-reinforced segmental retaining wall systems backfilled with a silty sand mixture. Their test results indicate that walls having 0.4-m vertical reinforcement spacing, backfilled with soil containing a large percentage of fines, performed better than those having good-quality sandy soil under otherwise identical conditions. The interactions between plastic soils and a PVC geomembranes were studied by Ling et al. (2001) using a direct shear test conducted on the cohesive soils of different plasticity. They determine on their study relationships between cohesion/adhesion, angle of friction, and plasticity index.

By using the conventional direct shear test on a box of 60 × 60 mm, the aim/objective of the present laboratory study was emphasizing to investigate the mechanical behavior of sand-silt-clay mixtures in terms of shear strength response. The effect of the plasticity of the fines content was addressed (silt as a low plasticity fines content and clay as a plastic fines content), considering two different initial relative densities (RD = 55 and 85%); five values of fines content (for both silt and clay) were taken into account, i.e., 0, 10, 20, 30, and 40%. Before the direct shear tests, the dry samples have been consolidated under three different normal stresses, σN = 100, 200, and 400 kPa. The paper displays the materials utilized as a part of the examination, the trial methodology, and a parametric study.

2 Materials, Device, and Testing Program

2.1 Description of Materials

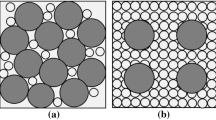

The three principal materials which the tests were carried out are Chlef clean sand, Chlef silt, and M’zilla clay. Several studies have been made on Chlef sand ((Arab et al. 2014); (Djafar Henni et al. 2013); (Merabet et al. 2019); (Della et al. 2015); (Benessalah et al. 2020); (Benessalah et al. 2019); (Krim et al. 2017); (Brahim et al. 2016); (Azaiez et al. 2020); (Benessalah 2017)). The silt was recovered from the same sand (extract the silts than clean the sand) by sieving on 0.08 mm. The clay used in the samples under study is from another country (M’zilla). Specific gravity for clean sand is GS = 2.67 and 2.69 for Chlef silt. Maximum and minimum void ratios (Fig. 1) were determined according to ASTM D 4253 (ASTM D 4253–00 2002) and ASTM D 4254 (ASTM D 4254–00 2002). The diameters of mixtures (D10 and D50) and the uniformity coefficient (CU) are given in Table 1. The table shows the variations of the global void ratios (maximum and minimum void ratios) of the sand-silt, sand-clay, and sand-silt-clay mixtures. We note that these two ratios decrease with the increase in the fraction of fines up to fC = 20% for all the mixtures, then increasing with the increase of the fines content (Fig. 1). The tests were carried out at a relative density (RD) = 65%. The particle size distribution was made according to ASTM D422-63 (2002) and is presented in Fig. 2. For fines that have a diameter less than 0.08 mm, the sedimentation analysis was carried out.

2.2 Experimental Procedures

A series of direct shear tests were carried out on the different mixtures (Fig. 3) of the sand containing 0, 10, 20, 30, or 40% fines content (silt or clay or both with the same proportion); the samples were consolidated under three normal stresses (100, 200, and 400 kPa) and two relative densities were taken into account: a medium relative density (RD = 55%) and high relative density (RD = 85%).

The sample preparation was set up in the shear box of dimension 60 × 60 mm. The initial height of the samples was 25 mm. The mass of the sample has been calculated based on the desired relative density and the physical characteristics of the mixtures following the equation (Eq. 1):

The dry deposition method was used to prepare the specimens. The test consisted of placing a sample directly in the shear box and was subjected to a normal stress or vertical load σn that represented the normal stress applied (100, 200, and 400 kPa) and a horizontal load (T) which was gradually increased ((Bouri et al. 2019); (Boutouba et al. 2019); (Aouali et al. 2018)) (Fig. 4). The samples were prepared in four layers by compaction; each layer was compacted to achieve the desired relative density mainly for dense state RD = 85%; however, for samples with medium dense state, no compaction was necessary to achieve the medium relative density of RD = 55%, so only the sample surface was leveled off. The displacement rate was kept constant for all the tests (1.00 mm/min) according to standard ASTM D3080 (2005). Shear stress readings as a function of horizontal displacement were recorded. The tests are completed when the shear strength becomes constant, usually at a horizontal displacement of 7 mm.

