Abstract

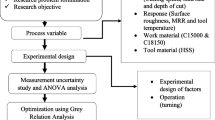

The turn-milling methods for machining operation have been developed to increase efficiency of conventional machines recently. These methods are used especially by coupling some apparatuses on the computer numerical control (CNC) machine to decrease the production time and machine costs, ensure the maximum production and increase the quality of machining. In this study, 100Cr6 bearing steel extensively used in industry has been machined by tangential turn-milling method. This paper presents an approach for optimization of the effects of the cutting parameters including cutter speed, workpiece speed, axial feed rate, and depth of cut on the surface roughness in the machining of 100Cr6 steel with tangential turn-milling method by using genetic algorithm (GA). Tangential turning-milling method has been determined to have optimum effects of cutting parameters on the machining of 100Cr6 steel. The experimental results show that the surface roughness quality is close to that of grinding process.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The turn-milling methods have been used in the processing of eccentric shaft or any other non-coaxial parts and have shown rapid development in recent years. In the turn-milling method, multi-edged cutting tools are used and the workpiece makes simultaneously rotational and feeding motion along its own axis. This new method can be considered as a combination of two different metal removal (turning and milling) methods and it is grouped together with the view of contact shapes of the cutting tool and workpiece axes. As shown in Fig. 1, the turn milling is divided into three groups as orthogonal, parallel to the axis and tangential.

The advantages of these methods can be listed as follows:

-

(i)

The metal removal process done with turning can be continuous or mass, but this method occurs only in the short chip. Thus, tool life increases.

-

(ii)

Instead of turning, milling and drilling operations, the processes in the turn-milling method can be performed by a single machine.

-

(iii)

Manufacturing time is shortened. Thus, processing costs are lower in mass production.

-

(iv)

The surface roughness is close to that of grinding quality.

Kountanya et al. [1] studied the chip morphology simulation of robust turning and effects of tool & edge geometry on the cutting conditions. In Ref. [1], a simulation of experiments conducted with different cutting conditions, tool & edge geometries and finite element method was concluded. Umbrello [2] used several experimental techniques in order to firstly validate the proposed simulation strategy, and successively analyze the influences of white and dark layers on residual stresses. He determined that the proposed finite element method (FEM) model was also suitable for studying the influences of white and dark layers on residual stresses during hard machining of AISI 52100 steel.

Mao et al. [3] carried out a systemic experimental investigation involving scanning electron microscopy, Vickers microhardness tester, X-ray diffraction, three-axis piezoelectric dynamometer, and thermocouple to analyze the affected layers formed in grinding of AISI 52100 steel. They determined that the dominant factor in annealed steel grinding was the plastic deformation, and the residual compressive stress was observed on the ground surface.

Mulik and Pandey [4] designed and fabricated a magnetic abrasive finishing set up mechanism which used different designs of electromagnet having alternate north and south poles. It was obtained that the least surface roughness value obtained was as low as 51 nm in 120 s processing time on a hardened AISI 52100 steel workpiece of 61 HRC hardness [4]. Savas and Ozay [5] determined the effect of surface roughness of cutting parameters for SAE1050 steel. The values of optimum cutting parameters given for the minimum surface roughness with the technique of genetic algorithm (GA) related to experimental results were obtained.

Savas and Ozay [6] used GA method to study the effects of cutting parameters of tangential turning-milling operations on surface roughness. They indicated that as the speed of the cutting tool was increased to a certain point, surface roughness increased. However if the speed overran this certain point, surface roughness decreased. Savas and Ozay studied the effects of cutting parameters on surface roughness of MS58 brass material machined with tangential turn-milling method. In Ref. [6], three levels of cutting parameters as cutting tool revolution, workpiece revolution, axial feed speed, the depth of cut and helix angle of the cutting tool had been taken into consideration. They obtained a surface quality approximately equal to that of grinding process with this new method [7]. Karaguzela et al. [8] showed a comprehensive process model for both orthogonal and tangential turn milling operations and made a comparison for different types of turn-milling operation and optimized the process. Reference [8] described the cutting speed for both configurations, formulated circularity in turn-milling and presented cutting force calculations for the chip geometry. Mahesh et al. [9] developed a predictive model to observe the effect of radial rake angle on the end milling cutting tool by considering the following machining parameters: spindle speed, feed rate, axial depth of cut, and radial depth of cut. By referring to the real machining case study, the second-order mathematical models have been developed using response surface methodology. Zhu et al. established two mathematical models to predict the roughness and topography of machined surface. Some simulations by MATLAB software and experiments were shown to clarify the effect of some parameters on surface. They determined that a better surface quality and tiny oil storage structure could be obtained if the cutting parameters were chosen in reason. Zhu et al. [10] developed a modern advanced method as called the co-simulation method in turn-milling centre design for structural improvement and optimization that this was a good way for solving the dynamics of rigid flexible coupling system. With this method, they simulated the system of turn-milling as dynamic [10]. Turn-milling is an intermittent cutting process which in turn causes periodic forces during cutting. The cutting forces in turn-milling are simulated using oblique transformation of orthogonal cutting data and the chip thickness expressions developed in Refs. [11, 12]. Yuan and Zheng [13] tried to model the surface roughness and analyze the influencing factors emphasized the effect of eccentricity on surface roughness.