3 Results and Discussion

3.1 Effect of Fines Content on the Shear Strength of Chlef Sand

Figure 5 (for a relative density RD = 55%) and Fig. 6 (RD = 85%) illustrate the variation of the shear strength as a function of shear displacement (horizontal displacement), highlighting the effect of silt content (Figs. 5a and 6a), clay content (Figs. 5b and 6b), and silt-clay content (Figs. 5c and 6c) on the shear strength of sand at a given relative density. It can be seen that the shear strength of the dry sand increases significantly with the progress of horizontal displacement, due to the good adhesion between the grains of dry sand. For the small deformations, it can be observed from the figures that the shear strength of the clean sand is much greater than that of the mixtures containing fines particles (regardless of its type). In order to analyze the effect of the fines content, it can be noticed that the horizontal displacement corresponding to the peak of shear stress is higher for the sand-silt mixture than that of the clean sand (fC = 0). On the other hand, for 2 mm horizontal displacement, the shear strength shows a linear decrease with the percentage of fines contents, while the residual strength remains constant. Our results are in good agreement with those found by Aouali et al. (2018) on the shear box apparatus and with Arab et al. (2014) and Belkhatir et al. (2010) on the triaxial apparatus. The shear strength curves of clean sand show a peak shear strength after around 2.5 mm horizontal displacement for the medium relative density, and after around 3 mm horizontal displacement for the high relative density, followed by reaching a plateau until the end of the test. This behavior tendency also appears for sand-silt mixtures, but the shear strength curves of sand-silt show peak (peak shear strength) at 3.5 and 5.5 mm horizontal displacement for the high dense state and medium dense state, respectively. After this value of horizontal displacement, the shear strength decreases and stabilizes after 6.5 mm of horizontal displacement. For the samples containing clay, the shear strength has taken more shear displacement to reach its peak. Contrariwise, the samples containing a fines formed by a combination between silt and clay (with a same proportion) have showed a higher shear strength compared with the other mixtures, especially for a fines content of fC = 30%, but with a similar trend where the shear stress grows with the horizontal displacement without reaching a plateau.

Our results indicate that the relative density has a significant influence on the shear strength; it is clear that samples with high relative density (RD = 85%) have high shear strength than the samples prepared with medium relative density (RD = 55%).

3.2 Effect of Fines Content on the Deformability Against the Shear Loading

Figures 7 and 8 illustrate the variation of the vertical displacement as function of shearing displacement during a direct shear test focusing on the effect of introducing fines particles. All the samples containing fines particles showed a contractiveness phase greater than that of clean sand for both cases of relative density. The sand-silt mixtures (Figs. 7a and 8a) showed a contractiveness phase which increase more and more with increasing silt content. Contrariwise, the contractiveness phase for the sand-clay and sand-silt-clay mixtures increased with increasing the fines content until a threshold of 20% fines content. In general, the behavior tendency of the sand containing fines content showed a contractiveness phase until a given horizontal displacement, followed by a less dilatant character, which means a minimization in the resistance against the deformations imposed loads, which can result in an amplification of expansion-contraction cracks of the specimens.

3.3 Effect of the Type of Fines Content on the Shear Failure Lines (Intrinsic Curves)

Figures 9 and 10 illustrate the intrinsic curves (failure lines) that represent the relationship between the peak shear strength (τmax) and the normal stress (σn) for the medium dense sample and the dense sample with relative density RD = 55% and RD = 85%, respectively; based on these curves (τ = σ. tgφ + c), we can determine the mechanical characteristics such as the friction angle at the peak (φ) and the cohesion (c) of the samples. It is observed that the slope of the failure line in sand-clay and sand-silt-clay mixtures has a greater value than the samples with sand-silt mixtures and this value of slope failure line decreases with the increase of silt content for the sand-silt mixtures but in the case of sand-clay and sand-silt-clay mixtures, this value decreases until 20% and increases after this value.

We can observe also that there are slight differences in peak shear strength between the samples, and an increase of the peak shear strength with increasing the normal stress which the samples have been consolidated under. It is clear also that the samples prepared with a high relative density have a greater value of peak shear strength compared to the samples prepared with a medium relative density.

3.4 Effect of Fines Content on the Peak Shear Strength

Figures 11 and 12 show the variation of peak shear strength versus the fines content, for the three normal stresses 100, 200, and 400 kPa and two relative densities RD = 55% and RD = 85%. For sand-silt samples (Figs. 11a and 12a), we can observe that the peak shear strength decreases more and more with increasing the silt content. However, the peak shear strength of the sand-clay mixtures (Figs. 11b and 12b) slightly decreases with the addition of the clay to the sand. Finally, for the sand-silt-clay samples (Figs. 11c and 12c), the peak shear strength presents a slight variation with the addition of the silt-clay content. It is clear from this figure that the samples with high relative density present a higher value of peak shear strength than the samples prepared in medium dense state. The behavior found in the case of sand-silt mixtures is due to the role of non-plastic fines in amplification of the contractiveness phase of the mixture during the test. But the phenomenon found in the sand-clay and sand-silt-clay mixtures is due to the plasticity of the clay and clayed-silt, which is activated when these fines are introduced in a higher percentage into the sand (more than 20%).

3.5 Effect of Fines Content on the Variation of the Mechanical Characteristics

Figures 13 and 14 show the variation of the interlocking between the particles (internal cohesion) and friction angle at the peak versus fines content. For the sand-silt mixtures, the cohesion increases with increasing the silt content to the mixture, and the friction angle at the peak decreases with the addition of silt content for two cases of relative density (RD = 55% and RD = 85%). For the sand-clay mixtures, the cohesion increases to 15.37 kPa for 20% of clay content in medium dense state and to 15.82 kPa at dense state and then decreases followed by a decrease until 40% clay content, and the friction angle at the peak decreases to 33.86° for 20% of clay in medium dense state and to 36.13° for 30% of clay content and then increases again. In the case of sand-silt-clay mixtures, the cohesion increases to 17.39 kPa for a threshold of 20% of silt-clay in medium dense state and to 17.33 in dense state for 30% of silt-clay content and then decreases and the friction angle at the peak decreases to 34.33° for 20% of silt-clay content in medium dense state and to 35.22° in dense state for 30% of silt-clay content and then increases. The behavior found in the case of sand-clay and sand-silt-clay mixtures is due to the addition of clay content in the sand with an amount higher than 20% that favors the sliding of the grains which destabilizes the consistency which is a cohesion factor. In general; the archived cohesion has a trend, as shown in Fig. 14; it is clear that the cohesion increased with increasing fines content for all the mixtures compared to clean sand which has an internal cohesion practically zero, after adding a certain fines content (around 20% fines content); the cohesion has been stabilized for the other mixtures containing more fines fraction.

The friction angle of the sand-clay mixtures and sand-silt-clay mixtures decreases with the addition of fines content until 20% and increases again; this is due to the decrease in the shear strength until 20%.

4 Conclusions

A series of direct shear tests on a square shear box of 60 × 60 mm dimension were carried out on the sand-silt-clay mixture (fC = 0, 10, 20, 30, and 40%). The dry samples were retrieved from a vulnerable soil taken from sites at Chlef River banks (Algeria). The effect of low plastic fines (silt) and a plastic fines (clay) or even a combination between both of them has been addressed on both the shear strength and the deformability against the exposed loading (shear load). The key findings can be summarized as follows:

-

For the small deformations, the shear strength of the clean sand is much greater than that of the mixtures containing fines particles (regardless of its type). In order to analyze the effect of the fines content, it can be noticed that the horizontal displacement corresponding to the peak of shear stress is higher for sand-silt-clay mixture than that of the clean sand (fC = 0). On the other hand, for 2 mm horizontal displacement, the shear strength shows a linear decrease with the percentage of fines contents.

-

The sand-silt mixtures showed a contractiveness phase which increase more and more with increasing silt content. Contrariwise, the contractiveness phase for the sand-clay and sand-silt-clay mixtures increased with increasing the fines content until a threshold of 20% fines content. In general, the behavior tendency of the sand containing fines content showed a contractiveness phase until a given horizontal displacement, followed by a less dilatant character, which means a minimization in the resistance against the deformations imposed loads, which can result in an amplification of expansion-contraction cracks of the specimens. In general, the fines reduce the dilatant character of the sand-fines mixtures and therefore increase their contractiveness. Based on that, the fines reduce the stability of the mixtures and therefore the resistance of the soil.

-

The samples prepared with a high relative density have a greater value of peak shear strength compared to the samples prepared with a medium relative density.

-

The dilatant character is more important for the samples with a high relative density compared to that of the samples with a medium relative density.

-

At a given relative density which the samples were tested, it is noted a reduction in the maximum and residual shear strengths with the increase of fines content, which involves a reduction of the physical characteristics such as the internal friction angle (at the peak of shear strength). It can be observed also that an increase on the interlocking (internal cohesion) for the mixtures containing fines particles is due to the small particles that occupy the spaces between the large particles.