It seems that there are different studies conducting on 100Cr6 steel with conventional methods. The residual stresses and hardness changes induced from heating and cooling between cutting tool and workpiece in machining with conventional methods of 100Cr6. Therefore, in these studies detailed surface structure of the material has been investigated. However, the machining methods have not been much developed and turn-milling methods have not been presented to process 100Cr6 bearing steel which is widely used in industry.

There is no continuous contact between tool and workpiece in the turn-milling processes, and the chip is short. Thus, the heat between tool and workpiece decreases. The residual stresses and hardness changes which occur on the surface of workpiece decrease, then the tool life also increases [8]. Therefore, in the processing of chromium-based steel, turn-milling method will be more effective to eliminate the disadvantages arising from processing methods. This is one of the most important advantages. In this study, DIN 100Cr6 (AISI 52100) bearing steel has been machined with a new method called tangential turn-milling method and the effects of cutting parameters on surface roughness have been investigated.

2 Experimental

2.1 Experimental setup mechanism

The experiments on turn-milling were carried out on a CNC JOHNFORD WMC-850 FANUC 0 M vertical milling machine in the accuracy of 0.001 mm. 20 mm diameter end-milling cutter of high speed steel material with four teeth and 30°. Helix rank was used as a cutting tool. The schematic diagram of experimental setup with the contact between cutting tool and workpiece is shown in Fig. 2. The cooling water was not used in the experiments.

2.2 Workpiece material

DIN100Cr6 bearing steel was machined with tangential turn-milling method. 100Cr6 bearing steel has a wide range of applications in industry such as arm grids, milling cutters, etc. The chemical analysis of 100Cr6 bearing steel is given in Table 1. The part was not exposed to any thermal process.

The 100Cr6 workpiece in tangential turn-milling operations was cut with 24 mm × 60 mm (diameter × length). The workpiece was prepared according to the ISO 3685 standard.

The cylindrical workpiece of DIN100Cr6 bearing steel of 40 mm diameter and 100 mm length was fixed between three jaw universal chucks and rolling centers on the machine bed using a special attachment. The workpiece and cutting tool were contacted wherein the tool axes were perpendicular and tangential to the workpiece axis. The parallelism between workpiece and X-axis of the machine was controlled with a comparator at precision 0.001 mm.

2.3 Determinations of experiment parameters

In the experiments, the parameters at different levels, including workpiece revolution, X-axis feed speed and the depth of cut, were obtained by exact factorial method. The parameters at three different levels are given in Table 2.

Turn-milling method is considered to be a combination of these two processes, therefore the parameters separately affecting these two operations are considered to cause effects on the new method. Before beginning the experimental study, the machining parameters and other effective parameters of the previous machining were determined. 81(34) experiments were performed by exact factorial method. In the experiments for an ideal tool life, the values of both workpiece and tool speed were computed separately by using Eq. (1) taking into consideration of cutting speed (v), workpiece and cutter diameter (D). The values were written in the CNC program.

The cutting speed equation was determined by cutting tool and workpiece speed at sub-levels and top-levels. The axial feed rate was taken into consideration to three different levels. The depth of cut written in the CNC programme was 0.1 mm or greater.

2.4 Measurement of surface roughness

The surfaces were measured using the MITUTOYO 211 surf test instrument with 0.01 μm at least count, which provided a numerical assessment of the surface roughness in terms of R a values. The measurements were conducted according to the ISO 1997 standards and the measuring range (0.8 mm × 5 mm). The measurements were conducted in the direction of the axis of the cylindrical workpiece. The arithmetical average of measurements was taken from four different points (see Fig. 3).

3 Results

Figures 4, 5, 6 show the effects of the process parameters on surface roughness. The parameters of 81 experiments and the values of average surface roughness were entered to MINITAB-15. Thus, the graphics were obscured in MINITAB-15 programme. Finally, the optimum values for workpiece and cutting speed were obtained. Since turn-milling processes are considered, it is seen that Eq. (2) gives the best result for workpiece and cutting tool speed. The values of the surface roughness obtained from the turn-milling experiment parallel with the values obtained from these equations. Besides, by increasing the depth of cut and axial feed rate, the surface roughness value also increases. Due to the increase of the feed rate and the cutting force, the vibration acceleration increases and this causes increment in surface roughness value [11].

The effects of workpiece speed and chip thickness on surface roughness for 100Cr6 bearing steel at the tangential turn-milling operations are given in Fig. 4. It shows that the lowest surface roughness value is on the second level of the workpiece revolution. The reason is that the centrifugal force takes greater values after the second level, and both the vibration acceleration and surface roughness increase. The centrifugal force in the first level takes the lover values. When the cutting speed between workpiece and cutting tool reduces, the cutting tool is forced to cut metal and the chip breakage is not smooth. Therefore, the surface roughness increases.

Figure 4 shows that it is directly proportional to the rate average surface roughness of the depth of cut and feed rate. The reason is that, increment of depth of cut and feed rate causes decrease of cutting force. When more chip is removed in unit time with the same cutting speed, surface roughness value also increases.

Another similar case is shown in Fig. 5. It is observed that average surface roughness value decreases or increases depending upon the speed of cutting tool. The surface roughness decreases when cutting tool speed is increased from the first to the second level. As known, ideal value of cutting speed varies on the type of the cutting tool in chip removing processes, such as milling, turning, drilling and grinding. The ideal cutting speed value was determined from related tables by the tests performed by the manufacturer company.

When the cutting tool speed is increased from the second level to the third level, the surface roughness value increases. With increment in speed, the cutting tool scrapes to the same spot more than normal. Thus, the values greater than the ideal cutting speed may cause increment in centrifugal force, which causes vibrations on the tool, therefore the surface roughness value increases.

As the feed rate and the depth of cut increase, the average surface roughness value increases. The reason is that the removed chip amount in unit time with constant cutting speed increases. However, feed rate has less influence on surface roughness.

3.1 Optimization of surface roughness

Solving many technical problems leads to the need for optimization that the R a function with many variables has to be minimized. The first step in the optimization of cutting technology is the definition of mathematical model. Because of the complexity of models (many factors influence the cutting process), more accurate mathematical models include linear and non-linear parts. In practice, models defined by the second-order polynomials are sufficient for the description of technological processes, as long as the possibility of description exists.

The effects of the cutting parameters over surface roughness in the tangential turn-milling process for machining of cylindrical workpiece have been investigated. The investigation was performed with four independent (input) variables: cutting tool speed, workpiece speed, depth of cut and feed. The preliminary tests were carried out to determine suitable parameter range. The maximum possible tool speed in our condition was 2 500 r/min, but at speeds higher than 800 r/min, the tool wear was too high. Therefore, cutting tool speed level varied between 460 r/min and 660 r/min; workpiece speeds varied between 280 r/min and 710 r/min; the depth of cut and feed varied between (f min = 2.0 mm/min, f max = 12.6 mm/min, a min = 0.1 mm and a max = 1.0 mm).

In this study, the surface roughness equation, according to the experimental parameters, has been obtained by the toolbar of surface response method of MINITAB-15 programme. These graphics show that the experimental results are compatible with Eq. (2).

It can be noticed that the residuals form a straight line, which means that the errors are normally distributed and the regression model is well fitted with the observed values. Other figure shows the residual values with fitted values for surface roughness. Figure 6 indicates that the maximum variation from −0.50 to 0.50 shows the high correlation that exists between the fitted values and the observed values.