Abbreviations

- G S :

-

Specific gravity of solids

- γ S :

-

Unit weight of the solid grain

- D 10 :

-

Effective grain diameter

- D 50 :

-

Average grain diameter

- C U :

-

Uniformity coefficient

- C C :

-

Coefficient of curvature

- C :

-

Cohesion

- e max :

-

Maximum void ratio

- e min :

-

Minimum void ratio

- RD:

-

Relative density

- σ n :

-

Normal stress

- τ peak :

-

Peak shear strength

- τ :

-

Shear strength

- φ :

-

Friction angle at the peak of shear stress

- Δ H :

-

Horizontal displacement

- Δ V :

-

Vertical displacement

- I P :

-

Plasticity index

- f C :

-

Fines content

- R 2 :

-

Coefficient of determination

References

Amini, F., Qi, G. Z.: Liquefaction testing of stratified silty sands. J. Geotech. Geoenviron. (2000). Serial URL: http://ojps.aip.org/gto

Aouali, N., Benessalah, I., Arab, A., Ali, B., Abed, M.: Shear strength response of fibre reinforced Chlef (Algeria) silty sand: laboratory study. Geotech. Geol. Eng. 37, 1047–1057 (2018). https://doi.org/10.1007/s10706-018-0641-5

Arab, A.: Monotonic and cyclic behaviour of silty sand. C. R. Mecanique. 337, 621–631 (2009)

Arab, A., Sadek, M., Belkhatir, M., Shahrour, I.: Monotonic preloading effect on the liquefaction resistance of Chlef silty sand. Arab. J. Sci. Eng. 39, 685–694 (2014)

ASTM D 4253–00.: Standard test method for maximum index density and unit weight of soils using a vibratory table. Annual Book of ASTM Standards, American Society for Testing and Materials, West Conshohocken, pp 1–14 (2002)

ASTM D 4254–00.: Standard test method for minimum index density and unit weight of soils and calculation of relative density. Annual Book of ASTM Standards, American Society for Testing and Materials, West Conshohocken, pp 1–9 (2002)

ASTM D3080.: Standard test method for direct shear test of soils under consolidated drained conditions, American Society for Testing and Materials, West Conshohocken, (2005)

ASTM D422–63.: Standard method for particle-size analysis of soils, annual book of standards, West Conshohoken, 1989, 86–92 (2002)

Azaiez, H., Cherif Taiba, A., Mahmoudi, Y., Belkhatir, M.: Characterization of granular materials treated with fly ash for road infrastructure applications. Transportation Infrastructure Geotechnology. (2020). https://doi.org/10.1007/s40515-020-00135-6

Belkhatir, M., Arab, A., Della, N., Missoum, H., Schanz, T.: Influence of inter-granular void ratio on monotonic and cyclic undrained shear response of sandy soils. C. R. Mecanique. 338, 290–303 (2010)

Belkhatir, M., Arab, A., Schanz, T., Missoum, H., Della, N.: Laboratory study on the liquefaction resistance of sand-silt mixtures: effect of grading characteristics. Granul. Matter. 13, 599–609 (2011)

Benessalah I.: Comportement des interfaces géosynthétiques sous chargement dynamique due à l’impact. Ph.D thesis, Faculty of Civil engineering & Architecture, University of Chlef (2017)

Benessalah, I., Arab, A., Sadek, M., Bouferra, R.: Laboratory study on the compressibility of sand–rubber mixtures under one dimensional consolidation loading conditions. Granul. Matter. 21, 7 (2019). https://doi.org/10.1007/s10035-018-0860-8

Benessalah, I., Sadek, M., Villard, P. and Arab A.: Undrained triaxial compression tests on three-dimensional reinforced sand: effect of the geocell height. European Journal of Environmental and Civil Engineering, 1–12 (2020)

Benghalia, Y., Bouafia, A., Canou, J., Dupla, J.C.: Liquefaction susceptibility study of sandy soils: effect of low plastic fines. Arab. J. Geosci. 8, 605–618 (2015). https://doi.org/10.1007/s12517-013-1255-0

Bouferra, R., Shahrour, I.: Influence of fines on the resistance to liquefaction of a clayey sand. Ground Improvement. (2004). https://doi.org/10.1680/grim.2004.8.1.1