The optimal selection of the cutting parameters should increase not only the utility for cutting economics, but also the product quality to a great extent by minimizing surface roughness. The process parameters of turn-milling are defined in the standard optimization format that is solved by a numerical optimization algorithm. An objective function to be minimized is necessary to define the standard optimization problem.

In process of tangential turn-milling, the optimization problem is to minimize R a(N, n, f, a) within ranges of cutting parameters: cutting tool speed 460 r/min < N < 660 r/min, workpiece speed 280 r/min < n < 710 r/min, feed rate 2.0 mm/min < f < 12.6 mm/min, depth of cut 0.1 mm < a < 1.0 mm.

The far too many values of surface roughness are obtained according to these given cutting parameters. Determining the surface roughness analytically is very difficult. Therefore, we have used GA to carry out numeric optimization. Researchers have proposed several approaches to predict surface roughness based on theoretical approach [14–17]. Analytical models had been created to predict tool life and surface roughness in terms of cutting speed, axial depth of cut and feed rate in milling method [18, 19], experimental investigations [20, 21], design of experiments [22, 23], and optimization techniques such as GA, neural network, neural fuzzy and fuzzy logic approaches to predict surface roughness [24, 25].

GAs are extensively used for optimization problems and were first developed by Holland [26] in the 1970s. These algorithms are based on biological evolution process. A similar analogy is used to solve the complex optimization problems. The notable feature of GAs is that it emulates the biological system’s characteristics like self-repair and reproduction. It is generally well known that the human being is a very good example of a decision maker. So researchers began to experiment with the natural systems and have developed methods like GAs and neural networks.

The actual differences between the GAs and other optimization methods are briefly summarized below. GAs move through the solution space starting from a population of points rather than a single one. This is similar to calculus based methods where we have to restart the solution from a number of points to ensure global convergence. GAs work with objective function information directly and not with any other auxiliary information like derivatives. Constraints are included in the objective function using some penalty function. GAs use probabilistic rules rather than deterministic rules. Therefore, applying to the optimization problem and the structure of GA is rather easy. Here, determining objective function and constraints are important. The critical parameters of GA are the size of the population, mutation rate, number of iterations (i.e., generations), etc. In this study, population size of 30, crossover rate of 2.0, mutation rate of 0.1, bit number for each variable of 16, and 3 000 iterations are utilized. Equation (2) solves the optimization technique of GA and gives the minimum surface roughness. The values obtained from Eq. (2) completely match with the values achieved in experiments (see Table 3).

4 Conclusions

In this study, 100Cr6 bearing steel was machined with tangential turn-milling method. The results given below are obtained from the conducted experiments and analysis:

-

(i)

In the case of tangential turn-milling, an ideal surface quality for the machined surface, taking into consideration of workpiece cutting speed, improves with Eqs. (1) and (2) calculated separately.

-

(ii)

A very high surface-finishing quality of machined surface can be achieved by tangential turn-milling for the machining of rotationally symmetrical workpieces. In the case of tangential turn-milling, R a value of the achieved surface roughness achieved is lower than that in the case of turning.

-

(iii)

In the case of tangential turn-milling, very small chips are produced contrary to the relatively longer chips produced in the case of turning of 100Cr6 bearing steel. However, the chip lengths are different depending on feed rate.

-

(iv)

According to additional measurement results, a good correlation is obtained between the value of surface roughness predicted by the GA and surface roughness obtained from experimental measurements in process of tangential turn-milling. Based on the GA prediction value, it can be concluded that the errors in measurement regions are between 2% and 7%.

-

(v)

The minimum surface roughness is determined with the objective function given in this study. Therefore, in the tangential turn-milling process, the assumed value of surface roughness will be easily determined according to cutting parameters.

References

Kountanya R, Al-Zkeri I, Altan T (2009) Effect of tool edge geometry and cutting conditions on experimental and simulated chip morphology in orthogonal hard turning of 100Cr6 steel. J Mater Process Technol 209:5068–5076

Umbrello D (2011) Influence of material microstructure changes on surface integrity in hard machining of AISI 52100 steel. Int J Adv Manuf Technol 54(9):887–898

Mao C, Zhou Z, Zhang J et al (2011) An experimental investigation of affected layers formed in grinding of AISI 52100 steel. Int J Adv Manuf Technol 54(5–8):515–523

Mulik RS, Pandey PM (2011) Magnetic abrasive finishing of hardened AISI 52100 steel. Int J Adv Manuf Technol 55(5):501–515

Savas V, Ozay C (2008) The optimization of the surface roughness in the process of tangential turn-milling using genetic algorithm. Int J Adv Manuf Technol 37:335–340

Savas V, Ozay C (2007) Analysis of the surface roughness of tangential turn-milling for machining with end milling cutter. J Mater Process Technol 186:279–283

Savas V, Ozay C (2009) Researching the effects of cutting parameters obtained from MS58 Brass tangential turning-milling processes on surface roughness. Electron J Mach Technol Cover 6(4):65–70

Karaguzela U, Bakkal M, Budak E (2012) Process modeling of turn-milling using analytical approach. In: 3rd CIRP conference on process machine interactions (3rd PMI), Procedia CIRP 4:131–139

Mahesh G, Muthu S, Devadasan SR (2015) Prediction of surface roughness of end milling operation using genetic algorithm. Int J Adv Manuf Technol 77:369–381

Zhu L, Li H, Wang W (2013) Research on rotary surface topography by orthogonal turn-milling. Int J Adv Manuf Technol 69:2279–2292

Budak E, Armarego EJA, Altintas Y (1996) Prediction of milling force coefficients from orthogonal cutting data. J Eng Ind 118(2):216–224

Altintas Y (2012) Manufacturing automation: metal cutting mechanics, machine tool vibrations, and CNC design, seconded. Cambridge University Press, New York

Yuan SM, Zheng WW (2012) The surface roughness modeling on turn-milling process and analysis of influencing factors. Appl Mech Mater 117:1614–1620

Zhu L, Tang L, Su C et al (2008) Co-simulation of rigid-flexible coupling system for turn-milling center. In: Proceedings of the 7th world congress on intelligent control and automation June 25–27, Chongqing

Tekaüt I, Günay M, Şeker U (2009) Researching the effects of cutting tool vibrations in turning process on surface roughness. In: 5th International advanced technologies symposium, Karabük, pp 1293–1297, Accessed 13–15 May 2009

Quintana G, Ciurana J, Ribatallada J (2010) Surface roughness generation and material removal rate in ball end milling perations. Mater Manuf Process 25(6):386–398

Mansour A, Abdalla H (2002) Surface roughness model for end milling: a semi-free cutting carbon casehardening steel (EN 32) in dry condition. J Mater Process Technol 124(1–2):183–191

Alauddin M, El Baradie MA, Hashmi MSJ (1997) Prediction of tool life in end milling by response surface methodology. J Mater Process Technol 71(3):456–465

Chang H, Kim J, Kim IH et al (2007) In-process surface roughness prediction using displacement signals from spindle motion. Int J Mach Tools Manuf 47(6):1021–1026

Coker SA, Shin YC (1996) In-process control of surface roughness due to tool wear using a new ultrasonic system. Int J Mach Tools Manuf 36(3):411–422

Gologlu C, Sakarya N (2008) The effects of cutter path strategies on surface roughness of pocket milling of 1.2738 steel based on Taguchi method. J Mater Process Technol 206(1–3):7–15

Lou SJ, Chen JC (1999) In-process surface roughness recognition (ISRR) system in end-milling operations. Int J Adv Manuf Technol 15(3):200–209

Tsai Y, Chen JC, Lou S (1999) An in-process surface recognition system based on neural networks in end milling cutting operations. Int J Mach Tools Manuf 39(4):583–605

Benardos PG, Vosniakos GC (2002) Prediction of surface roughness in CNC face milling using neural networks and Taguchi’s design of experiments. Robot Comput Integr Manuf 18(5–6):343–354

Chen JC, Lou MS (2000) Fuzzy-nets based approach using an accelerometer for in-process surface roughness prediction system in milling operations. J Comput Integr Manuf Syst 13(4):358–368

Holland JH (1975) Adaptation in natural and artificial systems. MIT press, Cambridge, pp 9–16

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Savas, V., Ozay, C. & Ballikaya, H. Experimental investigation of cutting parameters in machining of 100Cr6 with tangential turn-milling method. Adv. Manuf. 4, 97–104 (2016). https://doi.org/10.1007/s40436-016-0134-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40436-016-0134-9