Bouri, D., Krim, A., Brahim, A., Arab, A.: Shear strength of compacted Chlef sand: effect of water content, fines content and others parameters. Studia geotechnica et mechanica. 42, 18–35 (2019). https://doi.org/10.2478/sgem-2019-0027

Boutouba, K., Benessalah, I., Arab, A., Djafar Henni, A.: Shear strength enhancement of cemented reinforced sand: role of cement content on the macro-mechanical behavior. Studia Geotechnica et Mechanica. 41(4), 200–211 (2019)

Brahim, A., Arab, A., Belkhatir, M., Shahrour, I.: Laboratory study of geotextiles performance on reinforced sandy soil. J. Earth Sci. 27(6), 1060–1070 (2016)

Brahim, A., Arab, A., Sadek, M., Shahrour, I.: Laboratory investigation of the influence of geotextile on the stress–strain and volumetric change behavior of sand. Geotech. Geol. Eng. 36, 2077–2085 (2018). https://doi.org/10.1007/s10706-018-0446-6

Della, N., Belkhatir, M., Arab, A., Canou, J., Dupla, J. C.: Undrained monotonic response and instability of medium-dense sandy soil”, Marine Georesources & Geotechnology, 33:6, 487–495 (2015). https://doi.org/10.1080/1064119X.2014.954175

Djafar Henni, A., Arab, A., Belkhatir, M., Saaed, H.A., Khelafi, H.: Undrained behavior of silty sand: effect of the overconsolidation ratio. Arab. J. Geosci. 6, 297–307 (2013). https://doi.org/10.1007/s12517-011-0365-9

Krim, A.; Arab, A.; Chemmam M., Brahim, A., Sadek, M., ; Shahrour, I.: Experimental study on the liquefaction resistance of sand–clay mixtures: effect of clay content and grading characteristics. Marine Georesources & Geotechnology, (2017). https://doi.org/10.1080/1064119X.2017.1407974

Ling, H.I., Pamuk, A., Dechasakulsom, M., Mohri, Y., Burke, C.: Interaction of PVC geomembranes with cohesive soils. Journal of Geotechnical and Geoenvironmental Engineering, ASCE. 127(11), 950–954 (2001)

Ling, H.I., Wu, M.-H., Leshchinsky, D., Leshchinsky, B.: Centrifuge modeling of slope instability. J. Geotech. Geoenviron. Eng. ASCE. 135(6), 758–767 (2009)

Ling, H.I., Leshchinsky, D., Mohri, Y., Wang, J.-P.: Earthquake response of reinforced segmental retaining walls backfilled with substantial percentage of fines. J. Geotech. Geoenviron. 138(8), 934–944 (2012)

Merabet, K., Benessalah, I., Chemmam, M., Arab, A.: Laboratory study of shear strength response of Chlef natural sand: effect of saturation. Marine Georesources & Geotechnology. (2019). https://doi.org/10.1080/1064119X.2019.1595792

Monkul, M.M., Etminan, E., Şenol, A.: Influence of coefficient of uniformity and base sand gradation on static liquefaction of loose sands with silt soil. Dynamics and Earthquake Engineering. 89, 185–197 (2016). https://doi.org/10.1016/j.soildyn.2016.08.001

Monkul, M.M., Etminan, E., Şenol, A.: Coupled influence of content, gradation and shape characteristics of silts on static liquefaction of loose silty sands. Soil Dyn. Earthq. Eng. 101, 12–26 (2017). https://doi.org/10.1016/j.soildyn.2017.06.023

Thevanayagam, S., Martin, G.R.: Liquefaction in silty soils-screening and remediation issues. Soil Dyn. Earthq. Eng. 22, 1035–1042 (2002). https://doi.org/10.1016/S0267-7261(02)00128-8

Acknowledgments

The authors would like to thank the reviewers for their constructive and detailed comments. Tests were performed in the Laboratory of Material Sciences and Environment (LsmE) at UHBC University of Chlef.

Funding

The present study was financially supported by the General Directorate for Scientific Research and Technological Development (DGRSDT).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nougar, B., Brahimi, A., Bouri, D.E. et al. Laboratory Investigation into the Effect of Fines Plasticity on the Mechanical Behavior of Sand/Fines Mixtures. Transp. Infrastruct. Geotech. 8, 438–451 (2021). https://doi.org/10.1007/s40515-020-00144-5

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40515-020-00144-5